Durability of Starch Based Biodegradable Plastics Reinforced with Manila Hemp Fibers

Abstract

:1. Introduction

2. Experimental Procedures

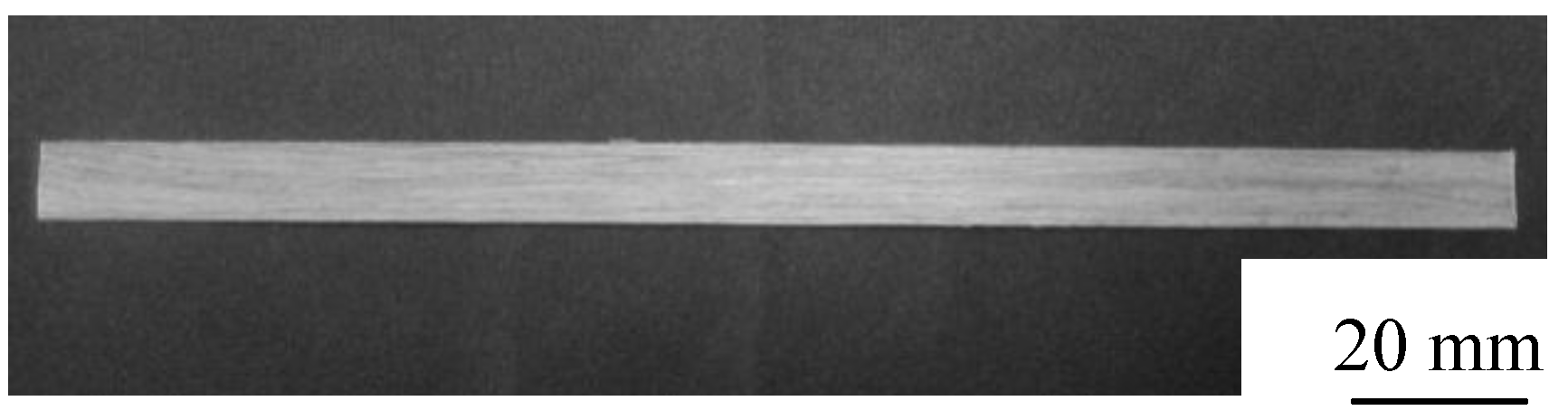

2.1. Materials

2.2. Specimen molding method

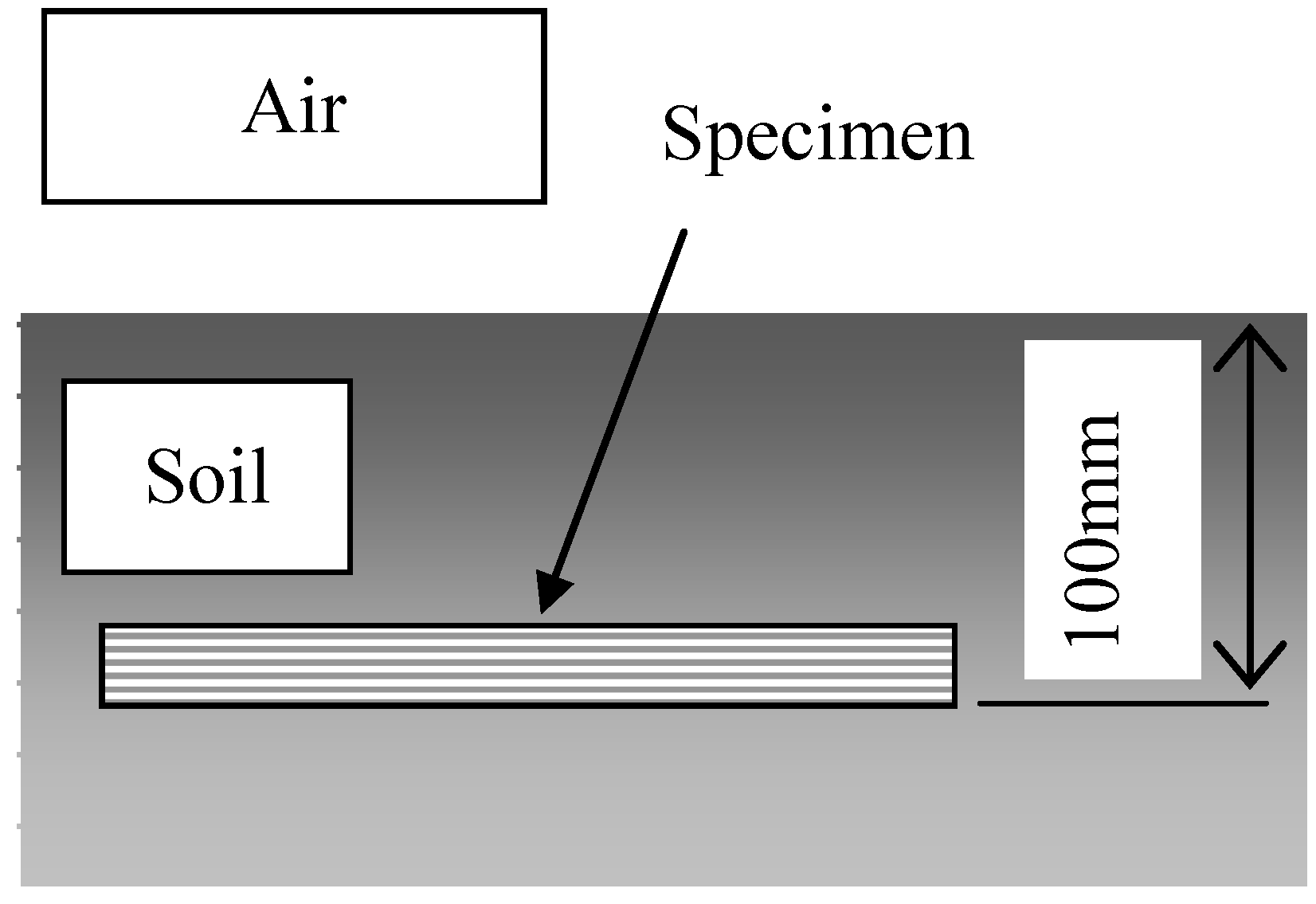

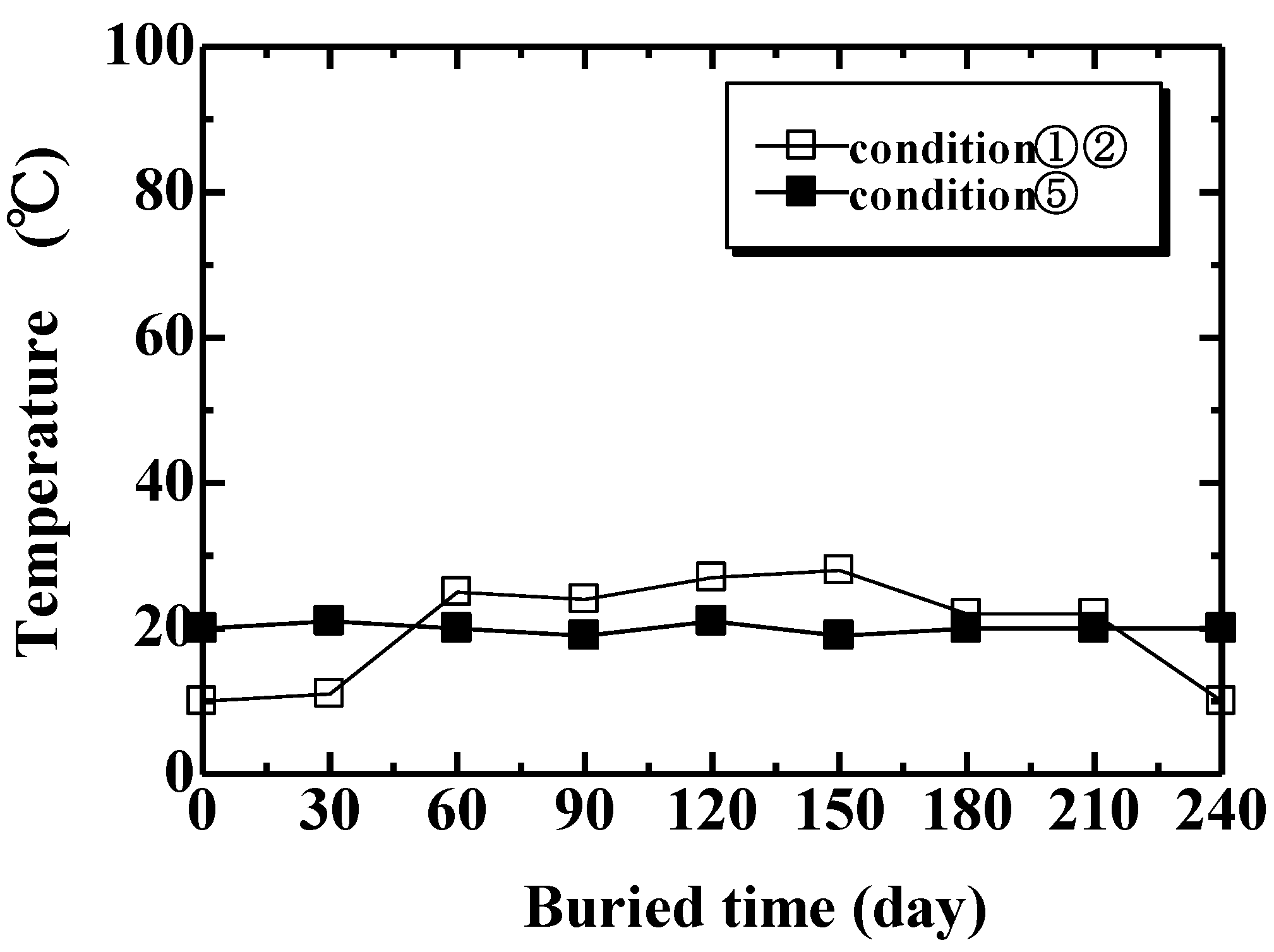

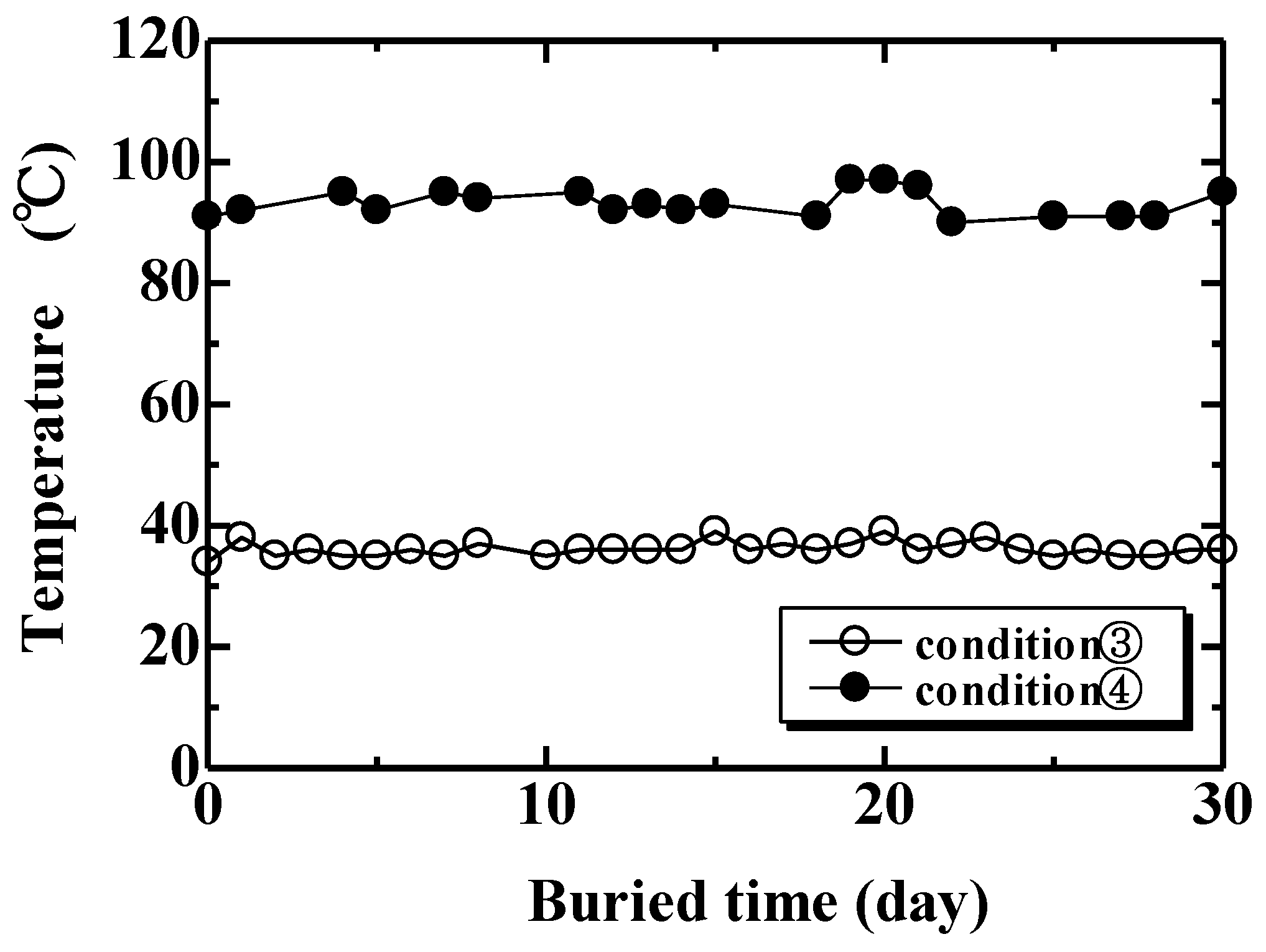

2.3. Biodegradability tests

2.4. Evaluation of biodegradability

3. Results and Discussions

3.1. Mechanical properties

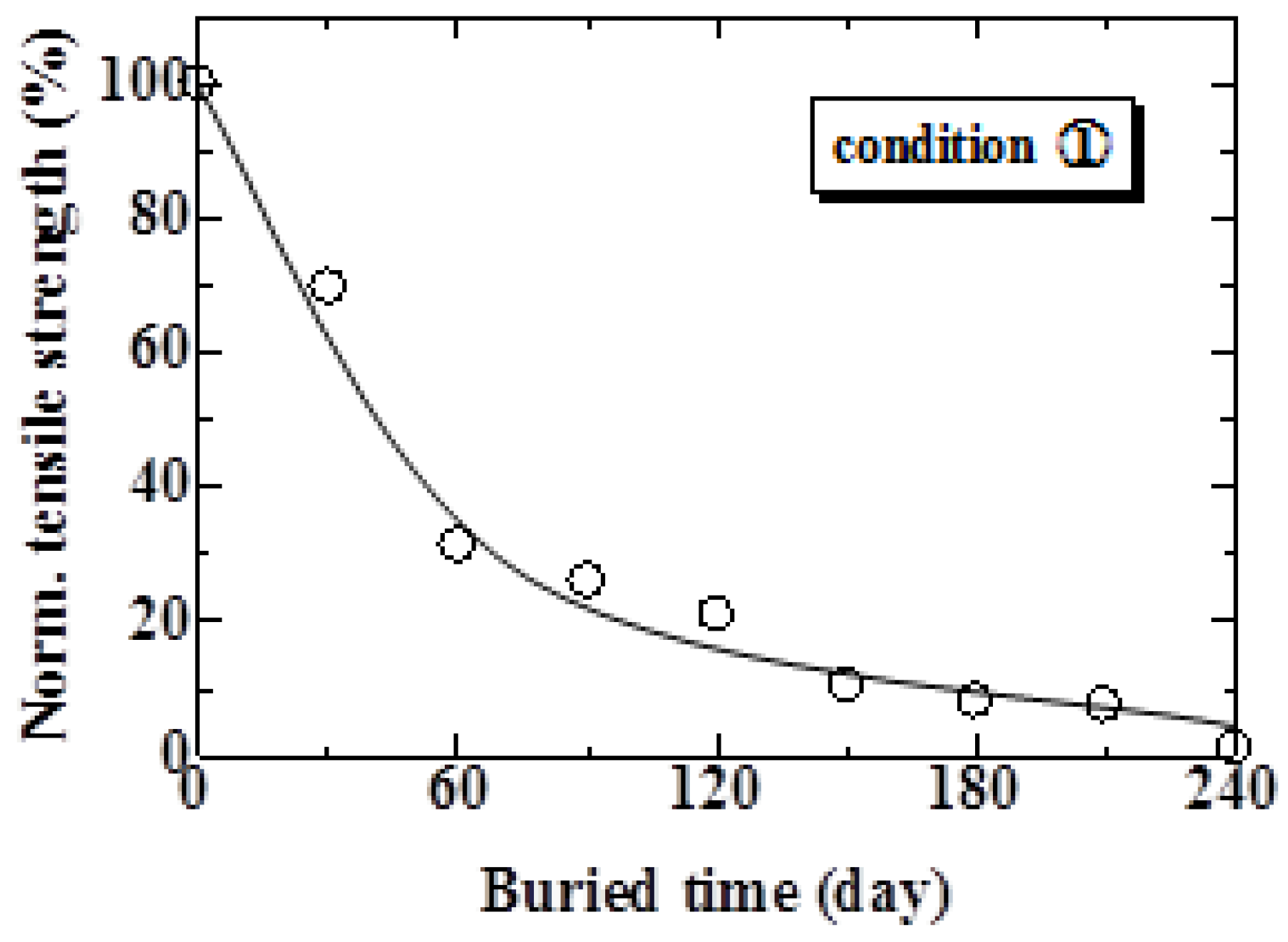

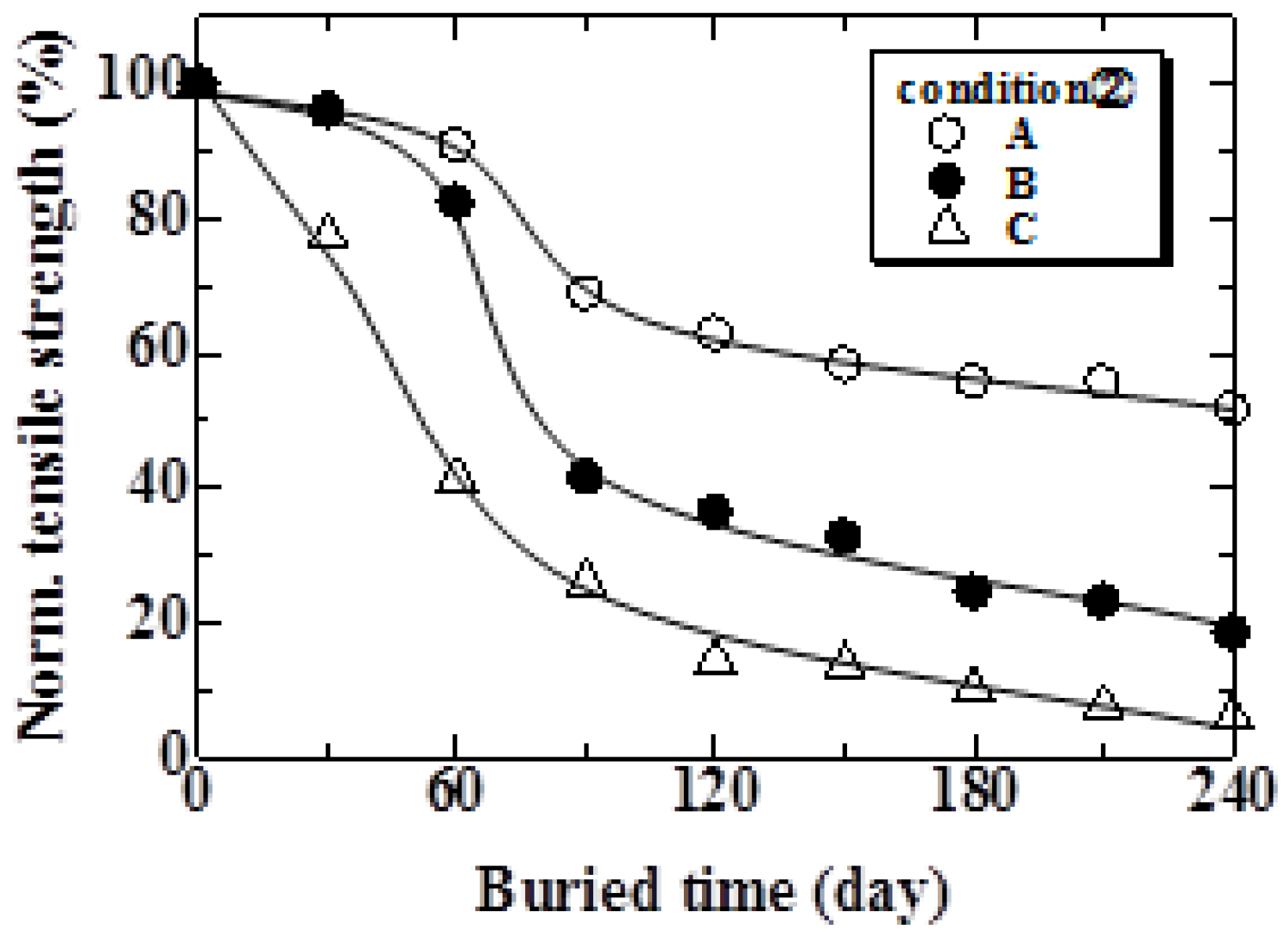

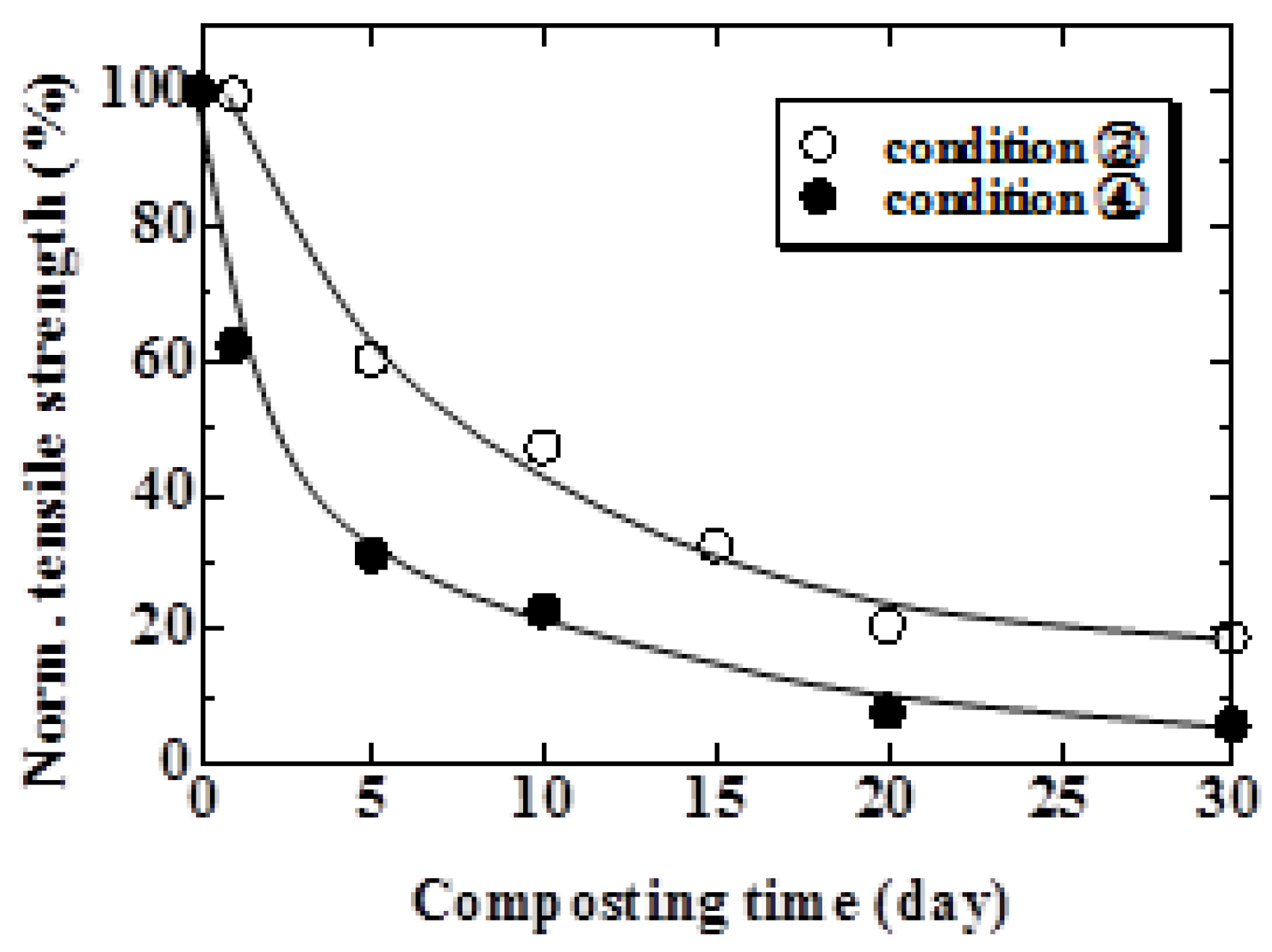

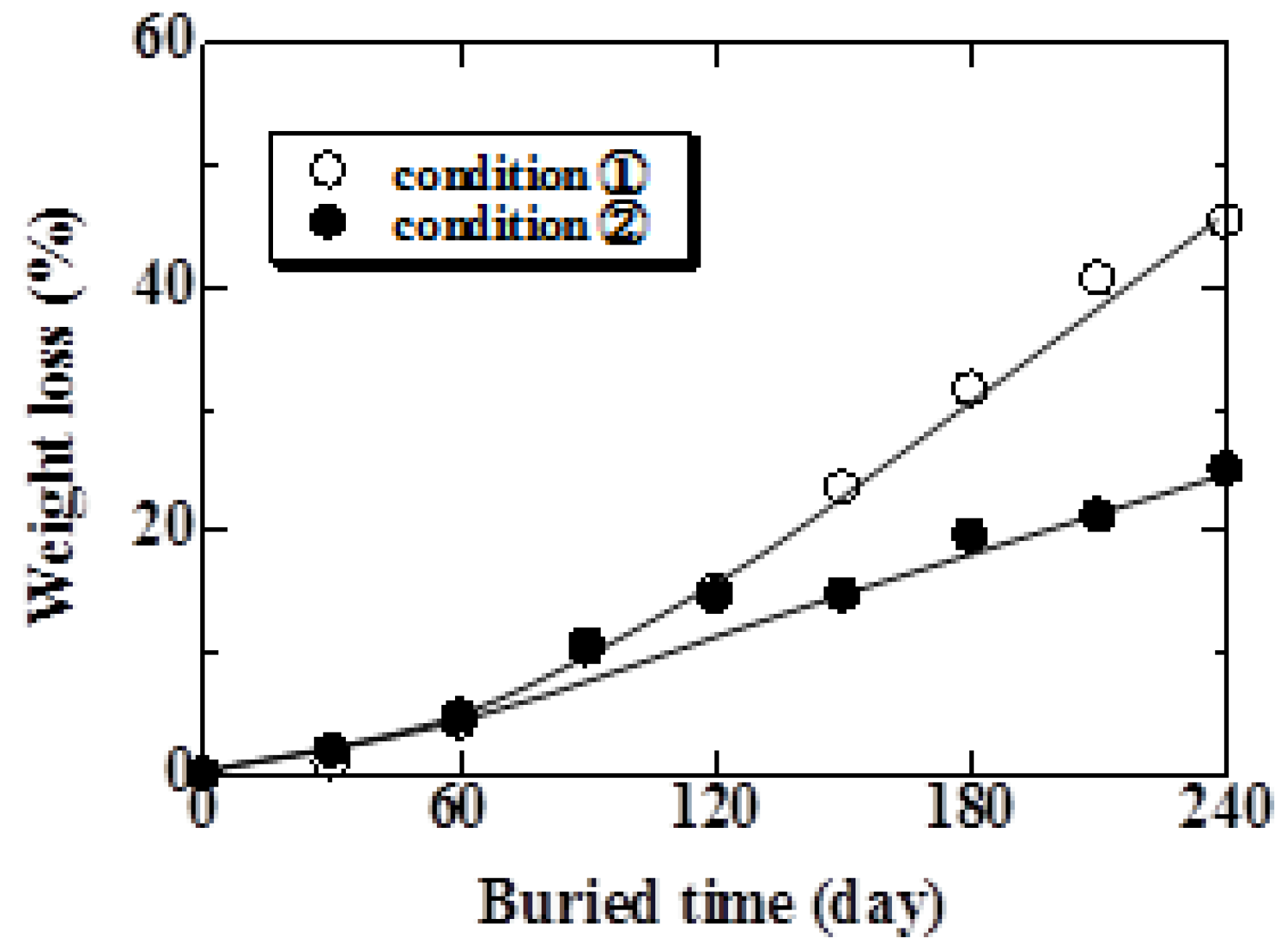

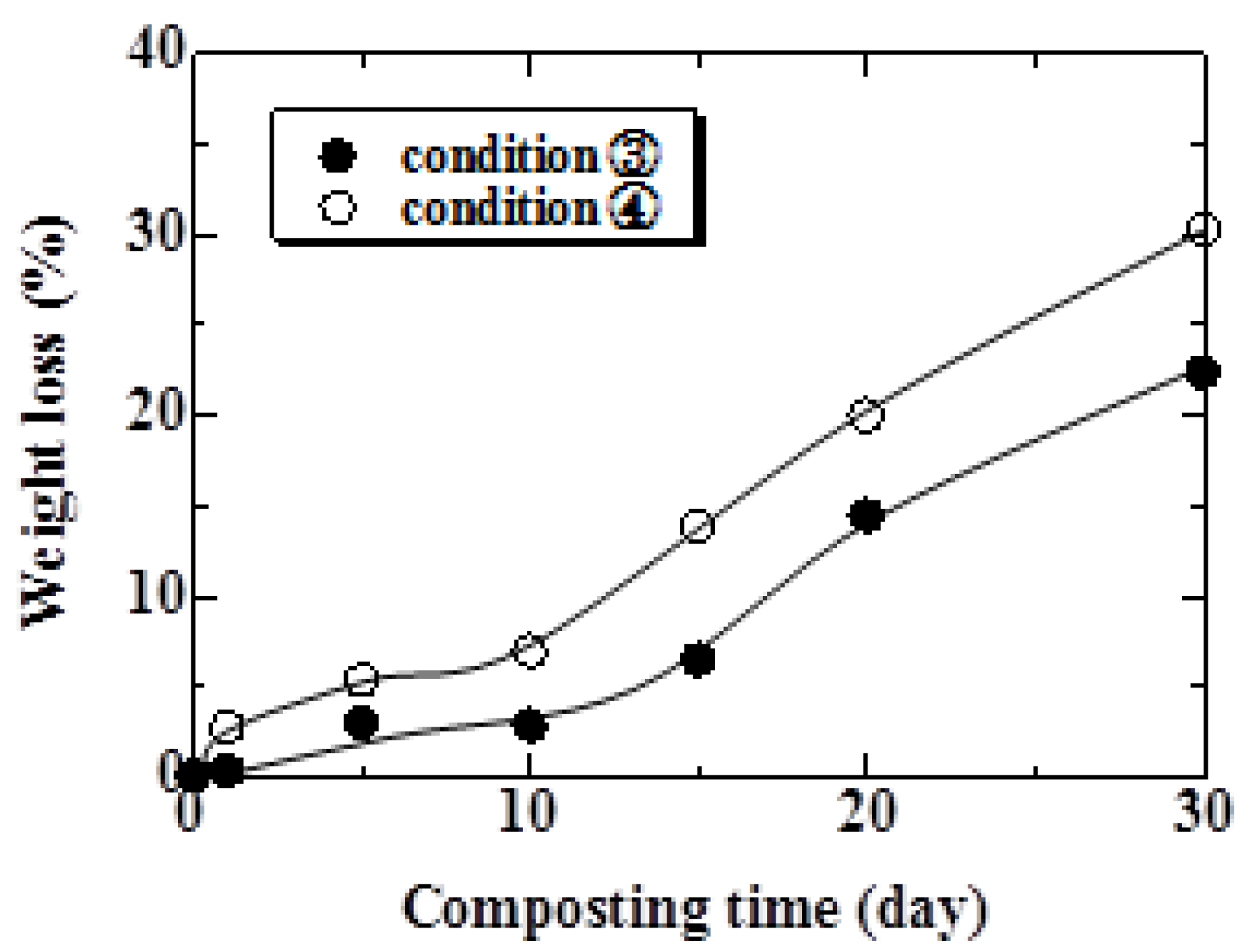

3.2. Biodegradation behavior

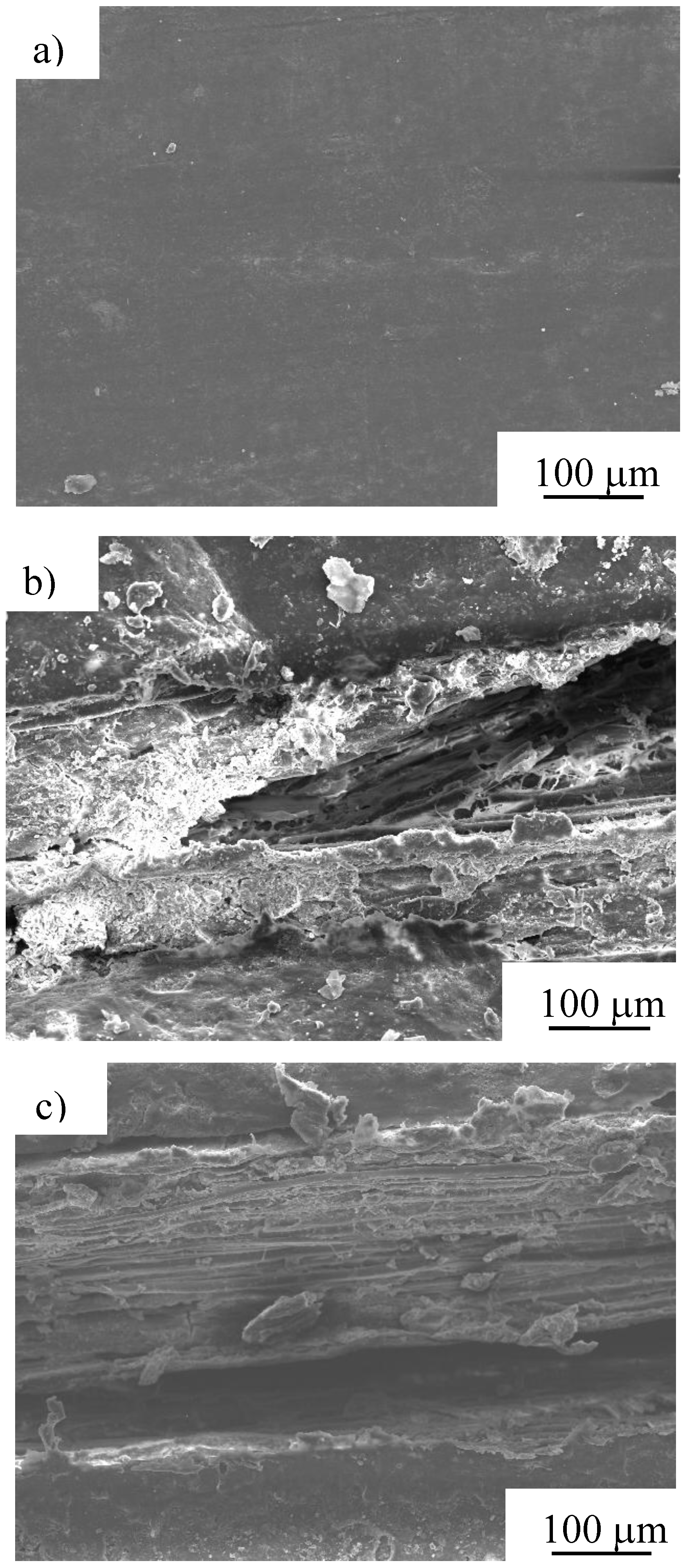

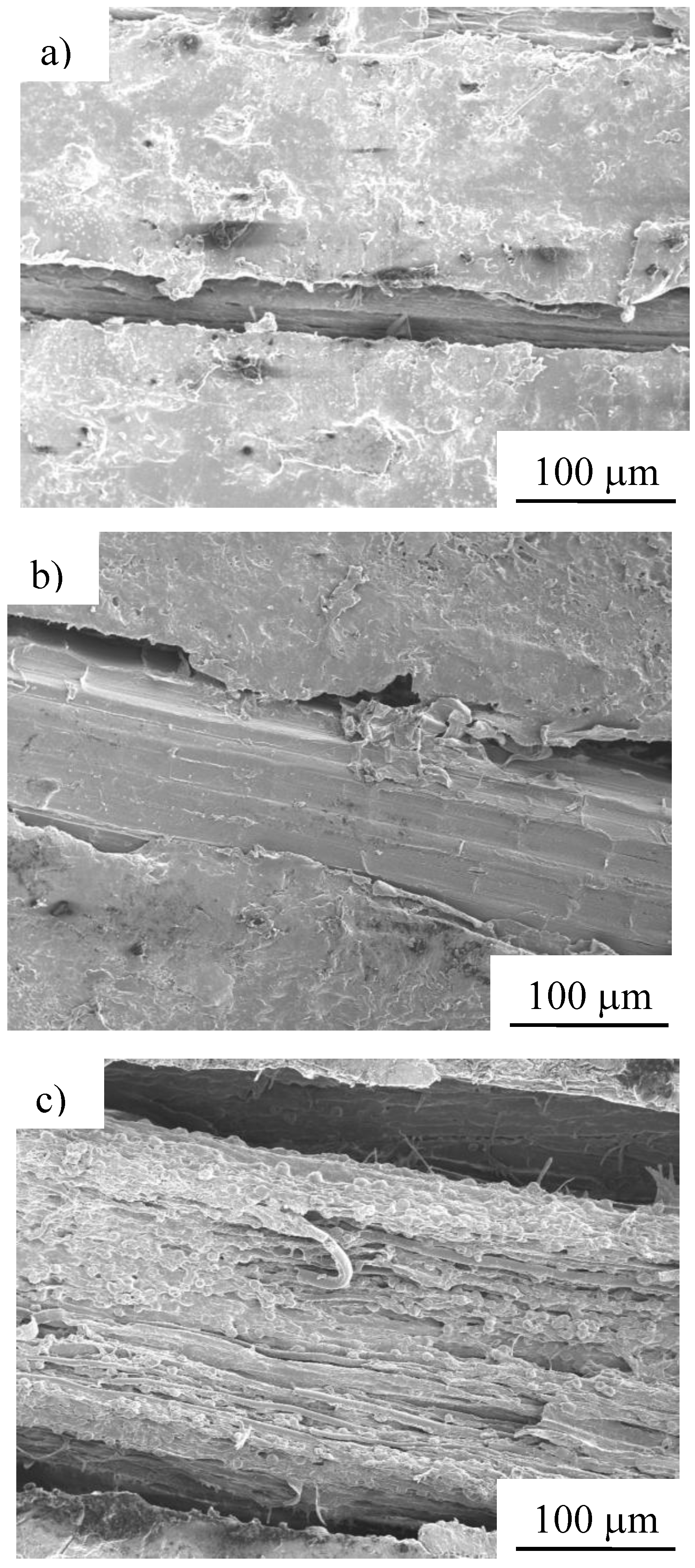

3.3. Microscopic observations

4. Conclusions

- (1)

- In the case of composting, the tensile strength of Manila hemp fiber reinforced composites decreased 80% after 20 days. In the case of a natural atmosphere, the tensile strength of specimens in soil decreased 80% after 90 days. Furthermore, differences of condition could be seen between parts of a differentially exposed specimen; strength decreased for the part under soil more so than the part exposed to air.

- (2)

- Weight loss of the specimen completely buried under the soil showed a value of approximately 1.8 times that of the specimen of which only half was buried under the soil at 240 days (45% vs. 25%, respectively). A weight loss of 30% was observed with the specimen in compost at 90 °C for 30 days and a similar level of weight loss was seen in natural environments at 180 days.

- (3)

- The state of the parts of the specimens in soil changed remarkably. In the atmosphere, biodegradation is negligible. On the other hand, when the specimen interacts with microbes in either the natural or compost soil, weight, tensile strength and state of the specimen change remarkably.

- (4)

- The decomposition sequence for MHFRP can be described as follows. The biodegradable resin at the specimen surface first decomposes, followed by exposure of the Manila hemp fiber bundles embedded within the resin. Next, the biodegradable resin in the vicinity of the fiber-resin interface decomposes, resulting in the formation of interfacial gaps. Finally, substantial decomposition of both the fibers and biodegradable resin occurs.

Acknowledgements

References and Notes

- Huang, X.; Netravali, A. Characterization of flax fiber reinforced soy protein resin based green composites modified with nano-clay particles. Compos. Sci. Tech. 2007, 67, 2005–2014. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications. Compos. Sci. Tech. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Liu, W.; Misra, M.; Askeland, P.; Drzal, L.T.; Mohanty, A.K. ‘Green’ composites from soy based plastic and pineapple leaf fiber: Fabrication and properties evaluation. Polymer 2005, 46, 2710–2721. [Google Scholar] [CrossRef]

- Arib, R.M.N.; Sapuan, S.M.; Ahmad, M.M.H.M.; Paridah, M.T.; Khairul Zaman, H.M.D. Mechanical properties of pineapple leaf fibre reinforced polypropylene composites. Mater. Des. 2006, 27, 391–396. [Google Scholar] [CrossRef]

- Huang, X.; Netravali, A. Biodegradable green composites made using bamboo micro/nano-fibrils and chemically modified soy protein resin. Compos. Sci. Tech. 2009, 69, 1009–1015. [Google Scholar] [CrossRef]

- Netravali, A.N.; Chabba, S. Composites get greener. Mater. Today 2003, 6, 22–29. [Google Scholar] [CrossRef]

- Chen, H.; Miao, M.; Ding, X. Influence of Moisture Absorption on the Interfacial Strength of Bamboo/Vinyl Ester Composites. Compos. Appl. Sci. Manuf. 2009, 40, 2013–2019. [Google Scholar] [CrossRef]

- Keller, A. Compounding and mechanical properties of biodegradable hemp fibre composites. Compos. Sci. Tech. 2003, 63, 1307–1316. [Google Scholar] [CrossRef]

- Placet, V. Characterization of the thermo-mechanical behaviour of Hemp fibres intended for the manufacturing of high performance composites. Compos. Appl. Sci. Manuf. 2009, 40, 1111–1118. [Google Scholar] [CrossRef] [Green Version]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced poly(lactic acid) (PLA) composites: An overview about mechanical characteristics and application areas. Compos. Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Progr. Polymer Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Lee, B.-H.; Kim, H.-S.; Lee, S.; Kim, H.-J.; Dorgan, J.R. Bio-composites of kenaf fibers in polylactide: Role of improved interfacial adhesion in the carding process. Compos. Sci. Tech. 2009, 69, 2573–2579. [Google Scholar] [CrossRef]

- Liu, W.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Influence of processing methods and fiber length on physical properties of kenaf fiber reinforced soy based biocomposites. Compos. B Eng. 2007, 38, 352–359. [Google Scholar] [CrossRef]

- Lodha, P.; Netravali, A.N. Characterization of stearic acid modified soy protein isolate resin and ramie fiber reinforced ‘green’ composites. Compos. Sci. Tech. 2005, 65, 1211–1225. [Google Scholar] [CrossRef]

- Ochi, S. Development of high strength biodegradable composites using Manila hemp fiber and starch-based biodegradable resin. Compos. Appl. Sci. Manuf. 2006, 37, 1879–1883. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, H.-J.; Lee, J.-W.; Choi, I.-G. Biodegradability of bio-flour filled biodegradable poly(butylene succinate) bio-composites in natural and compost soil. Polymer Degrad. Stabil. 2006, 91, 1117–1127. [Google Scholar] [CrossRef]

- Rose, D.D.S.; Rodrigues, T.C.; Gracas Fassina Guedes, C.D.; Calil, M.R. Effect of Thermal Aging on the Biodegradation of PCL, PHB-V, and Their Blends with Starch in Soil Compost. J. Appl. Polymer Sci. 2003, 89, 3539–3546. [Google Scholar]

- Testa, G.; Sardella, A.; Rossi, E.; Bozzi, C.; Seves, A. The kinetics of cellulose fiber degradation and correlation with some tensile properties. Acta Polymer. 1994, 45, 47–49. [Google Scholar] [CrossRef]

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ochi, S. Durability of Starch Based Biodegradable Plastics Reinforced with Manila Hemp Fibers. Materials 2011, 4, 457-468. https://doi.org/10.3390/ma4030457

Ochi S. Durability of Starch Based Biodegradable Plastics Reinforced with Manila Hemp Fibers. Materials. 2011; 4(3):457-468. https://doi.org/10.3390/ma4030457

Chicago/Turabian StyleOchi, Shinji. 2011. "Durability of Starch Based Biodegradable Plastics Reinforced with Manila Hemp Fibers" Materials 4, no. 3: 457-468. https://doi.org/10.3390/ma4030457