Microstructure Evolution and Mechanical Properties of AZ80 Mg Alloy during Annular Channel Angular Extrusion Process and Heat Treatment

Abstract

:1. Introduction

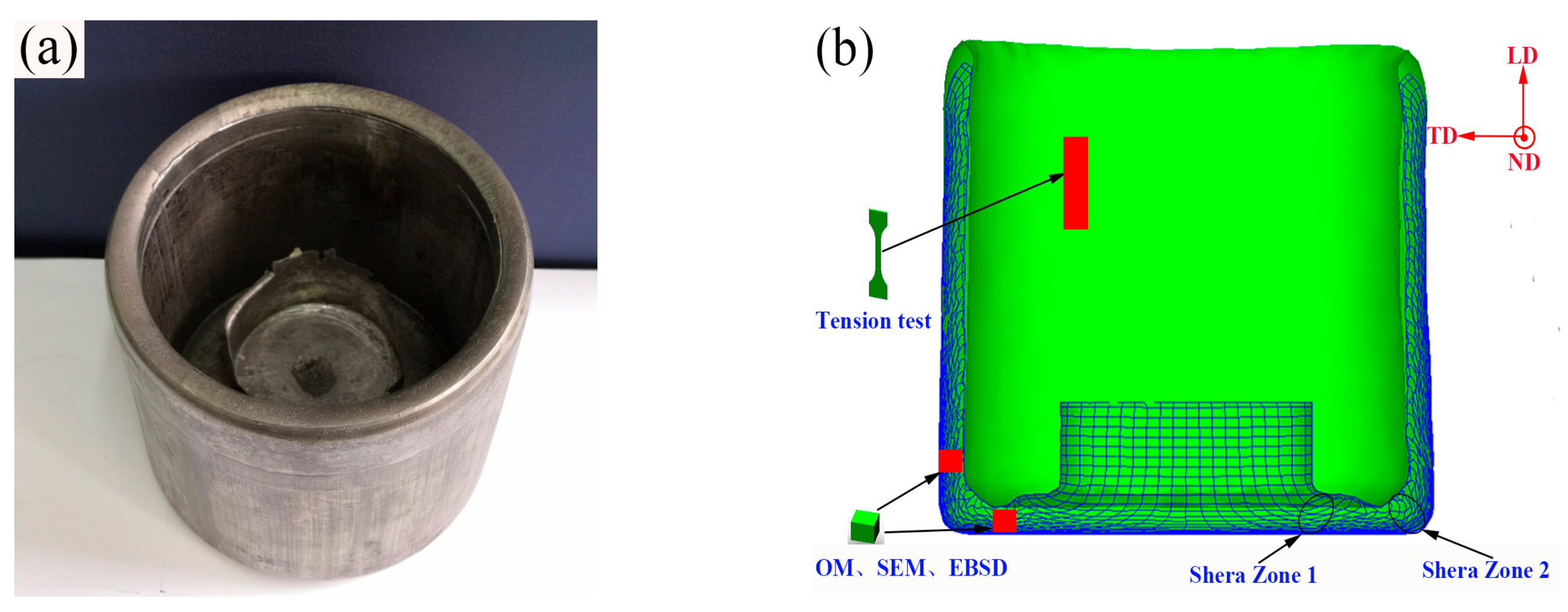

2. Materials and Methods

3. Results and Discussion

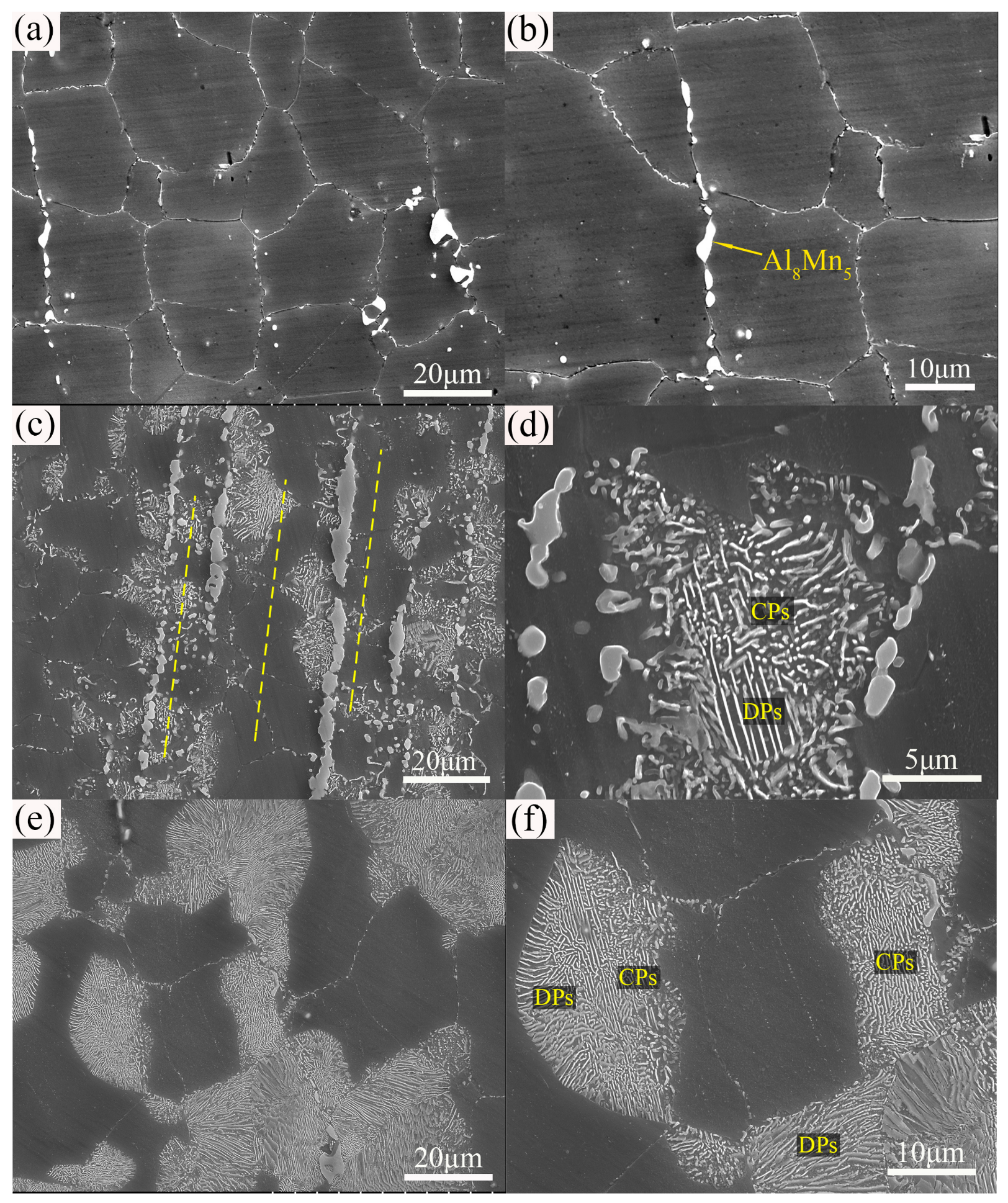

3.1. Initial Material State

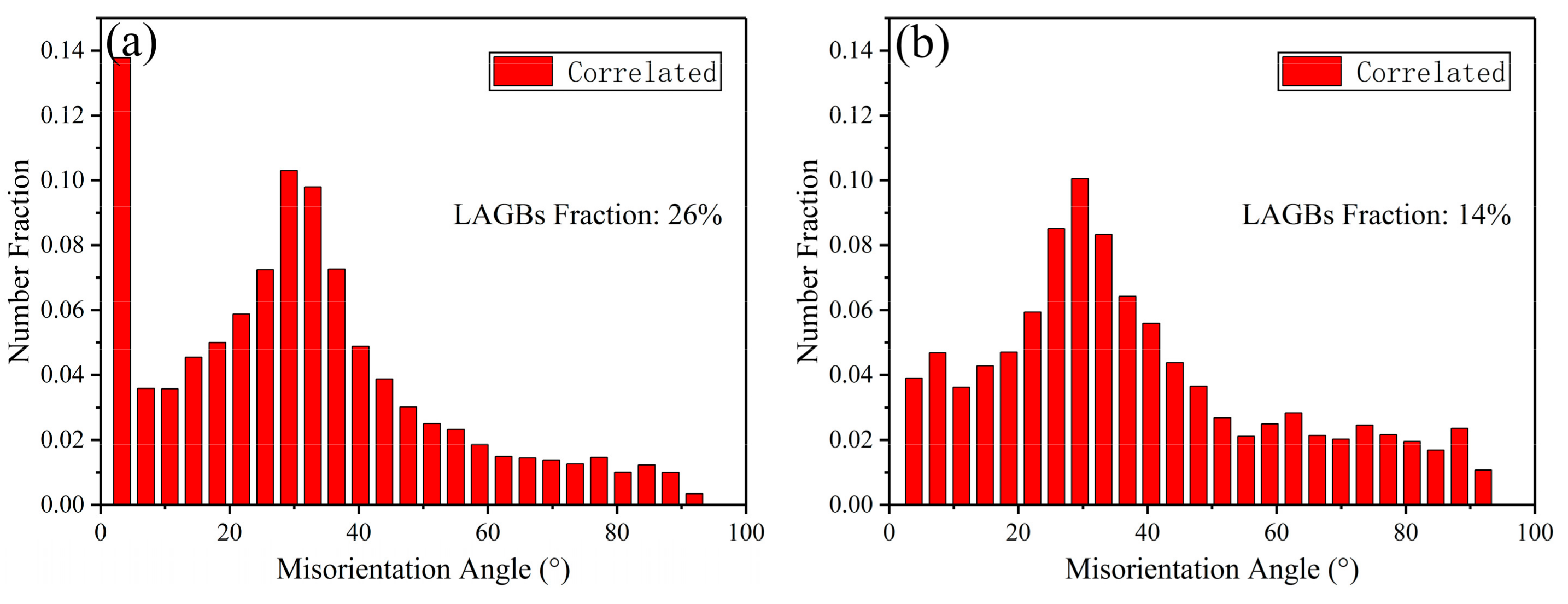

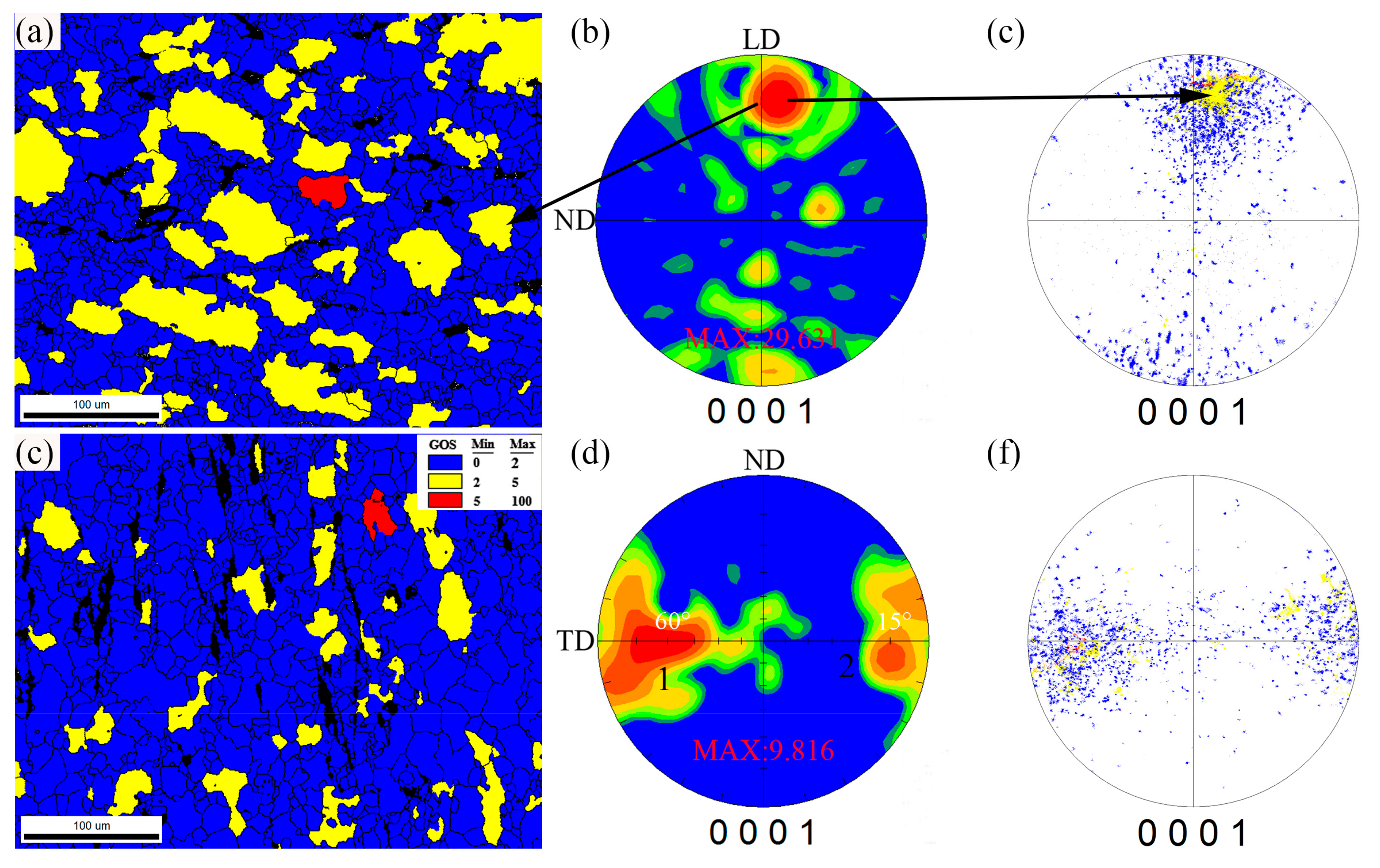

3.2. Effect of Extrusion on Microstructure and Texture

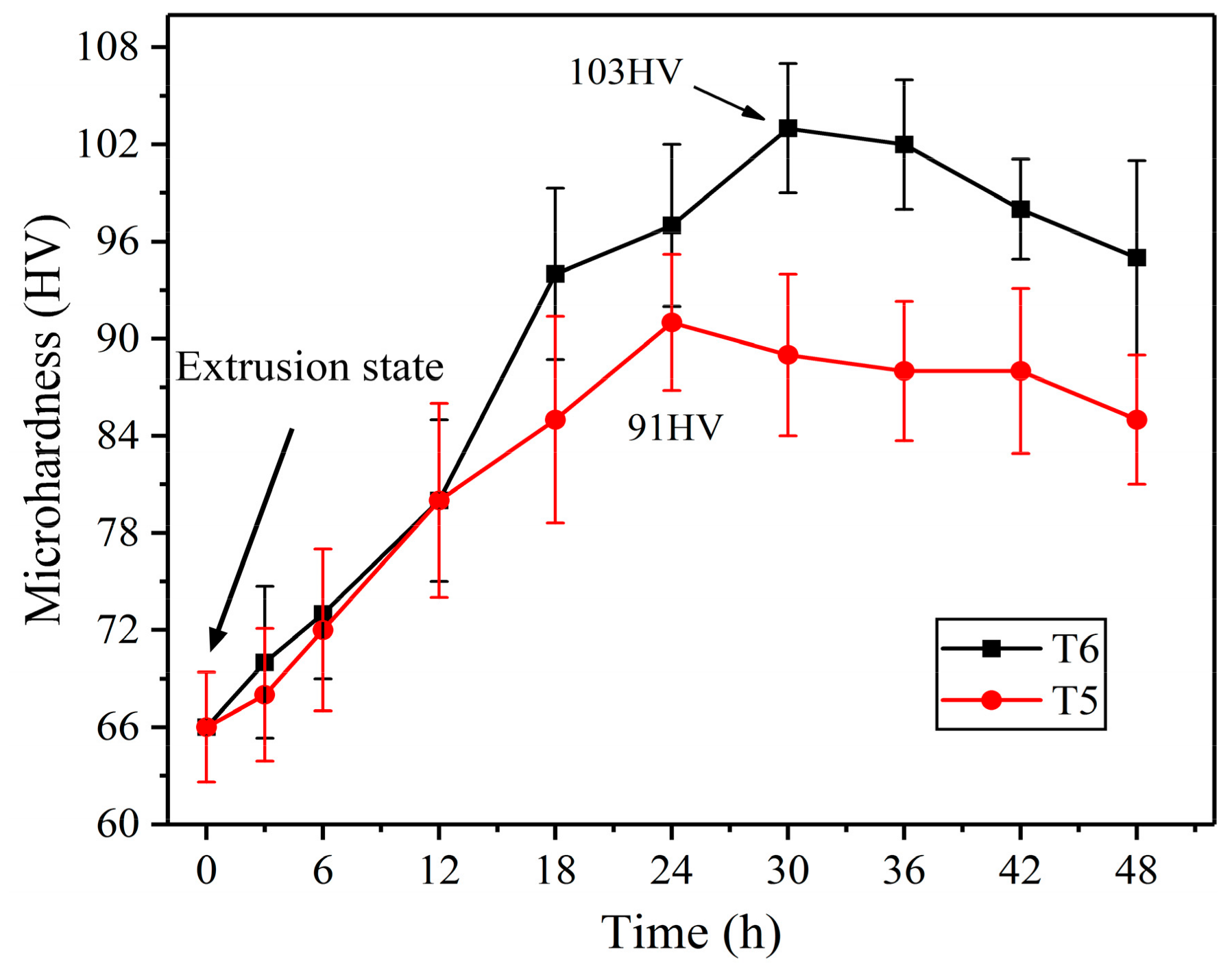

3.3. Effect of Heat Treatment on Microstructure

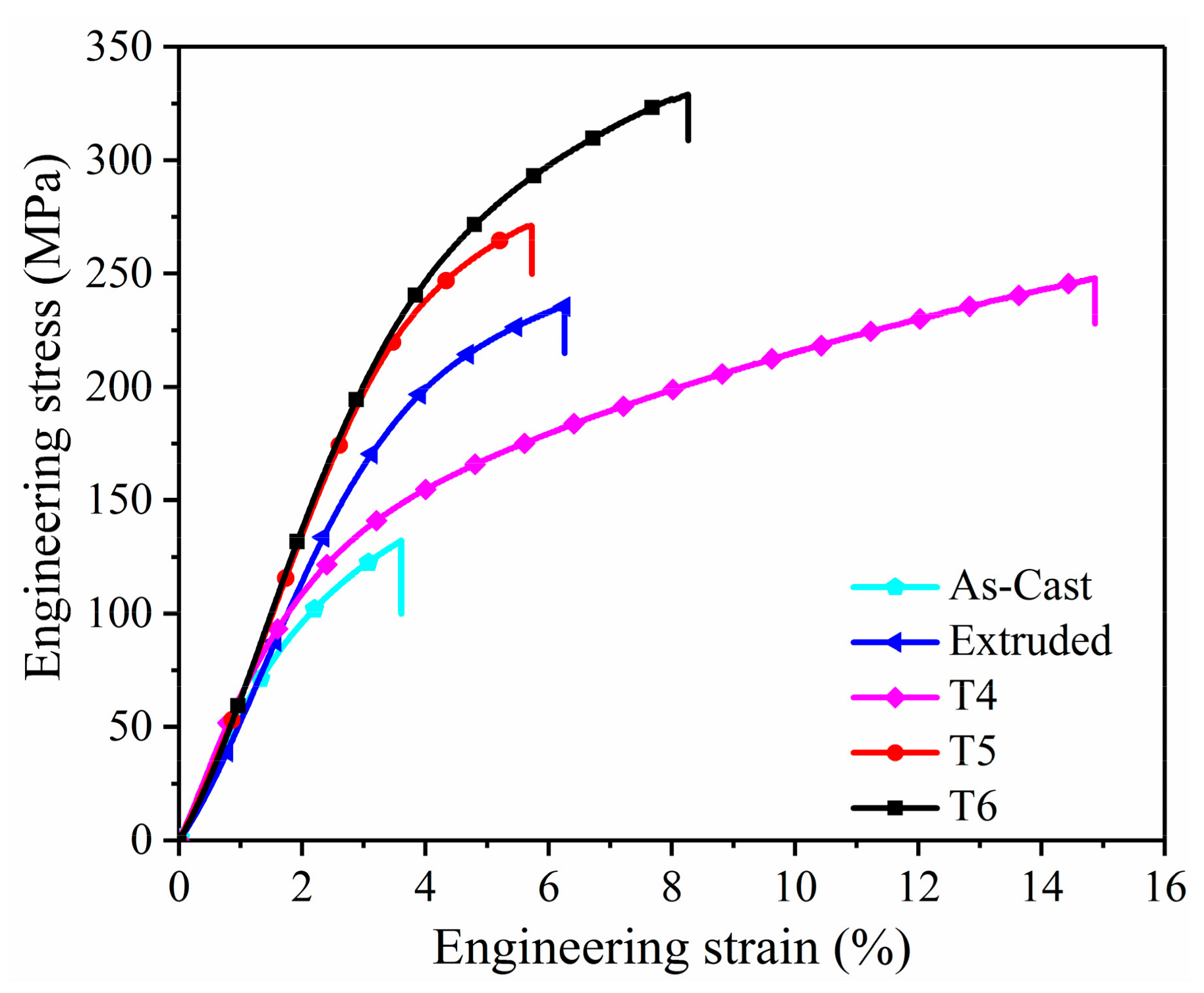

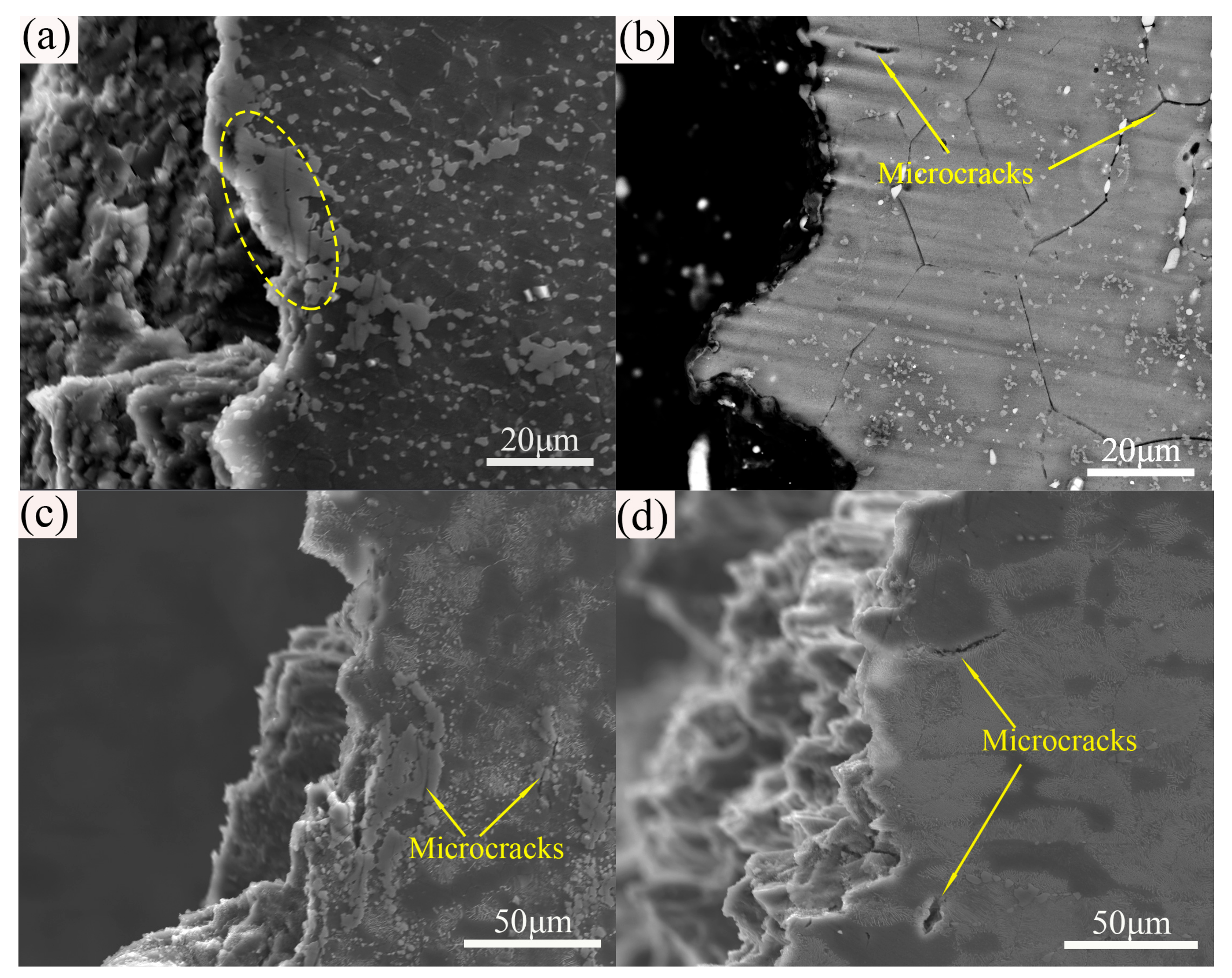

3.4. Mechanical Properties and Fracture Morphology

4. Conclusions

- (1)

- After ACAE pressing, DRX of Mg grains was developed and the network eutectic β-phases formed during the solidification were broken into small β-phase particles. Moreover, weak texture with two dominant peaks formed owing to the significantly grain refinement and the enhanced activation of pyramidal <c + a> slip at relative high temperature.

- (2)

- T4 treatment caused the dissolution of residual β-phases and the development of more equiaxed grains. After the T5 process, β-phases that both DPs and CPs were preferentially initiated at banded eutectic phases owing to high distributed Al content. The T6 heat treated samples obtained remarkable age hardening response with much more lamellar-shaped DPs and granular/short-lath-shaped CPs precipitated.

- (3)

- The residual eutectic β-phases were the main cause of the fracture of the alloy. T4 treatment greatly increased the elongation of the alloy owing to dissolution of the residual eutectic β-phases. After T5 treatment, the tensile properties of the alloy increased as the expense of elongation. The highest material YS of ~235 MPa and UTS of ~328 MPa were achieved after T6 treatment with appropriate elongation to failure of ~8.3%.

Author Contributions

Funding

Conflicts of Interest

References

- Uematsu, Y.; Tokaji, K.; Kamakura, M.; Uchida, K.; Shibata, H.; Bekku, N. Effect of extrusion conditions on grain refinement and fatigue behaviour in magnesium alloys. Mater. Sci. Eng. A 2006, 434, 131–140. [Google Scholar] [CrossRef]

- Yakubtsov, I.A.; Diak, B.J.; Sager, C.A.; Bhattacharya, B.; MacDonald, W.D.; Niewczas, M. Effects of heat treatment on microstructure and tensile deformation of Mg AZ80 alloy at room temperature. Mater. Sci. Eng. A 2008, 496, 247–255. [Google Scholar] [CrossRef]

- Yu, H.; Li, C.; Xin, Y.; Chapuis, A.; Huang, X.; Liu, Q. The mechanism for the high dependence of the Hall-Petch slope for twinning/slip on texture in Mg alloys. Acta Mater. 2017, 128, 313–326. [Google Scholar] [CrossRef]

- Wang, L.; Mostaed, E.; Cao, X.; Huang, G.; Fabrizi, A.; Bonollo, F.; Chi, C.; Vedani, M. Effects of texture and grain size on mechanical properties of AZ80 magnesium alloys at lower temperatures. Mater. Des. 2016, 89, 1–8. [Google Scholar] [CrossRef]

- Zhan, M.Y.; Li, Y.Y.; Chen, W.P.; Chen, W.D. Microstructure and mechanical properties of Mg–Al–Zn alloy sheets severely deformed by accumulative roll-bonding. J. Mater. Sci. 2007, 42, 9256–9261. [Google Scholar] [CrossRef]

- Fatemi-Varzaneh, S.M.; Zarei-Hanzaki, A. Processing of AZ31 magnesium alloy by a new noble severe plastic deformation method. Mater. Sci. Eng. A 2011, 528, 1334–1339. [Google Scholar] [CrossRef]

- Nie, K.B.; Deng, K.K.; Wang, X.J.; Xu, F.J.; Wu, K.; Zheng, M.Y. Multidirectional forging of AZ91 magnesium alloy and its effects on microstructures and mechanical properties. Mater. Sci. Eng. A 2015, 624, 157–168. [Google Scholar] [CrossRef]

- Pardis, N.; Chen, C.; Ebrahimi, R.; Toth, L.S.; Gu, C.F.; Beausir, B.; Kommel, L. Microstructure, texture and mechanical properties of cyclic expansion-extrusion deformed pure copper. Mater. Sci. Eng. A 2015, 628, 423–432. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Z.; Han, J.; Liu, H.; Song, D.; Jiang, J.; Ma, A. High strength and ductility AZ91 magnesium alloy with multi-heterogenous microstructures prepared by high-temperature ECAP and short-time aging. Mater. Sci. Eng. A 2018, 734, 485–490. [Google Scholar] [CrossRef]

- Shatermashhadi, V.; Manafi, B.; Abrinia, K.; Faraji, G.; Sanei, M. Development of a novel method for the backward extrusion. Mater. Des. (1980–2015) 2014, 62, 361–366. [Google Scholar] [CrossRef]

- Manafi, B.; Shatermashhadi, V.; Abrinia, K.; Faraji, G.; Sanei, M. Development of a novel bulk plastic deformation method: hydrostatic backward extrusion. Int. J. Adv. Manuf. Technol. 2016, 82, 1823–1830. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Abrinia, K.; Faraji, G. Applicability of a modified backward extrusion process on commercially pure aluminum. Mater. Des. (1980–2015) 2015, 65, 521–528. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Xue, Y.; Zhang, Z. An Investigation on Microstructure, Texture and Mechanical Properties of AZ80 Mg Alloy Processed by Annular Channel Angular Extrusion. Materials 2019, 12, 1001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barrett, C.D.; Imandoust, A.; Oppedal, A.L.; Inal, K.; Tschopp, M.A.; El Kadiri, H. Effect of grain boundaries on texture formation during dynamic recrystallization of magnesium alloys. Acta Mater. 2017, 128, 270–283. [Google Scholar] [CrossRef]

- Duly, D.; Simon, J.P.; Brechet, Y. On the competition between continuous and discontinuous precipitations in binary Mg Al alloys. Acta Metall. Mater. 1995, 43, 101–106. [Google Scholar]

- Braszczyńska-Malik, K.N. Discontinuous and continuous precipitation in magnesium-aluminium type alloys. J. Alloy. Compd. 2009, 477, 870–876. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, Z.; Zuo, M.; Geng, H. Effects of heat treatment on microstructure and mechanical properties of extruded AZ80 magnesium alloy. Mater. Des. (1980–2015) 2014, 56, 589–593. [Google Scholar] [CrossRef]

- Li, J.-Y.; Xie, J.-X.; Jin, J.-B.; Wang, Z.-X. Microstructural evolution of AZ91 magnesium alloy during extrusion and heat treatment. Trans. Nonferrous Met. Soc. China 2012, 22, 1028–1034. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, Z.; Ji, J.; Sun, Z. Effects of second phases on deformation behavior and dynamic recrystallization of as-cast Mg-4.3Li-4.1Zn-1.4Y alloy during hot compression. J. Alloy. Compd. 2019, 770, 540–548. [Google Scholar] [CrossRef]

- Borkar, H.; Gauvin, R.; Pekguleryuz, M. Effect of extrusion temperature on texture evolution and recrystallization in extruded Mg–1% Mn and Mg–1% Mn–1.6%Sr alloys. J. Alloy. Compd. 2013, 555, 219–224. [Google Scholar] [CrossRef]

- Xu, S.W.; Kamado, S.; Honma, T. Recrystallization mechanism and the relationship between grain size and Zener-Hollomon parameter of Mg–Al–Zn–Ca alloys during hot compression. Scr. Mater. 2010, 63, 293–296. [Google Scholar] [CrossRef]

- Wang, Q.; Song, J.; Jiang, B.; Tang, A.; Chai, Y.; Yang, T.; Huang, G.; Pan, F. An investigation on microstructure, texture and formability of AZ31 sheet processed by asymmetric porthole die extrusion. Mater. Sci. Eng. A 2018, 720, 85–97. [Google Scholar] [CrossRef]

- Maghsoudi, M.H.; Zarei-Hanzaki, A.; Abedi, H.R. Modification of the grain structure, γ phase morphology and texture in AZ81 Mg alloy through accumulative back extrusion. Mater. Sci. Eng. A 2014, 595, 99–108. [Google Scholar] [CrossRef]

- Jia, W.P.; Hu, X.D.; Zhao, H.Y.; Ju, D.Y.; Chen, D.L. Texture evolution of AZ31 magnesium alloy sheets during warm rolling. J. Alloy. Compd. 2015, 645, 70–77. [Google Scholar] [CrossRef]

- Minárik, P.; Král, R.; Čížek, J.; Chmelík, F. Effect of different c/a ratio on the microstructure and mechanical properties in magnesium alloys processed by ECAP. Acta Mater. 2016, 107, 83–95. [Google Scholar] [CrossRef]

- Jiang, M.G.; Xu, C.; Yan, H.; Fan, G.H.; Nakata, T.; Lao, C.S.; Chen, R.S.; Kamado, S.; Han, E.H.; Lu, B.H. Unveiling the formation of basal texture variations based on twinning and dynamic recrystallization in AZ31 magnesium alloy during extrusion. Acta Mater. 2018, 157, 53–71. [Google Scholar] [CrossRef]

- Chapuis, A.; Driver, J.H. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals. Acta Mater. 2011, 59, 1986–1994. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, J.; Chen, X.; Zhang, X.; Li, M. Fabrication of high-strength AZ80 alloys via multidirectional forging in air with no need of ageing treatment. J. Alloy. Compd. 2019, 787, 551–559. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.W.; Matsumoto, N.; Kamado, S.; Honma, T.; Kojima, Y. Effect of pre-aging treatment on microstructure and mechanical properties of hot compressed Mg–9Al–1Zn alloy. Mater. Sci. Eng. A 2009, 517, 354–360. [Google Scholar] [CrossRef]

- Yu, S.; Gao, Y.; Liu, C.; Han, X. Effect of aging temperature on precipitation behavior and mechanical properties of extruded AZ80-Ag alloy. J. Alloy. Compd 2015, 646, 431–436. [Google Scholar] [CrossRef]

- Li, Z.; Dong, J.; Zeng, X.Q.; Lu, C.; Ding, W.J. Influence of Mg17Al12 intermetallic compounds on the hot extruded microstructures and mechanical properties of Mg–9Al–1Zn alloy. Mater. Sci. Eng. A 2007, 466, 134–139. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, A.; Liu, H.; Sun, J.; Song, D.; Wang, C.; Yuan, Y.; Jiang, J. Multimodal Microstructure and Mechanical Properties of AZ91 Mg Alloy Prepared by Equal Channel Angular Pressing plus Aging. Metals 2018, 8, 763. [Google Scholar] [CrossRef] [Green Version]

- Pan, H.; Qin, G.; Huang, Y.; Ren, Y.; Sha, X.; Han, X.; Liu, Z.-Q.; Li, C.; Wu, X.; Chen, H.; et al. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater. 2018, 149, 350–363. [Google Scholar] [CrossRef] [Green Version]

- Zindal, A.; Jain, J.; Prasad, R.; Singh, S.S.; Cizek, P. Correlation of grain boundary precipitate characteristics with fracture and fracture toughness in an Mg-8Al-0.5 Zn alloy. Mater. Sci. Eng. A 2017, 706, 192–200. [Google Scholar] [CrossRef]

- Xu, S.W.; Kamado, S.; Honma, T. Effect of homogenization on microstructures and mechanical properties of hot compressed Mg–9Al–1Zn alloy. Mater. Sci. Eng. A 2011, 528, 2385–2393. [Google Scholar] [CrossRef]

- Chen, B.; Lin, D.-L.; Jin, L.; Zeng, X.-Q.; Lu, C. Equal-channel angular pressing of magnesium alloy AZ91 and its effects on microstructure and mechanical properties. Mater. Sci. Eng. A 2008, 483–484, 113–116. [Google Scholar] [CrossRef]

| Designation | Heat Treatment Schedule |

|---|---|

| T4 | Solution treated at 415 °C for 1.5 h |

| T5 | Aging at 175 °C for 24 h |

| T6 | Solution treated at 415 °C for 1.5 h, aging at 175 °C for 30 h |

| States | daverage (μm) | YS (MPa) | UTS (MPa) | EL (%) |

|---|---|---|---|---|

| As-cast | 252 (±7) | 71 (±5) | 132 (±4) | 3.6 (±0.5) |

| Extruded | 23.5 (±2.6) | 182 (±4) | 238 (±5) | 6.3 (±0.8) |

| T4 | 30.0 (±3.2) | 118 (±2) | 248 (±3) | 14 (±0.5) |

| T5 | 25.8 (±3.2) | 212 (±5) | 270 (±6) | 5.7 (±1.0) |

| T6 | 31.1 (±3.5) | 235 (±4) | 328 (±5) | 8.3 (±0.7) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Li, S.; Yan, F.; Zhang, Z.; Wu, Y. Microstructure Evolution and Mechanical Properties of AZ80 Mg Alloy during Annular Channel Angular Extrusion Process and Heat Treatment. Materials 2019, 12, 4223. https://doi.org/10.3390/ma12244223

Zhao X, Li S, Yan F, Zhang Z, Wu Y. Microstructure Evolution and Mechanical Properties of AZ80 Mg Alloy during Annular Channel Angular Extrusion Process and Heat Treatment. Materials. 2019; 12(24):4223. https://doi.org/10.3390/ma12244223

Chicago/Turabian StyleZhao, Xi, Shuchang Li, Fafa Yan, Zhimin Zhang, and Yaojin Wu. 2019. "Microstructure Evolution and Mechanical Properties of AZ80 Mg Alloy during Annular Channel Angular Extrusion Process and Heat Treatment" Materials 12, no. 24: 4223. https://doi.org/10.3390/ma12244223