InN Nanowires: Growth and Optoelectronic Properties

Abstract

:1. Introduction

2. Results and Discussion

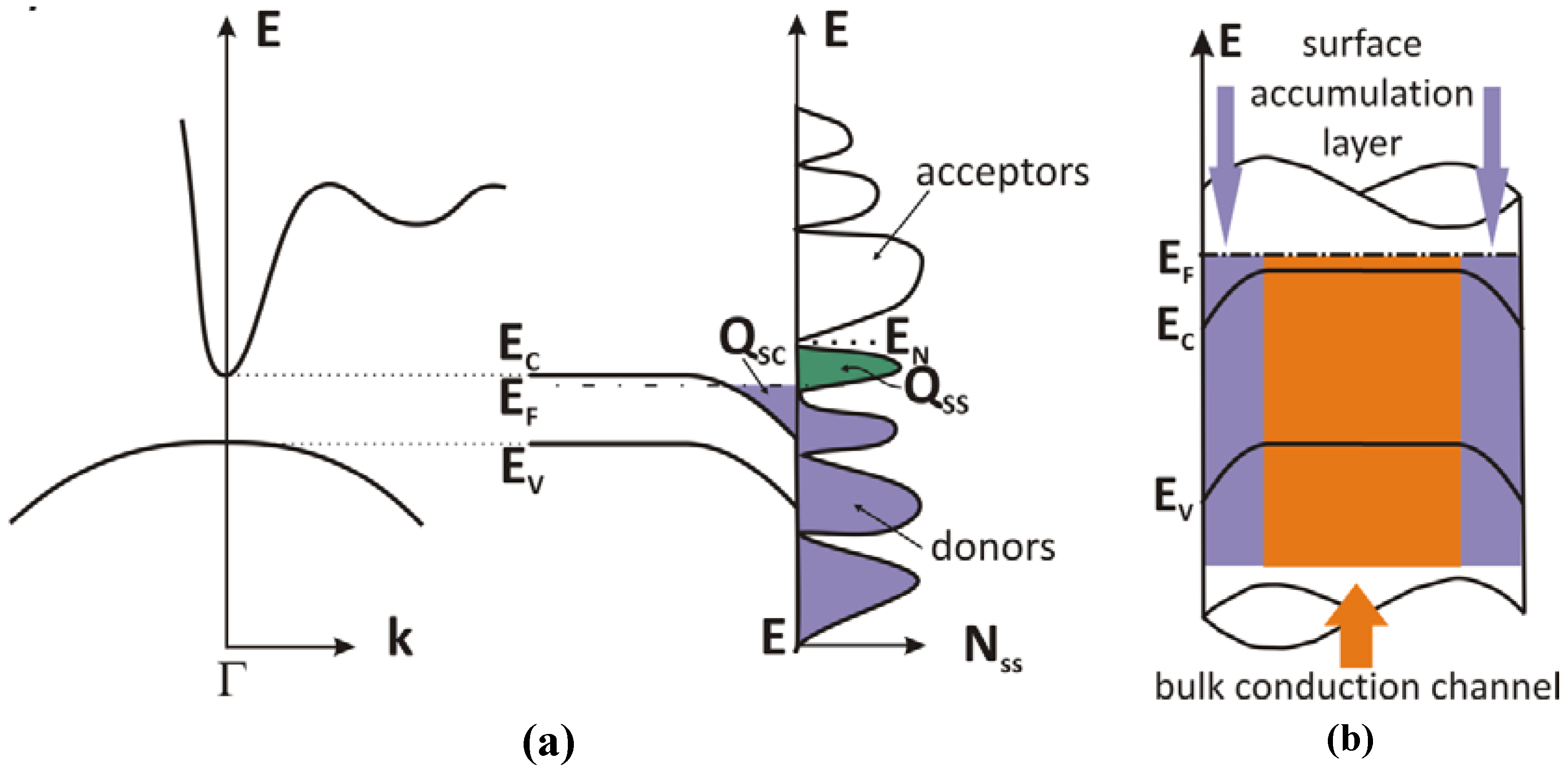

2.1. Fermi Level Pinning and Internal Electric Field

2.2. Polarization Fields

| III-nitrides | α-InN | α-GaN | α-AlN |

|---|---|---|---|

| Spontaneous polarization (C/m2) | −0.032 | −0.029 | −0.081 |

| Piezoelectric constant e31 (C/m2) | −0.57 | −0.49 | −0.60 |

| Piezoelectric constant e33 (C/m2) | +0.97 | +0.73 | +1.46 |

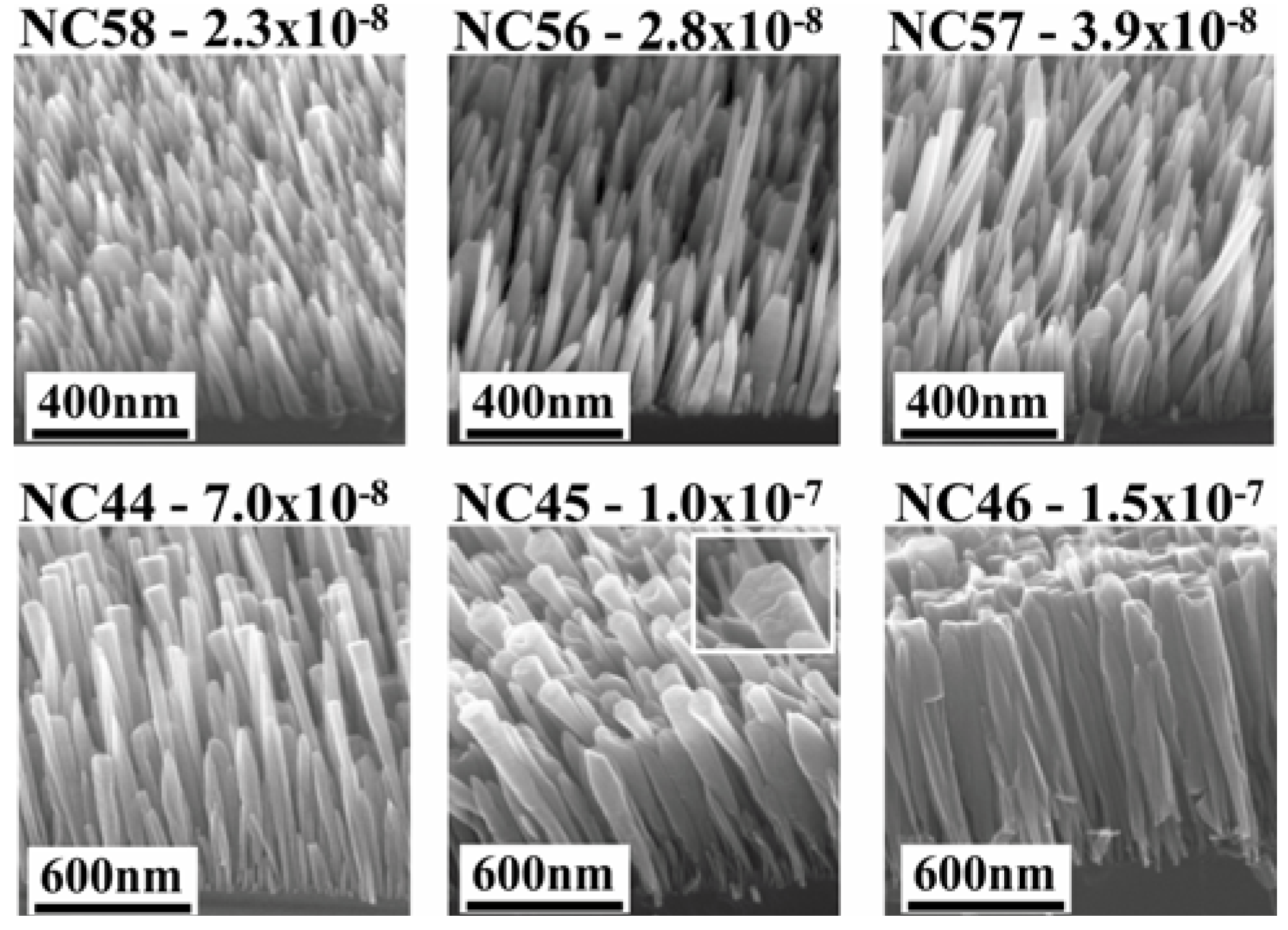

2.3. Synthesis of InN NWs

2.3.1. MBE

2.3.2. Vapour-Liquid-Solid Mechanism

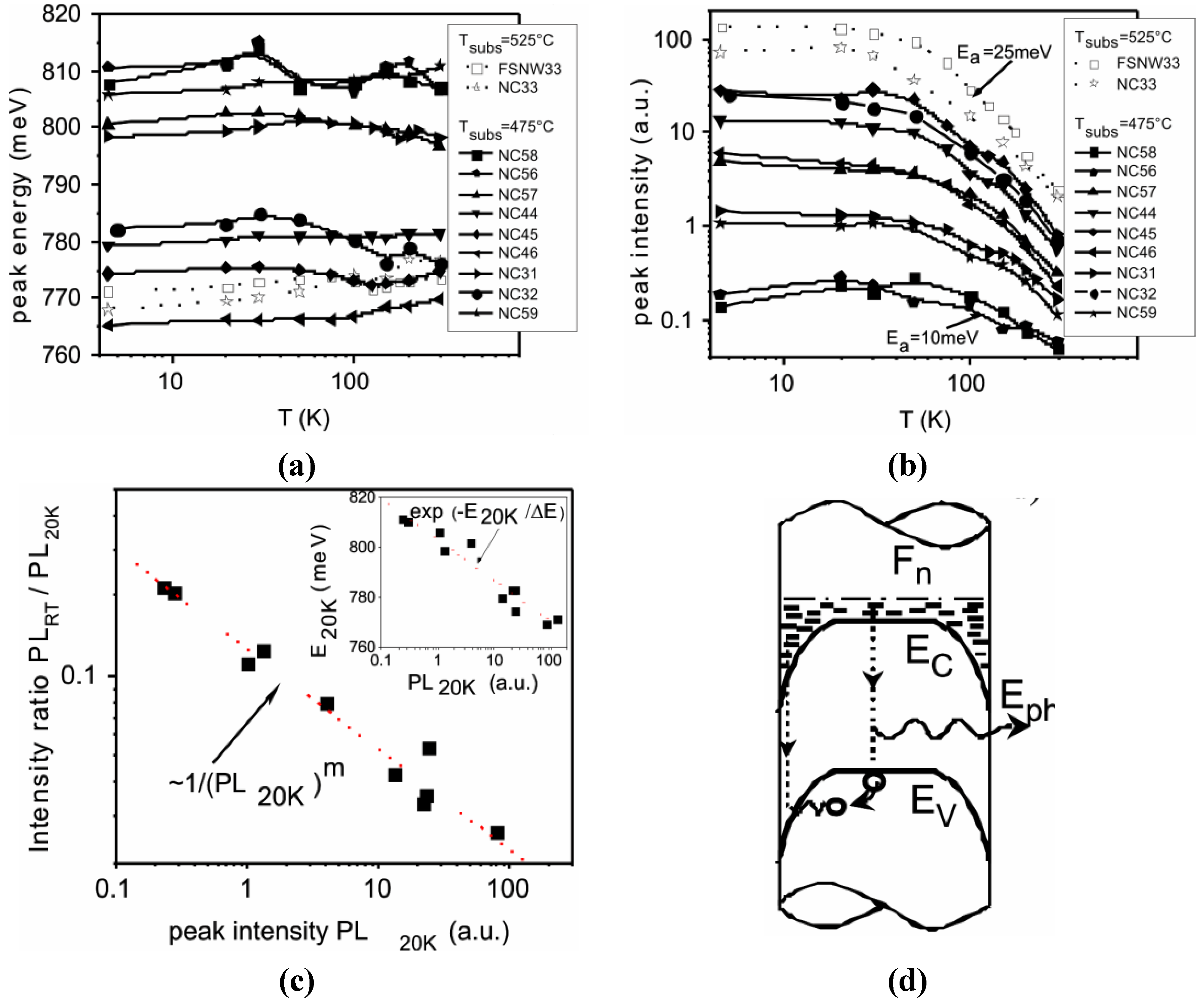

2.4. Optical Measurements

- local potential fluctuations, which cause fluctuations in the band edges;

- fluctuations of the Fermi level along the wire relative to the conduction band;

- Landsberg broadening due to the finite time of the final state of the electron-hole recombination.

2.5. Transport

3. Conclusions

Acknowledgments

References

- Wagner, R.S.; Ellis, W.C. Vapor-liquid-solid mechanism of single crystal growth. Appl. Phys. Lett. 1964, 4, 89–90. [Google Scholar] [CrossRef]

- Lieber, C.M. Semiconductor nanowires: A platform for nanoscience and nanotechnology. MRS Bull. 2011, 36, 1052–1063. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qian, F.; Xiang, J.; Lieber, C.M. Nanowire electronic and optoelectronic devices. Mater. Today 2006, 9, 18–27. [Google Scholar] [CrossRef]

- Huang, Y.; Duan, X.; Lieber, C.M. Nanowires for integrated multicolor nanophotonics. Small 2005, 1, 142–147. [Google Scholar] [CrossRef] [PubMed]

- Fan, H.J.; Werner, P.; Zacharias, M. Semiconductor nanowires: From self-organization to patterned growth. Small 2006, 2, 700–717. [Google Scholar] [CrossRef] [PubMed]

- Greytak, A.B.; Barrelet, C.J.; Li, Y.; Lieber, C.M. Semiconductor nanowire laser and nanowire waveguide electro-optic modulators. Appl. Phys. Lett. 2005, 87, 151103:1–151103:3. [Google Scholar] [CrossRef]

- Qian, F.; Gradecak, S.; Li, Y.; Wen, C.-Y.; Lieber, C.M. Core/Multishell nanowire heterostructures as multicolor, high-efficiency light-emitting diodes. Nano lett. 2005, 5, 2287–2291. [Google Scholar] [CrossRef] [PubMed]

- Patolsky, F.; Lieber, C.M. Nanowire nanosensors. Mater. Today 2005, 8, 20–28. [Google Scholar] [CrossRef]

- Patolsky, F.; Timko, B.; Zheng, G.; Lieber, C.M. Nanowire-based nanoelectronic devices in the life sciences. MRS Bull. 2007, 32, 142–149. [Google Scholar] [CrossRef]

- Patolsky, F.; Zheng, G.; Lieber, C.M. Nanowire-based biosensors. Anal. Chem. 2006, 78, 4260–4269. [Google Scholar] [CrossRef] [PubMed]

- Björk, M.T.; Ohlsson, B.J.; Sass, T.; Persson, A.I.; Thelander, C.; Magnusson, M.H.; Deppert, K.; Wallenberg, L.R.; Samuelson, L. Onedimensional heterostructures in semiconductor nanowhiskers. Appl. Phys. Lett. 2002, 80, 1058–1060. [Google Scholar] [CrossRef]

- Thelander, C.; Nilsson, H.A.; Jensen, L.E.; Samuelson, L. Nanowire single-electron memory. Nano Lett. 2005, 5, 635–638. [Google Scholar] [CrossRef] [PubMed]

- Palacios, T.; Shen, L.; Keller, S.; Chakraborty, A.; Heikman, S.; DenBaars, S.P.; Mishra, U.K.; Liberis, J.; Kiprijanovic, O.; Matulionis, A. Nitride-based high electron mobility transistors with a GaN spacer. Appl. Phys. Lett. 2006, 89, 073508:1–073508:3. [Google Scholar] [CrossRef]

- Calarco, R.; Stoica, T.; Brandt, O.; Geelhaar, L. Surface-induced effects in GaN nanowires. J. Mater. Res. 2011, 26, 2157–2168. [Google Scholar] [CrossRef]

- Stoica, T.; Calarco, R. Doping of III-nitride nanowires grown by molecular beam epitaxy. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 859–868. [Google Scholar] [CrossRef]

- Bertness, K.A.; Sanford, N.S.; Davydov, A.V. GaN nanowires grown by molecular beam epitaxy. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 847–858. [Google Scholar] [CrossRef]

- Geelhaar, L.; Chèze, C.; Jenichen, B.; Brandt, O.; Pfüller, C.; Münch, S.; Rothemund, R.; Reitzenstein, S.; Forchel, A.; Kehagias, T.; Komninou, P.; Dimitrakopulos, G.P.; Karakostas, T.; Lari, L.; Chalker, P.R.; Gass, M.H.; Riechert, H.; Ch, C.; Steffen, M. Properties of GaN nanowires grown by molecular beam epitaxy. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 878–888. [Google Scholar] [CrossRef]

- Tansley, T.L.; Foley, C.P. Optical band gap of indium nitride. J. Appl. Phys. 1986, 59, 3241–3244. [Google Scholar] [CrossRef]

- Lu, H.; Schaff, W.J.; Hwang, J.; Wu, H.; Yeo, W.; Pharkya, A.; Eastman, L.F. Improvement on epitaxial grown of InN by migration enhanced epitaxy. Appl. Phys. Lett. 2000, 77, 2548–2550. [Google Scholar] [CrossRef]

- Davydov, V.Y.; Klochikhin, A.A.; Emtsev, V.V.; Ivanov, S.V.; Vekshin, V.V.; Bechstedt, F.; Furthmüller, J.; Harima, H.; Mudryi, A.V.; Hashimoto, A.; Yamamoto, A.; Aderhold, J.; Graul, J.; Haller, E.E. Band gap of InN and in-rich InxGa1-xN alloys (0.36 < x < 1). Phys. Status Solid B 2002, 230, R4–R6. [Google Scholar] [CrossRef]

- Wu, J.; Walukiewicz, W.; Shan, W.; Yu, K.; Ager, J.; Haller, E.; Lu, H.; Schaff, W. Effects of the narrow band gap on the properties of InN. Phys. Rev. B 2002, 66, 201403:1–201403:4. [Google Scholar]

- Bechstedt, F.; Fuchs, F.; Furthmüller, J. Spectral properties of InN and its native oxide from first principles. Phys. Status Solid A 2010, 207, 1041–1053. [Google Scholar] [CrossRef]

- Wu, J.; Walukiewicz, W.; Li, S.X.; Armitage, R.; Ho, J.C.; Weber, E.R.; Haller, E.E.; Lu, H.; Schaff, W.J.; Barcz, A.; Jakiela, R. Effects of electron concentration on the optical absorption edge of InN. Appl. Phys. Lett. 2004, 84, 2805–2807. [Google Scholar] [CrossRef]

- Stoica, T.; Meijers, R.; Calarco, R.; Richter, T.; Lüth, H. MBE growth optimization of InN nanowires. J. Cryst. Growth 2006, 290, 241–247. [Google Scholar] [CrossRef]

- Chen, R.S.; Yang, T.H.; Chen, H.Y.; Chen, L.C.; Chen, K.H.; Yang, Y.J.; Su, C.H.; Lin, C.R. Photoconduction mechanism of oxygen sensitization in InN nanowires. Nanotechnology 2011, 22, 425702:1–425702:5. [Google Scholar]

- Bernardini, F.; Fiorentini, V.; Vanderbilt, D. Spontaneous polarization and piezoelectric constants of III-V nitrides. Phys. Rev. B 1997, 56, R10024–R10027. [Google Scholar] [CrossRef]

- Gallinat, C.S.; Koblmüller, G.; Brown, J.S.; Speck, J.S. A growth diagram for plasma-assisted molecular beam epitaxy of In-face InN. J. Appl. Phys. 2007, 102, 064907:1–064907:7. [Google Scholar] [CrossRef]

- Denker, C.; Malindretos, J.; Werner, F.; Limbach, F.; Schuhmann, H.; Niermann, T.; Seibt, M.; Rizzi, A. Self-organized growth of InN-nanocolumns on p-Si(111) by MBE. Phys. Status Solidi C 2008, 5, 1706–1708. [Google Scholar] [CrossRef]

- Dimakis, E.; Konstantinidis, G.; Tsagaraki, K.; Adikimenakis, A.; Iliopoulos, E.; Georgakilas, A. The role of nucleation temperature in In-face InN-on-GaN(0001)growth by plasma-assisted molecular beam epitaxy. Superlattices Microstruct. 2004, 36, 497–507. [Google Scholar] [CrossRef]

- Ambacher, O.; Brandt, M.; Dimitrov, R.; Metzger, T.; Stutzmann, M.; Fischer, R.; Miehr, A.; Bergmaier, A.; Dollinger, G. Thermal stability and desorption of group III nitrides prepared by metal organic chemical vapor deposition. J. Vac. Sci. Technol. B 1996, 14, 3532–3542. [Google Scholar] [CrossRef]

- Calarco, R.; Meijers, R.; Debnath, R.K.; Stoica, T.; Sutter, E.; Lüth, H. Nucleation and growth of GaN nanowires on Si(111) performed by molecular beam epitaxy. Nano Lett. 2007, 7, 2248–2251. [Google Scholar] [CrossRef] [PubMed]

- Debnath, R.K.; Meijers, R.; Richter, T.; Stoica, T.; Calarco, R.; Lüth, H. Mechanism of molecular beam epitaxy growth of GaN nanowires on Si(111). Appl. Phys. Lett. 2007, 90, 123117:1–123117:3. [Google Scholar] [CrossRef]

- Calleja, E.; Sánchez-García, M.; Basak, D.; Sánchez, F.; Calle, F.; Youinou, P.; Muñoz, E.; Serrano, J.; Blanco, J.; Villar, C.; et al. Effect of Ga/Si interdiffusion on optical and transport properties of GaN layers grown on Si(111) by molecular-beam epitaxy. Phys. Rev. B 1998, 58, 1550–1559. [Google Scholar] [CrossRef]

- Grandal, J.; Sánchez-García, M.A.; Calleja, E.; Luna, E.; Trampert, A. Accommodation mechanism of InN nanocolumns grown on Si(111) substrates by molecular beam epitaxy. Appl. Phys. Lett. 2007, 91, 021902:1–021902:3. [Google Scholar] [CrossRef]

- Nguyen, H.P.T.; Chang, Y.; Shih, I.; Mi, Z. InN p-i-n nanowire solar cells on Si. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 1062–1069. [Google Scholar] [CrossRef]

- Harui, S.; Tamiya, H.; Akagi, T.; Miyake, H.; Hiramatsu, K.; Araki, T.; Nanishi, Y. Transmission electron microscopy characterization of position-controlled InN nanocolumns. Jpn J. Appl. Phys. 2008, 47, 5330–5332. [Google Scholar] [CrossRef]

- Kamimura, J.; Kishino, K.; Kikuchi, A. Dislocation reduction via selective-area growth of InN accompanied by lateral growth by rf-plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett. 2010, 97, 141913:1–141913:3. [Google Scholar] [CrossRef]

- Liang, C.H.; Chen, L.C.; Hwang, J.S.; Chen, K.H.; Hung, Y.T.; Chen, Y.F. Selective-area growth of indium nitride nanowires on gold-patterned Si(100) substrates. Appl. Phys. Lett. 2002, 81, 22–24. [Google Scholar] [CrossRef]

- Huang, L.; Li, D.; Chang, P.; Chu, S.; Bozler, H.; Beloborodov, I.; Lu, J. Quantum transport in indium nitride nanowires. Phys. Rev. B 2011, 83, 245310:1–245310:5. [Google Scholar]

- Stoica, T.; Meijers, R.J.; Calarco, R.; Richter, T.; Sutter, E.; Lüth, H. Photoluminescence and intrinsic properties of MBE-Grown InN nanowires. Nano Lett. 2006, 6, 1541–1547. [Google Scholar] [CrossRef] [PubMed]

- Mahboob, I.; Veal, T.; McConville, C.; Lu, H.; Schaff, W. Intrinsic electron accumulation at clean InN surfaces. Phys. Rev. Lett. 2004, 92, 036804:1–036804:4. [Google Scholar] [CrossRef]

- Van de Walle, C.G.; Segev, D. Microscopic origins of surface states on nitride surfaces. J. Appl. Phys. 2007, 101, 081704:1–081704:6. [Google Scholar] [CrossRef]

- Segura-Ruiz, J.; Garro, N.; Cantarero, A.; Denker, C.; Malindretos, J.; Rizzi, A. Optical studies of MBE-grown InN nanocolumns: Evidence of surface electron accumulation. Phys. Rev. B 2009, 79, 115305:1–115305:9. [Google Scholar] [CrossRef]

- Lazić, S.; Gallardo, E.; Calleja, J.; Agulló-Rueda, F.; Grandal, J.; Sánchez-Garcia, M.; Calleja, E.; Luna, E.; Trampert, A. Phonon-plasmon coupling in electron surface accumulation layers in InN nanocolumns. Phys. Rev. B 2007, 76, 205319:1–205319:6. [Google Scholar]

- Cuscó, R.; Ibáñez, J.; Alarcón-Lladó, E.; Artús, L.; Yamaguchi, T.; Nanishi, Y. Raman scattering study of the long-wavelength longitudinal-optical-phonon–plasmon coupled modes in high-mobility InN layers. Phys. Rev. B 2009, 79, 155210:1–155210:9. [Google Scholar] [CrossRef]

- Demangeot, F.; Pinquier, C.; Frandon, J.; Gaio, M.; Briot, O.; Maleyre, B.; Ruffenach, S.; Gil, B. Raman scattering by the longitudinal optical phonon in InN: Wave-vector nonconserving mechanisms. Phys. Rev. B 2005, 71, 104305:1–104305:6. [Google Scholar] [CrossRef]

- Schäfer-Nolte, E.O.; Stoica, T.; Gotschke, T.; Limbach, F.; Sutter, E.; Sutter, P.; Grützmacher, D.; Calarco, R. Enhanced light scattering of the forbidden longitudinal optical phonon mode studied by micro-Raman spectroscopy on single InN nanowires. Nanotechnology 2010, 21, 315702:1–315702:6. [Google Scholar] [CrossRef]

- Cuscó, R.; Domènech-Amador, N.; Artús, L.; Gotschke, T.; Jeganathan, K.; Stoica, T.; Calarco, R. Probing the electron density in undoped, Si-doped and Mg-doped InN nanowires by means of Raman scattering. Appl. Phys. Lett. 2010, 97, 221906:1–221906:3. [Google Scholar]

- Domènech-Amador, N.; Cuscó, R.; Calarco, R.; Yamaguchi, T.; Nanishi, Y.; Artús, L. Double resonance Raman effects in InN nanowires. Phys. Status Solidi Rapid Res. Lett. 2012, 6, 160–162. [Google Scholar] [CrossRef]

- Domènech-Amador, N.; Cuscó, R.; Artús, L.; Stoica, T.; Calarco, R. Longer InN phonon lifetimes in nanowires. Nanotechnology 2012, 23, 085702–85706. [Google Scholar] [CrossRef] [PubMed]

- Richter, T.; Lüth, H.; Schäpers, T.; Meijers, R.; Jeganathan, K.; Estévez Hernández, S.; Calarco, R.; Marso, M. Electrical transport properties of single undoped and n-type doped InN nanowires. Nanotechnology 2009, 20, 405206:1–405206:6. [Google Scholar] [CrossRef]

- Werner, F.; Limbach, F.; Carsten, M.; Denker, C.; Malindretos, J.; Rizzi, A. Electrical conductivity of InN nanowires and the influence of the native indium oxide formed at their surface. Nano Lett. 2009, 9, 1567–1571. [Google Scholar] [CrossRef] [PubMed]

- Khanal, D.R.; Walukiewicz, W.; Grandal, J.; Calleja, E.; Wu, J. Determining surface Fermi level pinning position of InN nanowires using electrolyte gating. Appl. Phys. Lett. 2009, 95, 173114:1–173114:3. [Google Scholar] [CrossRef]

- Richter, T.; Blömers, Ch.; Lüth, H.; Calarco, R.; Indlekofer, M.; Marso, M.; Schäpers, Th. Flux quantization effects in InN nanowires. Nano Lett. 2008, 8, 2834–2838. [Google Scholar] [CrossRef] [PubMed]

- Blömers, Ch.; Lu, J.G.; Huang, L.; Witte, C.; Grützmacher, D.; Lüth, H.; Schäpers, Th. Electronic transport with dielectric confinement in degenerate InN nanowires. Nano Lett. 2012, 12, 2768–2772. [Google Scholar] [CrossRef] [PubMed]

© 2012 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Calarco, R. InN Nanowires: Growth and Optoelectronic Properties. Materials 2012, 5, 2137-2150. https://doi.org/10.3390/ma5112137

Calarco R. InN Nanowires: Growth and Optoelectronic Properties. Materials. 2012; 5(11):2137-2150. https://doi.org/10.3390/ma5112137

Chicago/Turabian StyleCalarco, Raffaella. 2012. "InN Nanowires: Growth and Optoelectronic Properties" Materials 5, no. 11: 2137-2150. https://doi.org/10.3390/ma5112137