Polylactide (PLA) Filaments a Biobased Solution for Additive Manufacturing: Correlating Rheology and Thermomechanical Properties with Printing Quality

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Methods

2.1.1. Materials

2.1.2. Specimens Manufacturing

2.2. Characterization

2.2.1. Mechanical Testing

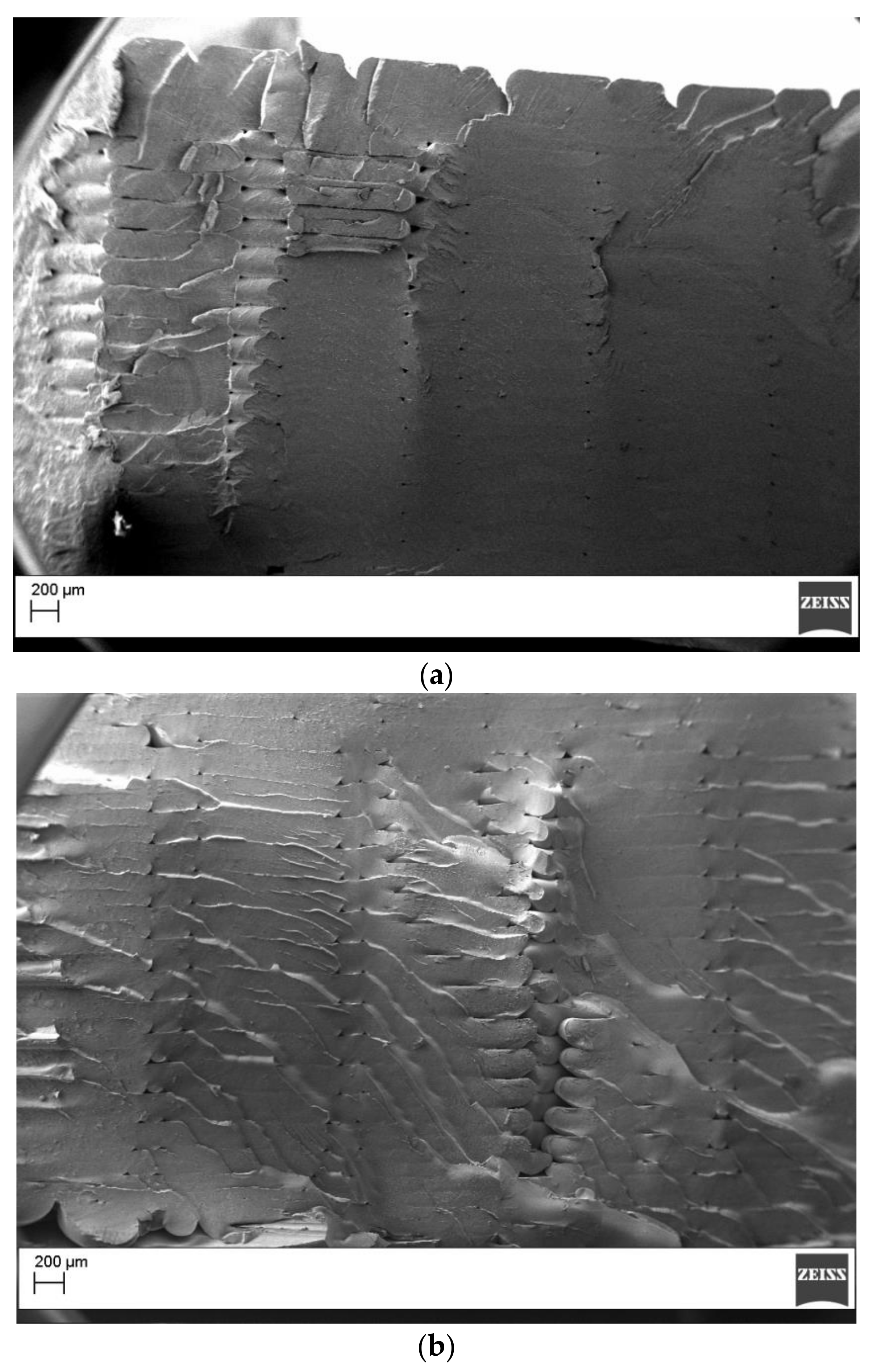

2.2.2. Scanning Electron Microscopy (SEM)

2.2.3. Rheological Analysis

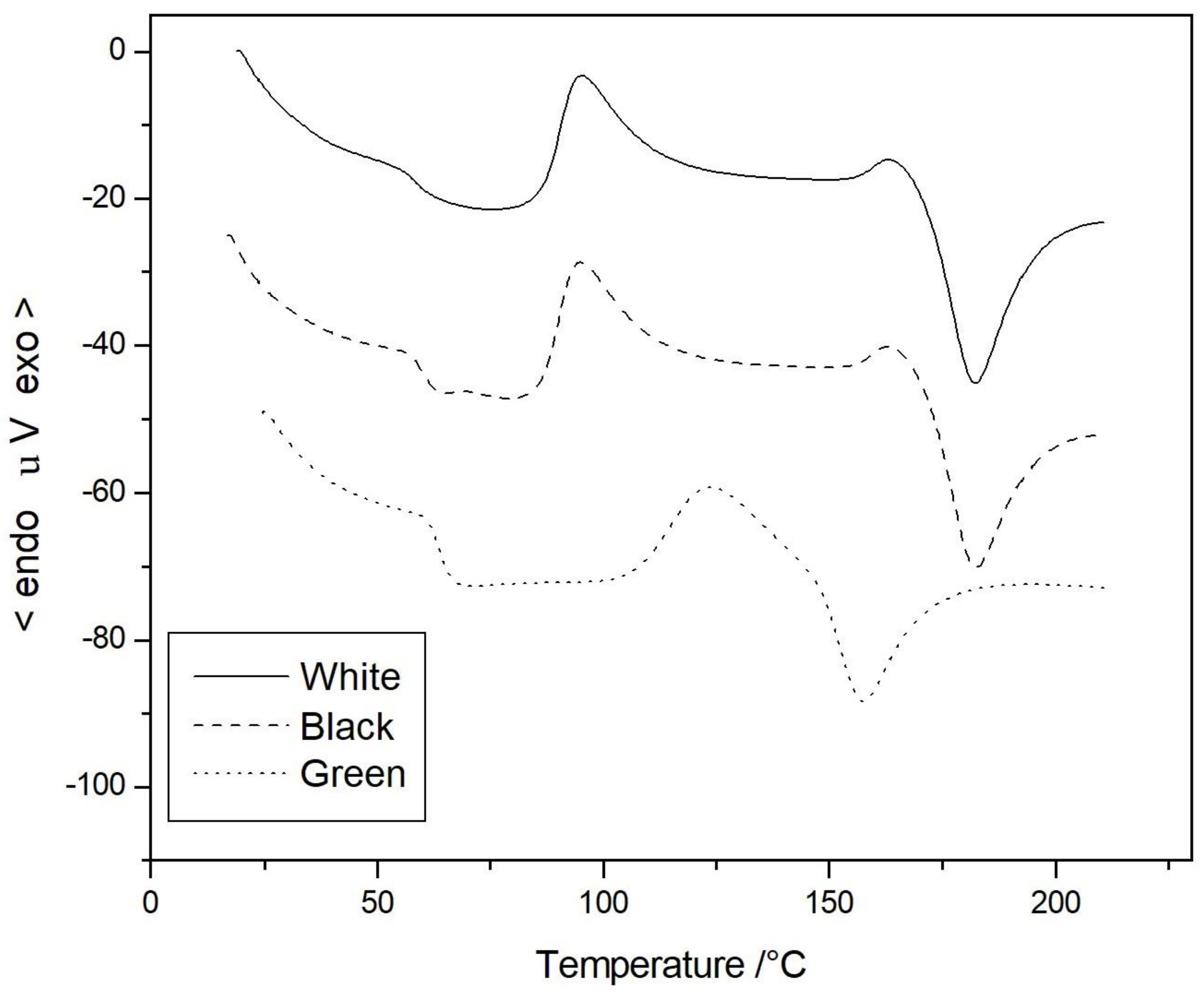

2.2.4. Thermal Analysis

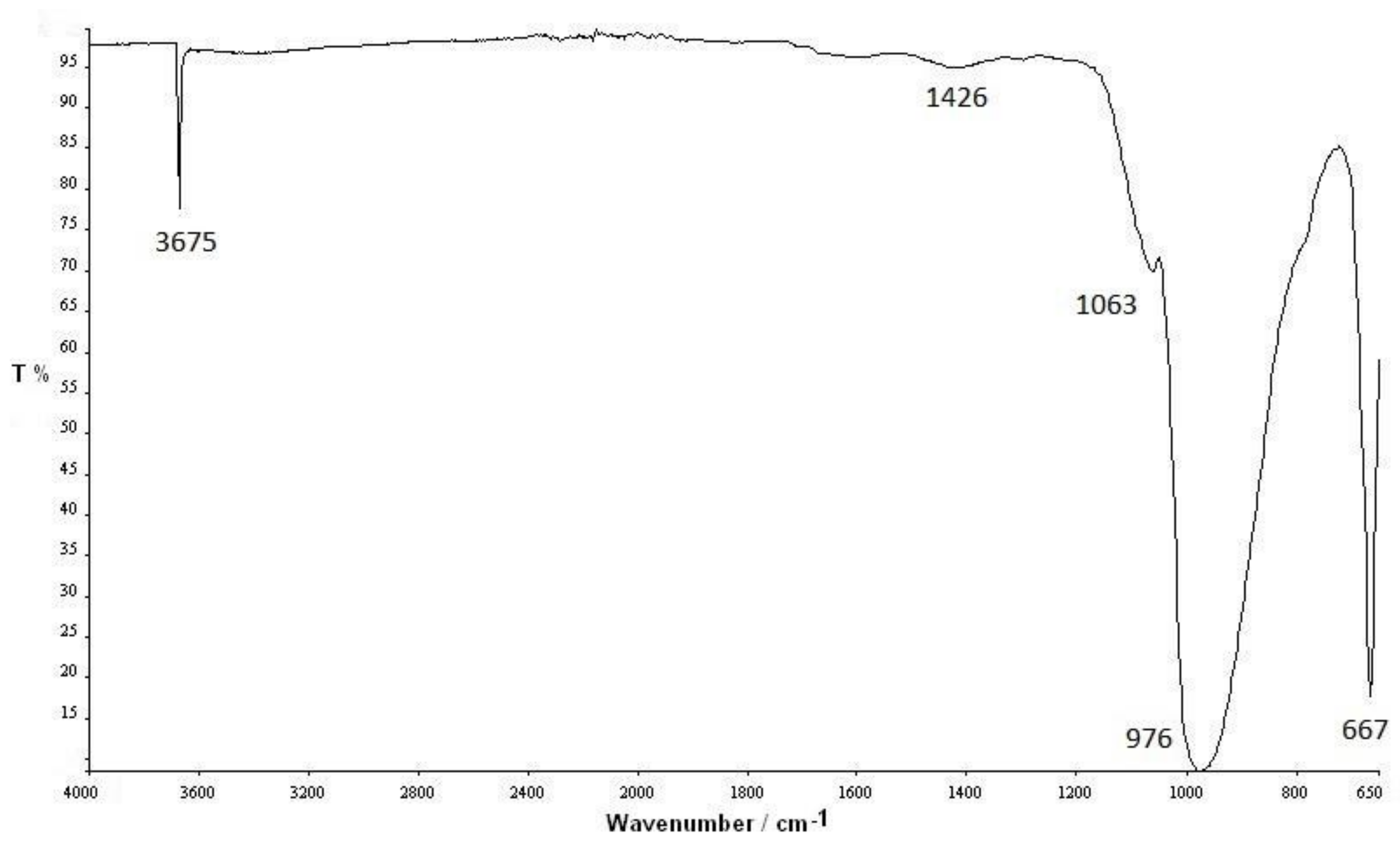

2.2.5. IR Spectroscopy

3. Results and Discussion

3.1. 3D Printing of PLA Filaments

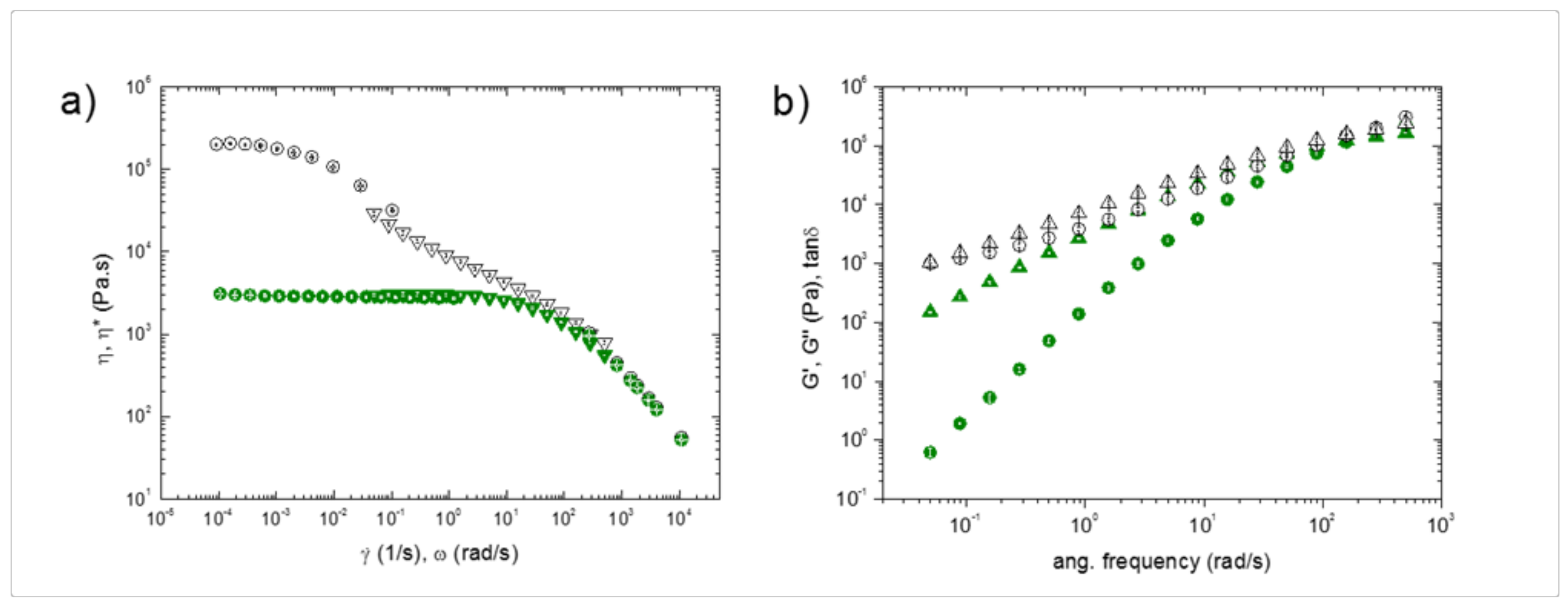

3.2. Rheological Properties of PLA Filaments

3.3. Morphological Analysis of PLA Filaments

3.4. Thermal Analysis of the PLA Filaments

3.5. Mechanical Properties of PLA-Printed Specimens

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 54, 3118–3132. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications, and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Wohlers. Wohlers Report 2011: Additive Manufacturing and 3D Printing State of the Industry; Annual Worldwide Progress Report; Wohlers: Fort Collins, CO, USA, 2011. [Google Scholar]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid. Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Fafenrot, S.; Grimmelsmann, N.; Wortmann, M.; Ehrmann, A. Three-dimensional (3D) printing of polymer-metal hybrid materials by fused deposition modeling. Materials 2017, 10, 1199. [Google Scholar] [CrossRef] [PubMed]

- Wong, J.Y.; Pfahnl, A.C. 3D printing of surgical instruments for long-duration space missions. Aviat. Space Environ. Med. 2014, 85, 758–763. [Google Scholar] [CrossRef] [PubMed]

- Comotti, C.; Regazzoni, D.; Rizzi, C.; Vitali, A. Additive Manufacturing to Advance Functional Design: An Application in the Medical Field. J. Comput. Inf. Sci. Eng. 2017, 17, 031006. [Google Scholar] [CrossRef]

- Yu, Y.Z.; Lu, J.R.; Liu, J. 3D printing for functional electronics by injection and package of liquid metals into channels of mechanical structures. Mater. Des. 2017, 122, 80–89. [Google Scholar] [CrossRef]

- Tronvoll, S.A.; Welo, T.; Elverum, C.W. The effects of voids on structural properties of fused deposition modelled parts: A probabilistic approach. Int. J. Adv. Manuf. Technol. 2018, 1–12. [Google Scholar] [CrossRef]

- Villanueva, M.P.; Galindo, B.; Moliner, E.; García, S.; Ruedas, V. Biobased conductive plastic materials for manufacturing capacitive lamps. Mater. Today Commun. 2018, 15, 105–108. [Google Scholar] [CrossRef]

- McLouth, T.D.; Severino, J.V.; Adams, P.M.; Patel, D.N.; Zaldivar, R.J. The impact of print orientation and raster pattern on fracture toughness in additively manufactured ABS. Addit. Manuf. 2017, 18, 103–109. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Witkin, D.B.; McLouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-Printed ULTEM 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Motaparti, K.P.; Taylor, G.; Leu, M.C.; Chandrashekhara, K.; Castle, J.; Matlack, M. Experimental investigation of effects of build parameters on flexural properties in fused deposition modelling parts. Virtual Phys. Prototyp. 2017, 12, 207–220. [Google Scholar] [CrossRef]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile strength of commercial polymer materials for fused filament fabrication 3D printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Cicala, G.; Latteri, A.; Del Curto, B.; Lo Russo, A.; Recca, G. Engineering thermoplastics for additive manufacturing: A critical perspective with experimental evidence to support functional applications. J. Appl. Biomater. Funct. Mater. 2017, 15, 10–18. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P.D. Deformation of an Amorphous Polymer during the Fused-Filament-Fabrication Method for Additive Manufacturing. J. Rheol. 2017, 61, 379. [Google Scholar] [CrossRef]

- McIlroy, C.; Olmsted, P.D. Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 2017, 123, 376–391. [Google Scholar] [CrossRef] [Green Version]

- Murphy, C.A.; Collins, M.N. Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym. Compos. 2018, 39, 1311–1320. [Google Scholar] [CrossRef]

- Cicala, G.; Ognibene, G.; Portuesi, S.; Blanco, I.; Rapisarda, M.; Pergolizzi, E.; Recca, G. Comparison of Ultem 9085 used in fused deposition modelling (FDM) with polytherimide blends. Materials 2018, 11, 285. [Google Scholar] [CrossRef] [PubMed]

- Badea, E.; Blanco, I.; Della Gatta, G. Fusion and solid-to-solid transitions of a homologous series of alkane-α, ω-dinitriles. J. Chem. Thermodyn. 2007, 39, 1392–1398. [Google Scholar] [CrossRef]

- Blanco, I.; Abate, L.; Bottino, F.A. Synthesis and thermal properties of new dumbbell-shaped isobutyl-substituted POSSs linked by aliphatic bridges. J. Therm. Anal. Calorim. 2014, 116, 5–13. [Google Scholar] [CrossRef]

- Blanco, I.; Bottino, F.A.; Abate, L. Influence of n-alkyl substituents on the thermal behaviour of Polyhedral Oligomeric Silsesquioxanes (POSSs) with different cage’s periphery. Thermochim. Acta 2016, 623, 50–57. [Google Scholar] [CrossRef]

- Cox, W.P.; Merz, E.H. Correlation of dynamic and steady flow viscosities. J. Polym. Sci. 1958, 28, 619–622. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Vogel, C.; Siesler, H.W. Thermal degradation of poly(ε-caprolactone), poly(L-lactic acid) and their blends with poly(3-hydroxy-butyrate) studied by TGA/FT-IR spectroscopy. Macromol. Symp. 2008, 265, 183–194. [Google Scholar] [CrossRef]

- Cicala, G.; Saccullo, G.; Blanco, I.; Samal, S.; Battiato, S.; Dattilo, S.; Sake, B. Polylactide/lignin blends: Effects of processing conditions on structure and thermo-mechanical properties. J. Therm. Anal. Calorim. 2017, 130, 515–524. [Google Scholar] [CrossRef]

- Database of ATR-FT-IR Spectra of Various Materials. Available online: http://lisa.chem.ut.ee/IR_spectra/paint/fillers/talc/ (accessed on 9 December 2015).

- Feng, Y.; Ma, P.; Xu, P.; Wang, R.; Dong, W.; Chen, M.; Joziasse, C. The crystallization behavior of poly(lactic acid) with different types of nucleating agents. Int. J. Biol. Macromol. 2018, 106, 955–962. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and application of wood flour-filled polylactic acid composite filament for 3 d printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef] [PubMed]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

| Specimen | Speed [mm/s] | In Fill [%] | In Fill Type | Raster Angle [deg] | Nozzle T [°C] | Bed T [°C] | Layer Height [µm] |

|---|---|---|---|---|---|---|---|

| Yoda | 35–45 | 10 | Grid | 210 | 50 | 120 | |

| Tensile tests | 35–45 | 100 | 0/90 | 210 | 50 | 120 |

| Filament | Tg [°C] | Tc [°C] | Tm [°C] | T5% [°C] | Residue [%] |

|---|---|---|---|---|---|

| White | 58.6 | 86.2 | 170.0 | 334.3 | 10.7 |

| Black | 59.9 | 85.6 | 168.6 | 311.7 | 10.8 |

| Green | 63.9 | 106.8 | 148.2 | 303.5 | 0 |

| Filament | Ultimate Tensile Strength [MPa] | Young Modulus [GPa] |

|---|---|---|

| White | 32.12 ± 3.80 | 3.40 ± 0.14 |

| Black | 34.43 ± 3.38 | 3.73 ± 0.14 |

| Green | 28.37 ± 1.46 | 2.66 ± 0.11 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cicala, G.; Giordano, D.; Tosto, C.; Filippone, G.; Recca, A.; Blanco, I. Polylactide (PLA) Filaments a Biobased Solution for Additive Manufacturing: Correlating Rheology and Thermomechanical Properties with Printing Quality. Materials 2018, 11, 1191. https://doi.org/10.3390/ma11071191

Cicala G, Giordano D, Tosto C, Filippone G, Recca A, Blanco I. Polylactide (PLA) Filaments a Biobased Solution for Additive Manufacturing: Correlating Rheology and Thermomechanical Properties with Printing Quality. Materials. 2018; 11(7):1191. https://doi.org/10.3390/ma11071191

Chicago/Turabian StyleCicala, Gianluca, Davide Giordano, Claudio Tosto, Giovanni Filippone, Antonino Recca, and Ignazio Blanco. 2018. "Polylactide (PLA) Filaments a Biobased Solution for Additive Manufacturing: Correlating Rheology and Thermomechanical Properties with Printing Quality" Materials 11, no. 7: 1191. https://doi.org/10.3390/ma11071191