Influence of the Type of Cement and the Addition of an Air-Entraining Agent on the Effectiveness of Concrete Cover in the Protection of Reinforcement against Corrosion

Abstract

1. Introduction

2. Materials and Methods

2.1. Test Specimens

- (a)

- C_I_a specimens—specimens made of concrete with Portland cement and the addition of an air-entraining agent;

- (b)

- C_I_n specimens—specimens made of concrete with Portland cement, without the addition of an air-entraining agent;

- (c)

- C_III_a specimens—specimens made of concrete with blast-furnace slag cement and the addition of an air-entraining agent;

- (d)

- C_III_n specimens—specimens made of concrete with blast-furnace slag cement, without the addition of an air-entraining agent.

- (a)

- stage I—reference measurements made 90 days after concreting the specimens, but before the freeze–thaw cycles;

- (b)

- stage II—measurements made 250 days after concreting the specimens, after 120 cycles of freezing and thawing.

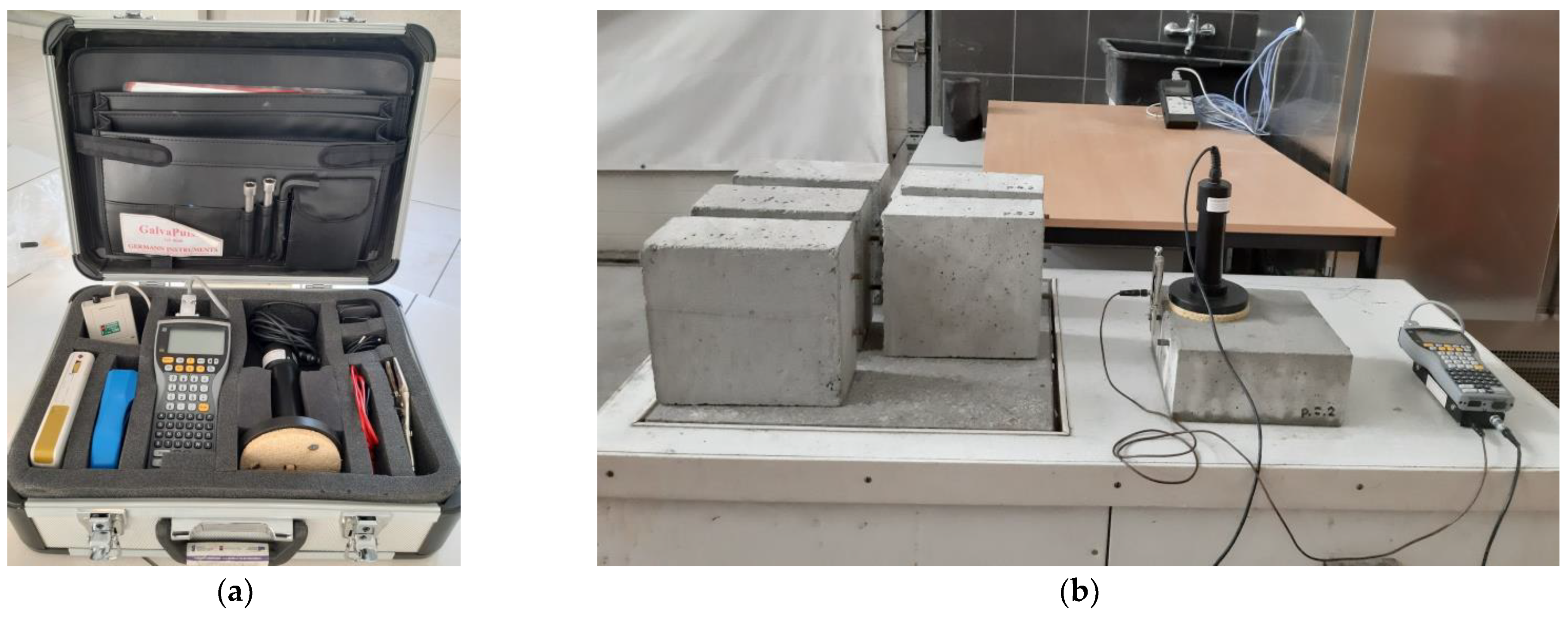

2.2. Galvanostatic Pulse Technique

3. Results and Discussion

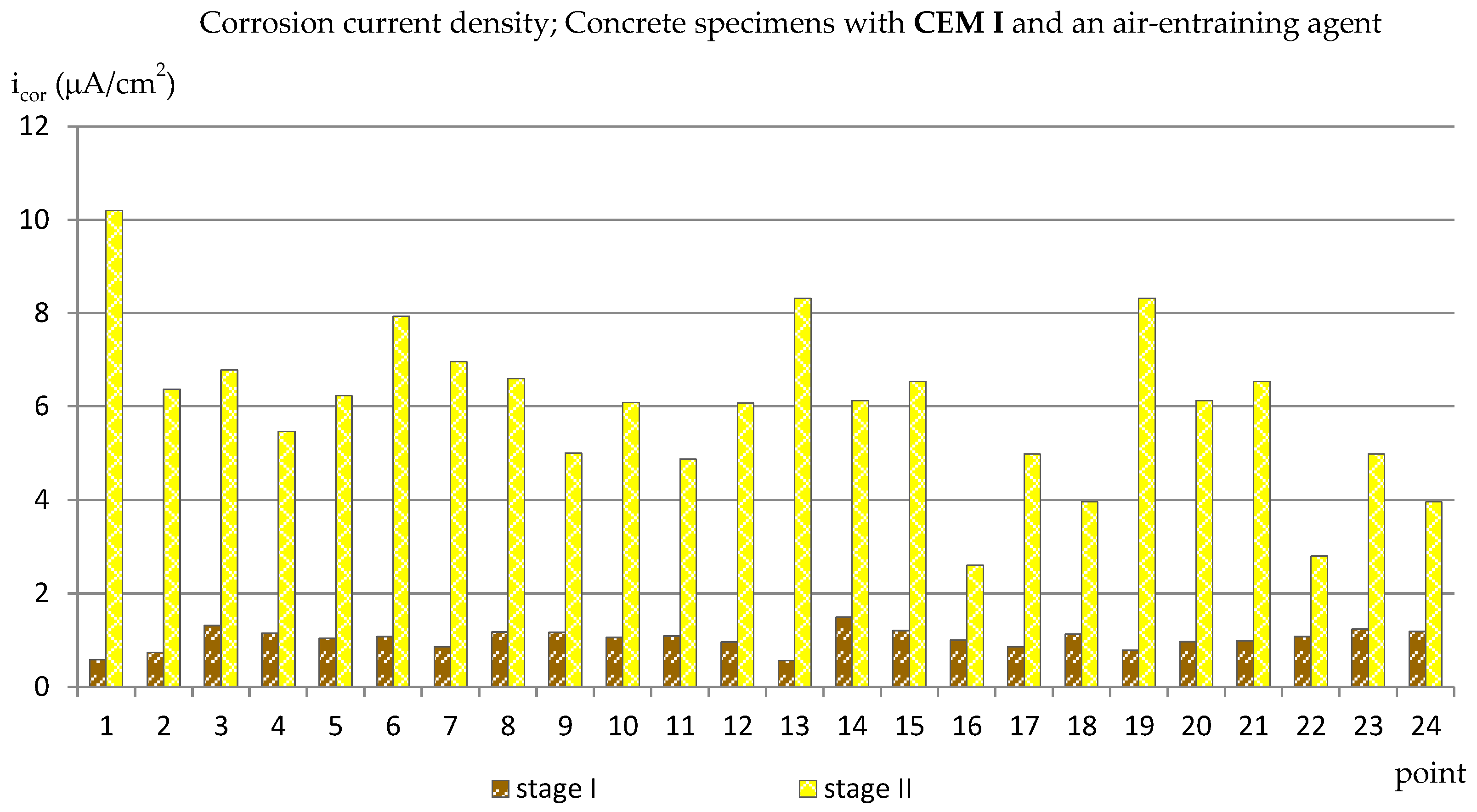

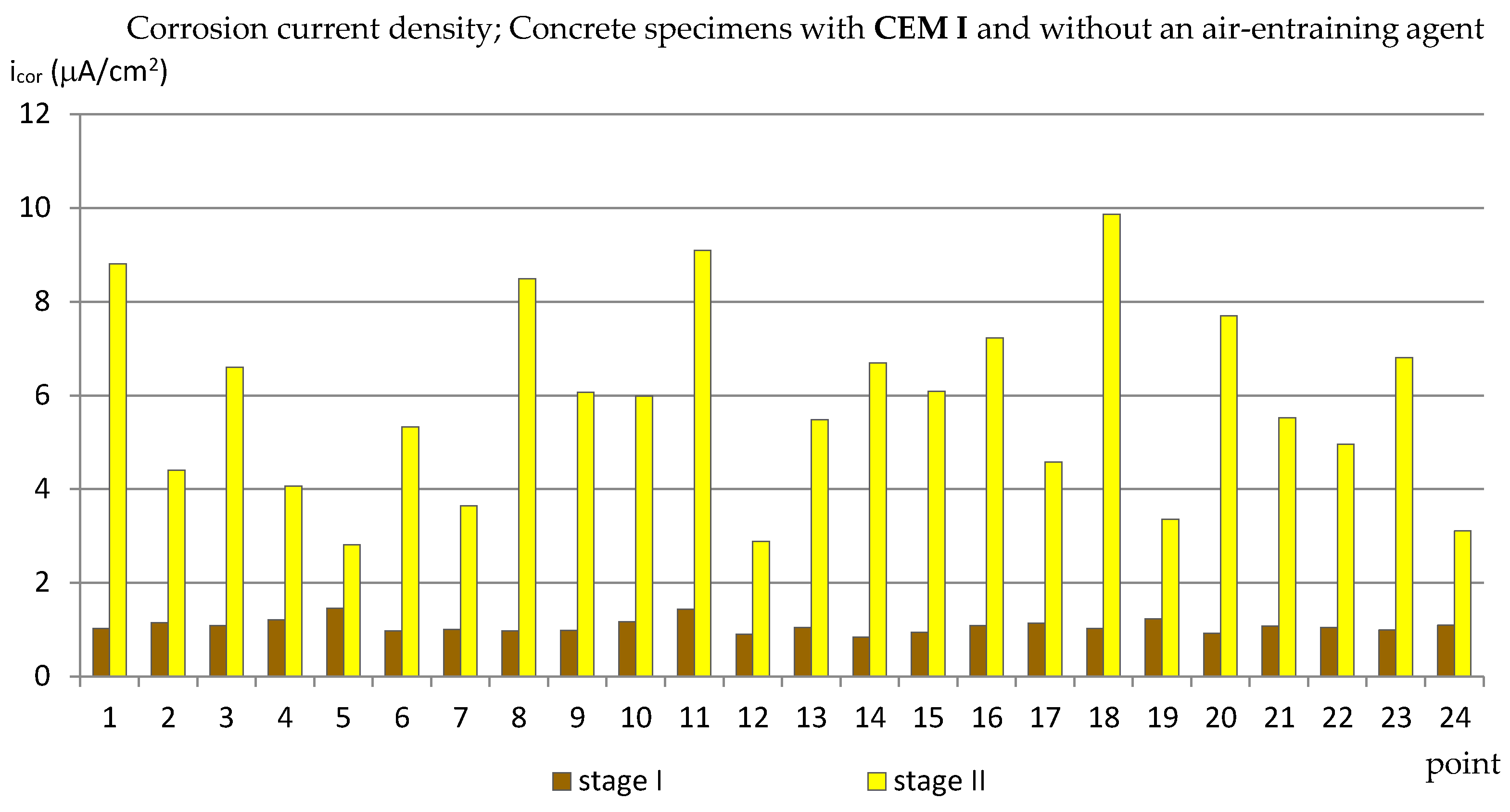

3.1. The Corrosion Current Density

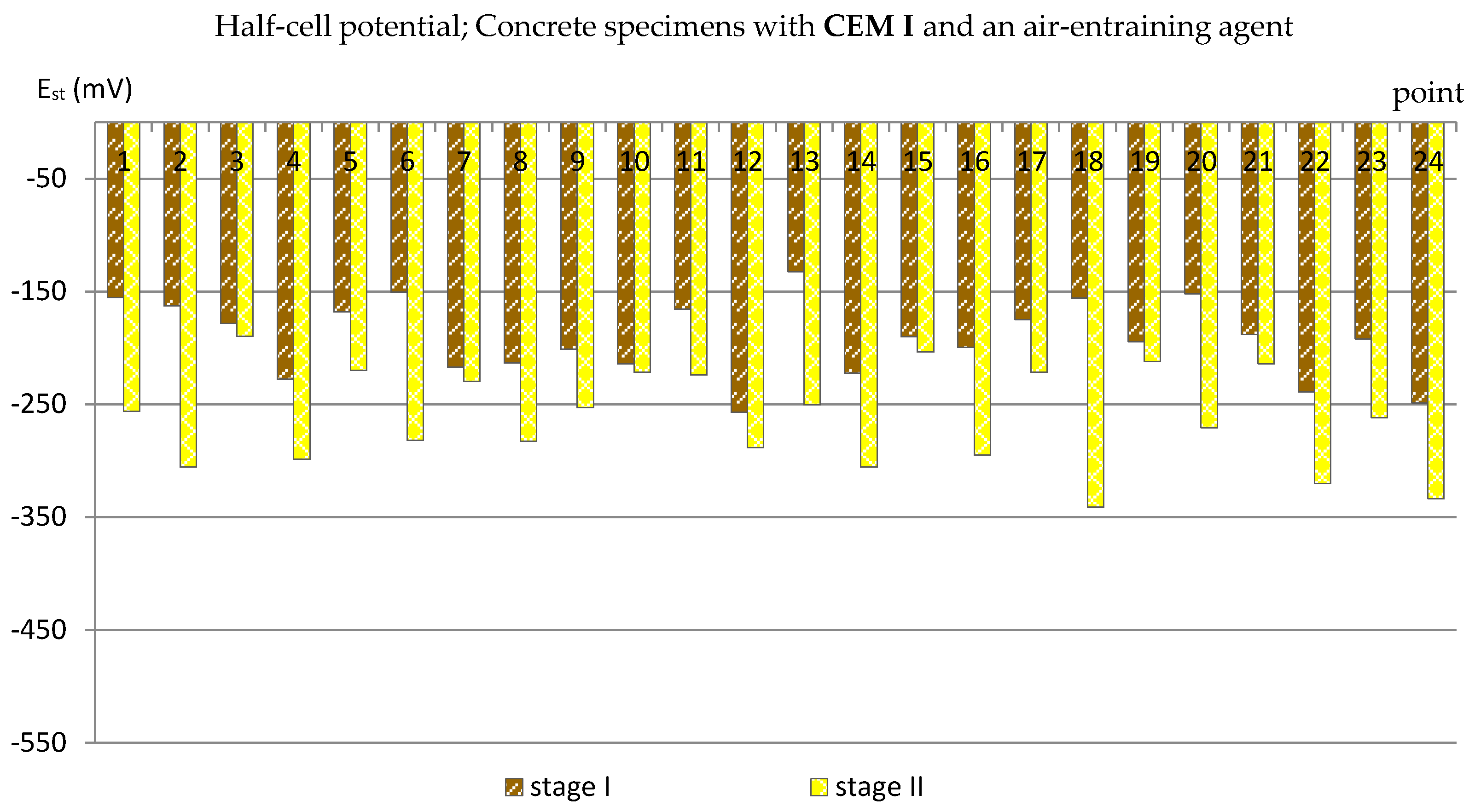

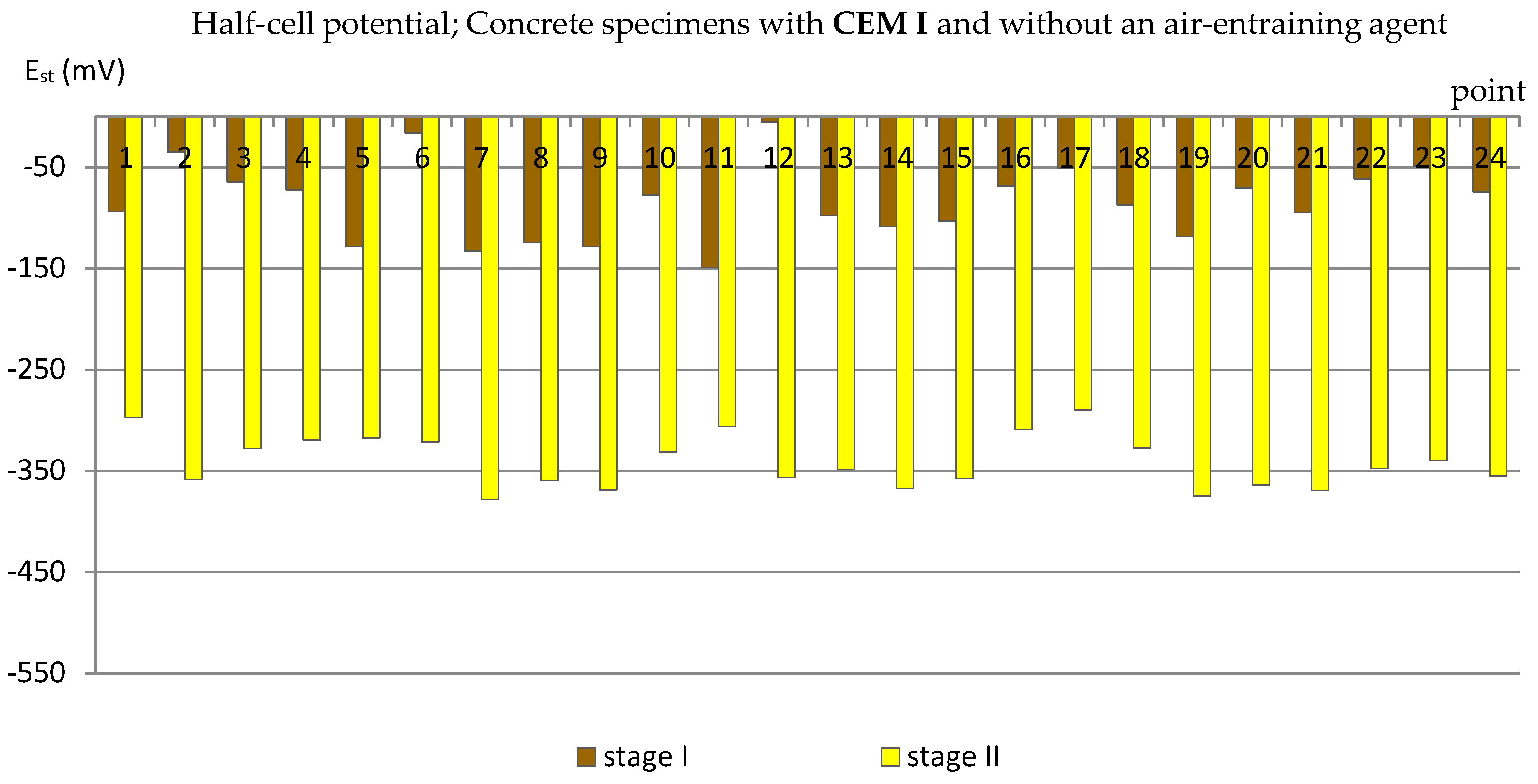

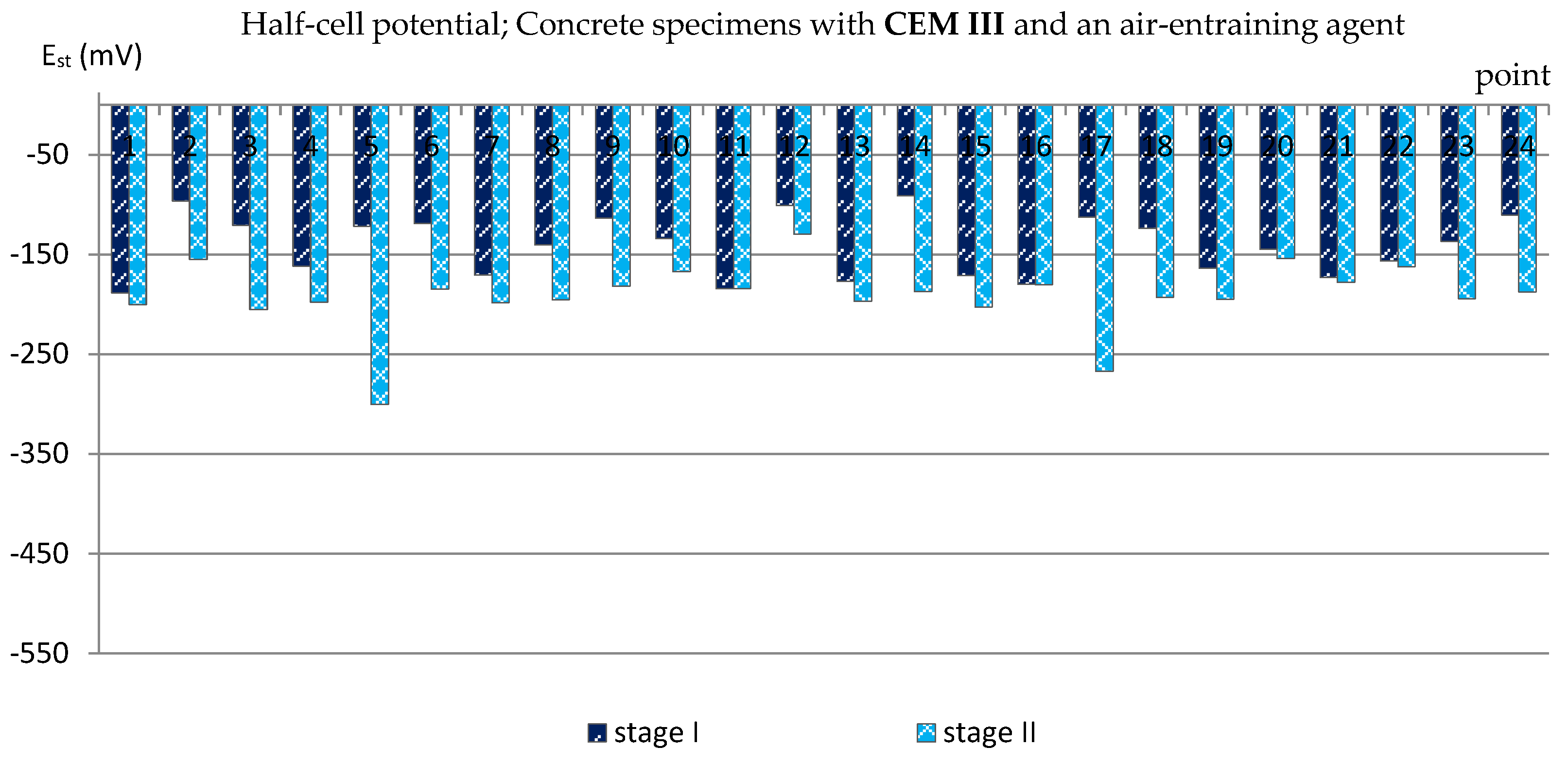

3.2. The Half-Cell Potential of Reinforcement

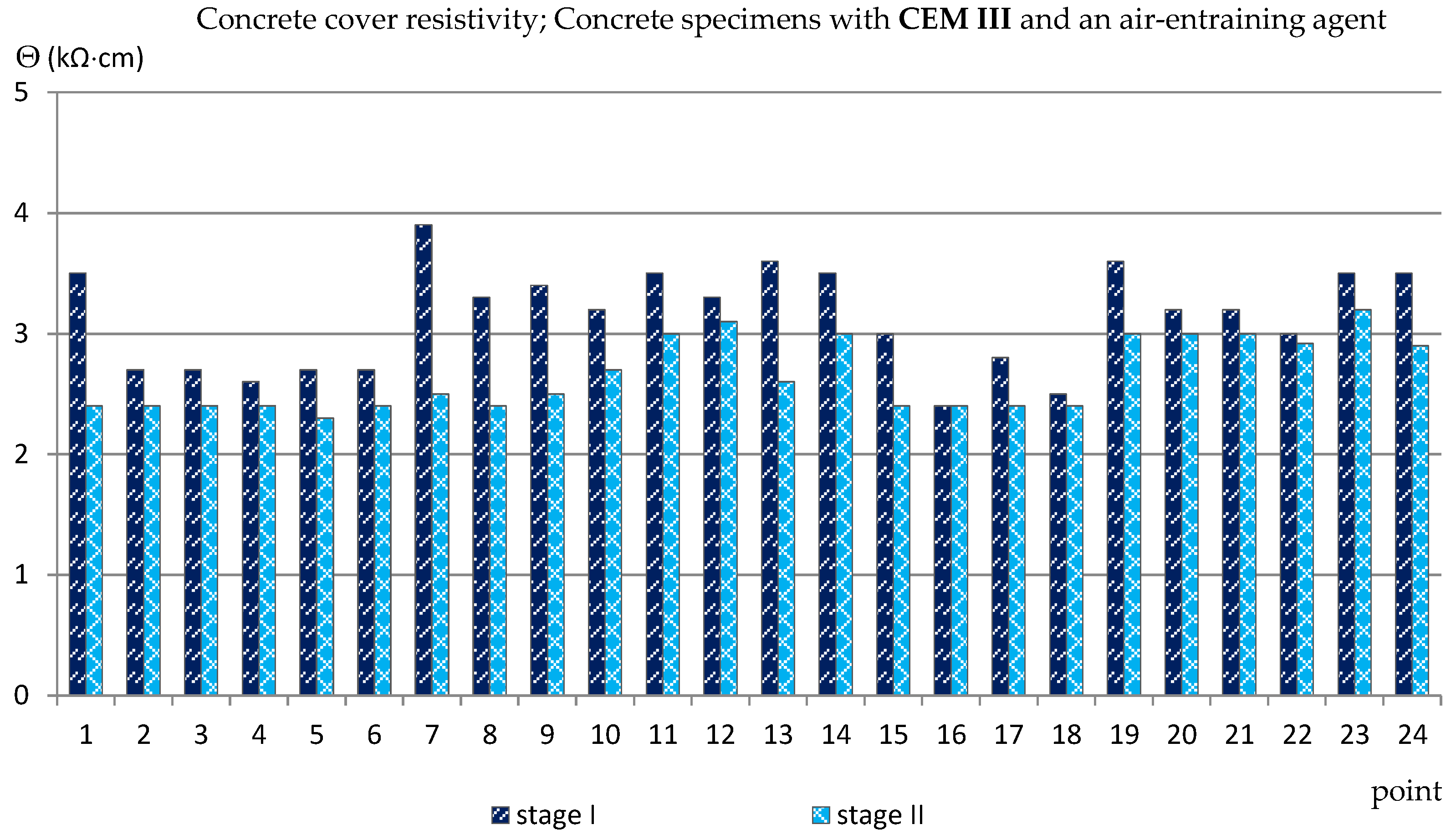

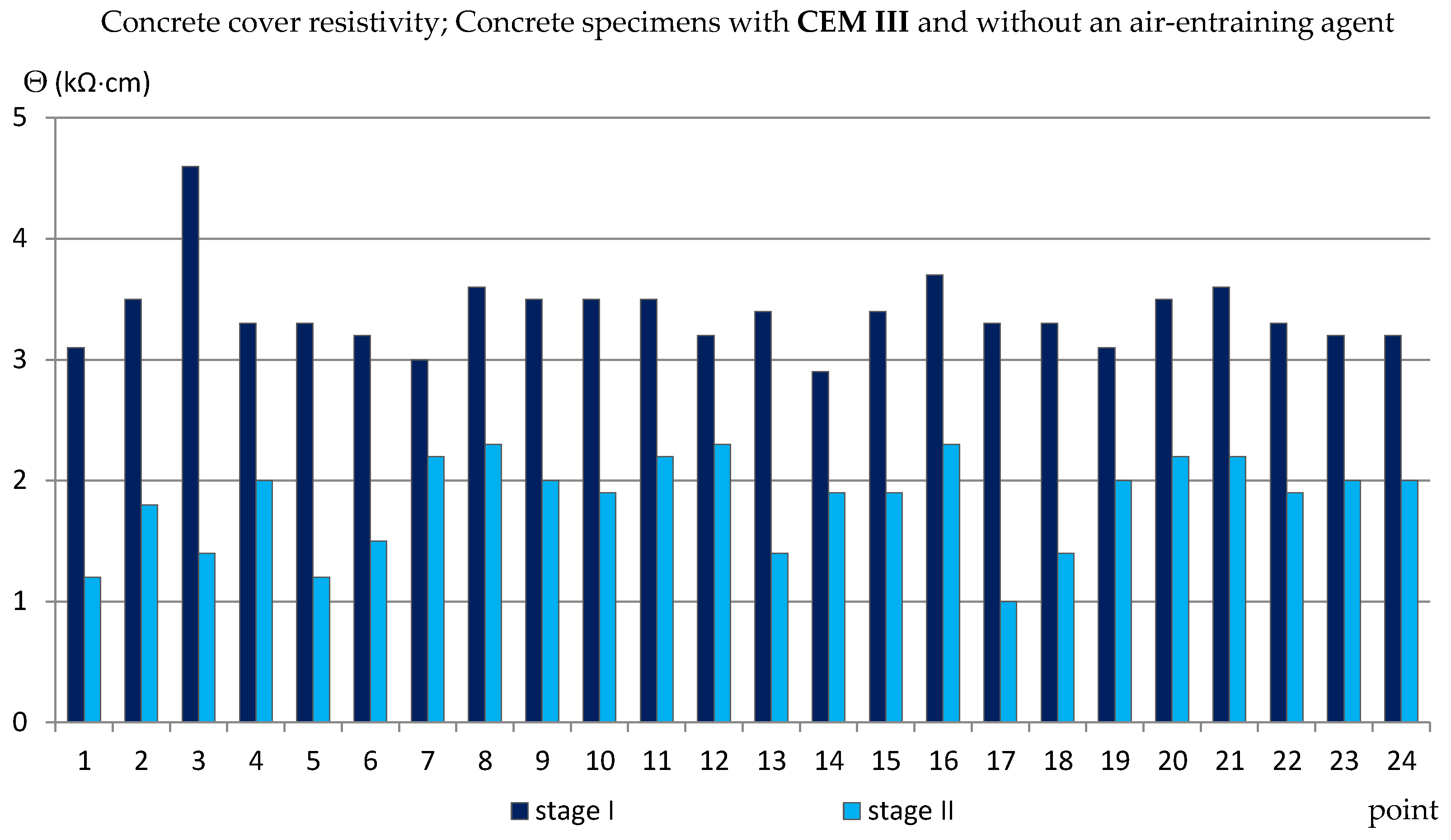

3.3. The Concrete Cover Resistivity

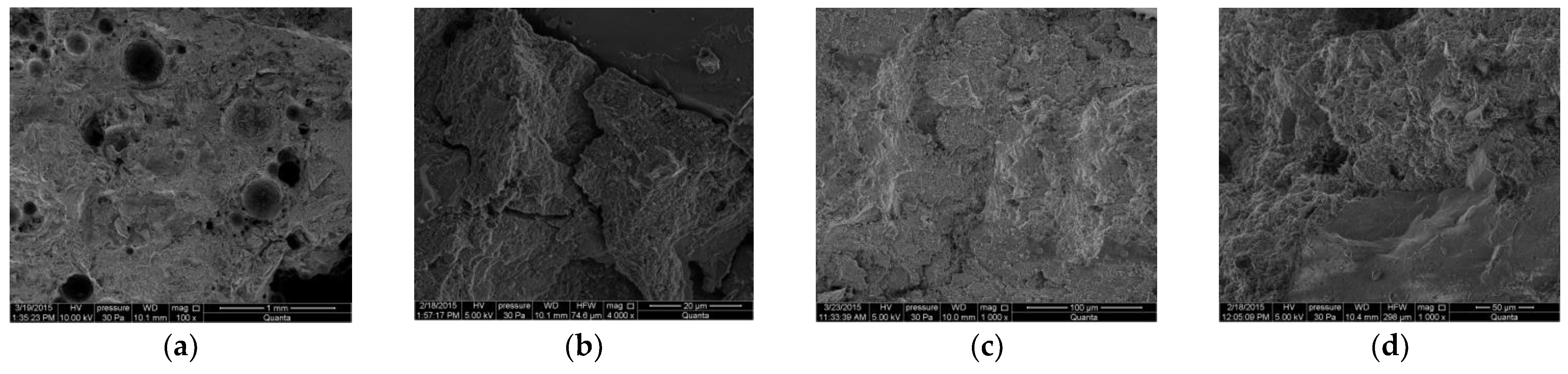

3.4. Microstructural Studies Using a Scanning Electron Microscope (SEM Analysis)

4. Conclusions

- Based on the results obtained from the measurements of the corrosion current density (the most reliable parameter), it was found that after the specimens were subjected to 120 freezing and thawing cycles in a 3% NaCl solution, the lowest corrosion activity of the reinforcement was recorded on the reinforcement in C_III_a specimens, i.e., specimens made of concrete with blast-furnace slag cement and an air-entraining agent addition. On the other hand, the use of blast-furnace slag cement for concrete, but without adding an air-entraining agent (C_III_n specimens), although this cement should protect against chloride corrosion, does not reduce the corrosive activity of the reinforcement. The results obtained on C_III_n specimens are comparable to the results obtained on C_I_a and C_I_n specimens. On the other hand, concrete with the addition of an air-entraining agent in which Portland cement was used (C_I_a specimens) is not effective in protecting against the simultaneous effects of chloride corrosion and frost.

- The results obtained from the measurements of the reinforcement half-cell potential and the concrete cover resistivity were less reliable than the measurement of the corrosion current density and m might be influence by concrete mixture and age of evaluation. Nevertheless, they confirmed the previous analyses. Concrete in C_III_a specimens turned out to be more effective in reducing the probability of reinforcement corrosion.

- Moreover, it was found that the measurements of the concrete cover resistivity performed by the galvanostatic pulse method are not very reliable in the case of tests on young (several months old) specimens.

- The observation of the microstructure of concrete under a scanning electron microscope showed that the most compact structure is characterized by concrete with blast-furnace slag cement and the addition of an air-entraining agent taken from the C_III_a specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Green, W.; Chess, P. Durability of Reinforced Concrete Structures, 1st ed.; Informa: London, UK, 2019. [Google Scholar]

- Ściślewski, Z. Durability of Reinforced Concrete Structures; Arkady: Warsaw, Poland, 1999. [Google Scholar]

- Bertolini, L.; Elsener, B.; Pedeferri, P.; Polder, R. Corrosion of Steel in Concrete, 2nd ed.; Wiley: Weinheim, Germany, 2004. [Google Scholar]

- Kurdowski, W. Cement and Concrete Chemistry; Springer: Dordrecht, The Nederlands, 2014. [Google Scholar] [CrossRef]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Monitoring corrosion of steel bars in reinforced concrete structures. Sci. World J. 2014, 2014, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Yeomans, S.R. Galvanized steel reinforcement. In Corrosion of Steel in Concrete Structures; Elsevier: Berlin/Heidelberg, Germany, 2016; pp. 111–129. [Google Scholar]

- Jaśniok, M.; Kołodziej, J.; Gromysz, K. An 18-month analysis of bond strength of hot-dip galvanized reinforcing steel B500SP and S235JR+AR to chloride contaminated concrete. Materials 2021, 14, 747. [Google Scholar] [CrossRef] [PubMed]

- Jaśniok, M.; Sozańska, M.; Kołodziej, J.; Chmiela, B. A two-year evaluation of corrosion-induced damage to hot galvanized reinforcing steel b500sp in chloride contaminated concrete. Materials 2020, 13, 3315. [Google Scholar] [CrossRef]

- Manalo, A.; Maranan, G.; Benmokrane, B.; Cousin, P.; Alajarmeh, O.; Ferdous, W.; Liang, R.; Hota, G. Comparative durability of GFRP composite reinforcing bars in concrete and in simulated concrete environments. Cem. Concr. Compos. 2020, 109, 103564. [Google Scholar] [CrossRef]

- Khotbehsara, M.M.; Manalo, A.; Aravinthan, T.; Ferdous, W.; Nguyen, K.T.; Hota, G. Ageing of particulate-filled epoxy resin under hygrothermal conditions. Constr. Build. Mater. 2020, 249, 118846. [Google Scholar] [CrossRef]

- Thamrin, R. Effect of end anchorage length and stirrup ratio on bond and shear capacity of concrete beams with nonmetallic reinforcement. J. Eng. Sci. Technol. 2016, 11, 768–787. [Google Scholar]

- Babiak, I. Research of non-metal composite basalt reinforcement of periodic profile and prospects of its use. Dorogi Mosti 2021, 2021, 144–157. [Google Scholar] [CrossRef]

- Mosley, C.P.; Tureyen, A.K.; Frosch, R.J. Bond strength of nonmetallic reinforcing bars. Aci. Struct. J. 2008, 105, 634–642. [Google Scholar]

- Ekenel, M.; y Basalo, F.D.C.; Nanni, A. Fiber-Reinforced Polymer Reinforcement for Concrete Members, ACI Committee 440 is Taking the Next Step toward Building Code Compliance. 2021. Available online: www.concreteinternational.com (accessed on 2 January 2021).

- Raczkiewicz, W. Effect of concrete addition of selected micro-fibers on the reinforcing bars corrosion in the reinforced concrete specimens. Adv. Mater. Sci. 2016, 16, 38–46. [Google Scholar] [CrossRef][Green Version]

- Ye, H.; Jin, N. Degradation mechanisms of concrete subjected to combined environmental and mechanical actions: A review and perspective. Comput. Concr. 2019, 23, 107–119. [Google Scholar] [CrossRef]

- Czarnecki, L.; Emmons, P.H. Repair and Protection of Concrete Structures; SPC: Krakow, Poland, 2002. [Google Scholar]

- Luo, D.; Li, Y.; Li, J.; Lim, K.-S.; Nazal, N.A.M.; Ahmad, H. A recent progress of steel bar corrosion diagnostic techniques in rc structures. Sensors 2018, 19, 34. [Google Scholar] [CrossRef]

- Jaśniok, M.; Jaśniok, T. Measurements on corrosion rate of reinforcing steel under various environmental conditions, using an insulator to delimit the polarized area. Procedia Eng. 2017, 193, 431–438. [Google Scholar] [CrossRef]

- CEN. PN-EN 1992-1-1:2008 Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- Owsiak, Z.; Grzmil, W. The evaluation of the influence of mineral additives on the durability of self-compacting concretes. KSCE J. Civ. Eng. 2014, 19, 1002–1008. [Google Scholar] [CrossRef]

- Raczkiewicz, W.; Grzmil, W. Assessment of the impact of cement type on the process of concrete carbonation and reinforcement corrosion in reinforced concrete specimens. Cem. Lime Concr. 2017, 4, 311–319. [Google Scholar]

- Aitcin, J.C. High-Performance Concrete; E. & F.N. Spon: London, UK, 1998. [Google Scholar]

- Małolepszy, J. Durability of concretes made of slag cements. In Proceedings of the Scientific-Technical Conference, Szczyrk, Poland, 17–21 May 2002; pp. 225–244. [Google Scholar]

- Giergiczny, Z. Cements with mineral additives as a component of durable concrete. Eng. Constr. 2010, 66, 5–6, 275–279. [Google Scholar]

- Deja, J. Corrosion durability of binders with different content of granulated blast furnace slag. Cement. Lime. Concr. 2007, 74, 280–283. [Google Scholar]

- Liu, J.; Jiang, Z.; Zhao, Y.; Zhou, H.; Wang, X.; Zhou, H.; Xing, F.; Li, S.; Zhu, J.; Liu, W. Chloride distribution and steel corrosion in a concrete bridge after long-term exposure to natural marine environment. Materials 2020, 13, 3900. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Li, Q.; Wu, L. Chloride ion concentration distribution characteristics within concrete covering-layer considering the reinforcement bar presence. Ocean Eng. 2019, 173, 608–616. [Google Scholar] [CrossRef]

- Kuziak, J.; Woyciechowski, P.P.; Kobyłka, R.; Wcisło, A. The content of chlorides in blast-furnace slag cement as a factor affecting the diffusion of chloride ions in concrete. MATEC Web Conf. 2018, 163, 05007. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Gazzaniga, G.; Pastore, T. Chloride Diffusion in Concrete Protected with a Silane-Based Corrosion Inhibitor. Materials 2020, 13, 2001. [Google Scholar] [CrossRef] [PubMed]

- Hájková, K.; Šmilauer, V.; Jendele, L.; Červenka, J. Prediction of reinforcement corrosion due to chloride ingress and its effects on serviceability. Eng. Struct. 2018, 174, 768–777. [Google Scholar] [CrossRef]

- Rusin, Z. Technology of Frost-Resistant Concrete; SPC: Krakow, Poland, 2002. [Google Scholar]

- Czarnecki, L.; Deja, J.; Flaga, K.; Kurdowski, W.; Małolepszy, J.; Radomski, W.; Śliwiński, J. Concrete frost resistance in bridge structures. Constr. Technol. Archit. 2015, 69, 66–69. [Google Scholar]

- Wawrzeńczyk, J.; Molendowska, A.; Juszczak, T. Determining k-value with regard to freeze-thaw resistance of concretes containing GGBS. Materials 2018, 11, 2349. [Google Scholar] [CrossRef] [PubMed]

- Raczkiewicz, W. Influence of the air-entraining agent in the concrete coating on the reinforcement corrosion process in case of simultaneous action of chlorides and frost. Adv. Mater. Sci. 2018, 18, 13–19. [Google Scholar] [CrossRef]

- GalvaPulse. Available online: http://www.germann.org/TestSystems/GalvaPulse/GalvaPulse.pdf (accessed on 20 March 2014).

- Helal, J.; Sofi, M.; Mendis, P. Non-destructive testing of concrete: A review of methods. Electron. J. Struct. Eng. 2015, 14, 97–105. [Google Scholar]

- Hoła, J.; Bien, J.; Sadowski, L.; Schabowicz, K. Non-destructive and semi-destructive diagnostics of concrete structures in assessment of their durability. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 87–96. [Google Scholar] [CrossRef]

- Raczkiewicz, W. Building Diagnostics. Selected Methods of Materials as Well as Elements and Structures Test; Kielce University of Technology: Kielce, Poland, 2019. [Google Scholar]

- Klinghoffer, O. In situ monitoring of reinforcement corrosion by means of electrochemical methods. Nord. Concr. Res. 1995, 1, 1–13. [Google Scholar]

- Elsner, B.; Klinghoffer, O.; Frolund, T.; Rislund, E.; Schiegg, Y.; Böhni, H. Assessment of reinforcement corrosion by means of galvanostatic pulse technique. In Proceedings of the International Conference Repair of Concrete Structures, Svolvaer, Norway, 28–30 May 1997. [Google Scholar]

- Frølund, T.; Klinghoffer, O.; Poulsen, E. Rebar Corrosion Rate Measurements for Service Life Estimates. In Proceedings of the ACI Fall Convention, Toronto, ON, Canada, 15 October 2000. [Google Scholar]

- Vedalakshmi, R.; Balamurugan, L.; Saraswathy, V.; Kim, S.-H.; Ann, K.Y. Reliability of galvanostatic pulse technique in assessing the corrosion rate of rebar in concrete structures: Laboratory vs. field studies. KSCE J. Civ. Eng. 2010, 14, 867–877. [Google Scholar] [CrossRef]

- ASTM. Standard test method for half-cell potentials of uncoated reinforcing steel in concrete. In American Society of Testing and Materials; ASTM: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Raczkiewicz, W.; Wójcicki, A. Some aspects of the reinforcing steel corrosion level prediction in concrete using electrochemical method. Weld. Technol. Rev. 2017, 89, 11. [Google Scholar] [CrossRef]

- Tworzewski, P.; Raczkiewicz, W.; Czapik, P.; Tworzewska, J. Diagnostics of concrete and steel in elements of an historic reinforced concrete structure. Materials 2021, 14, 306. [Google Scholar] [CrossRef]

- Ghosh, P.; Tran, Q. Correlation between bulk and surface resistivity of concrete. Int. J. Concr. Struct. Mater. 2014, 9, 119–132. [Google Scholar] [CrossRef]

- Raczkiewicz, W.; Kossakowski, P.G. Electrochemical diagnostics of sprayed fiber-reinforced concrete corrosion. Appl. Sci. 2019, 9, 3763. [Google Scholar] [CrossRef]

- Tran, Q.; Ghosh, P.; Lehner, P.; Konečný, P. Determination of time dependent diffusion coefficient aging factor of HPC mixtures. Key Eng. Mater. 2020, 832, 11–20. [Google Scholar] [CrossRef]

- Zhu, F.; Ma, Z.; Zhao, T. Influence of freeze-thaw damage on the steel corrosion and bond-slip behavior in the reinforced concrete. Adv. Mater. Sci. Eng. 2016, 2016, 1–12. [Google Scholar] [CrossRef]

| Group of Specimen | CEM I 42.5 N-MSR/NA | CEM III/A 42, 5 N-LH/HSR/NA | Basalt Grit f 2/8 mm | Basalt Grit f 8/16 mm | Mine Sand | Water | Plasticizer—Adva Flow 440 | Air-Entraining Agent—Darex AEA W (LP) |

|---|---|---|---|---|---|---|---|---|

| C_I_a | 384 | — | 600 | 650 | 680 | 166 | 0.6% | 0.5% |

| C_I_n | — | |||||||

| C_III_a | — | 384 | 0.5% | |||||

| C_III_n | — |

| Criteria for Assessing the Degree of Reinforcement Corrosion Risk 1 | ||||

|---|---|---|---|---|

| Advanced measurements | Corrosion current density, icor (μA/cm2) | <0.5 | not forecasted corrosion activity | |

| 0.5 ÷ 2.0 | irrelevant corrosion activity | |||

| 2.0 ÷ 5.0 | low corrosion activity | |||

| 5.0 ÷ 15.0 | moderate corrosion activity | |||

| Basic measurements | Reinforcement half-cell potential, Est (mV) | >−200 | 5% of corrosion probability | |

| −350 ÷ −200 | 50% of corrosion probability | |||

| <−350 | 95% of corrosion probability | |||

| Concrete cover resistivity, Θ (kΩ·cm) | ≥20 | small corrosion probability | ||

| 10 ÷ 20 | medium corrosion probability | |||

| ≤10 | high corrosion probability | |||

| Corrosion Current Density, icor (μA/cm2) | CEM_I_a | CEM_I_n | CEM_III_a | CEM_III_n | ||||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | |

| Reference measurement | 0.56 | 1.48 | 0.84 | 1.45 | 0.72 | 1.44 | 0.91 | 3.07 |

| Measurement after 120 cycles of freezing and thawing in 3% NaCl solution | 2.59 | 10.19 | 2.82 | 9.87 | 0.82 | 3.86 | 2.51 | 9.72 |

| Reinforcement Half-Cell Potential, Est (mV) | CEM_I_a | CEM_I_n | CEM_III_a | CEM_III_n | ||||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | |

| Reference measurement | −132 | −257 | −6 | −149 | −91 | −189 | −68 | −284 |

| Measurement after 120 cycles of freezing and thawing in 3% NaCl solution | −189 | −341 | −290 | −378 | −129 | −300 | −275 | −521 |

| Concrete Cover Resistivity, Θ (kΩ·cm) | CEM_I_a | CEM_I_n | CEM_III_a | CEM_III_n | ||||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | Min | Max | |

| Reference measurement | 1.2 | 1.7 | 1.1 | 1.3 | 2.4 | 3.9 | 2.9 | 4.6 |

| Measurement after 120 cycles of freezing and thawing in 3% NaCl solution | 1.0 | 1.6 | 0.4 | 0.6 | 2.3 | 3.2 | 1.0 | 3.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Raczkiewicz, W.; Koteš, P.; Konečný, P. Influence of the Type of Cement and the Addition of an Air-Entraining Agent on the Effectiveness of Concrete Cover in the Protection of Reinforcement against Corrosion. Materials 2021, 14, 4657. https://doi.org/10.3390/ma14164657

Raczkiewicz W, Koteš P, Konečný P. Influence of the Type of Cement and the Addition of an Air-Entraining Agent on the Effectiveness of Concrete Cover in the Protection of Reinforcement against Corrosion. Materials. 2021; 14(16):4657. https://doi.org/10.3390/ma14164657

Chicago/Turabian StyleRaczkiewicz, Wioletta, Peter Koteš, and Petr Konečný. 2021. "Influence of the Type of Cement and the Addition of an Air-Entraining Agent on the Effectiveness of Concrete Cover in the Protection of Reinforcement against Corrosion" Materials 14, no. 16: 4657. https://doi.org/10.3390/ma14164657

APA StyleRaczkiewicz, W., Koteš, P., & Konečný, P. (2021). Influence of the Type of Cement and the Addition of an Air-Entraining Agent on the Effectiveness of Concrete Cover in the Protection of Reinforcement against Corrosion. Materials, 14(16), 4657. https://doi.org/10.3390/ma14164657