Study on the Performance and Mechanisms of High-Performance Foamed Concrete

Abstract

:1. Introduction

2. Experimental Section

2.1. The Raw Materials

2.2. Preparation Method

- (1)

- (2)

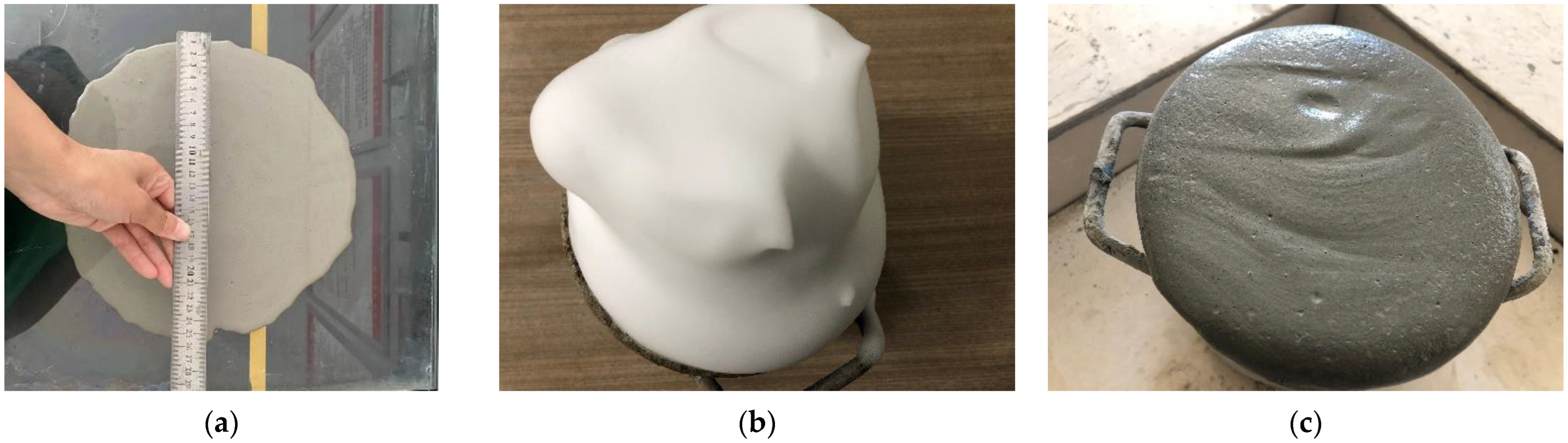

- The foaming agent was prepared in advance and the foaming mechanism was used to prepare the foam (Figure 3b). The foam was added to the slurry and stirred for 3 min to form the foamed concrete slurry (Figure 3c), which was then poured into the mold. After curing for 24 h, the mold was removed and test blocks were placed in the standard curing box.

- (3)

- It should be noted that, unless otherwise specified, the percentage sign of the mixing amount in this chapter represents the mass fraction of the cementitious material.

2.3. Test Methods

2.3.1. Physical Performance Test

2.3.2. SEM Analysis

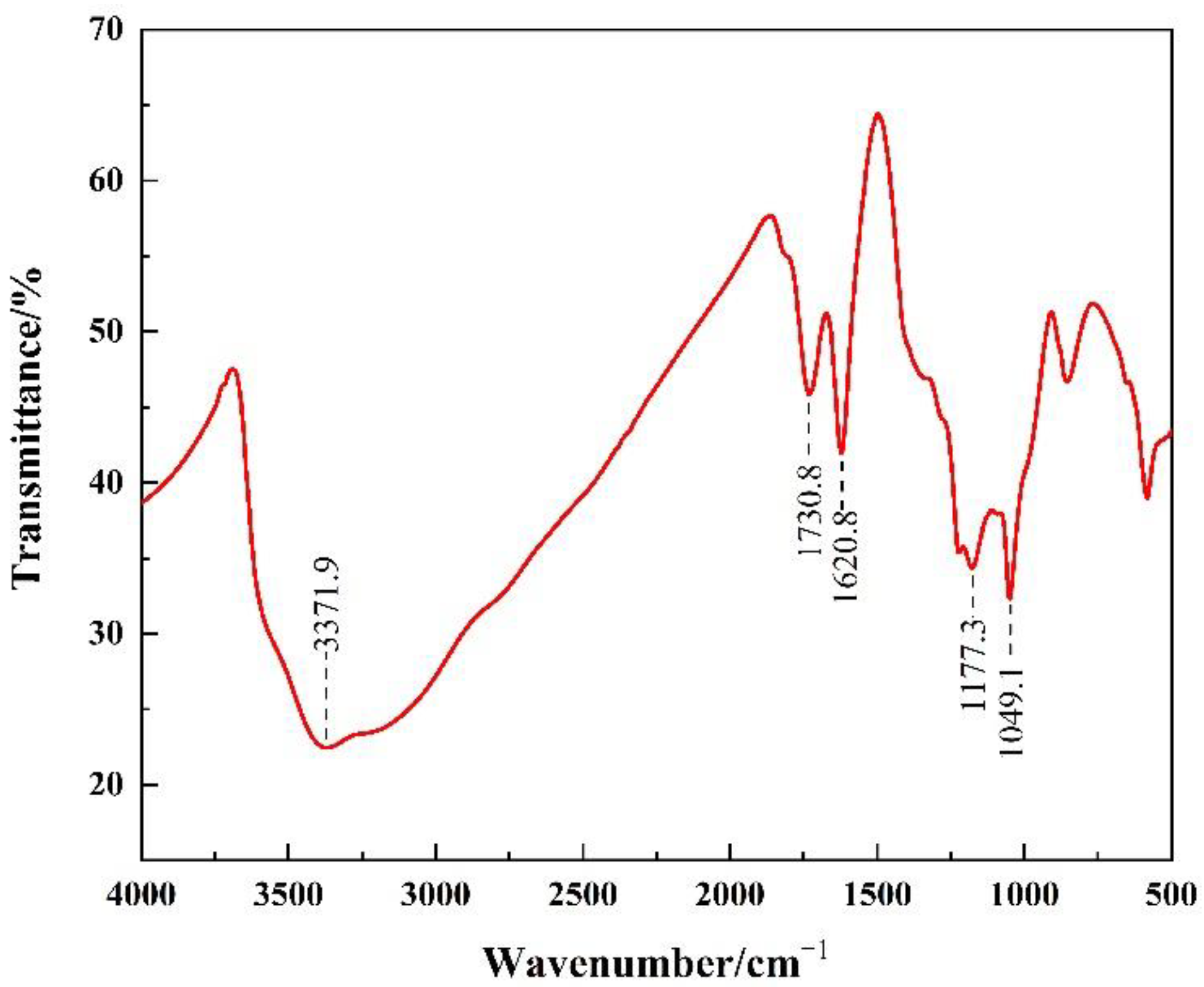

2.3.3. Performance Characterization of GO

2.3.4. Hydration Performance Test

3. Results and Discussion

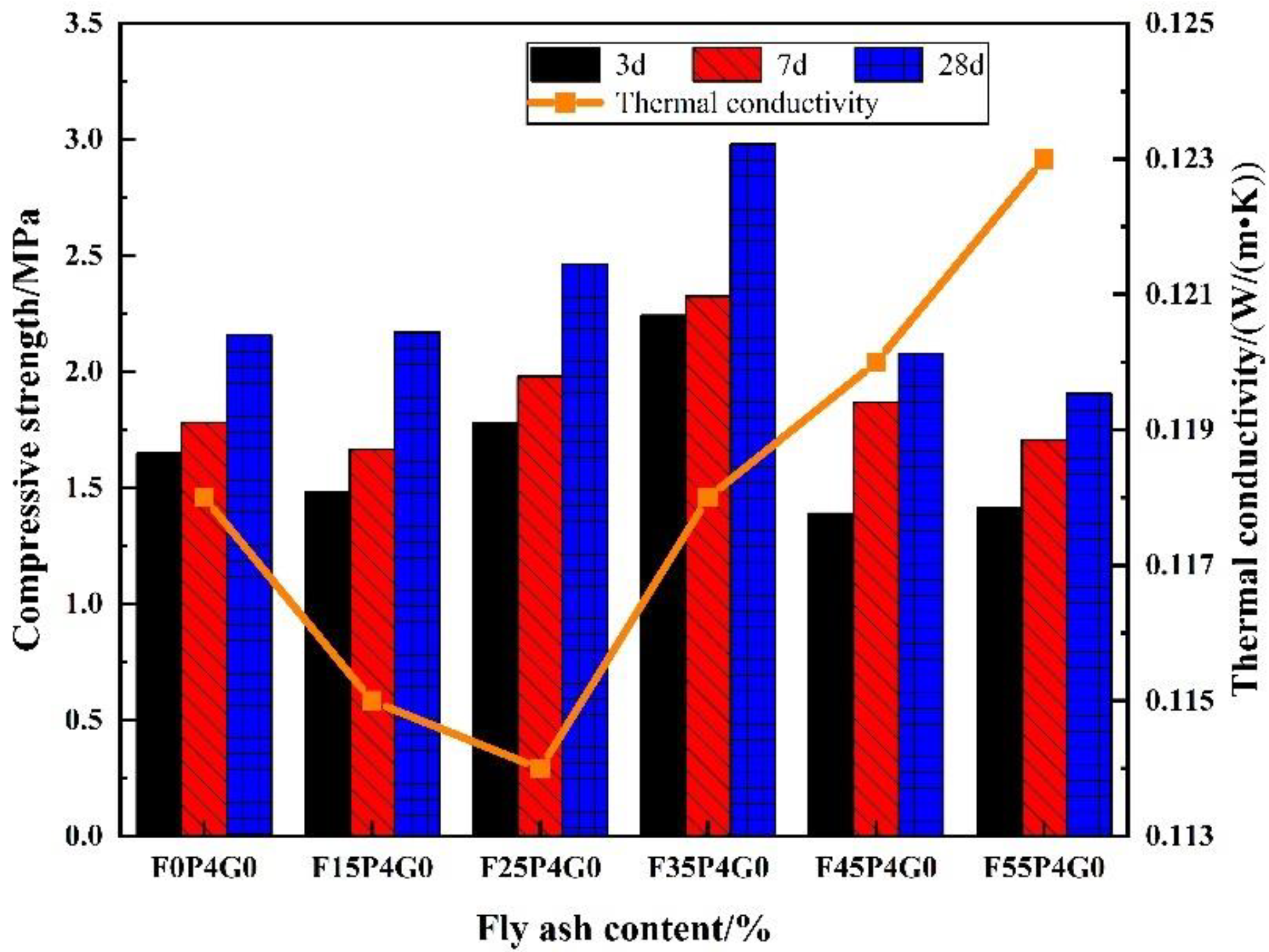

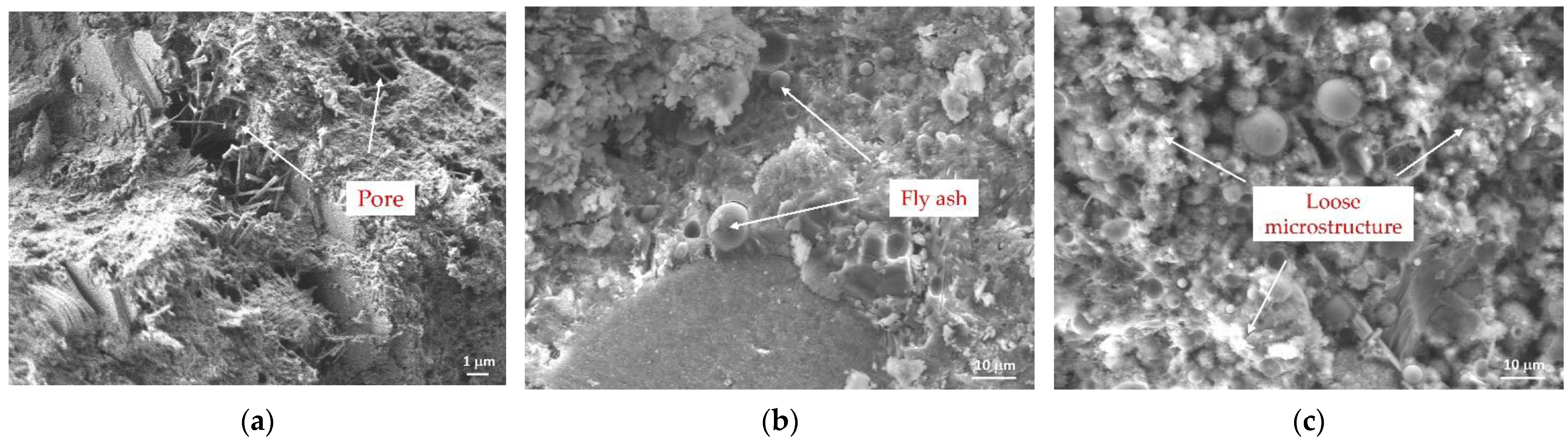

3.1. Effects of FA on the Properties and Microstructure of FC

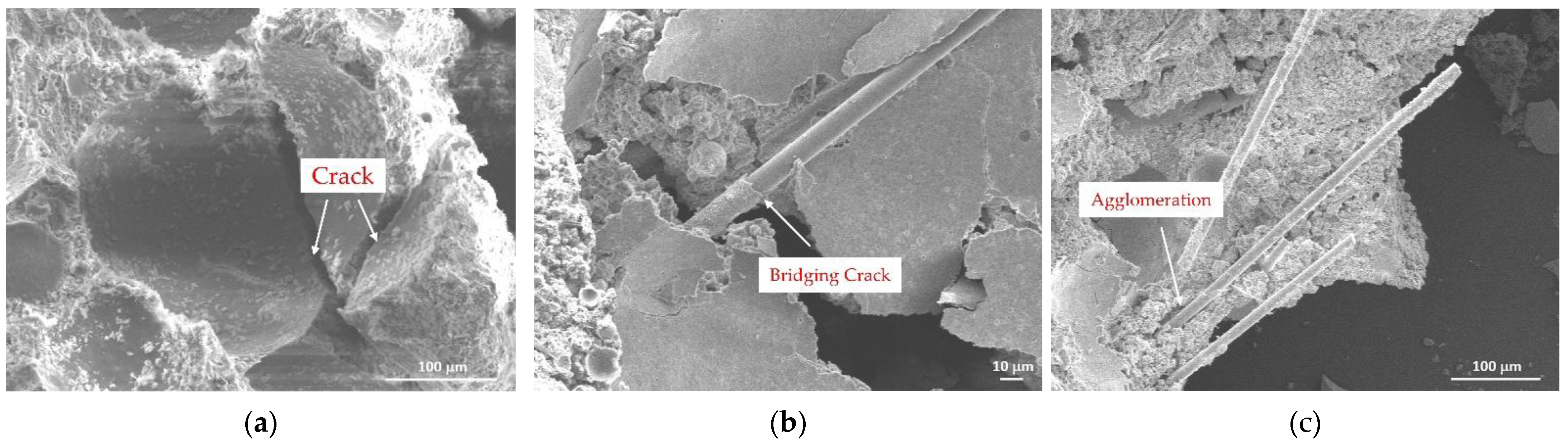

3.2. Effects of Fiber on the Performance and Microstructure of FC

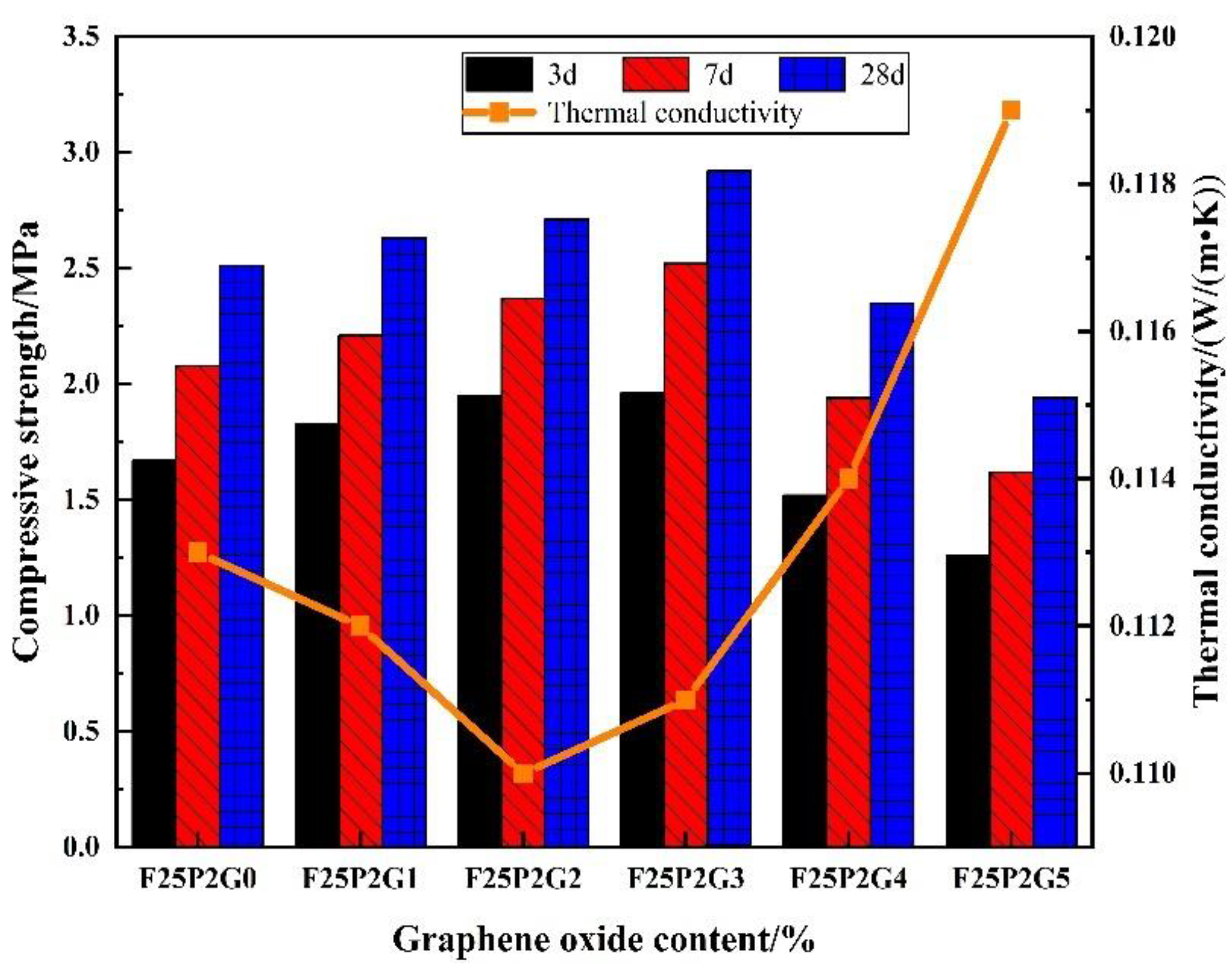

3.3. Effects of GO on the Performance and Microstructure of FC

3.4. Effects of GO on the Hydration of FC

3.4.1. X-ray Diffraction Analysis

3.4.2. Synchronizing Thermal Analysis

3.4.3. Heat-of-Hydration Analysis

4. Conclusions

- Compared with no admixture, when the FA content was 25–35 wt%, the FC’s compressive strength increased by up to 38.0%, while its thermal conductivity was reduced by up to 3.4%. When the PP fiber content was 0.2–0.4 wt%, the compressive strength increased by up to 10.1%, while the thermal conductivity was reduced by up to 1.7%. When the GO content was 0.02–0.03 wt%, the compressive strength increased by up to 16.3%, while the thermal conductivity was reduced by up to 2.6%. In addition, FC mixed in the above ranges had a denser microstructure.

- FA in FC mainly filled pores and was involved in secondary hydration reactions with calcium hydroxide and other substances. At the same time, the FC slurry’s fluidity was improved because the FA was ball-shaped. The PP fiber mainly played a role in refining pores and bridging cracks in the FC. At the same time, the disorderly distribution of the fiber in the slurry also played a skeletal role and significantly improved the early strength of the FC.

- GO mainly played the roles of templating and crack resistance in FC. Its template function was primarily due to its ultrahigh specific surface area, which adsorbed cementing material particles and water to provide growth points for hydration reactions. The crack resistance effect was mainly due to its ultrahigh mechanical properties, which absorb diffused energy, thereby slowing crack propagation.

- The addition of GO did not produce new hydration products, and its influence on the main hydration product contents of FC was insignificant. GO also did not significantly change the FC hydration reaction rate. In short, GO had no noticeable effect on the hydration process of FC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, B.; Han, S.; Wang, Y.; Wang, Y.; Li, J.; Wang, Y. Feasibility Assessment of the Carbon Emissions Peak in China’s Construction Industry: Factor Decomposition and Peak Forecast. Sci. Total Environ. 2020, 706, 135716. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Hybrid Input-Output Analysis for Life-Cycle Energy Consumption and Carbon Emissions of China’s Building Sector. Build. Environ. 2016, 104, 188–197. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental Investigation of Sound Transmission Loss in Concrete Containing Recycled Rubber Crumbs. Adv. Concr. Constr. 2021, 6, 31–140. [Google Scholar] [CrossRef]

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.A.; Farzampour, A. Investigation of Steel Fiber Effects on Concrete Abrasion Resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar] [CrossRef]

- Nafees, A.; Amin, M.N.; Khan, K.; Nazir, K.; Ali, M.; Javed, M.F.; Aslam, F.; Musarat, M.A.; Vatin, N.I. Modeling of Mechanical Properties of Silica Fume-Based Green Concrete Using Machine Learning Techniques. Polymers 2022, 14, 30. [Google Scholar] [CrossRef]

- Khan, K.; Ullah, M.F.; Shahzada, K.; Amin, M.N.; Bibi, T.; Wahab, N.; Aljaafari, A. Effective Use of Micro-Silica Extracted from Rice Husk Ash for the Production of High-Performance and Sustainable Cement Mortar. Constr. Build. Mater. 2020, 258, 119589. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano Silica and Metakaolin Effects on the Behavior of Concrete Containing Rubber Crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Farzampour, A. Temperature and Humidity Effects on Behavior of Grouts. Adv. Concr. Constr. 2017, 5, 659–669. [Google Scholar]

- Kishore, R.A.; Bianchi, M.V.A.; Booten, C.; Vidal, J.; Jackson, R. Enhancing Building Energy Performance by Effectively Using Phase Change Material and Dynamic Insulation in Walls. Appl. Energy 2021, 283, 116306. [Google Scholar] [CrossRef]

- Marin-Montin, J.; Roque, E.; Xu, Y.; Šavija, B.; Serrano-Ruiz, J.C.; Montero-Chacón, F. Thermomechanical Performance Analysis of Novel Cement-Based Building Envelopes with Enhanced Passive Insulation Properties. Materials 2022, 15, 4925. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive Building Energy Savings: A Review of Building Envelope Components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Y.; Liu, J. Optimization of the Thermal Conductivity Test for Building Insulation Materials under Multifactor Impact. Constr. Build. Mater. 2022, 332, 127380. [Google Scholar] [CrossRef]

- Majumder, A.; Canale, L.; Mastino, C.C.; Pacitto, A.; Frattolillo, A.; Dell’Isola, M. Thermal Characterization of Recycled Materials for Building Insulation. Energies 2021, 14, 3564. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Yi, L.; Sun, J. Heat Transfer Mechanism of Concurrent Flame Spread over Rigid Polyurethane Foam: Effect of Ambient Pressure and Inclined Angle. Int. J. Therm. Sci. 2020, 155, 106403. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Huei Lee, Y.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-Reinforced Foamed Concretes: A Review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Tikalsky, P.J.; Pospisil, J.; MacDonald, W. A Method for Assessment of the Freeze–Thaw Resistance of Preformed Foam Cellular Concrete. Cem. Concr. Res. 2004, 34, 889–893. [Google Scholar] [CrossRef]

- Zhang, S.; Cao, K.; Wang, C.; Wang, X.; Wang, J.; Sun, B. Effect of Silica Fume and Waste Marble Powder on the Mechanical and Durability Properties of Cellular Concrete. Constr. Build. Mater. 2020, 241, 117980. [Google Scholar] [CrossRef]

- Othman, R.; Jaya, R.P.; Muthusamy, K.; Sulaiman, M.; Duraisamy, Y.; Abdullah, M.M.A.B.; Przybył, A.; Sochacki, W.; Skrzypczak, T.; Vizureanu, P.; et al. Relation between Density and Compressive Strength of Foamed Concrete. Materials 2021, 14, 2967. [Google Scholar] [CrossRef]

- Oren, O.H.; Gholampour, A.; Gencel, O.; Ozbakkaloglu, T. Physical and Mechanical Properties of Foam Concretes Containing Granulated Blast Furnace Slag as Fine Aggregate. Constr. Build. Mater. 2020, 238, 117774. [Google Scholar] [CrossRef]

- Dhasindrakrishna, K.; Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Progress, Current Thinking and Challenges in Geopolymer Foam Concrete Technology. Cem. Concr. Compos. 2021, 116, 103886. [Google Scholar] [CrossRef]

- Yuan, H.; Ge, Z.; Sun, R.; Xu, X.; Lu, Y.; Ling, Y.; Zhang, H. Drying Shrinkage, Durability and Microstructure of Foamed Concrete Containing High Volume Lime Mud-Fly Ash. Constr. Build. Mater. 2022, 327, 126990. [Google Scholar] [CrossRef]

- She, W.; Du, Y.; Zhao, G.; Feng, P.; Zhang, Y.; Cao, X. Influence of Coarse Fly Ash on the Performance of Foam Concrete and Its Application in High-Speed Railway Roadbeds. Constr. Build. Mater. 2018, 170, 153–166. [Google Scholar] [CrossRef]

- Chung, S.-Y.; Kim, J.-S.; Lehmann, C.; Stephan, D.; Han, T.-S.; Elrahman, M.A. Investigation of Phase Composition and Microstructure of Foamed Cement Paste with Different Supplementary Cementing Materials. Cem. Concr. Compos. 2020, 109, 103560. [Google Scholar] [CrossRef]

- Jhatial, A.A.; Goh, W.I.; Mohamad, N.; Rind, T.A.; Sandhu, A.R. Development of Thermal Insulating Lightweight Foamed Concrete Reinforced with Polypropylene Fibres. Arab. J. Sci. Eng. 2020, 45, 4067–4076. [Google Scholar] [CrossRef]

- Yuan, X.; Niu, J.; Zeng, J.; Jing, Q. Cement-Induced Coagulation of Aqueous Graphene Oxide with Ultrahigh Capacity and High Rate Behavior. Nanomaterials 2018, 8, 574. [Google Scholar] [CrossRef] [Green Version]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Duan, W.H.; Wang, M.C. Mechanical Properties and Microstructure of a Graphene Oxide–Cement Composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Indukuri, C.S.R.; Nerella, R.; Madduru, S.R.C. Effect of Graphene Oxide on Microstructure and Strengthened Properties of Fly Ash and Silica Fume Based Cement Composites. Constr. Build. Mater. 2019, 229, 116863. [Google Scholar] [CrossRef]

- Lv, S.; Liu, J.; Sun, T.; Ma, Y.; Zhou, Q. Effect of GO Nanosheets on Shapes of Cement Hydration Crystals and Their Formation Process. Constr. Build. Mater. 2014, 64, 231–239. [Google Scholar] [CrossRef]

- Lin, C.; Wei, W.; Hu, Y.H. Catalytic Behavior of Graphene Oxide for Cement Hydration Process. J. Phys. Chem. Solids 2016, 89, 128–133. [Google Scholar] [CrossRef]

- Sharma, S.; Kothiyal, N.C.; Chitkara, M. Enhanced Mechanical Performance of Cement Nanocomposite Reinforced with Graphene Oxide Synthesized from Mechanically Milled Graphite and Its Comparison with Carbon Nanotubes Reinforced Nanocomposite. RSC Adv. 2016, 6, 103993–104009. [Google Scholar] [CrossRef]

- Peng, H.; Ge, Y.; Cai, C.S.; Zhang, Y.; Liu, Z. Mechanical Properties and Microstructure of Graphene Oxide Cement-Based Composites. Constr. Build. Mater. 2019, 194, 102–109. [Google Scholar] [CrossRef]

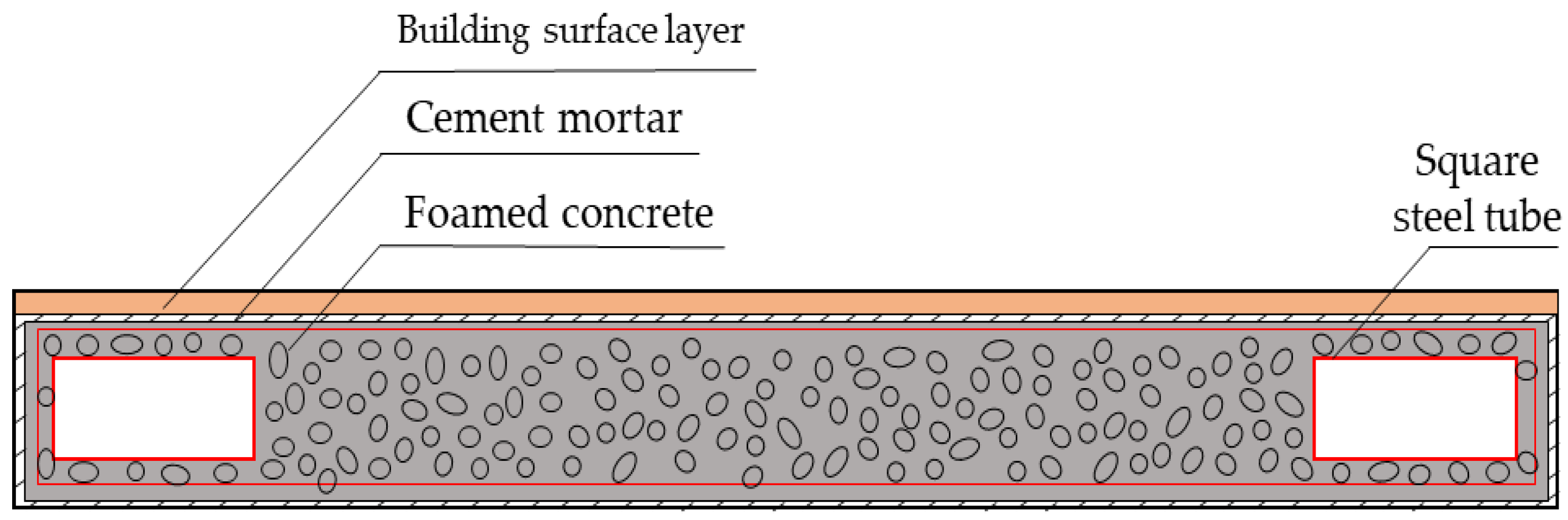

- Xu, Z.; Chen, Z.; Yang, S. Seismic Behavior of Cold-Formed Steel High-Strength Foamed Concrete Shear Walls with Straw Boards. Thin-Walled Struct. 2018, 124, 350–365. [Google Scholar] [CrossRef]

- Prabha, P.; Marimuthu, V.; Saravanan, M.; Palani, G.S.; Lakshmanan, N.; Senthil, R. Effect of Confinement on Steel-Concrete Composite Light-Weight Load-Bearing Wall Panels under Compression. J. Constr. Steel Res. 2013, 81, 11–19. [Google Scholar] [CrossRef]

- Othuman Mydin, M.A.; Wang, Y.C. Structural Performance of Lightweight Steel-Foamed Concrete–Steel Composite Walling System under Compression. Thin-Walled Struct. 2011, 49, 66–76. [Google Scholar] [CrossRef]

- JGJ/T 341-2014; Technical Specification for Application of Foamed Concrete. Ministry of Housing and Urban-Rural Development, China Architecture & Building Press: Beijing, China, 2014.

- JGJ/T 266-2011; Foamed concrete. Ministry of Housing and Urban-Rural Development, China Architecture & Building Press: Beijing, China, 2011.

- GB/T 10294-2018; Protective Hot plate Method for the Determination of Steady Thermal Resistance and Related Characteristics of Thermal Insulation Materials. Ministry of Housing and Urban-Rural Development, China Architecture & Building Press: Beijing, China, 2018.

| Gravity (kg/m3) | Setting Time (min) | Flexural Strength (MPa) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3 d | 28 d | 3 d | 28 d | |

| 3090 | 131 | 182 | 6.2 | 8.3 | 34.7 | 56.2 |

| Specimens | Water/ Cement Ratio | Cement (kg) | Fly Ash (kg) | Silica Fume (kg) | PP Fiber (g) | Foam (kg) | Water-Reducing Agent (g) | GO (g) | Dry Density(kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| Fly ash + 0.04 wt% PP fiber + 0 wt% GO group | |||||||||

| F0P4G0 | 0.6 | 17.81 | 0 | 0.94 | 75 | 0.75 | 46.9 | 0 | 557.2 |

| F15P4G0 | 0.6 | 15 | 2.81 | 0.94 | 75 | 0.75 | 46.9 | 0 | 532.3 |

| F25P4G0 | 0.6 | 13.12 | 4.69 | 0.94 | 75 | 0.75 | 46.9 | 0 | 536.8 |

| F35P4G0 | 0.6 | 11.25 | 6.56 | 0.94 | 75 | 0.75 | 46.9 | 0 | 571.1 |

| F45P4G0 | 0.6 | 9.37 | 8.44 | 0.94 | 75 | 0.75 | 46.9 | 0 | 590.2 |

| F55P4G0 | 0.6 | 7.5 | 10.31 | 0.94 | 75 | 0.75 | 46.9 | 0 | 605.3 |

| 25 wt% Fly ash + PP fiber + 0 wt% GO group | |||||||||

| F25P0G0 | 0.6 | 13.12 | 4.69 | 0.94 | 0 | 0.75 | 46.9 | 0 | 527.2 |

| F25P2G0 | 0.6 | 13.12 | 4.69 | 0.94 | 37.5 | 0.75 | 46.9 | 0 | 529.8 |

| F25P4G0 | 0.6 | 13.12 | 4.69 | 0.94 | 75 | 0.75 | 46.9 | 0 | 536.8 |

| F25P6G0 | 0.6 | 13.12 | 4.69 | 0.94 | 112.5 | 0.75 | 46.9 | 0 | 550.4 |

| F25P8G0 | 0.6 | 13.12 | 4.69 | 0.94 | 150 | 0.75 | 46.9 | 0 | 555.9 |

| F25P10G0 | 0.6 | 13.12 | 4.69 | 0.94 | 187.5 | 0.75 | 46.9 | 0 | 576.1 |

| 25 wt% Fly ash + 0.02 wt% PP fiber + GO group | |||||||||

| F25P2G0 | 0.6 | 13.12 | 4.7 | 0.94 | 37.5 | 0.75 | 46.9 | 0 | 529.8 |

| F25P2G1 | 0.6 | 13.12 | 4.7 | 0.94 | 37.5 | 0.75 | 46.9 | 1.9 | 522.3 |

| F25P2G2 | 0.6 | 13.12 | 4.7 | 0.94 | 37.5 | 0.75 | 46.9 | 3.8 | 519.4 |

| F25P2G3 | 0.6 | 13.12 | 4.7 | 0.94 | 37.5 | 0.75 | 46.9 | 5.7 | 527.6 |

| F25P2G4 | 0.6 | 13.12 | 4.7 | 0.94 | 37.5 | 0.75 | 46.9 | 7.6 | 548.7 |

| F25P2G5 | 0.6 | 13.12 | 4.7 | 0.94 | 37.5 | 0.75 | 46.9 | 9.5 | 577.8 |

| Samples | 450–550 °C Mass Loss (%) | 650–800 °C Mass Loss (%) | Calcium Hydroxide Content (%) |

|---|---|---|---|

| F25P2G0 | 2.40 | 1.46 | 12.31 |

| F25P2G1 | 2.48 | 1.37 | 12.50 |

| F25P2G2 | 2.19 | 2.21 | 12.70 |

| F25P2G3 | 2.22 | 2.04 | 12.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xian, G.; Liu, Z.; Wang, Z.; Zhou, X. Study on the Performance and Mechanisms of High-Performance Foamed Concrete. Materials 2022, 15, 7894. https://doi.org/10.3390/ma15227894

Xian G, Liu Z, Wang Z, Zhou X. Study on the Performance and Mechanisms of High-Performance Foamed Concrete. Materials. 2022; 15(22):7894. https://doi.org/10.3390/ma15227894

Chicago/Turabian StyleXian, Guodong, Zhe Liu, Zhen Wang, and Xuejun Zhou. 2022. "Study on the Performance and Mechanisms of High-Performance Foamed Concrete" Materials 15, no. 22: 7894. https://doi.org/10.3390/ma15227894