Tensile Property of ANSI 304 Stainless Steel Weldments Subjected to Cavitation Erosion Based on Treatment of Laser Shock Processing

Abstract

:1. Introduction

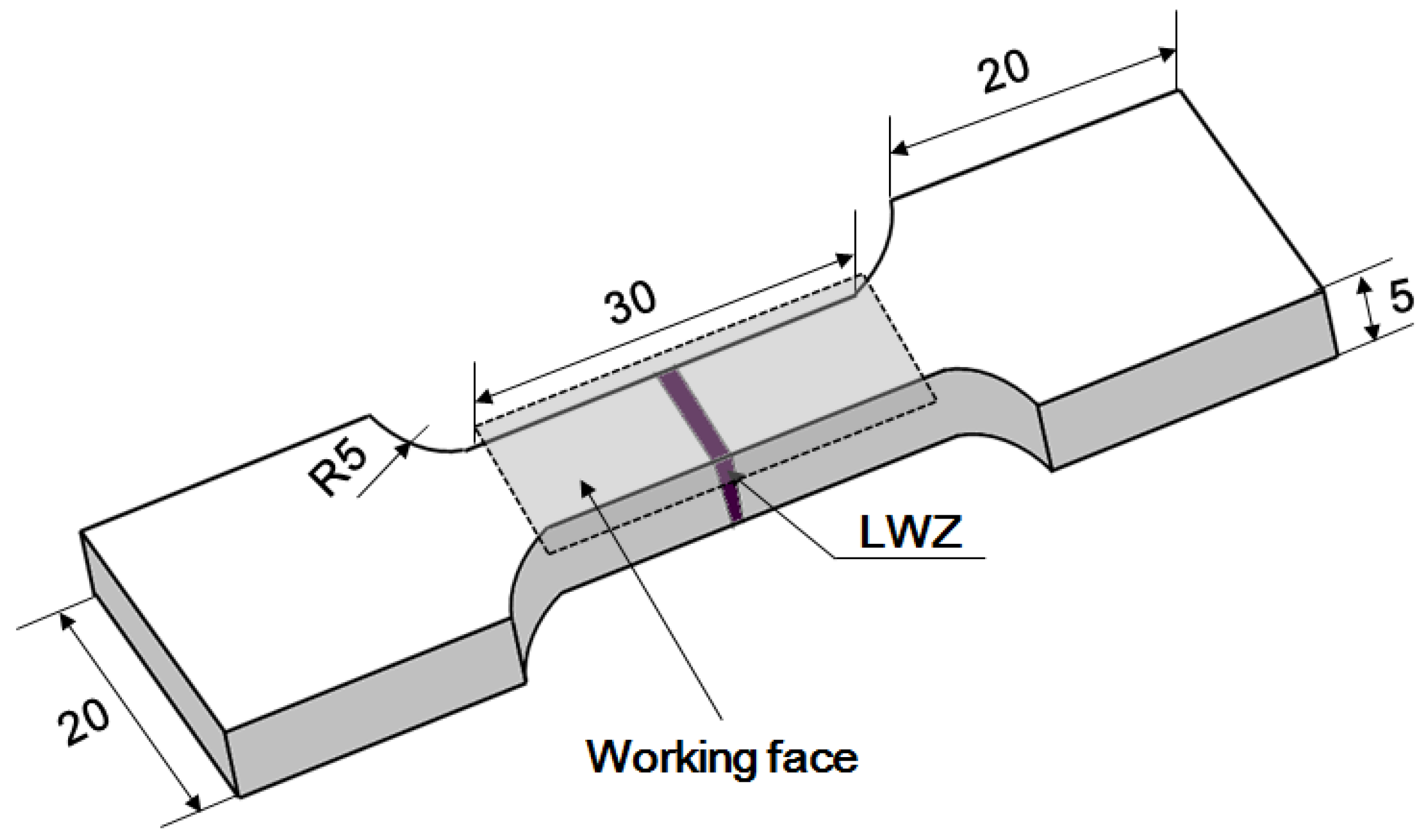

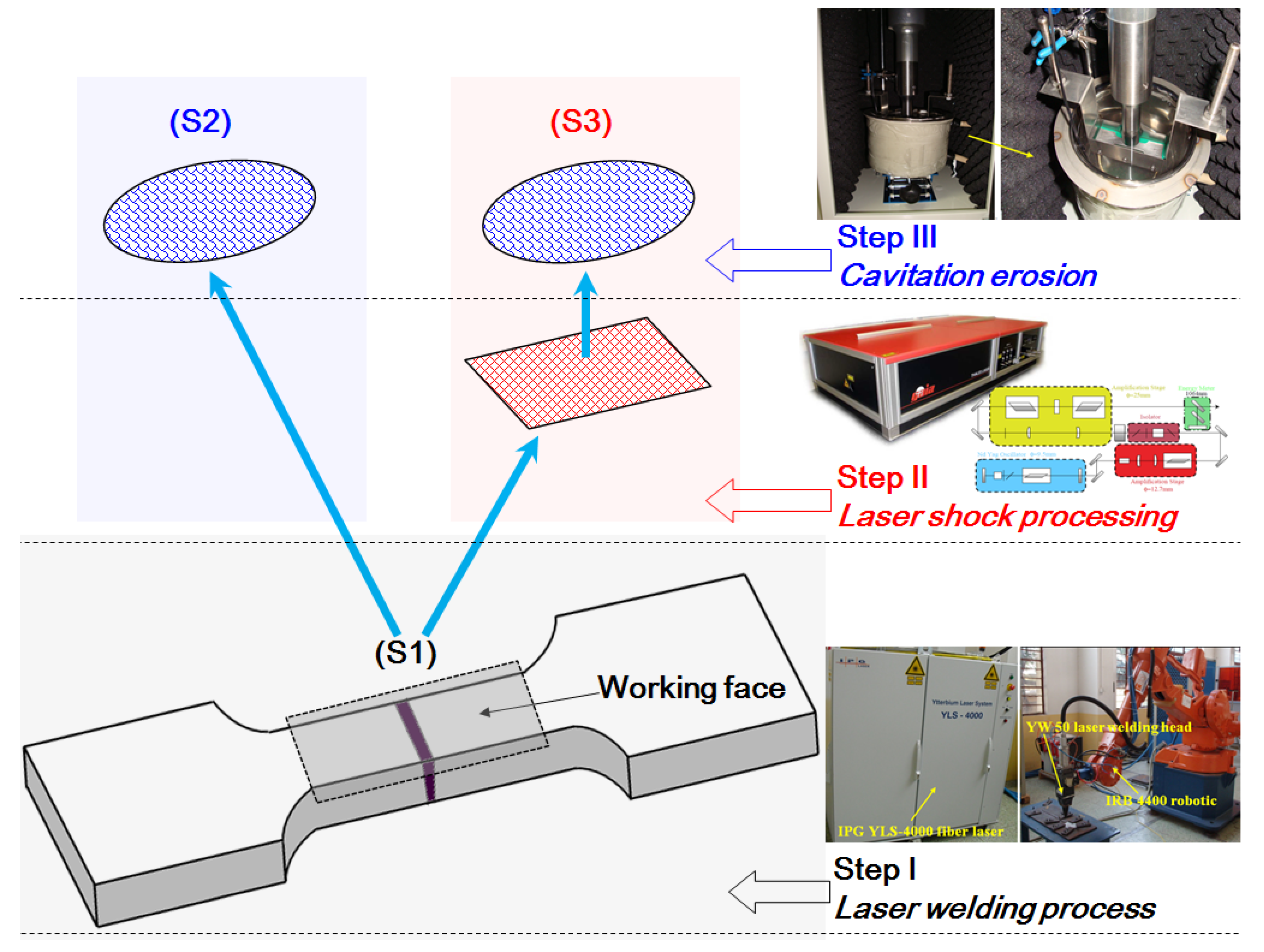

2. Materials and Methods

2.1. Materials and Laser Welding Procedure

2.2. Experimental Procedure of Laser Shock Processing

2.3. Cavitation Erosion Procedure of Tensile Samples

2.4. Mass Loss Measurement

2.5. Tensile Testing

2.6. Fracture Morphology

2.7. Statistical Analysis

3. Results and Discussion

3.1. Mass Loss Analysis of Samples Subjected to CE

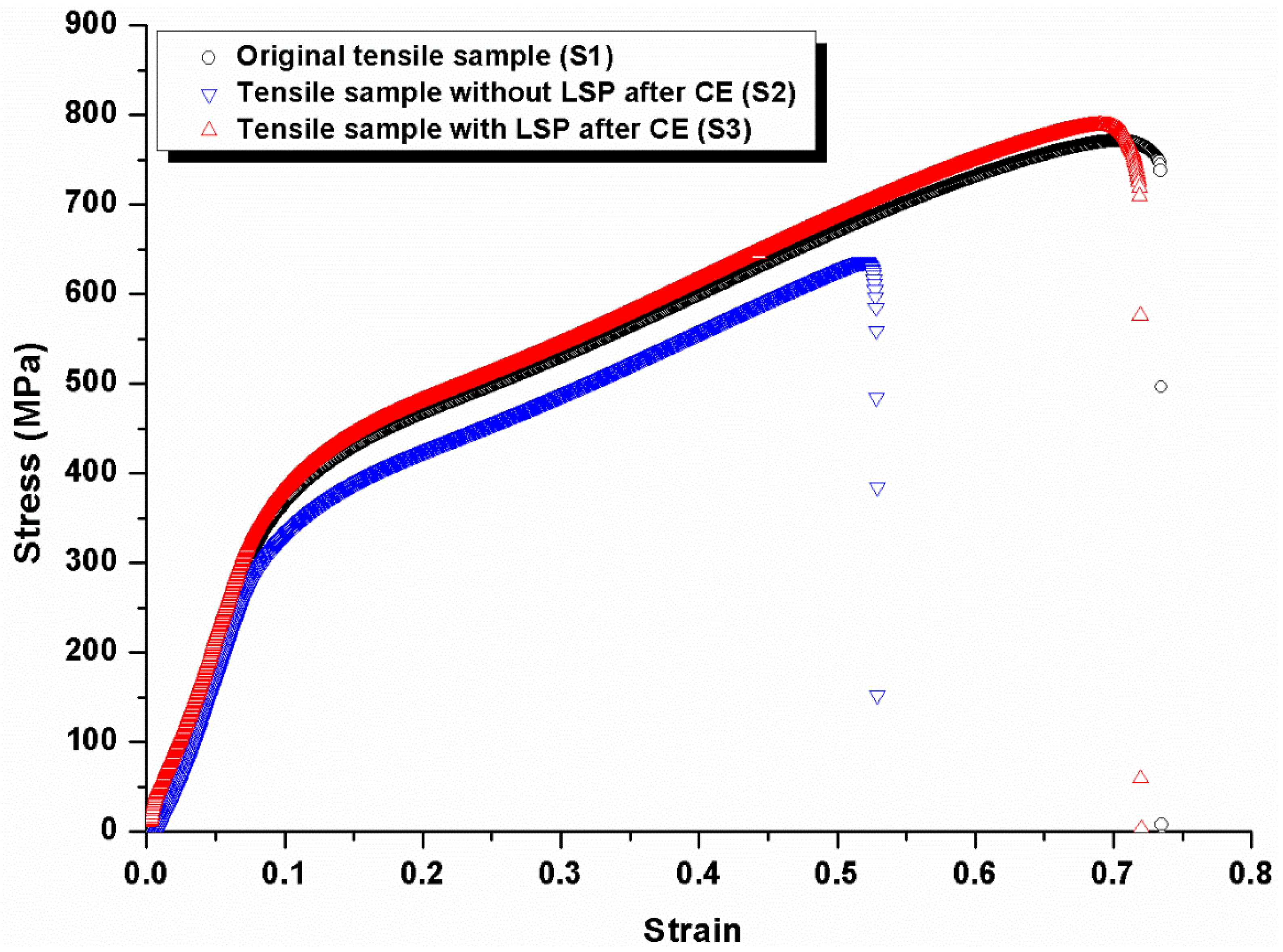

3.2. Analysis of Tensile Property

3.2.1. Elastic Deformation Stage

3.2.2. Plastic Deformation Stage

3.2.3. Fracture Stage

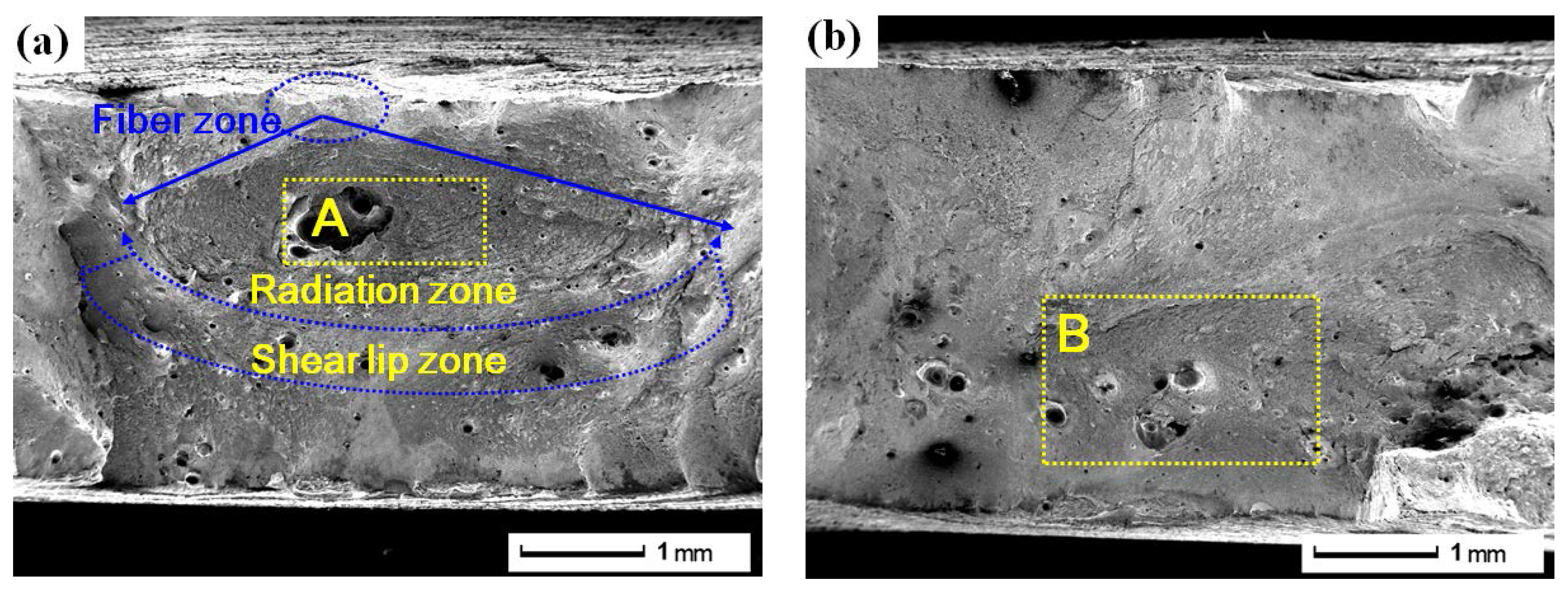

3.3. Analysis of Fracture Morphology

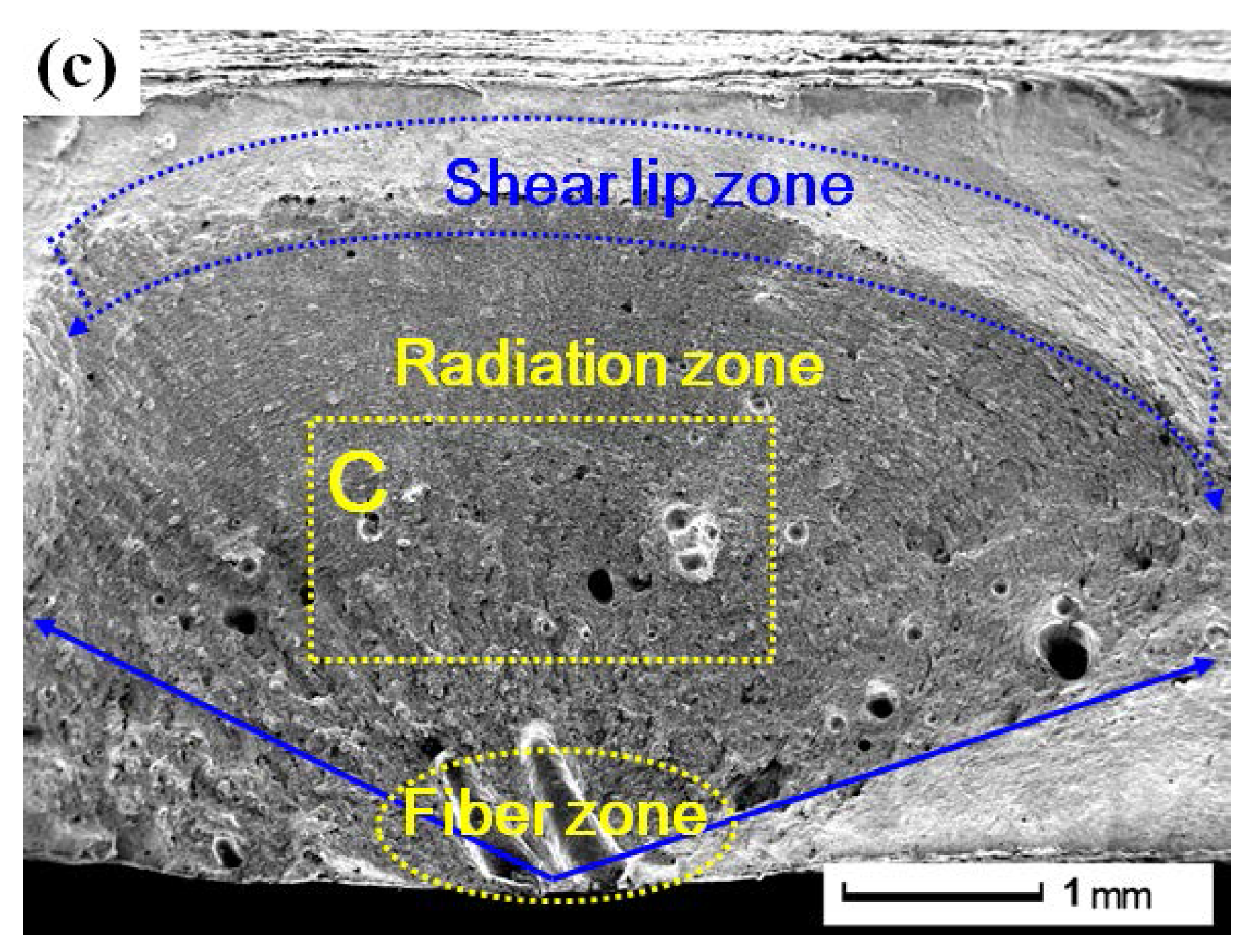

3.3.1. Macroscopic Fracture Morphology

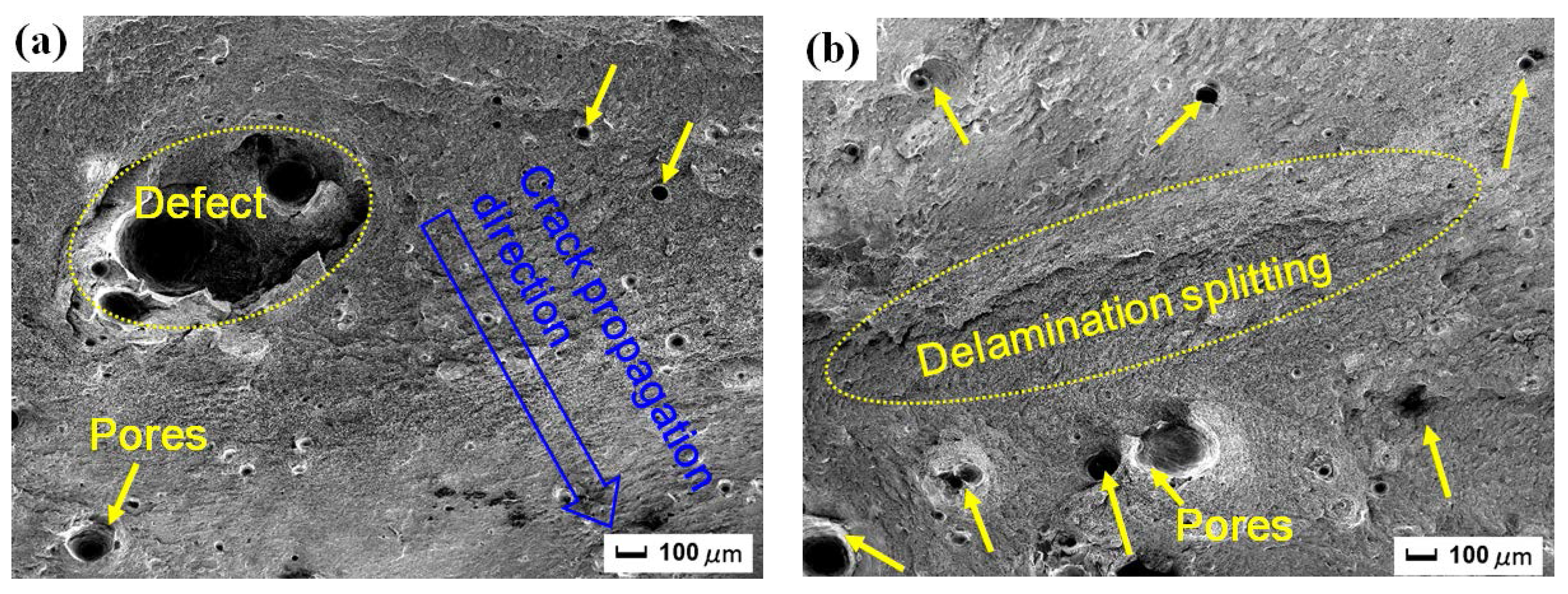

3.3.2. High Magnification SEM Micrographs

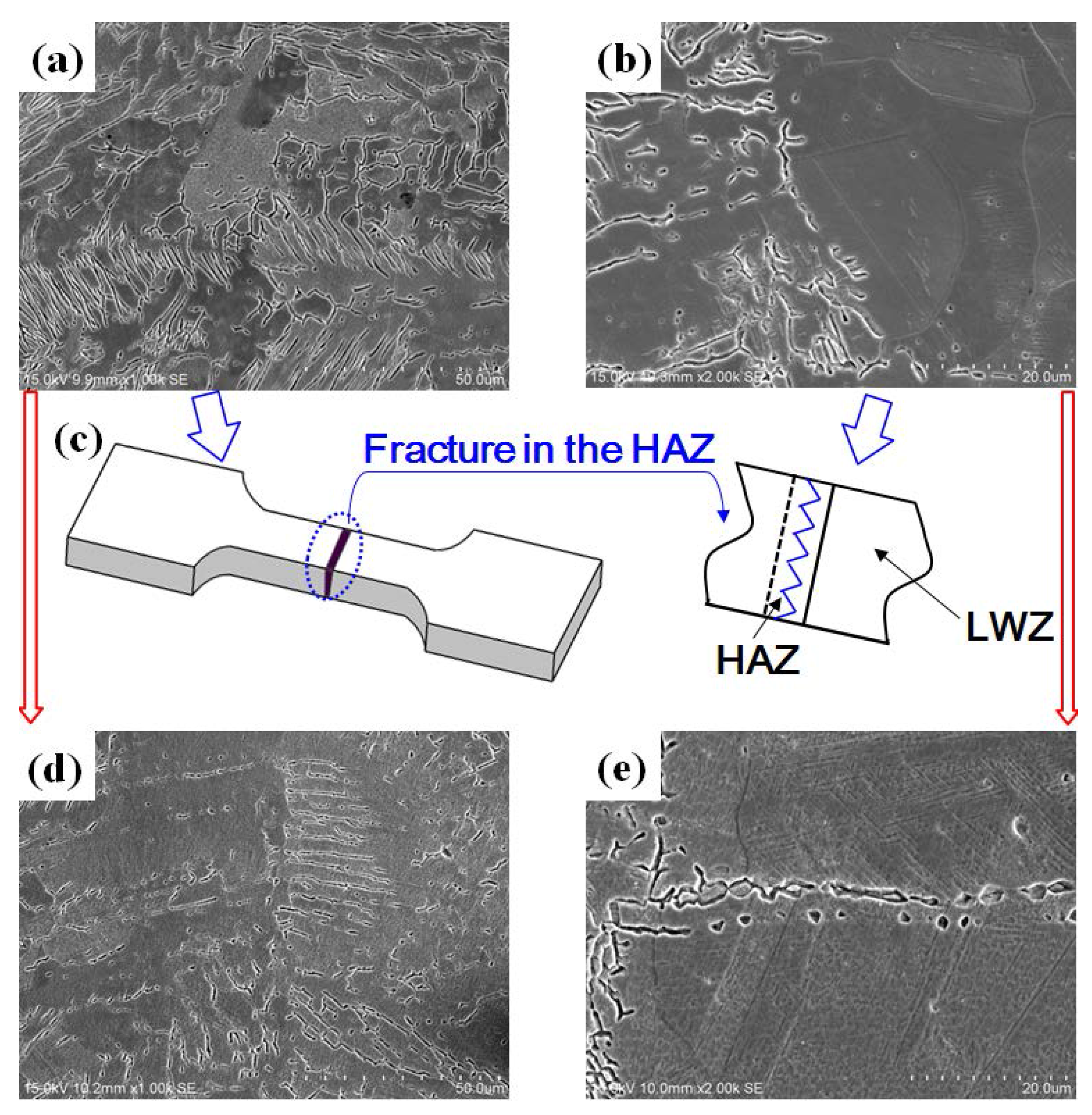

3.3.3. Fracture Morphology in the Fiber Zone

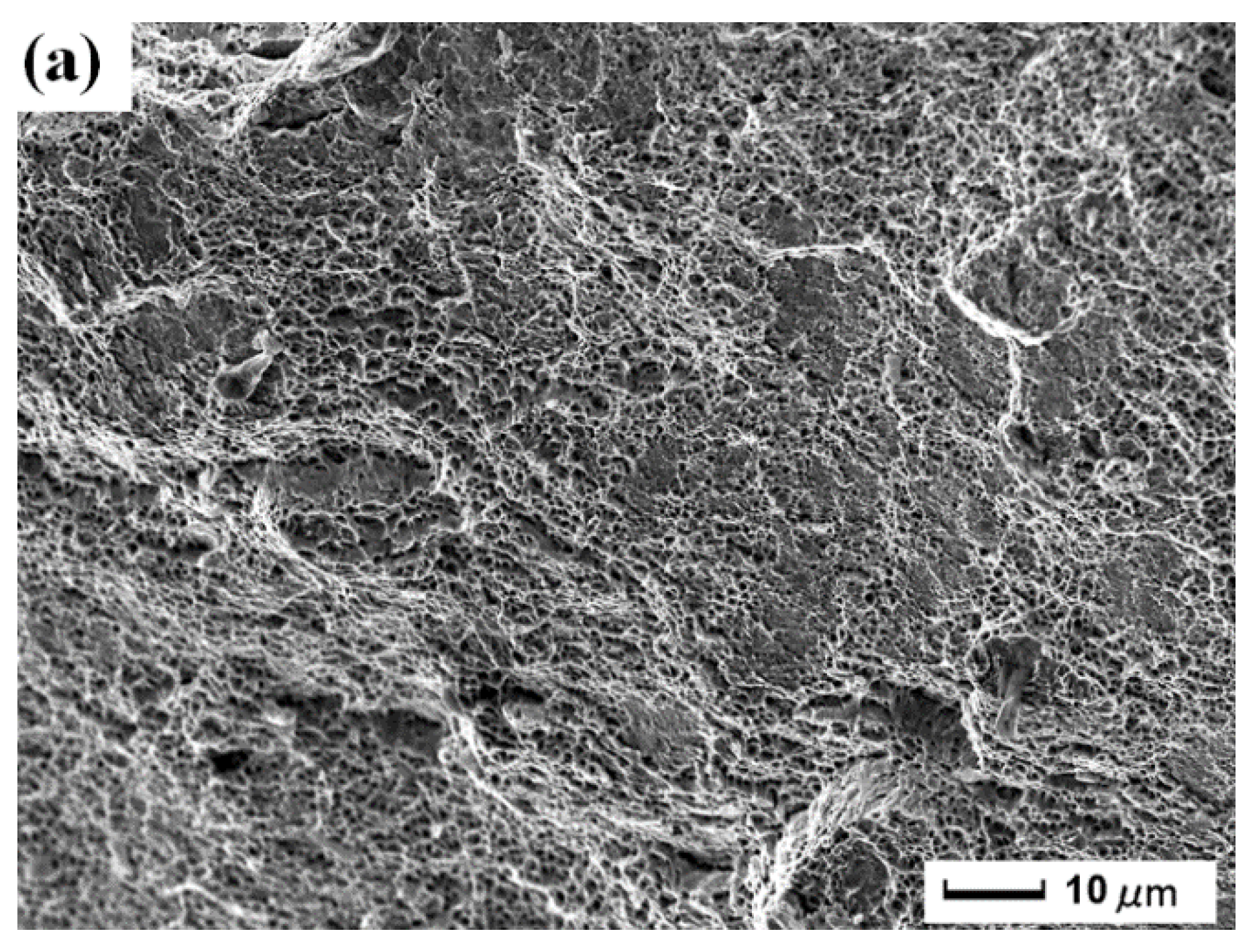

3.3.4. Dimples in the Fracture

3.4. Strengthening Mechanism Analysis during LSP

4. Conclusions

- (1)

- The mass loss of tensile sample without LSP after CE (S2) was thrice as much as that of tensile sample with LSP after CE (S3).

- (2)

- During the elastic deformation stage, the elastic limit of original tensile sample (S1), S2, and S3 was 364.4, 333.3, and 383.8 MPa, respectively. The elastic modulus of S1, S2, and S3 were 3968.9, 3869.8, and 4246.0 MPa, respectively. During the plastic deformation stage, the elongation and area reduction of S3 with LSP were a little smaller than that of S1, but larger than that of S2 without LSP. During the fracture stage, S1, S2, and S3 fractured with the ultimate tensile strength of 771.5, 636.7, and 788.9 MPa, respectively.

- (3)

- The fiber zone, radiation zone, and shear lip zone of S3 were more obvious than that of S1 and S2. The fracture mode of S2 was brittle fracture. The number and size of pores in the fracture surface of S3 were the smallest. The fracture surface of S3 was smoothest and the most uniform. The dimples of S3 were elongated along the unified direction and the elongated direction was in agreement with the crack propagation direction. Their distribution and shape were uniform. The dimples were the deepest and LSP enhanced the plasticity of S3.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sreedhar, B.K.; Albert, S.K.; Pandit, A.B. Cavitation damage: Theory and measurements—A review. Wear 2017, 372, 177–196. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, J.Z.; Zhang, Y.K.; Ma, H.L.; Luo, K.Y.; Dai, F.Z. Effects of laser shock processing on morphologies and mechanical properties of ANSI 304 stainless steel weldments subjected to cavitation erosion. Materials 2017, 10, 292. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhang, Y.K.; Lu, J.Z.; Dai, F.Z.; Feng, A.X.; Luo, K.Y.; Zhong, J.S.; Wang, Q.W.; Luo, M.; Qi, H. Effects of laser shock processing on electrochemical corrosion resistance of ANSI 304 stainless steel weldments after cavitation erosion. Corros. Sci. 2013, 66, 5–13. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, K.Y.; Lu, J.Z.; Zhang, Y.K.; Feng, A.X. Effects of laser shock processing on cavitation erosion resistance of laser weldments. Chin. J. Lasers 2013, 40, 0203001. [Google Scholar] [CrossRef]

- Han, M.X.; Liu, Y.S.; Wu, D.F.; Zhao, X.F.; Tan, H.J. A numerical investigation in characteristics of flow force under cavitation state inside the water hydraulic poppet valves. Int. J. Heat Mass Transf. 2017, 111, 1–16. [Google Scholar] [CrossRef]

- Kang, C.; Mao, N.; Zhang, W.B.; Gu, Y.P. The influence of blade configuration on cavitation performance of a condensate pump. Ann. Nucl. Eng. 2017, 110, 789–797. [Google Scholar] [CrossRef]

- Kwok, C.T.; Man, H.C.; Cheng, F.T.; Lo, K.H. Developments in laser-based surface engineering processes: With particular reference to protection against cavitation erosion. Surf. Coat. Technol. 2016, 291, 189–204. [Google Scholar] [CrossRef]

- Gujba, A.K.; Medraj, M. Laser peening process and its impact on materials properties in comparison with shot peening and ultrasonic impact peening. Materials 2014, 7, 7925–7974. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.H.; Zhou, L.C.; Wang, X.D.; Cao, X.; Nie, X.F.; He, W.F. Surface nanocrystallization and amorphization of dual-phase TC11 titanium alloys under laser induced ultrahigh strain-rate plastic deformation. Materials 2018, 11, 563. [Google Scholar] [CrossRef] [PubMed]

- Li, X.Y.; Yan, Y.G.; Ma, L.; Xu, Z.M.; Li, J.G. Cavitation erosion and corrosion behavior of copper-manganese-aluminum alloy weldment. Mater. Sci. Eng. A 2004, 382, 82–89. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, J.Z.; Luo, K.Y.; Feng, A.X.; Dai, F.Z.; Zhong, J.S.; Luo, M.; Zhang, Y.K. Residual stress, micro-hardness and tensile properties of ANSI 304 stainless steel thick sheet by fiber laser welding. Mater. Sci. Eng. A 2013, 561, 136–144. [Google Scholar] [CrossRef]

- Chandrasekar, G.; Kailasanathan, C.; Verma, D.K. Investigation on un-peened and laser shock peened weldment of Inconel 600 fabricated by ATIG welding process. Mater. Sci. Eng. A 2017, 690, 405–417. [Google Scholar] [CrossRef]

- Lu, G.X.; Liu, J.D.; Qiao, H.C.; Zhou, Y.Z.; Jin, T.; Zhao, J.B.; Sun, X.F.; Hu, Z.Q. Effect of laser shock on tensile deformation behavior of a single crystal nickel-base superalloy. Mater. Sci. Eng. A 2017, 686, 46–53. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, K.Y.; Lu, J.Z.; Zhang, Y.K.; Dai, F.Z.; Zhong, J.W. Effects of laser shock processing with different shocked paths on mechanical properties of laser welded ANSI 304 stainless steel joint. Mater. Sci. Eng. A 2011, 528, 4652–4657. [Google Scholar] [CrossRef]

- Chen, W.G.; Gu, C.Q.; Shen, F.S. Correlation of cavitation erosion resistance with mechanical properties of steels. J. Hydroelectr. Eng. 1998, 2, 79–88. [Google Scholar]

- Xiong, J.Z.; Yang, X.Q.; Lin, W.; Liu, K.X. Evaluation of inhomogeneity in tensile strength and fracture toughness of underwater wet friction taper plug welded joints for low-alloy pipeline steels. J. Manuf. Processes 2018, 32, 280–287. [Google Scholar] [CrossRef]

- Standard Test Method for Cavitation Erosion Using Vibratory Apparatus; G32−09; ASTM: West Conshohocken, PA, USA, 2009.

- Zhang, Y.K.; Zhang, L.; Luo, K.Y.; Sun, G.F.; Lu, J.Z.; Dai, F.Z.; Zhong, J.W. Effects of laser shock processing on mechanical properties of laser welded ANSI 304 stainless steel joint. Chin. J. Mech. Eng. 2012, 25, 285–292. [Google Scholar] [CrossRef]

- Xiong, Y.; He, T.T.; Guo, Z.Q.; He, H.Y.; Ren, F.Z.; Volinsky, A.A. Effects of laser shock processing on surface microstructure and mechanical properties of ultrafine-grained high carbon steel. Mater. Sci. Eng. A 2013, 570, 82–86. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, L.J.; Sun, G.F.; Luo, K.Y.; Zhang, Y.K.; Cai, J.; Cui, C.Y.; Luo, X.M. Microstructural response and grain refinement mechanism of commercially pure titanium subjected to multiple laser shock peening impacts. Acta Mater. 2017, 127, 252–266. [Google Scholar] [CrossRef]

- Chen, L.F.; Xiong, Y.; Li, H.P.; Lu, Y.; Ren, F.Z. Microstructure evolution and mechanical properties of 316LN austenitic stainless steel after tensile deformation at different temperatures. Trans. Mater. Heat Treat. 2016, 37, 131–137. [Google Scholar]

- Moćko, W.; Radziejewska, J.; Sarzyński, A.; Strzelec, M.; Marczak, J. Analysis of the plastic deformation of AISI 304 steel induced by the nanosecond laser pulse. Opt. Laser Technol. 2017, 90, 165–173. [Google Scholar] [CrossRef]

- Agrawal, A.K.; Singh, A. Limitations on the hardness increase in 316L stainless steel under dynamic plastic deformation. Mater. Sci. Eng. A 2017, 687, 306–312. [Google Scholar] [CrossRef]

- Paredes, M.; Wierzbicki, T.; Zelenak, P. Prediction of crack initiation and propagation in X70 pipeline steels. Eng. Fract. Mech. 2016, 168, 92–111. [Google Scholar] [CrossRef]

- Lu, J.Z.; Zhang, W.Q.; Jing, X.; Wu, L.J.; Luo, K.Y. Microstructural evolution in the welding zone of laser shock peened 316L stainless steel tube. J. Laser Appl. 2017, 29, 012007. [Google Scholar] [CrossRef]

- Lu, J.Z.; Deng, W.W.; Luo, K.Y.; Wu, L.J.; Lu, H.F. Surface EBSD analysis and strengthening mechanism of AISI304 stainless steel subjected to massive LSP treatment with different pulse energies. Mater. Charact. 2017, 125, 99–107. [Google Scholar] [CrossRef]

| Output Power (W) | Frequency (kHz) | Diameter of Vibrating Horn (mm) | Pulsed Mode | Total Testing Time (h) | Temperature (°C) | ||

|---|---|---|---|---|---|---|---|

| On-Time (s) | Off-Time (s) | ||||||

| 840 | 20 | 20 | 1.5 | 3 | 6 | 20 | |

| Group | Sample | Without LSP Impacts (S2) | With LSP Impacts (S3) |

|---|---|---|---|

| Mass before CE (g) | First sample | 51.633 | 51.631 |

| Second sample | 51.628 | 51.622 | |

| Third sample | 51.636 | 51.630 | |

| Mean values | 51.63 | 51.63 | |

| Mass after CE (g) | First sample | 51.598 | 51.624 |

| Second sample | 51.603 | 51.614 | |

| Third sample | 51.611 | 51.625 | |

| Mean values | 51.60 | 51.62 | |

| Mass loss (g) | First sample | 0.035 | 0.007 |

| Second sample | 0.025 | 0.008 | |

| Third sample | 0.025 | 0.005 | |

| Mean values | 0.03 | 0.01 |

| Tensile Property | Sample | Original Tensile Sample (S1) | Tensile Sample without LSP after CE (S2) | Tensile Sample with LSP after CE (S3) |

|---|---|---|---|---|

| Elongation | First sample | 0.708 | 0.523 | 0.689 |

| Second sample | 0.702 | 0.522 | 0.691 | |

| Third sample | 0.690 | 0.529 | 0.699 | |

| Mean values | 0.70 | 0.52 | 0.69 | |

| Area reduction | First sample | 0.411 | 0.282 | 0.340 |

| Second sample | 0.412 | 0.281 | 0.342 | |

| Third sample | 0.416 | 0.288 | 0.343 | |

| Mean values | 0.41 | 0.28 | 0.34 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Liu, Y.-H.; Luo, K.-Y.; Zhang, Y.-K.; Zhao, Y.; Huang, J.-Y.; Wu, X.-D.; Zhou, C. Tensile Property of ANSI 304 Stainless Steel Weldments Subjected to Cavitation Erosion Based on Treatment of Laser Shock Processing. Materials 2018, 11, 805. https://doi.org/10.3390/ma11050805

Zhang L, Liu Y-H, Luo K-Y, Zhang Y-K, Zhao Y, Huang J-Y, Wu X-D, Zhou C. Tensile Property of ANSI 304 Stainless Steel Weldments Subjected to Cavitation Erosion Based on Treatment of Laser Shock Processing. Materials. 2018; 11(5):805. https://doi.org/10.3390/ma11050805

Chicago/Turabian StyleZhang, Lei, Yue-Hua Liu, Kai-Yu Luo, Yong-Kang Zhang, Yong Zhao, Jian-Yun Huang, Xu-Dong Wu, and Chuang Zhou. 2018. "Tensile Property of ANSI 304 Stainless Steel Weldments Subjected to Cavitation Erosion Based on Treatment of Laser Shock Processing" Materials 11, no. 5: 805. https://doi.org/10.3390/ma11050805