Microstructure Evolution and Mechanical Behavior of 2219 Aluminum Alloys Additively Fabricated by the Cold Metal Transfer Process

Abstract

:1. Introduction

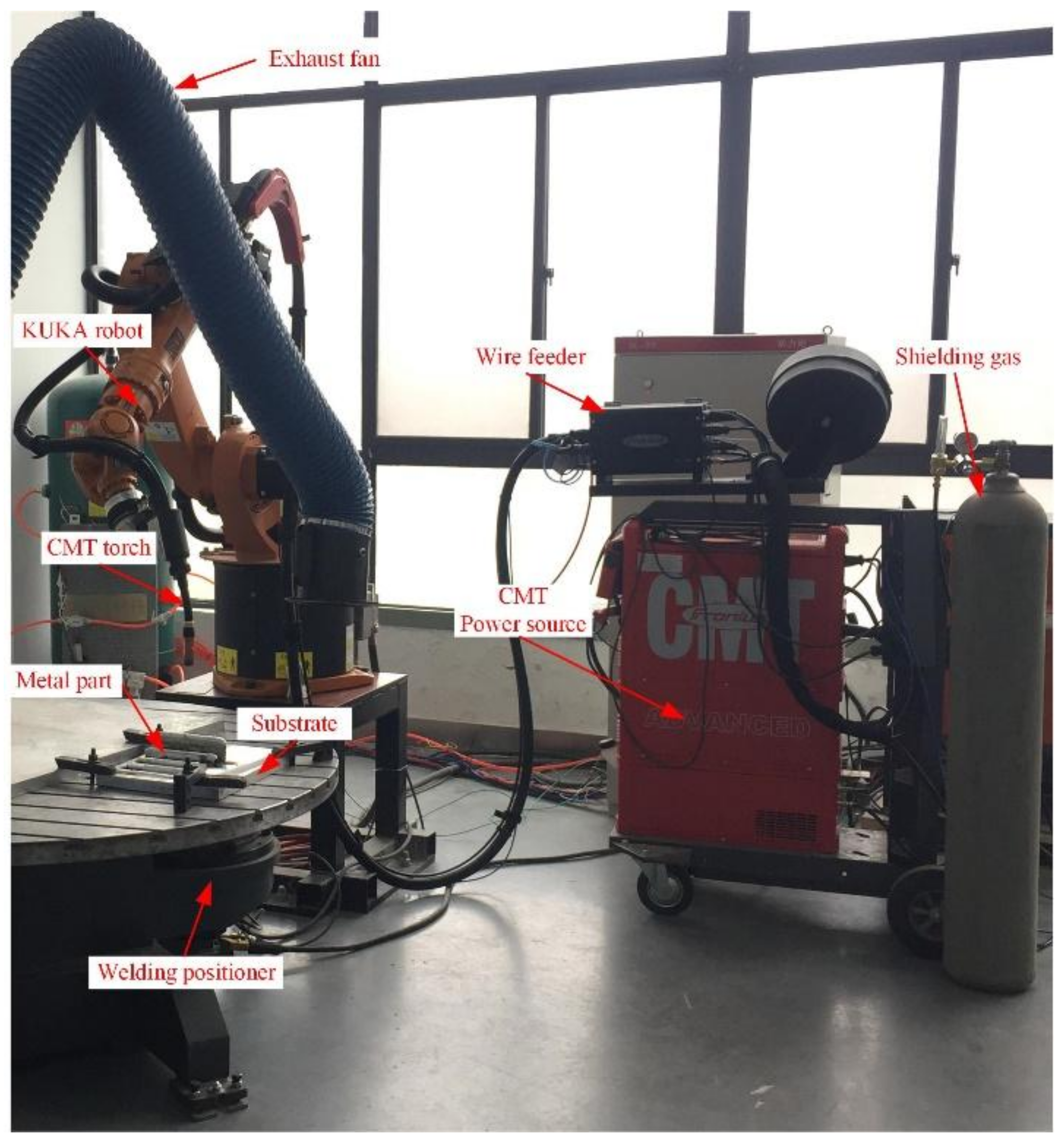

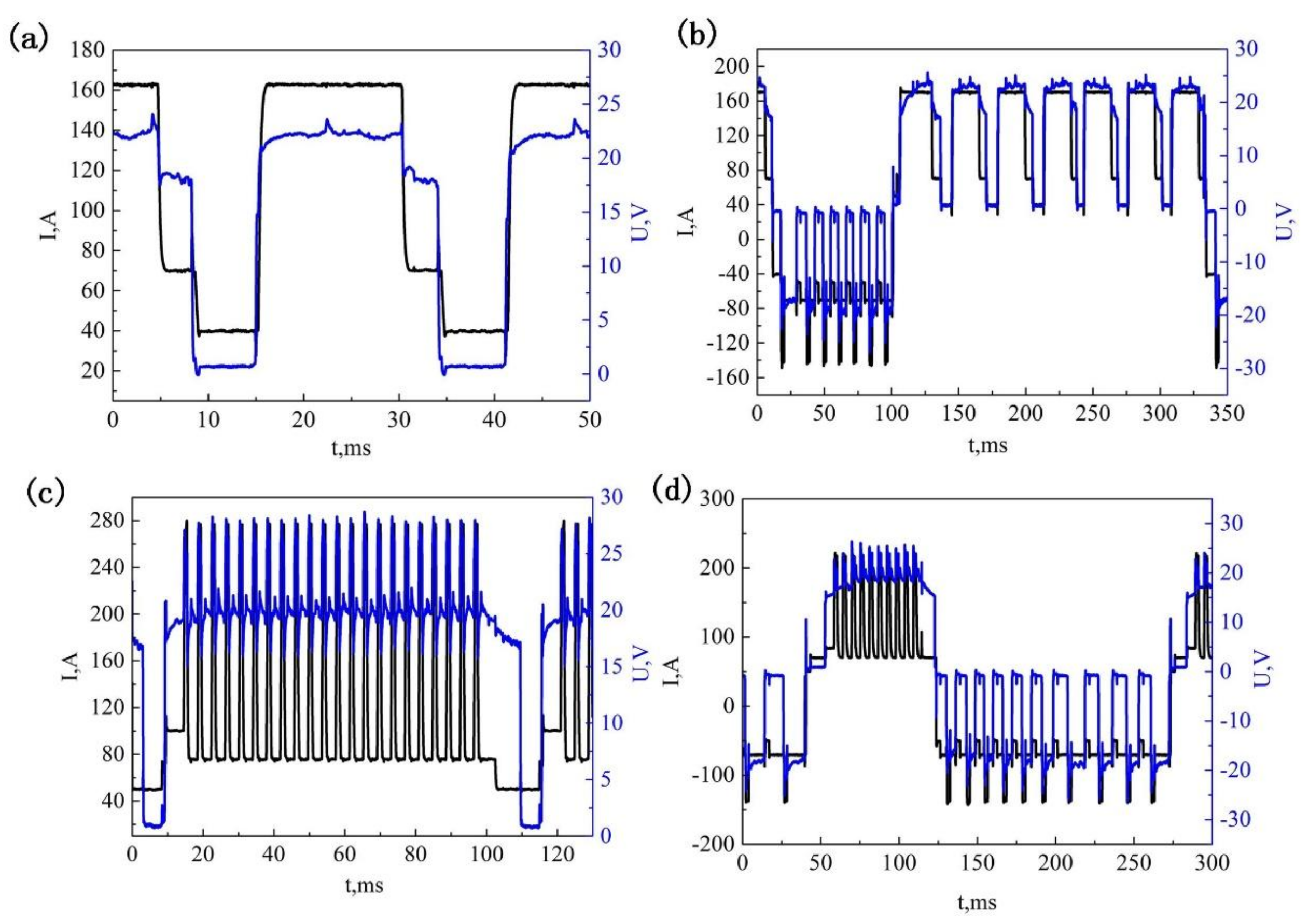

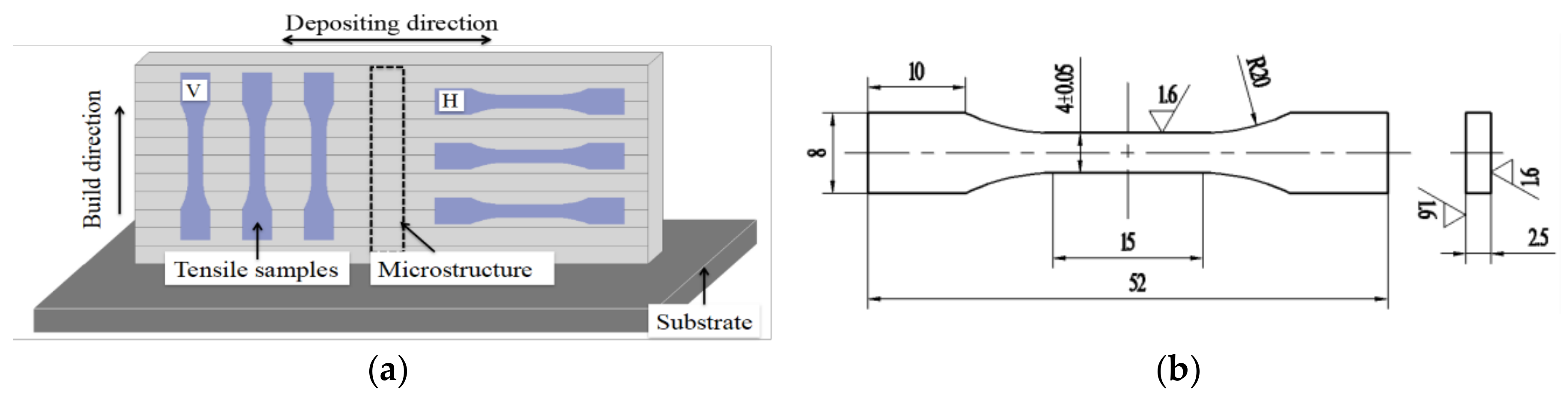

2. Experimental Procedure

3. Results and Discussion

3.1. Microstructure

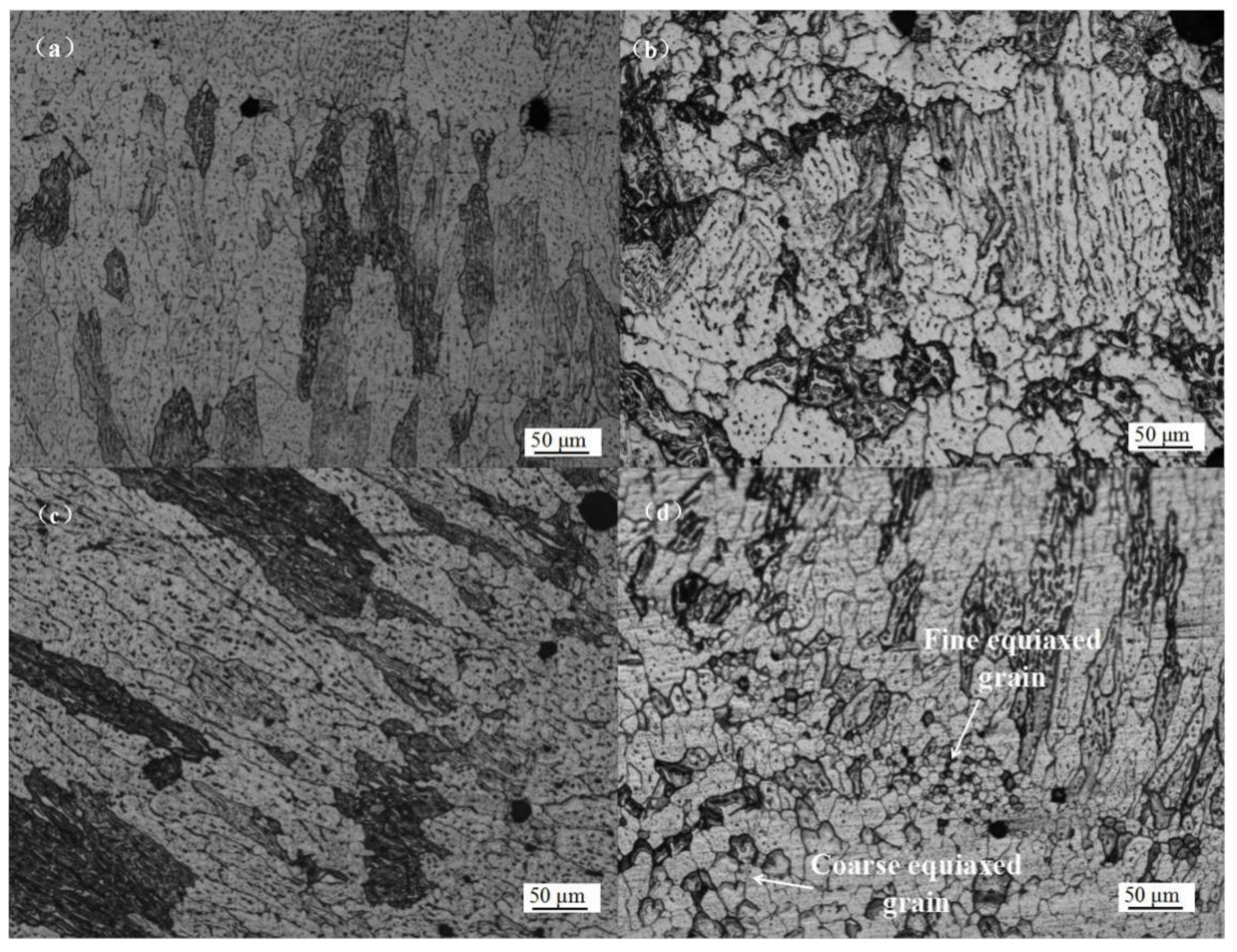

3.1.1. Optical Micrographs

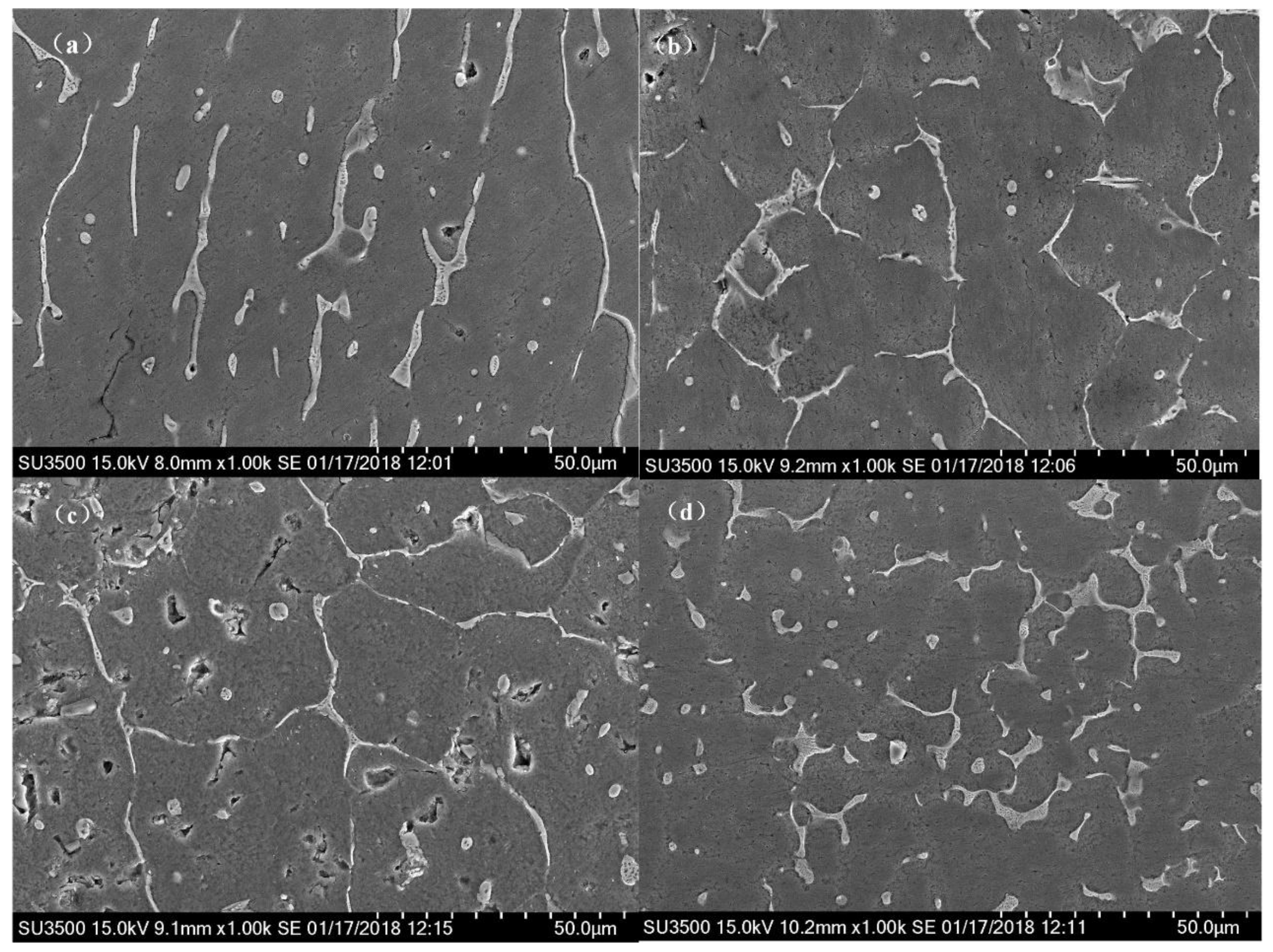

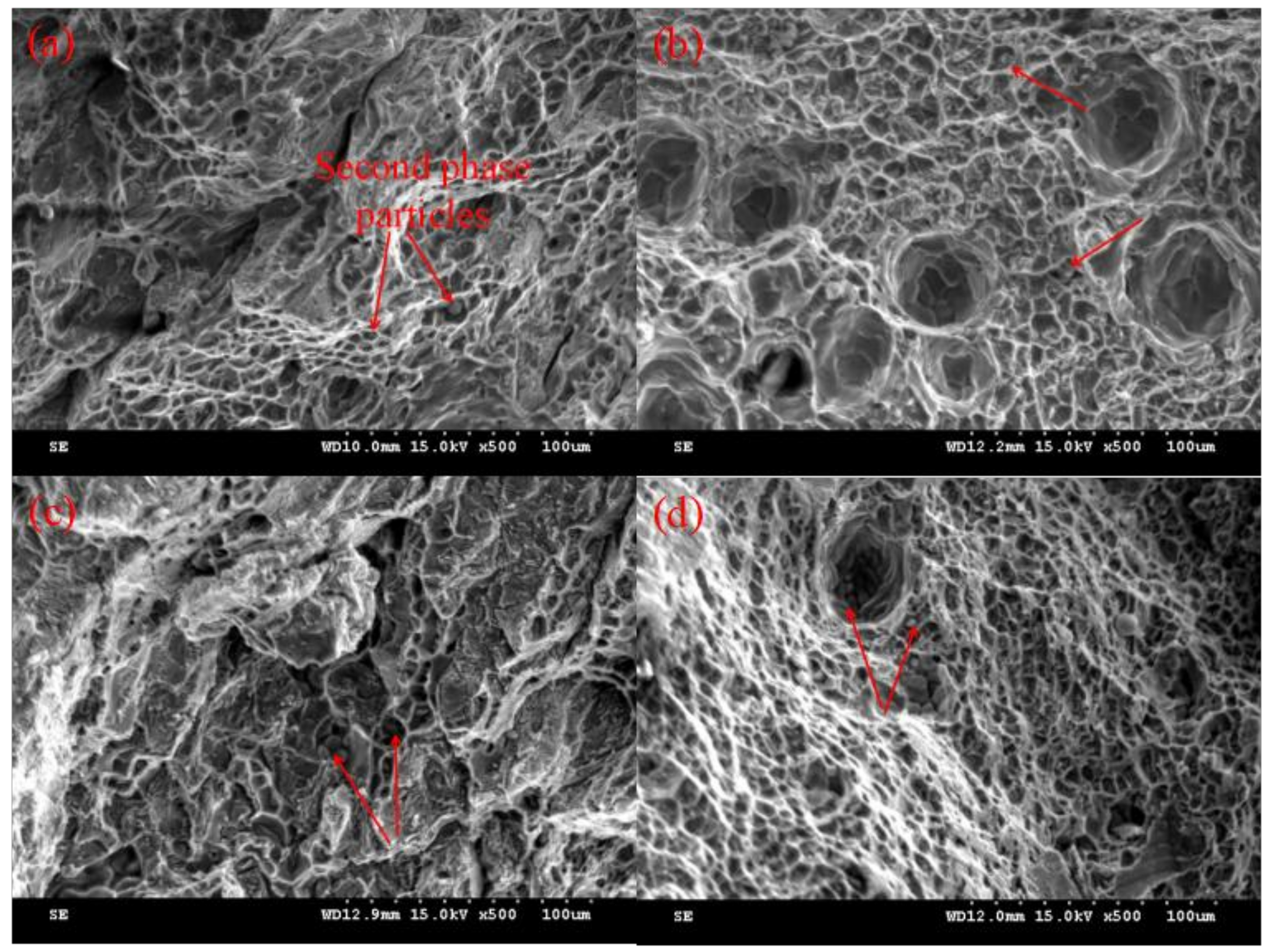

3.1.2. SEM Results

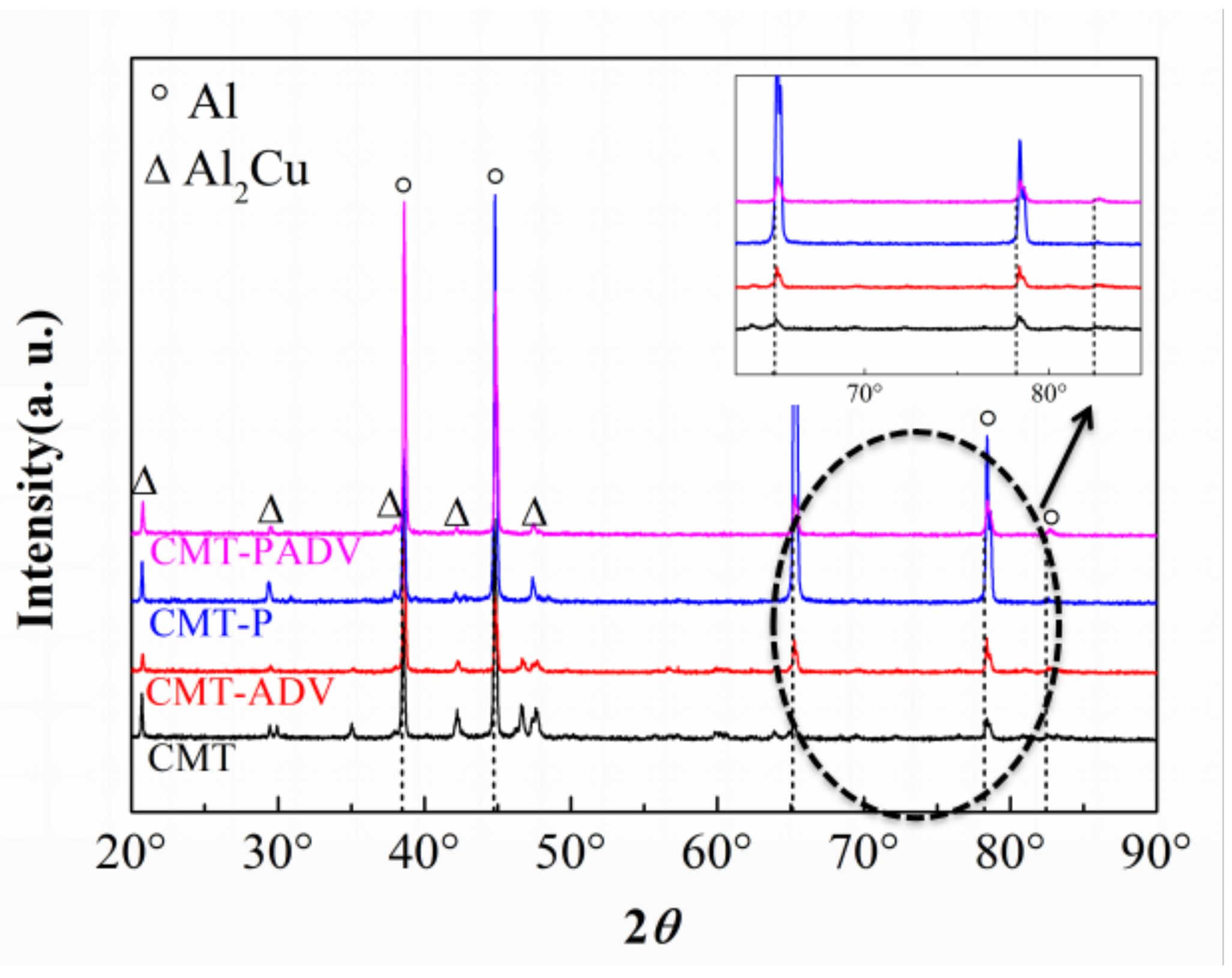

3.1.3. XRD Results

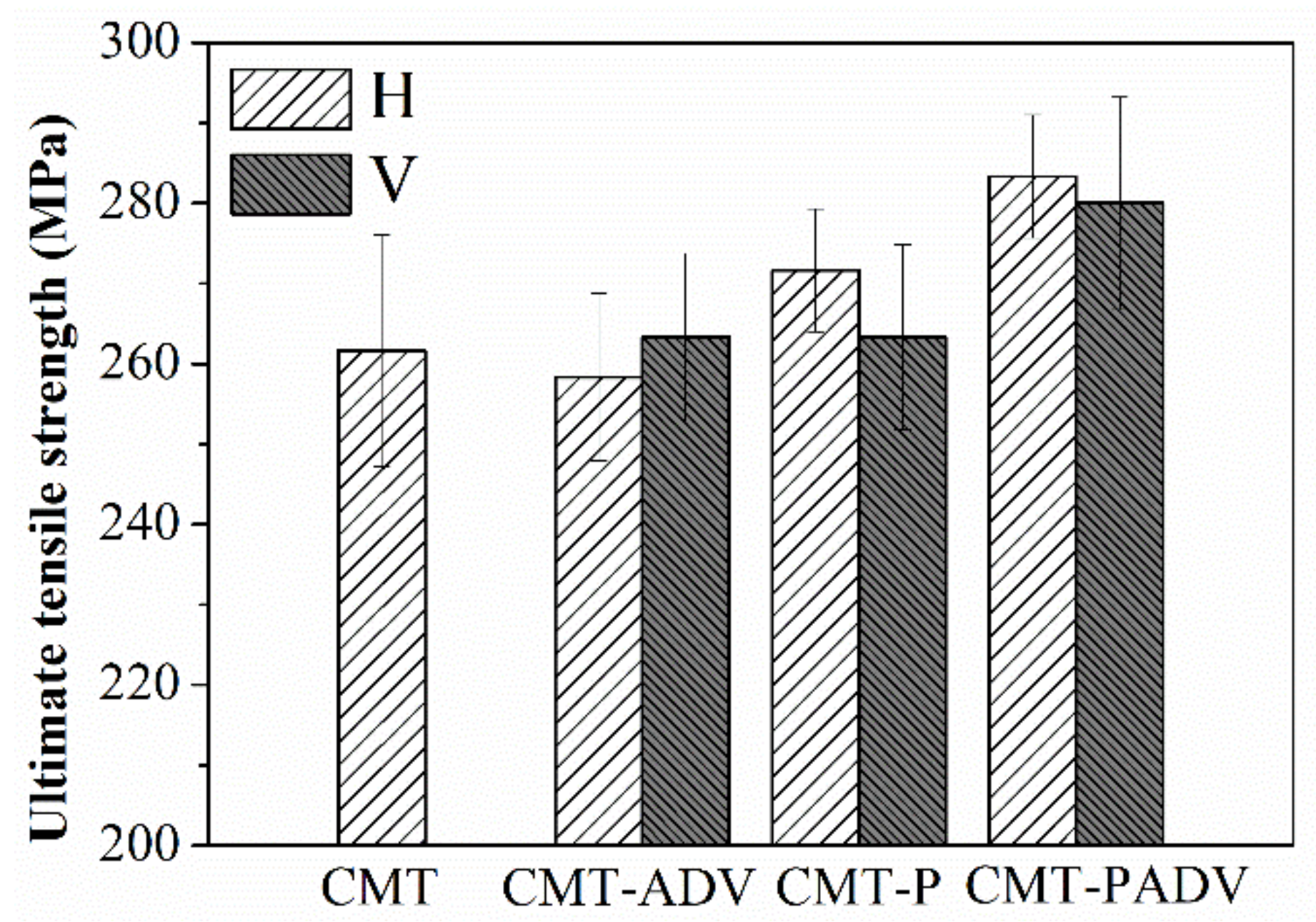

3.2. Tensile Properties

4. Conclusions

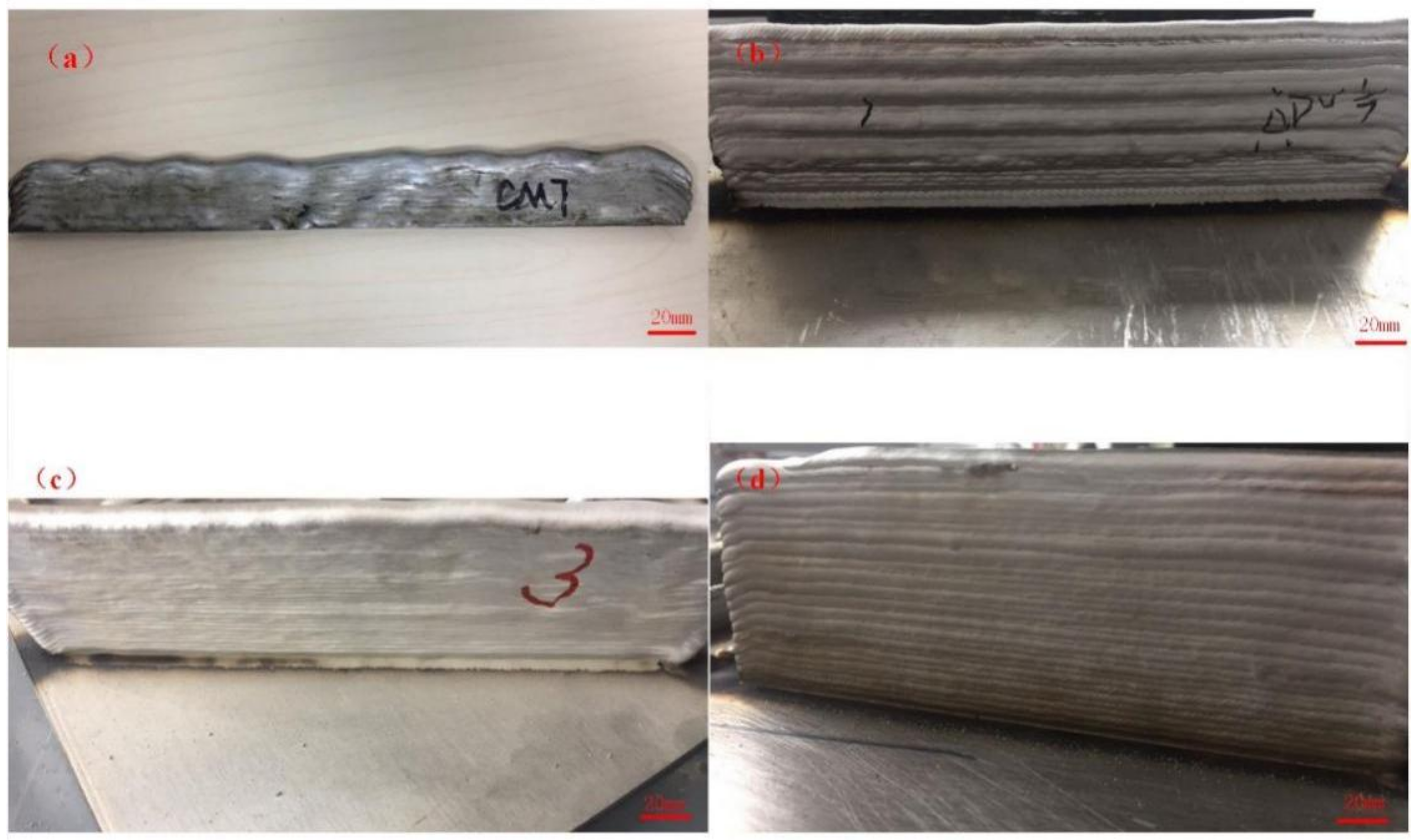

- The results showed that the 2219-Al wall fabricated CMT-P and CMT-ADV arc modes can generate smooth and uniform multilayer thin-wall parts.

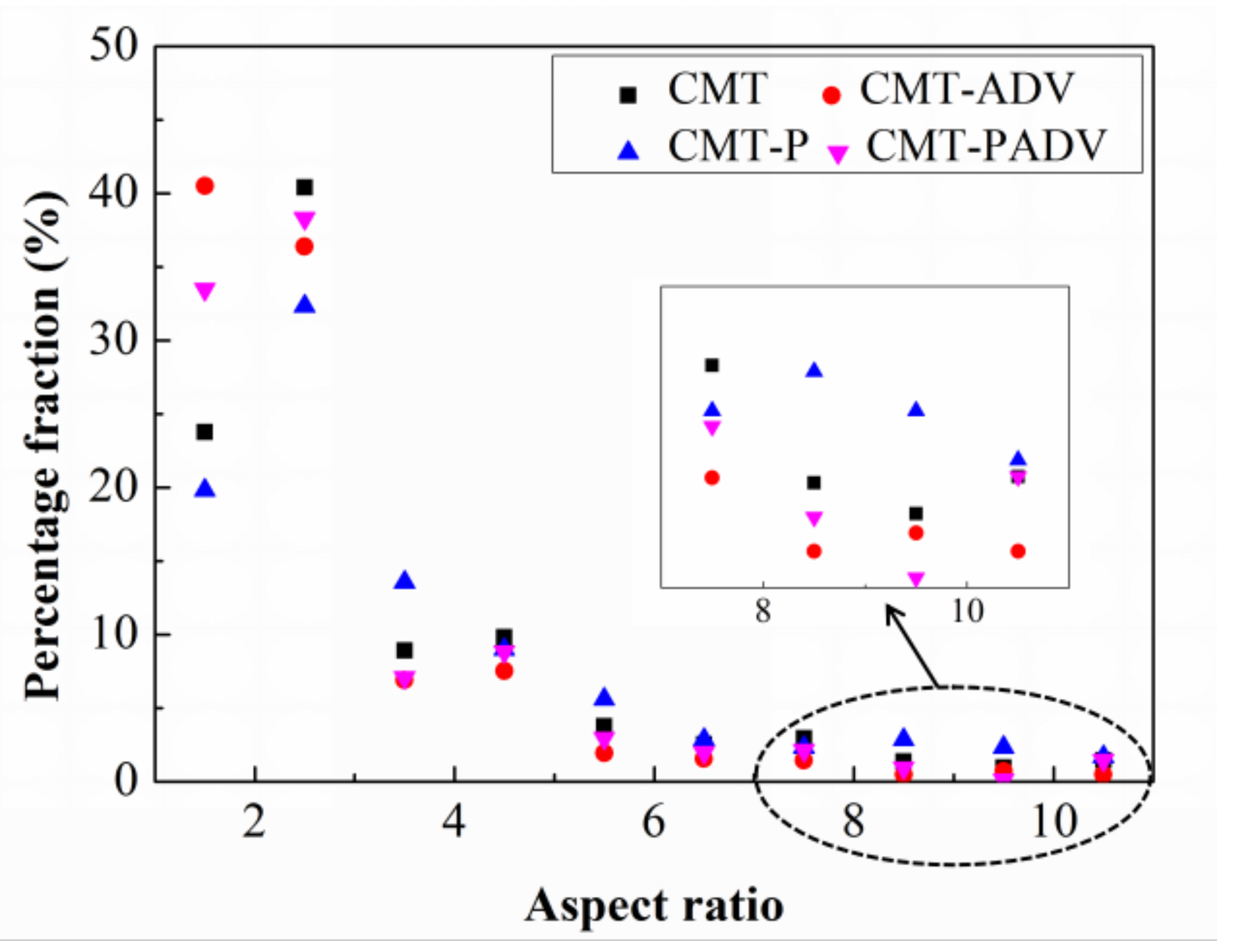

- The conventional CMT process produced the largest number of small gas pores. The mean diameter of the pores produced by the CMT-ADV process was the largest with the average size of 30.0 μm and some pores were even larger than 100 μm. However, In the CMT-PADV arc mode, the pore area percentage was the smallest (only 0.98%) and there were no gas pores larger than 100 μm. Equiaxed grains were distributed in the fusion zone and a mixture of coarse columnar grain and finer equiaxed grain structure was observed. In addition, the CMT-PADV samples have the smallest lattice parameter which indicates the highest solute level of Cu in Al alloys.

- The best tensile strength was obtained by the CMT-PADV mode. The tensile strength could reach 283 MPa in the horizontal direction. What’s more, the strength properties were nearly isotropic with only a difference of 5 MPa in the vertical and horizontal directions. It can be concluded that will with proper control and monitoring of the process parameters in the CMT-PADV arc mode, large size 2219 Al parts with excellent properties can be rapidly deposited.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Frazier, W.E. Digital Manufacturing of Metallic Components: Vision and Roadmap. In Solid Free Form Fabrication Proceedings; University of Texas at Austin: Austin, TX, USA, 2010; pp. 717–732. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2010. [Google Scholar]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 1–46. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2015, 7, 641–647. [Google Scholar] [CrossRef]

- Xiong, J.; Lei, Y.; Chen, H.; Zhang, G. Fabrication of inclined thin-walled parts in multi-layer single-pass gmaw-based additive manufacturing with flat position deposition. J. Mater. Process. Technol. 2017, 240, 397–403. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured ti-6al-4v. Metall. Mater. Trans. A 2013, 44, 968–977. [Google Scholar] [CrossRef]

- Xiong, X.; Zhang, H.; Wang, G. Metal direct prototyping by using hybrid plasma deposition and milling. J. Mater. Process. Technol. 2009, 209, 124–130. [Google Scholar] [CrossRef]

- Wu, Q.; Lu, J.; Liu, C.; Shi, X.; Ma, Q.; Tang, S.; Fan, H; Ma, S. Obtaining uniform deposition with variable wire feeding direction during wire-feed additive manufacturing. Mater. Manuf. Process. 2017, 32, 1881–1886. [Google Scholar] [CrossRef]

- Ding, D.; Shen, C.; Pan, Z.; Cuiuri, D.; Li, H.; Larkin, N.; van Duin, S. Towards an automated robotic arc-welding-based additive manufacturing system from cad to finished part. Comput.-Aided Des. 2016, 73, 66–75. [Google Scholar] [CrossRef]

- Pickin, C.G.; Williams, S.W.; Lunt, M. Characterisation of the cold metal transfer (CMT) process and its application for low dilution cladding. J. Mater. Process. Technol. 2011, 211, 496–502. [Google Scholar] [CrossRef] [Green Version]

- Gerhard, P.; Ferdinand, K.; Heinz, H.; Harald, C. Manufacturing of Turbine Blades by Shape Giving CMT-Welding. In Proceedings of the Metal Additive Manufacturing Conference, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Shang, J.; Wang, K.; Zhou, Q.; Zhang, D.; Huang, J.; Li, G. Microstructure characteristics and mechanical properties of cold metal transfer welding mg/al dissimilar metals. Mater. Des. 2012, 34, 559–565. [Google Scholar] [CrossRef]

- Azar, A.S. A heat source model for cold metal transfer (CMT) welding. J. Therm. Anal. Calorim. 2015, 122, 741–746. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, H.; He, P. The CMT short-circuiting metal transfer process and its use in thin aluminum sheets welding. Mater. Des. 2009, 30, 1850–1852. [Google Scholar] [CrossRef]

- Cong, B.; Ding, J.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Bai, J.Y.; Fan, C.L.; Lin, S.B.; Yang, C.L.; Dong, B.L. Effects of thermal cycles on microstructure evolution of 2219-Al during GTA-additive manufacturing. Int. J. Adv. Manuf. Technol. 2016, 87, 2615–2623. [Google Scholar] [CrossRef]

- Guo, X.; Yang, C.; Qian, B.; Qiang, X.U. Effects of inoculants Ti and Zr on the microstructures and properties of 2219 Al-Cu alloy welds. Acta Metall. Sin. 2005, 41, 397–401. [Google Scholar]

- Donlon, W.T.; Paige, C.; Morris, C.J.; Allison, J.E. The effects of casting defectsand microstructure on the mechanical properties of die cast AM50 magnesiumand 356 aluminum. In Proceedings of the TMS Materials Week 95 Symposium, Cleveland, OH, USA, 29 October–2 November 1996; pp. 17–27. [Google Scholar]

- Mendez, P.F.; Eagar, T.W. Penetration and defect formation in high-current arc welding. Weld. J. 2003, 82, 10–296. [Google Scholar]

- Sun, R.; Li, L.; Zhu, Y.; Guo, W.; Peng, P.; Cong, B.; Sun, J.; Che, Z.; Li, B.; Guo, C.; et al. Microstructure, residual stress and tensile properties control of wire-arc additive manufactured 2319 aluminum alloy with laser shock peening. J. Alloys Compd. 2018, 747, 255–265. [Google Scholar] [CrossRef]

- Zha, M.; Li, Y.; Mathiesen, R.H.; Bjørge, R.; Roven, H.J. Microstructure evolution and mechanical behavior of a binary Al–7Mg alloy processed by equal-channel angular pressing. Acta Mater. 2015, 84, 42–54. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Gao, M.; Zeng, X. Wire Arc Additive Manufacturing of Al-6Mg alloy Using Variable Polarity Cold Metal Transfer Arc as Power Source. Mater. Sci. Eng. A 2017, 711, 415–423. [Google Scholar] [CrossRef]

- Mayer, H.; Papakyriacou, M.; Zettl, B.; Stanzl-Tschegg, S.E. Influence of porosity on the fatigue limit of die cast magnesium and aluminum alloys. Int. J. Fatigue 2003, 25, 245–256. [Google Scholar] [CrossRef]

- Kobayashi, M.; Dorce, Y.; Toda, H.; Horikawa, H. Effect of local volume fraction of microporosity on tensile properties in AlSiMg cast alloy. Met. Sci. J. 2014, 26, 962–967. [Google Scholar]

- Radović, L.; Nikačević, M.; Jordović, B. Deformation behaviour and microstructure evolution of AlMg6Mn alloy during shear spinning. Trans. Nonferrous Met. Soc. China 2012, 22, 991–1000. [Google Scholar] [CrossRef]

- Sharma, V.M.J.; Kumar, K.S.; Rao, B.N.; Pathak, S.D. Effect of microstructure and strength on the fracture behavior of aa2219 alloy. Mater. Sci. Eng. A 2009, 502, 45–53. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.W.; Gu, H.; Bai, J.; Zhai, Y.; Ma, P. The strengthening effect of inter-layer cold working and post-deposition heat treatment on the additively manufactured Al–6.3Cu alloy. Mater. Sci. Eng. A 2016, 651, 18–26. [Google Scholar] [CrossRef]

| Alloys | Chemical Composition (wt %) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cu | Mn | Mg | Ti | Zr | V | Zn | Si | Fe | |

| ER2319 | 5.8–6.8 | 0.2–0.4 | <0.02 | 0.1–0.2 | 0.1–0.25 | 0.05–0.15 | <0.1 | <0.2 | <0.3 |

| 2219-T87 | 5.8–6.8 | 0.2–0.4 | <0.02 | 0.02–0.1 | 0.1–0.25 | 0.05–0.15 | <0.1 | <0.2 | <0.3 |

| Arc Mode | Welding Parameters |

|---|---|

| Cold metal transfer (CMT) | WFS = 6 m/min TS = 0.5 m/min HI = (220.9 J/mm) |

| CMT-Advanced (CMT-ADV) | WFS = 6 m/min TS = 0.5 m/min HI = (194.0 J/mm) |

| CMT-Pulse (CMT-P) | WFS = 5 m/min TS = 0.5 m/min HI = (231.8 J/mm) |

| CMT pulse advanced (CMT-PADV) | WFS = 7 m/min TS = 0.5 m/min HI = (130.1 J/mm) |

| Arc Mode | Number of Pores (In a Total Area of 34 mm2) | Mean Diameter (μm) | Area Percentage (%) | Mean Aspect Ratio |

|---|---|---|---|---|

| CMT | 1220 | 14.4 | 1.33 | 3.76 |

| CMT-ADV | 822 | 30.0 | 2.60 | 2.94 |

| CMT-P | 767 | 21.4 | 1.52 | 4.69 |

| CMT-PADV | 747 | 18.9 | 0.98 | 3.24 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, X.; Zhang, L.; Li, H.; Li, C.; Huang, K.; Lu, B. Microstructure Evolution and Mechanical Behavior of 2219 Aluminum Alloys Additively Fabricated by the Cold Metal Transfer Process. Materials 2018, 11, 812. https://doi.org/10.3390/ma11050812

Fang X, Zhang L, Li H, Li C, Huang K, Lu B. Microstructure Evolution and Mechanical Behavior of 2219 Aluminum Alloys Additively Fabricated by the Cold Metal Transfer Process. Materials. 2018; 11(5):812. https://doi.org/10.3390/ma11050812

Chicago/Turabian StyleFang, Xuewei, Lijuan Zhang, Hui Li, Chaolong Li, Ke Huang, and Bingheng Lu. 2018. "Microstructure Evolution and Mechanical Behavior of 2219 Aluminum Alloys Additively Fabricated by the Cold Metal Transfer Process" Materials 11, no. 5: 812. https://doi.org/10.3390/ma11050812