3.1. Capillary Electrophoresis Method for Corrosion Solution Chemistries Analysis

The most common alloying components are copper, nickel, iron, chromium, manganese and aluminium. Most of the widely used marine and aerospace alloys normally contain four to six of these metal alloying elements. In order to identify the possible metal cations produced during corrosion processes, it is important to conduct an analysis such that it is capable of detecting all of the corrosion products in a single CE run, especially when considering the very small corrosion solution volumes that can occur. To date, the separation of all aforementioned seven metal cations as well as chloride ions in a single analysis run has previously not been reported for CE or ion chromatography.

Anions and cations migrate in opposite directions in CE, and it is difficult to simultaneously determine metal cations and chloride anions in a single CE run. Thus, all the metal ions need to be transformed at first into negatively charged complexes to achieve simultaneous separation of all the target metal cations with negatively charged chloride ion in a single CE run. In addition, because these metal ions possess similar mobilities, it is also necessary to use a chelating agent to enhance separation efficiency and selectivity of these metal ions in order to realize the simultaneous and direct determination of these target metal ions in a single CE run. It has been reported that PDCA can form highly stable, negatively charged complexes with some heavy metal ions [

9,

20,

21,

22,

23]. PDCA was therefore used as a complexation agent and running buffer additive to establish CE methodology in our experiments. A buffer solution pH range of 3.5 to 4.0 was also reported as having achieved best separation selectivity and sensitivity for metal ions [

9,

20,

21,

22,

23]. In this study, a number of parameters, including PDCA concentrations in the buffer solution, surfactant types and their concentrations in the buffer solution, pH, sample pre-treatment methods, separation temperature and applied potentials, were investigated to optimise the separation conditions. The results from our investigations into the effect of buffer solution composition on metal ion separation is summarised in

Table 1, along with the effects of employing on-column or pre-column complexation sample pre-treatment methodologies.

For these optimisation experiments, all the measurements were performed with a bare fused silica capillary at a temperature of 20 °C with a running time of 1 h by using the standard metal ion solutions prepared from chloride salts of metal ions with a concentration of 10 ppm. For all the measurements, the peak for chloride ion was always detected and completely separated from those for the metal ions.

Table 1 shows that regardless of the buffer solution composition, better separation was achieved with pre-column complexation than on-column complexation. The results also show that when no surfactant was included in the buffer solution, the baseline signal at the detector exhibited significant levels of noise, making it difficult to discriminate peaks in the conductivity signal attributable to the different ions (

i.e., selectivity and sensitivity were poor). It was also observed that when CTAH was employed as the surfactant, a lower concentration of PDCA produced better separation efficiency irrespective of the complexation method used. Further experiments with the buffer solution containing 5 mM PDCA and 0.25 mM CTAH confirmed that the optimum buffer solution for reliable separation of all of the ions of interest is 10 mM PDCA and 0.5 mM CTAH at pH 4.0.

Table 1.

Optimisation of buffer solution and complexation method for separation of seven metal ions.

Table 1.

Optimisation of buffer solution and complexation method for separation of seven metal ions.

| PDCA | Surfactant | Complexation | Separation results |

|---|

| 20 mM | No surfactant | On-column | Very noisy signal baseline. No peaks observed for chloride or metal ions. |

| 20 mM | No surfactant | Pre-column | Very noisy baseline.Cu2+ and Ni2+ not separated and exhibit same migration time. |

| 20 mM | 0.5 mM CTAH | On-column | No separation detected for metal ions. |

| 20 mM | 0.5 mM CTAH | Pre-column | No peak detected for Cu2+, Ni2+ and Mn2+ ions. One peak observed for Al3+ and another peak for Fe2+/3+ and Cr3+ ions. |

| 10 mM | 5 mM TMAH | On-column | Cu2+, Ni2+ and Fe2+ not separated. Mn2+ completely separated from other metal ions. Al3+, Cr3+ and Fe3+ ions not detected. |

| 10 mM | 5 mM TMAH | Pre-column | Cu2+ and Ni2+ partially separated. Mn2+ completely separated from other metal ions. Remaining metal ions not separated. |

| 10 mM | 0.5 mM CTAH | On-column | Cu2+ and Ni2+ ions completely separated from each other. Remaining metal ions not detected. |

| 10 mM | 0.5 mM CTAH | Pre-column | Best separation with all 7 metal ions separated into 7 peaks. |

The electric field strength within the capillary is another important parameter in CE optimisation since it directly governs electrophoretic migration. The electric field strength is changed when either the applied voltage is varied or the capillary length is altered. In CE, increasing the voltage could improve separation resolution and shorten the analysis time, but the production of heat possibly limits the resolution improvement. Therefore, separation of all the target ions was investigated under different field strengths with applied voltages of −10 kV, −15 kV and −30 kV. The obtained results indicate that reasonable separation resolution and analysis time was achieved under an applied voltage of −15 kV with the used fused silica capillary under the optimized buffer solution compositions.

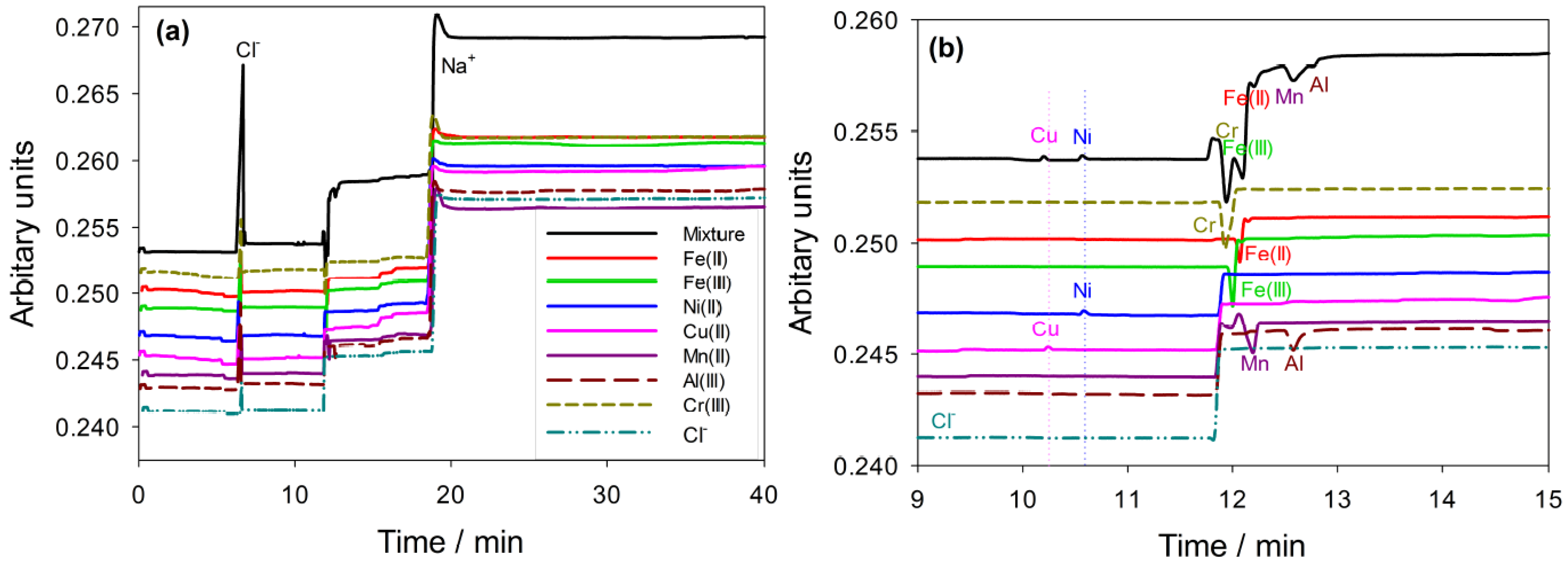

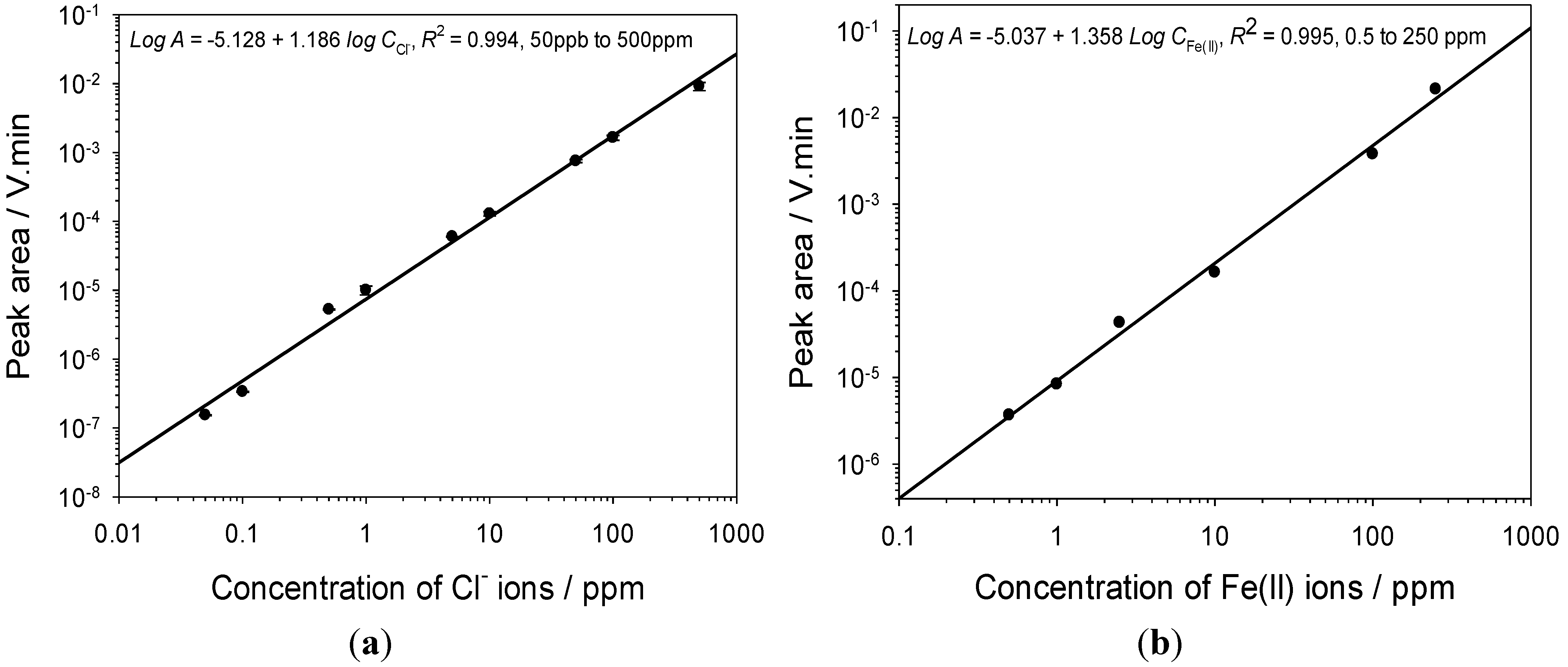

As a result, the best separation for all the seven metal cations and chloride anion can be achieved with the buffer solution of 10 mM PDCA and 0.5 mM CTAH at pH 4 using a pre-column complexation method and with the analysis performed at a temperature of 20 °C with an applied voltage of −15 kV. Electropherograms demonstrating the ion separation efficiency under these conditions are displayed in

Figure 3. Under the optimized conditions, chloride ion appeared with a very sharp peak before the seven metal ions due to its high mobility, see

Figure 3a. At the concentration of 10 ppm, all seven metal ions were separated into individual peaks. Moreover, as demonstrated in

Figure 3b, the peaks for Cu

2+ and Ni

2+ ions are positive while those for Fe

2+, Fe

3+, Mn

2+, Cr

3+, and Al

3+ ions are negative. This indicated that compared to the conductivity of the running buffer solution, the conductivities within the zones formed by the complexation of Cu

2+ ions with PDCA and the complexation of Ni

2+ ions with PDCA during the CE separation are greater, while those for PDCA and the other five metal ions are lower.

Figure 3.

Electropherograms showing separation of seven individual metal ions and chloride ion at the 10 ppm level and when in a mixture, under the optimised conditions described in the text.

Figure 3.

Electropherograms showing separation of seven individual metal ions and chloride ion at the 10 ppm level and when in a mixture, under the optimised conditions described in the text.

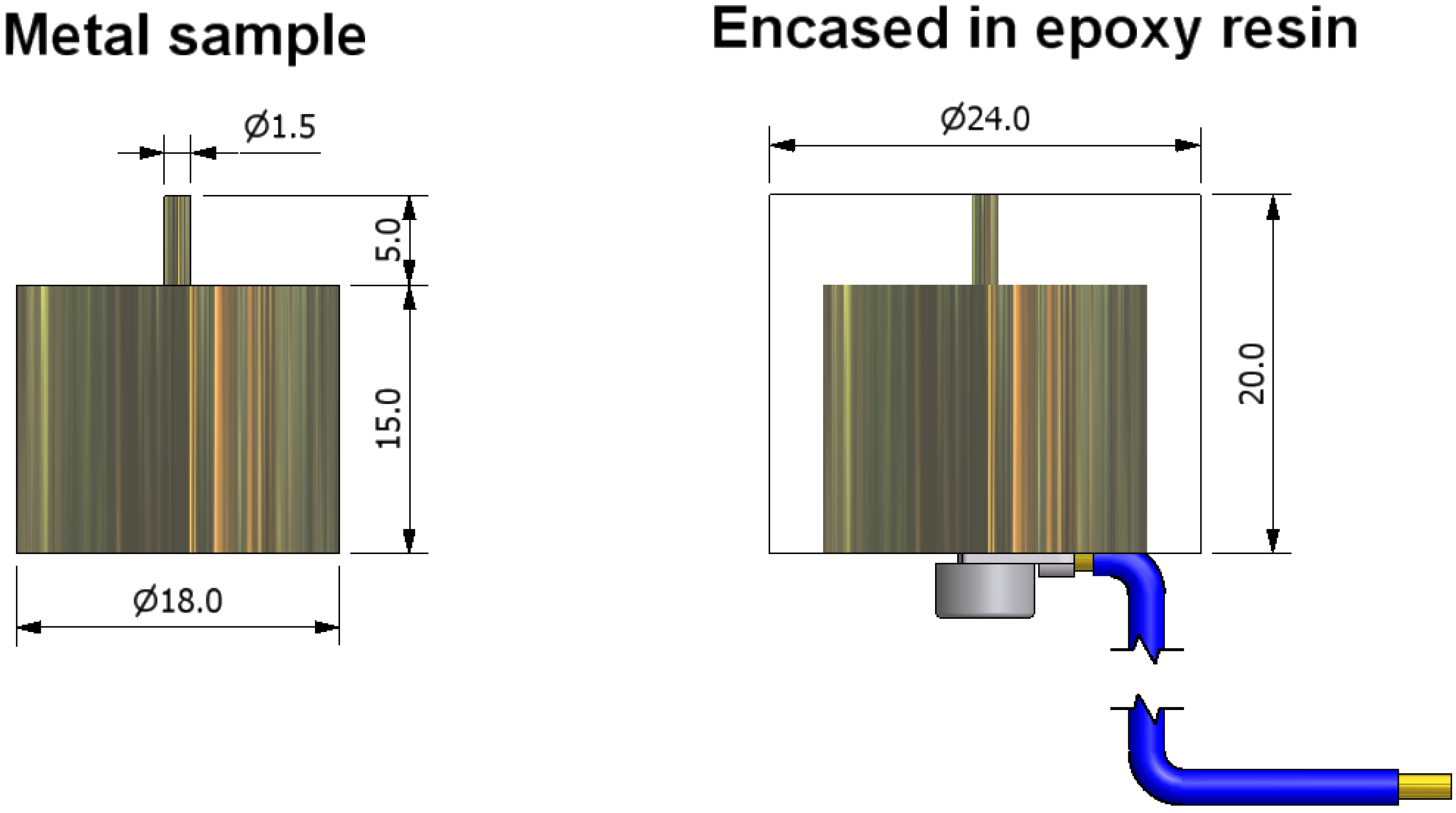

3.3. Solution Chemistries Analysis of Accelerated Pitting Corrosion of EN3A Carbon Steel

Potentiodynamic polarisations were performed for the carbon steel pencil electrode assembly in a 3.5% NaCl solution to determine an appropriate potential for the accelerated corrosion study.

Figure 5 shows the EN3A carbon steel exhibited typical polarisation behaviour for an actively corroding metal, with the corrosion potential (

Ecorr) at −0.618 V. An applied potential of −0.400 V, where carbon steel is within an active corrosion region, was selected for the accelerated corrosion tests in order to rapidly generate corrosion products within a microenvironment for CE identification.

The pH change was also monitored at the corrosion site of the pencil working electrode and around the counter electrode at pre-determined time intervals. As shown in

Figure 5, the pH of the solution around the counter electrode initially increased and reached a value of pH 11.5 after 5 h. By comparison, the solution pH initially decreased at the corrosion site and then stabilised at around pH 5.5 after 5 h.

Figure 5.

(a) Polarisation behaviour at scan rate of 0.150 mV·s−1; and (b) pH changes at accelerated corrosion sites as well as around counter electrode with accelerated corrosion time at applied potential of −0.400 V for the EN3A carbon steel pencil electrode in 3.5% NaCl solution.

Figure 5.

(a) Polarisation behaviour at scan rate of 0.150 mV·s−1; and (b) pH changes at accelerated corrosion sites as well as around counter electrode with accelerated corrosion time at applied potential of −0.400 V for the EN3A carbon steel pencil electrode in 3.5% NaCl solution.

The predominant cathodic process in an aerated 3.5% NaCl solution is oxygen reduction reaction (ORR):

In these circumstances, the products of the ORR are hydroxide ions, thus the solution around the counter electrode (cathode) becomes alkaline during the accelerated corrosion test.

The dissolution of the EN3A pencil electrode resulted in the formation of a pit cavity within the epoxy resin. Ferrous ions are initially considered to form as a primary corrosion product:

As corrosion continues this will lead to an increase in the concentration of dissolved metal ions within the pit cavity, and oxides or hydroxides are precipitated [

24]. These hydrolysis and precipitation reactions cause acidification within the pit cavity, in accordance with the following reactions.

In the chloride background media, the increase in the concentrations of Fe

2+ and H

+ cations in the cavity will be counterbalanced by an increase in the concentration of Cl

− ions, driven by diffusion from the bulk solution towards the cavity interior to maintain electroneutrality. This is confirmed by the chemical analysis results of corrosion solutions collected from the pit cavity during the accelerated corrosion process, see

Figure 6. From the CE analysis, the concentration of chloride and ferrous ions reach about 42,000 ppm (1.2 M in terms of NaCl) and 21,000 ppm (0.4 M in terms of FeCl

2) after 24 h, respectively.

Figure 6.

Concentration profiles of (a) chloride; and (b) ferrous ions as a function of accelerated corrosion time for the freshly polished carbon steel pencil electrode.

Figure 6.

Concentration profiles of (a) chloride; and (b) ferrous ions as a function of accelerated corrosion time for the freshly polished carbon steel pencil electrode.

3.4. Solution Chemistries Analysis of Cortest Crevice Corrosion of Q1N Carbon Steel

Q1N is a low alloy carbon steel and it exhibited a similar polarisation behaviour as that observed for the EN3A carbon steel. However, due to nickel and chromium contents, the corrosion potential at −0.570 V was slightly more positive than −0.618 V of EN3A steel in 3.5% NaCl solution. The CE analysis revealed the presence of ferric ions and nickel ions, as well as chloride within the Q1N crevice solution. The concentration profiles of the chloride and metal ions with time were established for the Q1N crevice corrosion for a period of about 8 weeks, see

Figure 7. As expected, in order to maintain charge neutrality, the chloride ions were drawn into the crevice site, and the concentration of chloride ions in the crevice increased significantly with corrosion time. The chloride ion concentration in the crevice solution reached a maximum of 106,000 ppm (

ca. 3.0 M in terms of NaCl) after 2 weeks, before decreasing to 40,000 ppm after 8 weeks. The Fe

3+ and Ni

2+ ions exhibited a similar concentration profile with time, rapidly increasing during the initial corrosion phase and then gradually decreasing. The observed trends in concentration profiles with time indicated that crevice corrosion of Q1N activated immediately once immersed in NaCl solution, followed by a resilient period, possibly due to precipitation of metal hydroxides and oxides on the metallic surface (thus hindering corrosion progress). The ferric ions detected within the crevice corrosion solution reached a concentration maximum of 6,700 ppm (

ca. 0.12 M in term of FeCl

3) at day 5, while the highest level of nickel ions (1,500 ppm, 0.026 M in terms of NiCl

2) was detected at the initial stage of crevice corrosion, just after 2 day in the 3.5% NaCl test solution.

Figure 7.

Concentration profiles of (a) chloride; (b) ferric and nickel ions as a function of immersion time for Q1N in 3.5% NaCl solution.

Figure 7.

Concentration profiles of (a) chloride; (b) ferric and nickel ions as a function of immersion time for Q1N in 3.5% NaCl solution.

3.5. Solution Chemistries Analysis of Accelerated Pitting Corrosion of NAB

NAB is a complex copper-based alloy and it is utilised in numerous marine applications due to its good corrosion performance. As previously reported [

25], the microstructure of NAB is predominantly constituted of copper-rich α-phase and retained martensitic β-phase, surrounded by a series of intermetallic κ-phases all different in shape and composition. In comparison with the two carbon steels, NAB exhibits a more localised corrosion mechanism. NAB corrosion usually initiates at selective sites, associated with the α-phase where dissolution of copper components occurs to form a cuprous dichloride anion complex (CuCl

2−) in the presence of concentrated chloride, or they precipitate on the metal surface in the form of cuprous chloride (CuCl, a white solid). In neutral solutions, the presence of high concentrations of CuCl

2− at the metal surface may result in a hydrolysis reaction and the formation of Cu

2O according to:

Alternatively, CuCl precipitates in a chloride media may lead to further Cu

2O growth:

As shown in

Figure 8, NAB exhibits active-passive corrosion behaviour in the 3.5% NaCl test solution. In the active region between the corrosion potential (

Ecorr = −0.208 V) and the pseudo-passivation potential (

Epp = −0.010 V), the predominant process is the dissolution of copper to form CuCl

2−, or the formation of CuCl on the NAB surface, both of which further hydrolyse to form a protective cuprous oxide layer [see Equations (7) and (8)] [

9,

25]. Due to the porous microstructure and the electrical conductivity of the Cu

2O passive layer, the current density is maintained at a relatively high and steady level in the passive region, where the corrosion rates are about two orders of magnitude higher than the corrosion rate at the corrosion potential. Once breakdown of the oxide protective film starts at

Epit = +0.630 V, the current increased significantly with applied potential. Therefore, for these accelerated corrosion tests, an applied potential of +0.730 V was chosen, which is 0.1 V greater than the passive film breakdown potential, so that corrosion products could be quickly generated.

During accelerated corrosion testing, a white solid was observed to cover the pit cavity with evidence of some red/brown coloured Cu

2O deposits. This is in agreement with previous reports on copper pitting mechanisms [

25,

26,

27], where the pit interior is covered with solid CuCl thus hindering the formation of a protective Cu

2O layer at the metal interface and also the low solubility of CuCl maintains a low activity of copper ions, thereby facilitating anodic dissolution. The formation of CuCl is often attributed to local conditions that restrict diffusion, for example a Cu

2O layer. Lucey reported that pitting required the formation of a Cu

2O layer that is sufficiently porous to allow the restricted diffusion of CuCl

2− through it and showed that the Cu

2O behaves as an electrically conductive layer, with the upper surface acting as a cathode and the lower surface as an anode [

27]. Thus, the CuCl trapped under the Cu

2O layer may be anodically oxidised to cupric on the lower surface of the Cu

2O layer and the resultant cupric ions can further attack the metallic copper alloy to reform cuprous ions. However, due to the restricted diffusion through the porous Cu

2O layer and the block of accumulated CuCl solid in the cavity, the corrosion rate will decrease to a very low level in the long run as observed from current response with corrosion times, as shown in

Figure 8.

Figure 8.

(a) Polarisation behaviour at scan rate of 0.150 mV·s−1; and (b) electrochemical response with accelerated corrosion time at applied potential of +0.730 V for NAB pencil electrode in 3.5% NaCl solution.

Figure 8.

(a) Polarisation behaviour at scan rate of 0.150 mV·s−1; and (b) electrochemical response with accelerated corrosion time at applied potential of +0.730 V for NAB pencil electrode in 3.5% NaCl solution.

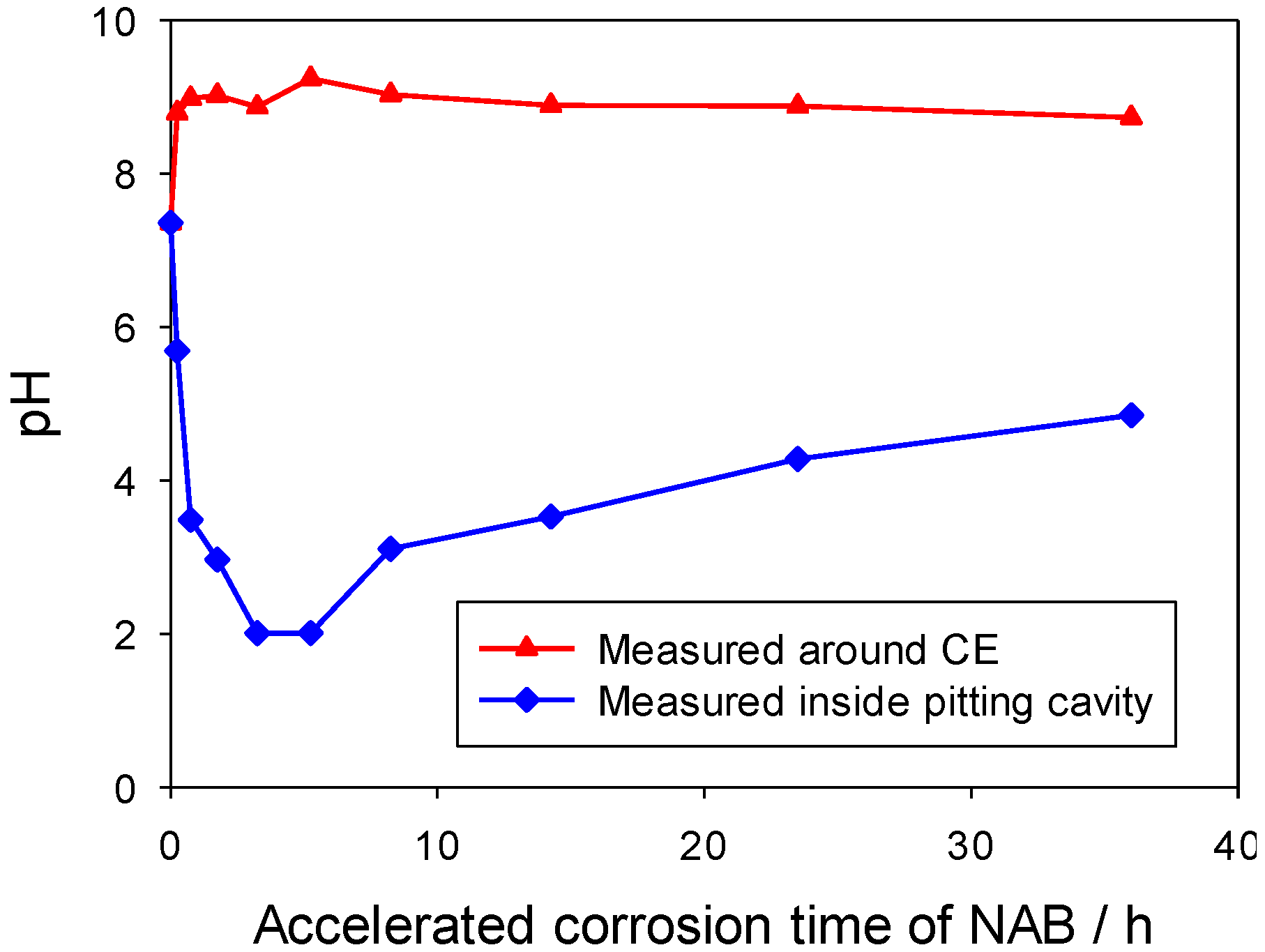

The solution pH around counter the electrode became alkaline due to the cathodic oxygen reduction reaction, while the solution at the accelerated corrosion cavity became acidic due to hydrolysis of corrosion products, see

Figure 9. It is noteworthy that the pH measured at the NAB corrosion site decreased to pH 2 during the initial stage of artificial pitting corrosion, and then rose slightly to pH 5. The lower pH levels in the NAB pitting cavity in comparison with the carbon steels may have resulted from the hydrolysis of other metal cations, such as the aluminium species.

Figure 9.

pH changes at pitting cavity site and around counter electrode with accelerated corrosion time at applied potential of +0.730 V for NAB pencil electrode in 3.5% NaCl solution.

Figure 9.

pH changes at pitting cavity site and around counter electrode with accelerated corrosion time at applied potential of +0.730 V for NAB pencil electrode in 3.5% NaCl solution.

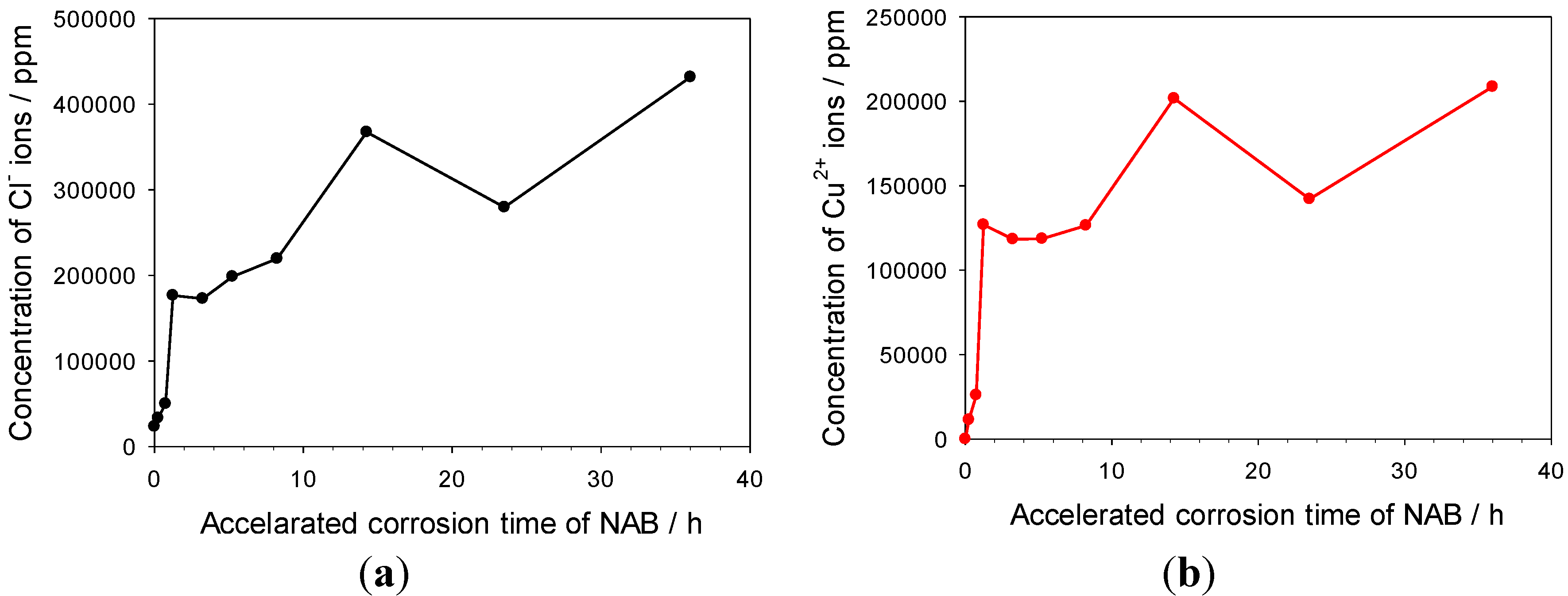

Figure 10 shows the chloride and cupric ion concentrations as a function of time. Due to the entrapment effect of the porous Cu

2O layer, the cupric ions, in addition to the chloride, were able to accumulate and concentrate under this layer. After 14 h, the chloride and cupric ion concentrations reached around 432,000 ppm (

ca. 12 M in terms of NaCl) and 208,000 ppm (

ca. 3.3 M in terms of CuCl

2−), respectively. In addition, metal ions for other alloy components including nickel, manganese, iron and aluminium found within NAB were also detected in the accelerated corrosion solution, and their concentrations reached the maximum within the initial 5 h. The maximum concentration of nickel ions detected in NAB accelerated corrosion solution is about 600 ppm, and the concentrations for manganese ions, ferrous ions and aluminium ions lower than 100 ppm.

Figure 10.

Concentration profiles of (a) chloride and (b) cupric ions as a function of accelerated corrosion time for NAB in 3.5% NaCl solution.

Figure 10.

Concentration profiles of (a) chloride and (b) cupric ions as a function of accelerated corrosion time for NAB in 3.5% NaCl solution.