Bio-Based Packaging Materials Containing Substances Derived from Coffee and Tea Plants

Abstract

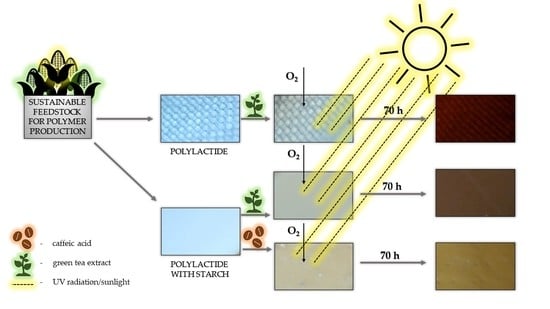

:1. Introduction

2. Materials and Methods

2.1. Components

2.2. Composites Preparation

2.3. Differential Scanning Calorimetry (DSC)

2.4. Thermogravimetric Analysis (TGA)

2.5. Dynamic Mechnical Analysis (DMA)

2.6. Colour Measurements

2.7. Vicat Softening Temperature

2.8. Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR-FTIR) Analysis

2.9. UV Exposure

2.10. Weathering Aging

3. Results and Discussion

3.1. Differential Scanning Calorimetry (DSC) Curves Interpretation

3.2. Thermogravimetric Analysis (TGA) Results of Selected Biomaterials with Substances of Plant Origin

3.3. Dynamic Mechanical Properities of PLA and PLA Containing Starch (sPLA) with Green Tea Extract and Caffeic Acid before and after UV Aging and Weathering

3.4. Colour Measurement Results Analysis of Polylactide and Polylctide with Starch Materials before and after Fifferent Types of Aging

3.5. Vicat Softening Temperature of Polylactide (PLA) and Starch-Containing Polylactide (sPLA) Materials before and after Different Types of Aging

3.6. ATR FT-IR Spectra Analysis of Polylactide (PLA) and Starch-Containing Polylactide (sPLA) Materials Enriched with Substances of Plant Origin before and after UV Exposure and Weathering

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Konstantoglou, A.; Folinas, D.; Fotiadis, T. Investigating Food Packaging Elements from a Consumer’s Perspective. Foods 2020, 9, 1097. [Google Scholar] [CrossRef] [PubMed]

- Grundey, D. Functionality of product packaging: Surveying consumers’ attitude towards selected cosmetic brands. Econ. Sociol. 2010, 3, 87–103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Szendiuch, I. Development in electronic Packaging-Moving to 3D system configuration. Radioengineering 2011, 20, 214–220. [Google Scholar]

- Mao, S. Research on Packaging Mode of Clothing Brand. In Proceedings of the 2nd International Conference on Arts, Design and Contemporary Education, Moscow, Russia, 23–25 May 2016; pp. 774–776. [Google Scholar]

- Regattieri, A.; Santarelli, A.R.A.G. The Important Role of Packaging in Operations Management; IntechOpen: London, UK, 2013; pp. 183–220. [Google Scholar]

- Wyrwa, J.; Barska, A. Packaging as a Source of Information about Food Products. Procedia Eng. 2017, 182, 770–779. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food packaging-Roles, materials, and environmental issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef] [PubMed]

- Nosáľová, M.; Loučanová, E.; Parobek, J. Perception of Packaging Functions and the Interest in Intelligent and Active Packaging. Probl. Agric. Econ. 2018, 357, 141–152. [Google Scholar] [CrossRef]

- Yam, K.L.; Takhistov, P.T.; Miltz, J. Intelligent Packaging:Concepts and Applications. J. Food Sci. 2005, 70, 1–10. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the Environmental Sustainability of Food Packaging: An Extended Life Cycle Assessment including Packaging-Related Food Losses and Waste and Circularity Assessment. Susteinability 2019, 11, 925. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Parada, L.; Mayuet, P.F.; Gámez, A.J. Custom Design of Packaging through Advanced Technologies: A Case Study Applied to Apples. Materials 2019, 12, 467. [Google Scholar] [CrossRef] [Green Version]

- Müller, P.; Schmid, M. Intelligent Packaging in the Food Sector: A Brief Overview. Foods 2019, 8, 16. [Google Scholar] [CrossRef] [Green Version]

- PlasticsEurope. Available online: https://www.plasticseurope.org/pl/resources/publications/1804-plastics-facts-2019 (accessed on 19 August 2020).

- Narancic, T.; Cerrone, F.; Beagan, N.; O’Connor, K.E. Recent advances in bioplastics: Application and biodegradation. Polymers 2020, 12, 920. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications-A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Delgado-Aguilar, M.; Puig, R.; Sazdovski, I.; Fullana-i-Palmer, P. Polylactic Acid/Polycaprolactone Blends: On the Path to Circular Economy, Substituting Single-Use Commodity Plastic Products. Materials 2020, 13, 2655. [Google Scholar] [CrossRef]

- Jem, K.J.; Tan, B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv. Ind. Eng. Polym. Res. 2020, 3, 60–70. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and Its Blends with Poly(butylene succinate) (PBS): A Brief Review. Polymers 2020, 11, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. Res. 2020, 3, 8–18. [Google Scholar] [CrossRef]

- Muller, J.; González-Martínez, C.; Chiralt, A. Combination Of Poly (lactic) acid and starch for biodegradable food packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef]

- Awale, R.J.; Ali, F.B.; Azmi, A.S.; Illi, N.; Puad, M.; Anuar, H.; Hassan, A. Enhanced Flexibility of Biodegradable Polylactic Acid/Starch Blends Using Epoxidized Palm Oil as Plasticizer. Polymers 2018, 10, 997. [Google Scholar] [CrossRef] [Green Version]

- Sikora, J.W.; Majewski, Ł.; Puszka, A. Modern Biodegradable Plastics—Processing and Properties: Part I. Materials 2020, 13, 1986. [Google Scholar] [CrossRef]

- Atli, A.; Candelier, K.; Alteyrac, J. Mechanical, Thermal and Biodegradable Properties of Bioplast-Spruce Green Wood Polymer Composites. Int. J. Mater. Metall. Eng. 2018, 12, 231–243. [Google Scholar]

- Santos, C.; Mateus, A.; Mendes, A.; Malça, C. Processing and Characterization of Thin Wall and Biodegradable Injected Pots. Procedia Manuf. 2017, 12, 96–105. [Google Scholar] [CrossRef]

- Iordanskii, A. Bio-Based and Biodegradable Plastics: From Passive Barrier to Active Packaging Behavior. Polymers 2020, 12, 1537. [Google Scholar] [CrossRef] [PubMed]

- Janjarasskul, T.; Suppakul, P. Active and intelligent packaging: The indication of quality and safety. Crit. Rev. Food Sci. Nutr. 2018, 58, 808–831. [Google Scholar] [CrossRef]

- Dobrucka, R.; Cierpiszewski, R. Active and Intelligent Packaging Food–Research and Development—A Review. Pol. J. Food Nutr. Sci. 2014, 64, 7–15. [Google Scholar] [CrossRef] [Green Version]

- Biji, K.B.; Ravishankar, C.N.; Mohan, C.O. Smart packaging systems for food applications: A review. J. Food Sci. Technol. 2015, 52, 6125–6135. [Google Scholar] [CrossRef]

- Yousefi, H.; Su, H.M.; Imani, S.M.; Alkhaldi, K.; Filipe, C.D.M.; Didar, T.F. Intelligent Food Packaging: A Review of Smart Sensing Technologies for Monitoring Food Quality. ACS Sens. 2019, 4, 808–821. [Google Scholar] [CrossRef]

- Park, Y.W.; Kim, S.M.; Lee, J.Y.; Jang, W. Application of biosensors in smart packaging. Mol. Cell. Toxicol. 2015, 11, 277–285. [Google Scholar] [CrossRef]

- Meng, X.; Kim, S.; Puligundla, P.; Ko, S. Carbon Dioxide and Oxygen Gas Sensors-Possible Application for Monitoring Quality, Freshness, and Safety of Agricultural and Food Products with Emphasis on Importance of Analytical Signals and Their Transformation. J. Korean Soc. Appl. Biol. Chem. 2014, 57, 723–733. [Google Scholar] [CrossRef]

- Mustafa, F.; Andreescu, S. Chemical and Biological Sensors for Food-Quality Monitoring and Smart Packaging. Foods 2018, 7, 168. [Google Scholar] [CrossRef] [Green Version]

- Mohebi, E.; Marquez, L. Intelligent packaging in meat industry: An overview. J. Optimiz. Theory App. 2015, 52, 3947–3964. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Oprea, O.C.; Ficai, A.; Andronescu, E. Smart Food Packaging Designed by Nanotechnological and Drug Delivery Approaches. Coatings 2020, 10, 806. [Google Scholar] [CrossRef]

- Kirschweng, B.; Tátraaljai, D.; Földes, E.; Pukánszky, B. Natural antioxidants as stabilizers for polymers. Polym. Degrad. Stab. 2017, 145, 25–40. [Google Scholar] [CrossRef] [Green Version]

- Bridson, J.H.; Kaur, J.; Zhang, Z.; Donaldson, L.; Fernyhough, A. Polymeric flavonoids processed with co-polymers as UV and thermal stabilisers for polyethylene films. Polym. Degrad. Stab. 2015, 122, 18–24. [Google Scholar] [CrossRef]

- Samper, M.D.; Fages, E.; Fenollar, O.; Boronat, T.; Balart, R. The Potential of Flavonoids as Natural Antioxidants and UV Light Stabilizers for Polypropylene. J. Appl. Polym. Sci. 2013, 1707–1716. [Google Scholar] [CrossRef]

- Marli, S.; Nachtigall, B.; Stoll, L.; Rech, R.; Hickmann, S. Carotenoids extracts as natural colorants in poly (lactic acid) films. J. Appl. Polym. Sci. 2018, 135, 46585. [Google Scholar] [CrossRef]

- Masek, A. Flavonoids as Natural Stabilizers and Color Indicators of Ageing for Polymeric Materials. Polymers 2015, 1125–1144. [Google Scholar] [CrossRef]

- Masek, A.; Latos, M.; Piotrowska, M.; Zaborski, M. The potential of quercetin as an e ff ective natural antioxidant and indicator for packaging materials. Food Packag. Shelf Life 2018, 16, 51–58. [Google Scholar] [CrossRef]

- Munteanu, S.B.; Vasile, C. Vegetable additives in food packaging polymeric materials. Polymers. 2020, 12, 28. [Google Scholar] [CrossRef] [Green Version]

- Masek, A.; Chrzescijanska, E.; Latos, M.; Zaborski, M.; Podsedek, A. Antioxidant and antiradical properties of green tea extract compounds. Int. J. Electrochem. Sci. 2017, 12, 6600–6610. [Google Scholar] [CrossRef]

- Nutr, J.C.B.; Mori, H.; Iwahashi, H. Antioxidant Activity of Caffeic Acid through a Novel Mechanism under UVA Irradiation. J. Clin. Biochem. Nutr. 2009, 45, 49–55. [Google Scholar]

- Shi, M.; Nie, Y.; Zheng, X.Q.; Lu, J.L.; Liang, Y.R.; Ye, J.H. Ultraviolet B (UVB) photosensitivities of tea catechins and the relevant chemical conversions. Molecules 2016, 21, 1345. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luzi, F.; Torre, L.; Puglia, D. Antioxidant Packaging Films Based on Ethylene Vinyl Alcohol Copolymer (EVOH) and Caffeic Acid. Molecules 2020, 25, 3953. [Google Scholar] [CrossRef] [PubMed]

- Kasmi, S.; Gallos, A.; Beaugrand, J.; Paës, G.; Allais, F. Ferulic acid derivatives used as biobased powders for a convenient plasticization of polylactic acid in continuous hot-melt process. Eur. Polym. J. 2019, 110, 293–300. [Google Scholar] [CrossRef]

- Gülçin, I. Antioxidant activity of caffeic acid (3,4-dihydroxycinnamic acid). Toxicology 2006, 217, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Agustin-Salazar, S.; Gamez-Meza, N.; Medina-Juárez, L.Á.; Malinconico, M.; Cerruti, P. Stabilization of Polylactic Acid and Polyethylene with Nutshell Extract: Efficiency Assessment and Economic Evaluation. ACS Sustain. Chem. Eng. 2017, 5, 4607–4618. [Google Scholar] [CrossRef]

- Hernández-Alamilla, M.; Valadez-Gonzalez, A. The effect of two commercial melt strength enhancer additives on the thermal, rheological and morphological properties of polylactide. J Polym. Eng. 2016, 36, 31–41. [Google Scholar] [CrossRef]

- Stepczyńska, M. Wpływ promieniowania UV-VIS na własściwosści termomechaniczne i structuré barwionej folii PLA. Polymers 2015, 60, 385–390. [Google Scholar] [CrossRef]

- Kachel-Jakubowska, M.; Matwijczuk, A.; Gagoś, M. Analysis of the physicochemical properties of post-manufacturing waste derived from production of methyl esters from rapeseed oil. Int. Agrophys. 2017, 31, 175–182. [Google Scholar] [CrossRef]

- Vyavahare, O.; Ng, D.; Hsu, S.L. Analysis of structural rearrangements of poly (lactic acid) in the presence of water. J. Phys. Chem. B 2014, 118, 4185–4193. [Google Scholar] [CrossRef]

- Pop, M.A.; Croitoru, C.; Bedő, T.; Geaman, V.; Radomir, I.; Coșnița, M.; Zaharia, S.M.; Chicoș, L.A.; Miloșan, I. Structural changes during 3D printing of bioderived and synthetic thermoplastic materials. J. Appl. Polym. Sci. 2019, 136, 47382. [Google Scholar] [CrossRef]

- Riba, J.R.; Cailloux, J.; Cantero, R.; Canals, T.; Maspoch, M.L. Multivariable methods applied to FTIR: A powerful technique to highlight architectural changes in poly (lactic acid). Polym. Test. 2018, 65, 264–269. [Google Scholar] [CrossRef]

- Yuniarto, K.; Purwanto, Y.A.; Purwanto, S.; Welt, B.A.; Purwadaria, H.K.; Sunarti, T.C. Infrared and Raman studies on polylactide acid and polyethylene glycol-400 blend. AIP Conf. Proc. 2016, 1725. [Google Scholar] [CrossRef] [Green Version]

| Type of Composite | Description |

|---|---|

| PLA | Polylactide (Ingeo™ Biopolymer 4043D) |

| PLA/GTE | Polylactide (Ingeo™ Biopolymer 4043D) mixed with green tea extract (polyphenon 60) (mass ratio: 3 parts of antioxidant per 100 parts of polymer pellet) |

| PLA/CA | Polylactide (Ingeo™ Biopolymer 4043D) mixed with caffeic acid (mass ratio: 3 parts of antioxidant per 100 parts of polymer pellet) |

| sPLA | Polylactide containing starch (Bioplast GS 2189) |

| sPLA/GTE | Polylactide containing starch (Bioplast GS 2189) mixed with green tea extract (polyphenon 60) (mass ratio: 3 parts of antioxidant per 100 parts of polymer pellet) |

| sPLA/CA | Polylactide containing starch (Bioplast GS 2189) mixed with caffeic acid (mass ratio: 3 parts of antioxidant per 100 parts of polymer pellet) |

| Sample | Tg [K] | ΔHcc [J/g] | Tcc [K] | ΔHm [J/g] | Tm [K] | ΔHo [J/g] | To [K] |

|---|---|---|---|---|---|---|---|

| PLA | 335 | 4.7 | 409 | 3.1 | 424 | 22.6 | 500 |

| PLA/GTE | 335 | 0.6 | 408 | 0.4 | 424 | 4.5 | 546 |

| PLA/CA | 334 | 5.3 | 404 | 4.92 | 423 | 2.2 | 552 |

| sPLA | 331 | 16.8 | 377 | 19.1 | 432 | 17.7 | 486 |

| sPLA/GTE | 333 | 18.4 | 380 | 19.4 | 430 | 5.8 | 549 |

| sPLA/CA | 331 | 16.6 | 376 | 18.2 | 425 | 1.2 | 556 |

| Sample | T5% [K] | T10% [K] | T20% [K] | T40% [K] | T80% [K] | T100% [K] |

|---|---|---|---|---|---|---|

| PLA | 613 | 621 | 630 | 639 | 653 | 867 |

| PLA/GTE | 609 | 618 | 628 | 639 | 653 | 837 |

| PLA/CA | 608 | 618 | 628 | 638 | 651 | 780 |

| sPLA | 561 | 574 | 593 | 615 | 769 | - |

| sPLA/GTE | 578 | 590 | 602 | 619 | 751 | - |

| sPLA/CA | 551 | 568 | 589 | 612 | 742 | - |

| Wavenumber [cm−1] | Assignments | Ref. |

|---|---|---|

| 3300 | –OH stretching mode (from absorbed water) | [53] |

| 2998–2847 | –C–H stretching modes | [54] |

| 1745–1757 | –C=O stretching band | [53] |

| 1650 | H–O–H bending (from absorbed water) | [53] |

| 1453 | –CH3 asymmetrical bending | [55] |

| 1360, 1382 | –CH symmetrical and asymmetrical bending | [55] |

| 1300 | –CH + –C–O–C- | [56] |

| 1268 | –C=O bending | [55] |

| 1184, 1130, 1093 | –C–O–C asymmetrical streching | [55] |

| 1045 | –C–CH3 streching | [55] |

| 956 | –CH3 rocking mode | [56] |

| 868 | C–C (amorphous phase) | [54] |

| 801 | –C–O–C symmetrical streching vibration- | [52] |

| 756 | Crystalline phase | [55] |

| 695 | –C=O | [56] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olejnik, O.; Masek, A. Bio-Based Packaging Materials Containing Substances Derived from Coffee and Tea Plants. Materials 2020, 13, 5719. https://doi.org/10.3390/ma13245719

Olejnik O, Masek A. Bio-Based Packaging Materials Containing Substances Derived from Coffee and Tea Plants. Materials. 2020; 13(24):5719. https://doi.org/10.3390/ma13245719

Chicago/Turabian StyleOlejnik, Olga, and Anna Masek. 2020. "Bio-Based Packaging Materials Containing Substances Derived from Coffee and Tea Plants" Materials 13, no. 24: 5719. https://doi.org/10.3390/ma13245719