Fractal Analysis of the Fracture Evolution of Freeze-Thaw Damage to Asphalt Concrete

Abstract

:1. Introduction

2. Experiment

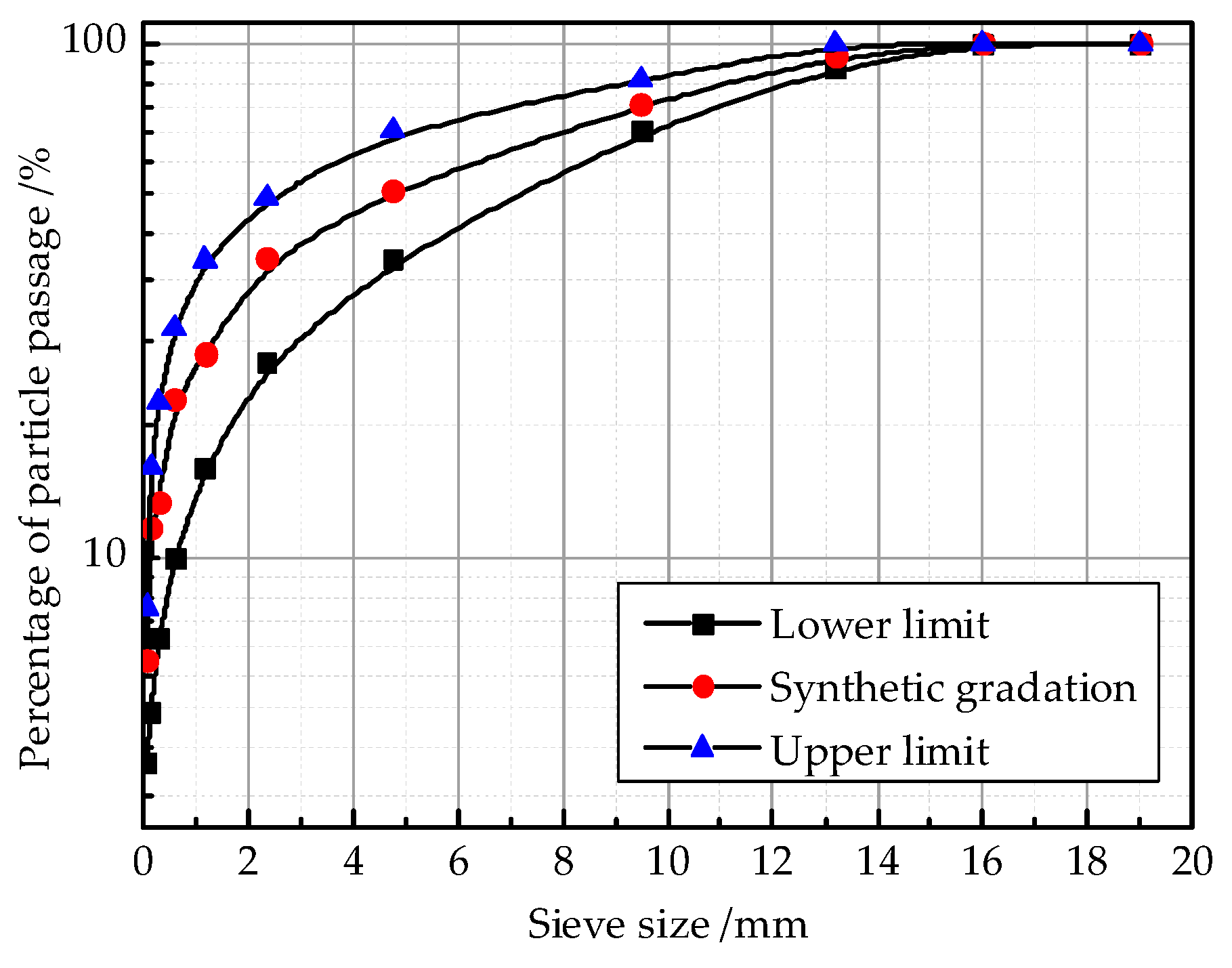

2.1. Materials and Methodology

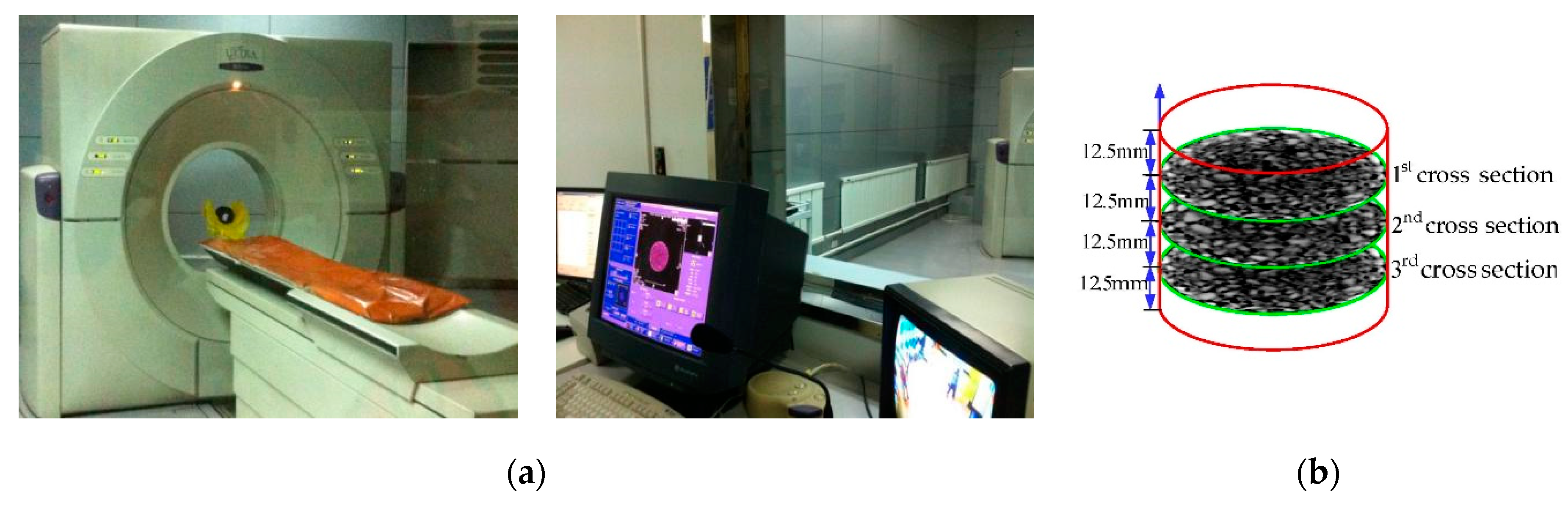

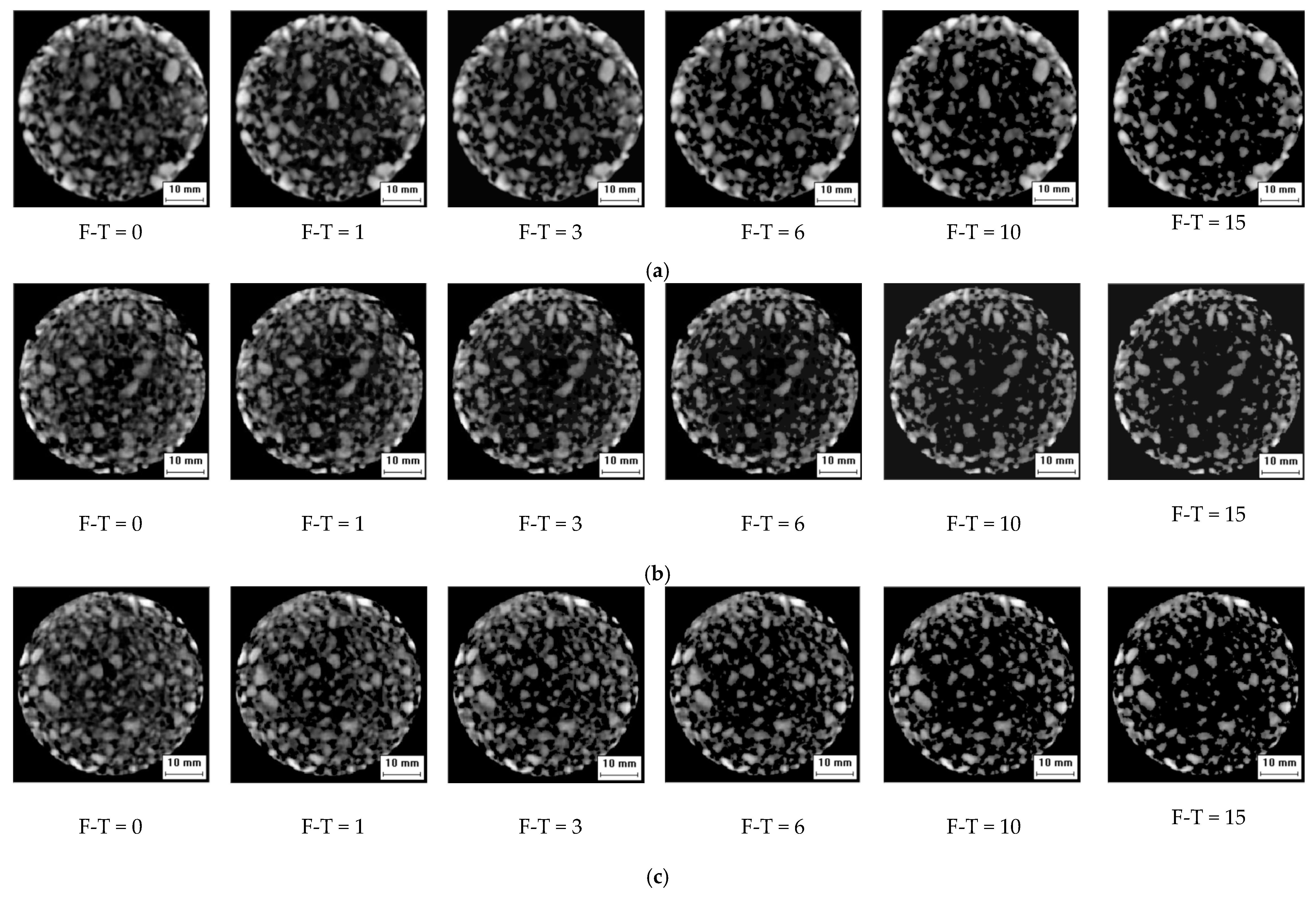

2.2. CT Scanning

3. Results Analysis

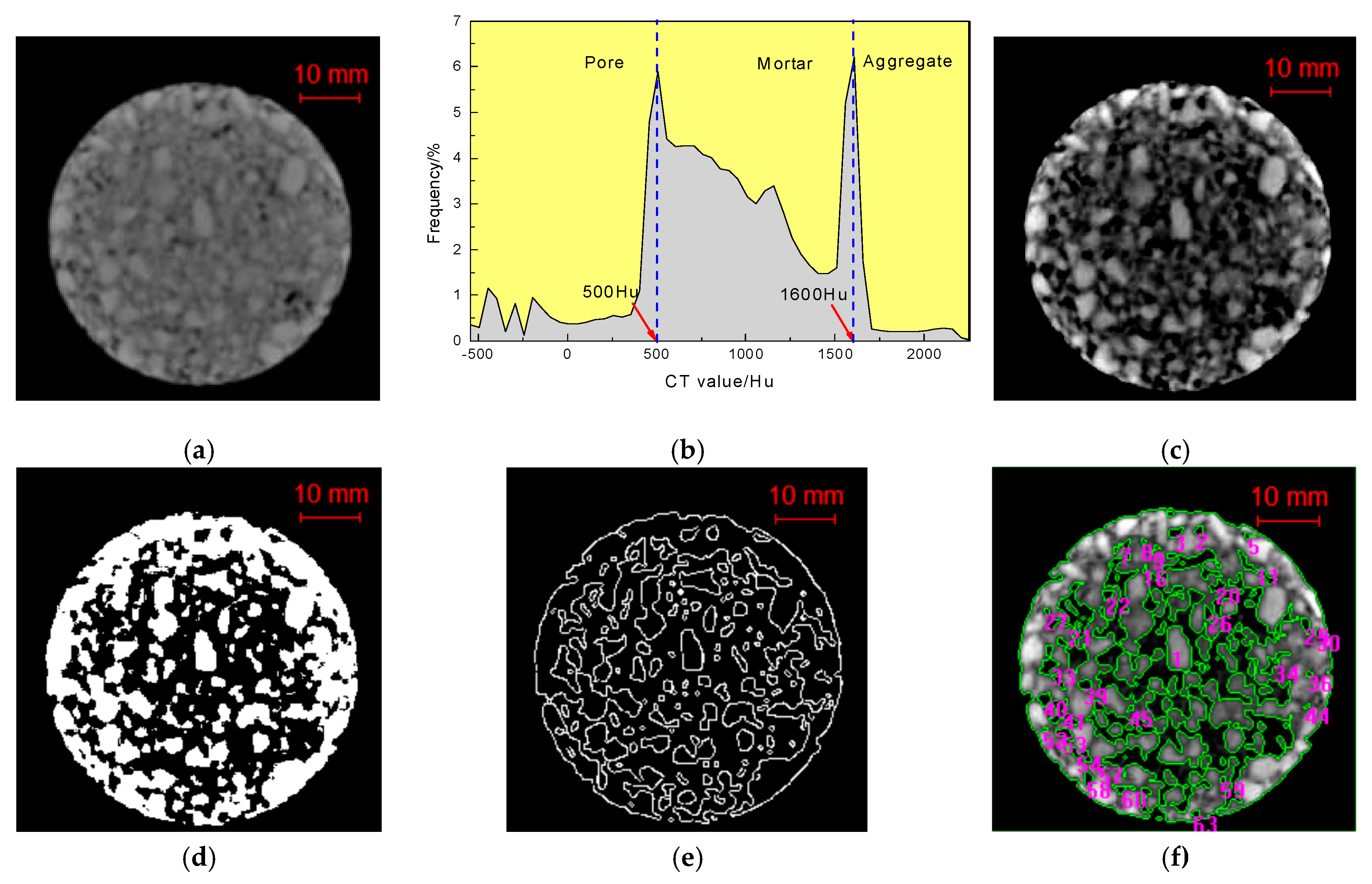

3.1. Digital Image Processing Technology

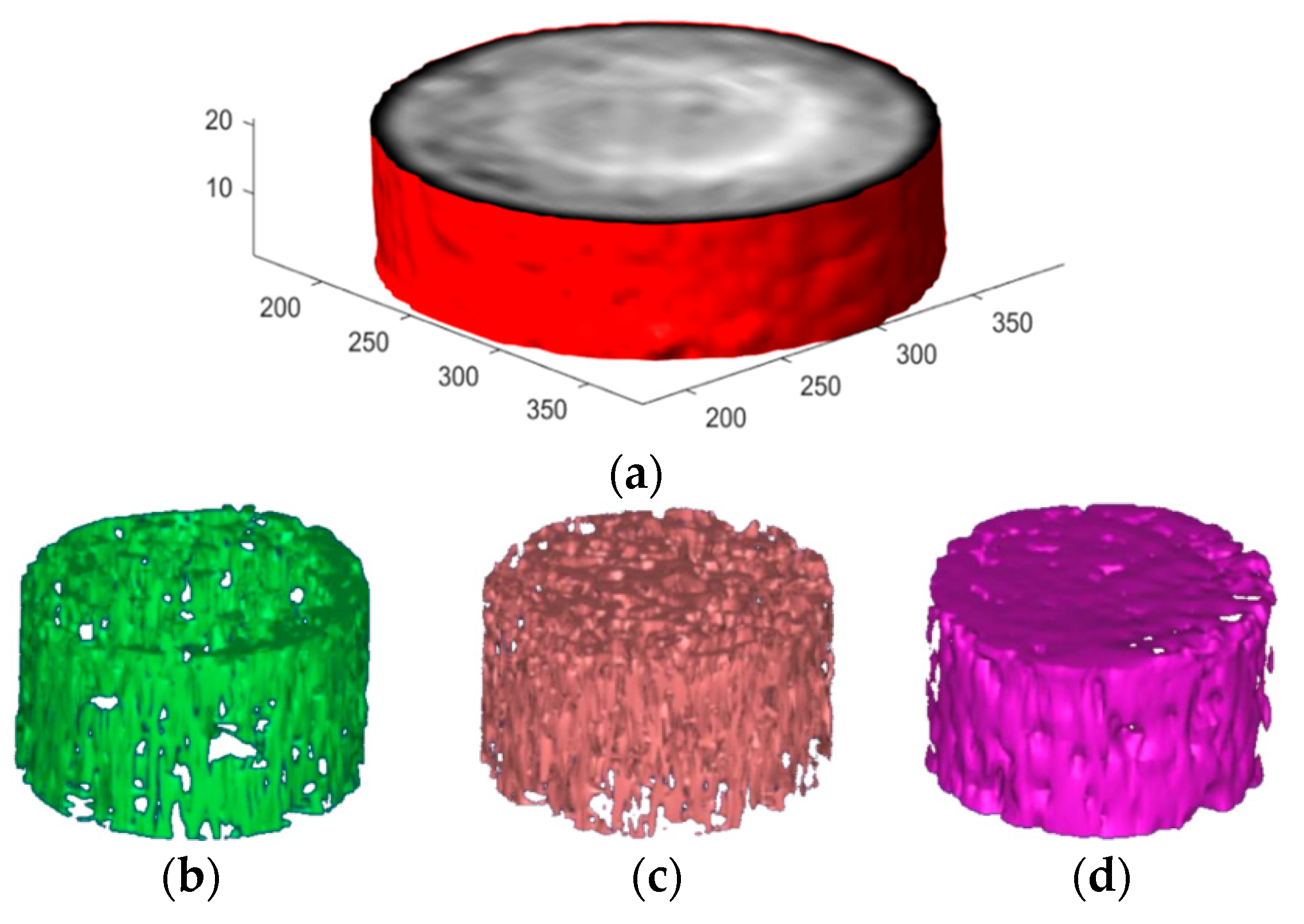

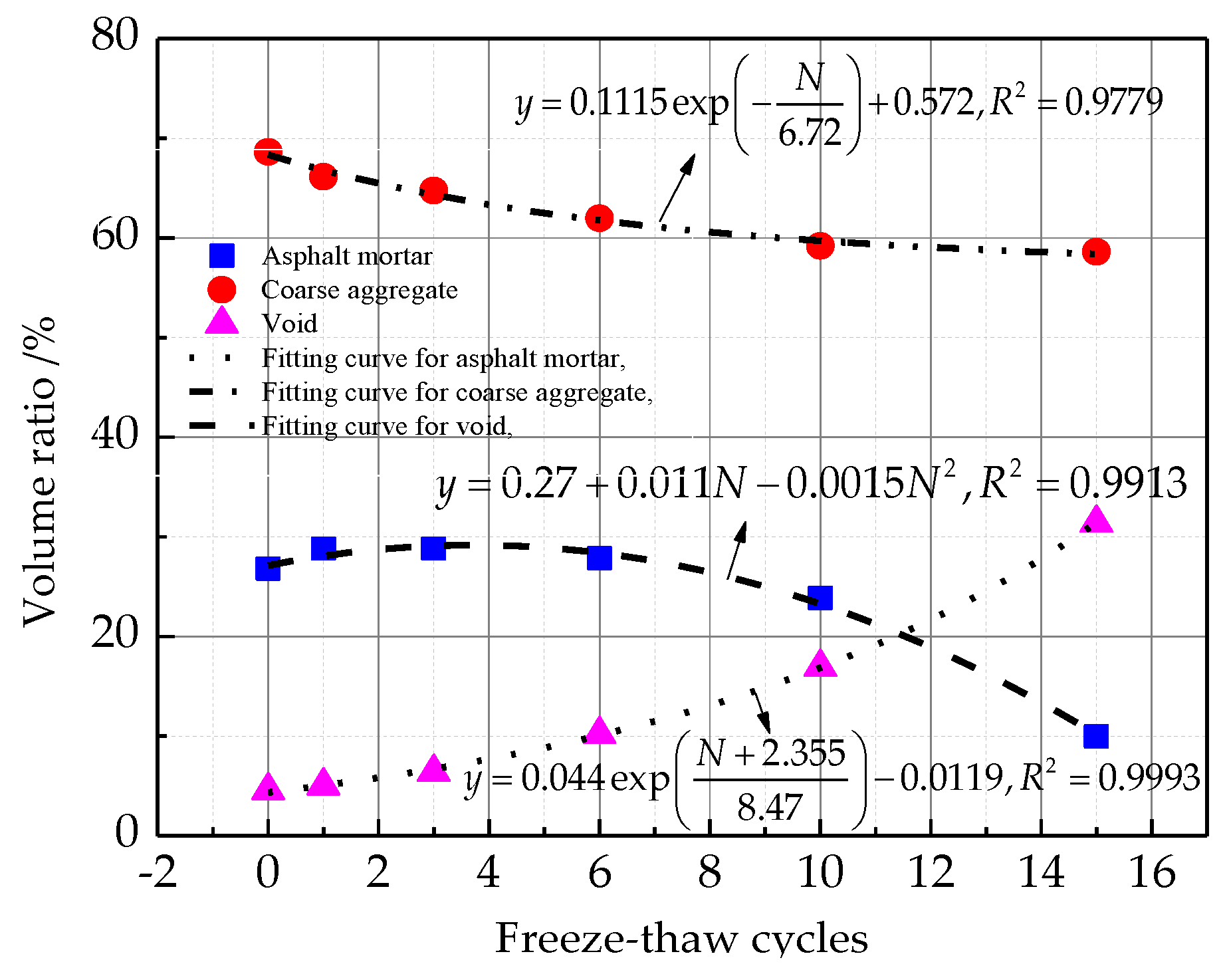

3.2. 3D Reconstruction Technology

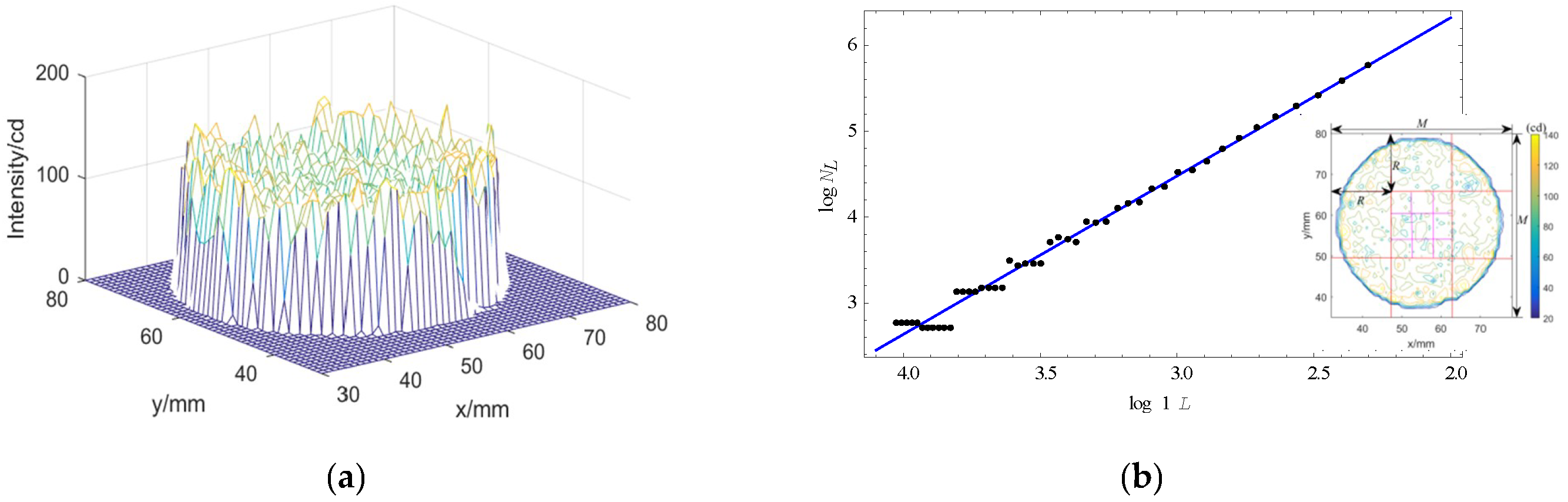

3.3. Fractal Dimension

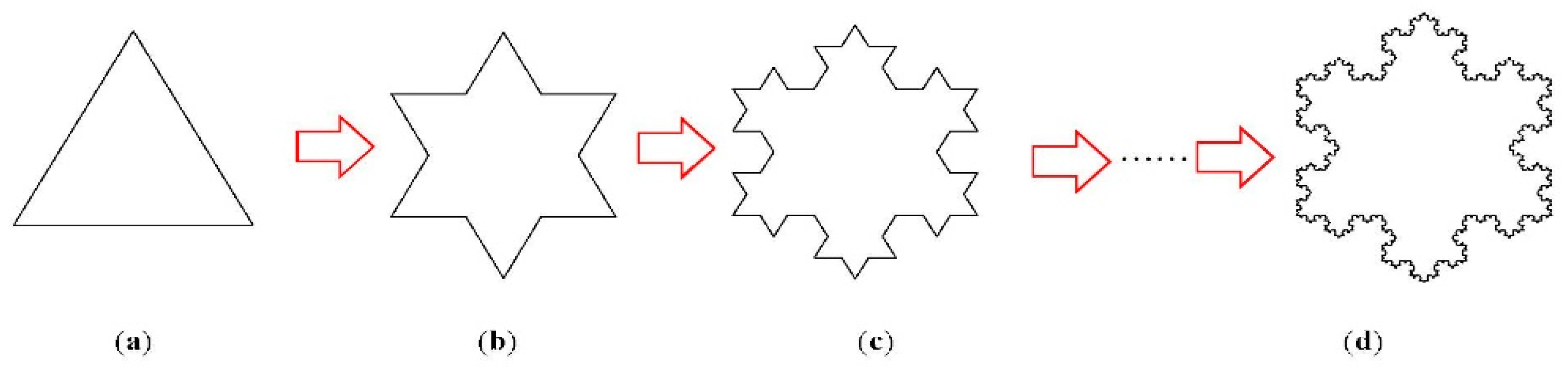

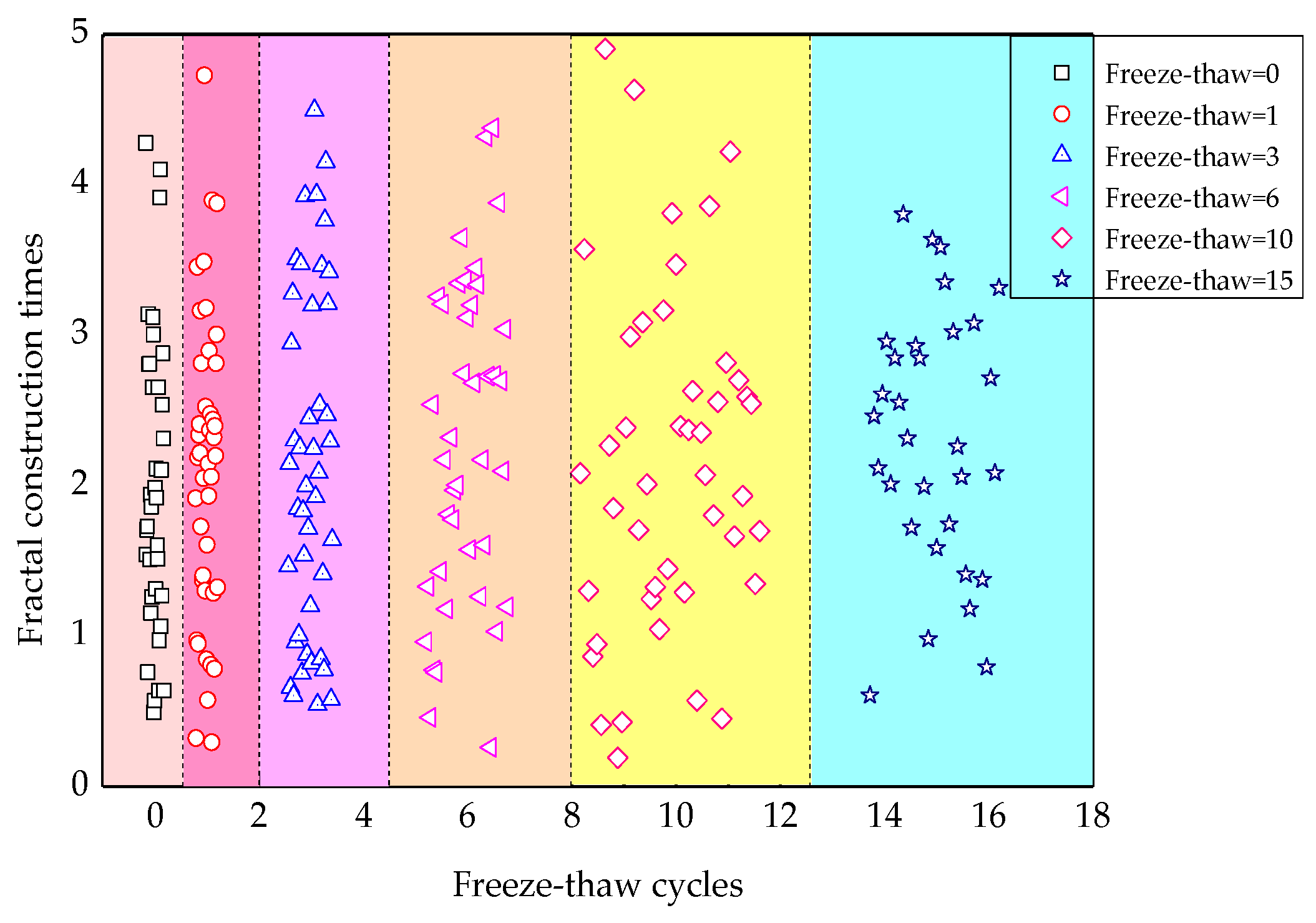

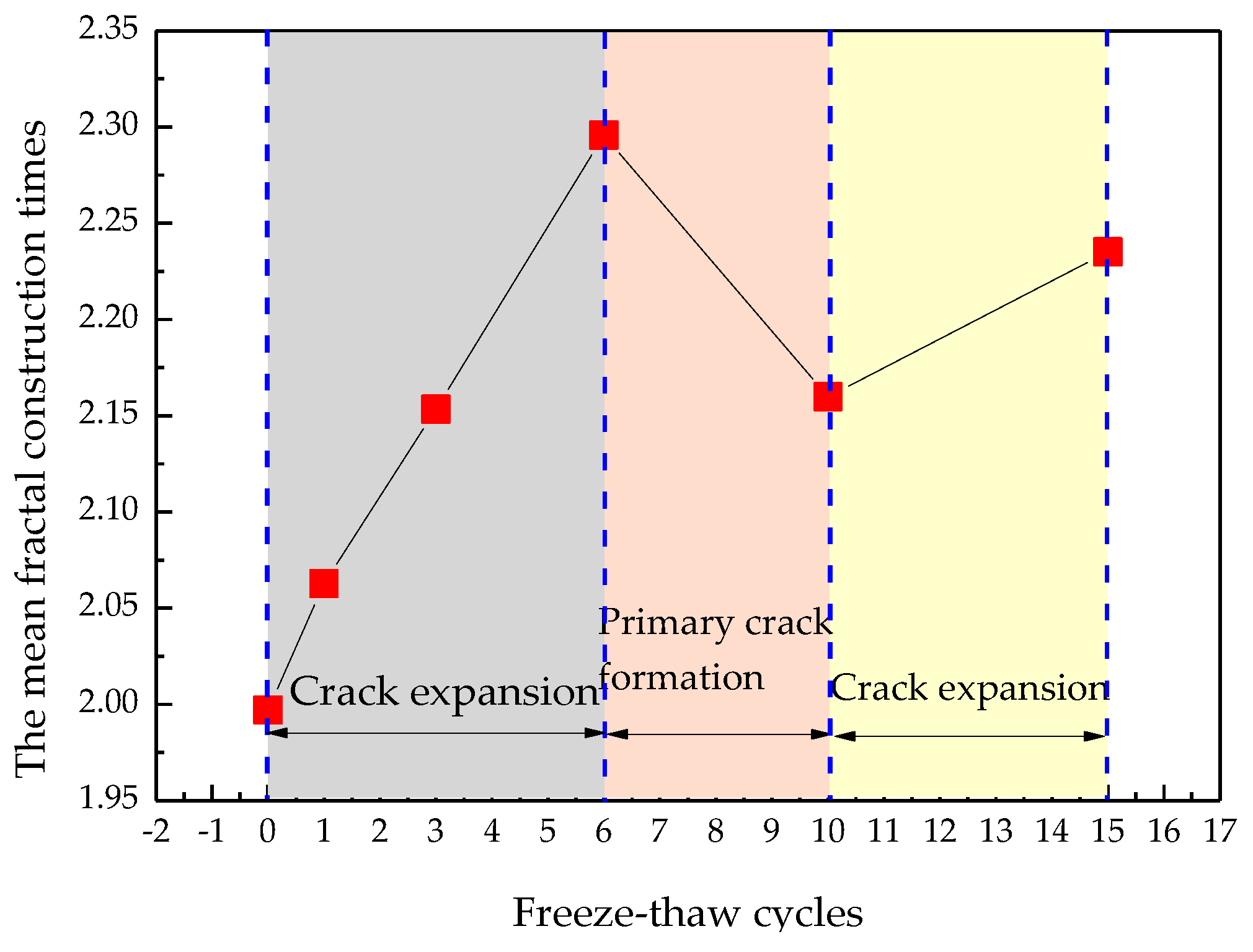

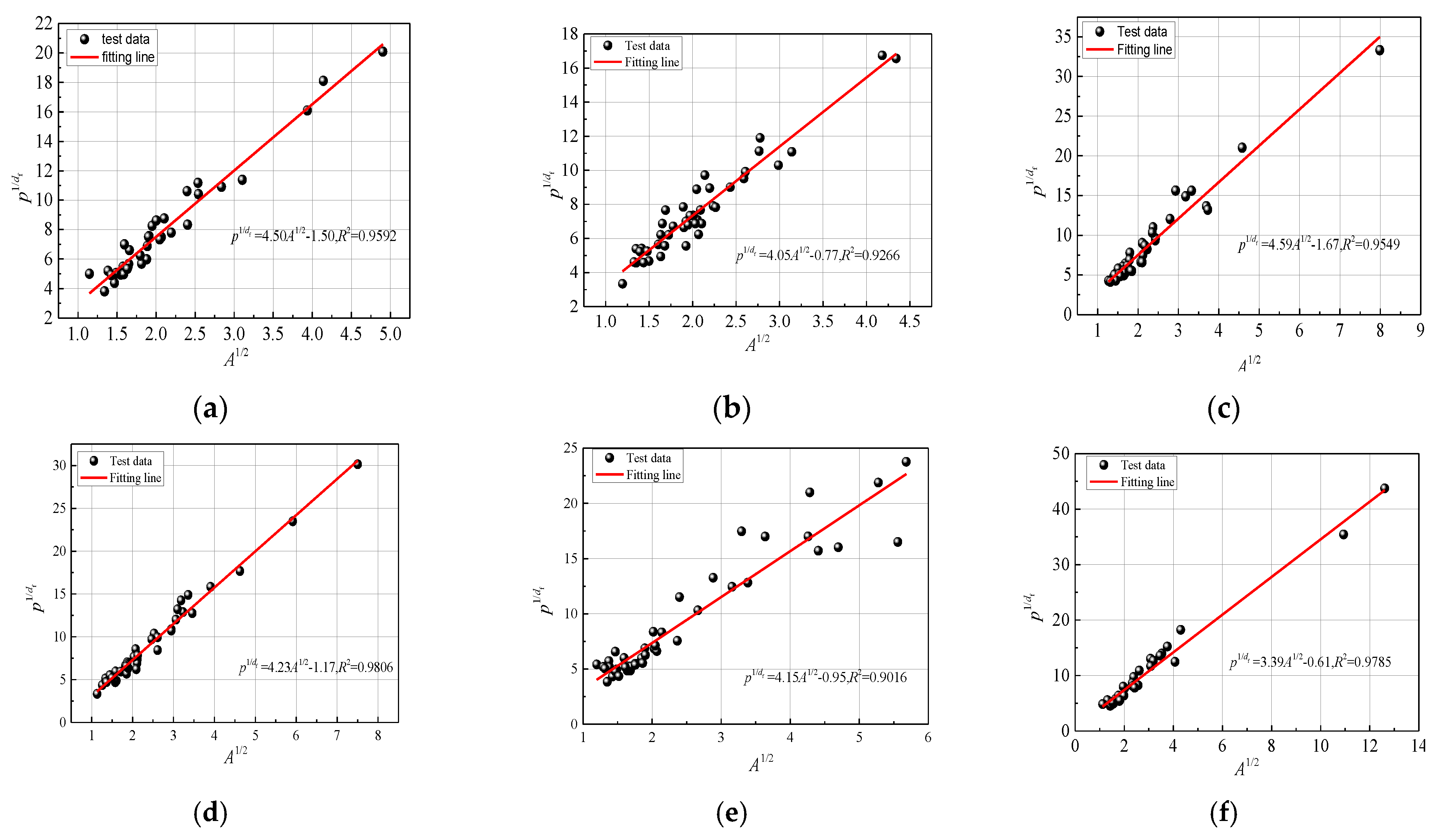

3.4. Fractal Construction of Cracks

4. Discussion

4.1. Fracture Toughness

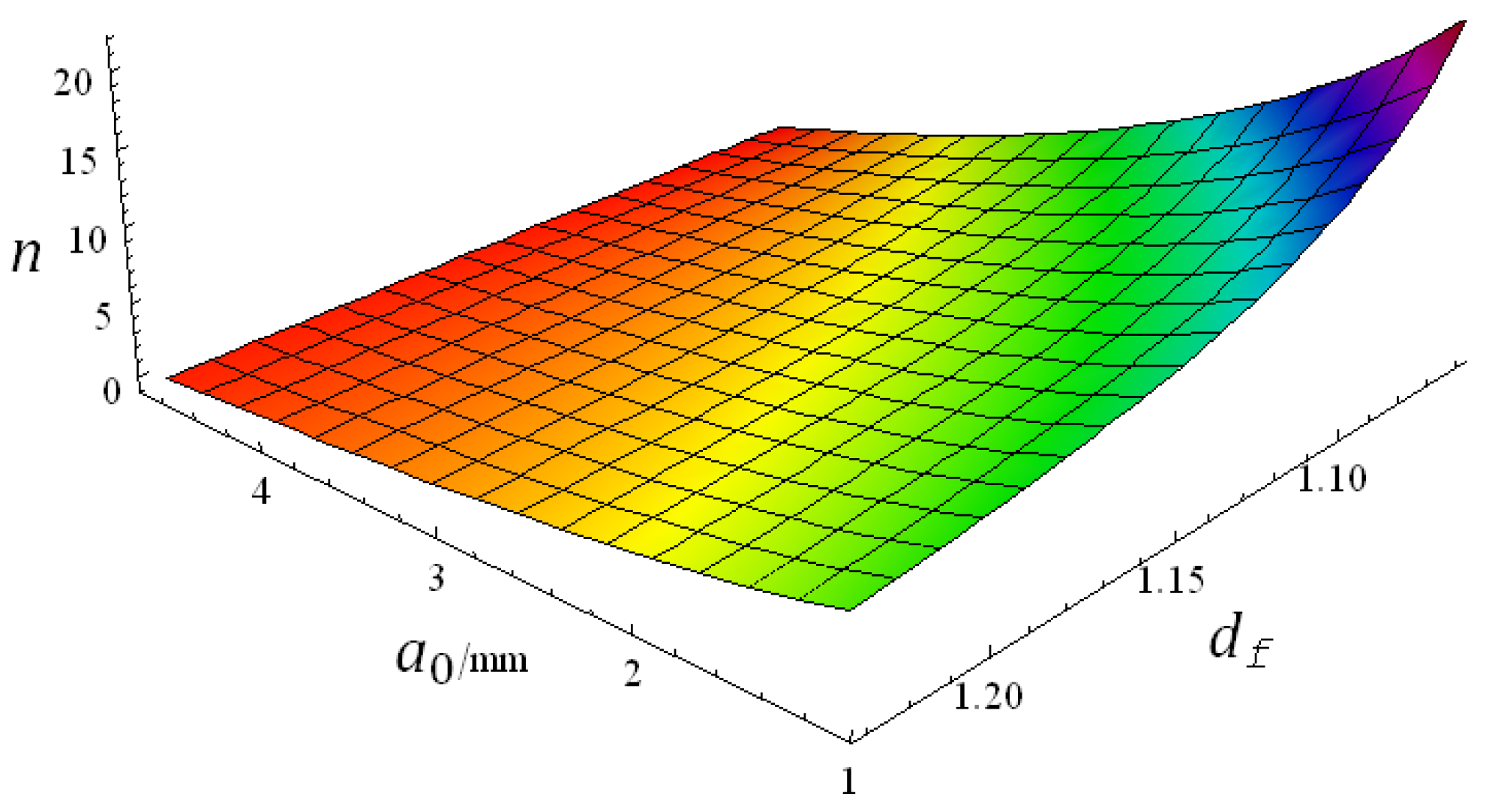

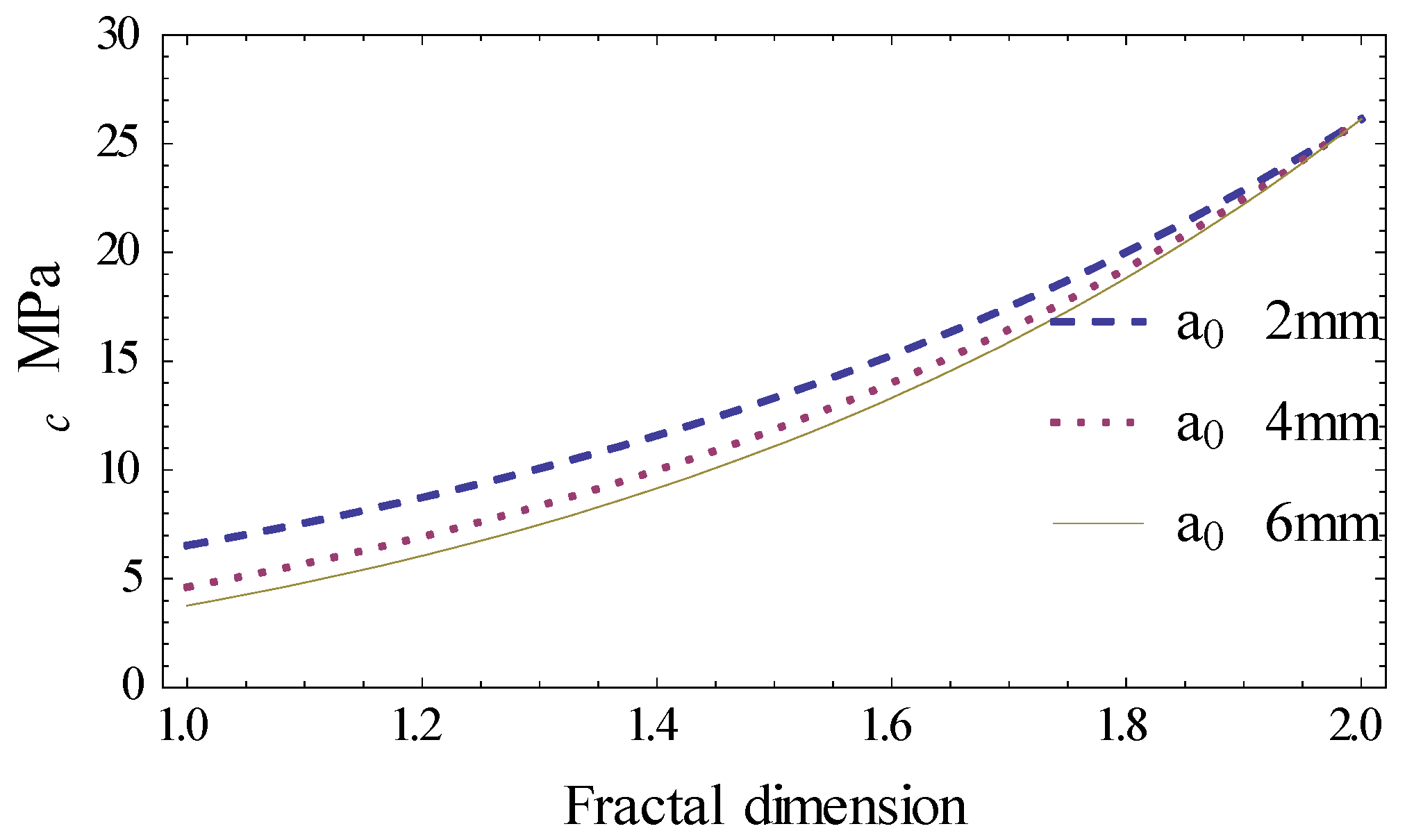

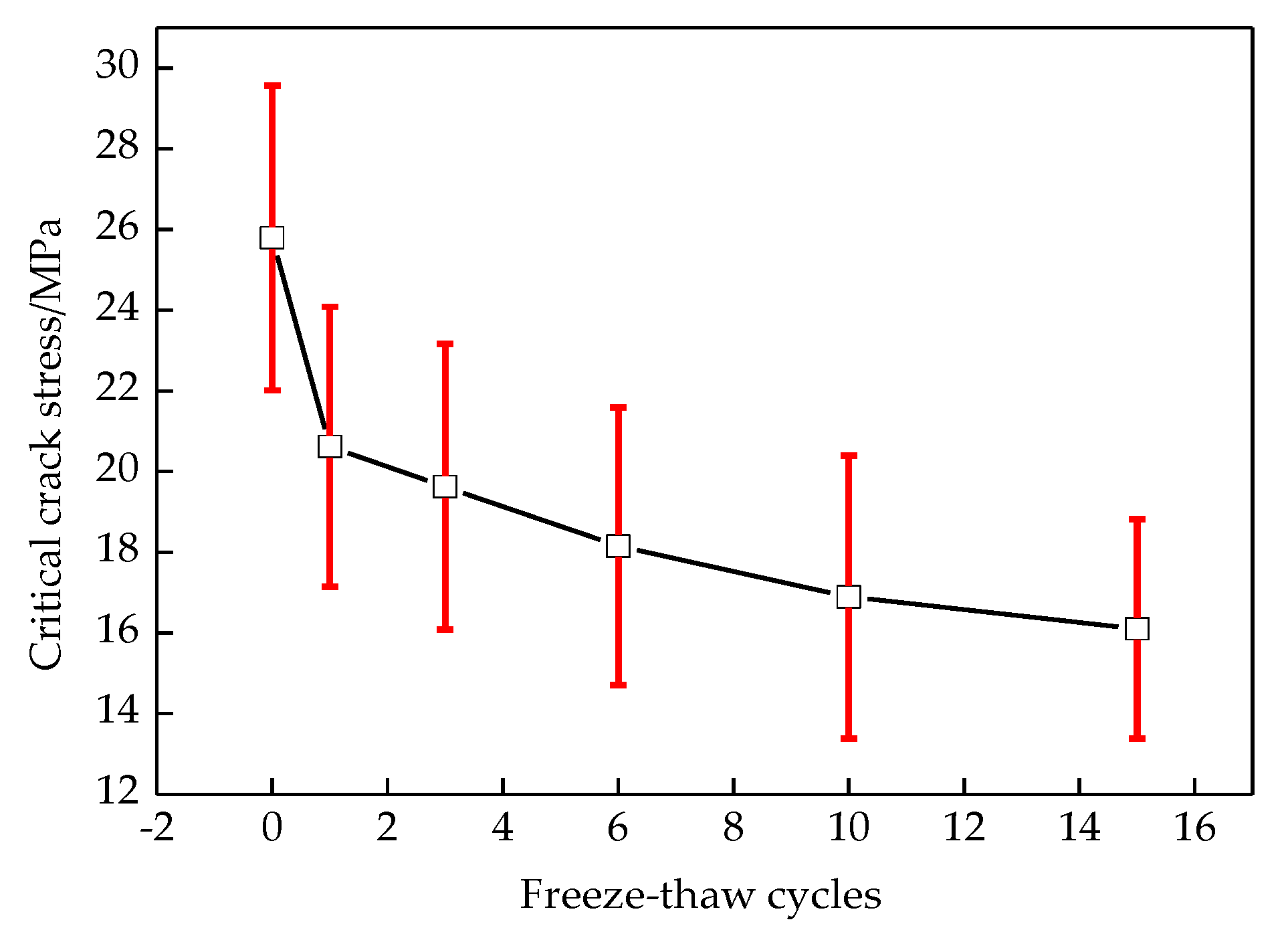

4.2. The Critical Cracking Stress

- The free surface energy γ = 0.5 J·m−2;

- The fractal proportional coefficient is c = 4.05;

- The fractal size δ = /32.

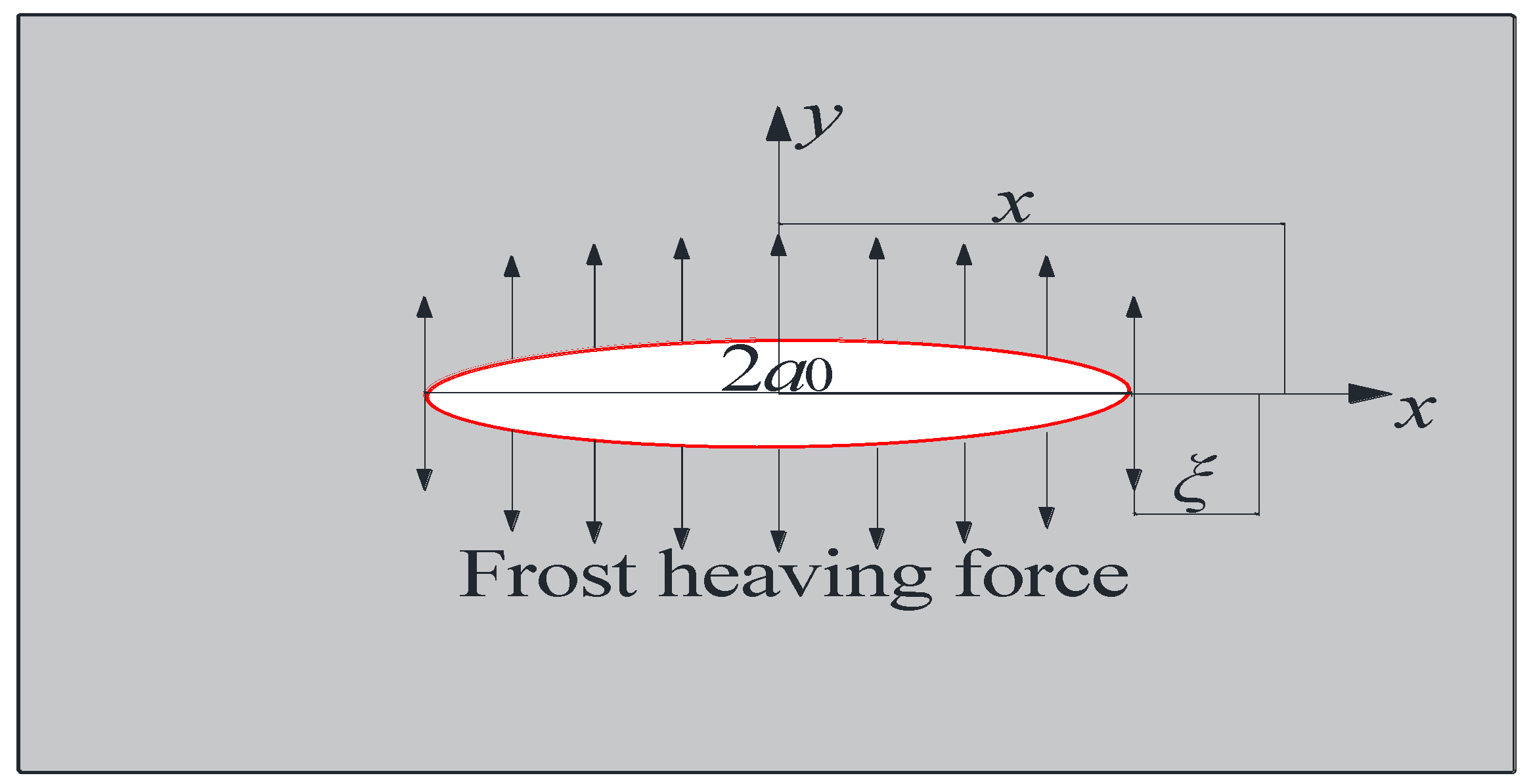

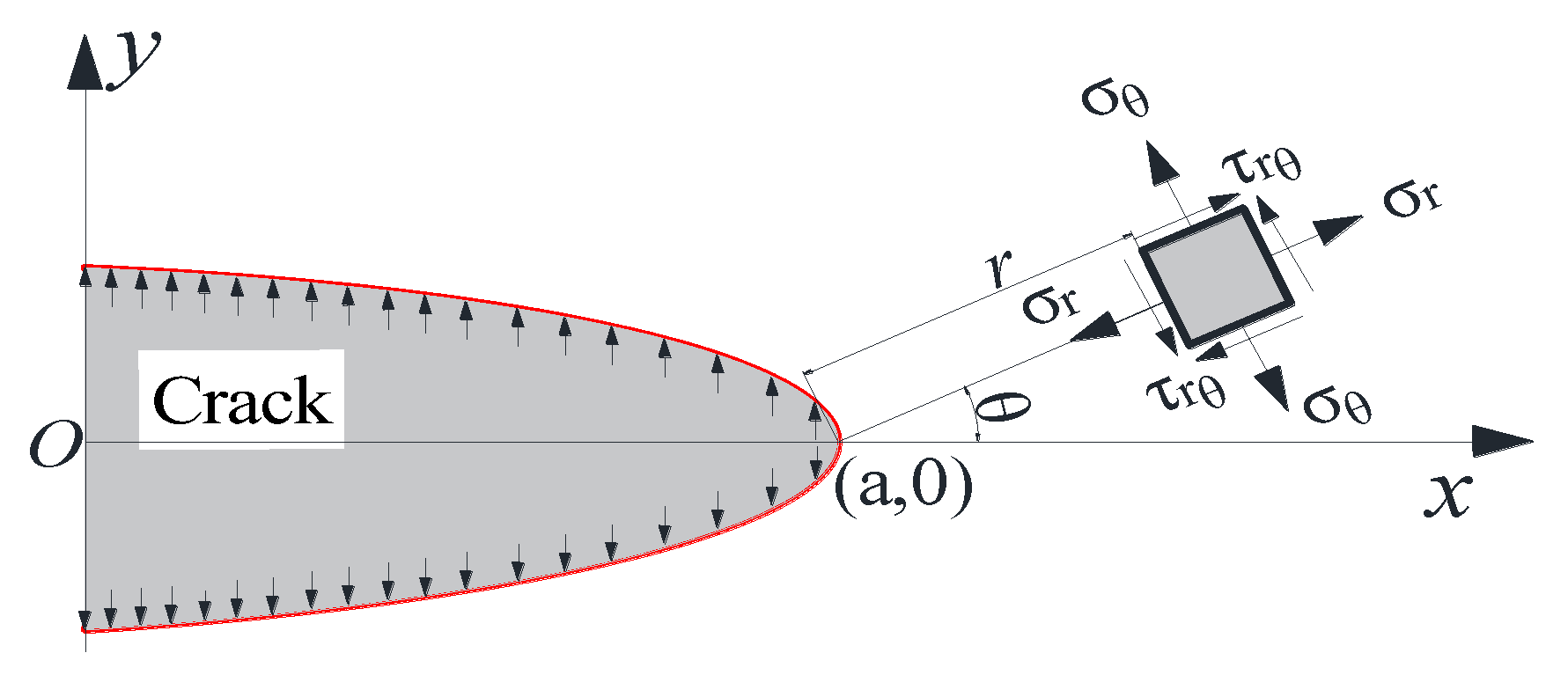

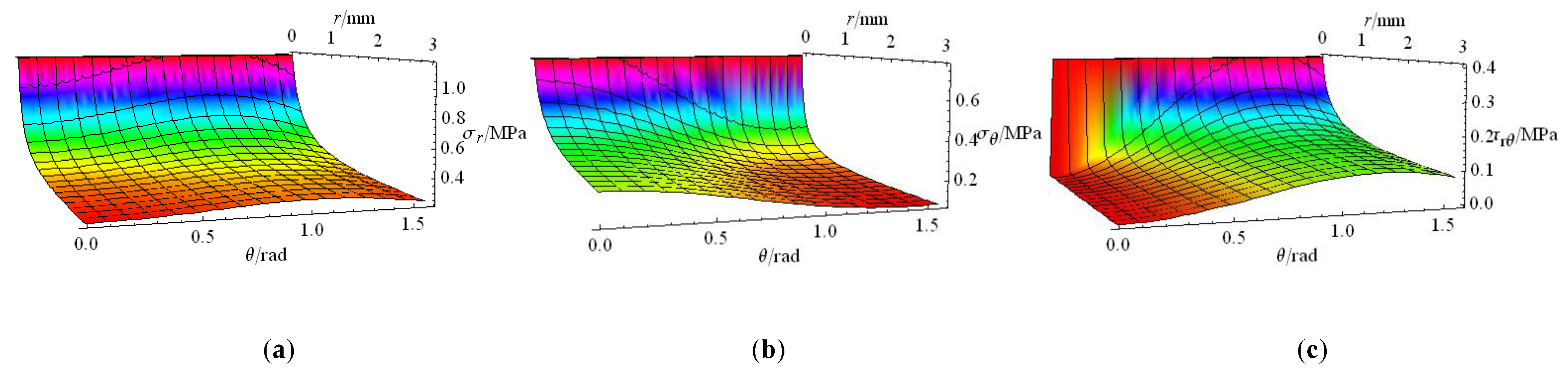

4.3. Intensity Factor of Frost Heave Stress

- when y = 0, , .

- when , .

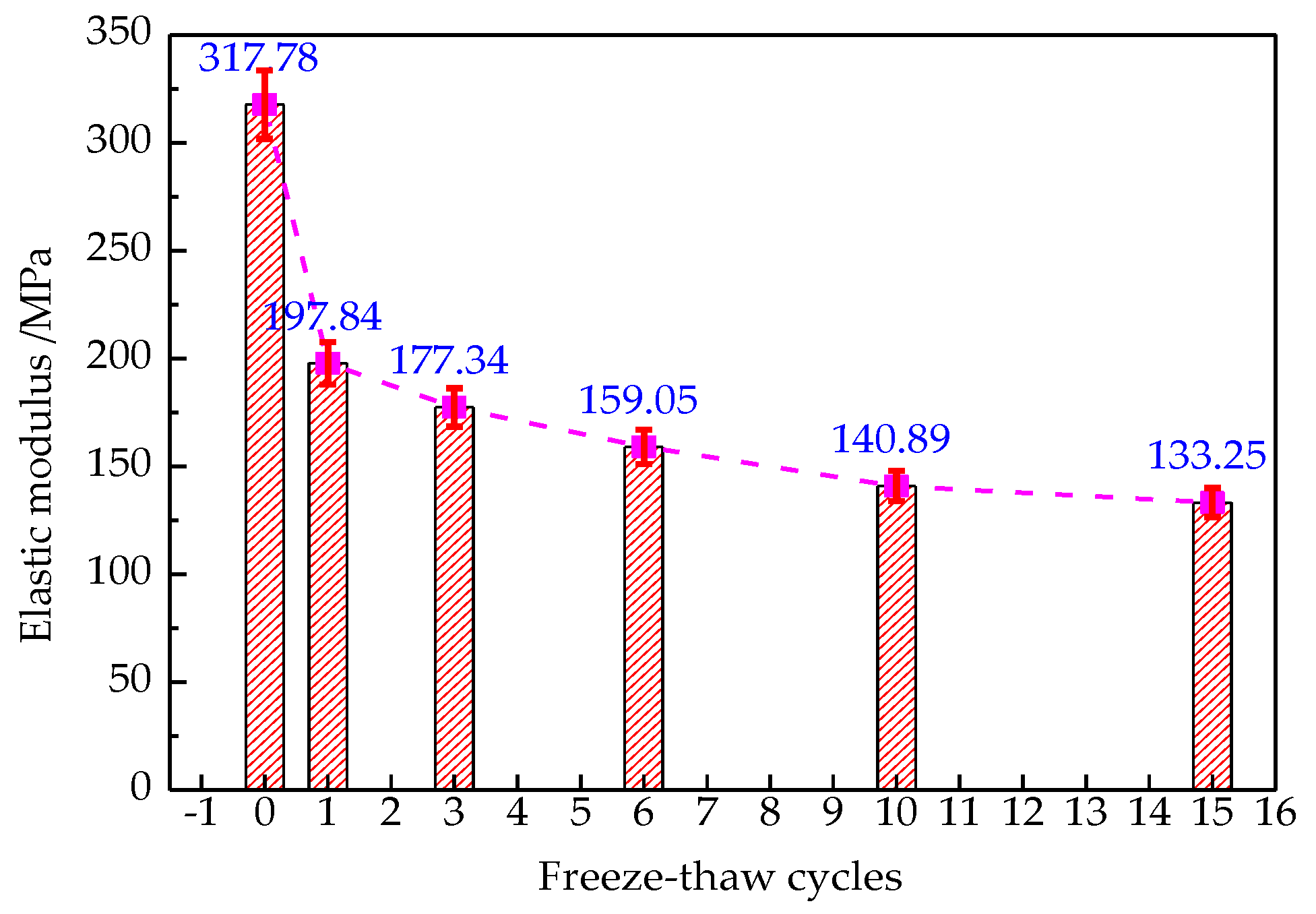

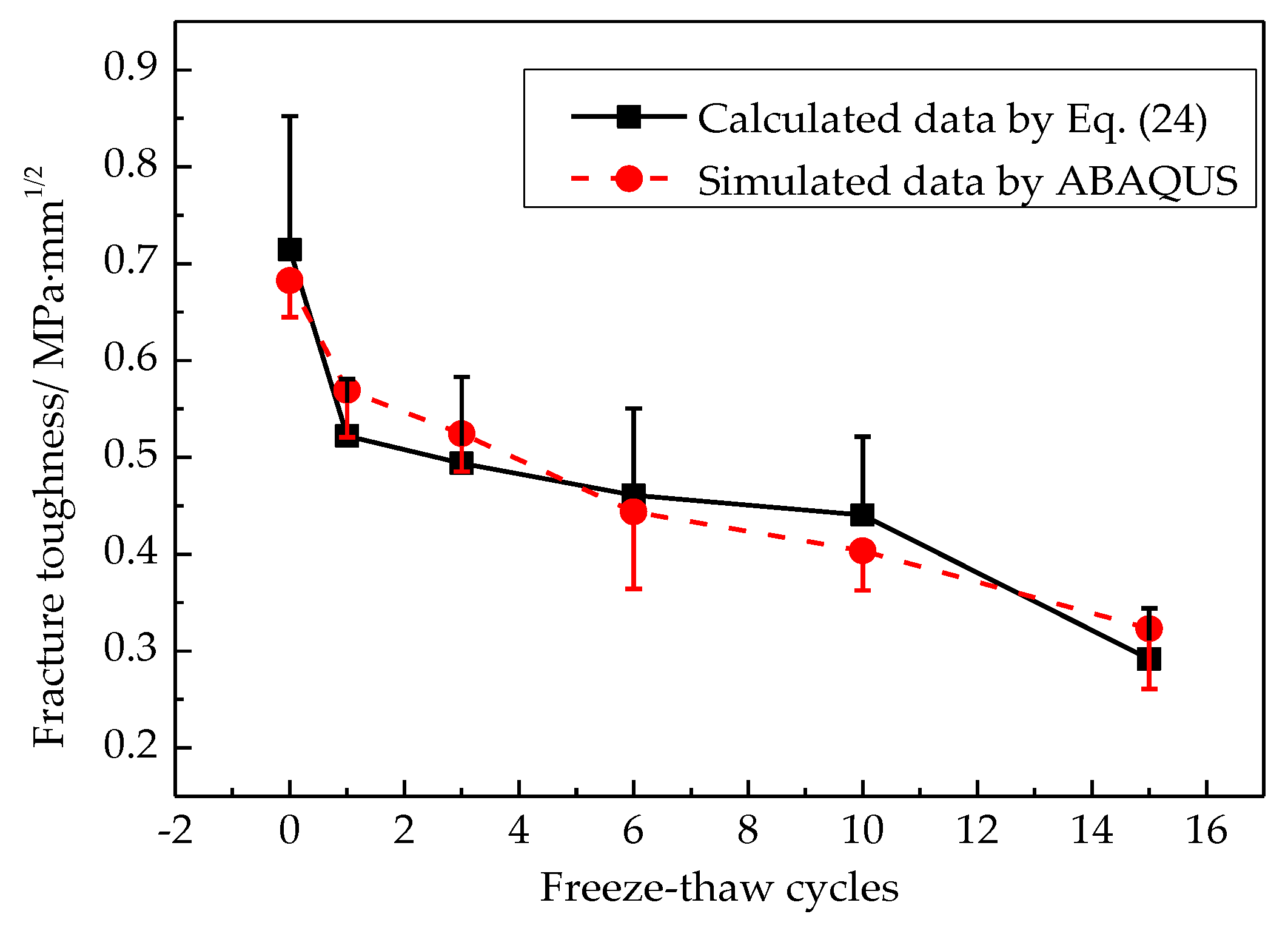

4.4. Fracture Toughness

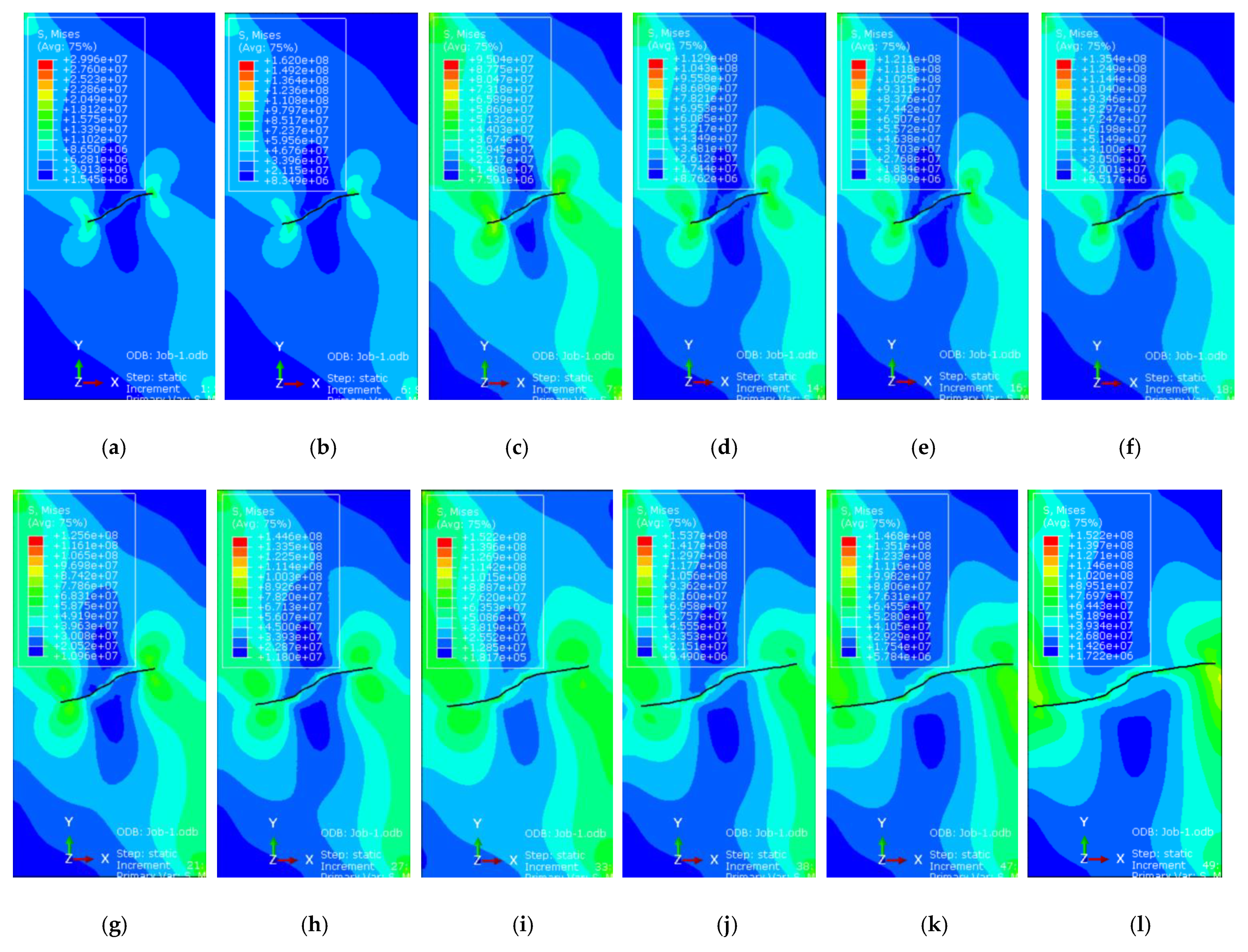

4.5. Certification

5. Conclusions

- A quantitative analysis of internal mesoscopic cracks could be regarded as the quantity index that reflected the freeze-thaw damage process of asphalt concrete. It confirmed that the fracture process of asphalt concrete accumulates gradually with the evolution of the cracks’ fractal dimensions. A transition develops from meso-crack to failure. Optical intensity was used to calculate the fractal dimension of the whole CT gray image, which ranged from 1.9 to 1.99.

- The digital image processing technique was successfully applied to this study by introducing a series of software, such as MATLAB, IPP, MATHEMATICA, and MIMICS. The spatial distribution state of aggregates, asphalt mortars, and pores can be visualized using 3D reconstruction and threshold segmentation based on CT number. The fractal dimension of a single crack was obtained using the function of IPP measurement.

- The law on the fracture and damage evolution is established by combining Griffith fracture theory and fractal theory. The calculation results show that critical stress grows with increasing the fractal dimension, and the longer the projection crack length, the less critical the crack stress will be. Meanwhile, the fracture toughness displays similar regularity. The calculation results, obtained using Equation (24), were very closed to the numerical simulation results obtained by ABAQUS.

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, Y.J.; Lin, H.W.; Han, Z.C.; Deng, C.Q. Fatigue Properties of Cold-Recycled Emulsified Asphalt Mixtures Fabricated by Different Compaction Methods. Sustainability 2019, 11, 3483. [Google Scholar] [CrossRef]

- Chen, Y.J.; Hu, K.; Cao, S.H. Thermal Performance of Novel Multilayer Cool Coatings for Asphalt Pavements. Materials 2019, 12, 1903. [Google Scholar] [CrossRef] [PubMed]

- Yang, Q.L.; Liu, Q.; Zhong, J.; Hong, B.; Wang, D.W.; Oeser, M. Rheological and micro-structural characterization of bitumen modified with carbon nanomaterials. Constr. Build. Mater. 2019, 201, 580–589. [Google Scholar] [CrossRef]

- Lan, T.; Wang, J. Settlement Prediction and Differential Settlement Criterion for Heightening and Thickening Levee. Appl. Sci. 2018, 8, 2392. [Google Scholar] [CrossRef]

- Qian, G.P.; Li, S.J.; Yu, H.N.; Gong, X.B. Interlaminar Bonding Properties on Cement Concrete Deck and Phosphorous Slag Asphalt Pavement. Materials 2019, 12, 1427. [Google Scholar] [CrossRef] [PubMed]

- Li, L.I.; He, Z.Y.; Liu, W.D.; Hu, C. A Study on the Application of Rock Asphalt from Sichuan China Based on Anti-Rutting Performance. Appl. Sci. 2019, 9, 870. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Wang, W.S.; Gong, Y.F.; Wang, S.R.; Yang, S.Y.; Sun, X. Comparative Study on the Damage Characteristics of Asphalt Mixtures Reinforced with an Eco-Friendly Basalt Fiber under Freeze-thaw Cycles. Materials 2018, 11, 2488. [Google Scholar] [CrossRef]

- Guo, S.C.; Dai, Q.L.; Hiller, J. Investigation on the freeze-thaw damage to the jointed plain concrete pavement under different climate conditions. Struct. Civ. Eng. 2018, 12, 227–238. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Yu, D.; Tan, G.J.; Zhu, C.F. Low-Temperature Performance and Damage Constitutive Model of Eco-Friendly Basalt Fiber–Diatomite-Modified Asphalt Mixture under Freeze-Thaw Cycles. Materials 2018, 11, 2148. [Google Scholar] [CrossRef]

- Teltayev, B.; Oliviero, C.; Izmailova, G.; Amirbayev, E. Effect of Freeze-Thaw Cycles on Mechanical Characteristics of Bitumens and Stone Mastic Asphalts. Appl. Sci. 2019, 9, 458. [Google Scholar] [CrossRef]

- Wang, W.S.; Cheng, Y.C.; Ma, G.R.; Tan, G.J.; Sun, X.; Yang, S.T. Further Investigation on Damage Model of Eco-Friendly Basalt Fiber Modified Asphalt Mixture under Freeze-Thaw Cycles. Appl. Sci. 2019, 9, 60. [Google Scholar] [CrossRef]

- Miao, Y.H.; Wu, J.Q.; Hou, Y.; Wang, L.B.; Yu, W.X.; Wang, S.D. Study on Asphalt Pavement Surface Texture Degradation Using 3-D Image Processing Techniques and Entropy Theory. Entropy 2019, 21, 208. [Google Scholar] [CrossRef]

- Xu, H.N.; Li, H.Z.; Tan, Y.Q.; Wang, L.B.; Hou, Y. A Micro-Scale Investigation on the Behaviors of Asphalt Mixtures under Freeze-Thaw Cycles Using Entropy Theory and a Computerized Tomography Scanning Technique. Entropy 2018, 20, 68. [Google Scholar] [CrossRef]

- Gong, Y.F.; Bi, H.P.; Liang, C.Y.; Wang, S.R. Microstructure Analysis of Modified Asphalt Mixtures under Freeze-Thaw Cycles Based on CT Scanning Technology. Appl. Sci. 2018, 8, 2191. [Google Scholar] [CrossRef]

- Ren, J.D.; Xing, C.; Tan, Y.Q.; Liu, N.; Liu, J.Y.; Yang, L.Y. Void Distribution in Zeolite Warm Mix Asphalt Mixture Based on X-ray Computed Tomography. Materials 2019, 12, 1888. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Guo, X.D.; Chen, W.X.; Li, Y.S.; Sun, M.Z.; Dai, W.T. Laboratory Assessment of Deteriorating Performance of Nano Hydrophobic Silane Silica Modified Asphalt in Spring-Thaw Season. Appl. Sci. 2019, 9, 2305. [Google Scholar] [CrossRef]

- Huang, T.; Qi, S.; Yang, M.; Lv, S.T.; Liu, H.F.; Zheng, J.L. Strength Criterion of Asphalt Mixtures in Three-Dimensional Stress States under Freeze-Thaw Conditions. Appl. Sci. 2018, 8, 1302. [Google Scholar] [CrossRef]

- Wang, J.; Zeng, W.; Qin, Y.C.; Huang, S.C.; Xu, J. Laboratory Evaluation of Rejuvenating Agent on Reclaimed SBS Modified Asphalt Pavement. Appl. Sci. 2017, 7, 743. [Google Scholar] [CrossRef]

- Gong, Y.F.; Bi, H.P.; Tian, Z.H.; Tan, G.J. Pavement Performance Investigation of Nano-TiO2/CaCO3 and Basalt Fiber Composite Modified Asphalt Mixture under Freeze‒Thaw Cycles. Appl. Sci. 2018, 8, 2581. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, H.N.; Yang, X. Low-temperature performance of SBS modified asphalt mixture in high altitude and cold regions. Int. J. Pavement Res. Technol. 2019, 12, 33–42. [Google Scholar]

- Guo, M.; Tan, Y.Q.; Wang, L.B.; Hou, Y. A state-of-the-art review on interfacial behavior between asphalt binder and mineral aggregate. Front. Struct. Civ. Eng. 2018, 12, 248–259. [Google Scholar] [CrossRef]

- Zhao, Q.; Ye, Z.J. A dimensional analysis on asphalt binder fracture and fatigue cracking. Front. Struct. Civ. Eng. 2018, 12, 201–206. [Google Scholar] [CrossRef]

- Omranian, S.R.; Hamzah, M.O.; Hasan, M.R.M. Introducing New Indicators to Evaluate Fracture Properties of Asphalt Mixtures Using Semicircular Bending Test. Iran. J. Sci. Technol. Trans. Civ. Eng. 2018, 12, 1–9. [Google Scholar] [CrossRef]

- Le, J.L.; Hendrickson, R.; Marasteanu, M.O.; Turos, M. Use of fine aggregate matrix for computational modeling of low temperature fracture of asphalt concrete. Mater. Struct. 2018, 51, 152–164. [Google Scholar] [CrossRef]

- Doll, B.; Ozer, H.; Jose, J.; Rivera-Perez, R.; Al-Qadi, I.L.; Lambros, J. Investigation of viscoelastic fracture fields in asphalt mixtures using digital image correlation. Int. J. Fract. 2017, 205, 37–56. [Google Scholar] [CrossRef]

- Hasheminejad, N.; Vuye, C.; Margaritis, A.; Ribbens, B.; Jacobs, G.; Blom, J.; Van den Bergh, W.; Dirckx, J.; Vanlanduit, S. Investigation of Crack Propagation and Healing of Asphalt Concrete Using Digital Image Correlation. Appl. Sci. 2019, 9, 2459. [Google Scholar] [CrossRef]

- Onifade, I.; Dinegdae, Y.; Birgisson, B. Hierarchical approach for fatigue cracking performance evaluation in asphalt pavements. Front. Struct. Civ. Eng. 2017, 11, 257–269. [Google Scholar] [CrossRef]

- Liu, P.F.; Chen, J.; Lu, G.Y.; Wang, D.W.; Oeser, M.; Leischner, S. Numerical Simulation of Crack Propagation in Flexible Asphalt Pavements Based on Cohesive Zone Model Developed from Asphalt Mixtures. Materials 2019, 12, 1278. [Google Scholar] [CrossRef]

- Xin, J.Y.; Pei, J.Z.; Akiyama, M.; Li, R.; Zhang, J.P.; Shao, L.B. A Study on the Design Method for the Material Composition of Small Particle-Size Asphalt Mixture for Controlling Cracks in Asphalt Pavement. Appl. Sci. 2019, 9, 1988. [Google Scholar] [CrossRef]

- JTG F40-2004. Technical Specification for Construction of Highway Asphalt Pavement; China Communications Press: Beijing, China, 2005. [Google Scholar]

- Pigeon, M.; Pleau, R.; Aitcin, P.C. Freeze-Thaw Durability of Concrete with and Without Silica Fume in ASTM C 666 (Procedure A) Test Method: Internal Cracking Versus Scaling. Cem. Concr. Aggreg. 1986, 8, 76–85. [Google Scholar]

- Ehrhard, K.; Oberholzer, K.; Gast, K.; Mildenberger, P.; Kreitner, K.F.; Thelen, M. Multi-slice CT (MSCT) in cardiac function imaging: threshold-value-supported 3D volume reconstructions to determine the left ventricular ejection fraction in comparison to MRI. Rofo 2002, 174, 1566–1569. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.F.; Jeng, D.S. Pore Structure of Grain-Size Fractal Granular Material. Materials 2019, 12, 2053. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhao, Y.X.; Li, P. Effect of the Heterogeneity on Sorptivity in Sandstones with High and Low Permeability in Water Imbibition Process. Processes 2019, 7, 260. [Google Scholar] [CrossRef]

- Anitas, E.M.; Marcelli, G.; Szakacs, Z.; Todoran, R.; Todoran, D. Structural Properties of Vicsek-like Deterministic Multifractals. Symmetry 2019, 11, 806. [Google Scholar] [CrossRef]

- Dinew, S.; Dinew, Ż. Differential Tests for Plurisubharmonic Functions and Koch Curves. Potential Anal. 2019, 50, 381–400. [Google Scholar] [CrossRef]

- Lei, X.L. Evolution of b-Value and Fractal Dimension of Acoustic Emission Events during Shear Rupture of an Immature Fault in Granite. Appl. Sci. 2019, 9, 2498. [Google Scholar] [CrossRef]

- Arasan, S.; Akbulut, S.; Hasiloglu, A.S. The relationship between the fractal dimension and shape properties of particles. KSCE J. Civ. Eng. 2011, 15, 1219–1225. [Google Scholar] [CrossRef]

- Carpinteri, A.; Invernizzi, S. Influence of damage on the fractal properties of concrete subjected to pure tension. Mater. Struct. 2001, 34, 605–611. [Google Scholar] [CrossRef]

- Bends, M.P.; Guedes, J.M.; Plaxton, S.; Taylor, J.E. Optimization of structure and material properties for solids composed of softening material. Int. J. Solids Struct. 1996, 33, 1799–1813. [Google Scholar] [CrossRef]

- Wang, X.H.; Peng, Y.; Wang, J.Y.; Zeng, Q. Pore Structure Damages in Cement-Based Materials by Mercury Intrusion: A Non-Destructive Assessment by X-Ray Computed Tomography. Materials 2019, 12, 2220. [Google Scholar] [CrossRef]

- Lei, Y.; O’Dowd, N.P.; Webster, G.A. Fracture mechanics analysis of a crack in a residual stress field. Int. J. Fract. 2000, 106, 195–216. [Google Scholar] [CrossRef]

- Ouyang, C.; Tang, T.; Shah, S.P. Relationship between fracture parameters from two parameter fracture model and from size effect model. Mater. Struct. 1996, 29, 79–86. [Google Scholar] [CrossRef]

- Wnuk, M.P.; Yavari, A. On estimating stress intensity factors and modulus of cohesion for fractal cracks. Eng. Fract. Mech. 2003, 70, 1659–1674. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Zhou, H.; Shi, Y.J.; Xiong, J. Fracture prediction of welded steel connections using traditional fracture mechanics and calibrated micromechanics based models. Int. J. Steel Struct. 2011, 11, 351–366. [Google Scholar] [CrossRef]

| Test Item | Unit | Test Result | |

|---|---|---|---|

| Density (15 °C) | g/cm3 | 1.0364 | |

| Penetration (25 °C,100 g, 5 s) | 0.1 mm | 89 | |

| Softening point TR&B | °C | 46 | |

| Flash point (COC) | °C | 254 | |

| Solubility (solvent: trichloroethylene) | % | 99.7 | |

| Wax content (distillation) | % | 2.0 | |

| Ductility (15 °C, 5 cm/min) | cm | >150 | |

| Film oven heating test (163 °C, 5 h) | Mass loss | % | 0.0198 |

| Penetration ratio | % | 72.8 | |

| Aging delay (25 °C) | cm | >150 | |

| Aging delay (15 °C) | cm | >140 | |

| Test Item | Unit | Test Result | |

|---|---|---|---|

| Apparent density | g/cm3 | 2.73 | |

| Size range | <0.6 mm | % | 100 |

| <0.15 mm | % | 100 | |

| <0.075 mm | % | 89.5 | |

| Hydrophilic coefficient | - | 0.87 | |

| Freeze-Thaw Cycles | Specimen No. | c | /mm | /MPa | ||||

|---|---|---|---|---|---|---|---|---|

| 0 | S1 | 4.50 | 3.385 | 1.161 | 0.081 | 317.78 | 0.404 | 0.5324 |

| S2 | 1.235 | 1.155 | 0.078 | 0.307 | 0.8003 | |||

| S3 | 2.125 | 1.123 | 0.062 | 0.998 | 0.6695 | |||

| S4 | 1.648 | 1.203 | 0.102 | 0.155 | 0.6776 | |||

| S5 | 1.219 | 1.169 | 0.085 | 1.788 | 0.8932 | |||

| 1 | S6 | 4.05 | 1.076 | 1.103 | 0.052 | 197.84 | 0.131 | 0.5859 |

| S7 | 1.582 | 1.120 | 0.060 | 1.109 | 0.5439 | |||

| S8 | 1.490 | 1.157 | 0.079 | 0.512 | 0.5406 | |||

| S9 | 1.761 | 1.195 | 0.098 | 0.040 | 0.4290 | |||

| S10 | 1.459 | 1.107 | 0.054 | 0.132 | 0.5108 | |||

| 3 | S11 | 4.59 | 2.677 | 1.213 | 0.107 | 177.34 | 0.535 | 0.4641 |

| S12 | 1.985 | 1.156 | 0.078 | 0.187 | 0.4859 | |||

| S13 | 1.236 | 1.207 | 0.104 | 0.600 | 0.6342 | |||

| S14 | 1.685 | 1.122 | 0.061 | 0.066 | 0.4966 | |||

| S15 | 3.030 | 1.120 | 0.060 | 0.083 | 0.3880 | |||

| 6 | S16 | 4.23 | 1.165 | 1.164 | 0.082 | 159.05 | 0.404 | 0.5545 |

| S17 | 1.327 | 1.174 | 0.087 | 0.307 | 0.5163 | |||

| S18 | 1.655 | 1.153 | 0.077 | 0.998 | 0.5025 | |||

| S19 | 2.531 | 1.176 | 0.088 | 0.155 | 0.3793 | |||

| S20 | 4.189 | 1.154 | 0.077 | 1.788 | 0.3512 | |||

| 10 | S21 | 4.15 | 1.099 | 1.143 | 0.072 | 140.89 | 0.136 | 0.4951 |

| S22 | 2.855 | 1.112 | 0.056 | 0.020 | 0.3013 | |||

| S23 | 1.404 | 1.137 | 0.069 | 0.148 | 0.4484 | |||

| S24 | 1.187 | 1.185 | 0.093 | 0.326 | 0.4997 | |||

| S25 | 1.568 | 1.130 | 0.065 | 0.536 | 0.4572 | |||

| 15 | S26 | 3.39 | 1.749 | 1.1772 | 0.089 | 133.25 | 0.299 | 0.3371 |

| S27 | 2.286 | 1.1479 | 0.074 | 0.044 | 0.2705 | |||

| S28 | 2.088 | 1.1944 | 0.097 | 0.081 | 0.2888 | |||

| S29 | 1.389 | 1.1372 | 0.069 | 0.072 | 0.3448 | |||

| S30 | 4.252 | 1.2023 | 0.101 | 0.081 | 0.2172 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wang, F.; Yi, F.; Ma, J.; Lin, Z. Fractal Analysis of the Fracture Evolution of Freeze-Thaw Damage to Asphalt Concrete. Materials 2019, 12, 2288. https://doi.org/10.3390/ma12142288

Li J, Wang F, Yi F, Ma J, Lin Z. Fractal Analysis of the Fracture Evolution of Freeze-Thaw Damage to Asphalt Concrete. Materials. 2019; 12(14):2288. https://doi.org/10.3390/ma12142288

Chicago/Turabian StyleLi, Jun, Fengchi Wang, Fu Yi, Jie Ma, and Zhenhuan Lin. 2019. "Fractal Analysis of the Fracture Evolution of Freeze-Thaw Damage to Asphalt Concrete" Materials 12, no. 14: 2288. https://doi.org/10.3390/ma12142288