Study on the Deterioration of Concrete under Dry–Wet Cycle and Sulfate Attack

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. The Mix Ratio of Concrete

2.3. Experimental Design

2.3.1. The Erosion Environment

- (1)

- Immerse the cured sample in sodium sulfate solution for 15 h at a temperature of 25 °C.

- (2)

- Discharge the solution immediately after soaking and then air dry for 1 h.

- (3)

- Dry the sample at a temperature of 80 °C for 6 h.

- (4)

- After that, the samples were cooled by air for 1.5 h, and finally cooled for 0.5 h, with the cooling temperature of 25 °C.

2.3.2. Mechanical Test

2.3.3. Industrial CT test

2.3.4. Nuclear Magnetic Resonance Test

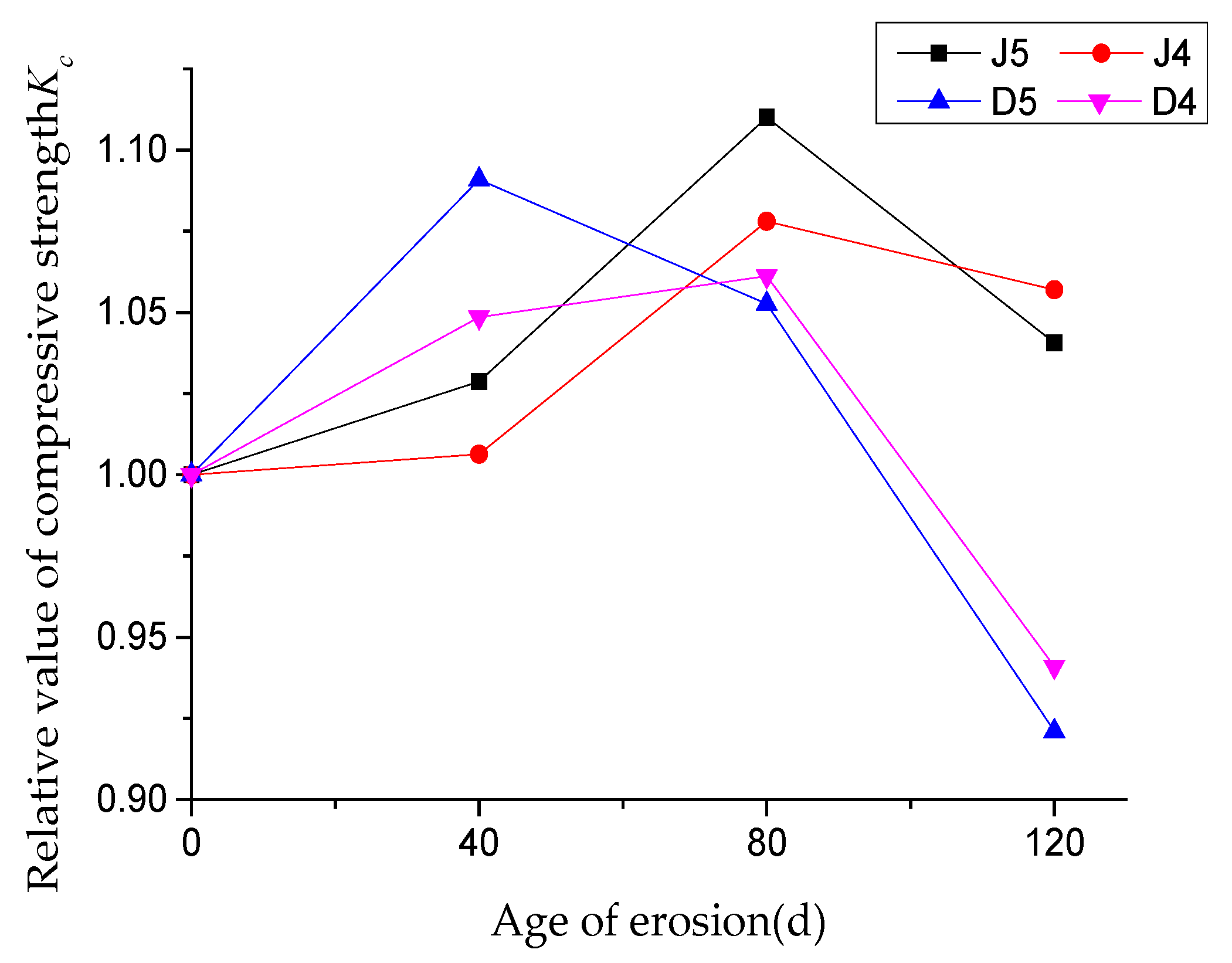

3. Test Results and Analysis of Compressive Strength

4. Analysis on Pore Development in Concrete

4.1. ICT Results of Concrete under the Action of Dry–Wet Cycles and Sulfate Attack

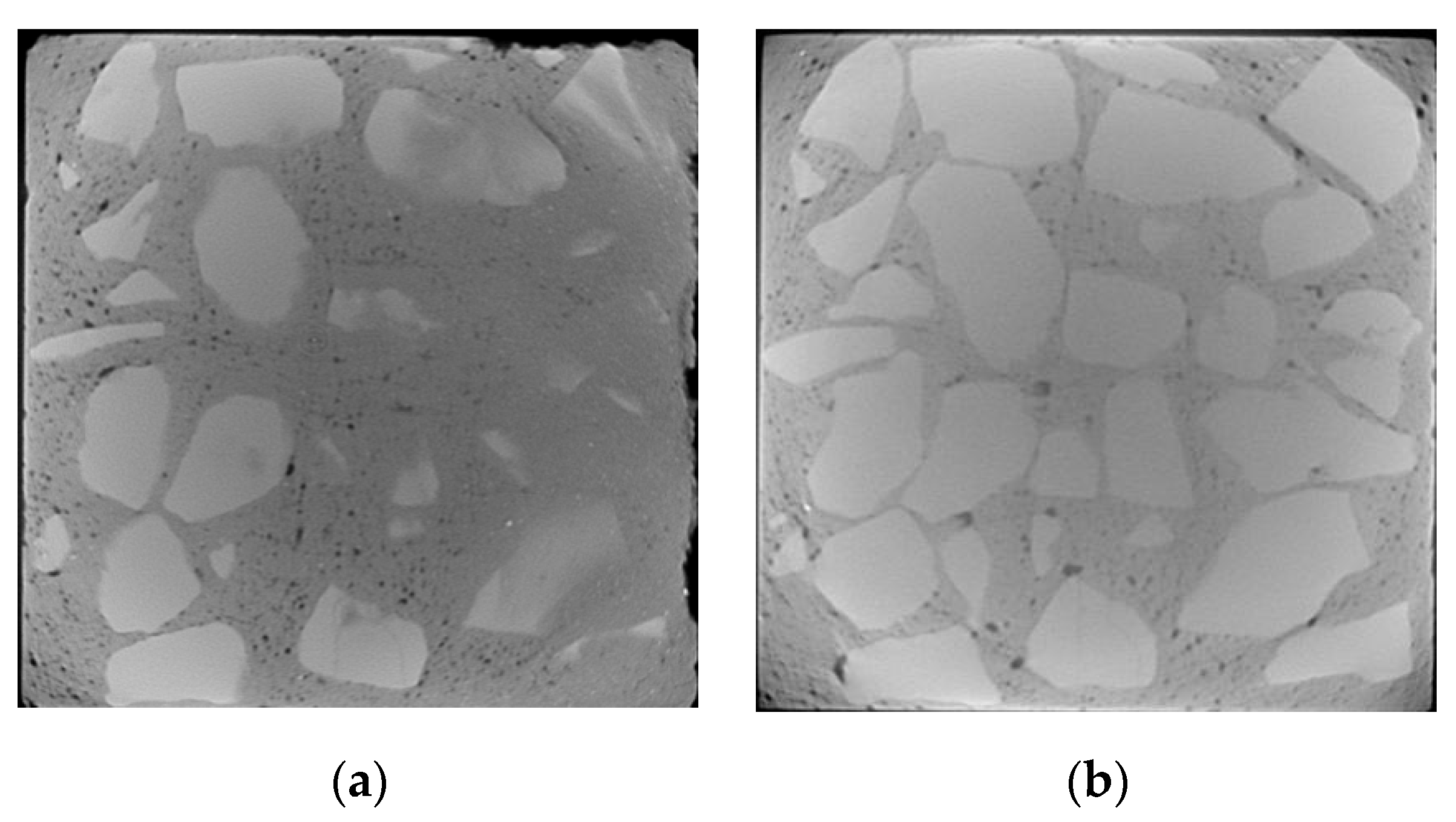

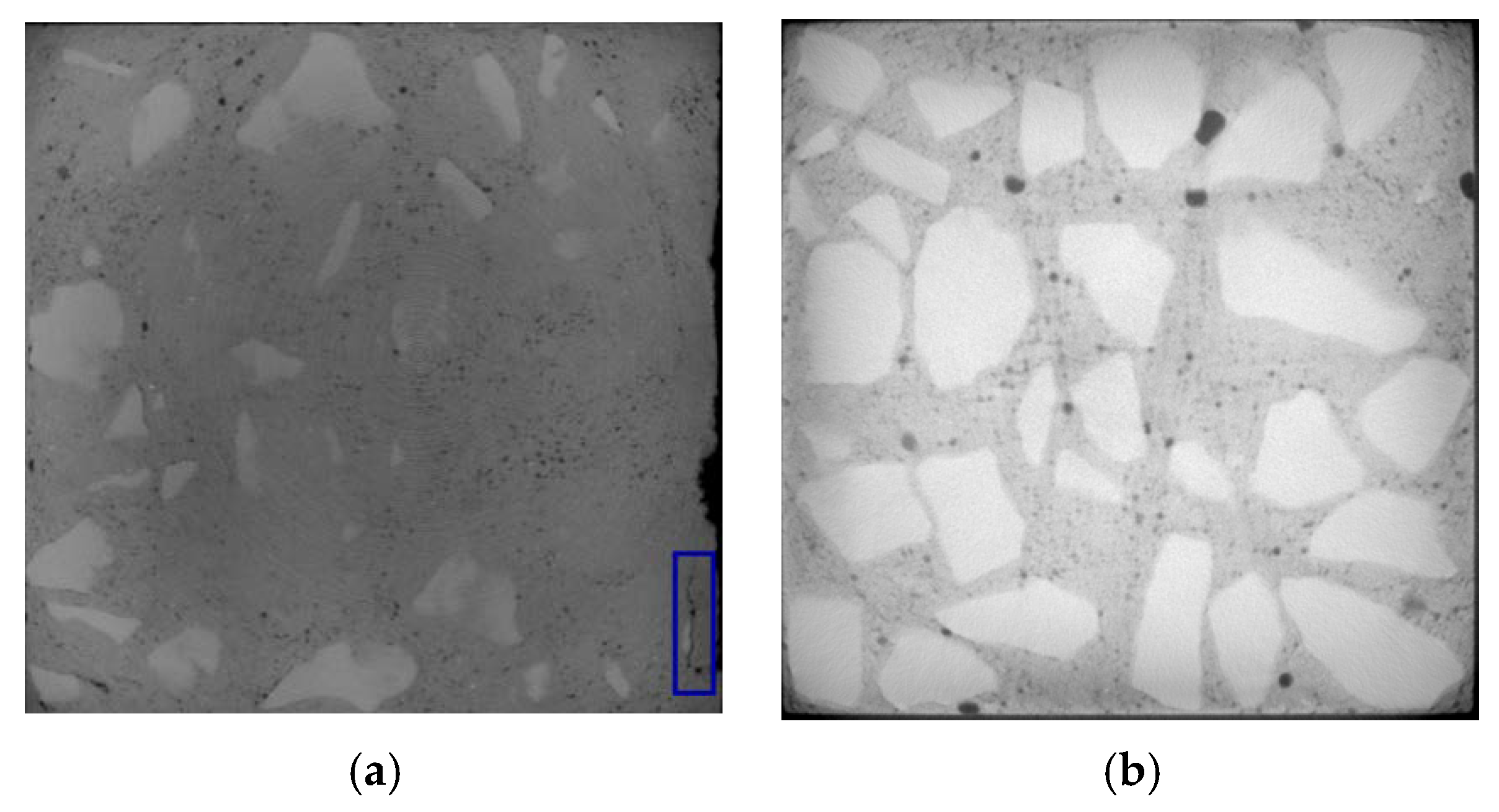

4.1.1. Pore Characteristics of Concrete

4.1.2. Analysis of Crack Growth in Concrete

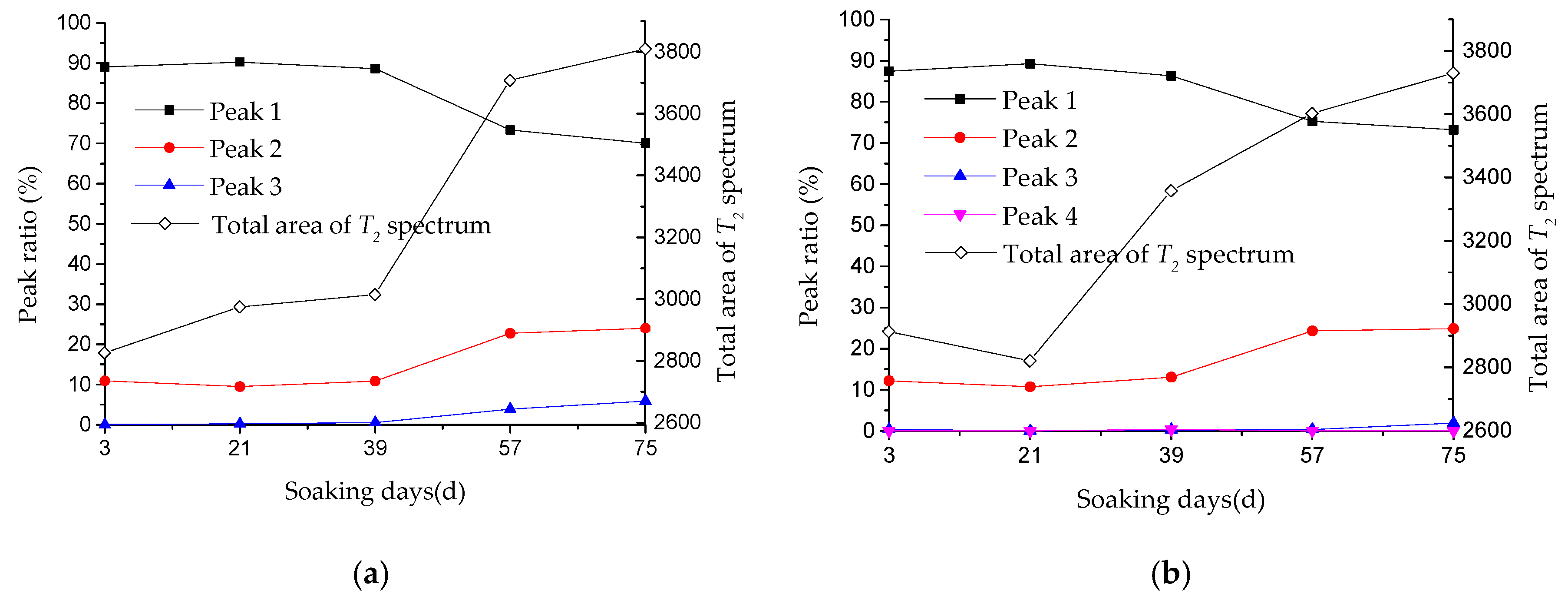

4.2. NMR Test Results of Concrete Soaked in Na2SO4 Solution at Room Temperature

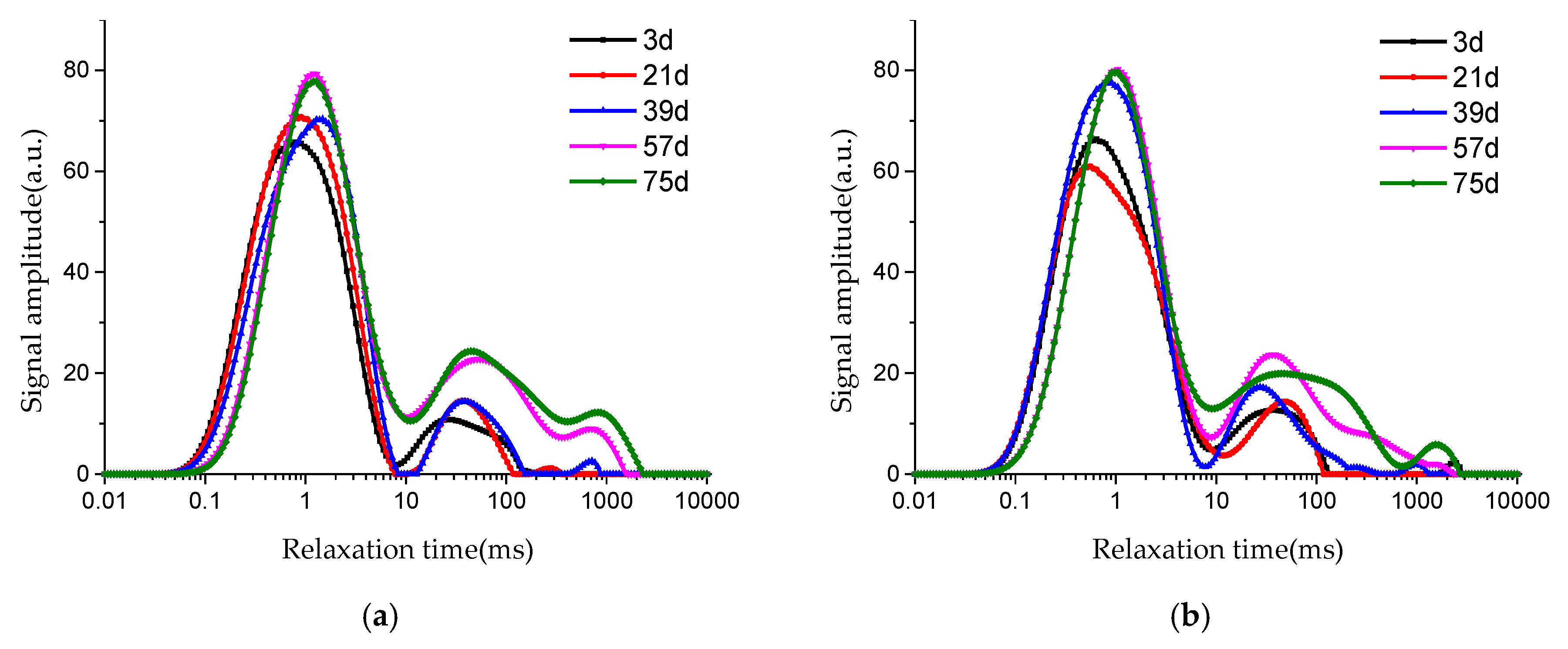

4.2.1. T2 Spectrum Distribution of Pore Fluid

4.2.2. T2 Spectrum Area of Pore Fluid

5. Conclusions

- (1)

- Under the two erosion environments of group D and group J, the compressive strength of concrete shows the similar trend of first increasing and then decreasing, and the dry–wet cycles accelerate sulfate corrosion.

- (2)

- According to ICT results, the number proportion of pores within the range of 0~0.01 mm3 in group D accounts for the most, which increases first and then decreases with the increase of dry–wet cycles. In the early erosion, larger pores in concrete are filled with erosion products and develop into small pores. In the later stage of erosion, the proportion of small pores decreases, while the proportion of larger pores increases, and cracks appear inside concrete.

- (3)

- After 80 dry–wet cycles, obvious cracks appear on the surface and inner layers of D5 with larger water cement ratio. Cracks on the surface layer of concrete, mainly distributed on the edge of concrete. From the surface layer to inner layer, the number of cracks gradually decreases.

- (4)

- Under soaking and erosion of Na2SO4 solution, the T2 spectrum distribution of pore fluid for group J is dominated by peak 1, and the main peak is much higher than the sub-peak, which indicates that the proportion of smaller pore fluid in concrete is in the majority. With the increase of soaking time in Na2SO4 solution, the T2 spectrum distribution curve gradually moves toward the larger pore size, and the signal intensity of larger pores generally shows an increasing trend.

Author Contributions

Funding

Conflicts of Interest

References

- Kim, I.-S.; Choi, S.Y.; Yang, E.-I. Evaluation of durability of concrete substituted heavyweight waste glass as fine aggregate. Constr. Build. Mater. 2018, 184, 269–277. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Al-Kheetan, M.; Ewens, P.; Wang, T.; Zhuang, J. Investigation of the interfacial bonding between flax/wool twine and various cementitious matrices in mortar composites. Constr. Build. Mater. 2020, 239, 117833. [Google Scholar] [CrossRef]

- Ostrowski, K.; Sadowski, Ł.; Stefaniuk, D.; Wałach, D.; Gawenda, T.; Oleksik, K.; Usydus, I. The Effect of the Morphology of Coarse Aggregate on the Properties of Self-Compacting High-Performance Fibre-Reinforced Concrete. Materials 2018, 11, 1372. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Kheetan, M.J.; Rahman, M.M.; Ghaffar, S.H.; Al-Tarawneh, M.; Jweihan, Y.S. Comprehensive investigation of the long-term performance of internally integrated concrete pavement with sodium acetate. Results Eng. 2020, 6, 100110. [Google Scholar] [CrossRef]

- Cattaneo, S.; Muciaccia, G. Adhesive anchors in high performance concrete. Mater. Struct. 2015, 49, 2689–2700. [Google Scholar] [CrossRef]

- Liu, T.; Zou, D.; Teng, J.; Yan, G. The influence of sulfate attack on the dynamic properties of concrete column. Constr. Build. Mater. 2012, 28, 201–207. [Google Scholar] [CrossRef]

- Talero, R. Performance of metakaolin and Portland cements in ettringite formation as determined by ASTM C 452-68: Kinetic and morphological differences. Cem. Concr. Res. 2005, 35, 1269–1284. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, L.-M.; Guo, J.-J.; Liu, W.-L.; Chen, H.-L. Mechanical Properties and Service Life Prediction of Modified Concrete Attacked by Sulfate Corrosion. Adv. Civ. Eng. 2018, 2018, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Al-Kheetan, M.J.; Rahman, M.M.; Balakrishna, M.N.; Chamberlain, D.A.; Rahman, M.; Muniswamappa, B.N. Performance enhancement of self-compacting concrete in saline environment by hydrophobic surface protection. Can. J. Civ. Eng. 2019, 46, 677–686. [Google Scholar] [CrossRef]

- Liu, P.; Chen, Y.; Yu, Z.; Lu, Z. Effect of sulfate solution concentration on the deterioration mechanism and physical properties of concrete. Constr. Build. Mater. 2019, 227, 116641. [Google Scholar] [CrossRef]

- Yin, G.-J.; Zuo, X.-B.; Tang, Y.-J.; Ayinde, O.; Wang, J.-L. Numerical simulation on time-dependent mechanical behavior of concrete under coupled axial loading and sulfate attack. Ocean Eng. 2017, 142, 115–124. [Google Scholar] [CrossRef]

- Nehdi, M.; Suleiman, A.; Soliman, A. Investigation of concrete exposed to dual sulfate attack. Cem. Concr. Res. 2014, 64, 42–53. [Google Scholar] [CrossRef]

- Gao, J.; Yu, Z.; Song, L.; Wang, T.; Sun, W. Durability of concrete exposed to sulfate attack under flexural loading and drying–wetting cycles. Constr. Build. Mater. 2013, 39, 33–38. [Google Scholar] [CrossRef]

- Li, K.; Li, C.; Chen, Z. Influential depth of moisture transport in concrete subject to drying–wetting cycles. Cem. Concr. Compos. 2009, 31, 693–698. [Google Scholar] [CrossRef]

- Santhanam, M. Studies on Sulfate Attack: Mechanisms, Test Method, and Modeling. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2001. [Google Scholar]

- Li, T.; Zhang, B. Stochastic Dynamic Model of Sulfate Corrosion Reactions in Concrete Materials considering the Effects of Colored Gaussian Noises. Complexity 2019, 2019, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.K.; Yang, Z.-Y.; Zhang, P.; Wang, Y.; Guo, J.; Guo, T. Effect of Dry–Wet Ratio on Properties of Concrete Under Sulfate Attack. Materials 2019, 12, 2755. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; You, Z.; Yang, X.; Wang, H. Macro-micro degradation process of fly ash concrete under alternation of freeze-thaw cycles subjected to sulfate and carbonation. Constr. Build. Mater. 2018, 181, 369–380. [Google Scholar] [CrossRef]

- Jaya, R.; Abu Bakar, B.H.; Johari, M.A.M.; Ibrahim, M.H.W.; Hainin, M.R.; Jayanti, D.S. Strength and microstructure analysis of concrete containing rice husk ash under seawater attack by wetting and drying cycles. Adv. Cem. Res. 2014, 26, 145–154. [Google Scholar] [CrossRef]

- Sobhan, K.; Gonzalez, L.; Reddy, D.V. Durability of a pavement foundation made from recycled aggregate concrete subjected to cyclic wet–dry exposure and fatigue loading. Mater. Struct. 2015, 49, 2271–2284. [Google Scholar] [CrossRef]

- Nehdi, M.; Hayek, M. Behavior of blended cement mortars exposed to sulfate solutions cycling in relative humidity. Cem. Concr. Res. 2005, 35, 731–742. [Google Scholar] [CrossRef]

- Smallwood, I.; Wild, S.; Morgan, E. The resistance of metakaolin (MK)–Portland cement (PC) concrete to the thaumasite-type of sulfate attack (TSA)––Programme of research and preliminary results. Cem. Concr. Compos. 2003, 25, 931–938. [Google Scholar] [CrossRef]

- Tang, Z.; Li, W.; Ke, G.; Zhou, J.L.; Tam, V.W. Sulfate attack resistance of sustainable concrete incorporating various industrial solid wastes. J. Clean. Prod. 2019, 218, 810–822. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y.; Zhang, W.; She, W. Study on sulfate resistance of concrete with initial damage under drying–wetting cycles. J. Sustain. Cem. Mater. 2018, 7, 311–322. [Google Scholar] [CrossRef]

- Yao, J.; Chen, J.; Lu, C. Entropy evolution during crack propagation in concrete under sulfate attack. Constr. Build. Mater. 2019, 209, 492–498. [Google Scholar] [CrossRef]

- Zhao, G.; Li, J.; Shi, M.; Fan, H.; Cui, J.; Xie, F. Degradation mechanisms of cast-in-situ concrete subjected to internal-external combined sulfate attack. Constr. Build. Mater. 2020, 248, 118683. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, J.; Tang, L.; Li, X. Resistance of concrete against combined attack of chloride and sulfate under drying–wetting cycles. Constr. Build. Mater. 2016, 106, 650–658. [Google Scholar] [CrossRef]

- Haufe, J.; Vollpracht, A. Tensile strength of concrete exposed to sulfate attack. Cem. Concr. Res. 2019, 116, 81–88. [Google Scholar] [CrossRef]

- Zhang, B. The Failure Process of Concrete in Different Erosion Environment Based on Industrial CT Technology. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2013. (In Chinese). [Google Scholar]

- Taylor, H. Cement Chemistry, 2nd ed.; Thomas Telford Ltd.: London, UK, 1997. [Google Scholar]

| SiO2 | Fe2O3 | Al2O3 | CaO | MgO | SO3 | Alkali | Loss on Ignition |

|---|---|---|---|---|---|---|---|

| 22.81 | 3.36 | 5.62 | 61.43 | 1.35 | 2.17 | 0.54 | 2.60 |

| Density (g/cm3) | Specific Surface Area (m2/kg) | Fineness (%) | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3 Days | 28 Days | 3 Days | 28 Days | |||

| 3.10 | 360 | 3.8 | 125 | 180 | 24.0 | 50.5 | 4.7 | 8.3 |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O, K2O |

|---|---|---|---|---|---|

| 49.02 | 31.56 | 6.97 | 4.88 | 0.83 | 1.78 |

| Fineness (45μm) | Water Requirement Ratio | Loss on Ignition | Water Content | SO3 |

|---|---|---|---|---|

| 18 | 94 | 3.65 | 0.3 | 1.2 |

| Appearance | Hydroxyl | PH | Moisture | Solubility |

|---|---|---|---|---|

| Light yellow to white flake | 22~27 | 5.0~7.0 | ≤0.5 | Soluble in water and various organic substances |

| W/C | W/CM | Cement (kg/m3) | Fly ash (kg/m3) | Sand (kg/m3) | Coarse Aggregate (kg/m3) | Water (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|

| 0.50 | 0.402 | 330 | 80 | 806 | 1026 | 165 | 7.6 |

| 0.45 | 0.375 | 365 | 75 | 776 | 1031 | 165 | 8.1 |

| Label | 0d (MPa) | 40d (MPa) | 80d (MPa) | 120d (MPa) |

|---|---|---|---|---|

| J5 | 41.8 ± 1.1 | 43.0 ± 1.3 | 46.4 ± 3.6 | 43.5 ± 1.8 |

| J4 | 47.4 ± 0.8 | 47.7 ± 0.4 | 51.1 ± 1.4 | 50.1 ± 3.0 |

| D5 | 41.8 ± 1.1 | 45.6 ± 1.9 | 44.0 ± 4.8 | 38.5 ± 1.2 |

| D4 | 47.4 ± 0.8 | 49.7 ± 1.2 | 50.3 ± 3.2 | 44.6 ± 1.9 |

| Label | Soak Days (d) | Total Area of T2 Spectrum | The Proportion of Peaks (%) | |||

|---|---|---|---|---|---|---|

| Peak 1 | Peak 2 | Peak 3 | Peak 4 | |||

| J5 | 3 | 2826.39 | 89.09 | 10.91 | \ | \ |

| 21 | 2974.90 | 90.27 | 9.50 | 0.24 | \ | |

| 39 | 3014.17 | 88.64 | 10.85 | 0.52 | \ | |

| 57 | 3708.11 | 73.36 | 22.78 | 3.87 | \ | |

| 75 | 3809.68 | 70.09 | 24.04 | 5.87 | \ | |

| J4 | 3 | 2913.03 | 87.45 | 12.16 | 0.38 | \ |

| 21 | 2820.78 | 89.25 | 10.75 | \ | \ | |

| 39 | 3357.62 | 86.29 | 13.08 | 0.26 | 0.38 | |

| 57 | 3602.63 | 75.31 | 24.31 | 0.35 | 0.03 | |

| 75 | 3729.39 | 73.21 | 24.87 | 1.92 | \ | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Zhang, T.; Luo, T.; Zhou, M.; Zhang, K.; Ma, W. Study on the Deterioration of Concrete under Dry–Wet Cycle and Sulfate Attack. Materials 2020, 13, 4095. https://doi.org/10.3390/ma13184095

Liu F, Zhang T, Luo T, Zhou M, Zhang K, Ma W. Study on the Deterioration of Concrete under Dry–Wet Cycle and Sulfate Attack. Materials. 2020; 13(18):4095. https://doi.org/10.3390/ma13184095

Chicago/Turabian StyleLiu, Fang, Tonghuan Zhang, Tao Luo, Mengzhen Zhou, Kunkun Zhang, and Weiwei Ma. 2020. "Study on the Deterioration of Concrete under Dry–Wet Cycle and Sulfate Attack" Materials 13, no. 18: 4095. https://doi.org/10.3390/ma13184095

APA StyleLiu, F., Zhang, T., Luo, T., Zhou, M., Zhang, K., & Ma, W. (2020). Study on the Deterioration of Concrete under Dry–Wet Cycle and Sulfate Attack. Materials, 13(18), 4095. https://doi.org/10.3390/ma13184095