Analysis and Comparison of Friction Stir Welding and Laser Assisted Friction Stir Welding of Aluminum Alloy

Abstract

:1. Introduction

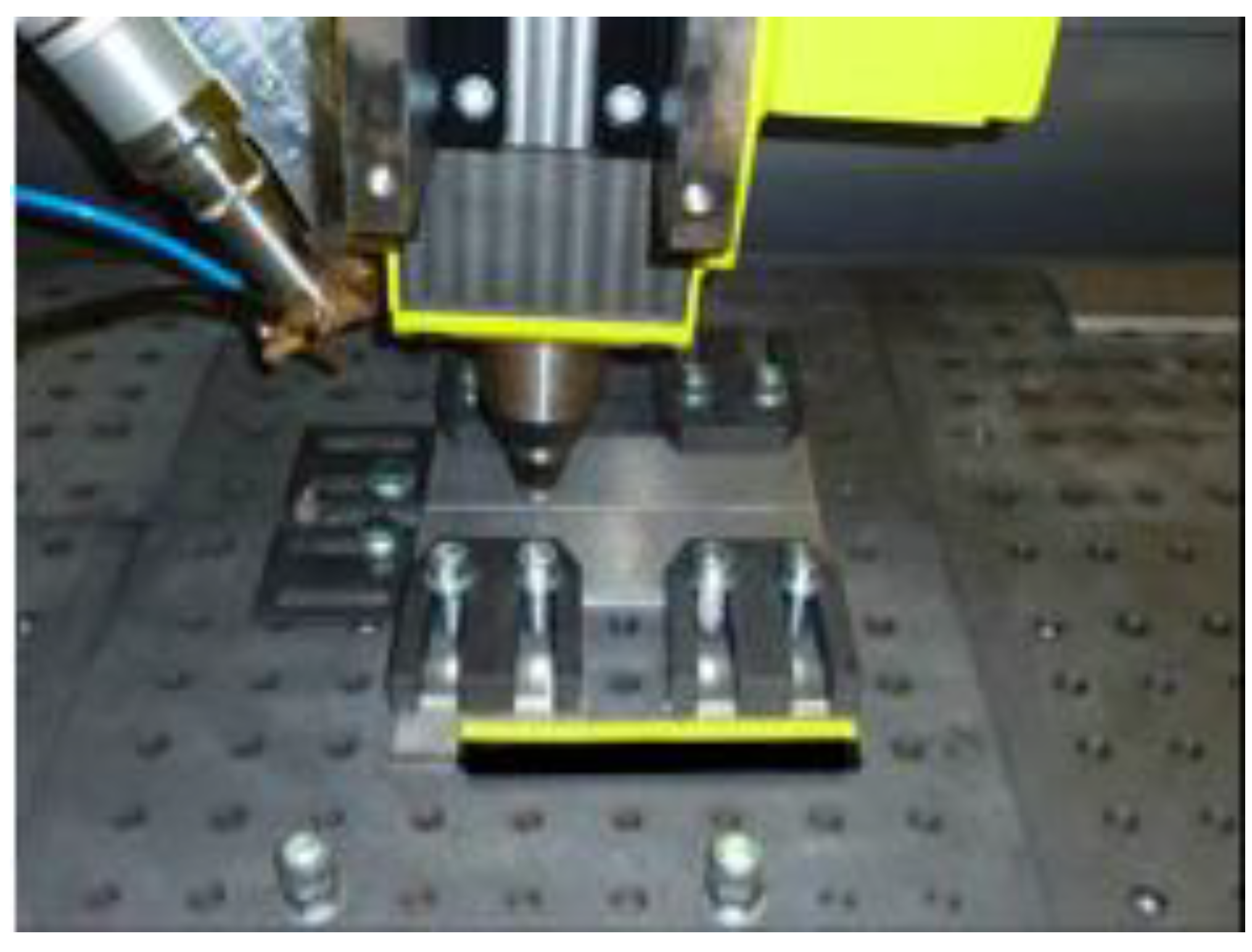

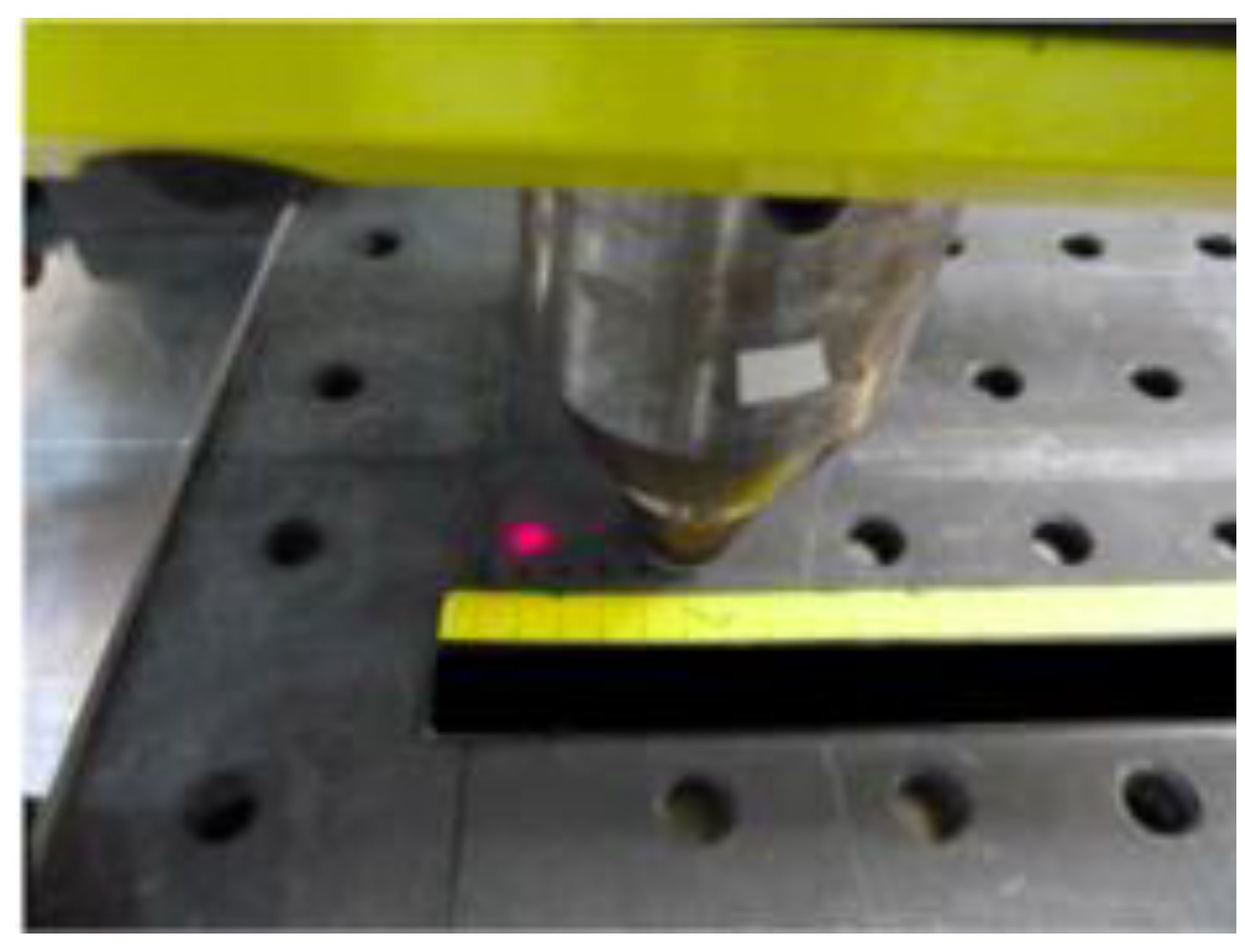

2. Experimental Tests and Finite Element Analysis

| Designation | Traverse speed (mm/min) | Tool rotation speed (rpm) | Dwell time (s) | Laser power (W) |

|---|---|---|---|---|

| 1 | 20 | 500 | 3 | – |

| 1L | 20 | 500 | 3 | 500 |

| 2L | 20 | 500 | 3 | 1000 |

| 3L | 20 | 500 | 3 | 2000 |

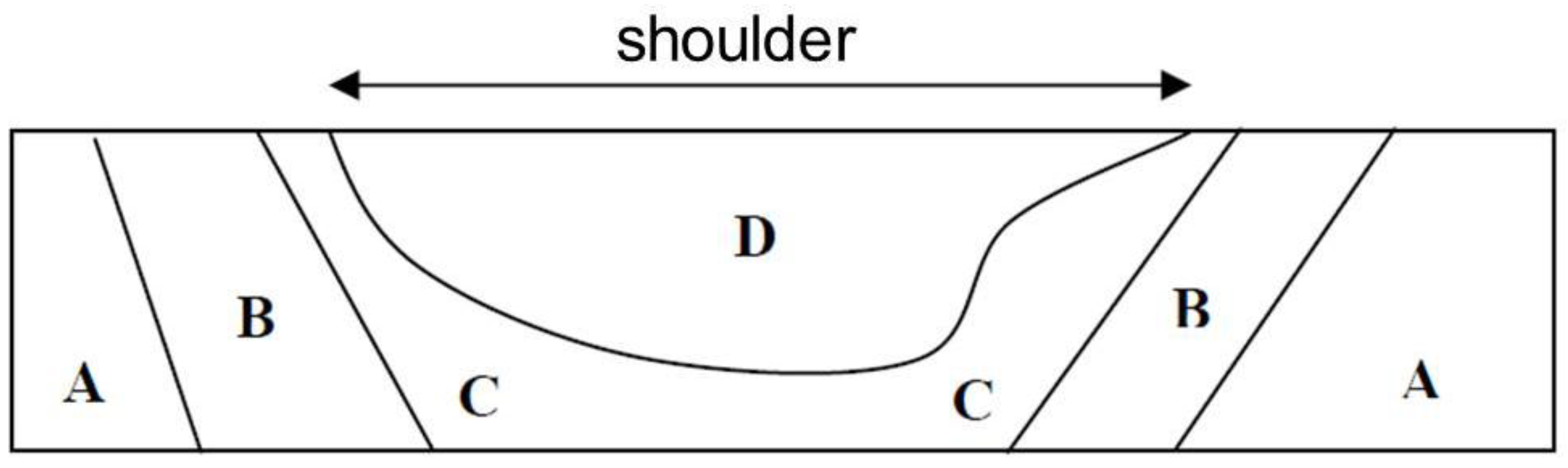

2.1. Welds Shape and Microstructure Analysis

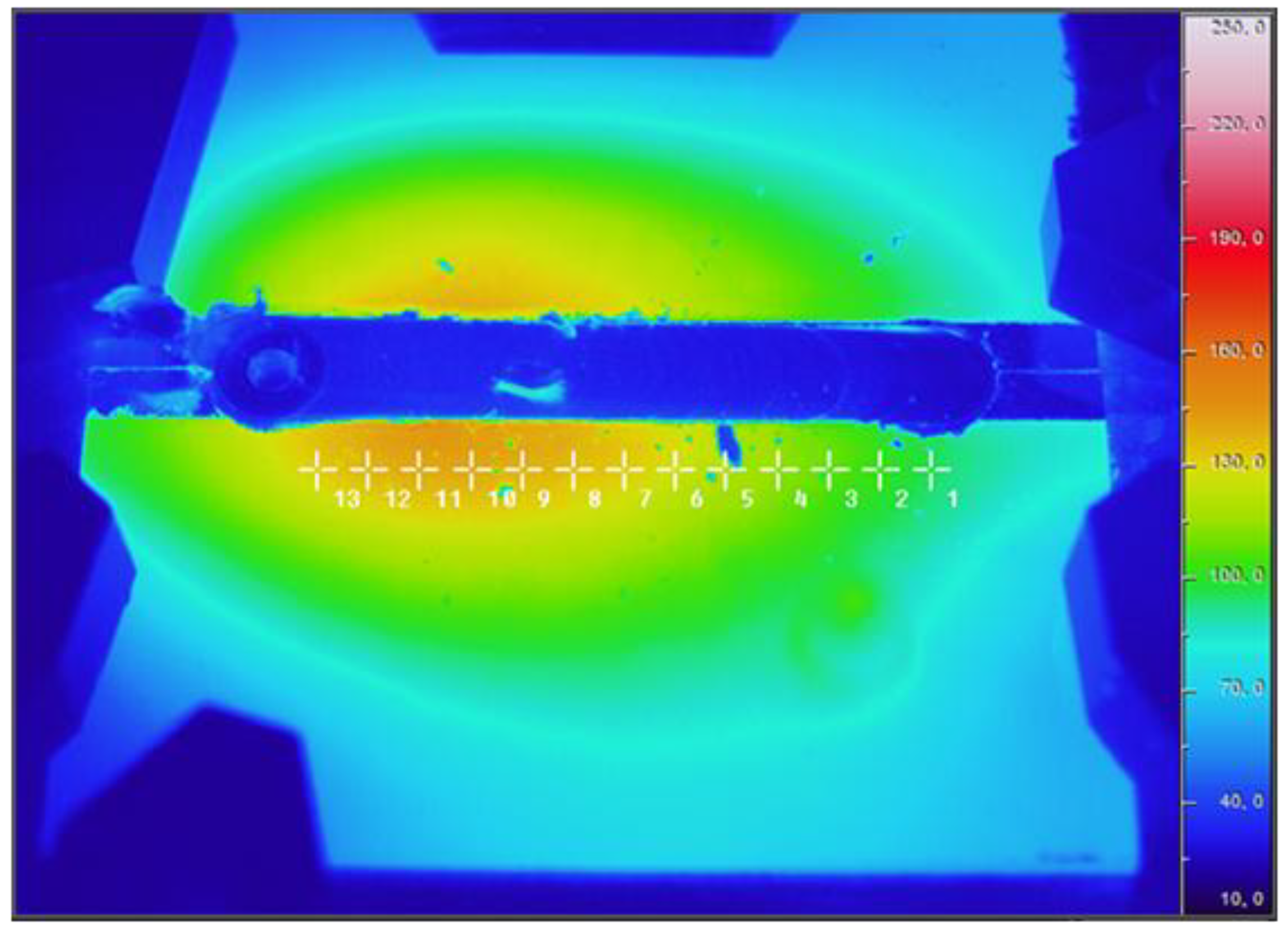

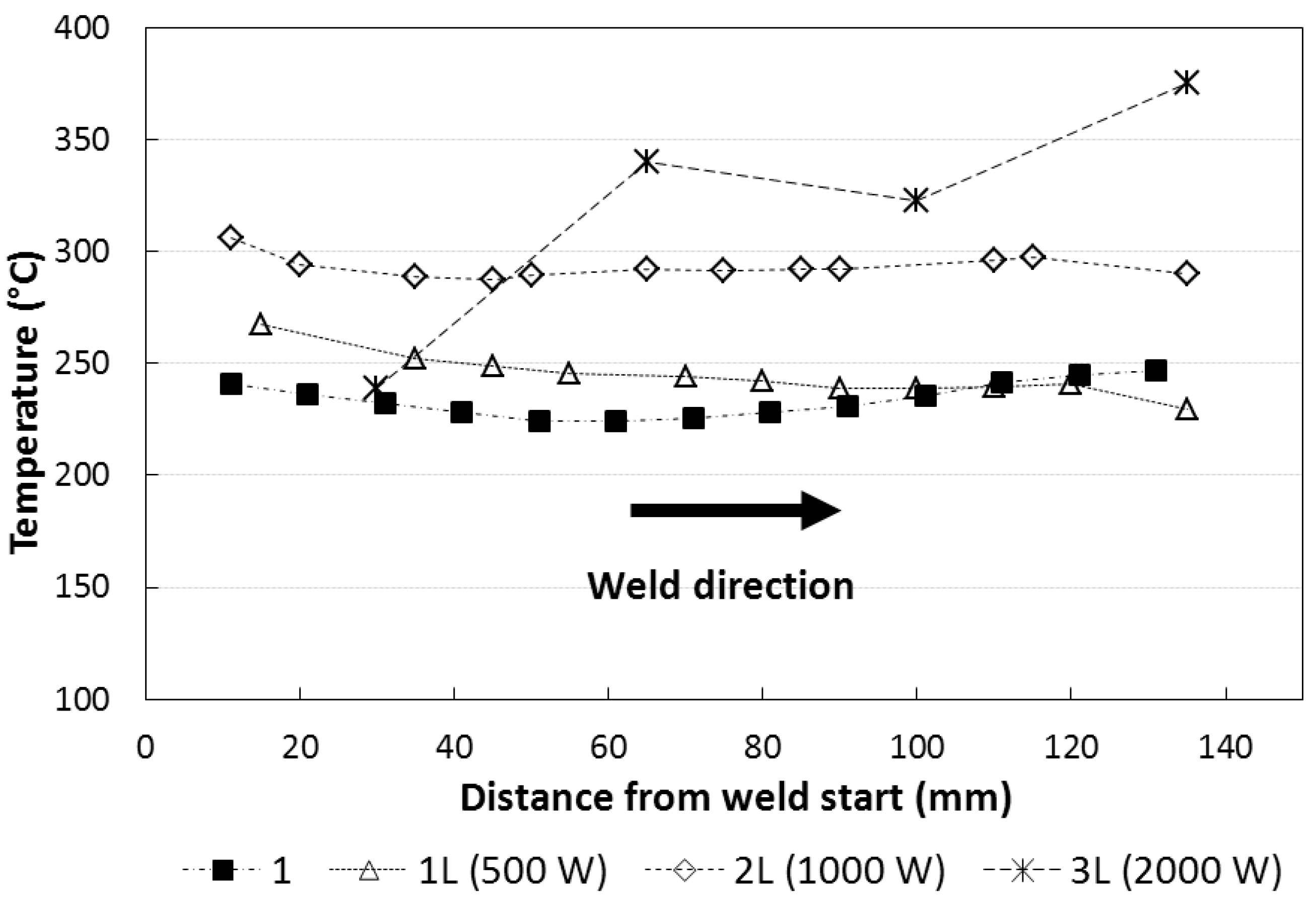

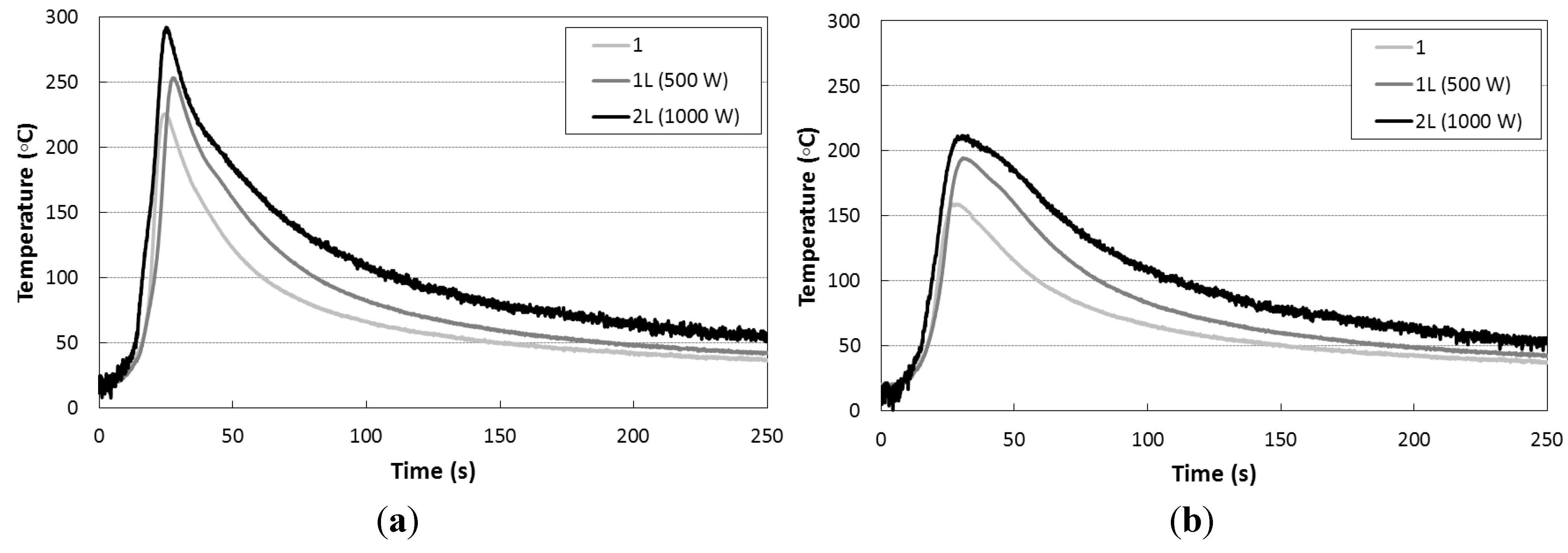

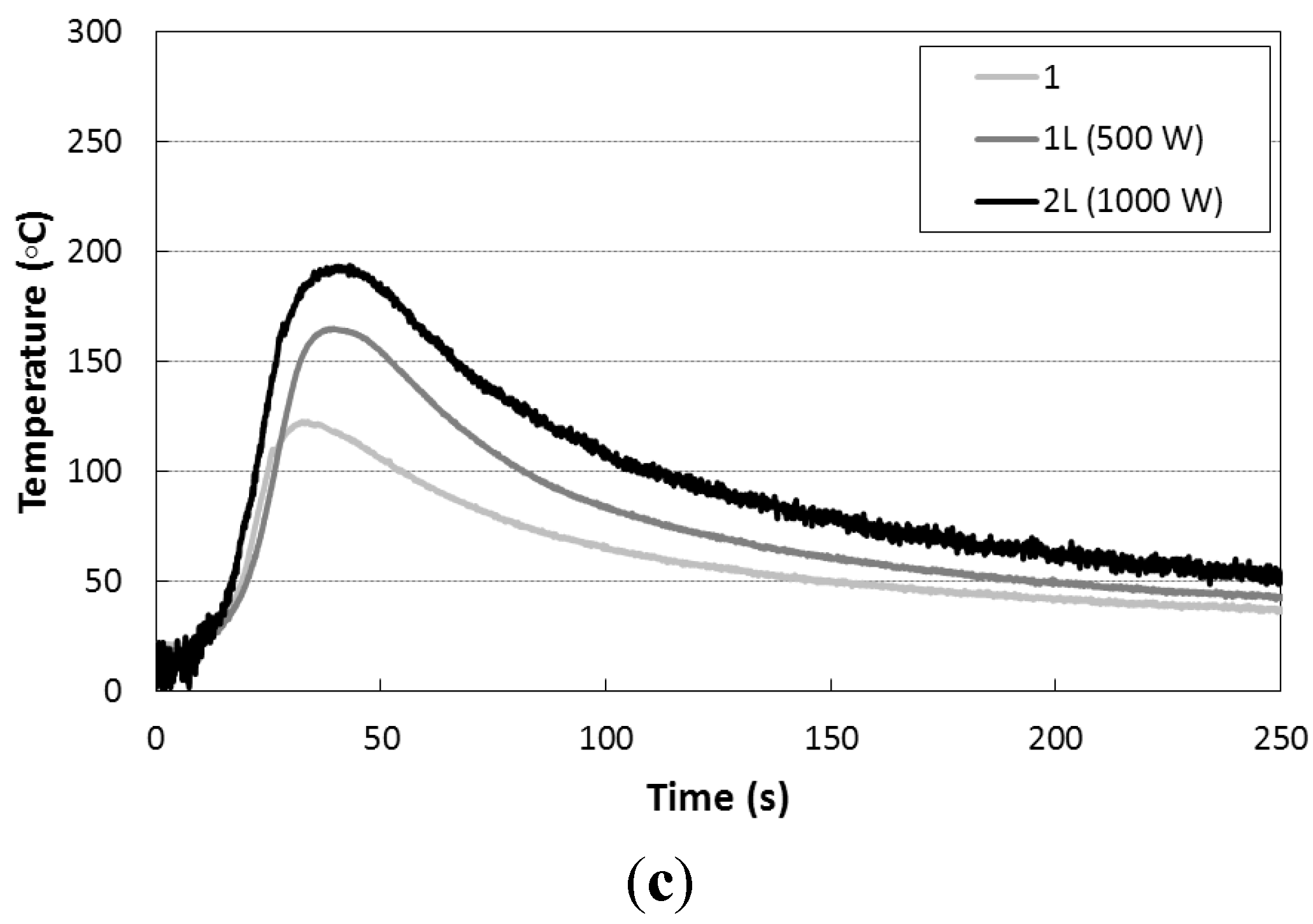

2.2. Temperature Measurement

2.3. Residual Stresses Measurement

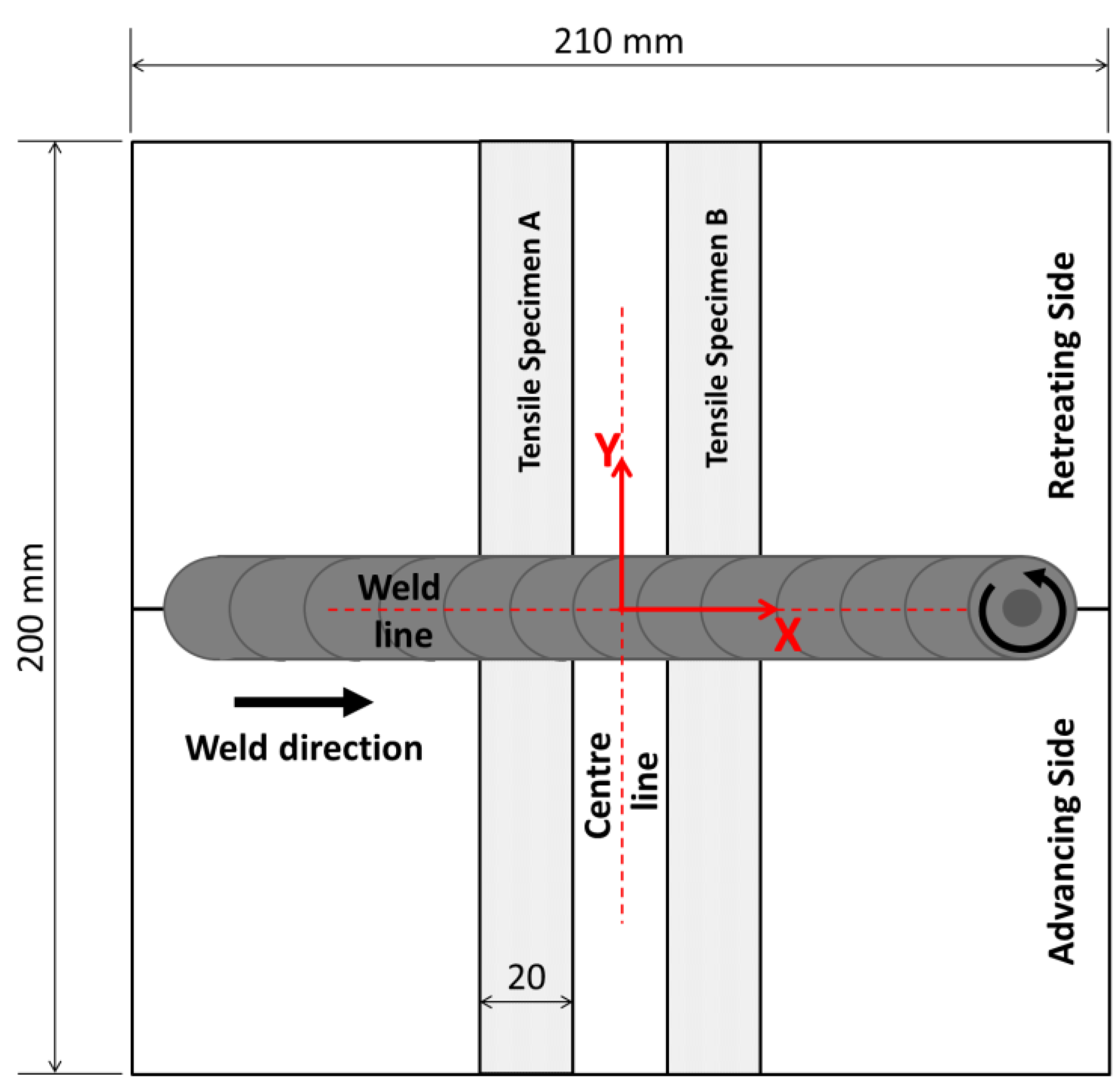

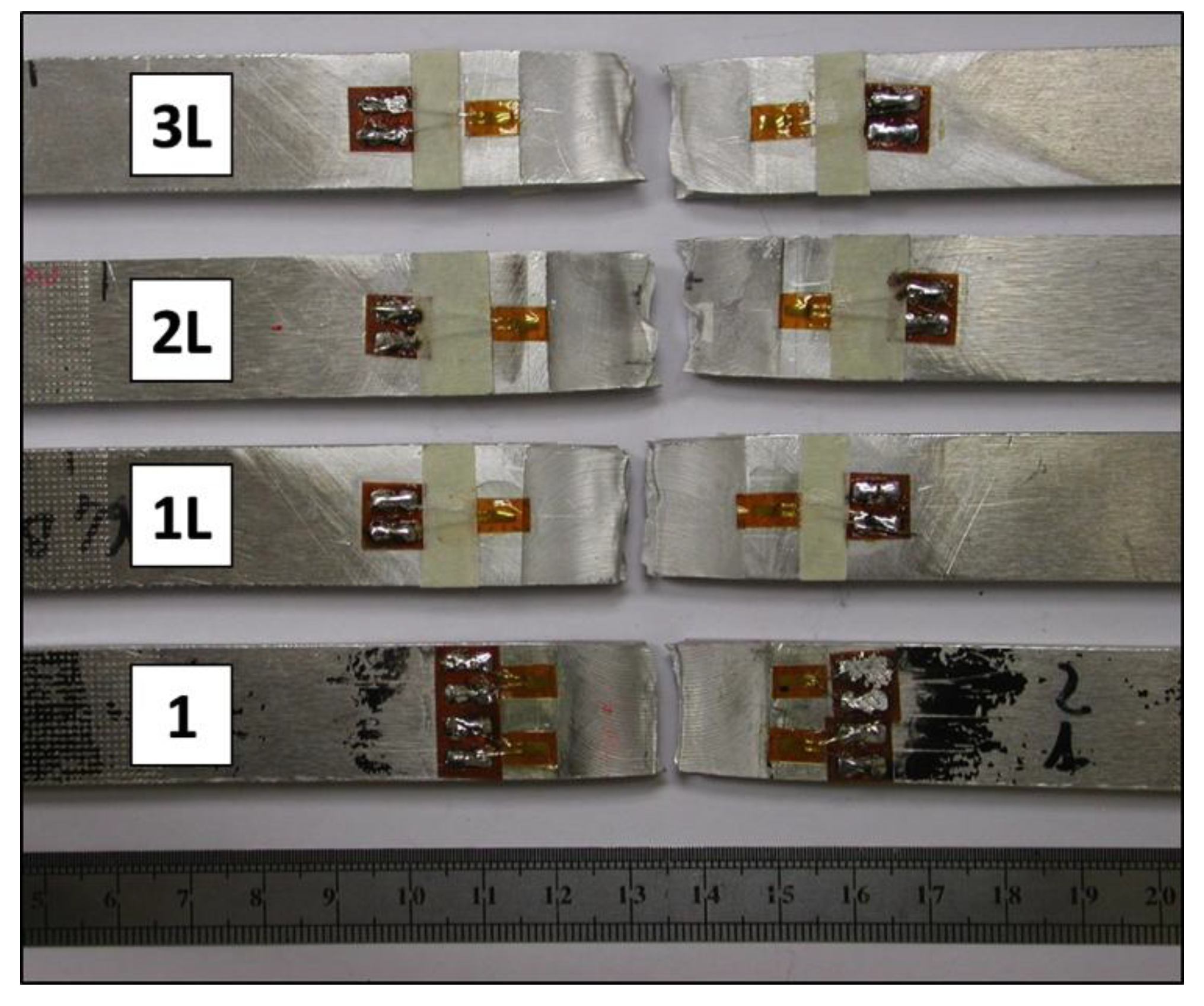

2.4. Microhardness and Tensile Test

3. Results and Discussion

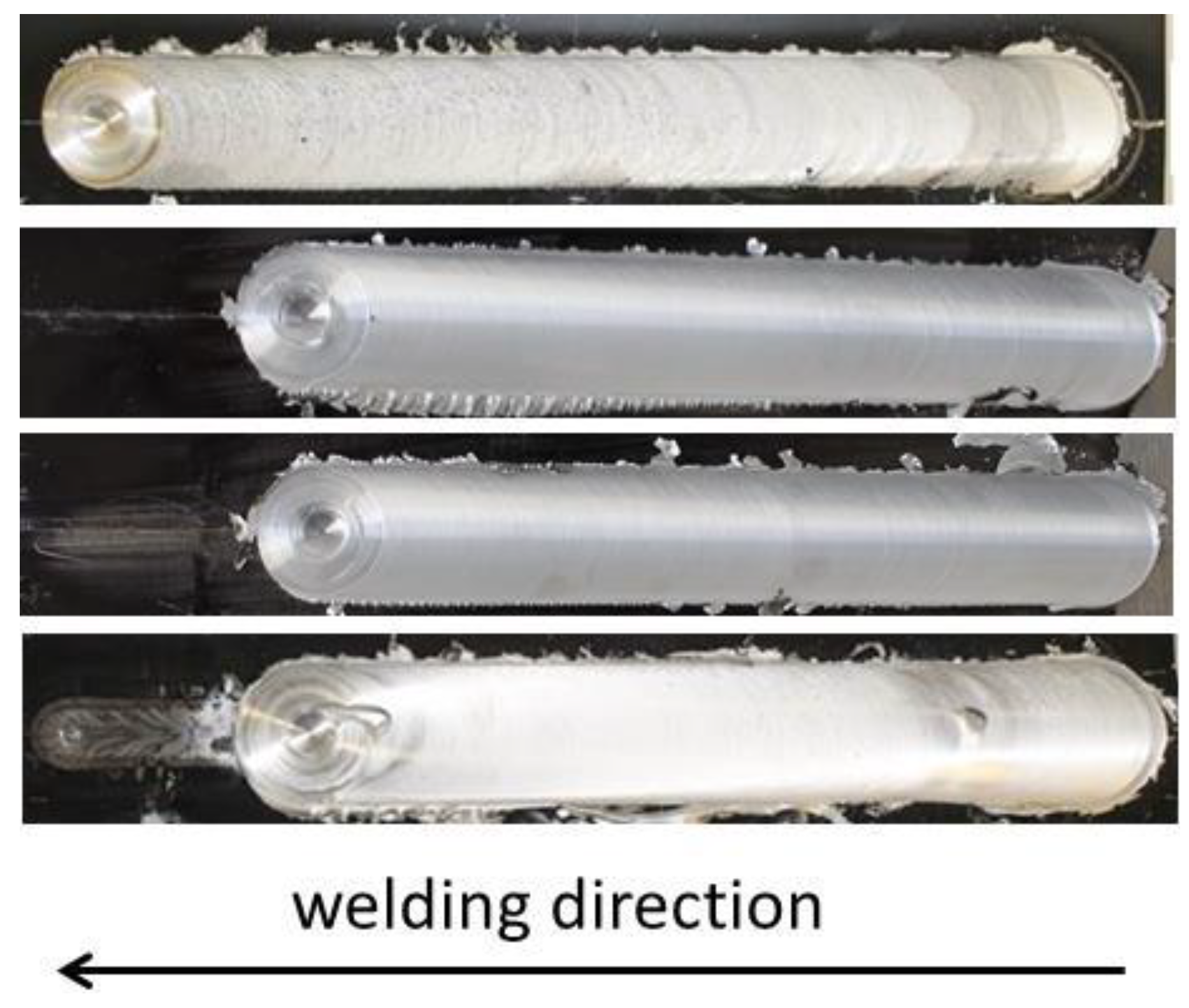

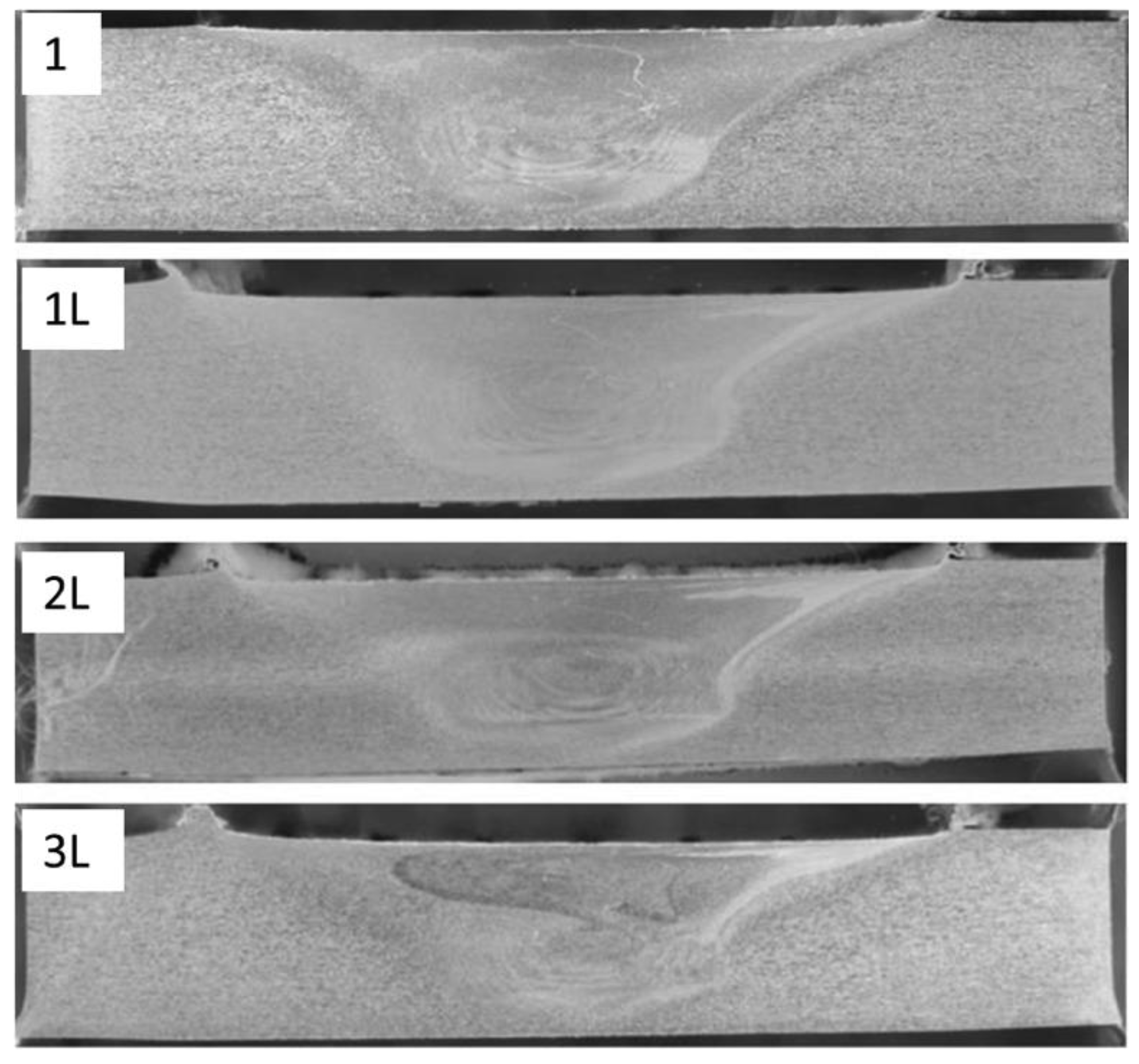

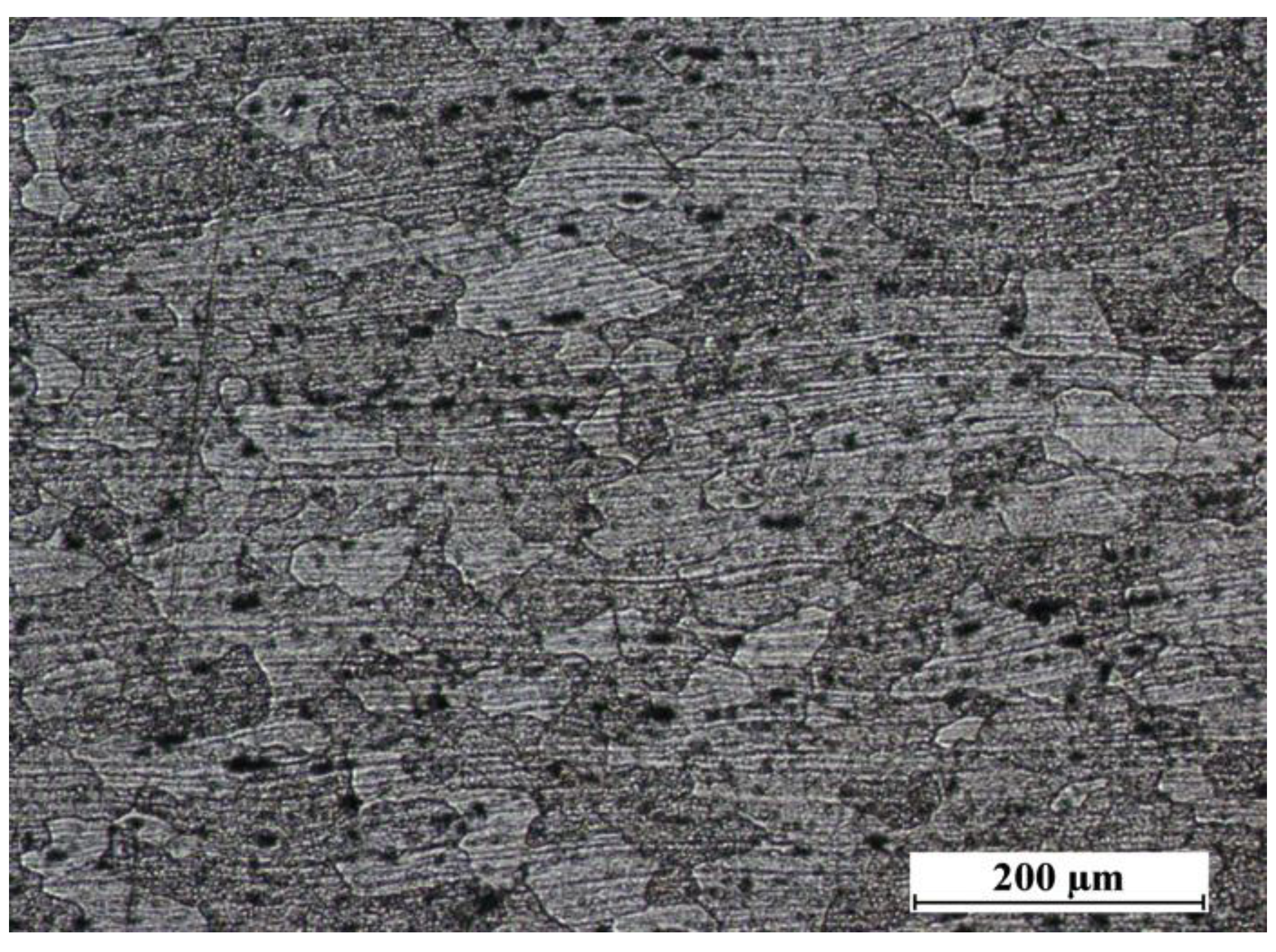

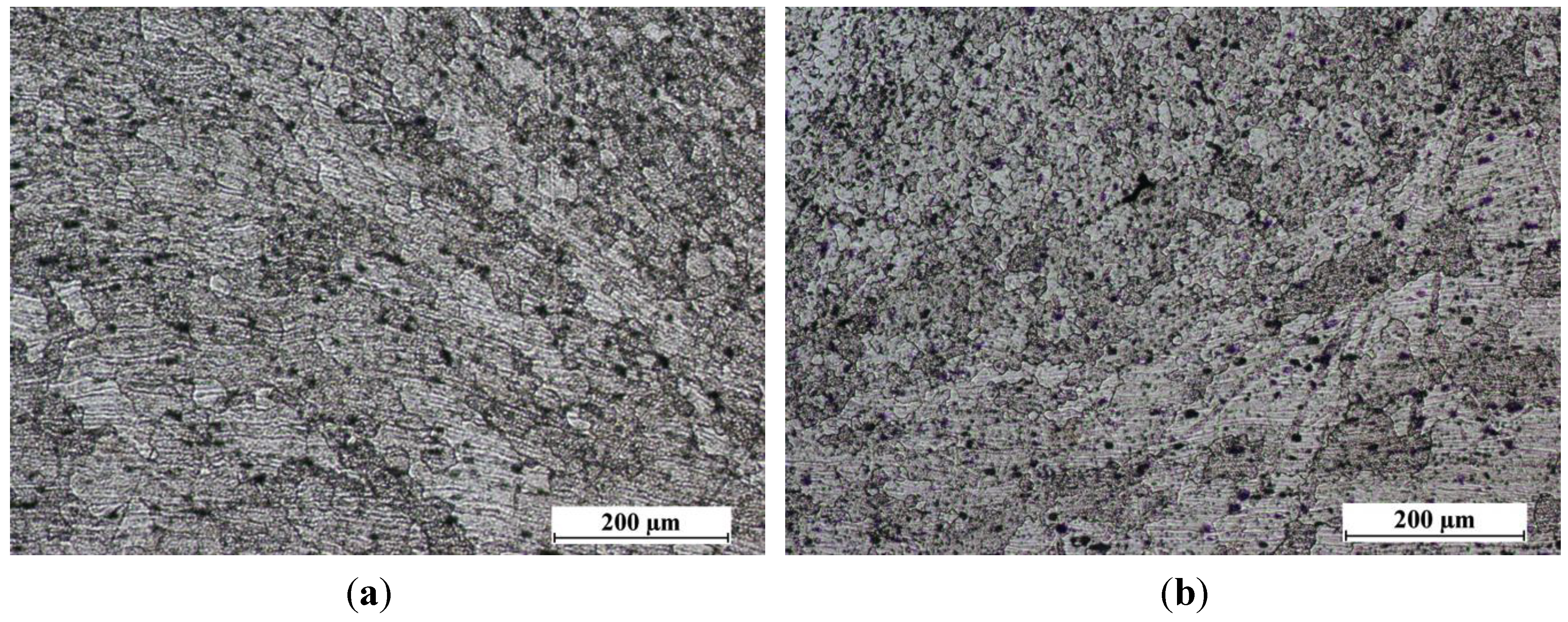

3.1. Weld Bead Shape and Microstructure

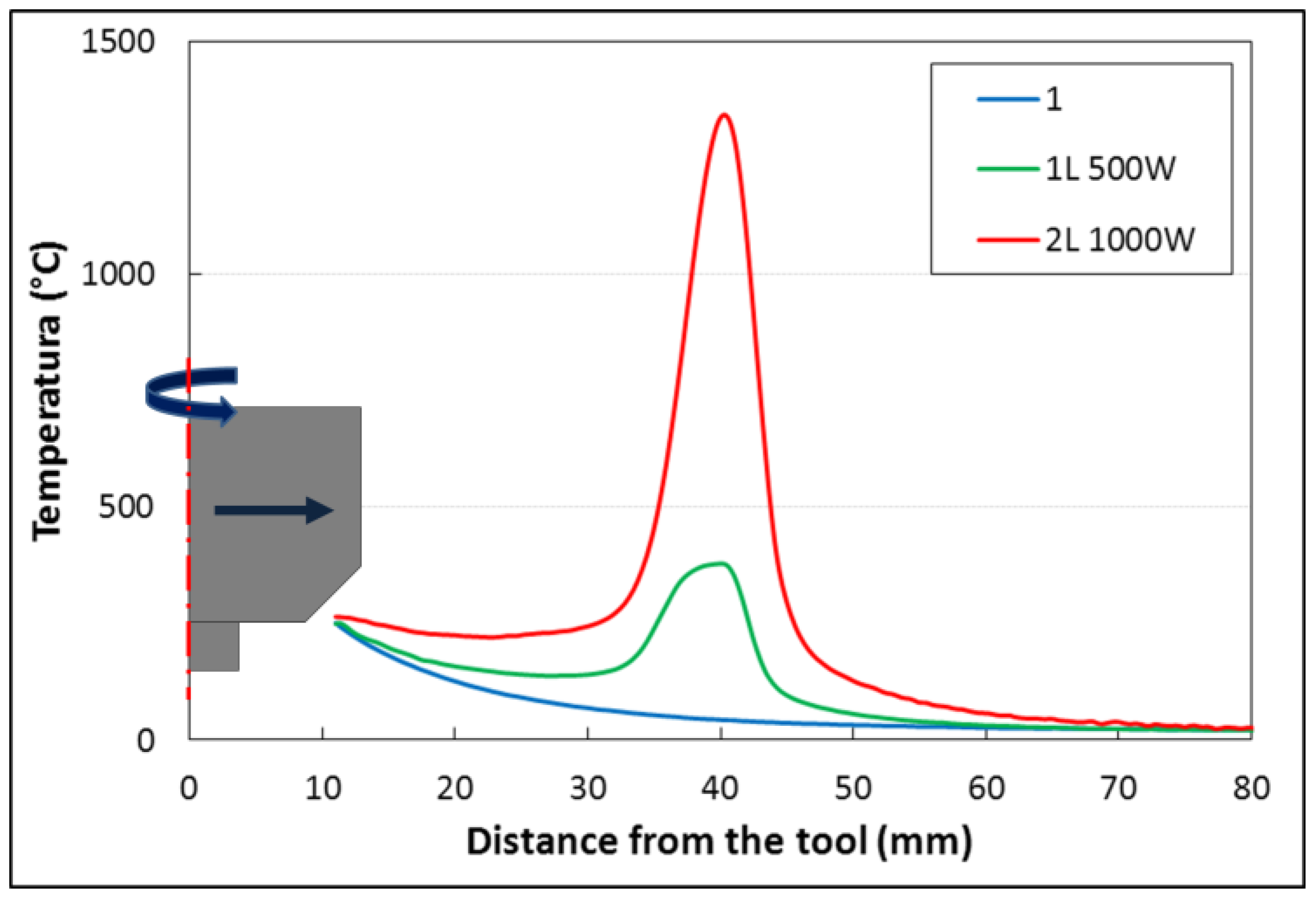

3.2. Temperature Measurement

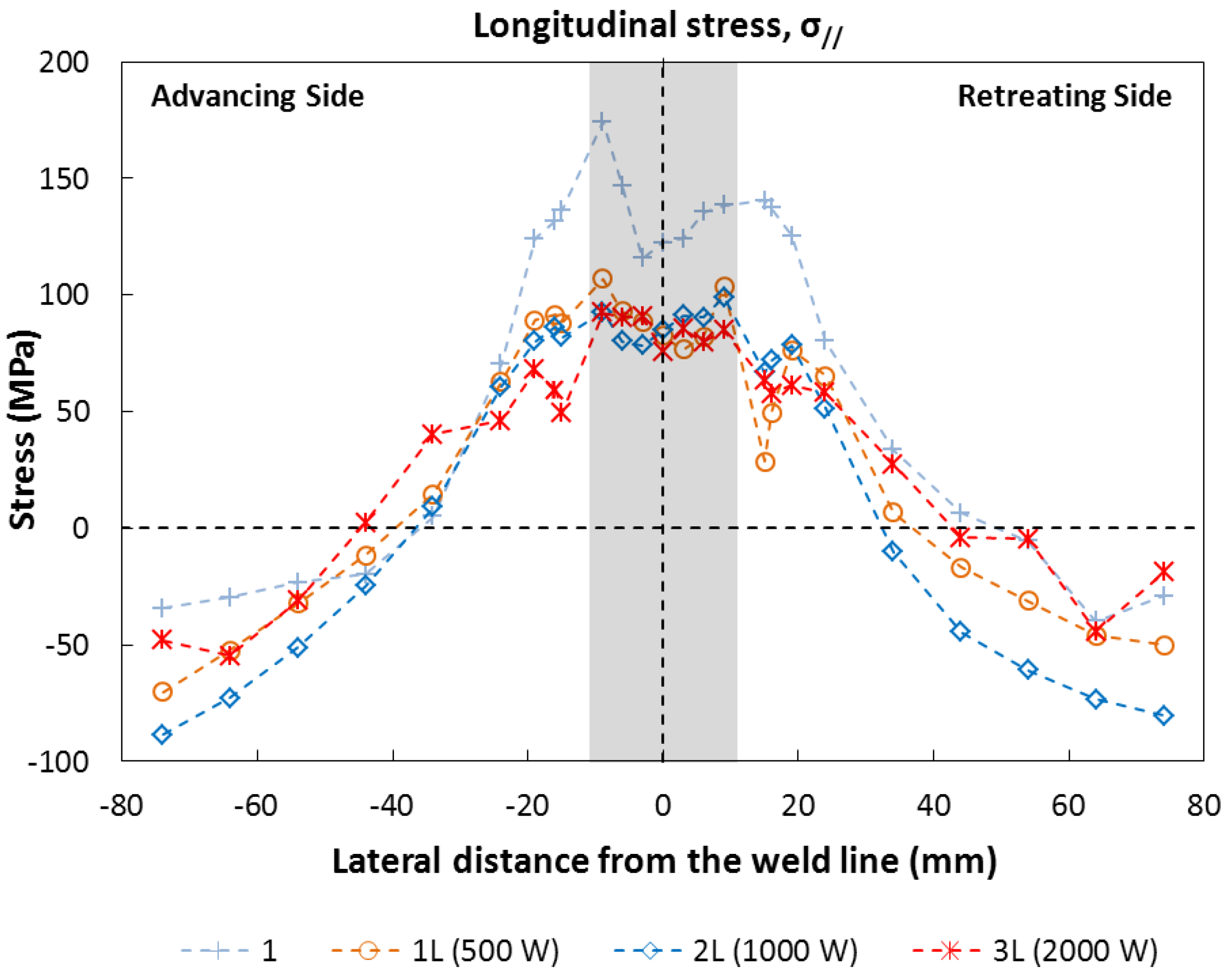

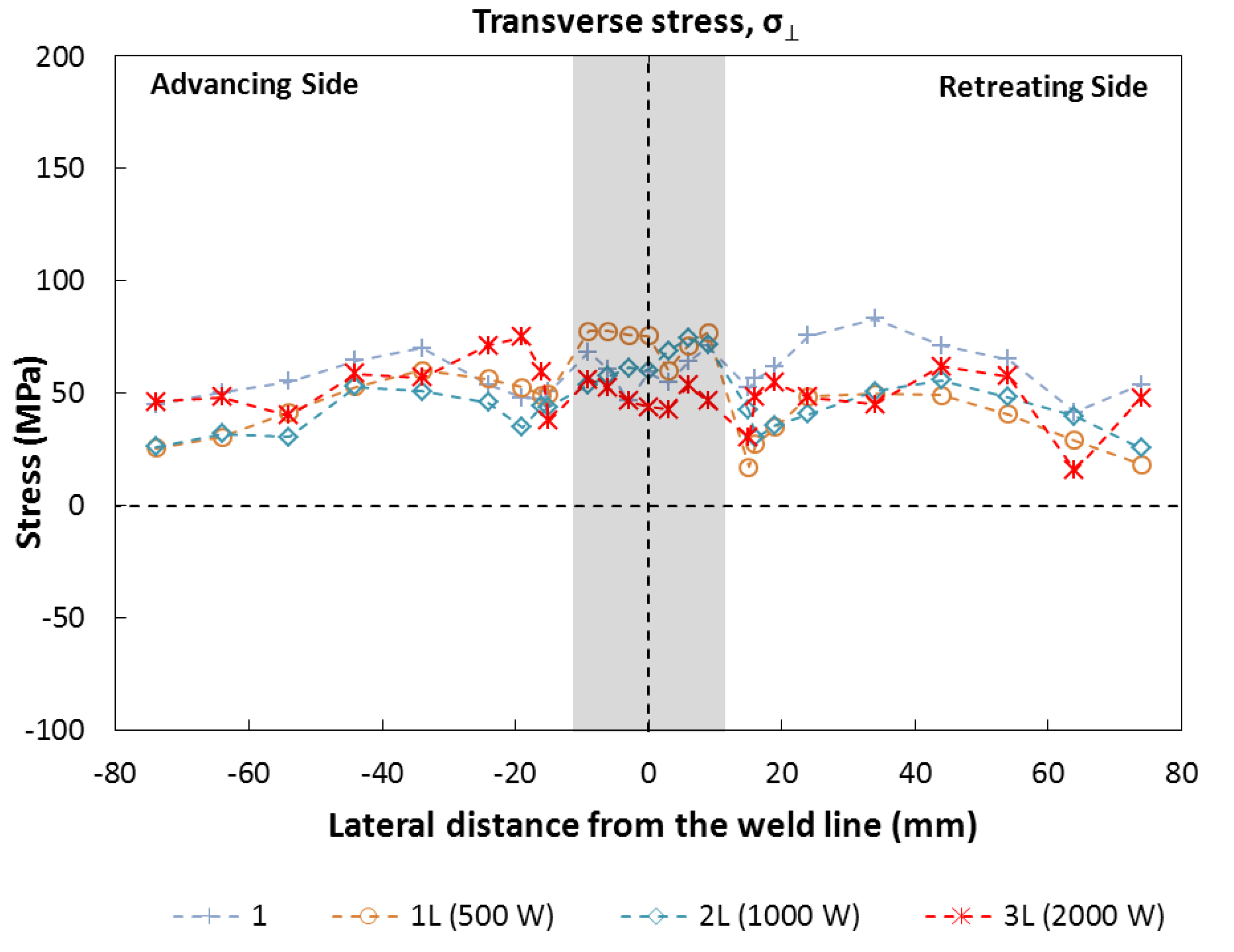

3.3. Residual Stress Measurement

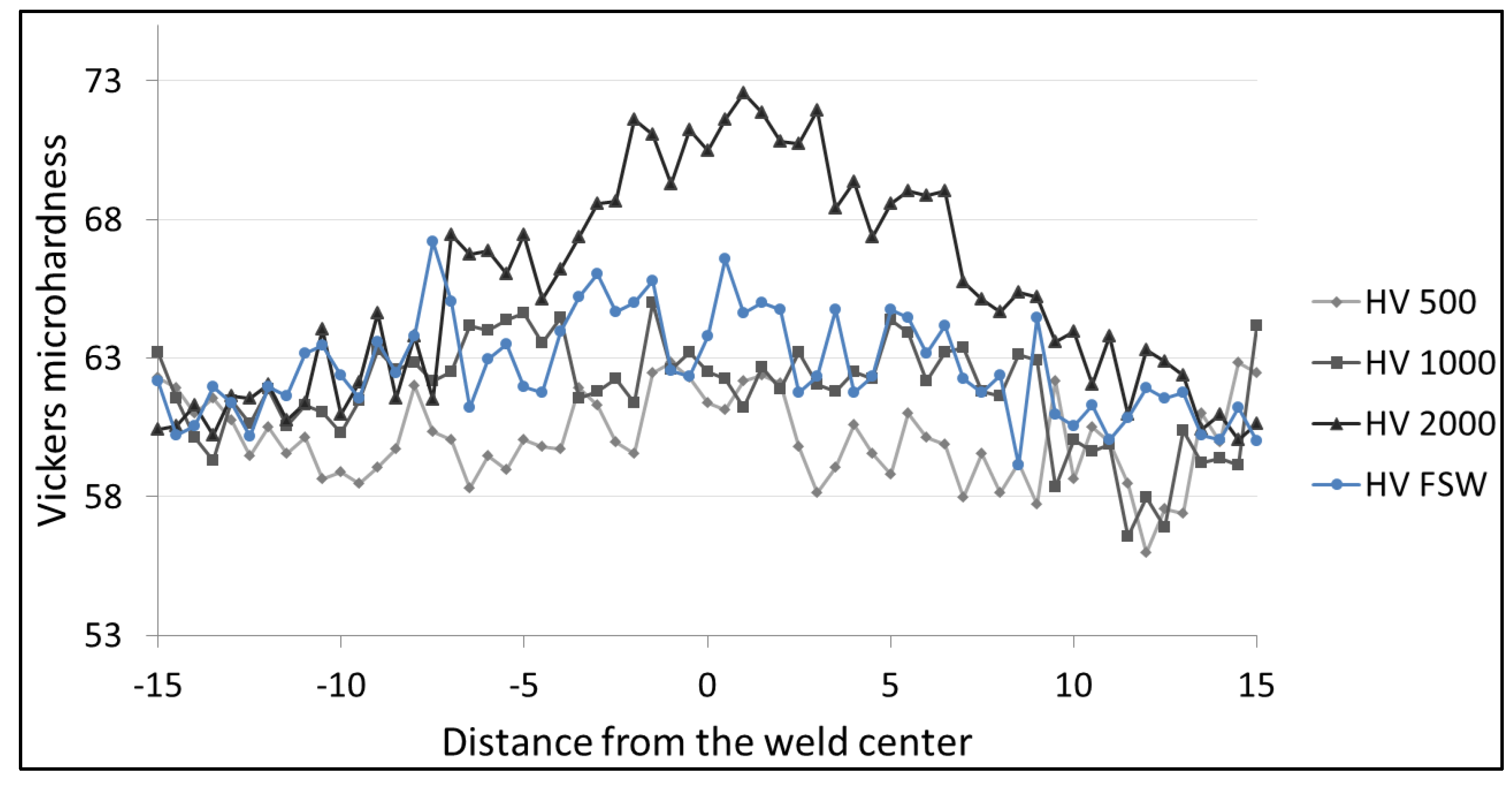

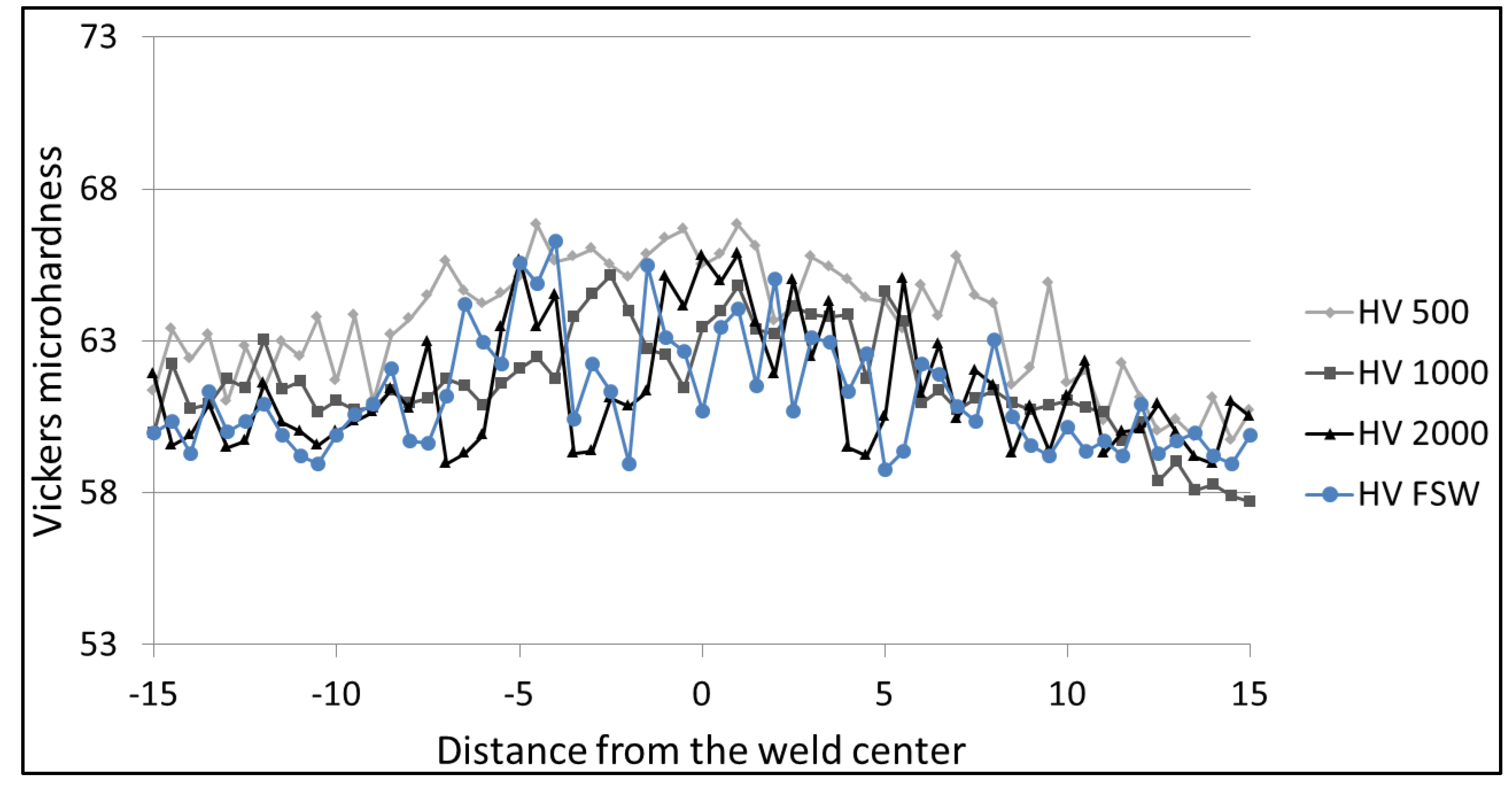

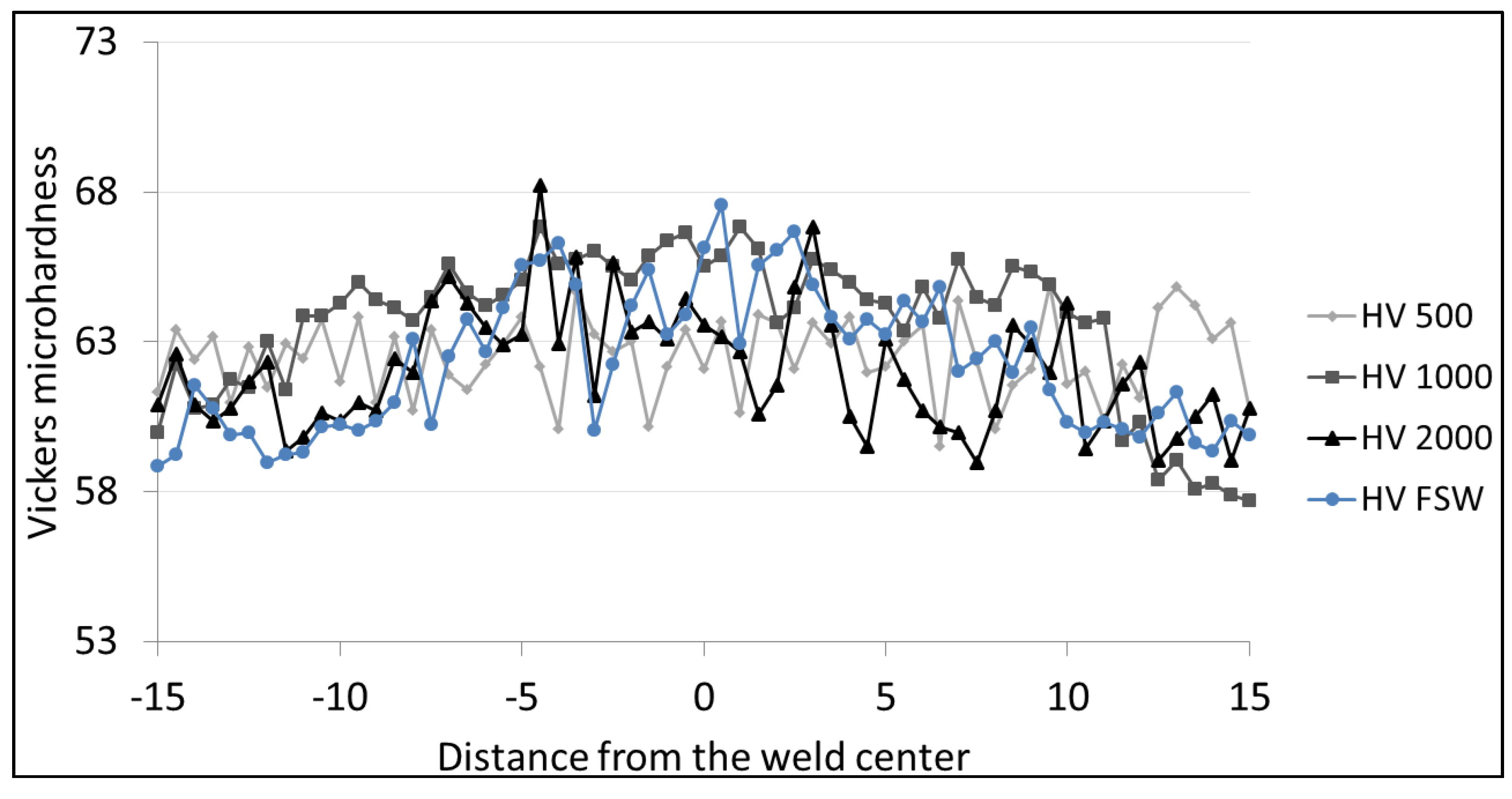

3.4. Microhardness

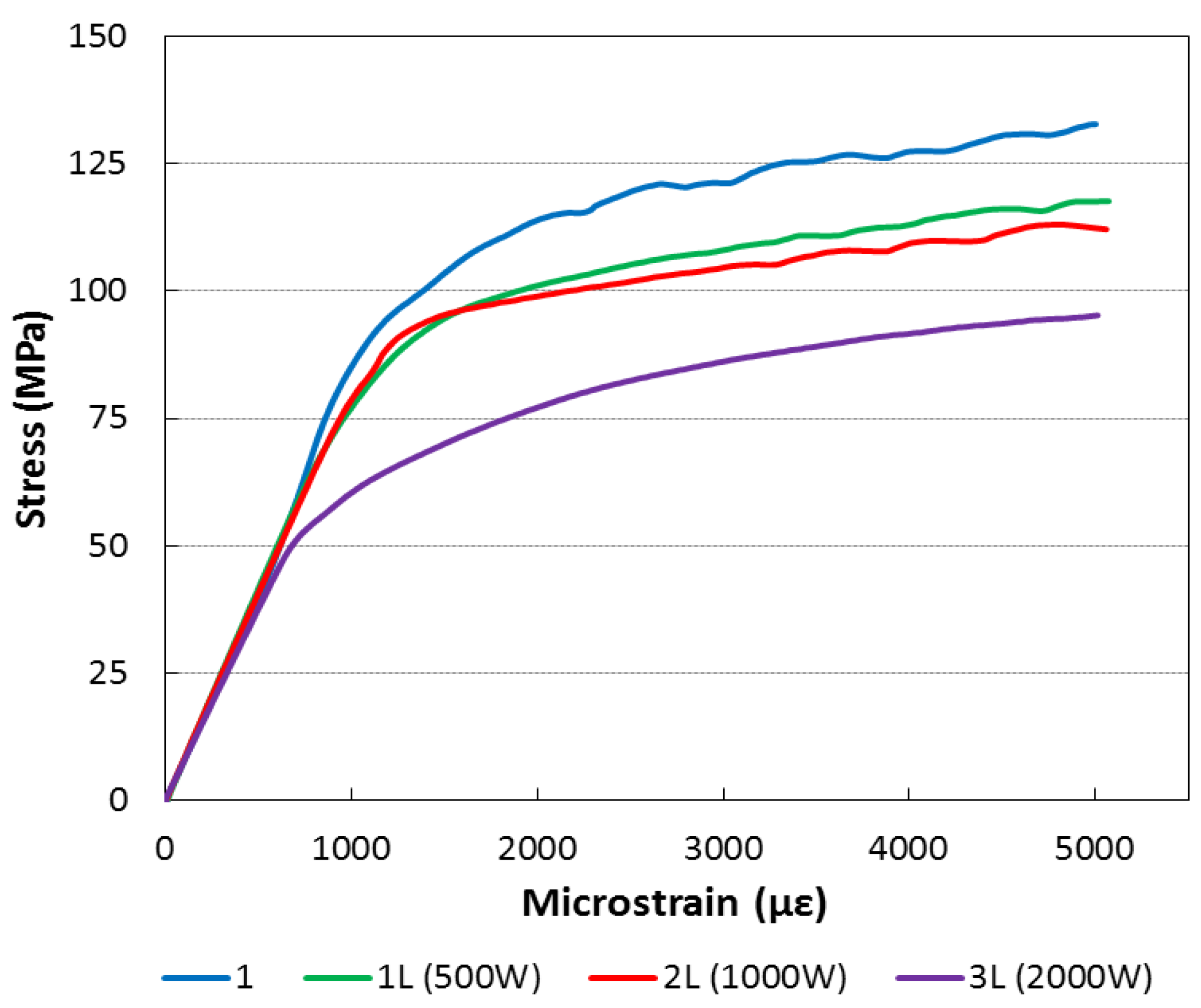

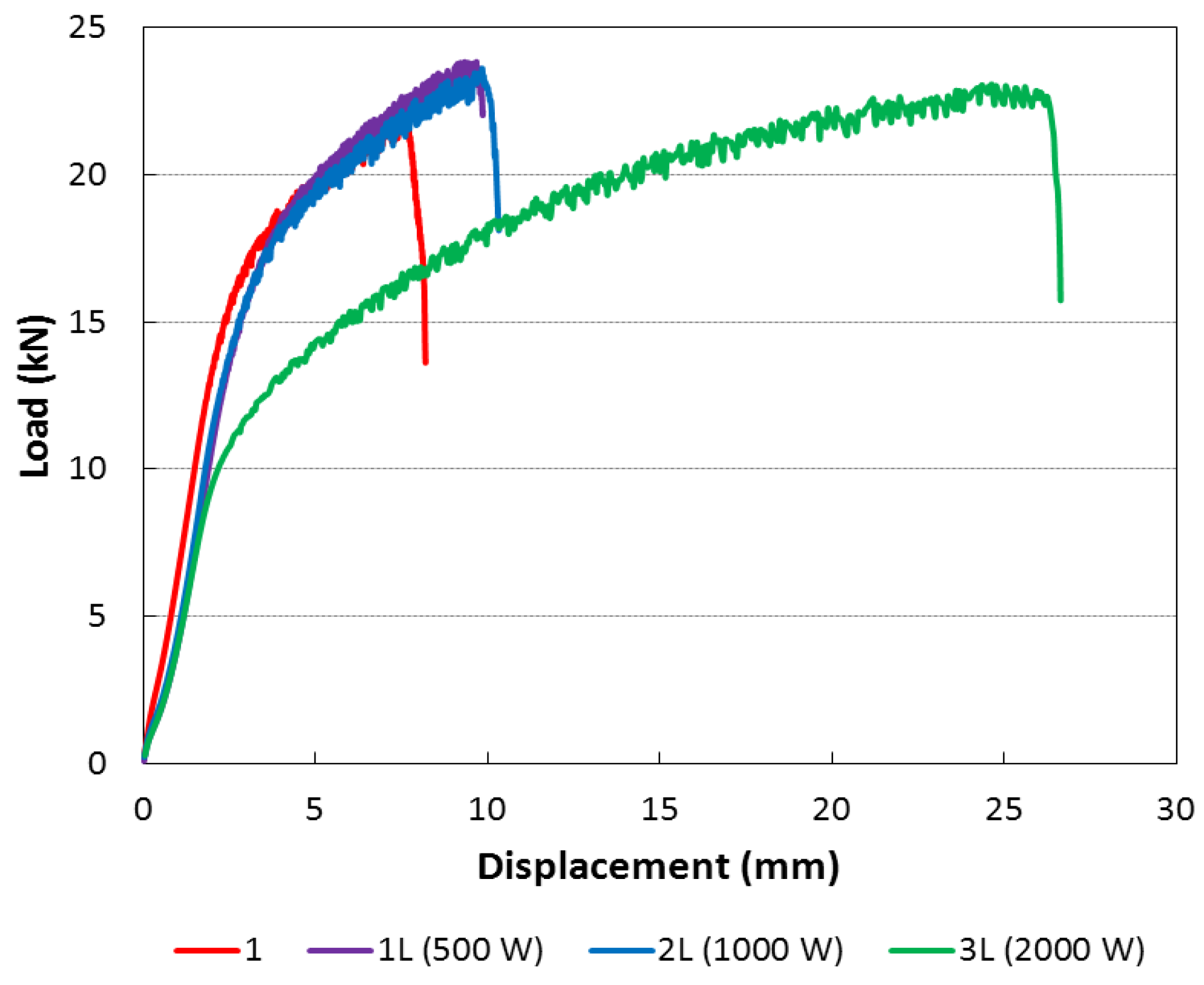

3.5. Tensile Test

| Designation | Proof stress 0.2% (MPa) | Tensile strength (MPa) | Elongation (%) |

|---|---|---|---|

| 1 | 113.9 | 201.3 | 8.9 |

| 1L | 101.0 | 207.3 | 9.4 |

| 2L | 98.9 | 204.1 | 9.4 |

| 3L | 77.2 | 206.9 | 14.8 |

4. Conclusion

Acknowledgments

Conflicts of Interest

References

- Sakayama, T.; Naito, Y.; Miyazakki, Y.; Nose, T.; Murayma, G.; Saita, K.; Oikawa, H. Dissimilar metal joining technologies for steel sheet and aluminum alloy sheet in auto body. Nippon Steel Tech. Rep. 2013, 103, 91–98. [Google Scholar]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Mishraa, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Fujii, H.; Cui, L.; Maeda, M.; Nogi, K. Effect of tool shape on mechanical properties and microstructure of friction stir welded aluminium alloys. Mater. Sci. Eng. 2006, 419, 25–31. [Google Scholar] [CrossRef]

- Arora, A.; Mehta, M.; De, A.; DebRoy, T. Load bearing capacity of tool pin during friction stir welding. Int. J. Adv. Manuf. Technol. 2012, 61, 911–920. [Google Scholar] [CrossRef]

- Forcellese, A.; Gabrielli, F.; Simoncini, M. Mechanical properties and microstructure of joints in AZ31 thin sheets obtained by friction stir welding using “pin” and “pinless” tool configurations. Mater. Des. 2012, 34, 219–229. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of tool pin profile and welding speed on the formation of friction stir processing zone in AA2219 aluminium alloy. J. Mater. Process. Technol. 2008, 200, 163–175. [Google Scholar] [CrossRef]

- Hilgert, J.; Schmidt, H.N.B.; dos Santos, J.F.; Huber, N. Thermal models for bobbin tool friction stir welding. J. Mater. Process. Technol. 2011, 211, 197–204. [Google Scholar] [CrossRef]

- Cerri, E.; Leo, P. Influence of high temperature thermal treatment on grain stability and mechanical properties of medium strength aluminium alloy friction stir welds. J. Mater. Process. Technol. 2011, 213, 75–83. [Google Scholar] [CrossRef]

- Fratini, L.; Pasta, S. Residual stresses in friction stir welded parts of complex geometry. Int. J. Adv. Manuf. Technol. 2012, 59, 547–557. [Google Scholar] [CrossRef]

- Bastier, A.; Maitournam, M.H.; Roger, F.; van Dang, K. Modelling of the residual state of friction stir welded plates. J. Mater. Process. Technol. 2008, 200, 25–37. [Google Scholar] [CrossRef]

- Kohn, G.; Greenberg, Y.; Makover, I.; Munitz, A. Laser-assisted friction stir welding. Weld. J. 2002, 81, 46–48. [Google Scholar]

- Casavola, C.; Lamberti, L.; Pappalettere, C.; Tattoli, F. A comprehensive numerical strain/stress analysis of laser beam welded titanium butt joints. J. Strain Anal. 2010, 45, 535–554. [Google Scholar] [CrossRef]

- Casavola, C.; Pluvinage, G.; Pappalettere, C. Fatigue resistance of titanium laser and hybrid welded joints. Mater. Des. 2011, 32, 3127–3135. [Google Scholar] [CrossRef]

- Chang, W.-S.; Rajesh, S.R.; Chun, C.-K.; Kimy, H.-J. Microstructure and mechanical properties of hybrid laser-friction stir welding between AA6061-T6 Al alloy and AZ31 Mg alloy. J. Mater. Sci. Technol. 2011, 27, 199–204. [Google Scholar] [CrossRef]

- Merklein, M.; Giera, A. Laser assisted Friction Stir Welding of drawable steel-aluminium tailored hybrids. Int. J. Mater. Form. 2008, 1, 1299–1302. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Ludovico, A.D.; Contuzzi, N.; Angelastro, A. Study of a fiber laser assited friction stir welding process. Proc. SPIE 2012, 8239. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Benyounis, K.Y.; Olabi, A.G. Methods of measuring residual stresses in components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef] [Green Version]

- Olabi, A.G.; Casalino, G.; Benyounis, K.Y.; Rotondo, A. Minimisation of the residual stress in the heat affected zone by means of numerical methods. Mater. Des. 2007, 28, 2295–2302. [Google Scholar] [CrossRef]

- Withers, P.J.; Bhadeshia, H.K.D. Residual stress Part 1—Measurement techniques. Mater. Sci. Technol. 2001, 17, 355–365. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Pappalettere, C. Feasibility of local stress relaxation by laser annealing and X-Ray measurement. Strain 2013, 49, 393–398. [Google Scholar]

- Casavola, C.; Pappalettere, C.; Tursi, F. Calibration of Barkhausen Noise for Residual Stress Measurement. In Experimental and Applied Mechanics, Proceedings of the 2012 Annual Conference on Experimental and Applied Mechanics; Costa Mesa, CA, USA, 11–14 June 2012, Ventura, C.E., Crone, W.C., Furlong, C., Eds.; Springer: New York, NY, USA, 2013; Volume 4, pp. 255–266. [Google Scholar]

- Owen, R. Neutron and synchrotron measurements of residual strain in TIG welded aluminium alloy 2024. Mater. Sci. Eng. 2003, 346, 159–167. [Google Scholar] [CrossRef]

- Withers, P.J.; Bhadeshia, H.K.D. Residual stress Part 2—Nature and origins. Mater. Sci. Technol. 2001, 17, 366–375. [Google Scholar] [CrossRef]

- Casavola, C.; Campanelli, S.L.; Pappalettere, C. Preliminary investigation on distribution of residual stress generated by the selective laser melting process. J. Strain Anal. 2009, 44, 93–104. [Google Scholar] [CrossRef]

- Casavola, C.; Pappalettere, C. Application of WELFARE Method on Aluminum Alloy Welded Joints. In Proceedings of the 2005 SEM Annual Conference and Exposition on Experimental and Applied Mechanics, Portland, OR, USA, 7–9 June 2005; Society for Experimental Mechanics, Inc.: Bethel, CT, USA, 2005; pp. 1555–1562. [Google Scholar]

- Hwang, Y.-M.; Kang, Z.-W.; Chiou, Y.-C.; Hsu, H.-H. Experimental study on temperature distributions within the workpiece during friction stir welding of aluminium alloys. Int. J. Mach. Tools Manuf. 2008, 48, 778–787. [Google Scholar] [CrossRef]

- Zhu, X.; Chao, Y. Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel. J. Mater. Process. Technol. 2004, 146, 263–272. [Google Scholar] [CrossRef]

- Song, M.; Kovacevic, R. Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int. J. Mach. Tools Manuf. 2003, 43, 605–615. [Google Scholar] [CrossRef]

- Peel, M.; Steuwer, A.; Preuss, M.; Withers, P.J. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta Mater. 2003, 51, 4791–4801. [Google Scholar] [CrossRef]

- Jata, K.; Sankaran, K.; Ruschau, J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Metall. Mater. Trans. Phys. Metall. Mater. Sci. 2000, 31, 2181–2192. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Campanelli, S.L.; Casalino, G.; Casavola, C.; Moramarco, V. Analysis and Comparison of Friction Stir Welding and Laser Assisted Friction Stir Welding of Aluminum Alloy. Materials 2013, 6, 5923-5941. https://doi.org/10.3390/ma6125923

Campanelli SL, Casalino G, Casavola C, Moramarco V. Analysis and Comparison of Friction Stir Welding and Laser Assisted Friction Stir Welding of Aluminum Alloy. Materials. 2013; 6(12):5923-5941. https://doi.org/10.3390/ma6125923

Chicago/Turabian StyleCampanelli, Sabina Luisa, Giuseppe Casalino, Caterina Casavola, and Vincenzo Moramarco. 2013. "Analysis and Comparison of Friction Stir Welding and Laser Assisted Friction Stir Welding of Aluminum Alloy" Materials 6, no. 12: 5923-5941. https://doi.org/10.3390/ma6125923