Effect of Compressive Stress on Copper Bonding Quality and Bonding Mechanisms in Advanced Packaging

Abstract

:1. Introduction

2. Experimental

2.1. Cu Film Electrodeposition

2.2. Pretreatment of the Specimens

2.3. Characterization of the Surface Roughness and Morphology

2.4. Bonding Process

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koester, S.J.; Young, A.M.; Yu, R.; Purushothaman, S.; Chen, K.-N.; La Tulipe, D.C.; Rana, N.; Shi, L.; Wordeman, M.R.; Sprogis, E.J. Wafer-level 3D integration technology. IBM J. Res. Dev. 2008, 52, 583–597. [Google Scholar] [CrossRef]

- Liu, D.; Park, S. Three-dimensional and 2.5 dimensional interconnection technology: State of the art. J. Electron. Packag. 2014, 136, 014001. [Google Scholar] [CrossRef]

- Chen, C.; Yu, D.; Chen, K.-N. Vertical interconnects of microbumps in 3D integration. MRS Bull. 2015, 40, 257–263. [Google Scholar] [CrossRef]

- Cho, D.H.; Seo, S.M.; Kim, J.B.; Rajendran, S.H.; Jung, J.P. A review on the fabrication and reliability of three-dimensional integration technologies for microelectronic packaging: Through-Si-via and solder bumping process. Metals 2021, 11, 1664. [Google Scholar] [CrossRef]

- Shie, K.-C.; Hsu, P.-N.; Li, Y.-J.; Tran, D.-P.; Chen, C. Failure Mechanisms of Cu–Cu bumps under thermal cycling. Materials 2021, 14, 5522. [Google Scholar] [CrossRef]

- Tu, K.-N.; Hsiao, H.-Y.; Chen, C. Transition from flip chip solder joint to 3D IC microbump: Its effect on microstructure anisotropy. Microelectron. Reliab. 2013, 53, 2–6. [Google Scholar] [CrossRef]

- Liang, Y.; Chen, C.; Tu, K.-N. Side wall wetting induced void formation due to small solder volume in microbumps of Ni/SnAg/Ni upon reflow. ECS Solid State Lett. 2012, 1, P60. [Google Scholar] [CrossRef]

- Oi, K.; Otake, S.; Shimizu, N.; Watanabe, S.; Kunimoto, Y.; Kurihara, T.; Koyama, T.; Tanaka, M.; Aryasomayajula, L.; Kutlu, Z. Development of new 2.5 D package with novel integrated organic interposer substrate with ultra-fine wiring and high density bumps. In Proceedings of the 2014 IEEE 64th Electronic components and technology conference (ECTC), Lake Buena Vista, FL, USA, 27–30 May 2014; pp. 348–353. [Google Scholar]

- Wang, L.; Fountain, G.; Lee, B.; Gao, G.; Uzoh, C.; McGrath, S.; Enquist, P.; Arkalgud, S.; Mirkarimi, L. Direct Bond Interconnect (DBI®) for fine-pitch bonding in 3D and 2.5 D integrated circuits. In Proceedings of the 2017 Pan Pacific Microelectronics Symposium (Pan Pacific), Kauai, HI, USA, 6–9 February 2017; pp. 1–6. [Google Scholar]

- Mudrick, J.P.; Sierra-Suarez, J.A.; Jordan, M.B.; Friedmann, T.A.; Jarecki, R.; Henry, M.D. Sub-10 µm Pitch Hybrid Direct Bond Interconnect Development for Die-to-Die Hybridization. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 648–654. [Google Scholar]

- Kim, S.-W.; Fodor, F.; Heylen, N.; Iacovo, S.; De Vos, J.; Miller, A.; Beyer, G.; Beyne, E. Novel Cu/SiCN surface topography control for 1 μm pitch hybrid wafer-to-wafer bonding. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; pp. 216–222. [Google Scholar]

- Utsumi, J.; Ide, K.; Ichiyanagi, Y. Cu/SiO2 hybrid bonding obtained by surface-activated bonding method at room temperature using Si ultrathin films. Micro Nano Eng. 2019, 2, 1–6. [Google Scholar] [CrossRef]

- Phommahaxay, A.; Suhard, S.; Bex, P.; Iacovo, S.; Slabbekoorn, J.; Inoue, F.; Peng, L.; Kennes, K.; Sleeckx, E.; Beyer, G. Enabling ultra-thin die to wafer hybrid bonding for future heterogeneous integrated systems. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 607–613. [Google Scholar]

- Zhengfeng, W.; Ling, Y.; Huan, N.S.; Luan, T.P. Chemical Mechanical Planarization; Singapore Institute of Manufacturing Technology: Singapore, 2001. [Google Scholar]

- Shauly, E.N.; Rosenthal, S. Coverage layout design rules and insertion utilities for CMP-related processes. J. Low Power Electron. Appl. 2020, 11, 2. [Google Scholar] [CrossRef]

- Kim, M.-K.; Park, S.; Jang, A.; Lee, H.; Baek, S.; Lee, C.; Kim, I.; Park, J.; Jee, Y.; Kang, U.-B. Characterization of die-to-wafer hybrid bonding using heterogeneous dielectrics. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 31 May–3 June 2022; pp. 335–339. [Google Scholar]

- Hu, H.-W.; Chen, K.-N. Development of low temperature CuCu bonding and hybrid bonding for three-dimensional integrated circuits (3D IC). Microelectron. Reliab. 2021, 127, 114412. [Google Scholar] [CrossRef]

- Ong, J.-J.; Chiu, W.-L.; Lee, O.-H.; Chiang, C.-W.; Chang, H.-H.; Wang, C.-H.; Shie, K.-C.; Yang, S.-C.; Tran, D.-P.; Tu, K.-N. Low-temperature Cu/SiO2 hybrid bonding with low contact resistance using (111)-oriented Cu surfaces. Materials 2022, 15, 1888. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Mirkarimi, L.; Workman, T.; Fountain, G.; Theil, J.; Guevara, G.; Liu, P.; Lee, B.; Mrozek, P.; Huynh, M. Low temperature Cu interconnect with chip to wafer hybrid bonding. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 628–635. [Google Scholar]

- Gambino, J.; Winzenread, R.; Thomas, K.; Muller, R.; Truong, H.; Defibaugh, D.; Price, D.; Goshima, K.; Hirano, T.; Watanabe, Y. Reliability of hybrid bond interconnects. In Proceedings of the 2017 IEEE International Interconnect Technology Conference (IITC), Hsinchu, Taiwan, 16–18 May 2017; pp. 1–3. [Google Scholar]

- Lin, H.-E.; Tran, D.-P.; Chiu, W.-L.; Chang, H.-H.; Chen, C. In-situ measurement of thermal expansion in Cu/SiO2 hybrid structures using atomic force microscopy at elevated temperatures. Appl. Surf. Sci. 2024, 662, 160103. [Google Scholar] [CrossRef]

- Lu, T.-F.; Hsu, K.-N.; Hsu, C.-C.; Hsu, C.-Y.; Wu, Y.S. Effect of Cu Film Thickness on Cu Bonding Quality and Bonding Mechanism. Materials 2024, 17, 2150. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, J.; Kim, H.; Lee, H.; Kim, D.; Seo, S.-K.; Jo, C.; Kim, D.-W. Die to Wafer Hybrid Cu Bonding for Fine Pitch 3D-IC Applications. In Proceedings of the 2023 IEEE 73rd Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2023; pp. 1043–1047. [Google Scholar]

- Ji, L.; Che, F.X.; Ji, H.M.; Li, H.Y.; Kawano, M. Bonding integrity enhancement in wafer to wafer fine pitch hybrid bonding by advanced numerical modelling. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; pp. 568–575. [Google Scholar]

- Wu, Y.S.; Lai, T.-Y.; Li, M.; Lu, T.-F.; Wang, Y.H.; Tseng, T.Y. Bonding mechanisms of roughened nanotwinned-Cu surface at temperature as low as 120 °C. ECS J. Solid State Sci. Technol. 2020, 9, 124005. [Google Scholar] [CrossRef]

- Derby, B.; Wallach, E. Diffusion bonds in copper. J. Mater. Sci. 1984, 19, 3140–3148. [Google Scholar] [CrossRef]

- Wu, Y.S.; Li, M.; Lai, T.-Y.; Lu, T.-F.; Wang, Y.H.; Chang, J.-W. Effect of Compressive Stress on Evolution and Healing Kinetics of Artificial Voids in Highly (111)-Oriented Cu-Cu Wafer Bonding at 300 °C. ECS J. Solid State Sci. Technol. 2021, 10, 044004. [Google Scholar] [CrossRef]

- Lu, T.-F.; Lai, T.-Y.; Chu, Y.Y.; Wu, Y.S. Effect of nanotwin boundary on the Cu–Cu bonding. ECS J. Solid State Sci. Technol. 2021, 10, 074001. [Google Scholar] [CrossRef]

- Juang, J.-Y.; Lu, C.-L.; Li, Y.-J.; Hsu, P.-N.; Tsou, N.-T.; Tu, K.-N.; Chen, C. A solid state process to obtain high mechanical strength in Cu-to-Cu joints by surface creep on (111)-oriented nanotwins Cu. J. Mater. Res. Technol. 2021, 14, 719–730. [Google Scholar] [CrossRef]

- Gondcharton, P.; Imbert, B.; Benaissa, L.; Verdier, M. Voiding phenomena in copper-copper bonded structures: Role of creep. ECS J. Solid State Sci. Technol. 2015, 4, P77. [Google Scholar] [CrossRef]

- Tu, K.-N. Electronic Thin-Film Reliability; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

| M3 | M4 | M5 | |

|---|---|---|---|

| 250 °C | 29.17 MPa | 41.77 MPa | 53.64 MPa |

| 300 °C | 35.65 MPa | 51.06 MPa | 65.56 MPa |

| M3B250t0 | M4B250t0 | M5B250t0 | M3B250t1 | M4B250t1 | M5B250t1 | |

|---|---|---|---|---|---|---|

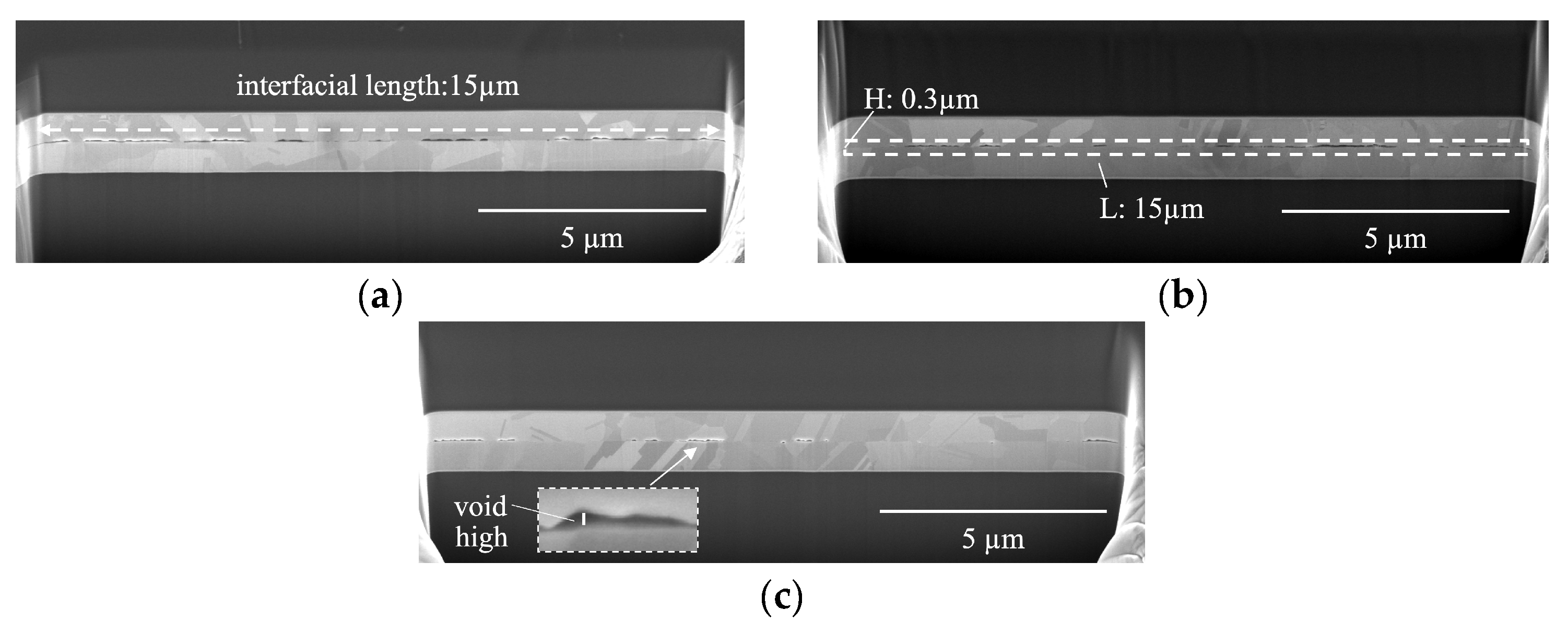

| BF (%) | 25.12 | 43.55 | 66.91 | 50.63 | 63.82 | 87.77 |

| VF (%) | 5.53 | 4.57 | 1.99 | 4.17 | 2.89 | 1.54 |

| VH (nm) | 25.4–95.2 | 22.2–66.6 | 41.2–63.5 | 44.4–88.8 | 24.4–57.5 | 44.4–158.6 |

| M3B300t0 | M4B300t0 | M5B300t0 | M3B300t1 | M4B300t1 | M5B300t1 | |

|---|---|---|---|---|---|---|

| BF (%) | 60.9 | 68.43 | 71.84 | 88.51 | 88.81 | 94.16 |

| VF (%) | 3.16 | 2.97 | 1.61 | 1.85 | 1.84 | 1.09 |

| VH (nm) | 50.8–114.2 | 34.9–60.3 | 28.6–47.6 | 82.5–209.4 | 120.6–222.1 | 63.5–209.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, T.-F.; Lee, P.-Y.; Wu, Y.S. Effect of Compressive Stress on Copper Bonding Quality and Bonding Mechanisms in Advanced Packaging. Materials 2024, 17, 2236. https://doi.org/10.3390/ma17102236

Lu T-F, Lee P-Y, Wu YS. Effect of Compressive Stress on Copper Bonding Quality and Bonding Mechanisms in Advanced Packaging. Materials. 2024; 17(10):2236. https://doi.org/10.3390/ma17102236

Chicago/Turabian StyleLu, Tsan-Feng, Ping-Yang Lee, and YewChung Sermon Wu. 2024. "Effect of Compressive Stress on Copper Bonding Quality and Bonding Mechanisms in Advanced Packaging" Materials 17, no. 10: 2236. https://doi.org/10.3390/ma17102236