The Effect of Curing Conditions on the Service Life of 3D Printed Concrete Formwork

Abstract

:1. Introduction

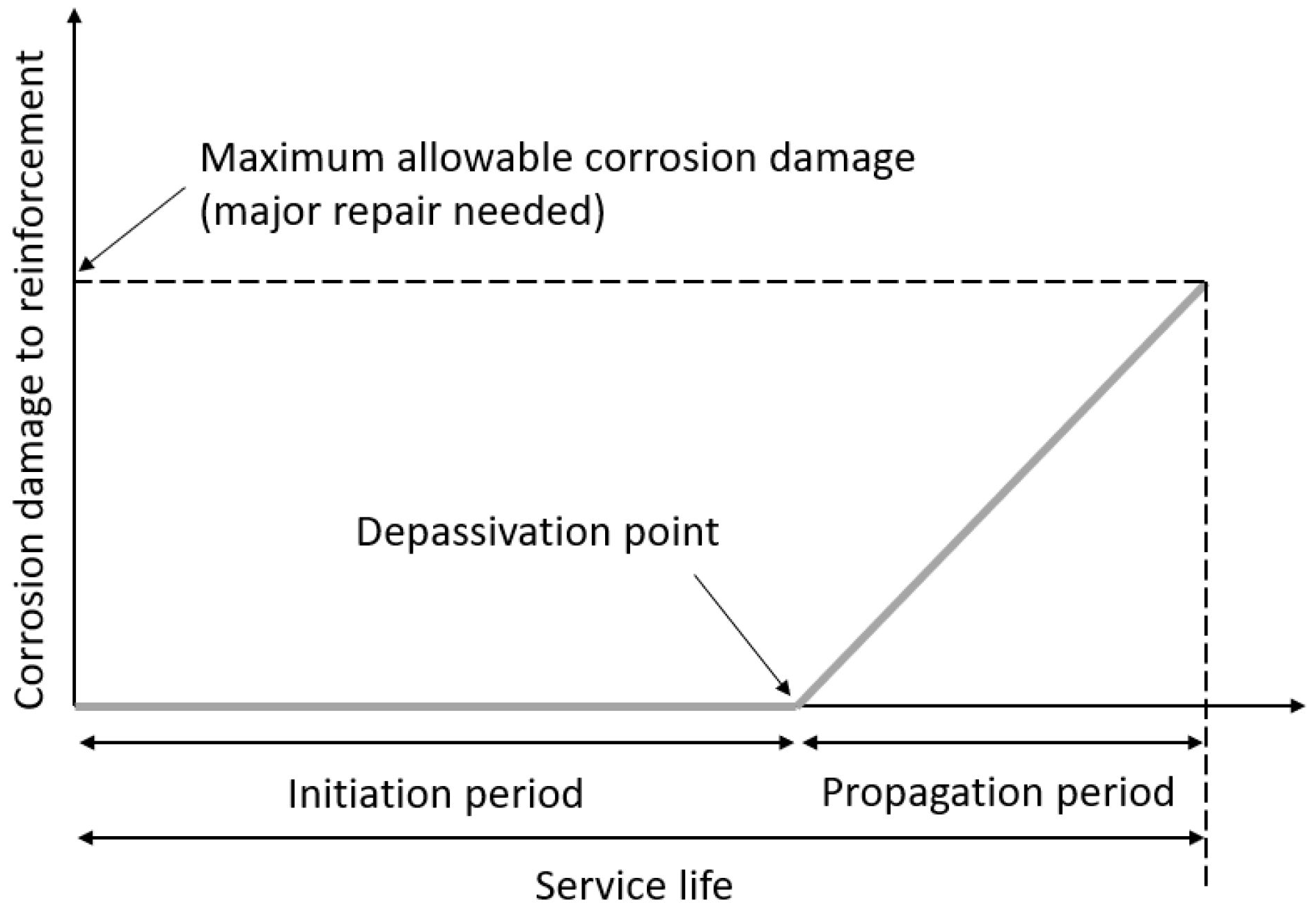

2. Durability

2.1. Design of the Concrete Cover

2.2. Effect of Curing on Durability

2.3. Curing of 3D Printed Concrete

2.4. Effect of Printing on Durability

3. Materials and Methods

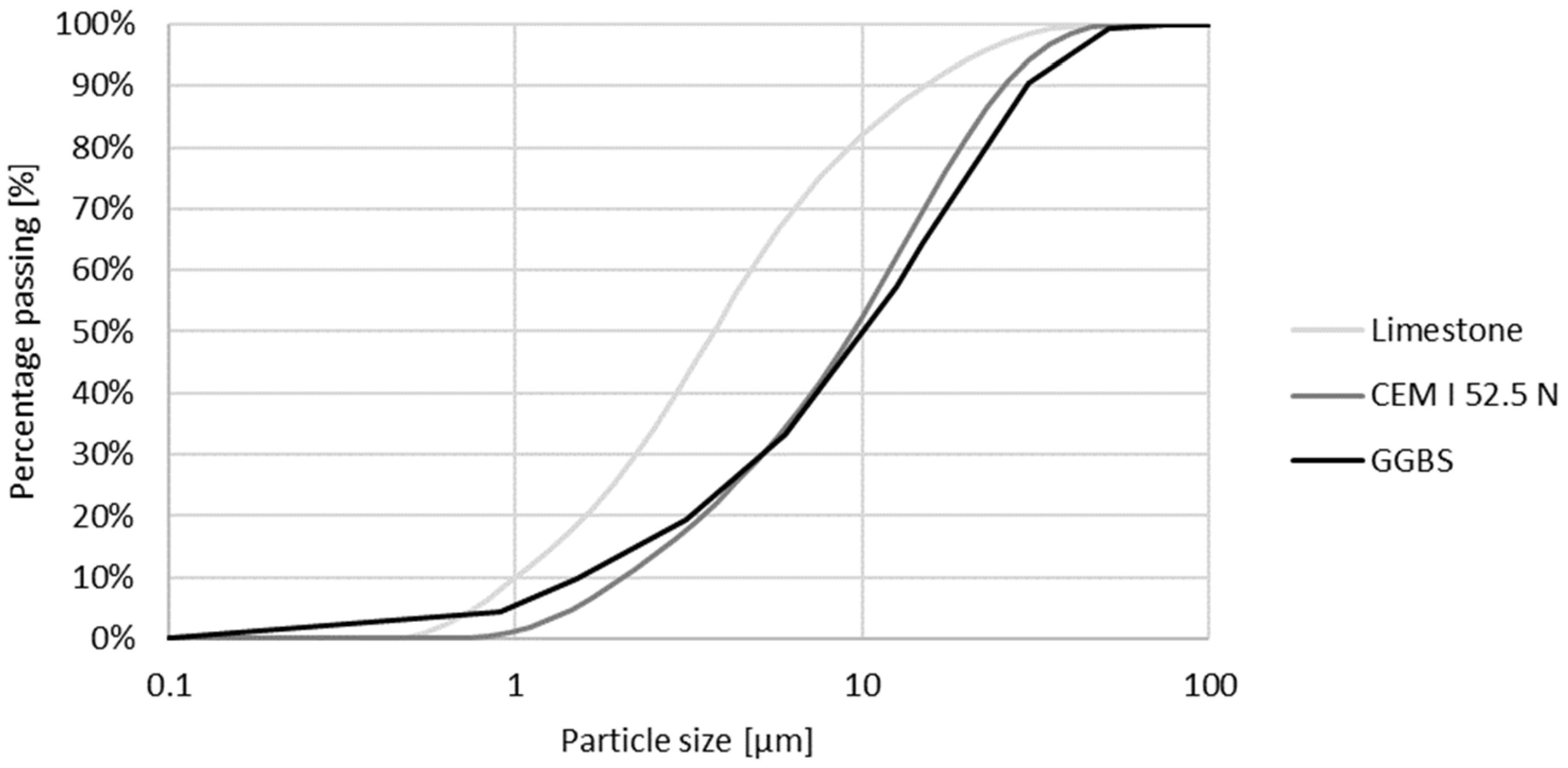

3.1. Materials and Mix Composition

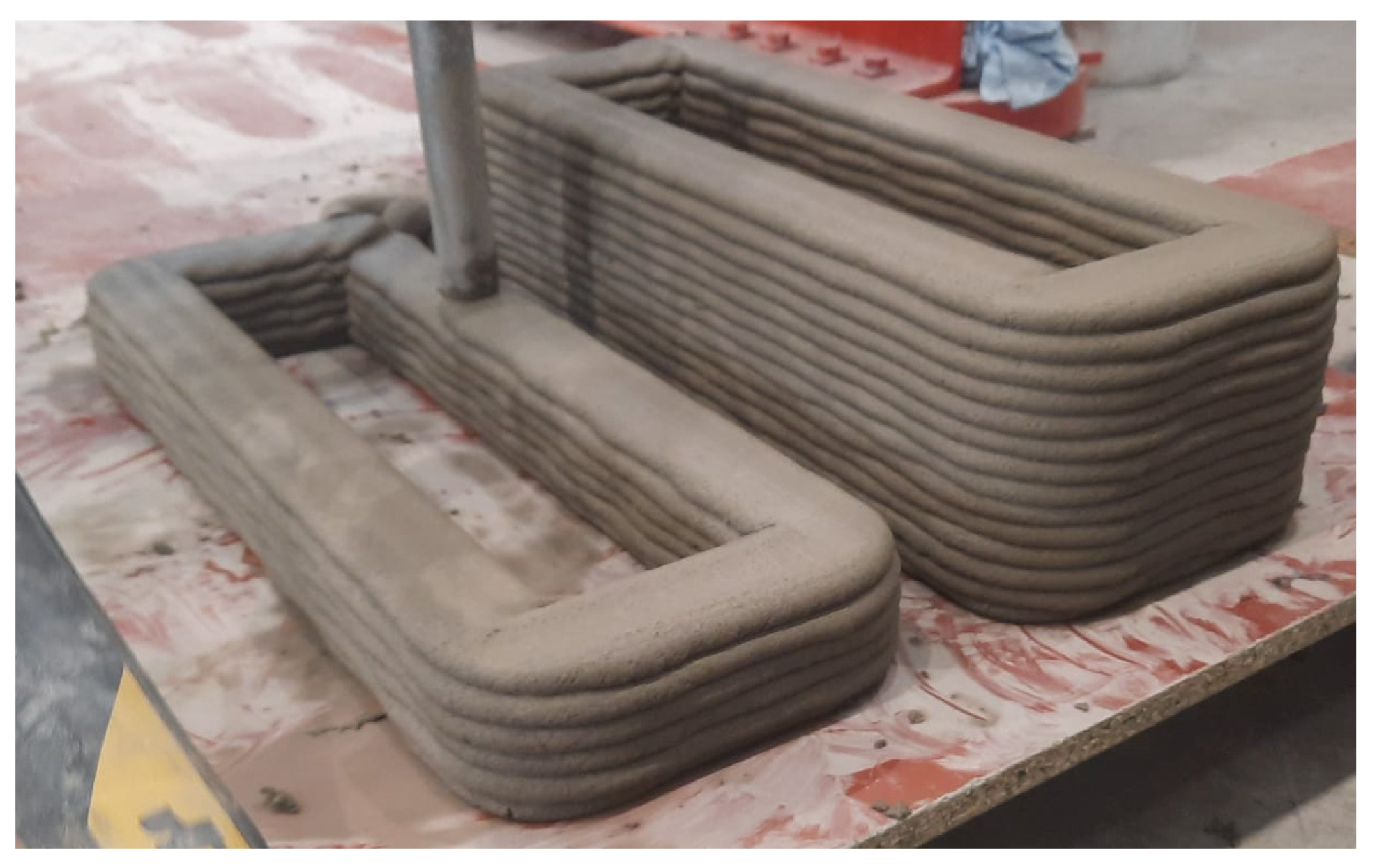

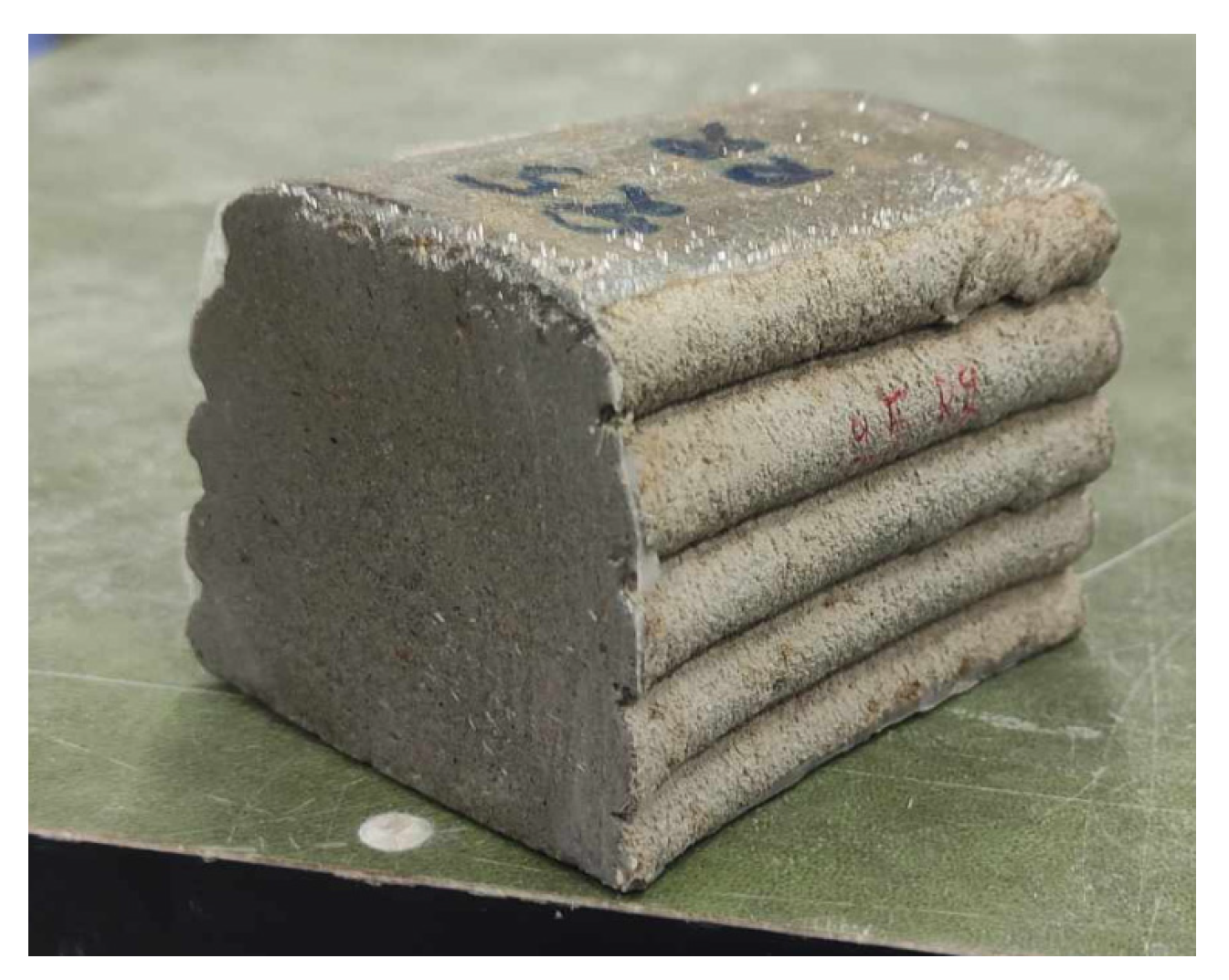

3.2. Printing Procedures

3.2.1. Sequence 1: The Effect of the Formwork Curing Conditions

3.2.2. Sequence 2: The Performance of Properly Cured Elements

3.3. Testing Methods: Effects Based on Experimental Methods

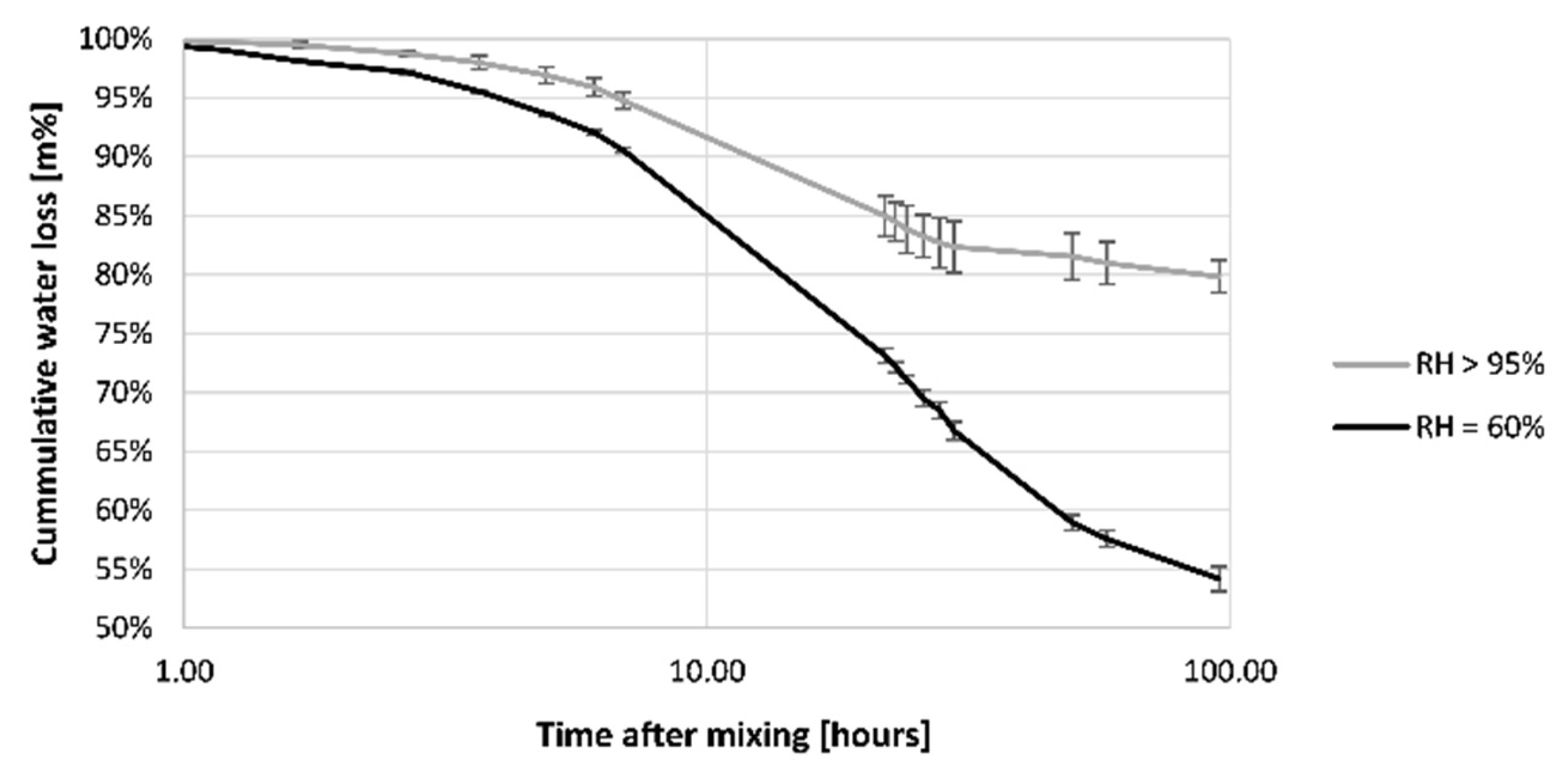

3.3.1. Evaporation of Water

3.3.2. Porosity Based on Vacuum Saturation

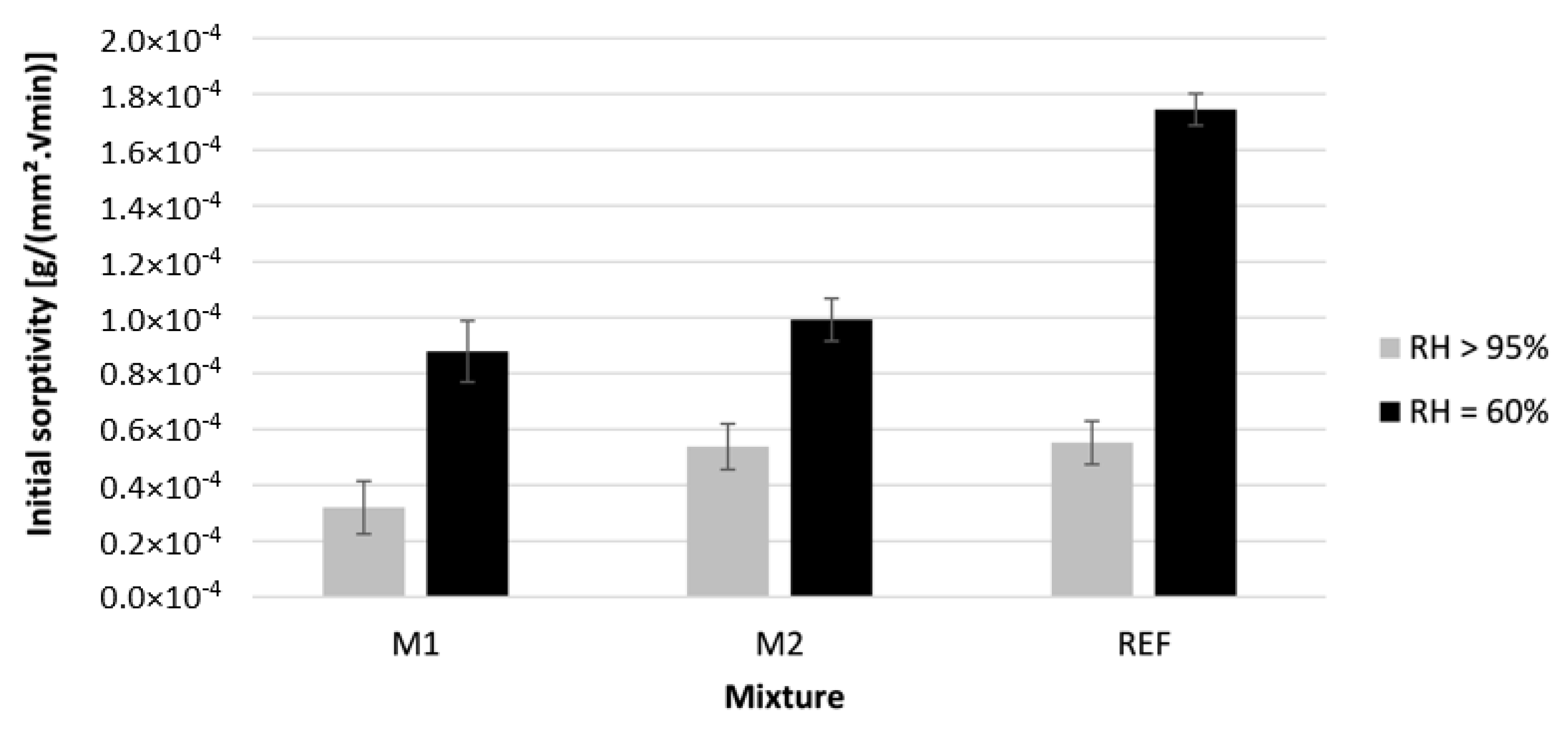

3.3.3. Water Absorption

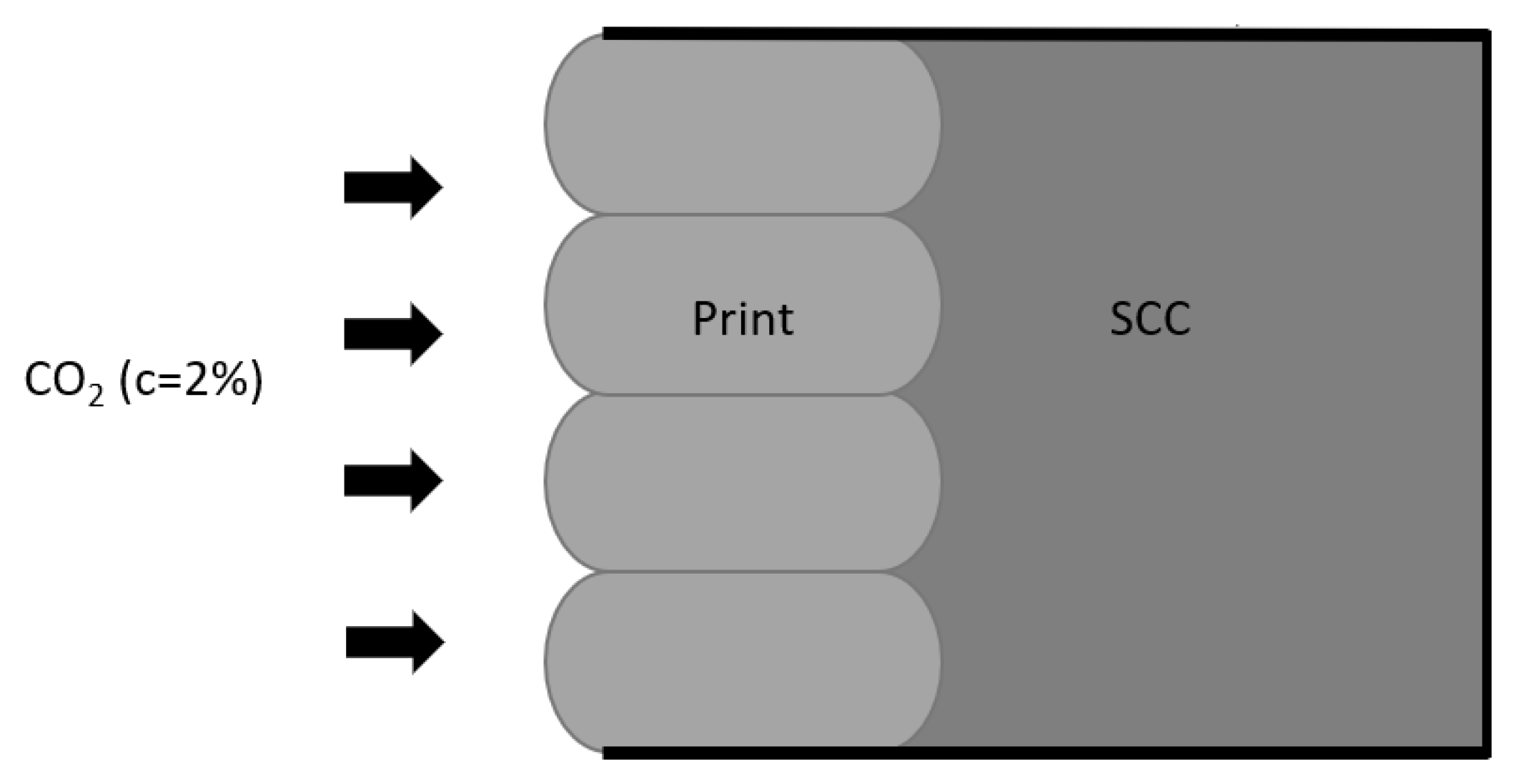

3.3.4. Accelerated Carbonation (AC)

- Sequence 1: The effect of the formwork curing conditions

- Sequence 2: The performance of properly cured elements

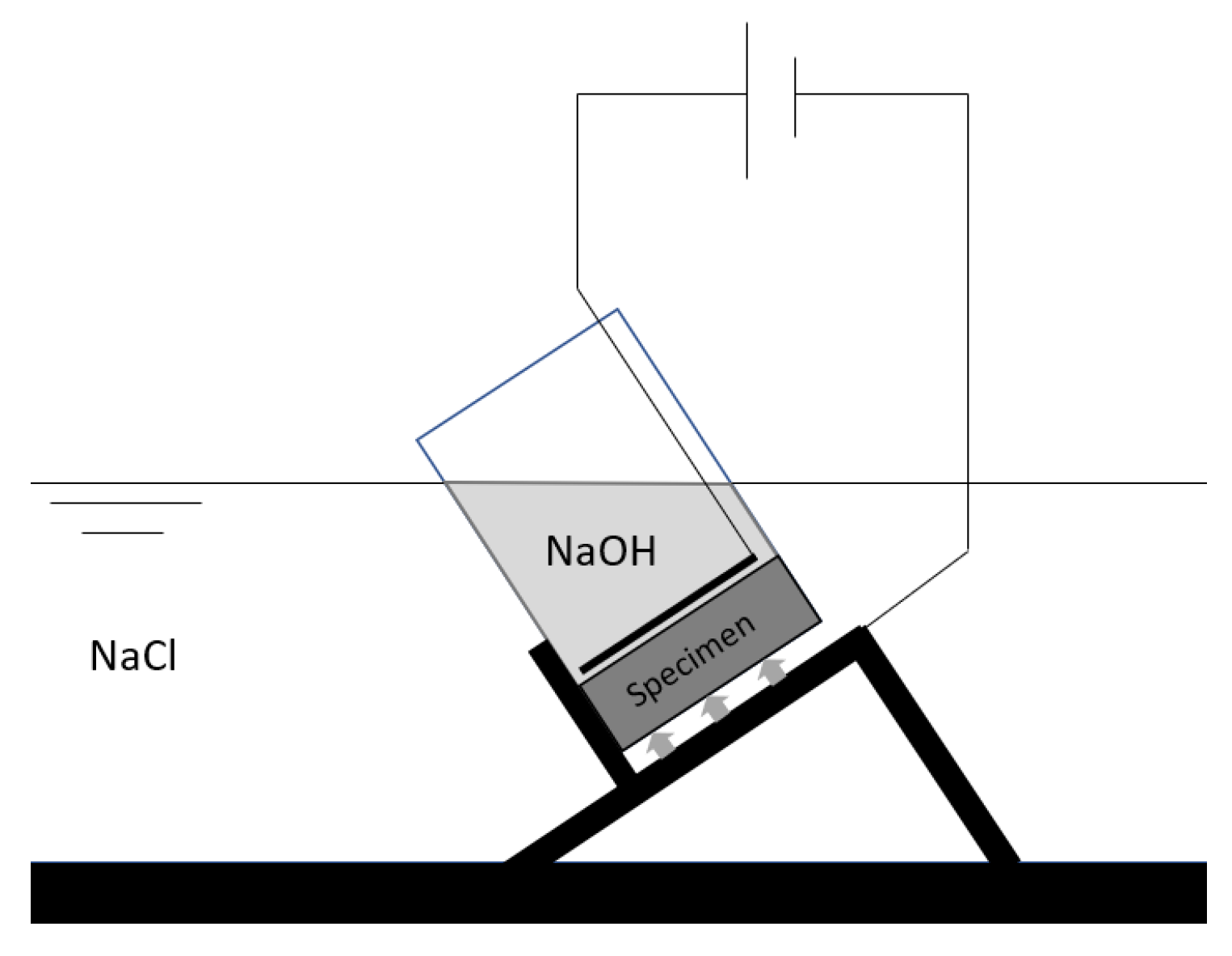

3.3.5. Rapid Chloride Migration (RCM)

- Sequence 1: The effect of the formwork curing conditions

- Sequence 2: The performance of a combined element

- Testing procedure of RCM

3.4. Numerical Method: Effects Based on Service Life Analyses

3.4.1. Specification Regarding the Concrete Cover Design

- The designed structure is located in the exposure class XS1. The metrological data is taken from the Belgian coastal area;

- The structure is designed for a service life of 50 years. This is the default design service life for buildings and common structures;

- The used experimental values are the bulk properties of the printed concrete.

3.4.2. Carbonation-Induced Corrosion

- In the prescribed test method, a carbonation concentration of 2% is requested. However, this concentration created a too-high carbonation rate for sequence 1. Therefore, the concentration was lowered to 1%. According to Audenaert [37], the carbonation coefficients are related to the exposed CO2-concentration, as shown in Equation (12).where and are the carbonation rates under respectively 1% and 2% CO2 concentration and and are the corresponding concentrations of CO2. Similar conversions have been performed by Van den Heede et al. [38] and Sisomphon and Franke [39]. However, they pointed out that such a conversion is allowed with a maximum CO2 concentration of 3% [38];

- The ingress of the carbonation front after 28 days () was calculated based on the obtained carbonation rate after regression instead of the data obtained after 28 days of exposure. It is believed that this would reduce the measurement error. The regression equation was of the form:where t is the exposure time [days], is the carbonation rate, and x is the carbonation ingress.

3.4.3. Chloride-Induced Corrosion

4. Effects Based on the Experimental Results

4.1. Evaporation

4.2. Open Porosity Based on Vacuum Saturation

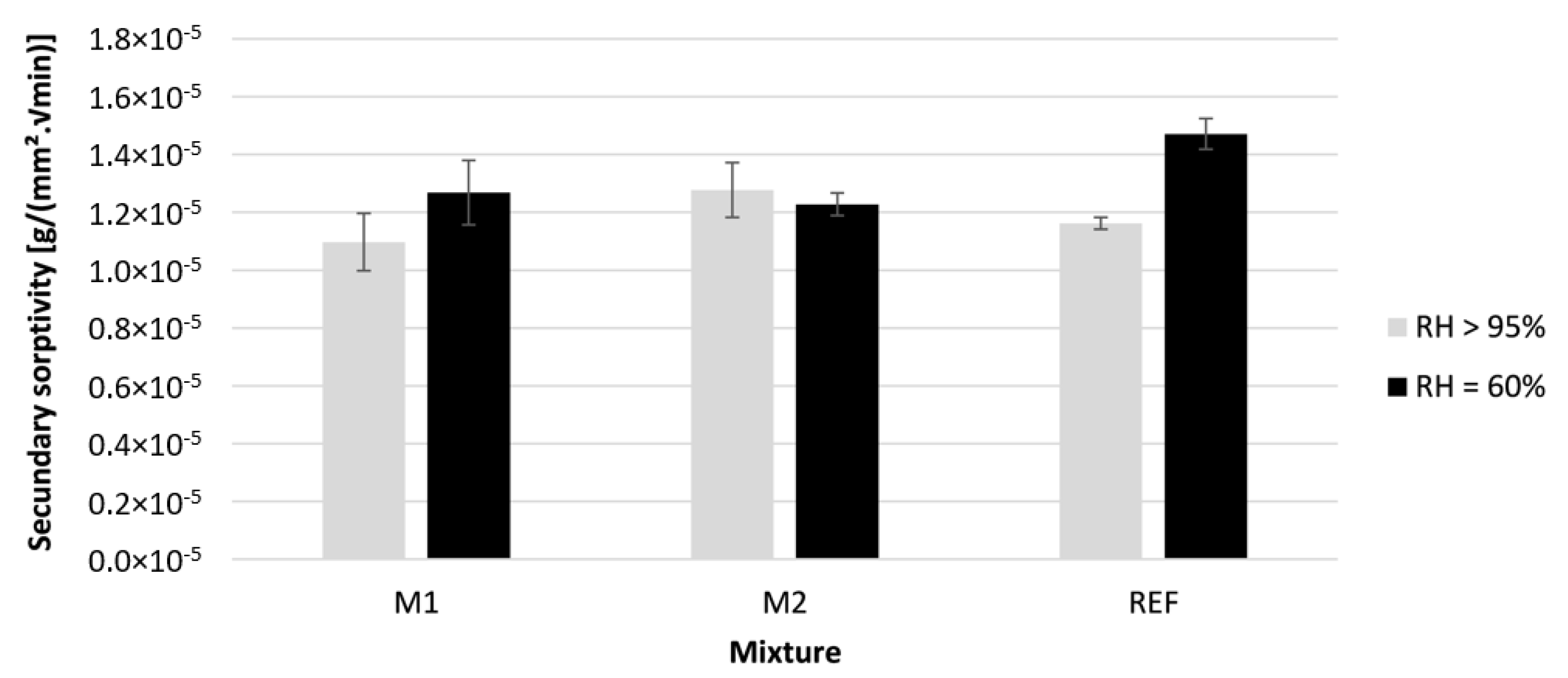

4.3. Water Absorption

4.4. Accelerated Carbonation

4.4.1. Sequence 1: The Effect of the Formwork Curing Conditions

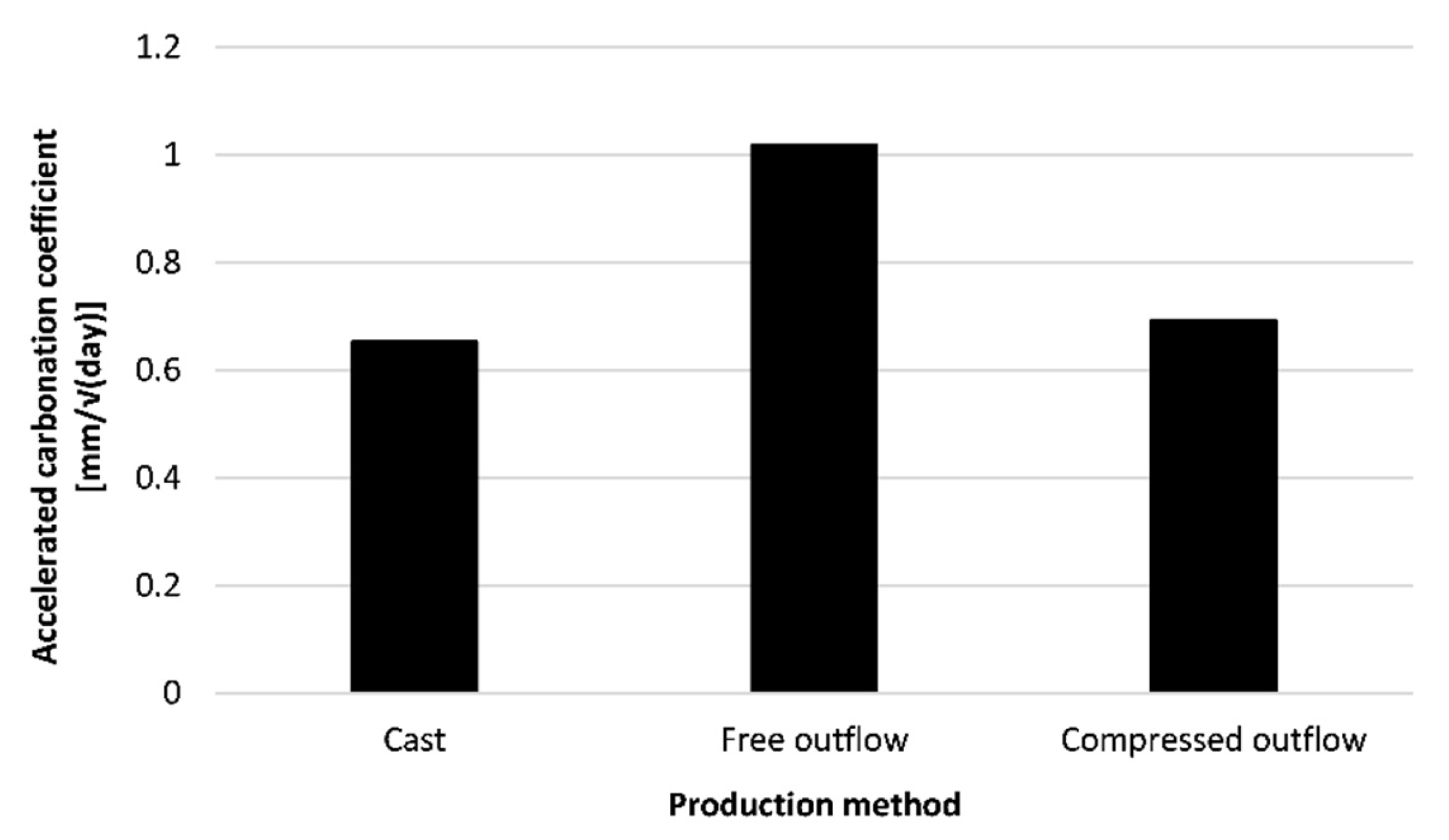

4.4.2. Sequence 2: The Performance of Properly Cured Elements

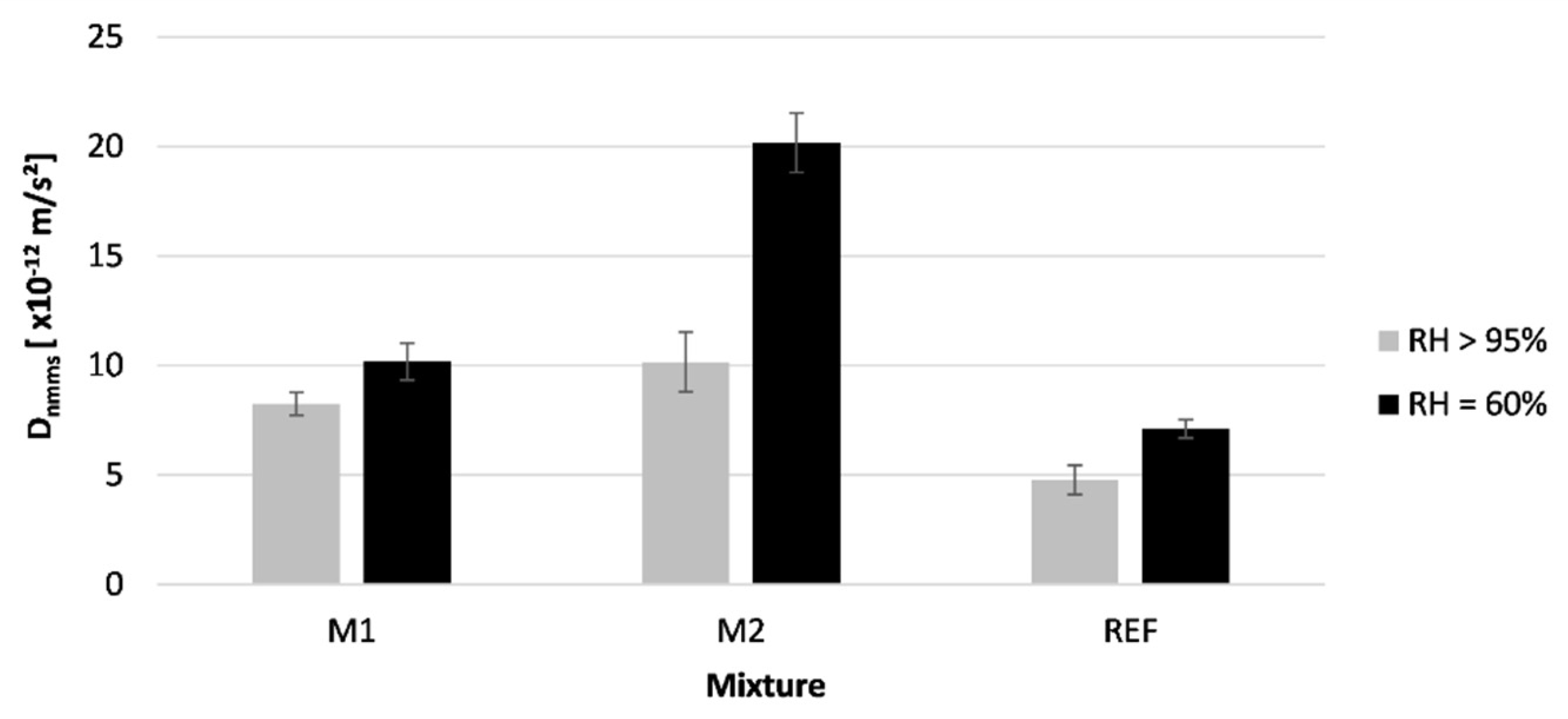

4.5. Rapid Chloride Migration

4.5.1. Sequence 1: The Effect of the Formwork Curing Conditions

4.5.2. Sequence 2: The Performance of Properly Cured Elements

5. Numerical Results: Effects Based on Service Life Analyses

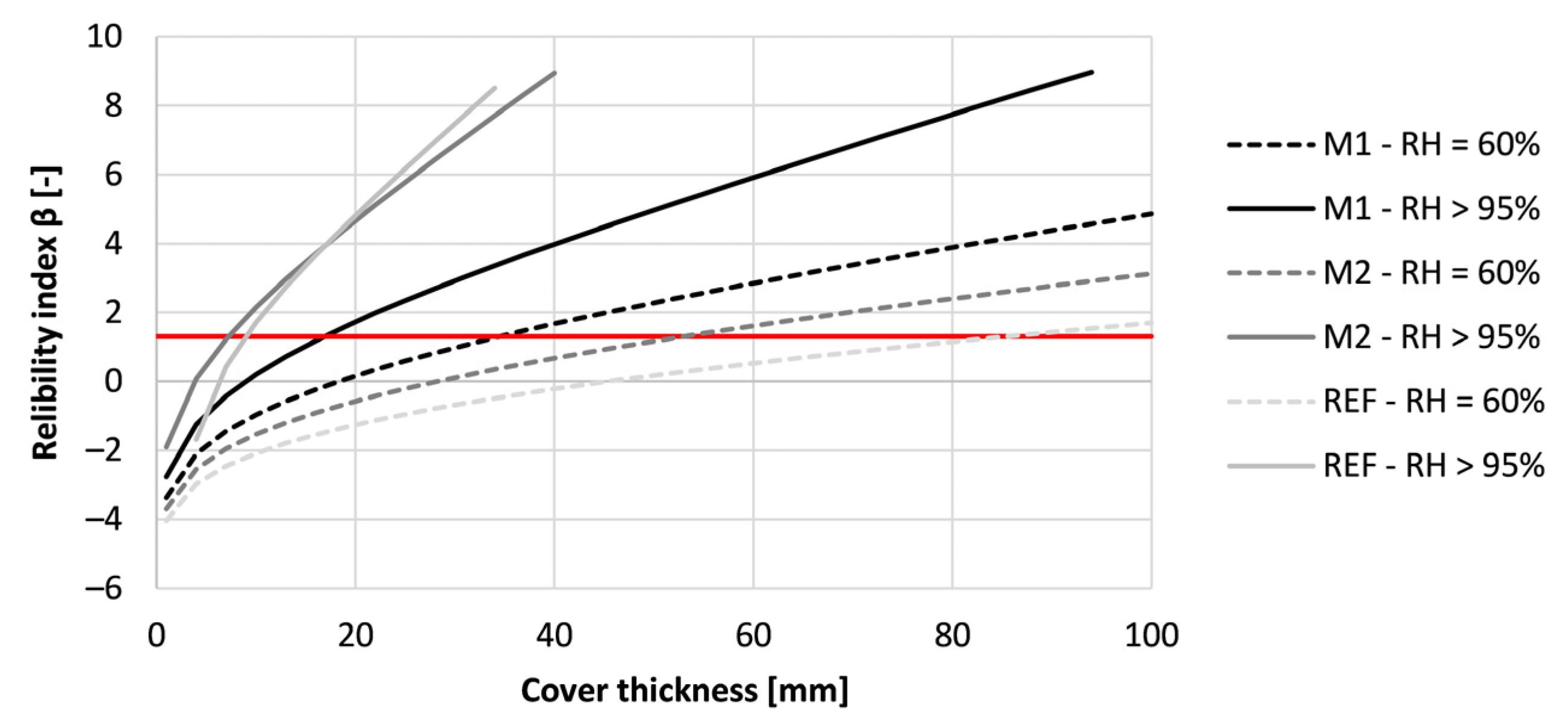

5.1. Carbonation-Induced Corrosion

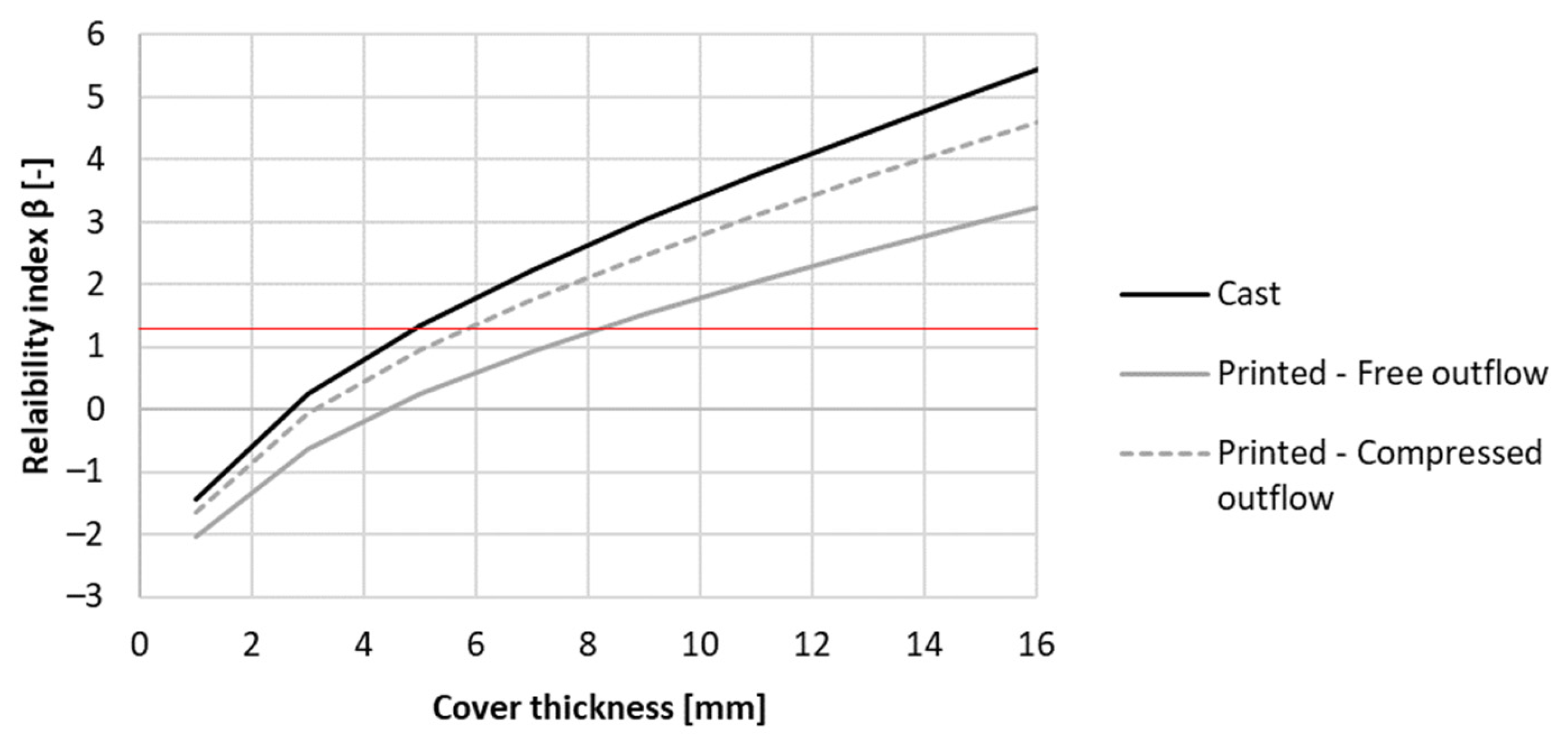

5.1.1. Sequence 1: The Effect of the Formwork Curing Conditions

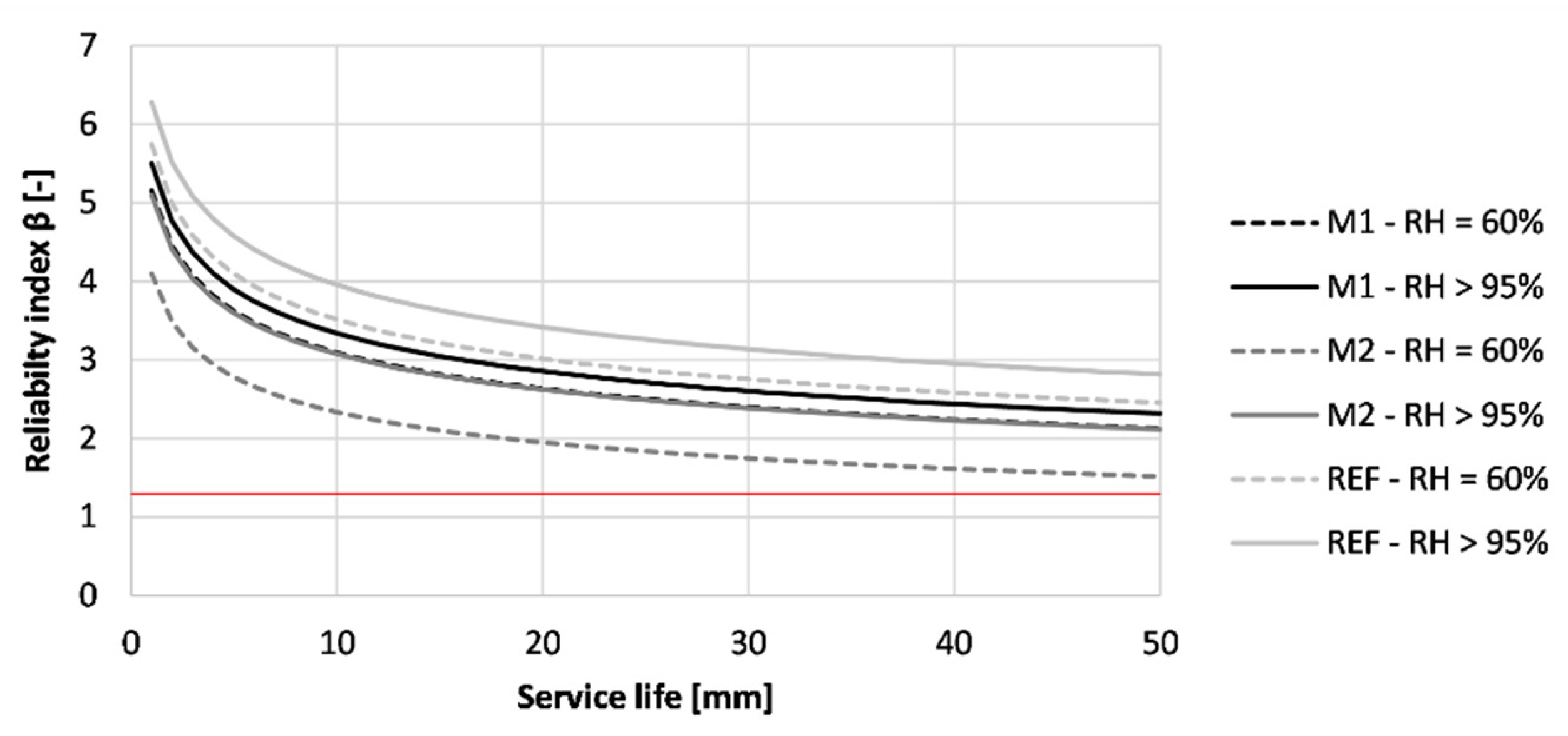

5.1.2. Sequence 2: The Performance of Properly Cured Elements

5.2. Chloride-Induced Corrosion

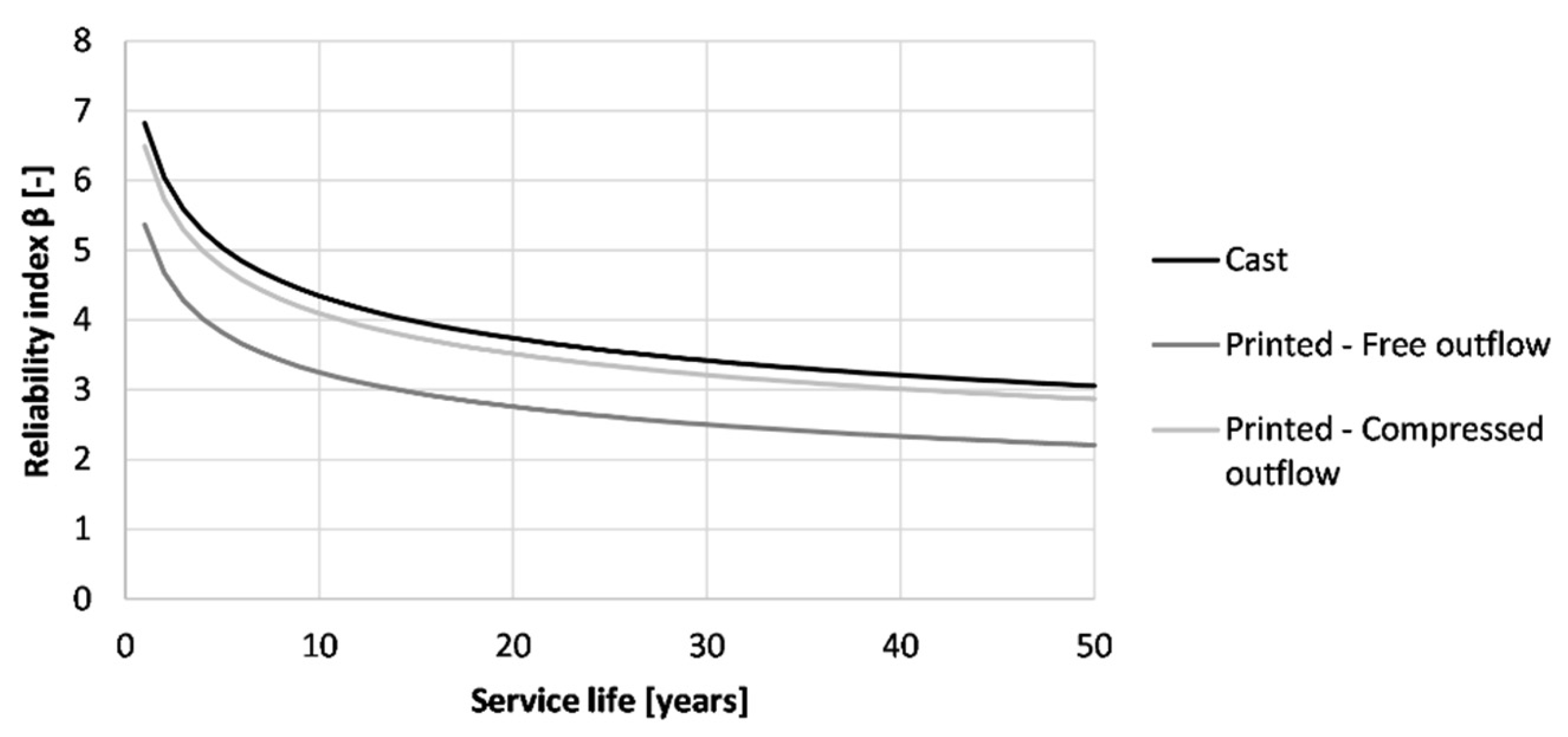

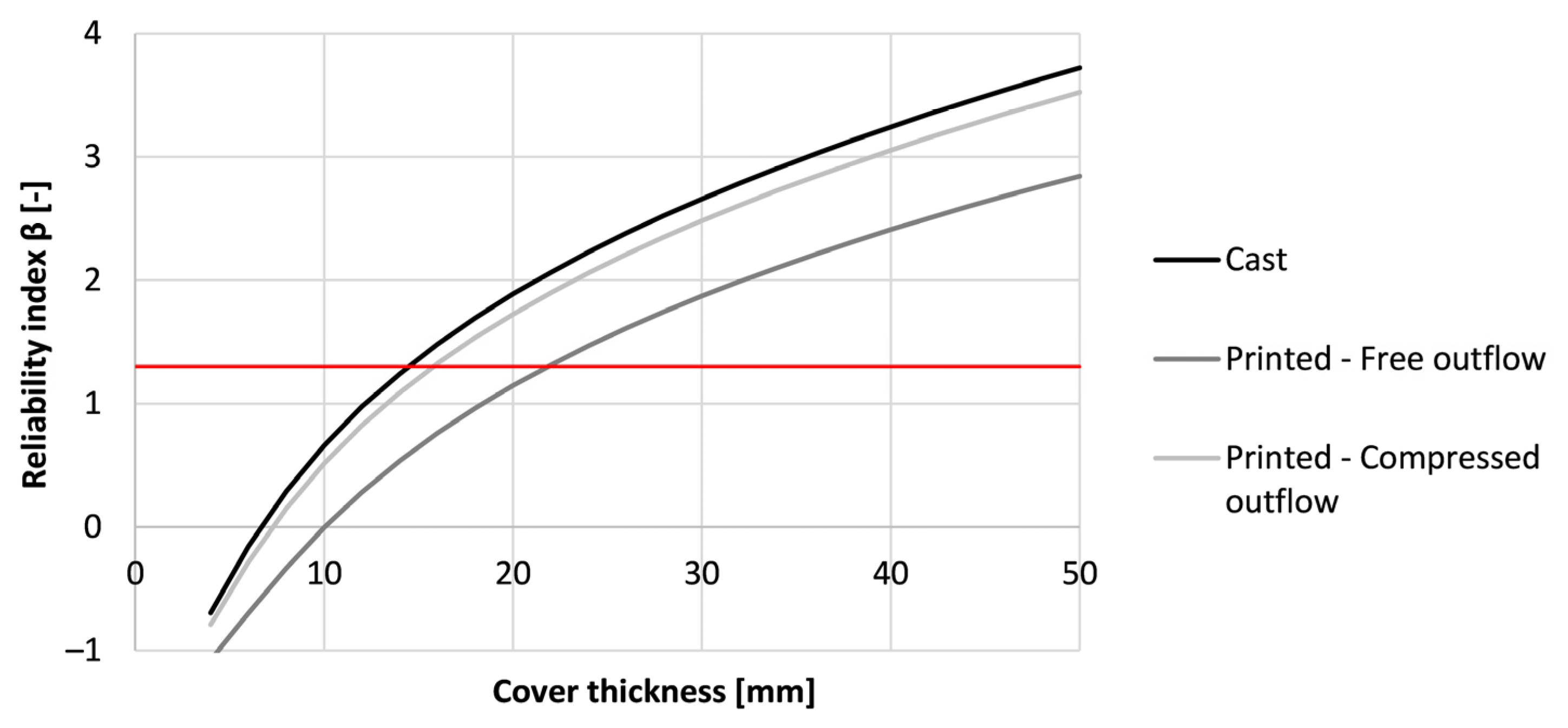

5.2.1. Sequence 1: The Effect of the Formwork Curing Conditions

5.2.2. Sequence 2: The Performance of Properly Cured Elements

5.3. Limitations to the Prediction Method

6. Conclusions

- Evaporation has a significant effect on the durability of the printed concrete. Early-age drying resulted in an increase in porosity, an increase in water absorption, and a decrease in carbonation resistance. Therefore, evaporation of the mixing water should be prevented;

- The incorporation of GGBS in the 3D printed mixture makes the concrete more prone to the effects of evaporation on the durability parameters such as porosity, chloride ingress, and carbonation resistance;

- Nozzle adjustments such as side trowels can improve the durability of printed structures. The carbonation and chloride resistance of the printed concrete compared to a free outflow are increased;

- The 3D printed formwork is suitable as a concrete cover when correctly applied. In the performed analysis, properly cured (RH > 95%) printed formwork was suitable when designed according to Eurocode 2, whereas improperly cured (RH = 60%) printed formwork was rarely applicable. Therefore, special measurements have to be taken during construction to ensure proper curing in a way that the required service life is obtained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Valente, M.; Sibai, A.; Sambucci, M. Extrusion-Based Additive Manufacturing of Concrete Products: Revolutionizing and Remodeling the Construction Industry. J. Compos. Sci. 2019, 3, 88. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-Scale Digital Concrete Construction—CONPrint3D Concept for on-Site, Monolithic 3D-Printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Zhu, B.; Nematollahi, B.; Pan, J.; Zhang, Y.; Zhou, Z.; Zhang, Y. 3D Concrete Printing of Permanent Formwork for Concrete Column Construction. Cem. Concr. Compos. 2021, 121, 104039. [Google Scholar] [CrossRef]

- Zuo, C.; Liu, Y.; Liu, Y. Service Life Prediction of Concrete Structures under Chloride Environment Based on Monte Carlo Method. In Proceedings of the 4th International RILEM Conference on Microstructure Related Durability of Cementitious Composites, Delft, The Netherlands, 29 April 2021; pp. 690–697. [Google Scholar]

- Ranjith, A.; Balaji Rao, K.; Manjunath, K. Evaluating the Effect of Corrosion on Service Life Prediction of RC Structures—A Parametric Study. Int. J. Sustain. Built Environ. 2016, 5, 587–603. [Google Scholar] [CrossRef]

- Tuutti, K. Corrosion of Steel in Concrete, 4th ed.; Swedish Cement and Concrete Research Institute: Stockholm, Sweden, 1982; Volume 4. [Google Scholar]

- Schiessl, P.; Helland, S.; Gehlen, C.; Nilsson, L.O.; Rostam, S. Model Code for Service Life Design; FIB: Lausanne, Switzerland, 2006; Volume 1, ISBN 9872166013. [Google Scholar]

- Polder, R.B.; Boutz, M.; Ottelé, M. Procedure for Determining the Remaining Time to Initiation of Chloride Induced Reinforcement Corrosion for Existing Concrete Structures. MATEC Web. Conf. 2022, 361, 00001. [Google Scholar] [CrossRef]

- Féderation International du Béton (fib) Fib Bulletin 76—Benchmarking of Deemed to Satisfy Provisions in Standards; FIB: Lausanne, Switzerland, 2015; ISBN 9788578110796. [CrossRef]

- Moelich, G.M.; Kruger, J.; Combrinck, R. Plastic Shrinkage Cracking in 3D Printed Concrete. Compos. B Eng. 2020, 200, 108313. [Google Scholar] [CrossRef]

- Flatt, R.J.; Scherer, G.W.; Bullard, J.W. Why Alite Stops Hydrating below 80% Relative Humidity. Cem. Concr. Res. 2011, 41, 987–992. [Google Scholar] [CrossRef]

- Jensen, O.M. Thermodynamic Limitation of Self-Desiccation. Cem. Concr. Res. 1995, 25, 157–164. [Google Scholar] [CrossRef]

- Jankovic, K.; Nikolic, D.; Bojovic, D.; Loncar, L.; Romakov, Z. The Estimation of Compressive Strength of Normal and Recycled Aggregate Concrete. Facta Univ.-Ser. Archit. Civ. Eng. 2011, 9, 419–431. [Google Scholar] [CrossRef]

- Younsi, A.; Cherif, R.; Trabelsi, A.; Hamami, A.E.A.; Belarbi, R.; Aït-Mokhtar, A. Hydration-Drying Interactions in a High-Volume Ground Granulated Blast-Furnace Slag Mortar. Constr. Build. Mater. 2021, 279, 122427. [Google Scholar] [CrossRef]

- Gruyaert, E. Effect of Blast-Furnace Slag as Cement Replacement on Hydration, Microstructure, Strength and Durability of Concrete. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2010. [Google Scholar]

- Jozić, D.; Ljubičić, B.; Petrović, A.; Čović, A.; Juradin, S. The Influence of GGBFS as an Additive Replacement on the Kinetics of Cement Hydration and the Mechanical Properties of Cement Mortars. Buildings 2023, 13, 1960. [Google Scholar] [CrossRef]

- Darquennes, A.; Espion, B.; Staquet, S. How to Assess the Hydration of Slag Cement Concretes? Constr. Build. Mater. 2013, 40, 1012–1020. [Google Scholar] [CrossRef]

- Younsi, A.; Turcry, P.; Aït-Mokhtar, A.; Staquet, S. Accelerated Carbonation of Concrete with High Content of Mineral Additions: Effect of Interactions between Hydration and Drying. Cem. Concr. Res. 2013, 43, 25–33. [Google Scholar] [CrossRef]

- Gruyaert, E.; Van Den Heede, P.; De Belie, N. Carbonation of Slag Concrete: Effect of the Cement Replacement Level and Curing on the Carbonation Coefficient—Effect of Carbonation on the Pore Structure. Cem. Concr. Compos. 2013, 35, 39–48. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Reviewing the Carbonation Resistance of Concrete. J. Mater. Eng. Struct. 2016, 3, 35–57. [Google Scholar]

- Ma, L.; Zhang, Q.; Jia, Z.; Liu, C.; Deng, Z.; Zhang, Y. Effect of Drying Environment on Mechanical Properties, Internal RH and Pore Structure of 3D Printed Concrete. Constr. Build. Mater. 2022, 315, 125731. [Google Scholar] [CrossRef]

- Federowicz, K.; Kaszyńska, M.; Zieliński, A.; Hoffmann, M. Effect of Curing Methods on Shrinkage Development in 3D-Printed Concrete. Materials 2020, 13, 2590. [Google Scholar] [CrossRef]

- Van Der Putten, J. Mechanical Properties and Durability of 3D Printed Cementitious Materials. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2021. [Google Scholar]

- Moelich, G.M.; Kruger, P.J.; Combrinck, R. Mitigating Early Age Cracking in 3D Printed Concrete Using Fibres, Superabsorbent Polymers, Shrinkage Reducing Admixtures, B-CSA Cement and Curing Measures. Cem. Concr. Res. 2022, 159, 106862. [Google Scholar] [CrossRef]

- Moelich, G.M.; Kruger, P.J.; Combrinck, R. The Effect of Restrained Early Age Shrinkage on the Interlayer Bond and Durability of 3D Printed Concrete. J. Build. Eng. 2021, 43, 102857. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Lee, K.M.; Bang, J.W.; Kwon, S.J. Effect of W/C Ratio on Durability and Porosity in Cement Mortar with Constant Cement Amount. Adv. Mater. Sci. Eng. 2014, 2014, 273460. [Google Scholar] [CrossRef]

- Aïssoun, B.M.; Gallias, J.L.; Khayat, K.H. Influence of Formwork Material on Transport Properties of Self-Consolidating Concrete near Formed Surfaces. Constr. Build. Mater. 2017, 146, 329–337. [Google Scholar] [CrossRef]

- Kruger, J.; du Plessis, A.; van Zijl, G. An Investigation into the Porosity of Extrusion-Based 3D Printed Concrete. Addit. Manuf. 2021, 37, 101740. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. Mechanical Characterization of 3D Printable Concrete. Constr. Build. Mater. 2019, 227, 116710. [Google Scholar] [CrossRef]

- Van Der Putten, J.; Snoeck, D.; De Coensel, R.; De Schutter, G.; Van Tittelboom, K. Early Age Shrinkage Phenomena of 3D Printed Cementitious Materials with Superabsorbent Polymers. J. Build. Eng. 2021, 35, 102059. [Google Scholar] [CrossRef]

- Sanchez, A.M.A.; Wangler, T.; Stefanoni, M.; Angst, U. Microstructural Examination of Carbonated 3D-Printed Concrete. J. Microsc. 2022, 286, 141–147. [Google Scholar] [CrossRef] [PubMed]

- Wangler, T.; Aguilar Sanchez, A.M.; Anton, A.; Dillenburger, B.; Flatt, R.J. Two Year Exposure of 3D Printed Cementitious Columns in a High Alpine Environment. In RILEM Bookseries; Springer Science and Business Media B.V.: Berlin/Heidelberg, Germany, 2022; Volume 37, pp. 182–187. [Google Scholar]

- Mohan, M.K.; Rahul, A.V.; Van Tittelboom, K.; De Schutter, G. Rheological and Pumping Behaviour of 3D Printable Cementitious Materials with Varying Aggregate Content. Cem. Concr. Res. 2021, 139, 106258. [Google Scholar] [CrossRef]

- Desnerck, P.; De Schutter, G.; Taerwe, L. Stress-Strain Behaviour of Self-Compacting Concretes Containing Limestone Fillers. Struct. Concr. 2012, 13, 95–101. [Google Scholar] [CrossRef]

- NBN EN 1936:2007; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. Bureau de Normalisation Belge: Grimbergen, Belgium, 2007.

- NT Build 492; Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments. Nordtest: Espoo, Finland, 1999.

- Audenaert, K. Transportmechanismen in Zelfverdichtend Beton in Relatie Met Carbonatatie en Chloridepenetratie, Structural Engineering and Building Materials. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2006. [Google Scholar]

- Van Den Heede, P.; De Belie, N. A Service Life Based Global Warming Potential for High-Volume Fly Ash Concrete Exposed to Carbonation. Constr. Build. Mater. 2014, 55, 183–193. [Google Scholar] [CrossRef]

- Sisomphon, K.; Franke, L. Carbonation Rates of Concretes Containing High Volume of Pozzolanic Materials. Cem. Concr. Res. 2007, 37, 1647–1653. [Google Scholar] [CrossRef]

- RMI Klimatologische Overzichten Van. 2021. Available online: www.meteo.be (accessed on 15 August 2023).

- Debrie, E. Een Grondige Statistische Studie van Het Belgische Kustklimaat. Master Thesis, Ghent University, Ghent, Belgium, 2017. [Google Scholar]

- ACI Commitee 305. 305R-10 Guide to Hot Weather Concreting; American Concrete Institute: Farmington Hills, MI, USA, 2010; Volume 28, p. 6. [Google Scholar]

- Bakhshi, M.; Mobasher, B.; Soranakom, C. Moisture Loss Characteristics of Cement-Based Materials under Early-Age Drying and Shrinkage Conditions. Constr. Build. Mater. 2012, 30, 413–425. [Google Scholar] [CrossRef]

- Arnold, J.R.; Garrabrants, A.C.; Samson, E.; Flach, G.P.; Langton, C.A. Moisture Transport Review; International Atomic Energy Agency: Vienna, Austria, 2009. [Google Scholar]

- Ortega, J.M.; Ferrandiz, V.; Antón, C.; Climent, M.A.; Sánchez, I. Influence of Curing Conditions on the Mechanical Properties and Durability of Cement Mortars. WIT Trans. Eng. Sci. 2009, 64, 381–391. [Google Scholar] [CrossRef]

- Zhuang, S.; Wang, Q.; Zhang, M. Water Absorption Behaviour of Concrete: Novel Experimental Findings and Model Characterization. J. Build. Eng. 2022, 53, 104602. [Google Scholar] [CrossRef]

- ASTM C1585-20; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2020.

- Mikhailenko, P.; Cassagnabère, F.; Emam, A.; Lachemi, M. Influence of Physico-Chemical Characteristics on the Carbonation of Cement Paste at High Replacement Rates of Metakaolin. Constr. Build. Mater. 2018, 158, 164–172. [Google Scholar] [CrossRef]

- Hall, C.; Hamilton, A. Beyond the Sorptivity: Definition, Measurement, and Properties of the Secondary Sorptivity. J. Mater. Civ. Eng. 2018, 30, 04018049. [Google Scholar] [CrossRef]

- Ting, M.Z.Y.; Wong, K.S.; Rahman, M.E.; Selowara Joo, M. Mechanical and Durability Performance of Marine Sand and Seawater Concrete Incorporating Silicomanganese Slag as Coarse Aggregate. Constr. Build. Mater. 2020, 254, 119195. [Google Scholar] [CrossRef]

- Thunuguntla, C.S.; Gunneswara Rao, T.D. Effect of Mix Design Parameters on Mechanical and Durability Properties of Alkali Activated Slag Concrete. Constr. Build. Mater. 2018, 193, 173–188. [Google Scholar] [CrossRef]

- Girish, S.; Ajay, N.; Soumya, T. Sorptivity as a Durability Index for Service Life Prediction of Self-Compacting Concrete. In Trends in Civil Engineering and Challenges for Sustainability; Narasimhan, M.C., George, V., Udayakumar, G., Kumar, A., Eds.; Springer: Singapore, 2021; pp. 295–309. [Google Scholar]

- Al-Ameeri, A.; Rafiq, M.I.; Tsioulou, O. Influence of Cracks on the Carbonation Resistance of Concrete Structures. In Proceedings of the 6th International Conference on Durability of Concrete Structures, ICDCS 2018, Leeds, UK, 18–20 July 2018; pp. 358–366. [Google Scholar]

| Unit | REF | M1 | M2 | |

|---|---|---|---|---|

| Sea sand (0/1) | Kg/m3 | 943 | 1222 | 1222 |

| CEM I 52.5 N (MF) | Kg/m3 | 472 | 815 | 611 |

| GGBS | Kg/m3 | 472 | 0 | 204 |

| Water | Kg/m3 | 330 | 285 | 285 |

| Superplasticizer | Kg/m3 | 2.1 | 4.2 | 3.2 |

| VMA | Kg/m3 | 0.9 | 0.8 | 0.8 |

| Density | Kg/m3 | 2220 | 2327 | 2326 |

| Water-to-binder ratio | - | 0.35 | 0.35 | 0.35 |

| Sand-to-binder ratio | - | 1 | 1.5 | 1.5 |

| Unit | SCC | |

|---|---|---|

| Rhine sand (0/4) | Kg/m3 | 853 |

| Rhine gravel (2/8) | Kg/m3 | 263 |

| Rhine gravel (8/16) | Kg/m3 | 434 |

| Limestone | Kg/m3 | 240 |

| CEM I 52.5 N (MF) | Kg/m3 | 360 |

| Water | Kg/m3 | 165 |

| Superplasticizer | Kg/m3 | 3.2 |

| Density | Kg/m3 | 2318 |

| Water-to-binder ratio | - | 0.46 |

| Test | Curing Condition | Mixtures | Testing Dates | Samples/Testing Date |

|---|---|---|---|---|

| Evaporation of water | RH = 60, RH > 95 | REF | 0, 1, 2, 4 days after mixing | 3 |

| Porosity based on vacuum saturation | RH = 60, RH > 95 | REF, M1, M2 | 28 days after printing | 3 |

| Water absorption | RH = 60, RH > 95 | REF, M1, M2 | 28 days after printing | 3 |

| Accelerated carbonation | RH = 60, RH > 95 | REF, M1, M2 | 0, 1,7, 14, 28 after printing | 3 |

| Rapid chloride migration test | RH = 60, RH > 95 | REF, M1, M2 | 28 days after printing | 3 |

| Test | Production Method | Testing Dates | Samples/Testing Date |

|---|---|---|---|

| Accelerated carbonation | Printed with free outlet, printed without free outlet, cast | 64, 71, 78, 92, 120 days after printing | 1 |

| Rapid chloride migration test | Printed with free outlet, printed without free outlet, cast | 64 days after printing | 3 |

| Parameter | Distribution | Values | |

|---|---|---|---|

| Relative humidity real life | Beta | BetaD (75/9/40/100) | |

| Relative humidity reference | Constant | 65 | |

| Exponent | Constant | 5.0 | |

| Exponent | Constant | 2.5 | |

| Period of curing | Constant | Sequence-dependent | |

| Exponent of regression | Normal | ND (−0.567/0.024) | |

| Natural CO2 concentration | Normal | ND (0.00082/0.0001) | |

| Time reference | Constant | 0.153 | |

| Carbonation ingress after 28 days of exposure | Normal | Test data | |

| Time constant | Constant | 420 | |

| Regression parameter | Normal | ND (1.25/0.35) | |

| Error term | Normal | ND (315.5/48) | |

| Probability of driving rain | Constant | 0.5 | |

| Exponent of regression | Normal | ND (0.446/0.163) | |

| Time of wetness | Constant | ND (0.33/0.05) | |

| Concrete cover | d | Lognormal | LOGND (45/6) |

| Parameter | Distribution | Values | |

|---|---|---|---|

| Chloride migration coefficient | DRCM (t0) | Normal | Based on results |

| Aging coefficient | Beta | BetaD (0.65/0.12/0/1.0) | |

| Testing date RCM | t0 | Constant | 0.175 |

| Temperature coefficient | Normal | ND (4800/700) | |

| Ambient air temperature | Normal | ND (283/6.2) | |

| Reference temperature | Constant | 293 | |

| Chloride content at a certain time at depth d | Lognormal | LND (1.5/1.45) | |

| Initial chloride content | Constant | 0 | |

| Critical chloride content | Beta | BetaD (0.60/0.15/0.2/2) | |

| Convection zone | Constant | 0 | |

| Concrete cover | d | Normal | ND (45/6) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bekaert, M.; Van Tittelboom, K.; De Schutter, G. The Effect of Curing Conditions on the Service Life of 3D Printed Concrete Formwork. Materials 2023, 16, 6972. https://doi.org/10.3390/ma16216972

Bekaert M, Van Tittelboom K, De Schutter G. The Effect of Curing Conditions on the Service Life of 3D Printed Concrete Formwork. Materials. 2023; 16(21):6972. https://doi.org/10.3390/ma16216972

Chicago/Turabian StyleBekaert, Michiel, Kim Van Tittelboom, and Geert De Schutter. 2023. "The Effect of Curing Conditions on the Service Life of 3D Printed Concrete Formwork" Materials 16, no. 21: 6972. https://doi.org/10.3390/ma16216972