Effects of Filler–Bitumen Ratio and Mineral Filler Characteristics on the Low-Temperature Performance of Bitumen Mastics

Abstract

:1. Introduction

2. Experimental Materials

3. Research Method

3.1. Technology Roadmap

3.2. Quantitative Test of the Fixed and Free Bitumens

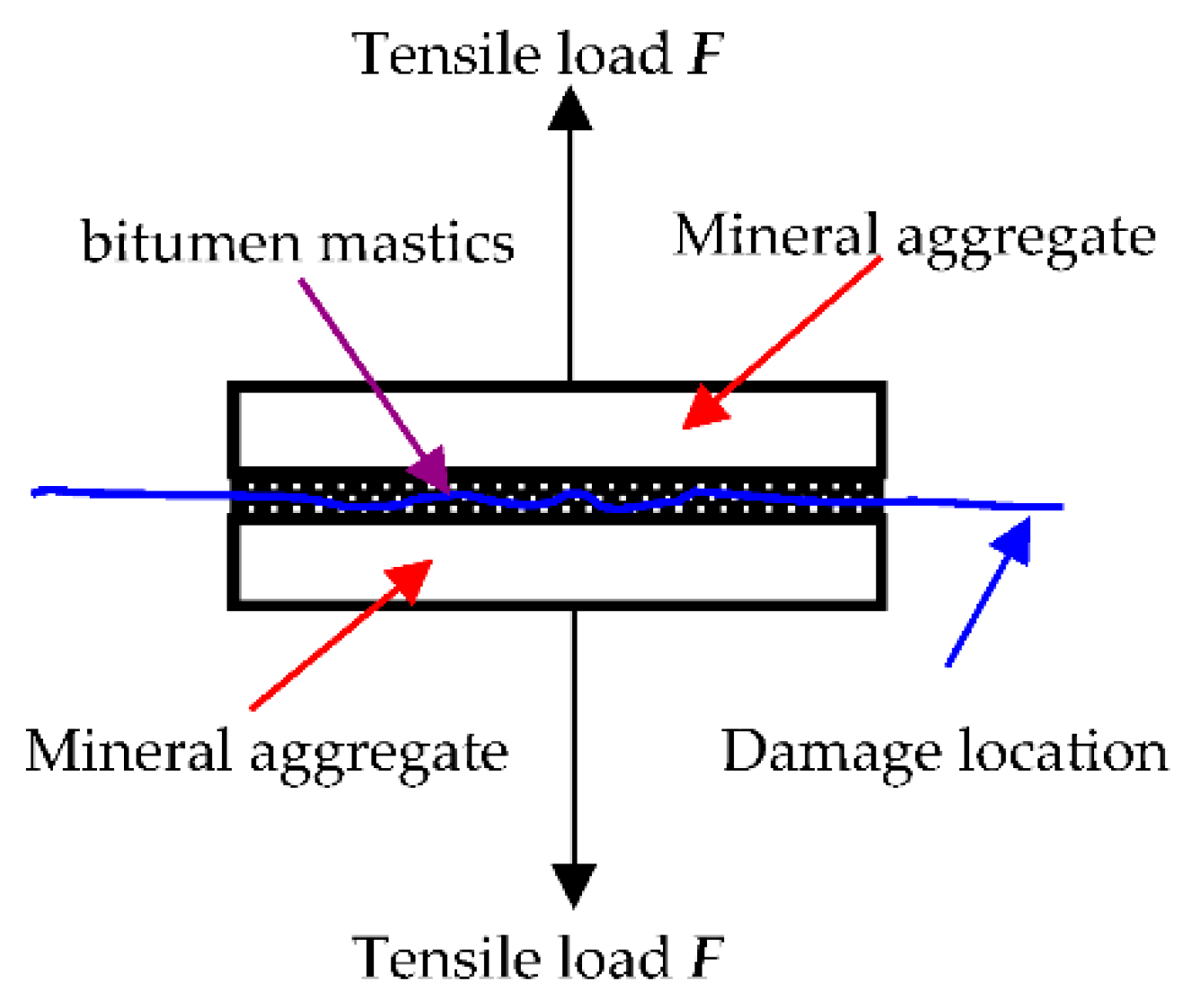

3.3. Quantitative Testing of the Low-Temperature Cohesive Strength of Bitumen Mastics

3.4. Rheological Effect of Bitumen Mastics

4. Test Result

4.1. Rigden Void Test Results for the Four Mineral Fillers

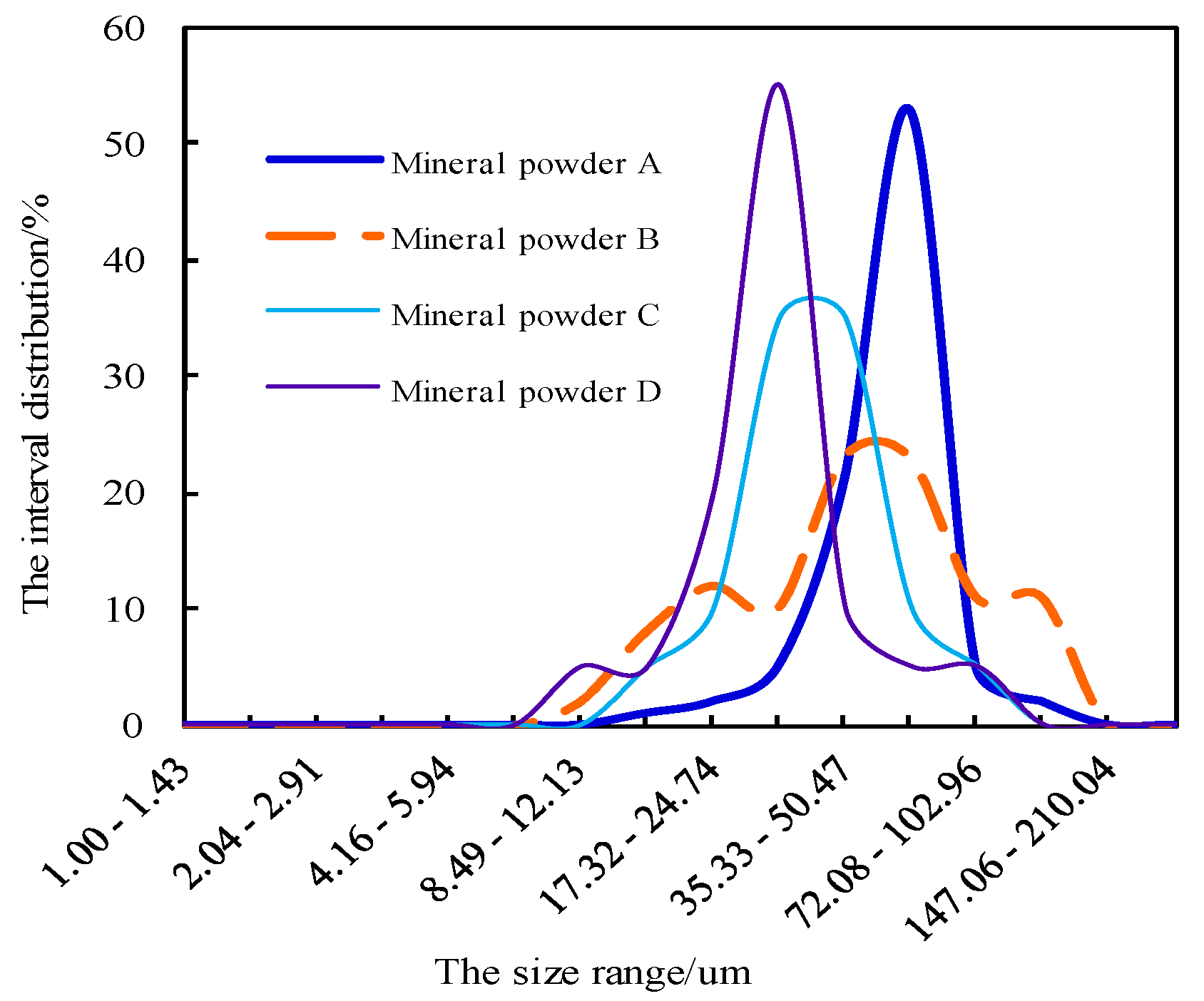

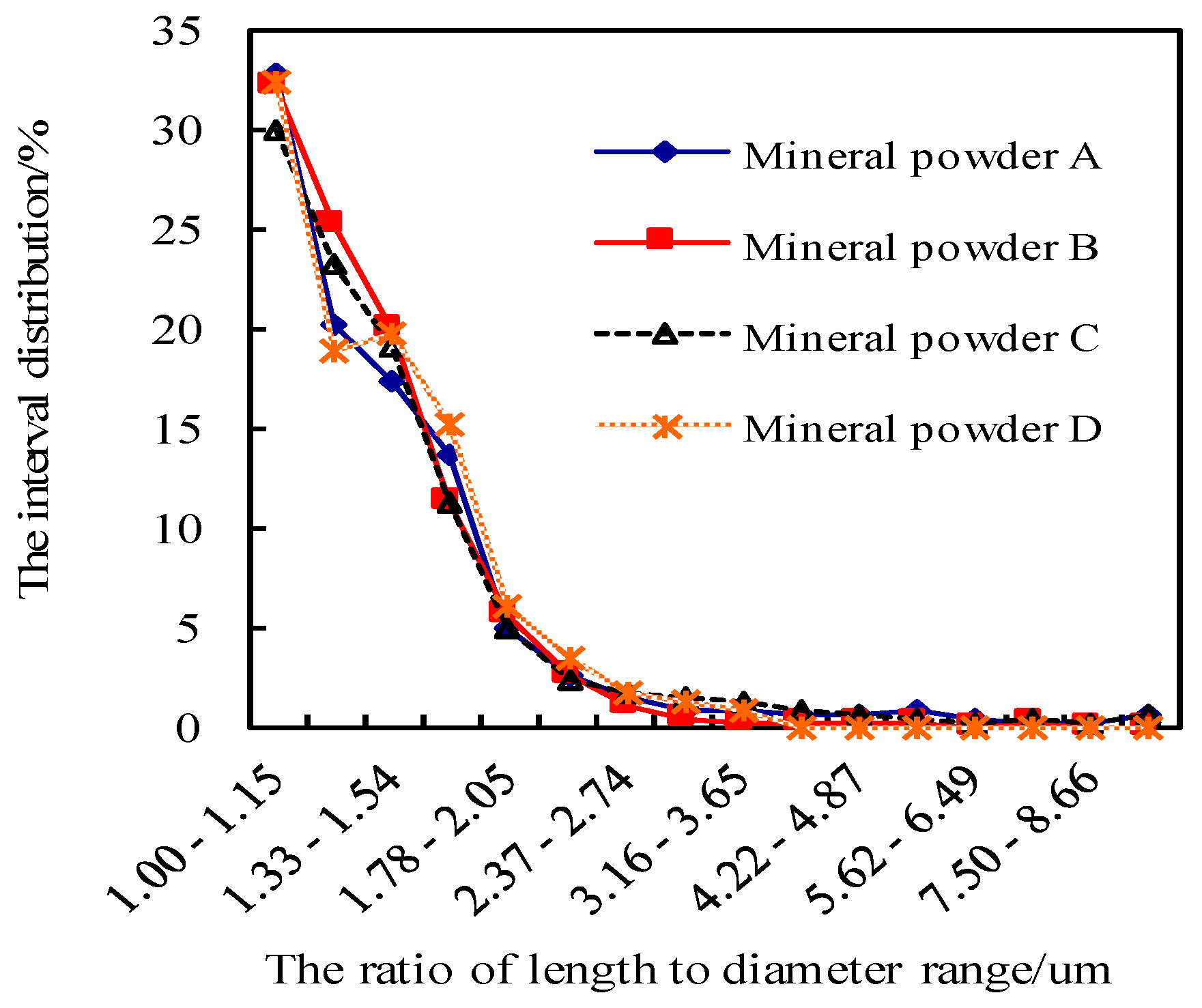

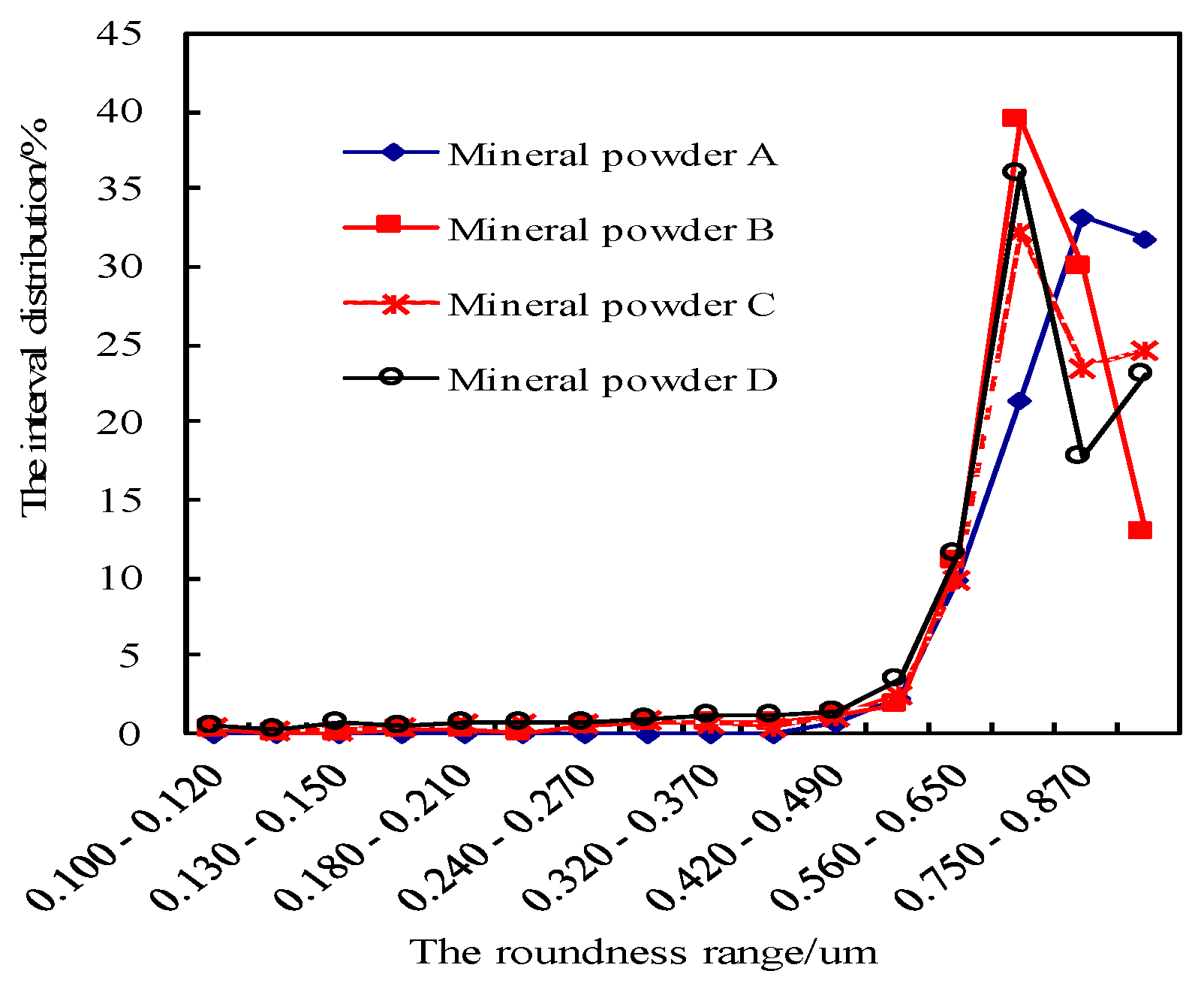

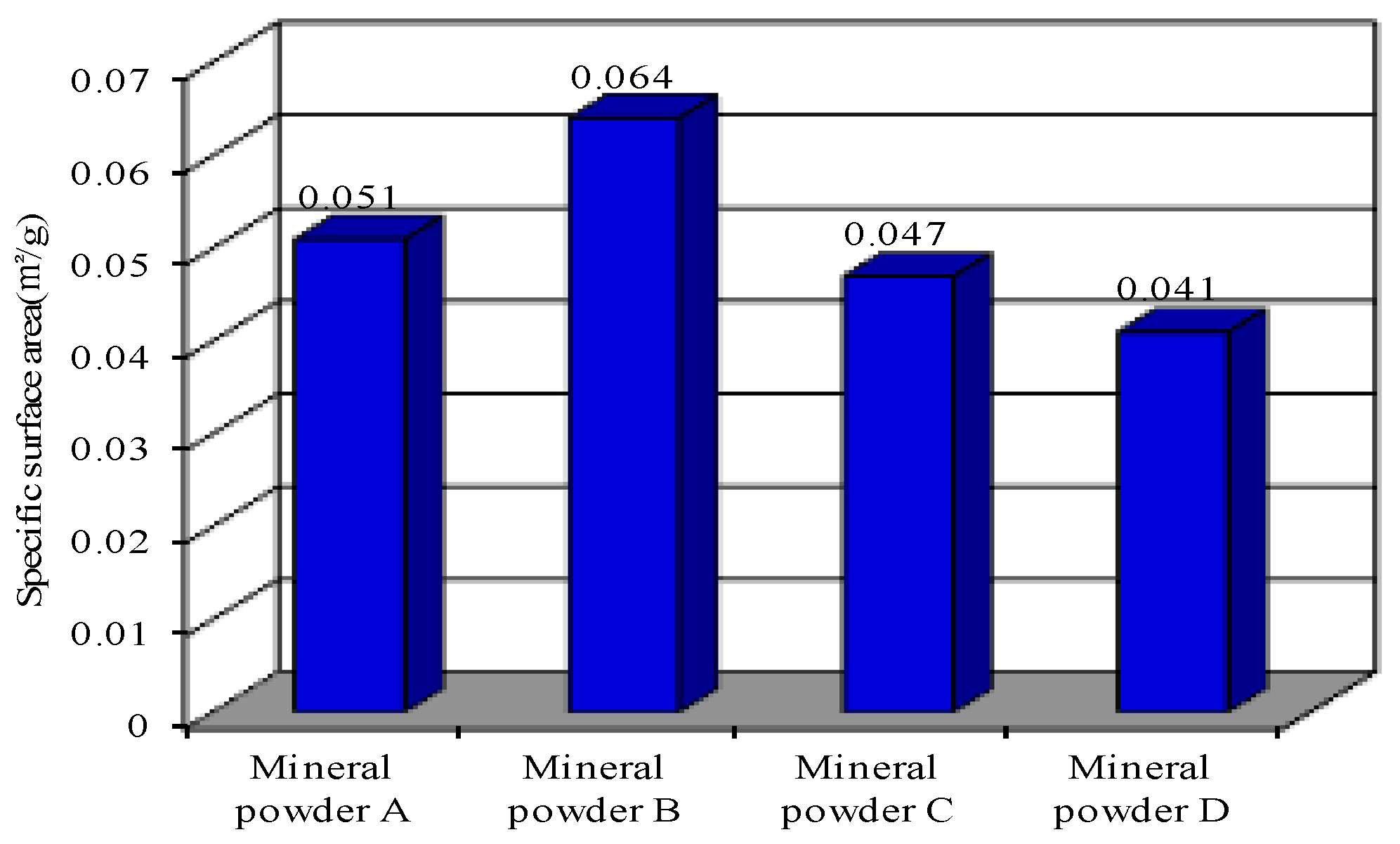

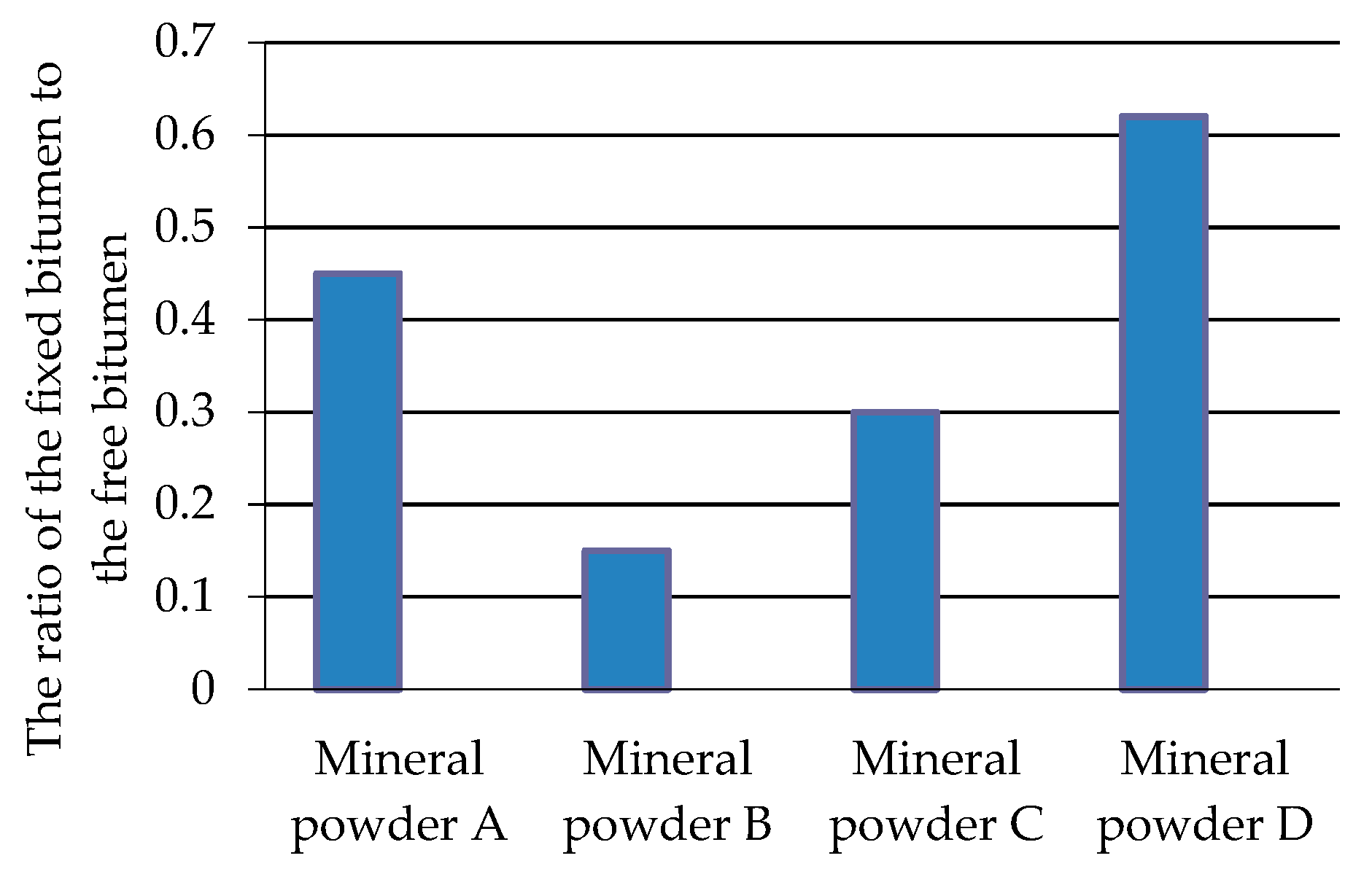

4.2. Filler–Bitumen Interaction of the Content and the Meso Characteristics of the Mineral Filler

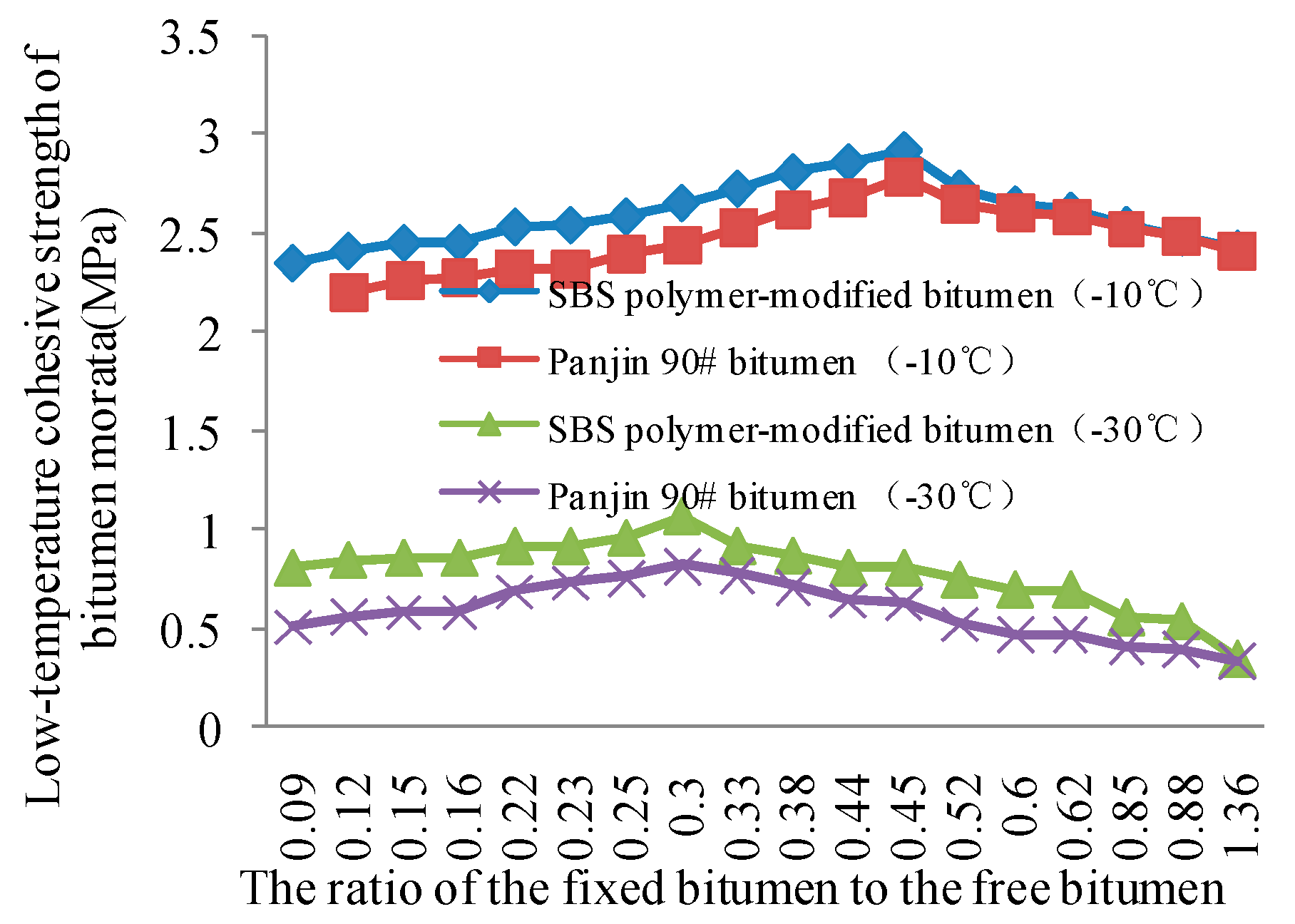

4.3. Quantitative Test Results for Low-Temperature Cohesive Strength of Bitumen Mastics

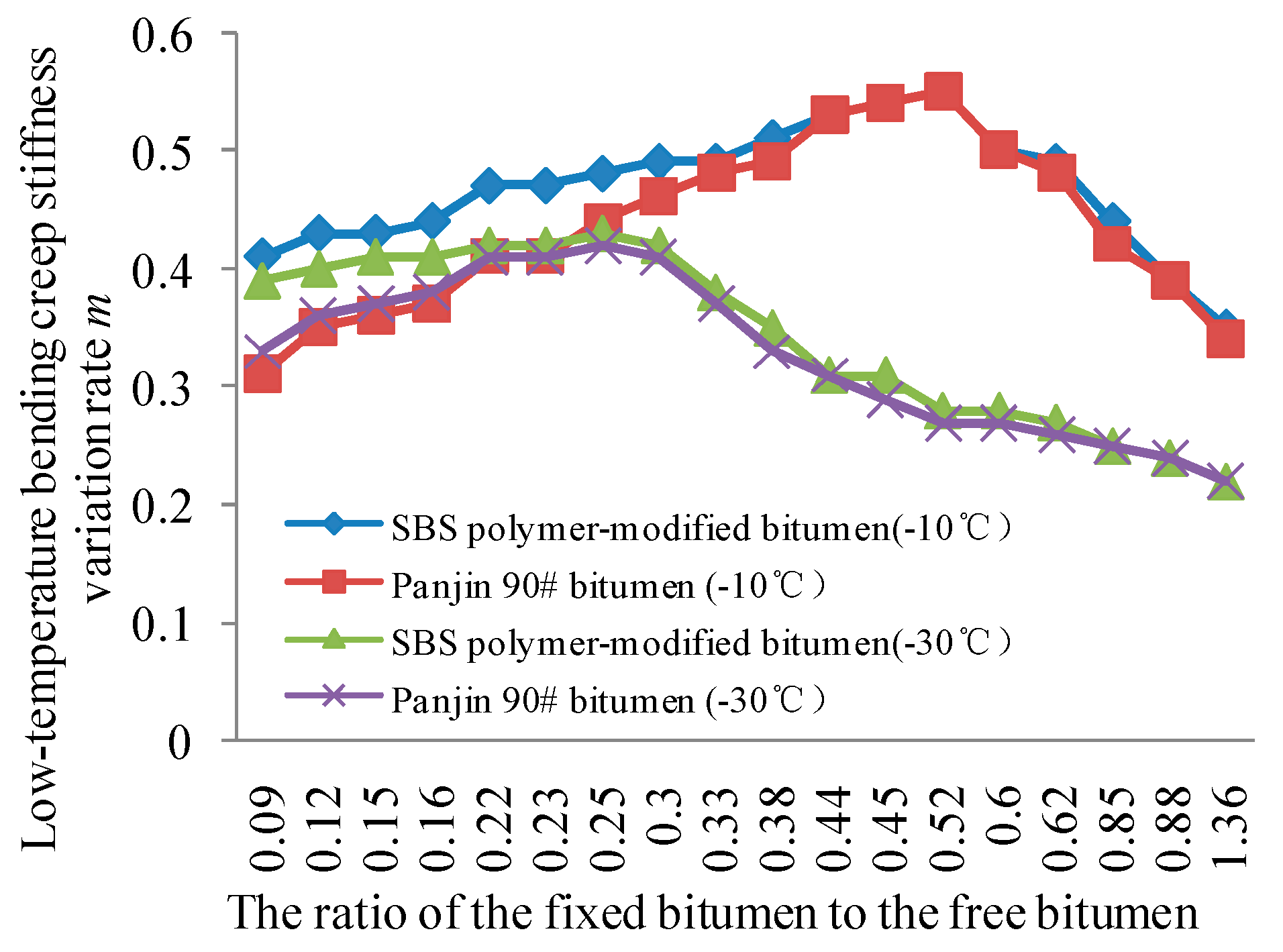

4.4. Test Results for the Rheological Properties of Bitumen Mastics

5. Analysis and Discussion

5.1. Optimal Fixed Bitumen–Free Bitumen Ratio

5.2. Control Strategy for the Mineral Filler Content

6. Conclusions

- (1)

- Although different mineral fillers satisfy the particle size control standard, the meso powder characteristics of different mineral fillers considerably vary. Results show that the meso powder characteristics of the mineral filler significantly influence the low-temperature pavement performance of bitumen mastics.

- (2)

- The fixed bitumen–free bitumen ratio is influenced by the content and the meso powder characteristics of the mineral filler, and the filler–bitumen interaction of the content and the meso powder characteristics of mineral filler can be analyzed according to this ratio. This research proves that filler–bitumen interaction exists, and its effect is significant. The filler–bitumen interaction should be paid more attention in future research.

- (3)

- Following previous research, this study used the low-temperature cohesive strength of bitumen mastics as the control index for critical damage and the variation rate of low-temperature bending creep stiffness as the control index for fatigue damage.

- (4)

- Results of laboratory investigations demonstrated the effects of the fixed bitumen–free bitumen ratio on the critical damage and fatigue damage control indexes. under extreme cold condition (−30 °C) and normal cold condition (−10 °C) can be determined through comprehensive analysis.

- (5)

- By considering the filler–bitumen interaction of the content and the meso voids characteristics of mineral filler, the mineral filler content can be determined reversely according to RJZ and Vg. Thus, the mineral filler content can be precisely controlled, and effective control strategies for the mineral filler content can be provided. It provides a method to accurately control the mineral powder content and provide a reasonable control strategy for mineral powder design.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kuity, A.; Jayaprakasan, S.; Das, A. Laboratory investigation on volume proportioning scheme of mineral fillers in asphalt mixture. Constr. Build. Mater. 2014, 68, 637–643. [Google Scholar] [CrossRef]

- Uzun, I.; Terzi, S. Evaluation of andesite waste as mineral filler in asphaltic concrete mixture. Constr. Build. Mater. 2012, 31, 284–288. [Google Scholar] [CrossRef]

- Barra, B.; Momm, L.; Guerrero, Y.; Bernucci, L. Characterization of granite and limestone powders for use as fillers in bituminous mastics dosage. Anais Acad. Bras. Cienc. 2014, 86, 995–1002. [Google Scholar] [CrossRef] [Green Version]

- Kutuk-Sert, T.; Kutuk, S. Physical and Marshall Properties of Borogypsum Used as Filler Aggregate in Asphalt Concrete. J. Mater. Civ. Eng. 2013, 25, 266–273. [Google Scholar] [CrossRef]

- Chen, M.Z.; Lin, J.T.; Wu, S.P.; Liu, C.H. Utilization of recycled brick powder as alternative filler in asphalt mixture. Constr. Build. Mater. 2011, 25, 1532–1536. [Google Scholar] [CrossRef]

- Wu, S.P.; Zhu, J.Q.; Zhong, J.J.; Wang, D.M. Experimental investigation on related properties of asphalt mastic containing recycled red brick powder. Constr. Build. Mater. 2011, 25, 2883–2887. [Google Scholar] [CrossRef]

- Kuciel, S.; Jakubowska, P.; Kuzniar, P. A study on the mechanical properties and the influence of water uptake and temperature on biocomposites based on polyethylene from renewable sources. Compos. Part B Eng. 2014, 64, 72–77. [Google Scholar] [CrossRef]

- Moon, K.H.; Falchetto, A.C.; Marasteanu, M.; Turos, M. Using recycled asphalt materials as an alternative material source in asphalt pavements. KSCE J. Civ. Eng. 2014, 18, 149–159. [Google Scholar] [CrossRef]

- Zulkati, A.; Wong, Y.D.; Sun, D.D. Effects of Fillers on Properties of Asphalt-Concrete Mixture. J. Transp. Eng. 2012, 138, 902–910. [Google Scholar] [CrossRef]

- Alvarez, A.E.; Ovalles, E.; Caro, S. Assessment of the effect of mineral filler on asphalt-aggregate interfaces based on thermodynamic properties. Constr. Build. Mater. 2012, 28, 599–606. [Google Scholar] [CrossRef]

- Liao, M.C.; Chen, J.S.; Tsou, K.W. Fatigue Characteristics of Bitumen-Filler Mastics and Asphalt Mixtures. J. Mater. Civ. Eng. 2012, 24, 916–923. [Google Scholar] [CrossRef]

- Liao, M.C.; Chen, J.S. Zero Shear Viscosity of Bitumen-Filler Mastics. J. Mater. Civ. Eng. 2011, 23, 1672–1680. [Google Scholar] [CrossRef]

- Clopotel, C.; Velasquez, R.; Bahia, H. Measuring Physico-Chemical Interaction in Mastics Using Glass Transition. Road Mater. Pavement Des. 2012, 13, 304–320. [Google Scholar] [CrossRef]

- Chen, J.S.; Lin, K.Y. Mechanism and behavior of bitumen strength reinforcement using fibers. J. Mater. Sci. 2005, 40, 87–95. [Google Scholar] [CrossRef]

- Gai, G.S.; Yang, Y.F.; Fan, S.M.; Cai, Z.F. Preparation and properties of composite mineral powders. Powder Technol. 2005, 153, 153–158. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. Properties of the Warm Mix Asphalt involving clinoptilolite and Na-P1 zeolite additives. Constr. Build. Mater. 2016, 114, 556–563. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. A Review of the Application of Zeolite Materials in Warm Mix Asphalt Technologies. Appl. Sci. 2017, 7, 293. [Google Scholar] [CrossRef]

- Lv, D.; Zheng, C.F.; Qin, Y.; Bi, H.; Li, K.Y.; Huang, J.F. Analysing the effects of the mesoscopic characteristics of mineral powder fillers on the cohesive strength of asphalt mortars at low temperatures. Constr. Build. Mater. 2014, 65, 330–337. [Google Scholar]

- Grabowski, W.; Wilanowicz, J. The structure of mineral fillers and their stiffening properties in filler-bitumen mastics. Mater. Struct. 2008, 41, 793–804. [Google Scholar] [CrossRef]

- Guo, M.; Bhasin, A.; Tan, Y.Q. Effect of mineral fillers adsorption on rheological and chemical properties of asphalt binder. Constr. Build. Mater. 2017, 141, 152–159. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Tao, J.L.; Jiao, Y.B.; Guo, Q.L.; Li, C. Influence of Diatomite and Mineral Powder on Thermal Oxidative Ageing Properties of Asphalt. Adv. Mater. Sci. Eng. 2015. [Google Scholar] [CrossRef]

- Horak, E.; Mukandila, E.M. Exploratory use of Rigden voids as design criteria for the design of sand treated with emulsion. Road Mater. Pavement Des. 2008, 9, 525–535. [Google Scholar] [CrossRef]

- Mo, L.T.; Huurman, M.; Wu, S.P.; Molenaar, A.A.A. Bitumen-stone adhesive zone damage model for the meso-mechanical mixture design of ravelling resistant porous asphalt concrete. Int. J. Fatigue 2011, 33, 1490–1503. [Google Scholar] [CrossRef]

- Mo, L.T.; Huurman, M.; Wub, S.P.; Molenaar, A.A.A. 2D and 3D meso-scale finite element models for ravelling analysis of porous asphalt concrete. Finite Elem. Anal. Des. 2008, 44, 186–196. [Google Scholar] [CrossRef]

- Zheng, C.F.; Zhao, D.J.; Xiang, N.L.; Song, Z.F. Mechanism of low-temperature adhesion failure in asphalt mixtures with dense-suspension and void-skeleton structures. Constr. Build. Mater. 2012, 36, 711–718. [Google Scholar]

- Lyne, A.L.; Krivosheeva, O.; Birgisson, B. Adhesion between bitumen and aggregate: Implementation of spectroscopic ellipsometry characterisation and estimation of Hamaker’s constant. Mater. Struct. 2013, 46, 1737–1745. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Airey, G.D.; Grenfell, J.R.A. Experimental evaluation of cohesive and adhesive bond strength and fracture energy of bitumen-aggregate systems. Mater. Struct. 2016, 49, 2653–2667. [Google Scholar] [CrossRef]

- Zheng, C.F.; Zhao, D.J.; Chen, C.J.; Song, Z.F.; Zheng, S. Quantitative test technology study on the mesoscopic strength parameters of the mineral aggregate contact surface of bituminous-stabilized macadam. Constr. Build. Mater. 2013, 40, 622–631. [Google Scholar] [CrossRef]

- Faheem, A.F.; Bahia, H.U. Modelling of Asphalt Mastic in Terms of Filler-Bitumen Interaction. Road Mater. Pavement Des. 2010, 11, 281–303. [Google Scholar] [CrossRef]

- Ho, C.H.; Romero, P. Using Asphalt Mixture Beams in the Bending Beam Rheometer Experimental and Numerical Approach. Road Mater. Pavement Des. 2011, 12, 293–314. [Google Scholar]

- Sun, Z.J.; Yi, J.Y.; Huang, Y.D.; Feng, D.C.; Guo, C.Y. Properties of asphalt binder modified by bio-oil derived from waste cooking oil. Constr. Build. Mater. 2016, 102, 496–504. [Google Scholar] [CrossRef]

- Sustersic, E.; Nikonov, A.; Valant, A.Z. Influence of ageing on viscoelastic properties of PMMA/ATH modified bitumen. Polym. Compos. 2015, 36, 1738–1747. [Google Scholar] [CrossRef]

| Bitumen Type | Penetration/0.1 mm | Ductility at 15 °C/cm | Softening Point/°C | Standard Viscosity/Pa·s | ||

|---|---|---|---|---|---|---|

| 5 °C | 25 °C | 60 °C | 90 °C | |||

| Panjin 90# bitumen | 7.1 | 93.8 | 98 | 43.1 | 4120 | 2658 |

| SBS polymer-modified bitumen | 7.5 | 97.2 | 115 | 51.4 | 6246 | 3820 |

| Size Range (mm) | <0.6 mm | <0.15 mm | <0.075 mm |

|---|---|---|---|

| Cumulative pass rate (%) | 100 | 90–100 | 75–100 |

| Mineral Filler Sample | Volume after Compaction Vfb (cm3) | Sample Quantity (g) | Limestone Density (g/cm3) | Actual volume of Mineral Filler Particles Vfs (cm3) | Internal Residual Meso Void Vfb − Vfs (cm3) | Ration of Residual Meso Void (%) | Internal Residual Meso Void in Unit Mass Vg (cm3/g) |

|---|---|---|---|---|---|---|---|

| A | 6.3 | 10 | 2.7 | 3.7 | 2.6 | 41.2 | 0.26 |

| B | 4.8 | 10 | 2.7 | 3.7 | 1.1 | 22.9 | 0.11 |

| C | 5.6 | 10 | 2.7 | 3.7 | 1.9 | 33.9 | 0.19 |

| D | 6.9 | 10 | 2.7 | 3.7 | 3.2 | 46.4 | 0.32 |

| RFB | Mineral Filler Quantity (g) | Mineral Filler A Vg = 0.26 | Mineral Filler B Vg = 0.11 | Mineral Filler C Vg = 0.19 | Mineral Filler D Vg = 0.32 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S (g) | F (g) | S/F | S (g) | F (g) | S/F | S (g) | F (g) | S/F | S (g) | F (g) | S/F | ||

| 0.6 | 60 | 18.72 | 81.28 | 0.23 | 7.92 | 92.08 | 0.09 | 13.68 | 86.32 | 0.16 | 23.04 | 76.96 | 0.30 |

| 0.8 | 80 | 24.96 | 75.04 | 0.33 | 10.56 | 89.44 | 0.12 | 18.24 | 81.76 | 0.22 | 30.72 | 69.28 | 0.44 |

| 1 | 100 | 31.2 | 68.8 | 0.45 | 13.2 | 86.8 | 0.15 | 22.8 | 77.2 | 0.30 | 38.40 | 61.60 | 0.62 |

| 1.2 | 120 | 37.44 | 62.56 | 0.60 | 15.84 | 84.16 | 0.19 | 27.36 | 72.64 | 0.38 | 46.08 | 53.92 | 0.85 |

| 1.5 | 150 | 46.8 | 53.2 | 0.88 | 19.8 | 80.20 | 0.25 | 34.20 | 65.80 | 0.52 | 57.60 | 42.40 | 1.36 |

| Temperature (°C) | Optimum Proportion of the Fixed Bitumen–Free Bitumen Ratio | Mineral Filler Categories | |||

|---|---|---|---|---|---|

| Mineral Filler A Vg = 0.26 | Mineral Filler B Vg = 0.11 | Mineral Filler C Vg = 0.19 | Mineral Filler D Vg = 0.32 | ||

| −30 | 0.25 | 0.64 | 1.52 | 0.88 | 0.52 |

| −10 | 0.45 | 0.99 | 2.35 | 1.36 | 0.81 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, C.; Li, R.; Zou, L.; Lv, D.; Xu, Y. Effects of Filler–Bitumen Ratio and Mineral Filler Characteristics on the Low-Temperature Performance of Bitumen Mastics. Materials 2018, 11, 1155. https://doi.org/10.3390/ma11071155

Zheng C, Li R, Zou L, Lv D, Xu Y. Effects of Filler–Bitumen Ratio and Mineral Filler Characteristics on the Low-Temperature Performance of Bitumen Mastics. Materials. 2018; 11(7):1155. https://doi.org/10.3390/ma11071155

Chicago/Turabian StyleZheng, Chuanfeng, Ruiming Li, Linlin Zou, Dan Lv, and Yazhi Xu. 2018. "Effects of Filler–Bitumen Ratio and Mineral Filler Characteristics on the Low-Temperature Performance of Bitumen Mastics" Materials 11, no. 7: 1155. https://doi.org/10.3390/ma11071155