Surface Quality Enhancement of Fused Deposition Modeling (FDM) Printed Samples Based on the Selection of Critical Printing Parameters

Abstract

:1. Introduction

1.1. Additive Manufacturing

1.2. Surface Quality in FDM Processes

2. Materials and Methods

2.1. Materials

2.2. Experimental Plan

- Material extrusion: temperature, viscosity, density, type of material, and mechanical properties.

- Chamber: temperature, pressure, vibrations, position of the platform, position of the extruder, system coordinates, and heat evacuation.

- Extruder: speed, angle of inclination, diameter of extrusion, vibration, and acceleration.

- Deposition characteristics: building direction, wall thickness, layer height, orientation, external geometry, and speed.

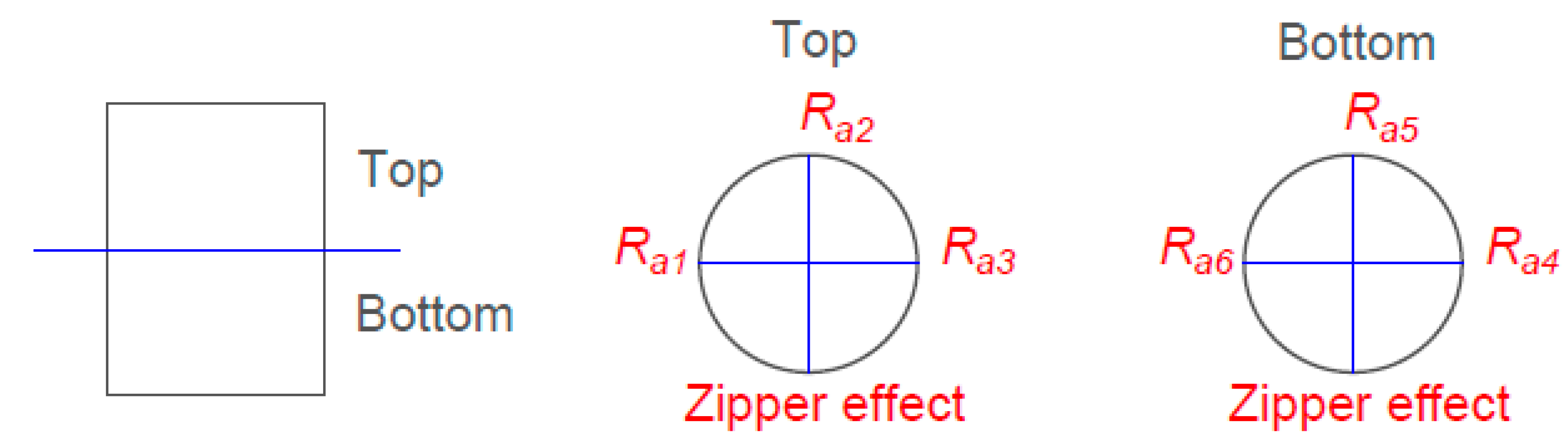

2.3. Surface Roughness Evaluation

3. Results and Discussion

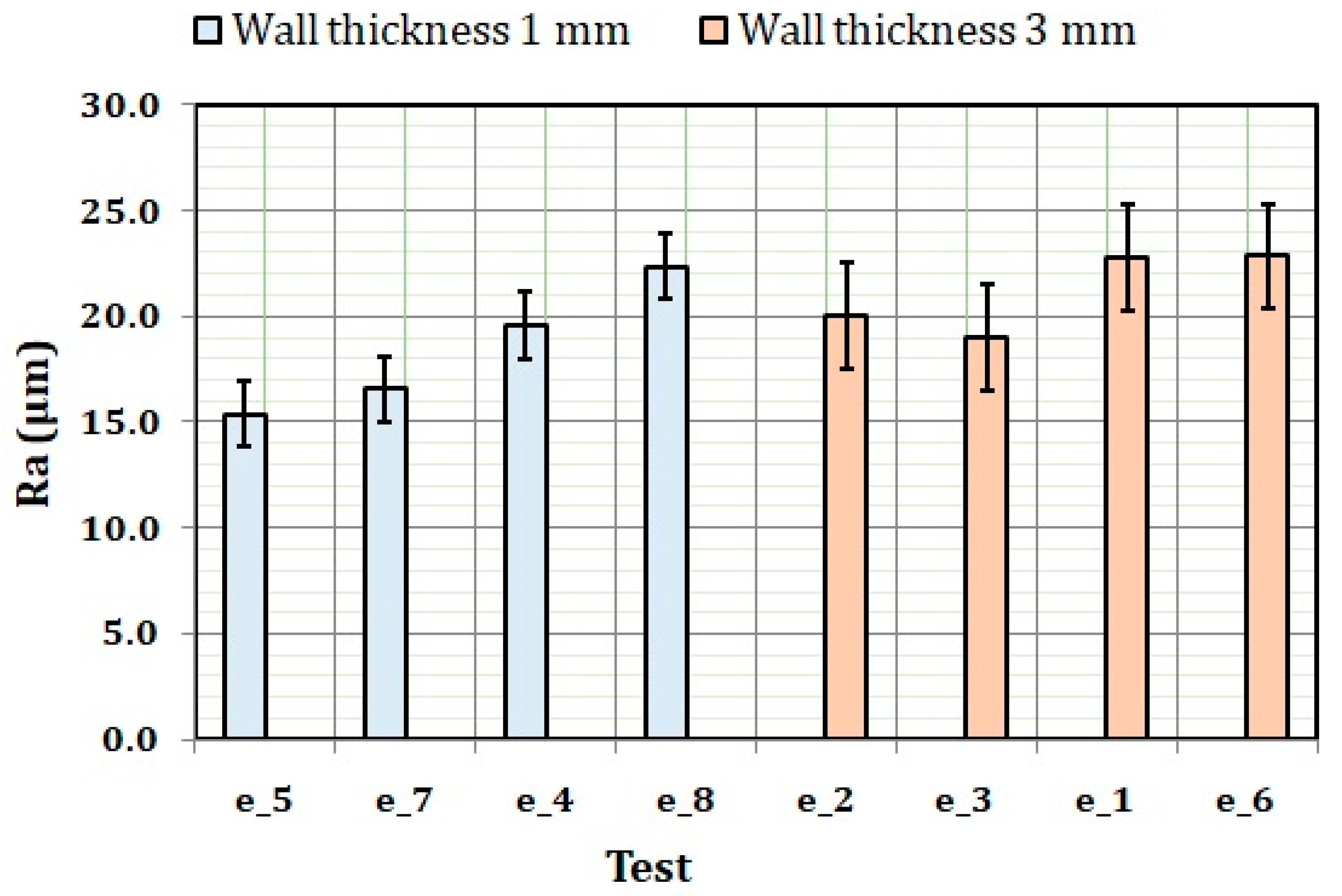

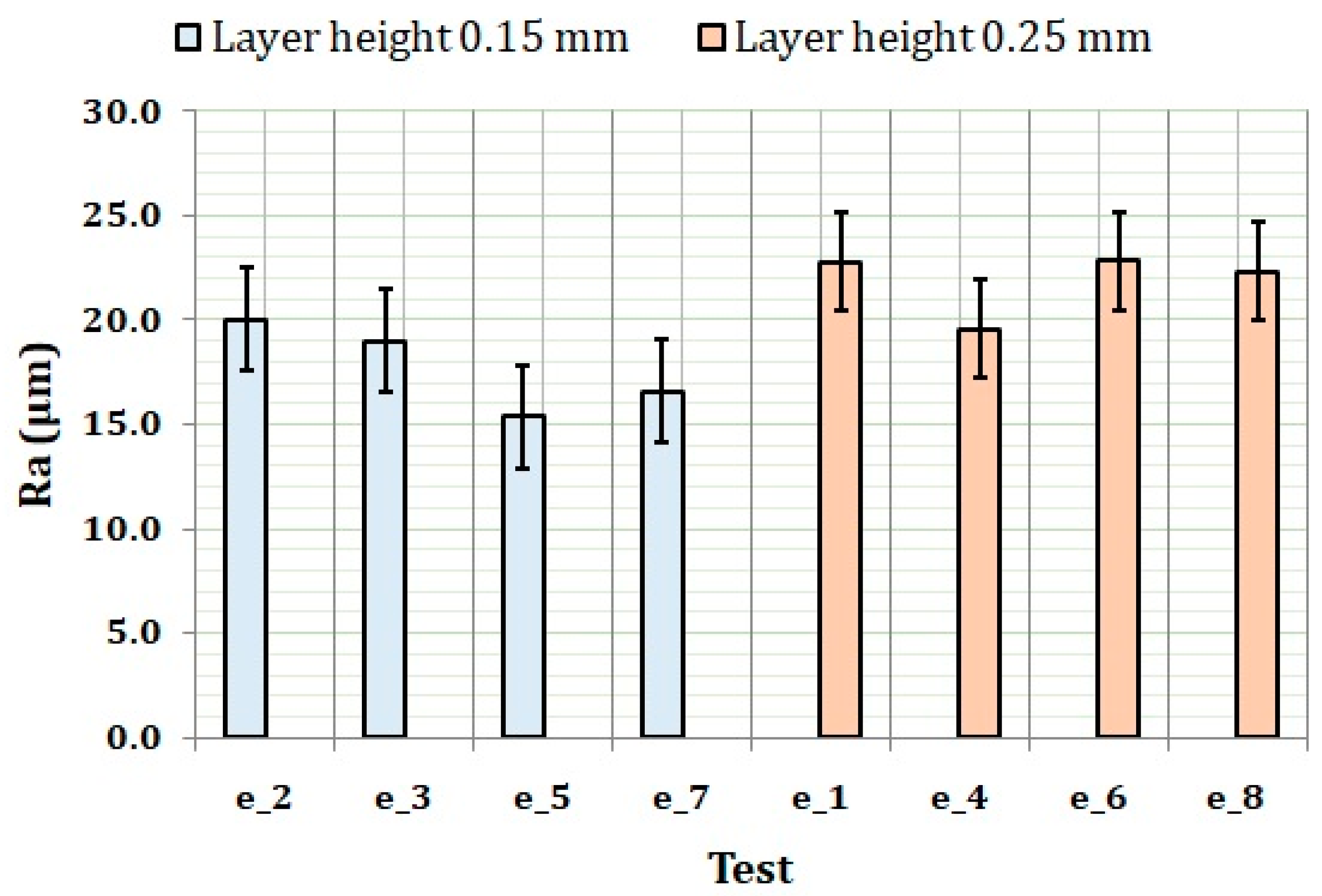

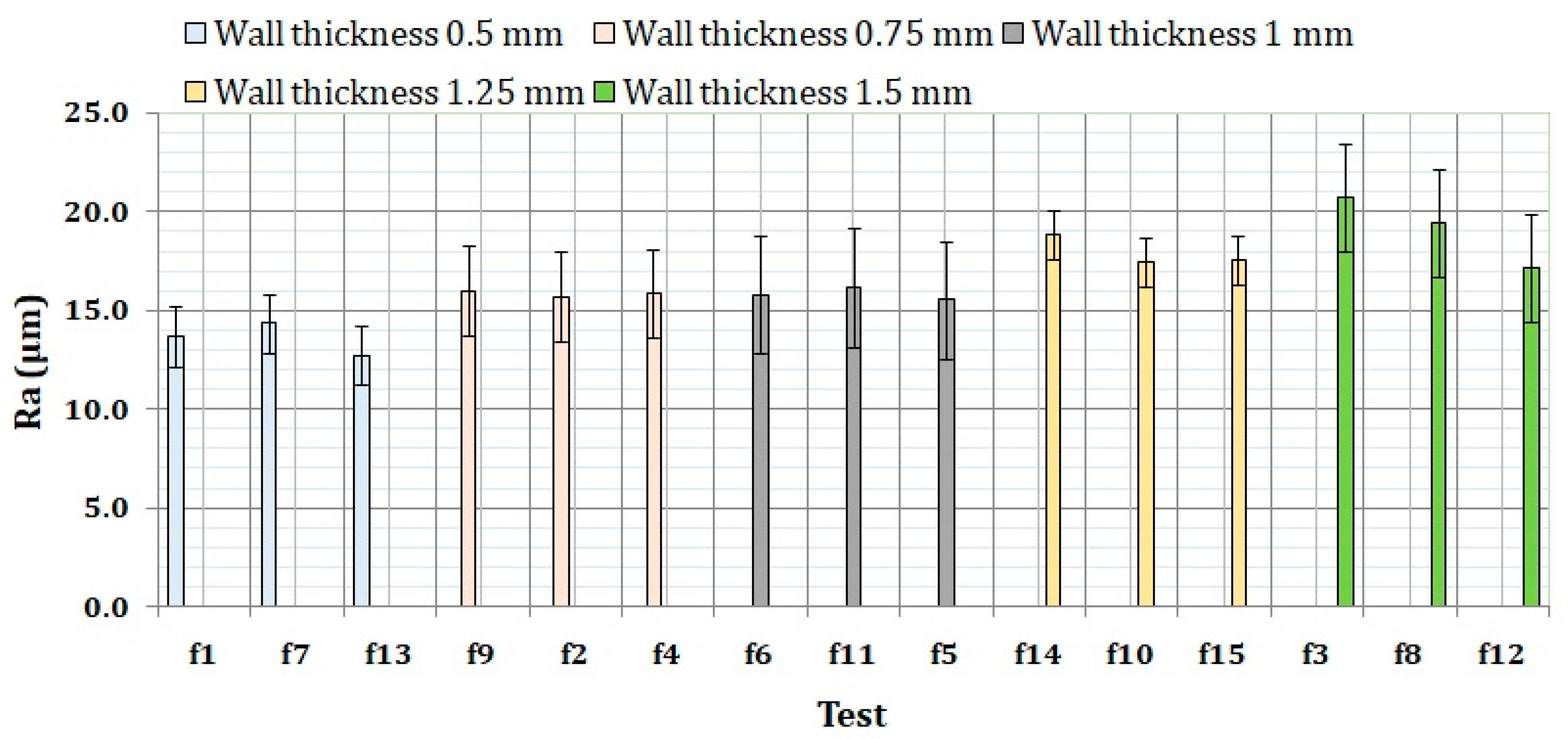

3.1. Surface Roughness Results

3.2. Identification of Critical Factors

3.3. Correlations between Surface Roughness and the Analyzed Factors

4. Conclusions and Future Work

- The quality of the manufactured parts depends greatly on the selection of the printing parameters. In particular, previous results that indicate that the layer height is a critical factor were validated using Analysis of Variance. But, in addition, it was found that wall thickness has an important influence on the results, which was given less attention by researchers.

- Some parameters seem to have no clear influence on the results, specifically, printing path, printing speed, and temperature. However, it should be noted that only three printing strategies were analyzed in the present study: grid, concentric, and zig-zag.

- By using Spearman’s ρ and Kendall’s τ correlation coefficients, the influence of layer height and wall thickness on the results was verified, especially, for experiment 2, obtaining correlation coefficients very close to +1 with p-values lower than 0.05.

- The effect of the layer height and wall thickness on surface roughness is to worsen the quality of the surface when one of these parameters is increased or when both are increased.

- As criteria for improving surface quality in FDM manufacturing processes, it is recommended to use reduced values of layer height, diminishing the importance of the staircase effect and also wall thickness that is generally selected based on the size of the nozzle extruder.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hopkinson, N.; Hague, R.; Dickens, P. Rapid Manufacturing: An Industrial Revolution for the Digital Age; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 9780470032862. [Google Scholar]

- Sugavaneswaran, M.; Arumaikkannu, G. Modelling for randomly oriented multi material additive manufacturing component and its fabrication. Mater. Des. 2014, 54, 779–785. [Google Scholar] [CrossRef]

- Oropallo, W.; Piegl, L.A. Ten challenges in 3D printing. Eng. Comput. 2015, 32, 135–148. [Google Scholar] [CrossRef]

- ASTM International. Standard Terminology for Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Chua, C.K.; Chou, S.M.; Wong, T.S. A study of the state-of-the-art rapid prototyping technologies. Int. J. Adv. Manuf. Technol. 1998, 14, 146–152. [Google Scholar] [CrossRef]

- Jacobs, P.F. Rapid Prototyping & Manufacturing: Fundamentals of Stereolithography; Society of Manufacturing Engineers: Dearborn, MI, USA, 1992; ISBN 9780872634251. [Google Scholar]

- Yang, J.; Ouyang, H.; Wang, Y. Direct metal laser fabrication: Machine development and experimental work. Int. J. Adv. Manuf. Technol. 2009, 46, 1133–1143. [Google Scholar] [CrossRef]

- Mueller, B.; Kochan, D. Laminated object manufacturing for rapid tooling and patternmaking in foundry industry. Comput. Ind. 1999, 39, 47–53. [Google Scholar] [CrossRef]

- Hutmacher, D.W.; Schantz, T.; Zein, I.; Ng, K.W.; Teoh, S.H.; Tan, K.C. Mechanical properties and cell cultural response of polycaprolactone scaffolds designed and fabricated via fused deposition modeling. J. Biomed. Mater. Res. 2001, 55, 203–216. [Google Scholar] [CrossRef]

- Yan, X.; Gu, P. A review of rapid prototyping technologies and systems. Comput. Aided Des. Appl. 1996, 28, 307–318. [Google Scholar] [CrossRef]

- Griffiths, C.A.; Howarth, J.; De Almeida-Rowbotham, G.; Rees, A. A design of experiments approach to optimise tensile and notched bending properties of fused deposition modelling parts. Proc. Inst. Mech. Eng. Pt. B J. Eng. Manuf. 2016, 230, 1502–1512. [Google Scholar] [CrossRef]

- Raju, M.; Gupta, M.K.; Bhanot, N.; Sharma, V.S. A hybrid PSO–BFO evolutionary algorithm for optimization of fused deposition modelling process parameters. J. Intell. Manuf. 2018. [Google Scholar] [CrossRef]

- Winder, J.; Bibb, R. Medical rapid prototyping technologies: State of the art and current limitations for application in oral and maxillofacial surgery. J. Oral Maxillofac. Surg. 2005, 63, 1006–1015. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Altan, M.; Eryildiz, M.; Gumus, B.; Kahraman, Y. Effects of process parameters on the quality of PLA products fabricated by fused deposition modeling (FDM): Surface roughness and tensile strength. Mater. Test. 2018, 60, 471–477. [Google Scholar] [CrossRef]

- Mahmood, S.; Qureshi, A.J.; Talamona, D. Taguchi based process optimization for dimension and tolerance control for fused deposition modelling. Addit. Manuf. 2018, 21, 183–190. [Google Scholar] [CrossRef]

- Garg, H.; Singh, R. Tribological Properties of Fe–Nylon6 Composite Parts Prepared Using Fused Deposition Modelling. Trans. Indian Inst. Met. 2016, 70, 1241–1244. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Strano, G.; Hao, L.; Everson, R.M.; Evans, K.E. Surface roughness analysis, modelling and prediction in selective laser melting. J. Mater. Process. Technol. 2013, 213, 589–597. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, V.; Dhande, S.G. Slicing procedures in layered manufacturing: A review. Rapid Prototyp. J. 2003, 9, 274–288. [Google Scholar] [CrossRef]

- Adel, M.; Abdelaal, O.; Gad, A.; Nasr, A.B.; Khalil, A. Polishing of fused deposition modeling products by hot air jet: Evaluation of surface roughness. J. Mater. Process. Technol. 2018, 251, 73–82. [Google Scholar] [CrossRef]

- Boschetto, A.; Bottini, L.; Veniali, F. Finishing of Fused Deposition Modeling parts by CNC machining. Robot. Comput. Integr. Manuf. 2016, 41, 92–101. [Google Scholar] [CrossRef]

- Jin, Y.; Wan, Y.; Zhang, B.; Liu, Z. Modeling of the chemical finishing process for polylactic acid parts in fused deposition modeling and investigation of its tensile properties. J. Mater. Process. Technol. 2017, 240, 233–239. [Google Scholar] [CrossRef]

- Campbell, R.I.; Martorelli, M.; Lee, H.S. Surface roughness visualisation for rapid prototyping models. Comput. Aided Des.Appl. 2002, 34, 717–725. [Google Scholar] [CrossRef]

- Akande, S.O. Dimensional Accuracy and Surface Finish Optimization of Fused Deposition Modelling Parts using Desirability Function Analysis. Int. J. Eng. Res. Appl. 2015. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Hällgren, S.; Pejryd, L.; Ekengren, J. Additive Manufacturing and High Speed Machining -cost Comparison of short Lead Time Manufacturing Methods. Procedia CIRP 2016, 50, 384–389. [Google Scholar] [CrossRef]

- Umaras, E.; Tsuzuki, M.S.G. Additive Manufacturing—Considerations on Geometric Accuracy and Factors of Influence. IFAC-Pap. OnLine 2017, 50, 14940–14945. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2015, 83, 389–405. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 9781119113478. [Google Scholar]

- Noorani, R. 3D Printing: Technology, Applications, and Selection; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781351651547. [Google Scholar]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods used to Improve Surface Finish of Products which are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. (India) Ser. C 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Carou, D.; Rubio, E.M.; Lauro, C.H.; Davim, J.P. Experimental investigation on finish intermittent turning of UNS M11917 magnesium alloy under dry machining. Int. J. Adv. Manuf. Technol. 2014, 75, 1417–1429. [Google Scholar] [CrossRef]

- Gotway, C.A.; Helsel, D.R.; Hirsch, R.M. Statistical Methods in Water Resources. Technometrics 1994, 36, 323. [Google Scholar] [CrossRef]

- Bodenhofer, U.; Krone, M.; Klawonn, F. Testing noisy numerical data for monotonic association. Inf. Sci. 2013, 245, 21–37. [Google Scholar] [CrossRef] [Green Version]

| Chemical Name | Composition | Density (g/cm3) | Printing Temperature (°C) | Diameter (mm) |

|---|---|---|---|---|

| Polylactic Acid | PLA (Polylactide Resin) 99% CAS: 9051-89-2 | 1.24 | 220 ± 20 | 1.75 ± 0.03 |

| Factor | Symbol | Units | Levels |

|---|---|---|---|

| Layer height | LH | mm | 0.15, 0.25 |

| Printing speed | PS | mm/s | 40, 80 |

| Temperature | T | °C | 195, 225 |

| Wall thickness | WT | mm | 1, 3 |

| Test | LH (mm) | PS (mm/s) | T (°C) | WT (mm) |

|---|---|---|---|---|

| 1 | 0.25 | 40 | 195 | 3 |

| 2 | 0.15 | 40 | 225 | 3 |

| 3 | 0.15 | 80 | 195 | 3 |

| 4 | 0.25 | 80 | 195 | 1 |

| 5 | 0.15 | 40 | 195 | 1 |

| 6 | 0.25 | 80 | 225 | 3 |

| 7 | 0.15 | 80 | 225 | 1 |

| 8 | 0.25 | 40 | 225 | 1 |

| Factor | Symbol | Units | Levels |

|---|---|---|---|

| Layer height | LH | mm | 0.15 |

| Printing speed | PS | mm/s | 80 |

| Temperature | T | °C | 225 |

| Printing path | PP | - | Concentric, zig-zag, grid |

| Wall thickness | WT | mm | 0.50, 0.75, 1.00, 1.25, 1.50 |

| Test | LH (mm) | PS (mm/s) | T (°C) | PP | WT (mm) |

|---|---|---|---|---|---|

| 1 | 0.15 | 80 | 225 | Zig-zag | 0.5 |

| 2 | 0.15 | 80 | 225 | Grid | 0.75 |

| 3 | 0.15 | 80 | 225 | Zig-zag | 1.5 |

| 4 | 0.15 | 80 | 225 | Concentric | 0.75 |

| 5 | 0.15 | 80 | 225 | Concentric | 1 |

| 6 | 0.15 | 80 | 225 | Zig-zag | 1 |

| 7 | 0.15 | 80 | 225 | Grid | 0.5 |

| 8 | 0.15 | 80 | 225 | Concentric | 1.5 |

| 9 | 0.15 | 80 | 225 | Zig-zag | 0.75 |

| 10 | 0.15 | 80 | 225 | Concentric | 1.25 |

| 11 | 0.15 | 80 | 225 | Grid | 1 |

| 12 | 0.15 | 80 | 225 | Grid | 1.5 |

| 13 | 0.15 | 80 | 225 | Concentric | 0.5 |

| 14 | 0.15 | 80 | 225 | Zig-zag | 1.25 |

| 15 | 0.15 | 80 | 225 | Grid | 1.25 |

| Test | Ra1 (μm) | Ra2 (μm) | Ra3 (μm) | Ra4 (μm) | Ra5 (μm) | Ra6 (μm) | Ra (μm) | SD (μm) |

|---|---|---|---|---|---|---|---|---|

| 1 | 26.045 | 20.202 | 23.188 | 23.284 | 19.558 | 24.358 | 22.773 | 2.474 |

| 2 | 20.473 | 20.497 | 20.565 | 17.776 | 18.318 | 22.525 | 20.026 | 1.728 |

| 3 | 17.937 | 18.46 | 21.145 | 17.205 | 18.182 | 21.051 | 18.997 | 1.680 |

| 4 | 19.756 | 17.258 | 21.908 | 18.732 | 19.511 | 20.347 | 19.585 | 1.559 |

| 5 | 16.066 | 15.252 | 15.338 | 14.842 | 15.239 | 15.524 | 15.377 | 0.405 |

| 6 | 25.138 | 24.092 | 25.052 | 19.995 | 20.064 | 22.725 | 22.844 | 2.348 |

| 7 | 18.252 | 16.929 | 17.705 | 14.073 | 15.709 | 16.697 | 16.561 | 1.499 |

| 8 | 23.226 | 23.809 | 23.547 | 21.582 | 19.814 | 22.063 | 22.340 | 1.512 |

| Test | Ra1 (μm) | Ra2 (μm) | Ra3 (μm) | Ra4 (μm) | Ra5 (μm) | Ra6 (μm) | Ra (μm) | SD (μm) |

|---|---|---|---|---|---|---|---|---|

| 1 | 12.761 | 14.304 | 13.034 | 12.87 | 16.46 | 12.586 | 13.669 | 1.499 |

| 2 | 15.695 | 16.514 | 13.67 | 15.371 | 16.64 | 16.431 | 15.720 | 1.123 |

| 3 | 19.471 | 21.602 | 22.279 | 19.625 | 20.775 | 20.536 | 20.715 | 1.096 |

| 4 | 16.733 | 18.797 | 14.103 | 13.592 | 17.96 | 14.047 | 15.872 | 2.250 |

| 5 | 16.108 | 16.705 | 15.439 | 15.04 | 15.91 | 13.965 | 15.528 | 0.955 |

| 6 | 16.082 | 18.292 | 16.925 | 14.068 | 14.827 | 14.734 | 15.821 | 1.590 |

| 7 | 11.591 | 13.259 | 14.995 | 11.947 | 19.792 | 14.446 | 14.338 | 2.987 |

| 8 | 18.971 | 19.016 | 20.688 | 19.352 | 20.013 | 18.499 | 19.423 | 0.797 |

| 9 | 16.789 | 16.559 | 16.638 | 14.482 | 16.302 | 15.181 | 15.992 | 0.939 |

| 10 | 16.39 | 17.199 | 19.007 | 16.626 | 18.918 | 16.354 | 17.416 | 1.236 |

| 11 | 17.142 | 14.435 | 14.746 | 16.892 | 17.001 | 16.796 | 16.169 | 1.232 |

| 12 | 16.283 | 16.893 | 18.545 | 16.305 | 17.521 | 17.145 | 17.115 | 0.849 |

| 13 | 10.698 | 12.158 | 12.455 | 11.721 | 18.122 | 11.319 | 12.746 | 2.706 |

| 14 | 18.357 | 19.093 | 19.091 | 17.274 | 20.99 | 17.999 | 18.801 | 1.275 |

| 15 | 18.175 | 18.1 | 20.777 | 16.035 | 15.569 | 16.799 | 17.576 | 1.891 |

| Source of Variation | Df | Sum sq | Mean sq | F Value | Pr (>F) |

|---|---|---|---|---|---|

| LH | 1 | 34.366 | 34.366 | 41.3466 | 0.007625 |

| PS | 1 | 0.799 | 0.799 | 0.9619 | 0.399039 |

| T | 1 | 3.174 | 3.174 | 3.8186 | 0.145684 |

| WT | 1 | 14.518 | 14.518 | 17.4669 | 0.024956 |

| Residuals | 3 | 2.494 | 0.831 | ||

| Total | 7 | 55.351 |

| Source of Variation | Df | Sum sq | Mean sq | F Value | Pr (>F) |

|---|---|---|---|---|---|

| PP | 2 | 2.184 | 1.0918 | 1.2238 | 0.3438 |

| WT | 4 | 54.192 | 13.5480 | 15.1850 | 8.139 × 10−4 |

| Residuals | 8 | 7.138 | 0.8922 | ||

| Total | 14 | 63.514 |

| Experiment 1 | Experiment 2 | |||

|---|---|---|---|---|

| Spearman’s ρ- p-value | Kendall’s τ- p-value | Spearman’s ρ- p-value | Kendall’s τ- p-value | |

| Layer height | 0.7637626 0.0274 * | 0.6614378 0.04331 * | - | - |

| Printing speed | −0.1091089 0.797 | −0.09449112 0.7728 | - | - |

| Temperature | 0.3273268 0.4287 | 0.2834734 0.3865 | - | - |

| Wall thickness | 0.5455447 0.1619 | 0.4724556 0.1489 | 0.8946933 6.729 × 10−6 * | 0.7612299 0.0001789 * |

| Printing path | - | - | 0.1322876 0.6384 | 0.1014185 0.6345 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pérez, M.; Medina-Sánchez, G.; García-Collado, A.; Gupta, M.; Carou, D. Surface Quality Enhancement of Fused Deposition Modeling (FDM) Printed Samples Based on the Selection of Critical Printing Parameters. Materials 2018, 11, 1382. https://doi.org/10.3390/ma11081382

Pérez M, Medina-Sánchez G, García-Collado A, Gupta M, Carou D. Surface Quality Enhancement of Fused Deposition Modeling (FDM) Printed Samples Based on the Selection of Critical Printing Parameters. Materials. 2018; 11(8):1382. https://doi.org/10.3390/ma11081382

Chicago/Turabian StylePérez, Mercedes, Gustavo Medina-Sánchez, Alberto García-Collado, Munish Gupta, and Diego Carou. 2018. "Surface Quality Enhancement of Fused Deposition Modeling (FDM) Printed Samples Based on the Selection of Critical Printing Parameters" Materials 11, no. 8: 1382. https://doi.org/10.3390/ma11081382