Optimized Slurries for Spray Drying: Different Approaches to Obtain Homogeneous and Deformable Alumina-Zirconia Granules

Abstract

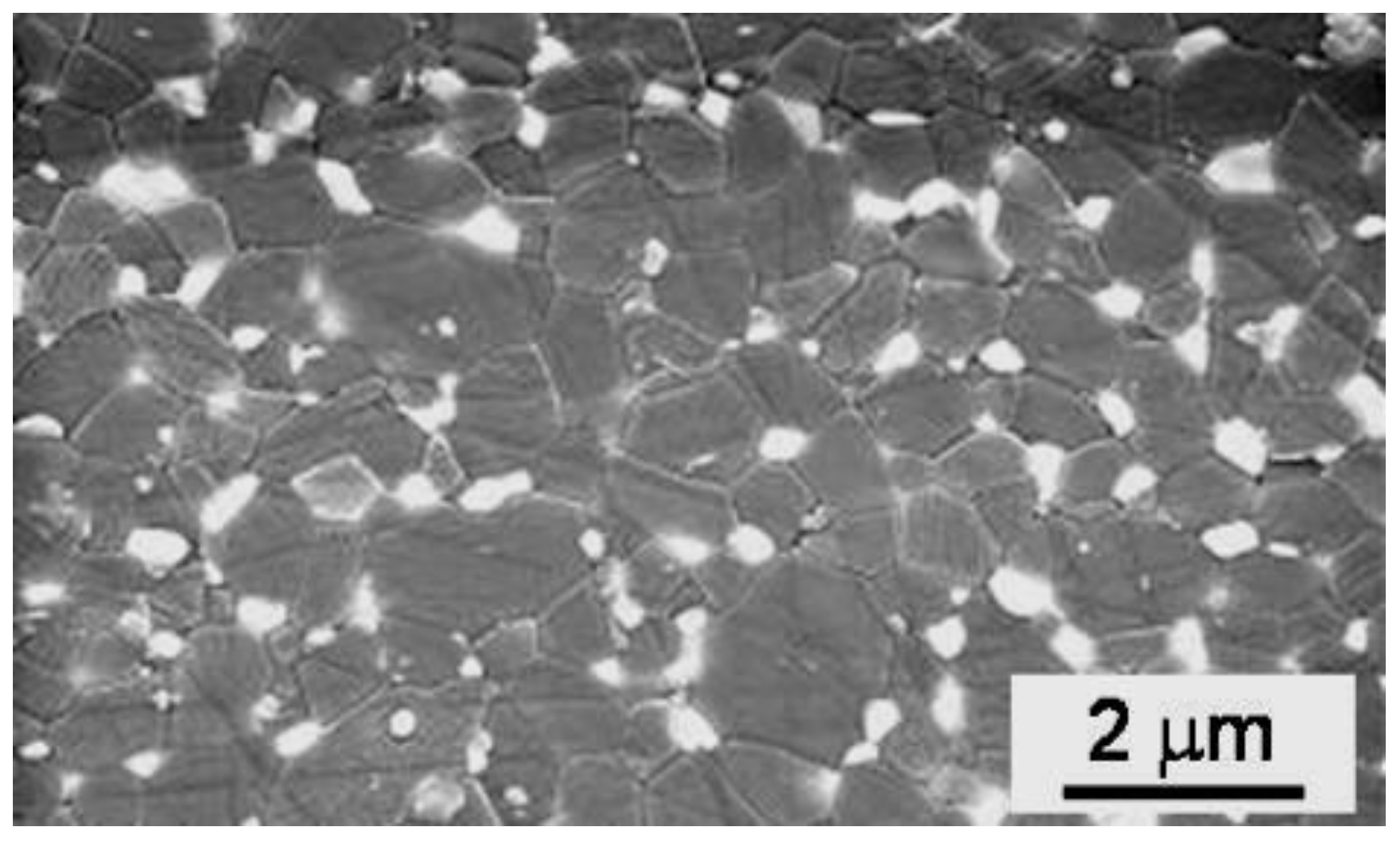

:1. Introduction

2. Results

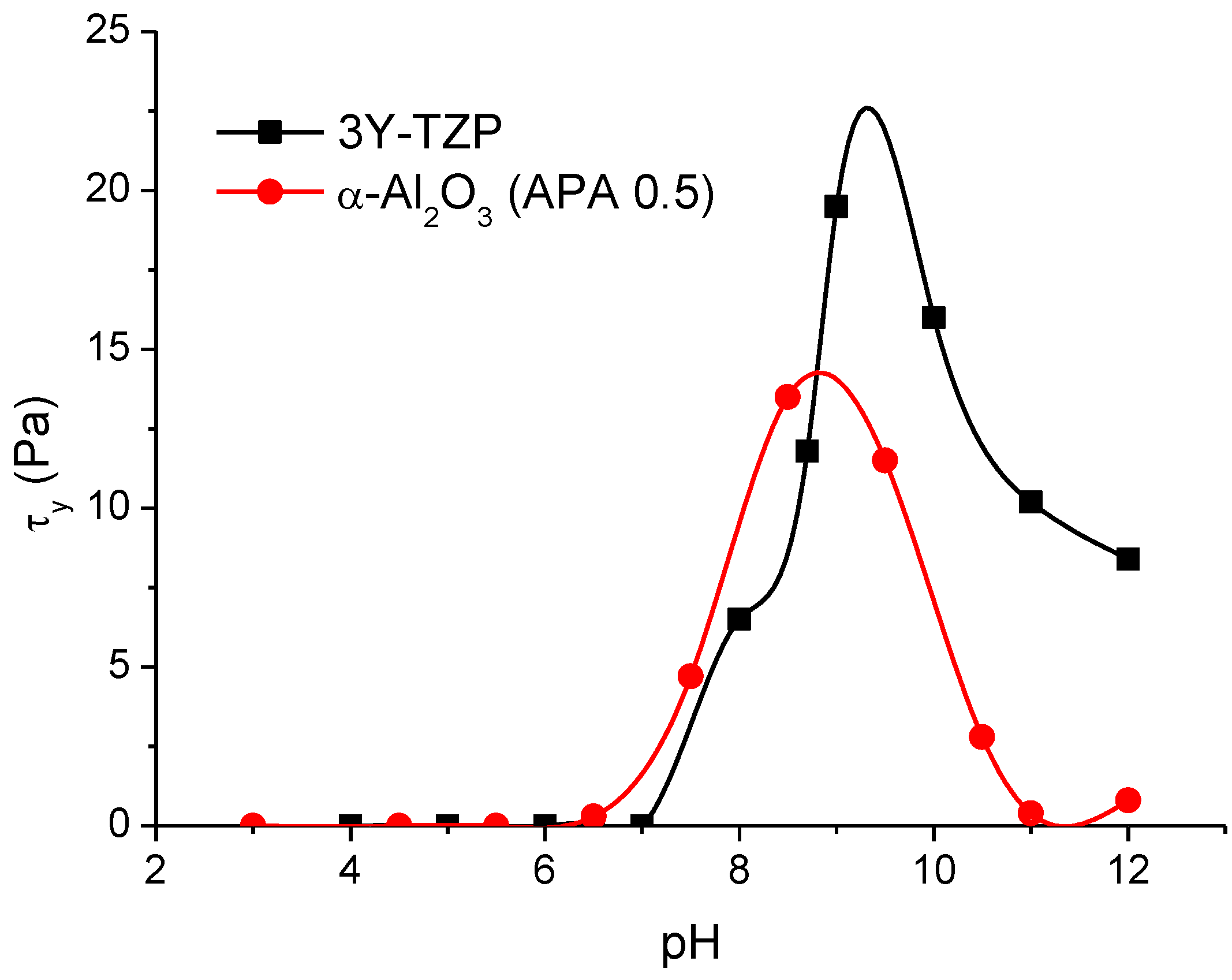

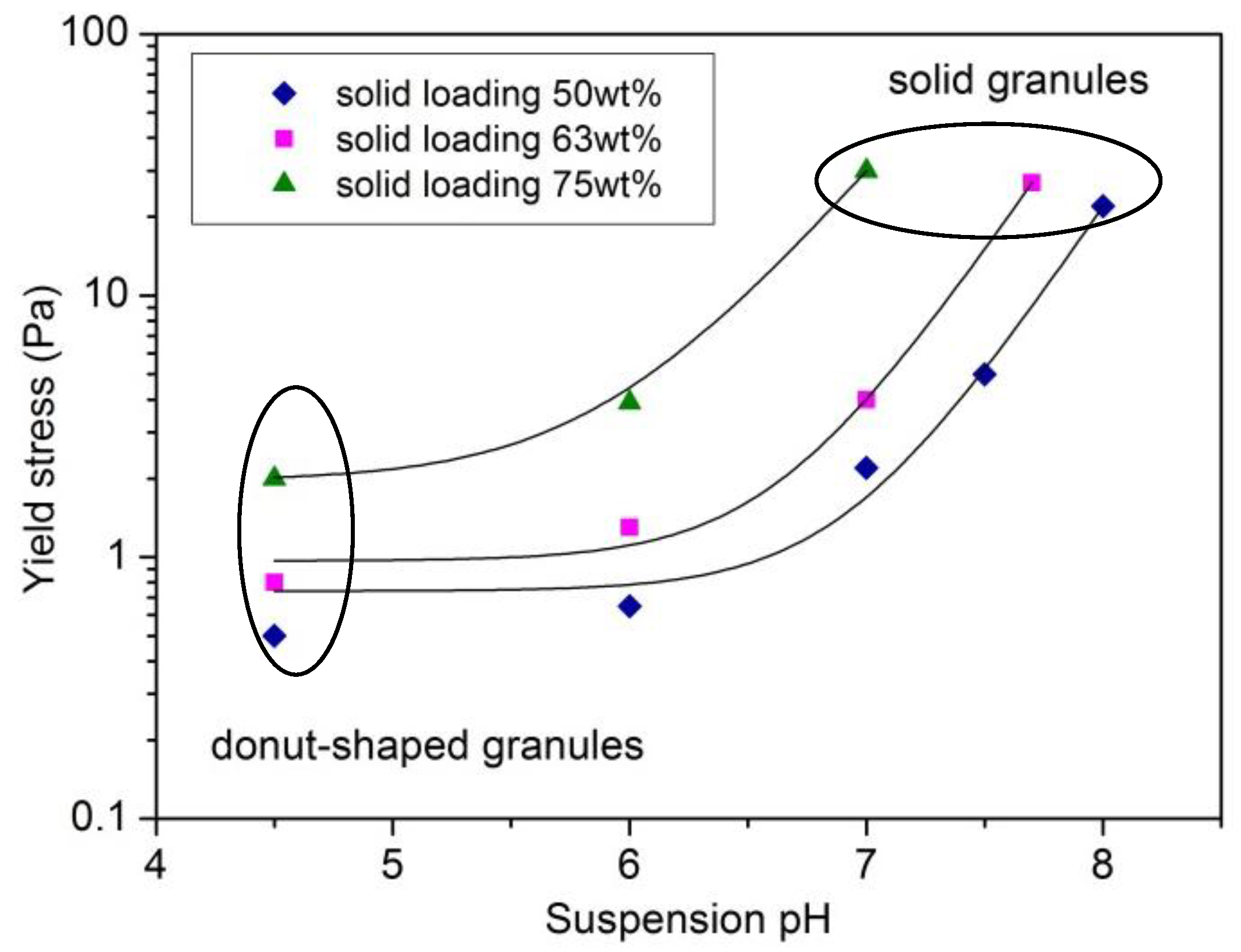

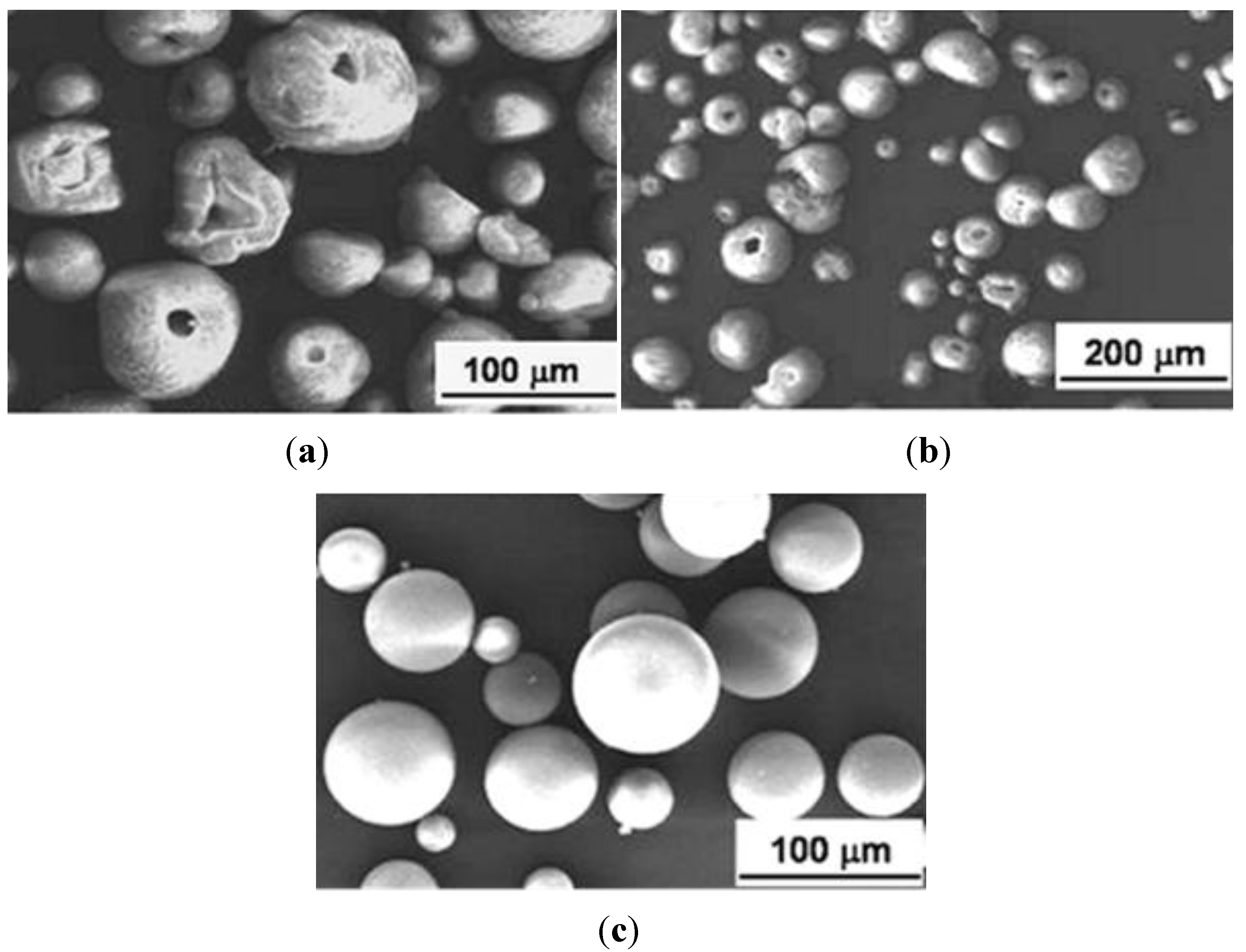

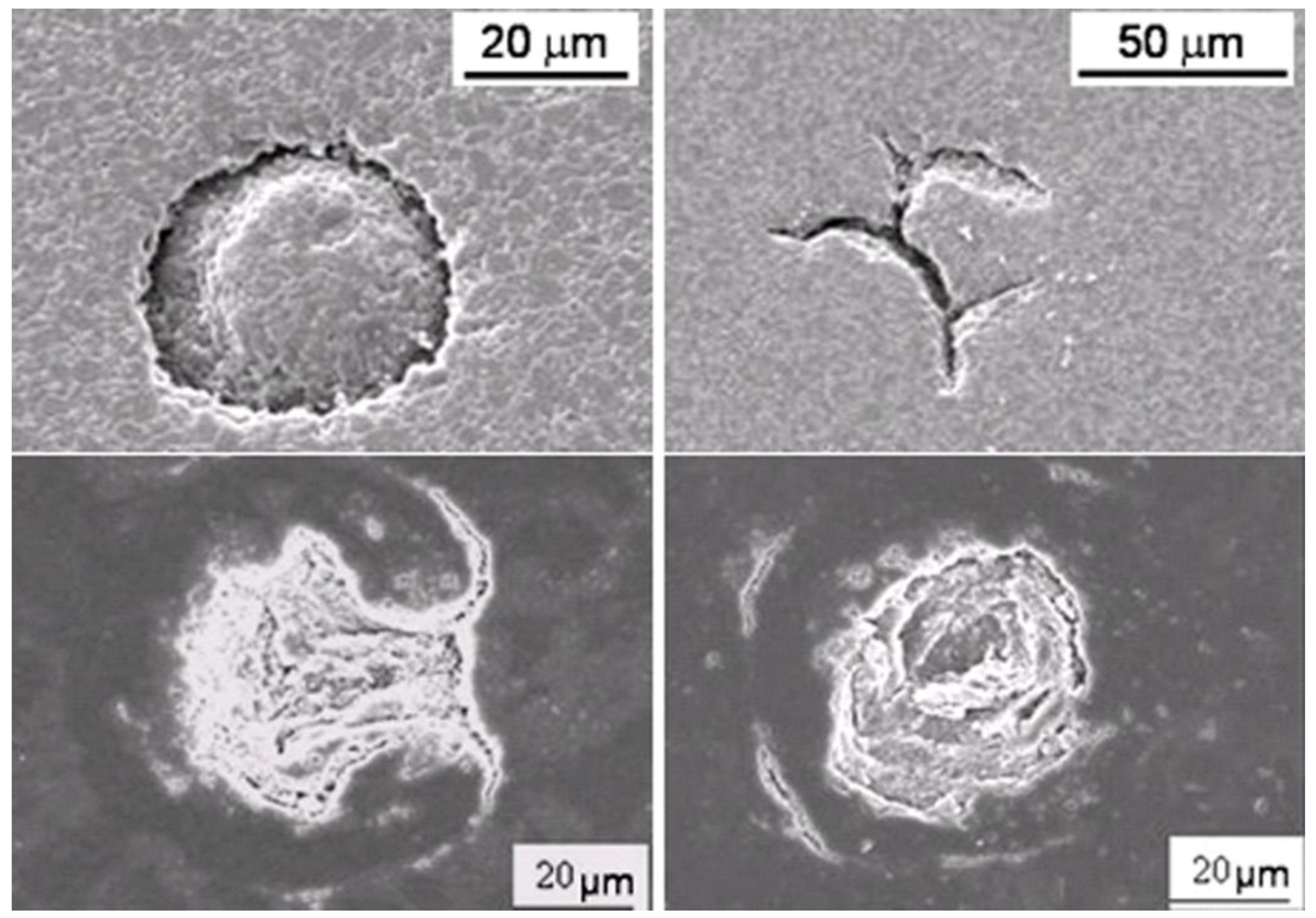

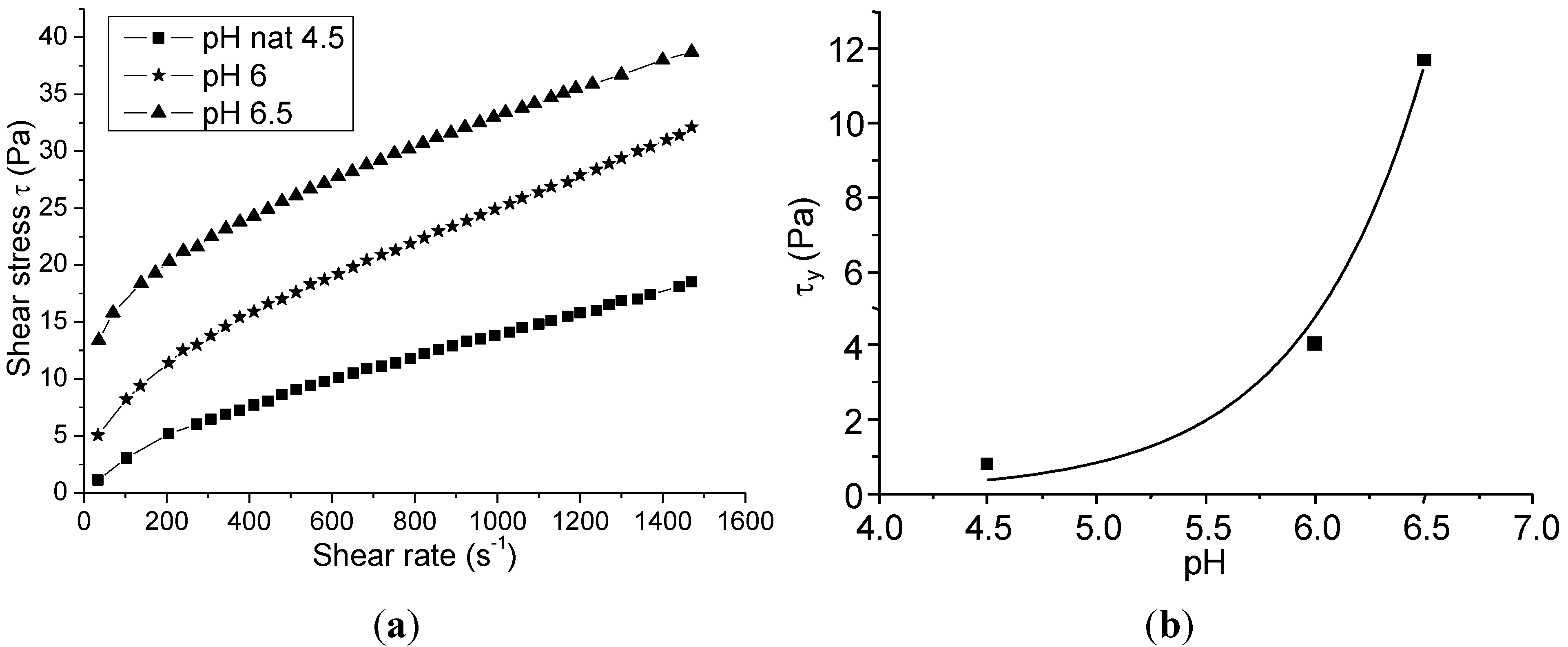

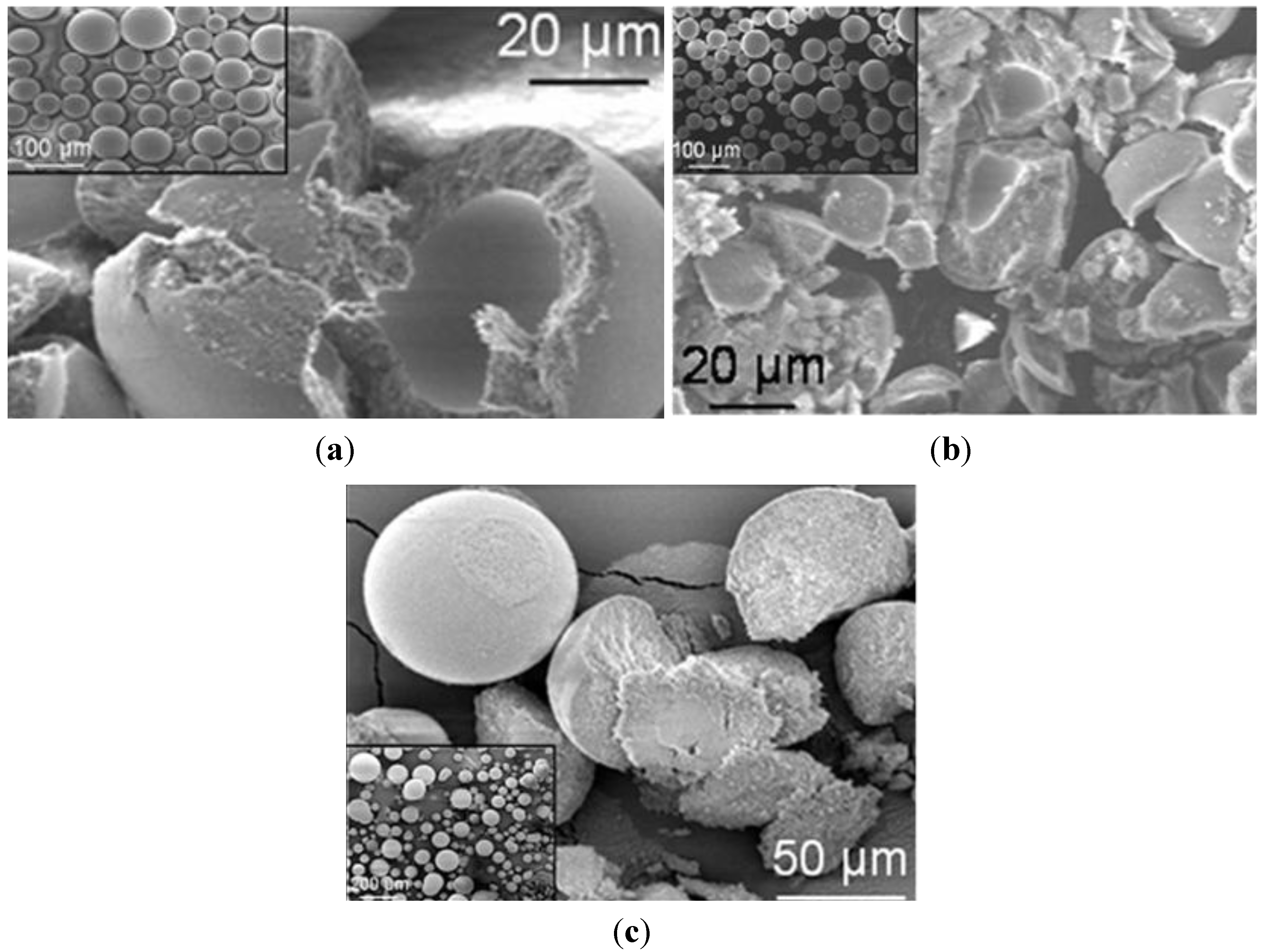

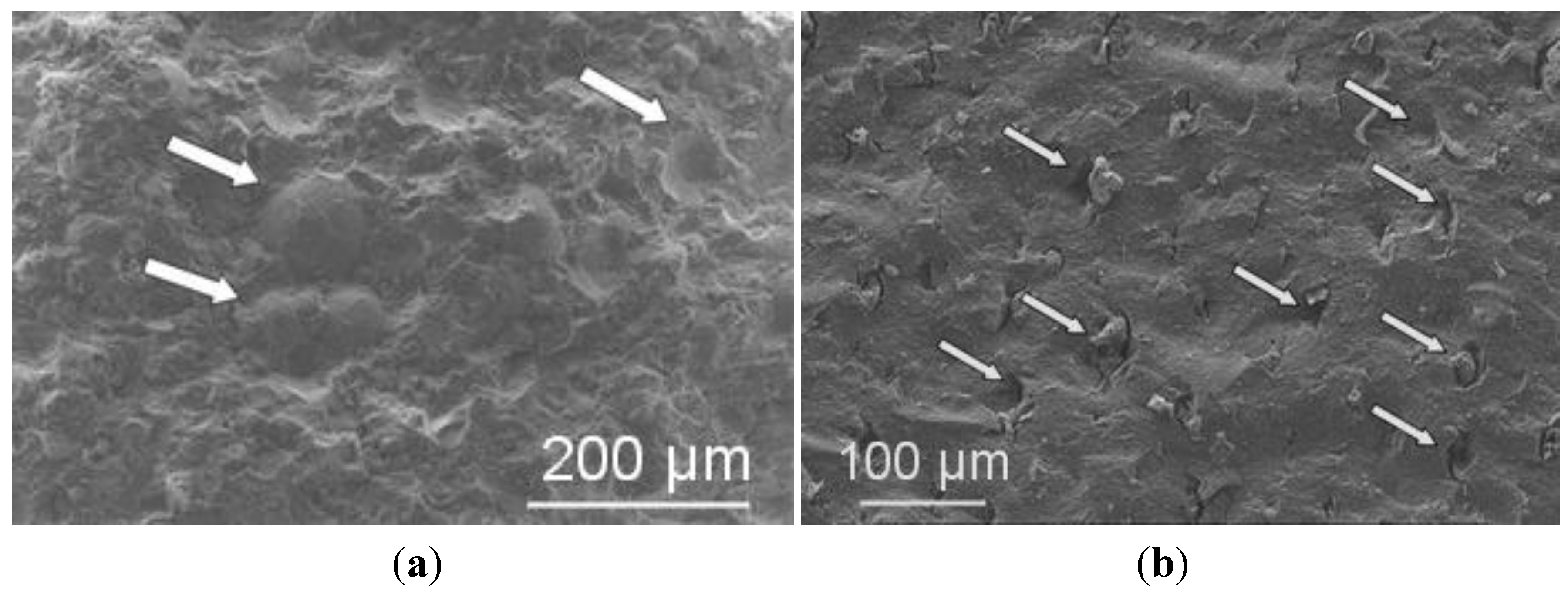

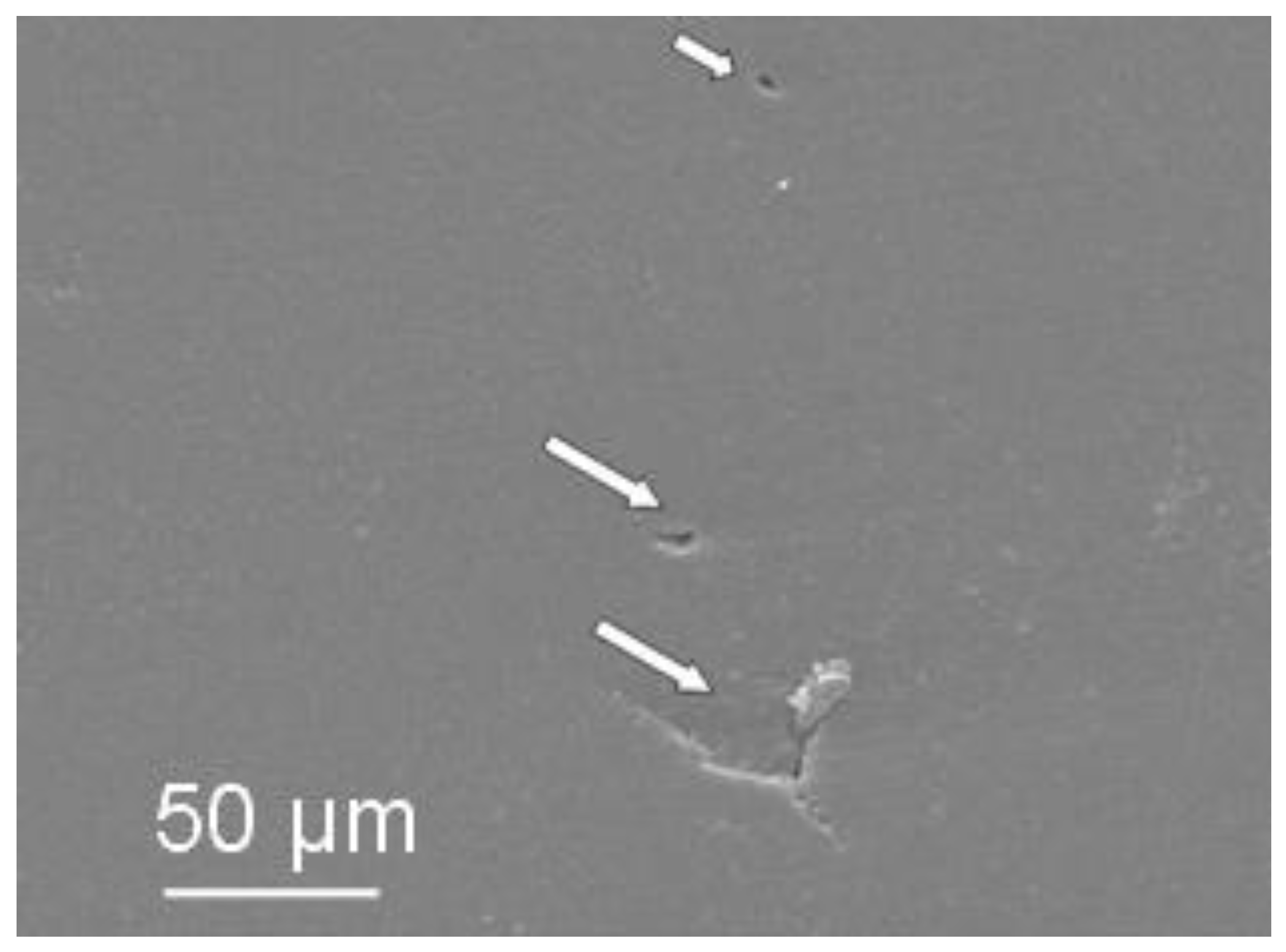

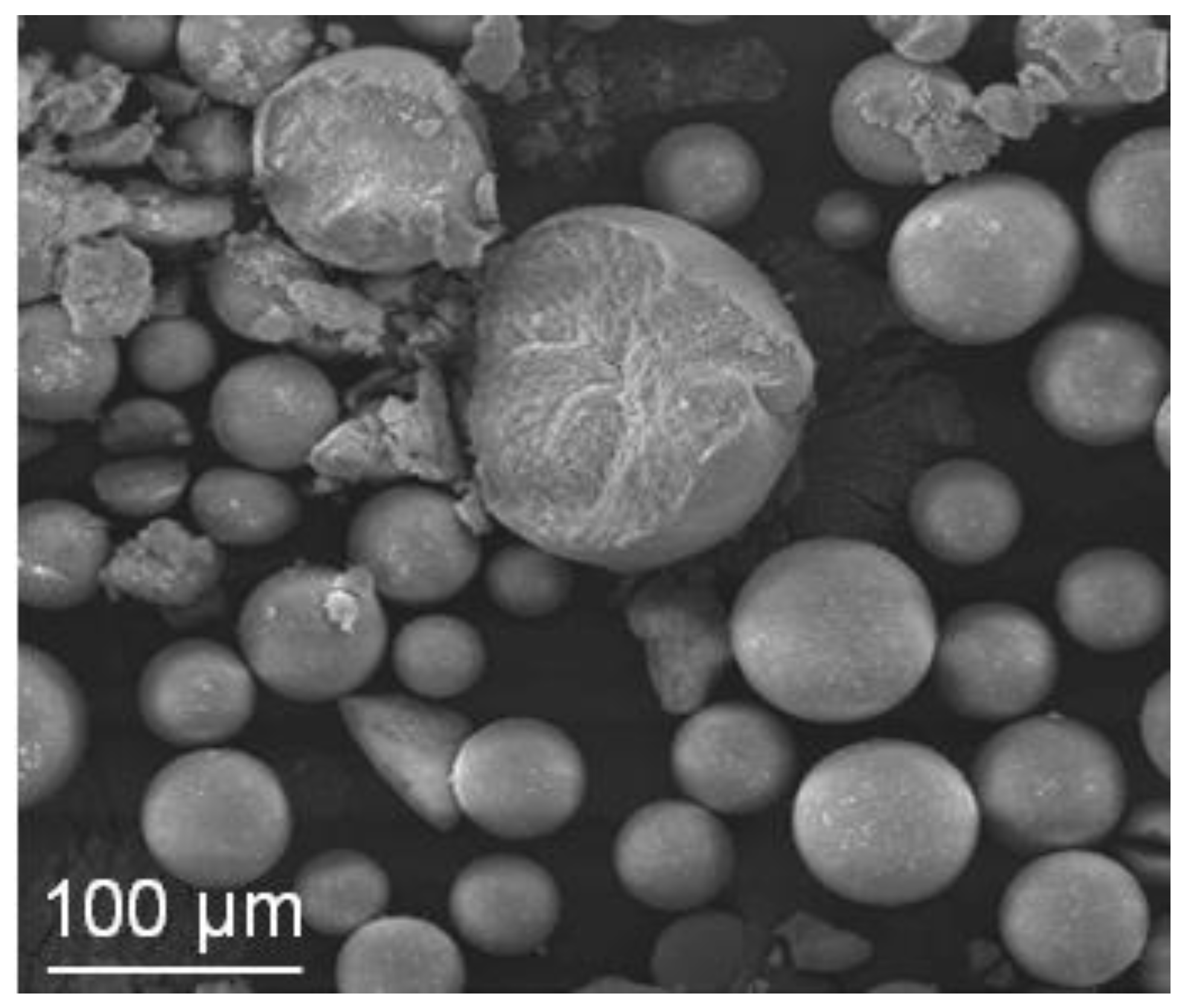

2.1. Powder Mixing Procedure

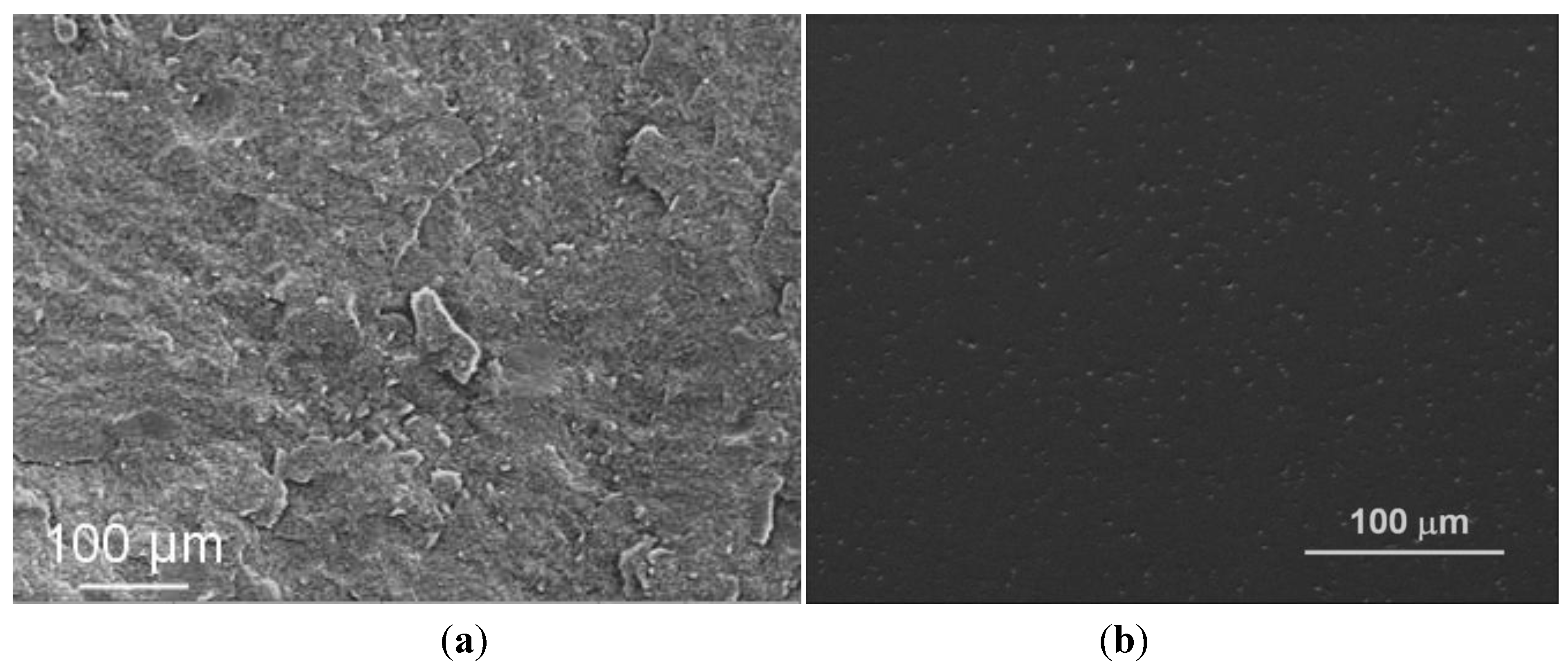

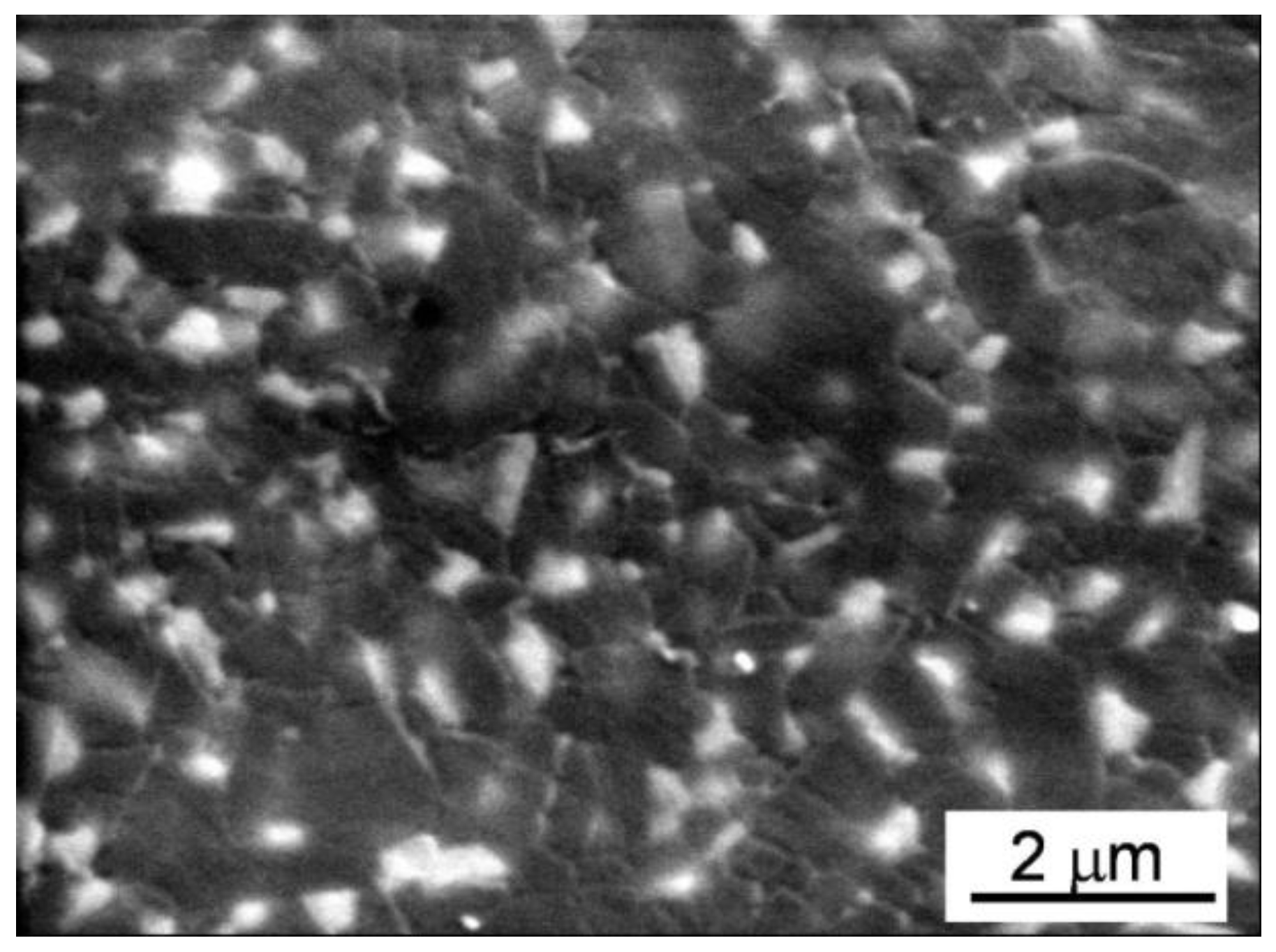

2.2. Surface-Modification Procedure

3. Discussion

4. Experimental Section

4.1. Commercial Powders

| Powders | Mean particle size (μm) | BET specific surface area (m2/g) | Impurities (%) | Isoelectric point (pH) |

|---|---|---|---|---|

| α-Al2O3 APA-0.5 (Ceralox APA 05, Hamburg, Germany) | 0.35 | 8.1 | 0.04 | 9.5 [8,32] |

| ZrO2 (3Y-TZP, Tosoh Corporation, Tokyo, Japan) | 0.6 | 14 | ≤ 0.07 | 10 [8,32] |

| α-Al2O3 TM-DAR (Taimei Chemicals Co., Tokyo, Japan) | 0.10 | 14.5 | ≤ 0.01 | 9 [33,34] |

4.2. Powder Mixing Technique

4.3. Surface Modification Technique

4.4. Viscosity Measurements

4.5. Spray Drying

4.6. Forming and Sintering

5. Conclusions

Conflicts of Interest

References

- Chevalier, J.; Gremillard, L. Ceramics for medical application: A picture for the next 20 years. J. Eur. Ceram. Soc. 2009, 29, 1245–1255. [Google Scholar] [CrossRef]

- De Aza, A.H.; Chevalier, J.; Fantozzi, G.; Schehl, M.; Torrecillas, R. Crack growth resistance of alumina, zirconia and zirconia toughened alumina ceramics for joint prostheses. Biomaterials 2002, 23, 937–945. [Google Scholar]

- Deville, S.; Chevalier, J.; Fantozzi, G.; Bartolomé, J.F.; Requena, J.; Moya, J.S.; Torrecillas, R.; Diaz, L.A. Low-temperature ageing of zirconia-toughened alumina ceramics and its implication in biomedical implants. J. Eur. Ceram. Soc. 2003, 23, 2975–2982. [Google Scholar] [CrossRef]

- Morita, Y.; Nakata, K.; Ikeuchi, K. Wear properties of zirconia/alumina combination for joint prostheses. Wear 2003, 254, 147–153. [Google Scholar] [CrossRef]

- De Aza, A.H.; Chevalier, J.; Fantozzi, G.; Schehl, M.; Torrecillas, R. Slow-Crack-Growth behaviour of zirconia-toughened alumina ceramics processed by different methods. J. Am. Ceram. Soc. 2003, 86, 115–120. [Google Scholar]

- Rafferty, A.; Alsebaie, A.M.; Olabi, A.G.; Prescott, T. Properties of zirconia-toughened-alumina prepared via powder processing and colloidal processing routes. J. Colloid Interf. Sci. 2009, 329, 310–315. [Google Scholar] [CrossRef]

- Leriche, A.; Moortgat, G.; Cambier, F.; Homerin, P.; Thevenot, F.; Orange, G.; Fantozzi, G. Preparation and characterization of a dispersion toughened ceramic for thermomechanical uses (ZTA). Part I: Material preparation. Characterization of microstructure. J. Eur. Ceram. Soc. 1992, 9, 169–176. [Google Scholar] [CrossRef]

- Gutknecht, D.; Chevalier, J.; Garnier, V.; Fantozzi, G. Key role of processing to avoid low temperature ageing in alumina zirconia composites for orthopaedic application. J. Eur. Ceram. Soc. 2007, 27, 1547–1552. [Google Scholar] [CrossRef]

- Deville, S.; Chevalier, J.; Dauvergne, C.; Fantozzi, G.; Bartolomé, J.F.; Moya, J.S.; Torrecillas, R. Microstructural investigation of the aging behaviour of (3Y-TZP)-Al2O3 composites. J. Am. Ceram. Soc. 2005, 88, 1273–1280. [Google Scholar] [CrossRef]

- Herrmann, M.; Seipel, B.; Schilm, J.; Nickel, K.G.; Michael, G.; Krell, A. Hydrothermal corrosion of zirconia-toughened alumina (ZTA) at 200 °C. J. Eur. Ceram. Soc. 2005, 25, 1805–1812. [Google Scholar] [CrossRef]

- Heuer, A.H.; Claussen, N.; Kriven, W.M.; Rühle, M. Stability of tetragonal ZrO2 particles in ceramic matrices. J. Am. Ceram. Soc. 1982, 65, 642–650. [Google Scholar] [CrossRef]

- Lange, F.F. Powder processing science and technology for increased reliability. J. Am. Ceram. Soc. 1989, 72, 3–15. [Google Scholar] [CrossRef]

- Walker, W.J.; Reed, J.S.; Verma, S.K. Influence of slurry parameters on the characteristics of spray-dried granules. J. Am. Ceram. Soc. 1999, 82, 1711–1719. [Google Scholar] [CrossRef]

- Naito, M.; Fukuda, Y.; Yoshikawa, N.; Kamiya, H.; Tsubaki, J. Optimization of suspension characteristics for shaping processes. J. Eur. Ceram. Soc. 1997, 17, 251–257. [Google Scholar] [CrossRef]

- Tsetsekou, A.; Agrafiotis, C.; Leon, I.; Milias, A. Optimization of the rheological properties of alumina slurries for ceramic processing applications. Part II: Spray-drying. J. Eur. Ceram. Soc. 2001, 21, 493–506. [Google Scholar] [CrossRef]

- Mahdjoub, H.; Roy, P.; Filiate, C.; Bertrand, G.; Coddet, C. The effect of the slurry formulation upon the morphology of the spray-dried yttria stabilized zirconia particles. J. Eur. Ceram. Soc. 2003, 23, 1637–1648. [Google Scholar] [CrossRef]

- Bertrand, G.; Filiate, C.; Mahdjoub, H.; Foissy, A.; Coddet, C. Influence of slurry characteristics on the morphology of spray-dried alumina powders. J. Eur. Ceram. Soc. 2003, 23, 263–271. [Google Scholar] [CrossRef]

- Walker, W.J.; Reed, J.S.; Verma, S.K. Influence of granules character on strength and Weibull modulus of sintered alumina. J. Am. Ceram. Soc. 1999, 82, 50–56. [Google Scholar] [CrossRef]

- Tsubaki, J.; Yamakawa, H.; Mori, T.; Mori, H. Optimization of granules and slurries for press forming. J. Eur. Ceram. Soc. Jpn. 2002, 110, 894–898. [Google Scholar] [CrossRef]

- Shinohara, N.; Katori, S.; Okumiya, M.; Hotta, T.; Nakahira, K.; Naito, M.; Cho, Y.; Uematsu, K. Effect of heat treatment on alumina granules on the compaction behaviour and properties of green and sintered bodies. J. Eur. Ceram. Soc. 2002, 22, 2841–2848. [Google Scholar] [CrossRef]

- Tanaka, S.; Pin, C.C.; Uematsu, K. Effect of organic binder segregation on sintered strength of dry-pressed alumina. J. Am. Ceram Soc. 2006, 89, 1903–1907. [Google Scholar] [CrossRef]

- Baklouti, S.; Chartied, T.; Baumard, J.F. Binder distribution in spray-dried alumina agglomerates. J. Eur. Ceram. Soc. 1998, 108, 2117–2121. [Google Scholar] [CrossRef]

- Shinohara, N.; Okumiya, M.; Hotta, T.; Makahira, K.; Maito, M.; Uematsu, K. Formation mechanisms of processing defects and their relevance to the strength in alumina ceramics made by powder compaction process. J. Mater. Sci. 1999, 34, 4271–4277. [Google Scholar] [CrossRef]

- Kim, D.-J.; Jung, J.-Y. Granule performance of zirconia/alumina composite powders spray-dried using polyvinyl pyrrolidone binder. J. Eur. Ceram. Soc. 2007, 27, 3177–3182. [Google Scholar] [CrossRef]

- Kara, F.; Kara, A.; Turan, S.; Mandal, H. Pressing behaviour of spray dried alumina-zirconia granules. Key Eng. Mater. 2004, 264–268, 233–236. [Google Scholar] [CrossRef]

- Naglieri, V.; Palmero, P.; Montanaro, L.; Chevalier, J. Elaboration of alumina-zirconia composites: Role of the zirconia content on the microstructure and mechanical properties. Materials 2013, 6, 2090–2102. [Google Scholar] [CrossRef]

- Naglieri, V.; Palmero, P.; Montanaro, L. Preparation and characterization of alumina-doped powders for the design of multi-phasic nano-microcomposites. J. Therm. Anal. Calorim. 2009, 97, 231–237. [Google Scholar] [CrossRef]

- Palmero, P.; Naglieri, V.; Spina, G.; Lombardi, M. Microstructural design and elaboration of multiphase ultra-fine ceramics. Ceram. Int. 2011, 37, 139–144. [Google Scholar] [CrossRef]

- Palmero, P.; Sola, A.; Naglieri, V.; Bellucci, D.; Lombardi, M.; Cannillo, V. Elaboration and mechanicalcharacterization of multi-phasealumina-based ultra-fine composites. J. Mater. Sci. 2012, 47, 1077–1084. [Google Scholar] [CrossRef]

- Naglieri, V.; Joly-Pottuz, L.; Chevalier, J.; Lombardi, M.; Montanaro, L. Follow-up of zirconia crystallization on a surface modified alumina powder. J. Eur. Ceram. Soc. 2010, 30, 3377–3387. [Google Scholar] [CrossRef]

- Casson, N. A Flow Equation for Pigment-Oil Suspensions of the Printing Ink Type. In Rheology of Dispersesy Stems, Proceedings of the Conference of the British Society of Rheology, London, UK, 1–2 October 1959; Mill, C.C., Ed.; Pergamon Press: New York, NY, USA, 1959; pp. 84–101. [Google Scholar]

- Gutknecht, D. Elaboration et Charactérisation de Micro- et Nano Composites Alumine-Zircone Pour Application Orthopédique (in French). Ph.D. Thesis, Institut National des Sciences Appliquées de Lyon, Lyon, France, 2006. [Google Scholar]

- Suárez, M.; Fernandez, A.; Menendez, J.L.; Nygren, M.; Torrecillas, R.; Zhao, Z. Effect of freeze-drying treatment on the optical properties of SPS-sintered alumina. Ceram. Int. 2013, 39, 6669–6674. [Google Scholar] [CrossRef]

- Gizowska, M.; Konopka, K.; Szafran, M. Properties of water-based slurries for fabrication of ceramic-metal composites by slip casting method. Arch. Metall. Mater. 2011, 56, 1105–1110. [Google Scholar]

- Kern, F.; Palmero, P. Microstructure and mechanical properties of alumina 5 vol % zirconia nanocomposites prepared by powder coating and powder mixing routes. Ceram. Int. 2013, 39, 673–682. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Naglieri, V.; Gutknecht, D.; Garnier, V.; Palmero, P.; Chevalier, J.; Montanaro, L. Optimized Slurries for Spray Drying: Different Approaches to Obtain Homogeneous and Deformable Alumina-Zirconia Granules. Materials 2013, 6, 5382-5397. https://doi.org/10.3390/ma6115382

Naglieri V, Gutknecht D, Garnier V, Palmero P, Chevalier J, Montanaro L. Optimized Slurries for Spray Drying: Different Approaches to Obtain Homogeneous and Deformable Alumina-Zirconia Granules. Materials. 2013; 6(11):5382-5397. https://doi.org/10.3390/ma6115382

Chicago/Turabian StyleNaglieri, Valentina, Dan Gutknecht, Vincent Garnier, Paola Palmero, Jérôme Chevalier, and Laura Montanaro. 2013. "Optimized Slurries for Spray Drying: Different Approaches to Obtain Homogeneous and Deformable Alumina-Zirconia Granules" Materials 6, no. 11: 5382-5397. https://doi.org/10.3390/ma6115382

APA StyleNaglieri, V., Gutknecht, D., Garnier, V., Palmero, P., Chevalier, J., & Montanaro, L. (2013). Optimized Slurries for Spray Drying: Different Approaches to Obtain Homogeneous and Deformable Alumina-Zirconia Granules. Materials, 6(11), 5382-5397. https://doi.org/10.3390/ma6115382