The Alternatives to Traditional Materials for Subsoil Stabilization and Embankments

Abstract

:1. Introduction

2. Literature Review

2.1. Ash Utilization for Soil Stabilization

2.2. Ash Utilization as a Material for Embankment

3. Materials

3.1. Soil

3.2. Ash and Slag

3.3. Binders (Activators)

4. Testing Methods and Laboratory Program

4.1. Testing Methods

- Specific gravity was determined in accordance with [50].

- Grain size distribution was determined using the hydrometer method, in accordance with [51].

- Аtterberg limits were determined using a motorized Casagrande liquid limit device (Controls, Milan, Italy), in accordance with [52].

- The Proctor compaction test was done in accordance with [53]. Optimum moisture content (OMC) and maximum dry density γd,max were determined using a compaction energy of 600 kJ/m3.

- Unconfined compression (UCS) tests were done using a controlled strain rate machine (Controls, Milan, Italy), on the cylindrical specimens with a diameter of 38 mm and height of 76 mm. The tests were done in accordance with SRPS U.B1.029:1996 [54]. The rate of vertical displacement was 0.5 mm/min.

- Direct shear tests were performed in drained conditions, using machines with a constant strain rate and square shear box (60 mm × 60 mm × 30 mm), in accordance with [55]. Specimens were initially saturated in a separate consolidation device (Controls, Milan, Italy) during 24 hours. After saturation, specimens were consolidated with vertical loading of 100, 200 and 400 kPa and then sheared with the constant velocity of 5–15 μ/min (CH clay stabilization) and of 20–40 μ/min (fly ash and ash-slag mixtures).

- One-dimensional consolidation tests were done in accordance with [56], on cylindrical specimens with diameter of 70 mm and height of 20 mm. The specimens were soaked for 24 hours prior to compression. After soaking, the vertical load was applied step by step to achieve the maximum vertical stress of 400 kPa, according to the following scheme: 25/50/100/200/400/200/100/50/25 kPa

- California bearing ratio (CBR) tests were done on fully soaked samples, in accordance with [57].

- Frost resistance tests were done in accordance with [58]. After 15 cycles of freezing and thawing, the UCS reduction was measured. One cycle consisted of 16 hours freezing on temperature −10 °C and 8 hours thawing on temperature +25 °C.

- Free swell tests were performed in the oedometer apparatus (Controls, Milan, Italy) on remolded samples compacted at standard Proctor’s maximum dry density and optimum moisture content and without any vertical surcharge load [48]. Upon completion of the swelling process, in order to capture the swelling pressure, the vertical load was gradually applied until swelling deformation was eliminated.

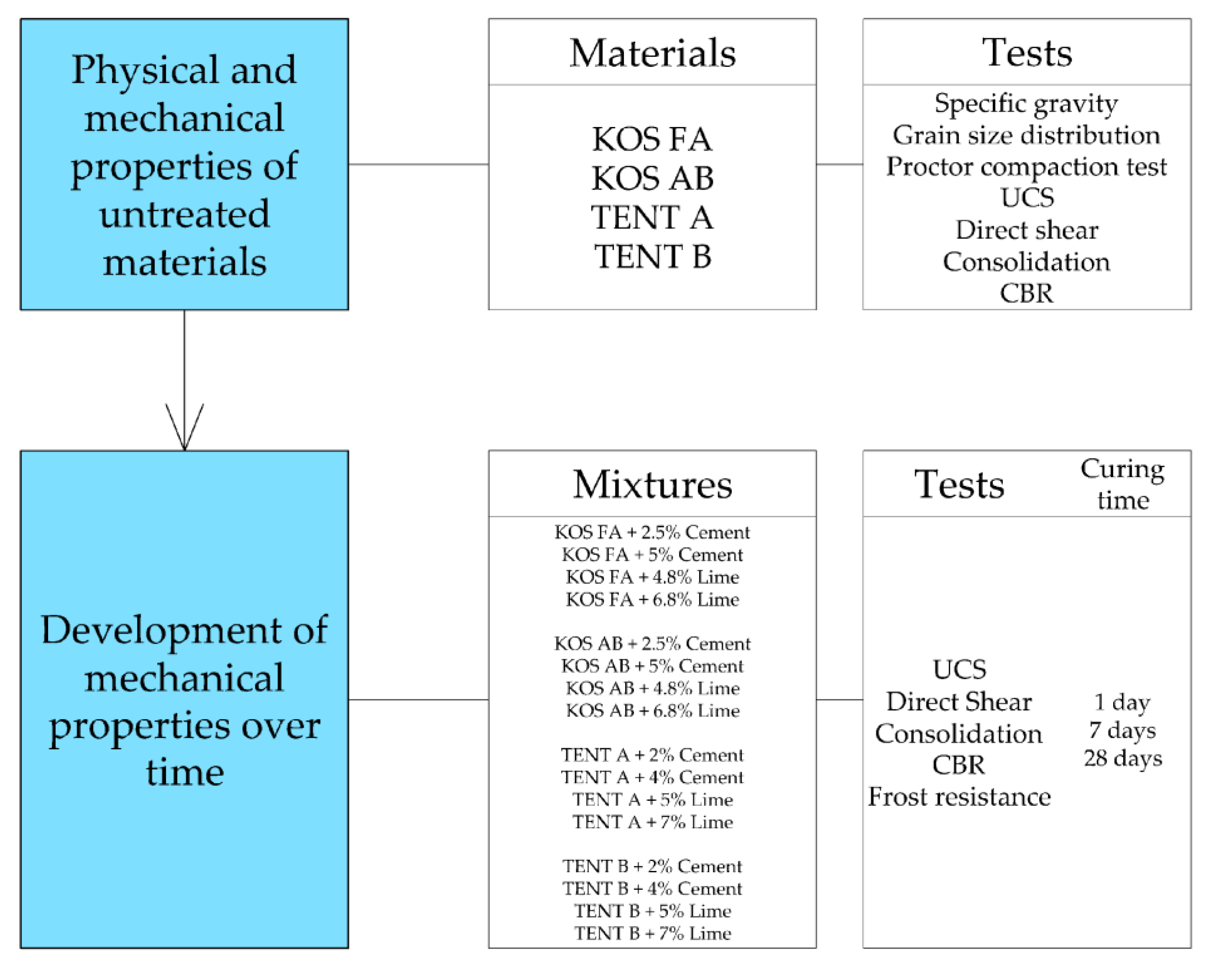

4.2. Laboratory Testing Program

4.3. Specimen Preparation and Curing

4.4. Optimal % of Fly Ash (Only for Soil Stabilization)

4.5. Used % of Binders

5. Results and Discussion

5.1. Stabilization of High Plasticity (CH) Clay

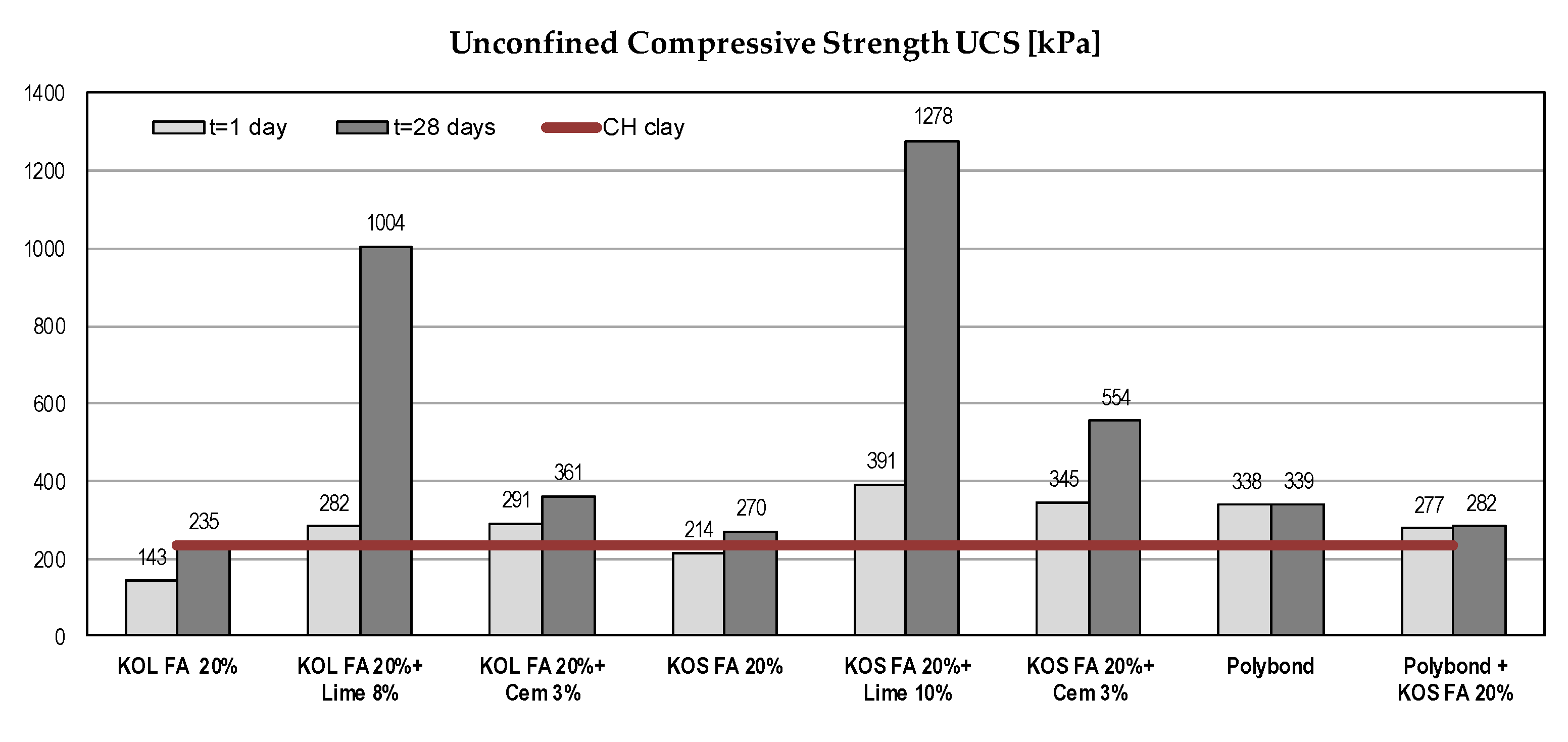

5.1.1. Unconfined Compressive Strength (UCS)

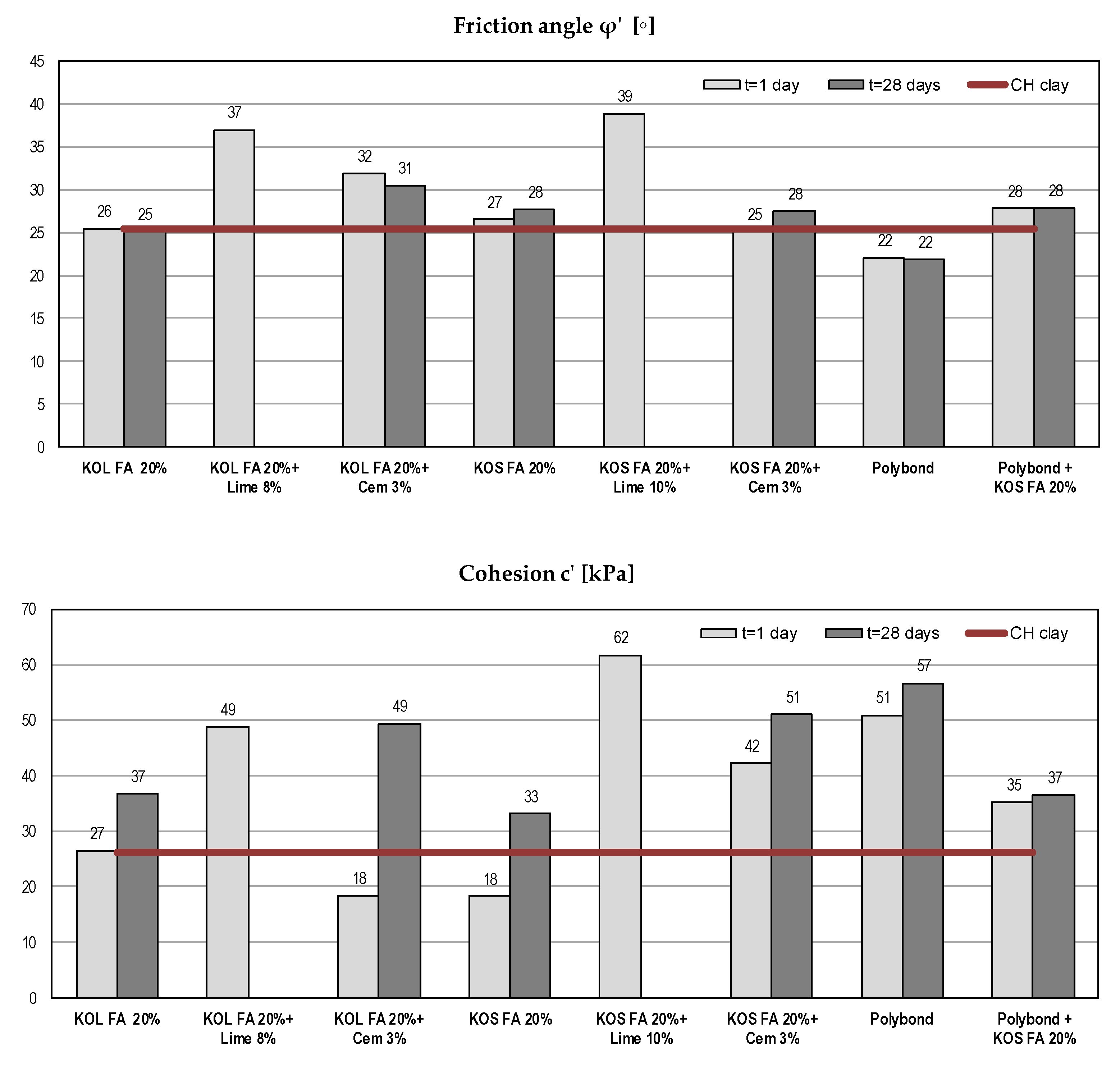

5.1.2. Shear Strength Parameters in Terms of Effective Stresses

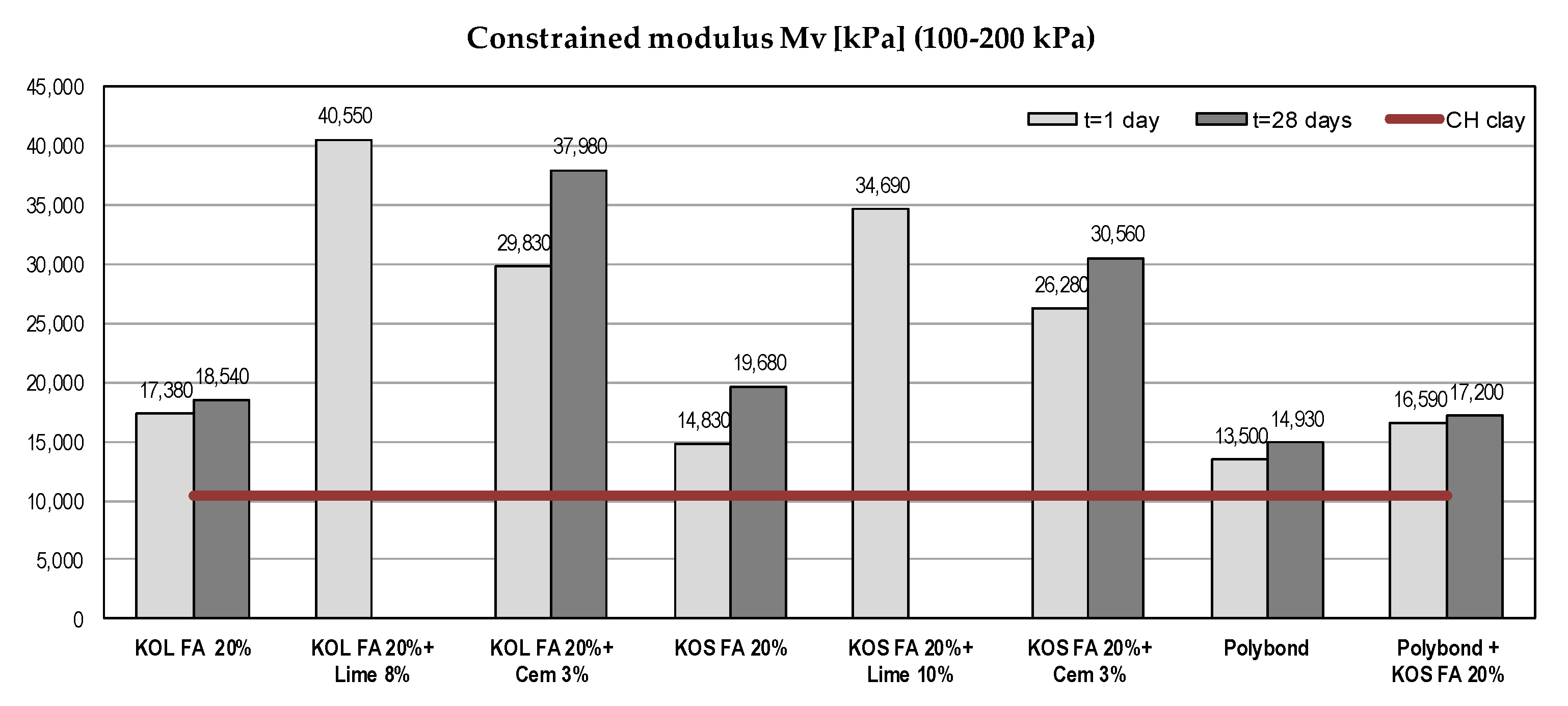

5.1.3. Compressibility Parameters

5.1.4. California Bearing Ratio (CBR)

5.1.5. Swell Potential

5.2. Fly Ash and Ash-Slag Mixtures as a Material for Embankment

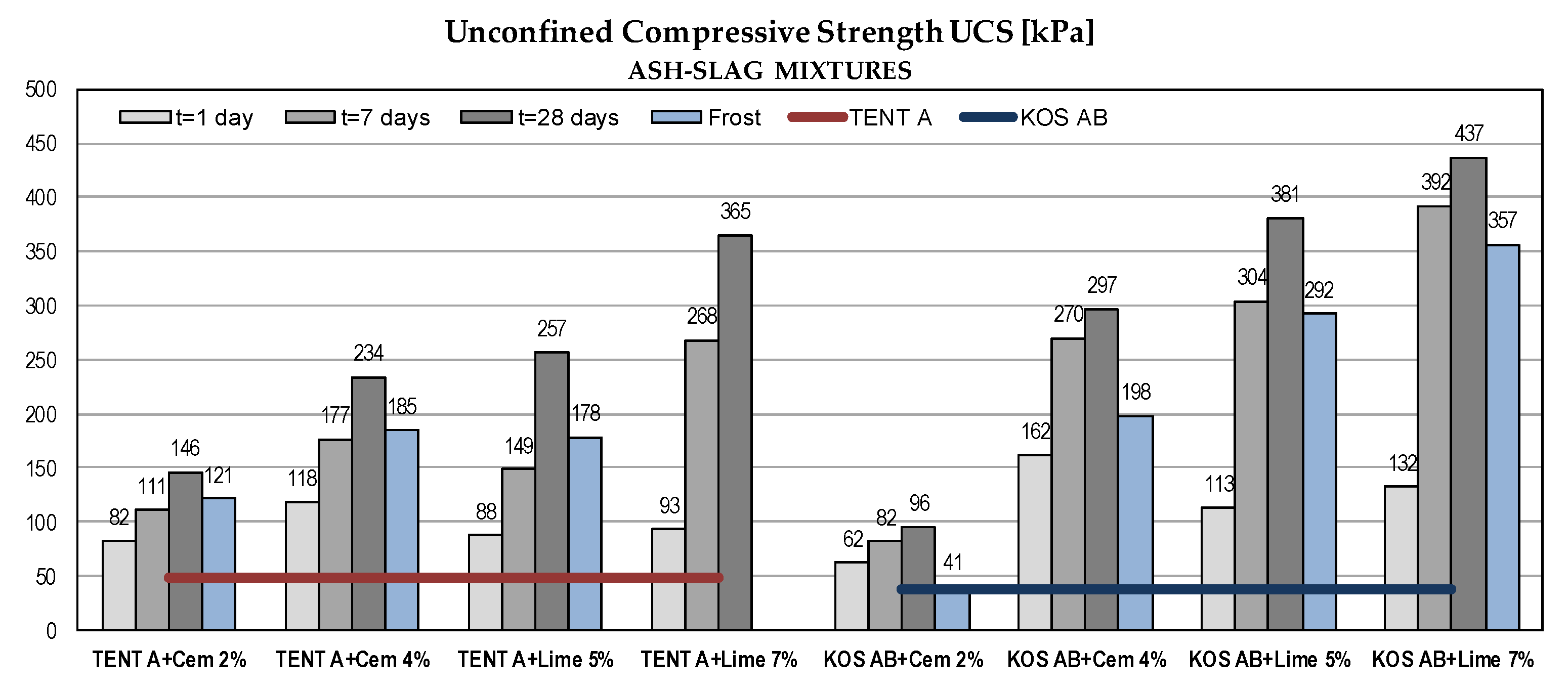

5.2.1. Unconfined Compressive Strength (UCS)

5.2.2. Effect of Frost

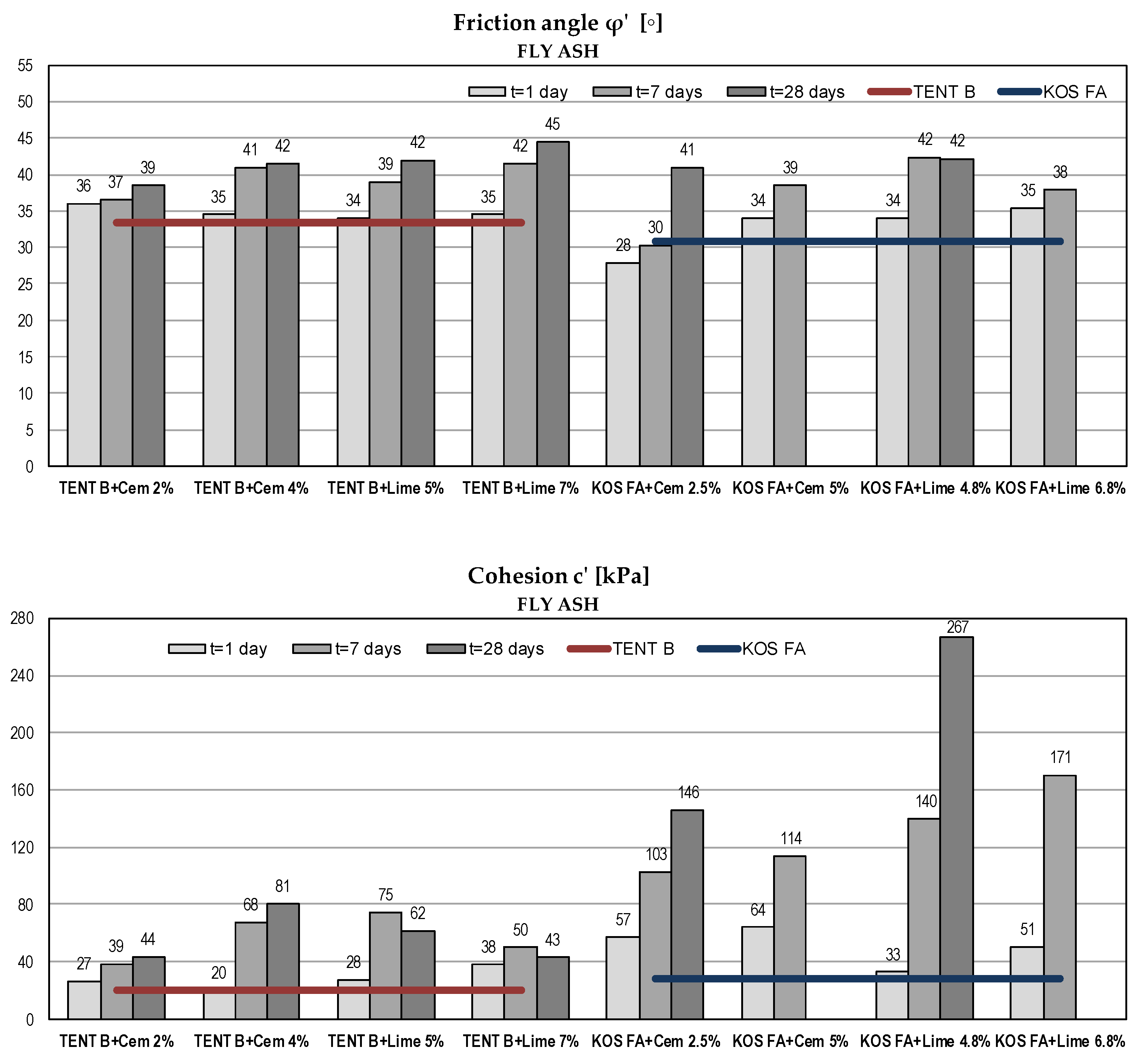

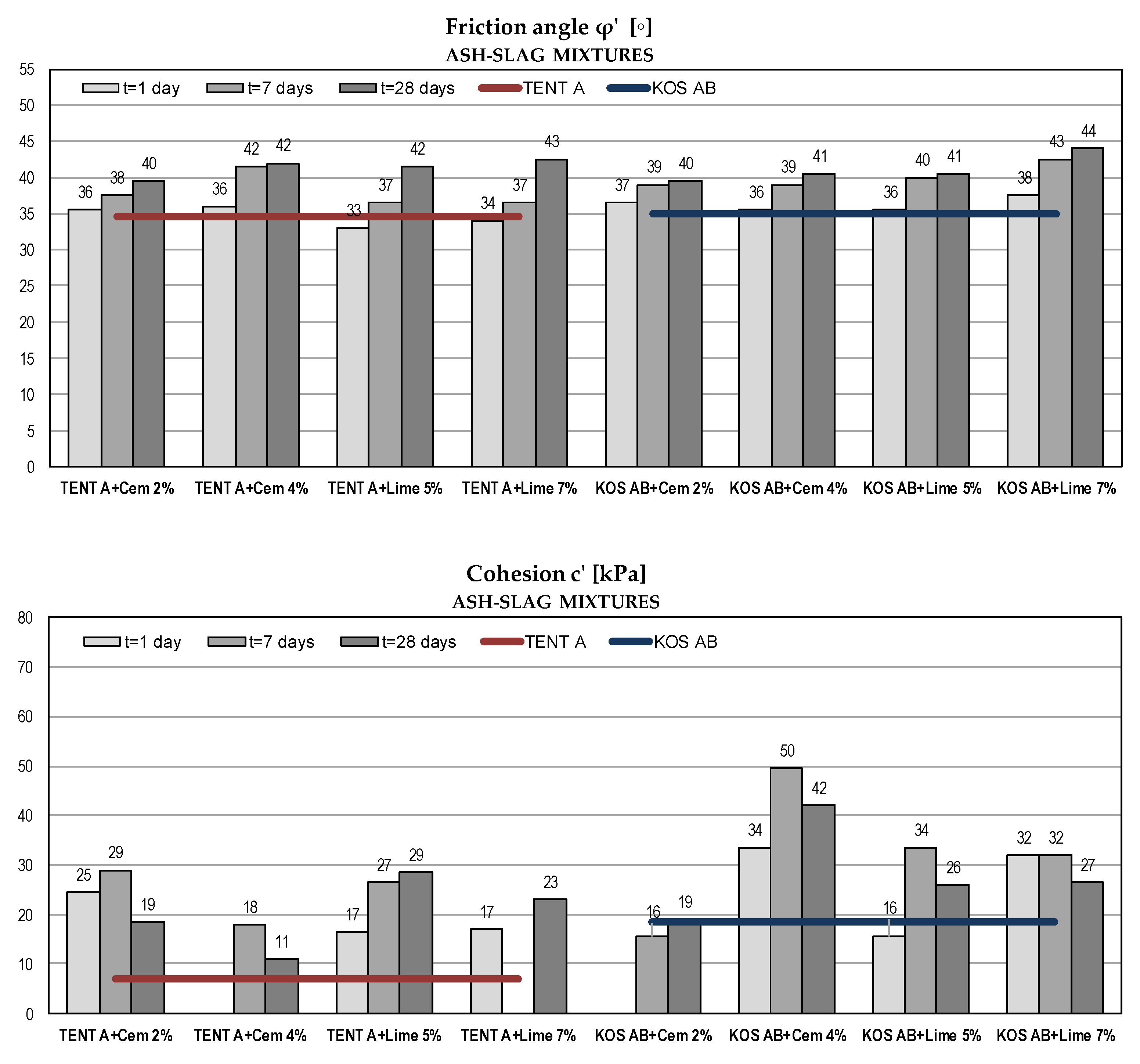

5.2.3. Shear Strength Parameters in Terms of Effective Stresses

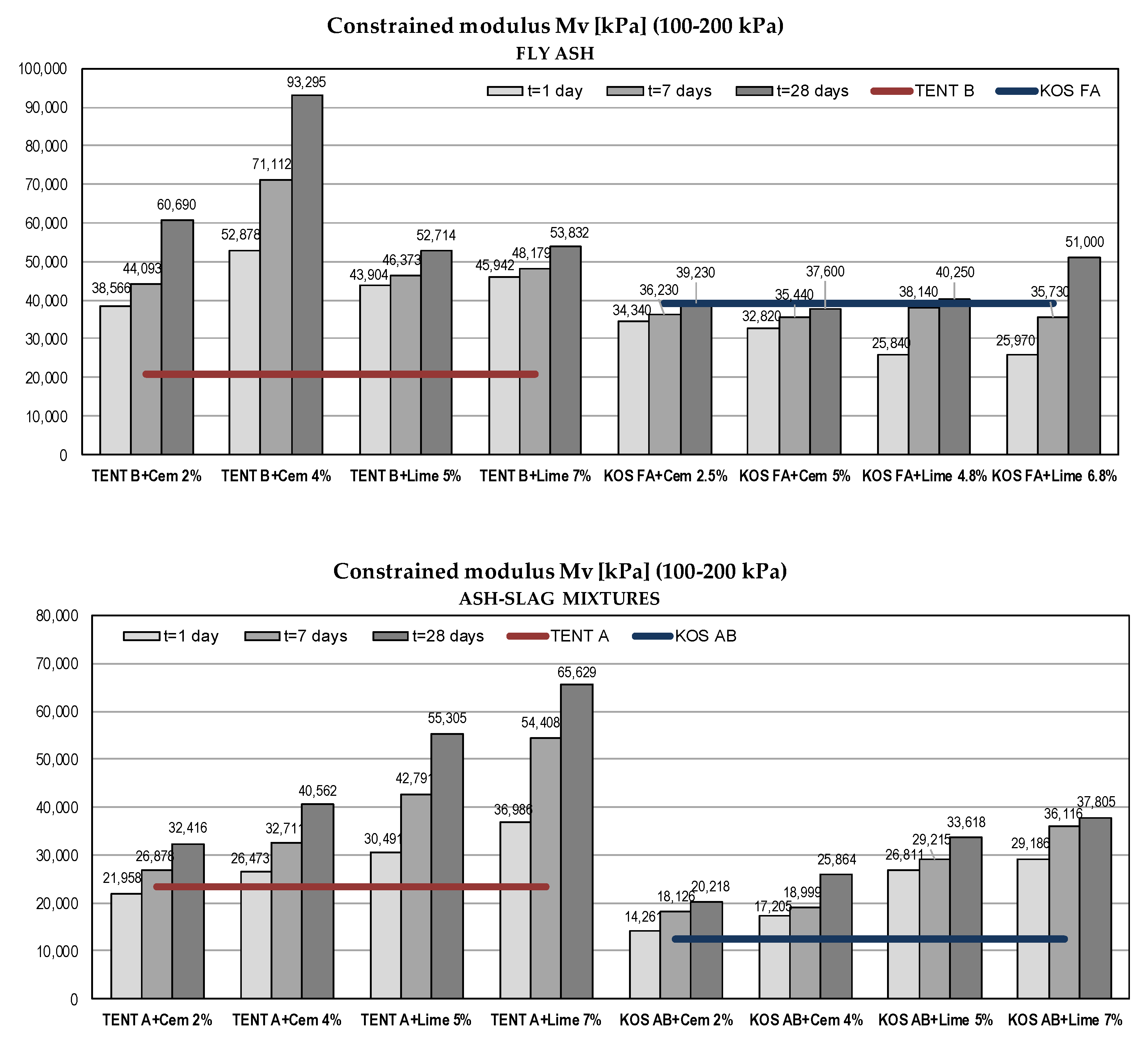

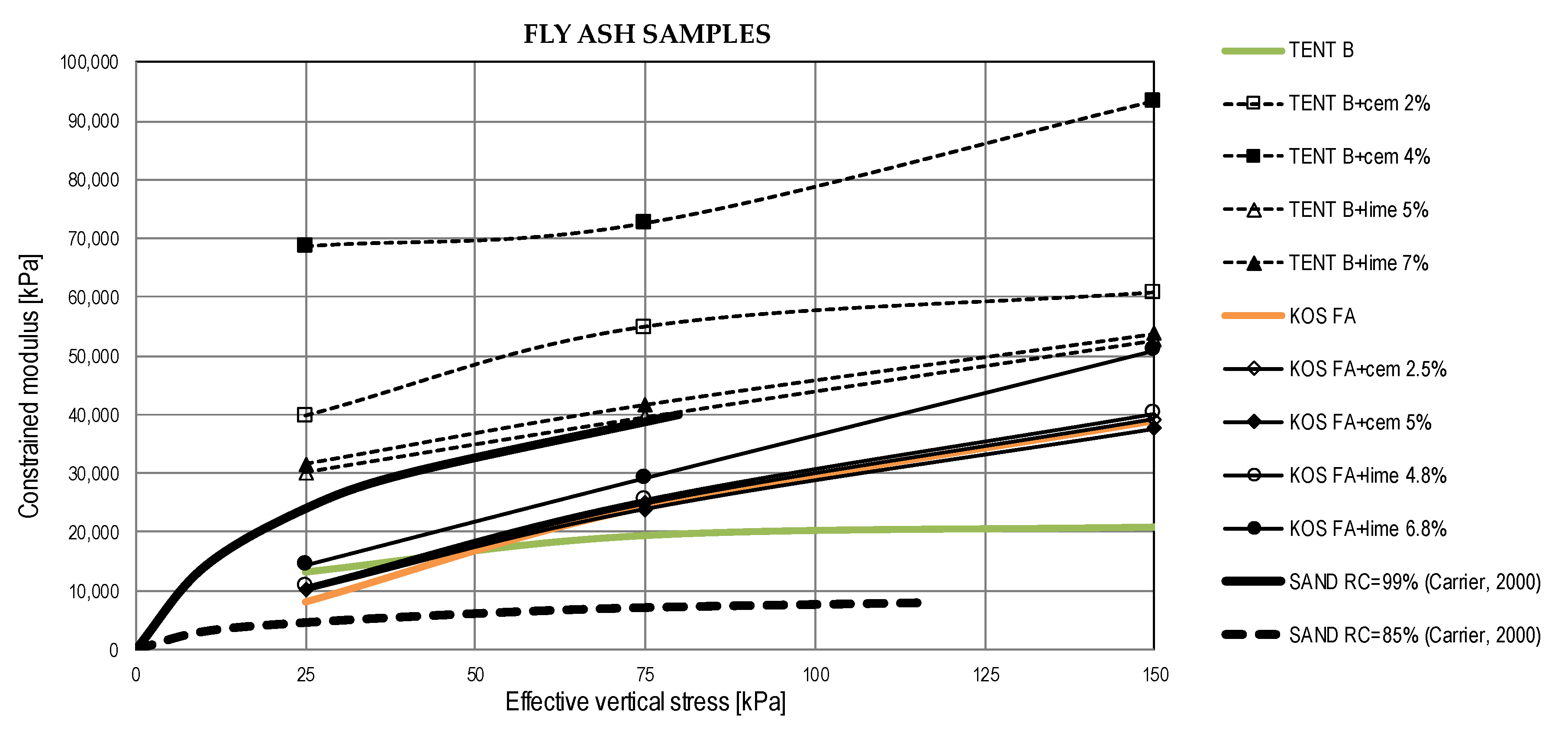

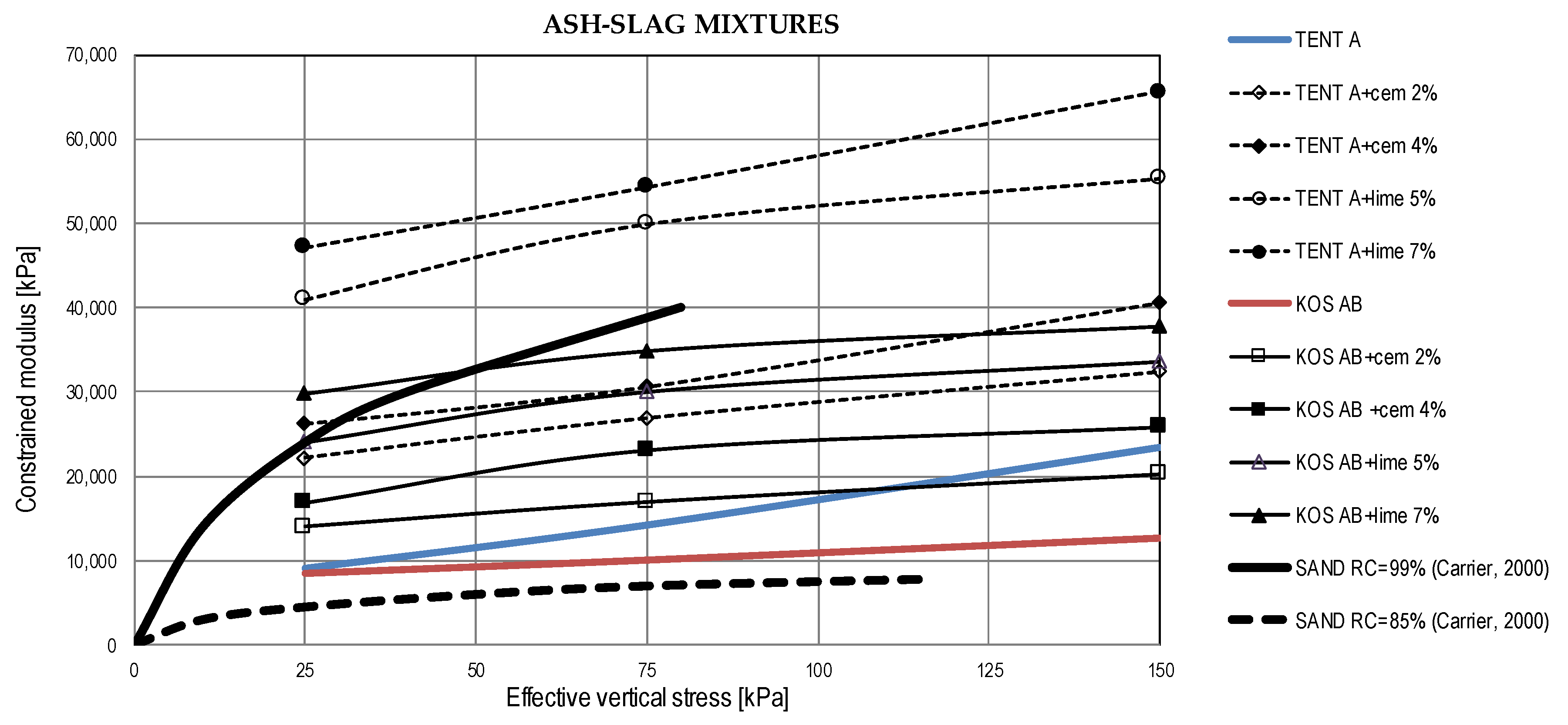

5.2.4. Compressibility Parameters

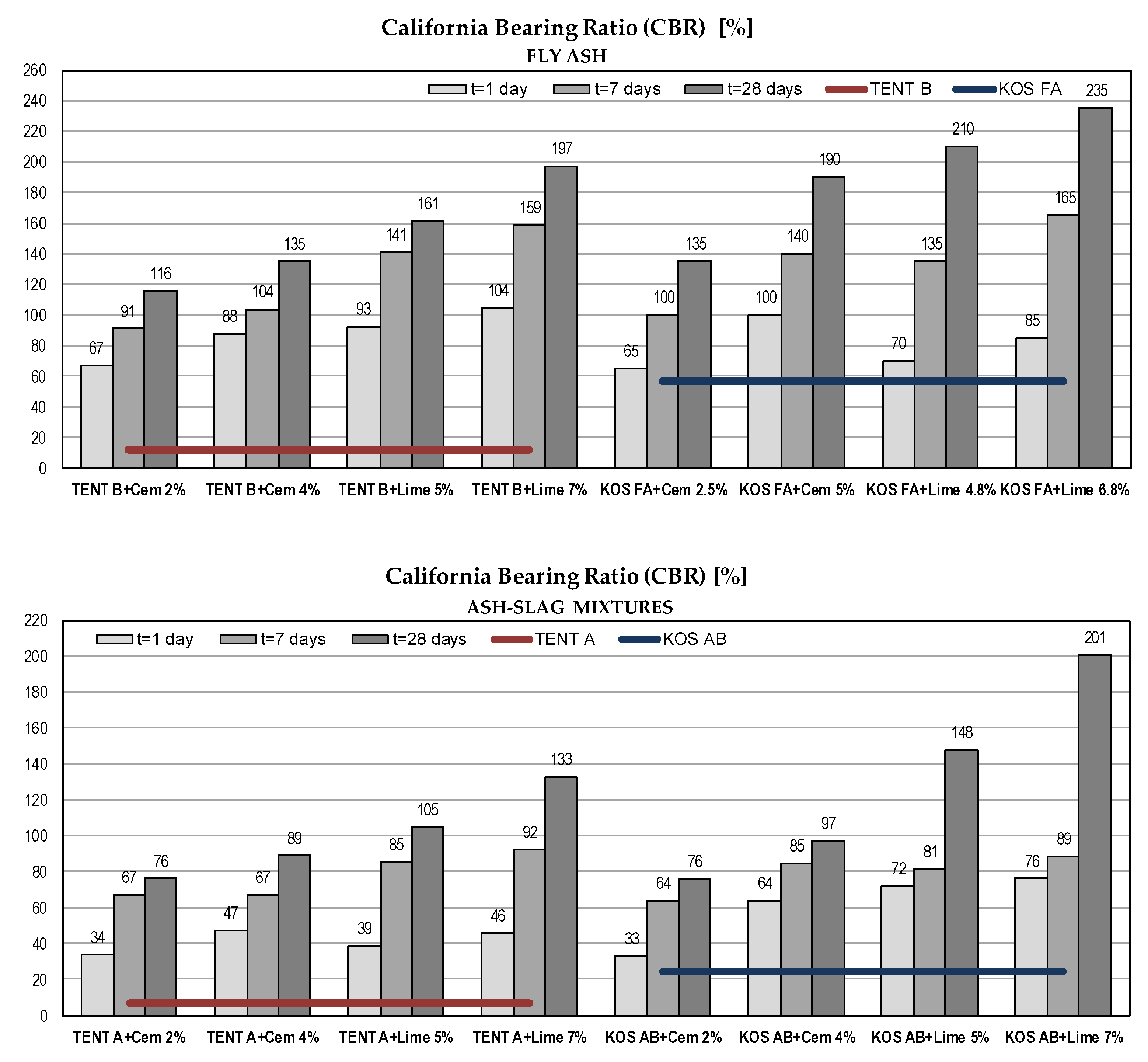

5.2.5. California Bearing Ratio (CBR)

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Electricity Production from Oil, Gas and Coal Sources. Available online: https://data.worldbank.org/indicator/EG.ELC.FOSL.ZS (accessed on 1 July 2019).

- European Coal Combustion Products Association. Available online: http://www.ecoba.com/ecobaccpprod.html (accessed on 1 July 2019).

- Cmiljanić, S.; Jotić, S.; Tošović, S. Prethodni rezultati istraživačko razvojnog programa-primena elektrofilterskog pepela u putogradnji. In Proceedings of the Simpozijum o Istraž. i Primeni Savremenih Dostignuća u Našem Građevinarstvu u Oblasti Materijala i Konstrukcija, Divčibare, Serbia; 2008; pp. 3–13. (In Serbian). [Google Scholar]

- Cmiljanić, S.; Vujanić, V.; Rosić, B.; Vuksanović, B.; Tošović, S.; Jotić, S. Physical-mechanical properties of fly-ash originating from thermo-electric power plants of Serbia. In Proceedings of the 14th Danube-European Conference on Geotechnical Engineering: From Research to Design in European Practice, Bratislava, Slovakia, 2–4 June 2010. [Google Scholar]

- Cmiljanić, S. Study: Use of Fly Ash and Slag Produced in the Thermal Power Plants “Nikola Tesla A/B” and “Kostolac A/B” for the Needs of Road Construction; Highway Institute, Contractor: Public Enterprise “Roads of Serbia”: Belgrade, Serbia, 2008. (In Serbian) [Google Scholar]

- Šušić, N. Study: Application and Placement of Ash Produced at “Elektroprivreda Srbije” Power Plants; Institute for testing materials, Contractor: Public Company “Elektroprivreda Srbije”: Belgrade, Serbia, 2011. (In Serbian) [Google Scholar]

- Despotović, J. Study: The Use of Fly Ash of Thermal Power Plants for Soil Stabilization, Self-Compacting and Rolling (RCC) Concrete with Emphasis on Durability of Cement Mortar and Fine Grained Concrete; University of Belgrade—Faculty of Civil Engineering, Contractor: Public Company “Elektroprivreda Srbije”: Belgrade, Serbia, 2014. (In Serbian) [Google Scholar]

- Vukićević, M. Study: The Use of Fly Ash and Slag from "Elektroprivreda Srbije" Thermal Power Plants in Railways; Institute for testing materials/University of Belgrade—Faculty of Civil Engineering, Contractor: Public Company “Elektroprivreda Srbije”: Belgrade, Serbia, 2015. (In Serbian) [Google Scholar]

- Uredba o Tehničkim i Drugim Zahtevima Za Pepeo, Kao Građevinski Materijal Namenjen Za Upotrebu u Izgradnji, Rekonstrukciji, Sanaciji I Održavanju Infrastrukturnih Objekata Javne Namene; Official Gazette of RS, 56/2015: Belgrade, Serbia, 2015. (In Serbian)

- Pravilnik o Granicama Radioaktivne Kontaminacije Životne Sredine i o Načinu Sprovođenja Dekontaminacije; Official Gazette of FRY: Belgrade, Serbia, 1999. (In Serbian)

- Vilotijević, M.; Vukićević, M.; Lazarević, L.; Popović, Z. Sustainable railway infrastructure and specific environmental issues in the Republic of Serbia. Teh. Vjesn. 2018, 25, 516–532. [Google Scholar] [CrossRef]

- Izquierdo, M.; Querol, X. Leaching behaviour of elements from coal combustion fly ash: An overview. Int. J. Coal Geol. 2012, 94, 54–66. [Google Scholar] [CrossRef] [Green Version]

- ASTM C618-15: Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2015.

- Ferguson, G.; Leverson, S.M. Soil and Pavement Base Stabilization with Self-Cementing Coal Fly Ash; American Coal Ash Association International: Alexandria, VA, USA, 1999. [Google Scholar]

- SRPS EN 14227-4: Hydraulically Bound Mixtures—Specifications—Part 4: Fly Ash for Hydraulically Bound Mixtures; Institute for Standardization of Serbia: Belgrade, Serbia, 2014.

- Ferguson, G. Use of self-cementing fly ashes as a soil stabilization agent. ASCE Geotech. Spec. Publ. 1993, 36, 1–14. [Google Scholar]

- Çokça, E. Use of class C fly ashes for the stabilization of an expansive soil. J. Geotech. Geoenviron. 2001, 127, 568–573. [Google Scholar] [CrossRef]

- Acosta, H.A.; Edil, T.B.; Benson, C.H. Soil Stabilization and Drying using Fly Ash. In Geo Engineering Report No. 3; Geo Engineering Program, University of Wisconsin-Madison: Madison, WI, USA, 2003. [Google Scholar]

- Mackiewicz, S.M.; Ferguson, E.G. Stabilization of Soil with Self-Cementing Coal Ashes; 2005 World of Coal Ash (WOCA): Lexington, KY, USA, 2005; pp. 1–7. [Google Scholar]

- Parsons, R.L. Subgrade Improvement through Fly Ash Stabilization; Miscellaneous Report; Kansas University Transportation Center, University of Kansas: Lawrence, KS, USA, 2002. [Google Scholar]

- Parsons, R.L.; Kneebone, E. Field performance of fly ash stabilized subgrades. Proc. ICE Ground Improv. 2005, 9, 33–38. [Google Scholar] [CrossRef]

- White, D.J.; Harrington, D.; Thomas, Z. Fly ash soil stabilization for non-uniform subgrade soils, Volume I: Engineering properties and construction guidelines. In Report No. IHRB Project TR-461, FHWA Project 4; Center for Transportation Research and Education, Iowa State University: Raleigh, NC, USA, 2005. [Google Scholar]

- Senol, A.; Edil, T.B.; Bin-Shafique, M.S.; Acosta, H.A.; Benson, C.H. Soft subgrades’ stabilization by using various fly ashes. Resour. Conserv. Recycl. 2006, 46, 365–376. [Google Scholar] [CrossRef]

- American Coal Ash Association. Fly ash facts for highway engineers. In Technical Report No. FHWA-IF-03-019; FHWA: Washington, DC, USA, 2003. [Google Scholar]

- Pandian, N.S.; Krishna, K.C.; Leelavathamma, B. Effect of fly ash on the CBR behaviour of soils. In Proceedings of the Indian Geotechnical Conference, Allahabad, India, 20–22 December 2002; Volume 1, pp. 183–186. [Google Scholar]

- Ramadas, T.L.; Kumar, N.D.; Yesuratnam, G. A study on strength and swelling characteristics of three expansive soils treated with fly ash. In Proceedings of the International Symposium on Ground Improvement (IS-GI Brussels 2012)—Recent research, Advances & Execution Aspects of Ground Improvement Works, Brussels, Belgium, 30 May–1 June 2012; pp. 459–466. [Google Scholar]

- Kolay, P.K.; Sii, H.Y.; Taib, S.N.L. Tropical peat soil stabilization using class F pond ash from coal fired power plant. IJCEE 2011, 3, 79–83. [Google Scholar] [CrossRef]

- Kumar, S.P. Cementitious compounds formation using pozzolans and their effect on stabilization of soils of varying engineering properties. In Proceedings of the International Conference on Environment Science and Engineering IPCBEE, Singapore, 26–28 February 2011; Volume 8, pp. 212–215. [Google Scholar]

- Vukićević, M.; Maraš-Dragojević, S.; Jocković, S.; Marjanović, M.; Pujević, V. Research results of fine-grained soil stabilization using fly ash from Serbian electric power plants. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering “Challenges and Innovations in Geotechnics”, Paris, France, 2–6 September 2013; pp. 3267–3270. [Google Scholar]

- Nalbantoglu, Z.; Gucbilmez, E. Utilization of an industrial waste in calcareous expansive clay stabilization. Geotech. Test. J. 2002, 25, 78–84. [Google Scholar] [CrossRef]

- Edil, T.B.; Acosta, H.A.; Benson, C.H. Stabilizing soft fine-grained soils with fly ash. J. Mater. Civ. Eng. 2006, 18, 283–294. [Google Scholar] [CrossRef]

- Zia, N.; Fox, P.J. Engineering properties of loess-fly ash mixtures for roadbase construction. Transp. Res. Rec. 2000, 1714, 49–56. [Google Scholar] [CrossRef]

- Meij, R.; Berg, J. Coal fly ash management in Europe trends, regulations and health & safety aspects. In Proceedings of the International Ash Utilization Symposium, Lexington, KY, USA, 20–24 October 2001. [Google Scholar]

- Murthy, A.V.S.R.; Guru, U.K.; Havanagi, V.G. Construction of road embankments using fly ash. In Fly Ash Disposal and Deposition: Beyond 2000 AD; Narosa Publishing House: New Delhi, India, 2000. [Google Scholar]

- McKerall, W.C.; Ledbetter, W.B.; Teague, D.J. Analysis of Fly Ashes Produced in Texas; Texas Transportation Institute, Research Report No. 240-1; Texas A&M University: College Station, TX, USA, 1982. [Google Scholar]

- DiGioia, A.M.; McLaren, R.J.; Burns, D.L.; Miller, D.E. Fly Ash Design Manual for Road and Site Application; Vol. 1: Dry or conditioned placement. Manual Prepared for EPRI, CS-4419, Research, Project 2422-2, Interim Report; Electric Power Research Institute: Palo Alto, CA, USA, 1986. [Google Scholar]

- Kim, B.; Prezzi, M.; Salgado, R. Geotechnical properties of fly and bottom ash mixtures for use in highway embankments. J. Geotech. Geoenviron. 2005, 131, 914–924. [Google Scholar] [CrossRef]

- Sridharan, A.; Pandian, N.S.; Rao, P.S. Shear strength characteristics of some Indian fly ashes. Proc. Inst. Civ. Eng. Ground Improv. 1998, 2, 141–146. [Google Scholar] [CrossRef]

- Chesner, W.H.; Collins, R.J.; MacKay, M.H.; Emery, J. User Guidelines for Waste and By-Product Materials in Pavement Construction; No. FHWA-RD-97-148, Guideline Manual, Rept No. 480017; Recycled Materials Resource Center: Madison, WI, USA, 1998. [Google Scholar]

- Yoder, E.J.; Witczak, M.W. Principles of Pavement Design, 2nd ed.; John Wiley and Sons: Hoboken, NJ, USA, 1975. [Google Scholar]

- Kaniraj, S.R.; Gayathri, V. Permeability and consolidation characteristics of compacted fly ash. J. Energy Eng. 2004, 130, 18–43. [Google Scholar] [CrossRef]

- Kaniraj, S.R.; Havanagi, V. Geotechnical characteristics of fly ash-soil mixtures. Geotech. Eng. 1999, 30, 129–147. [Google Scholar]

- McLaren, R.J.; DiGioia, A.M. The typical engineering properties of fly ash. In Proceedings of the Conference on Geotechnical Practice for Waste Disposal, Ann Arbor, MI, USA, 15–17 June 1987; Woods, R.D., Ed.; ASCE: New York, NY, USA, 1987; pp. 683–697. [Google Scholar]

- Kim, B.; Prezzi, M. Evaluation of the mechanical properties of class-F fly ash. Waste Manag. 2008, 28, 49–59. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Maroto, J.M.; Alonso-Azcárate, J. Plastic limit and other consistency parameters by a bending method and interpretation of plasticity classification in soils. Geotech. Test. J. 2017, 40, 467–482. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Alonso-Azcárate, J. What is clay? A new definition of “clay” based on plasticity and its impact on the most widespread soil classification systems. Appl Clay Sci. 2018, 161, 57–63. [Google Scholar] [CrossRef]

- Barnes, G.E. An apparatus for the plastic limit and workability of soils. Proc. Inst. Civ. Eng. Geotech. Eng. 2009, 162, 175–185. [Google Scholar] [CrossRef]

- Seed, H.B.; Woodward, R.J.; Lundgren, R. Prediction of swelling potential for compacted clays. J. Soil Mech. Found Div. 1962, 88, 53–88. [Google Scholar]

- SuperRoads—Innovative Technology in Road Construction. Available online: http://superroads.rs/technology.html (accessed on January 2015).

- Institute for Standardization of Serbia. SRPS U.B1.014: Testing of Soils—Determination of Density; Institute for Standardization of Serbia: Belgrade, Serbia, 1988. [Google Scholar]

- Institute for Standardization of Serbia. SRPS U.B1.018: Testing of Soils—Determination of Particle Size Distribution; Institute for Standardization of Serbia: Belgrade, Serbia, 2005. [Google Scholar]

- Institute for Standardization of Serbia. SRPS U.B1.020: Testing of Soils—Determination of Atterberg Limits; Institute for Standardization of Serbia: Belgrade, Serbia, 1980. [Google Scholar]

- Institute for Standardization of Serbia. SRPS U.B1.038: Testing of Soil—Determination of the Relation Moisture Content—Density of Soil; Institute for Standardization of Serbia: Belgrade, Serbia, 1997. [Google Scholar]

- Institute for Standardization of Serbia. SRPS.U.B1.029: Testing of Soils—Triaxial Compression Test; Institute for Standardization of Serbia: Belgrade, Serbia, 1996. [Google Scholar]

- Institute for Standardization of Serbia. SRPS.U.B1.028: Testing of Soils—Direct Shear Test; Institute for Standardization of Serbia: Belgrade, Serbia, 1996. [Google Scholar]

- Institute for Standardization of Serbia. SRPS.U.B1.032: Testing of Soils—Determination of Soil Compressibility; Institute for Standardization of Serbia: Belgrade, Serbia, 1970. [Google Scholar]

- Institute for Standardization of Serbia. SRPS EN 13286-47: Unbound and Hydraulically Bound Mixtures—Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling; Institute for Standardization of Serbia: Belgrade, Serbia, 2012. [Google Scholar]

- Institute for Standardization of Serbia. SRPS U.B1.050: Testing of Soils—Resistance Cement Stabilized Soils to Freezing; Institute for Standardization of Serbia: Belgrade, Serbia, 1970. [Google Scholar]

- Terrel, R.L.; Epps, J.A.; Barenberg, E.J.; Mitchell, J.K.; Thompson, M.R. Soil Stabilization in Pavement Structures, A Users Manual; Mixture Design Considerations FHWA-IP-80-2; Federal Highway Administration, Department of Transportation: Washington, DC, USA, 1979; Volume 2. [Google Scholar]

- American Coal Ash Association. Flexible Pavement Manual; American Coal Ash Association: Washington, DC, USA, 1991. [Google Scholar]

- Sharma, N.K.; Swain, S.K.; Umesh, C.S. Stabilization of a clayey soil with fly ash and lime: A micro level investigation. Geotech. Geol. Eng. 2012, 30, 1197–1205. [Google Scholar] [CrossRef]

- STO 69646750-001-2011: Soil and Asphalt-Granules-Concrete Mixtures Reinforced with Soil Stabilizer PolybondTM for Use during Automobile Road, Railroad and Airfield Constructions; SuperRoadRus: Moscow, Russia, 2011.

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics in Engineering Practice, 3rd ed.; John Wiley and Sons: New York, NY, USA, 1967; pp. 241–290. [Google Scholar]

- Bowles, J.E. Foundation Analysis and Design, 5th ed.; McGraw-Hill: New York, NY, USA, 1996. [Google Scholar]

- Davis, E.H. The California bearing ratio method for the design of flexible roads and runways. Géotechnique 1949, 1, 249–263. [Google Scholar] [CrossRef]

- Briaud, J.L. Geotechnical Engineering: Unsaturated and Saturated Soils, 1st ed.; John Wiley and Sons: New York, NY, USA, 2013; p. 122. [Google Scholar]

- Jones, D.E., Jr.; Holtz, W.G. Expansive soils-the hidden disaster. Civ. Eng. 1973, 43, 49–51. [Google Scholar]

- Nalbantoğlu, Z. Effectiveness of class C fly ash as an expansive soil stabilizer. Constr. Build. Mater. 2004, 18, 377–381. [Google Scholar] [CrossRef]

- U. S. Navy. Design Manual—Soil Mechanics, Foundations, and Earth Structures; NAVFAC DM 7; U. S. Navy: Alexandria, VA, USA, 1986.

- Carrier, W.D. Compressibility of a compacted sand. J. Geotech. Geoenviron. 2000, 126, 273–275. [Google Scholar] [CrossRef]

| Gs | Grain Size Distribution | Atterberg Limits | Swell % | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Clay <0.002 mm | Silt 0.002–0.06 mm | Sand 0.06–2 mm | Gravel 2–60 mm | Fines <0.075 mm | LL % | PL % | PI % | ||

| 2.67 | 22 | 72 | 6 | - | 96 | 51.0 | 31.5 | 19.5 | 2.2 |

| Material | Gs | Grain Size Distribution (%) | ||||

|---|---|---|---|---|---|---|

| Clay <0.002 mm | Silt 0.002–0.06 mm | Sand 0.06–2.0 mm | Gravel 2–60 mm | Fines <0.075 mm | ||

| KOL FA | 2.13 | 0–2 | 60–65 | 35–38 | - | 67–72 |

| KOS FA | 2.22 | - | 75 | 25 | - | 80 |

| KOS AB | 2.41 | 2 | 10–22 | 77–89 | - | 14–27 |

| TENT A | 2.39 | 0–1 | 40–41 | 57–58 | - | 49–50 |

| TENT B | 2.26 | 2 | 14–31 | 65–82 | 2 | 22–40 |

| Material | Chemical Composition (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | SO3 | P2O5 | |

| KOL FA [7] | 50.21 | 23.83 | 9.89 | 4.79 | 3.12 | 0.44 | 0.35 | 0.54 | 5.24 | 0.060 |

| KOS FA [7] | 56.38 | 17.57 | 10.39 | 7.46 | 2.13 | 0.57 | 0.38 | 0.52 | 0.95 | 0.025 |

| KOS AB [6] | 53.61 | 17.72 | 8.05 | 7.44 | 1.78 | 1.22 | 0.86 | 0.51 | 0.12 | 0.068 |

| TENT A [6] | 56.14 | 15.93 | 5.77 | 7.54 | 1.48 | 1.23 | 0.86 | 0.52 | 0.12 | 0.058 |

| TENT B [6] | 59.73 | 20.97 | 5.99 | 5.83 | 2.21 | 1.18 | 0.41 | 0.57 | 0.48 | 0.023 |

| Consistency (%) | Setting Time (min) | Compressive Strength After 2 Days (MPa) | Compressive Strength After 28 Day (MPa) |

|---|---|---|---|

| 27–29 | 160–250 | 26–28 | 49.5–54.5 |

| Material | Compaction | Compressibility | Strength | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Proctor Test (600 kJ/m3) | Mv (kPa) | Direct shear | UCS | ||||||

| OMC (%) | γd,max (kN/m3) | 50–100 kPa | 100–200 kPa | 200–400 kPa | φ’ (°) | c’ (kN/m2) | qu (kN/m2) | CBR (%) | |

| CH clay | 19.1 | 16.6 | 14300 | 10400 | 10800 | 25.5 | 26.0 | 231 | 4.5 |

| KOL FA | 49.8–55.0 | 8.0 | 17700 | 24900 | 31400 | 29.5 | 36.5 | 83 | 13 |

| KOS FA | 37.5–43.9 | 9.0–9.8 | 25800 | 39200 | 42900 | 31.0 | 28.5 | 87 | 57 |

| Material | Compaction | Compressibility | Strength | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Proctor Test (600 kJ/m3) | Mv (kPa) | Direct Shear | UCS | ||||||

| OMC (%) | γd,max (kN/m3) | 50–100 kPa | 100–200 kPa | 200–400 kPa | φ’ (°) | c’ (kN/m2) | qu (kN/m2) | CBR (%) | |

| KOS FA | 37.5–43.9 | 9.0–9.8 | 25800 | 39200 | 42900 | 31.0 | 28.5 | 87 | 57 |

| KOS AB | 48.1 | 9.1 | 10000 | 12600 | 22700 | 35.0 | 18.5 | 37 | 24 |

| TENT A | 48.5 | 8.9 | 14100 | 23300 | 34200 | 34.5 | 7.0 | 49 | 7 |

| TENT B | 33.7 | 10.4 | 19300 | 20700 | 26200 | 33.5 | 20.0 | 87 | 12 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vukićević, M.; Marjanović, M.; Pujević, V.; Jocković, S. The Alternatives to Traditional Materials for Subsoil Stabilization and Embankments. Materials 2019, 12, 3018. https://doi.org/10.3390/ma12183018

Vukićević M, Marjanović M, Pujević V, Jocković S. The Alternatives to Traditional Materials for Subsoil Stabilization and Embankments. Materials. 2019; 12(18):3018. https://doi.org/10.3390/ma12183018

Chicago/Turabian StyleVukićević, Mirjana, Miloš Marjanović, Veljko Pujević, and Sanja Jocković. 2019. "The Alternatives to Traditional Materials for Subsoil Stabilization and Embankments" Materials 12, no. 18: 3018. https://doi.org/10.3390/ma12183018