Enhancement of the Adhesive Strength between Ag Films and Mo Substrate by Ag Implanted via Ion Beam-Assisted Deposition

Abstract

:1. Introduction

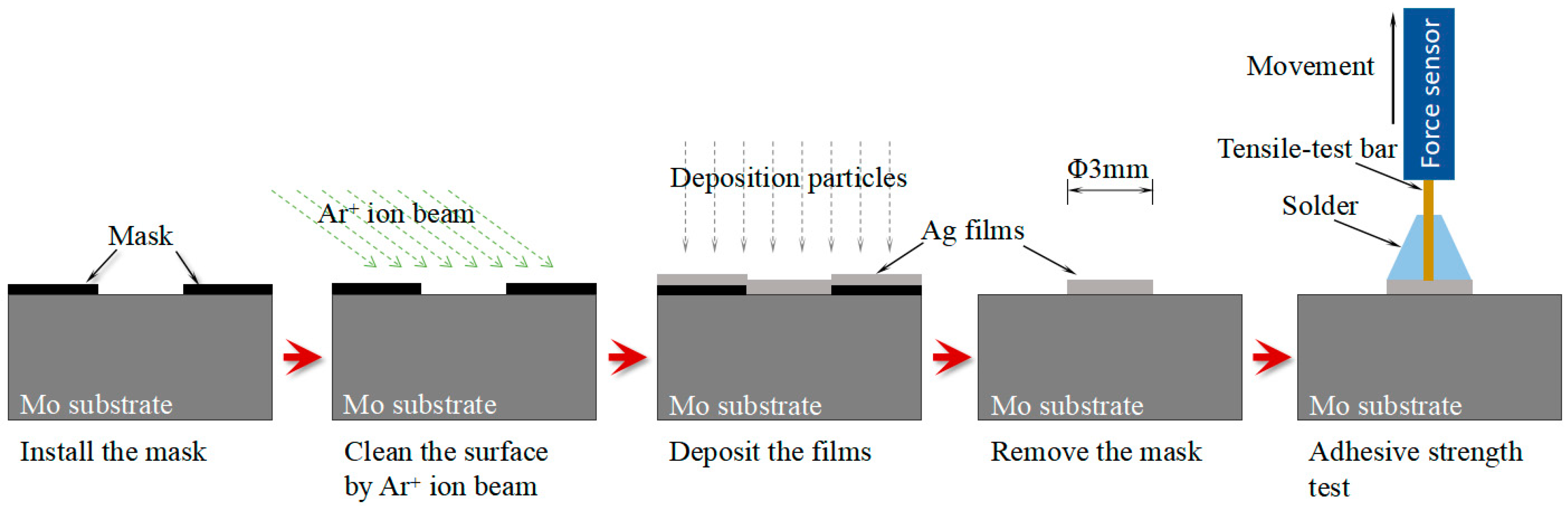

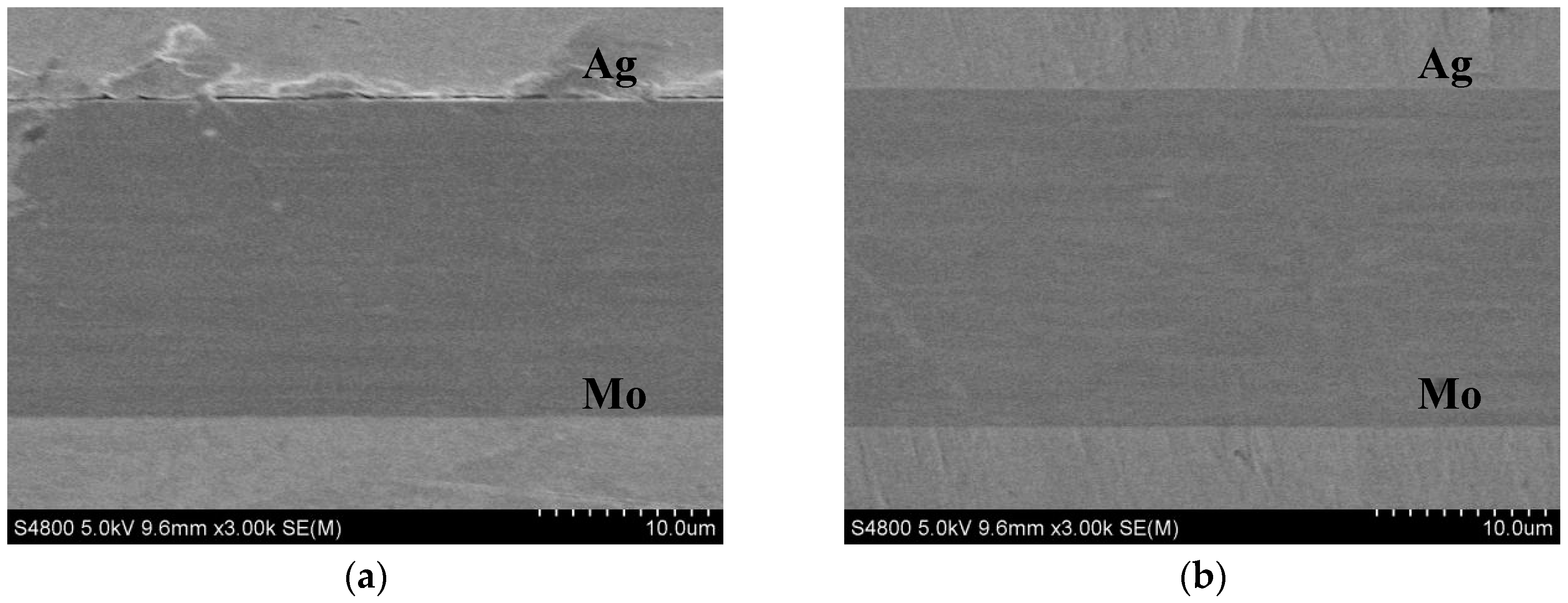

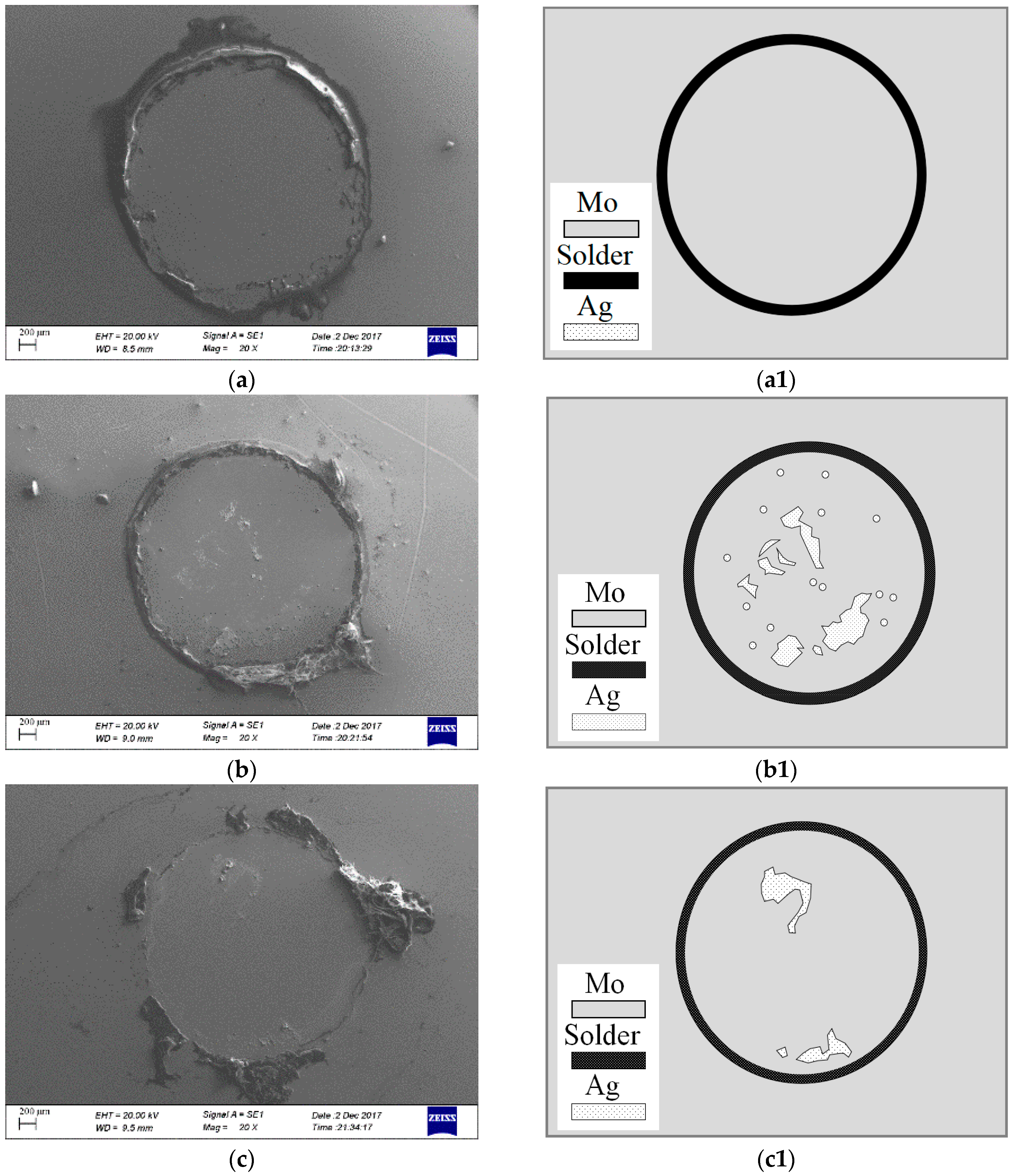

2. Materials and Methods

2.1. Sample Preparation

2.2. Evaluation

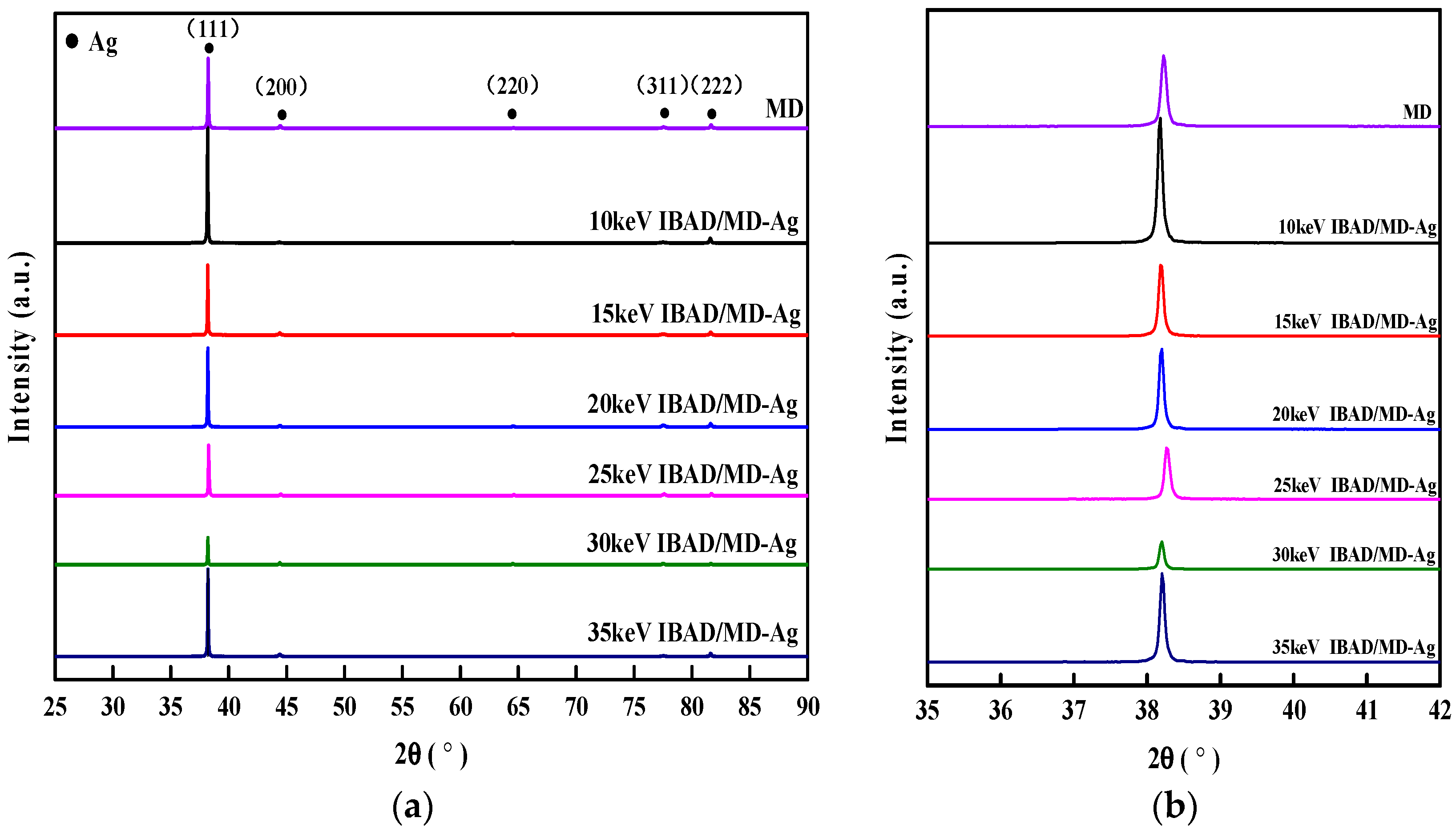

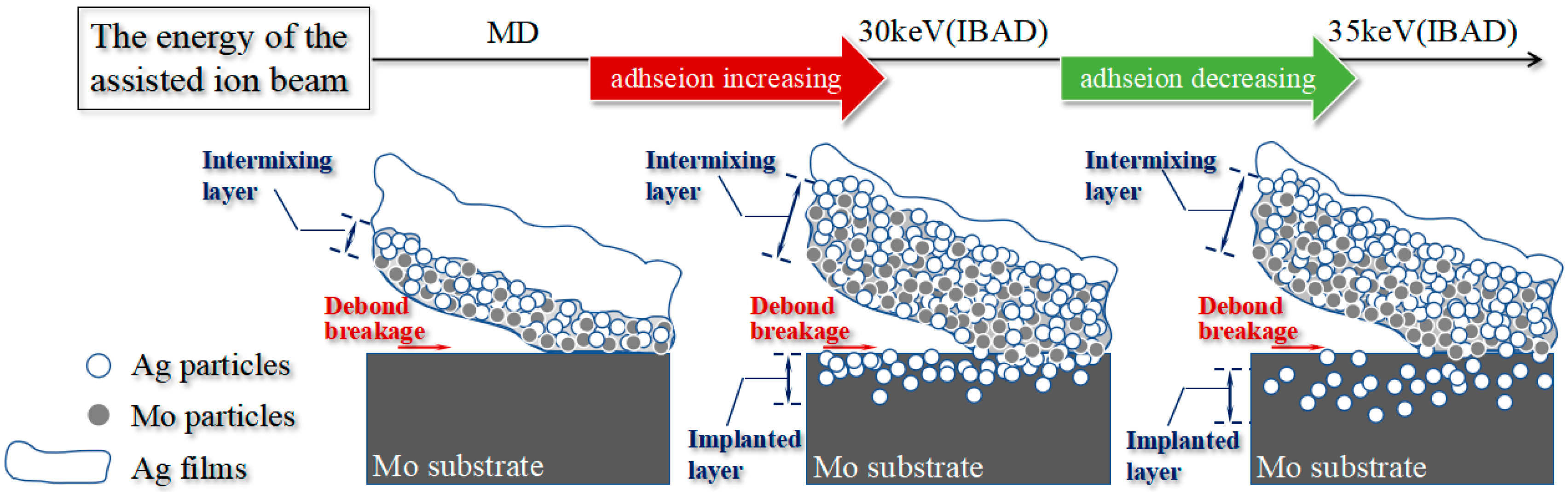

3. Results and Discussion

4. Conclusions

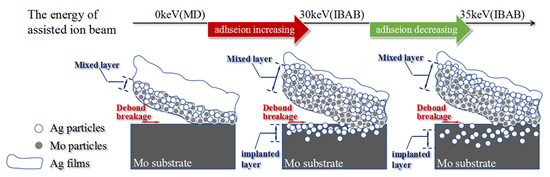

- Because of its implanted and atom-intermixed effect, IBAD process enhances the adhesive strength between Ag films and Mo substrate effectively.

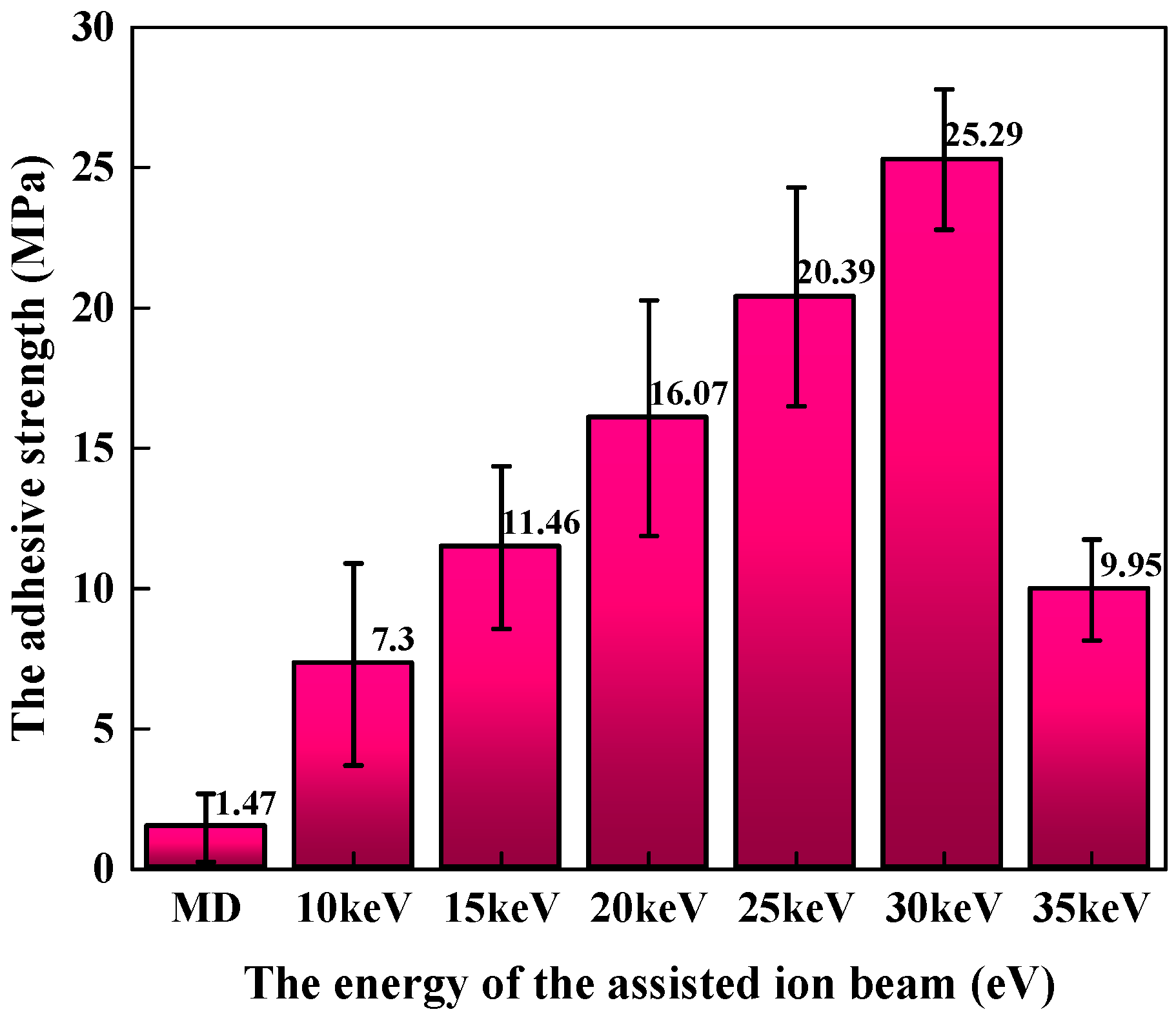

- With the increasing of energy of the assisted ion beam, the adhesive strength first increased and then decreased due to the concentration change of the Ag particles in the implanted surface layer.

- The maximum value of the adhesive strength of Ag films on Mo substrate reaches 25.29 MPa.

Author Contributions

Funding

Conflicts of Interest

References

- Interconnect and Bonding Technologies for Large Flexible Solar Arrays. Lockheed Missiles & Space Co Report. 1976. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19760025565.pdf (accessed on 24 March 2014).

- Bischof, F.V. Space Station Solar Array Technology Evaluation Program Final Report; Lockheed Missiles & Space Co.: Sunnyvale, CA, USA, 1973. [Google Scholar]

- Svelto, F.; Flores, C.; Paletta, F.; Passoni, D.; Signorini, C.; Rossi, E. Review of the GaAs solar cell Italian national programme. Acta Astronaut. 1990, 21, 421–427. [Google Scholar] [CrossRef]

- Reddy, M.R. Effect of low earth orbit atomic oxygen on spacecraft materials. J. Mater. Sci. 1995, 30, 281–307. [Google Scholar] [CrossRef]

- Hu, M.; Gao, X.M.; Sun, J.Y.; Weng, L.J.; Zhou, F.; Liu, W.M. The effects of nanoscaled amorphous Si and SiNx protective layers on the atomic oxygen resistant and tribological properties of Ag film. Appl. Surf. Sci. 2012, 258, 5683–5688. [Google Scholar] [CrossRef]

- Flores, C.; Campesato, R.; Paletta, F.; Timb, G.L.; Svelt, F. Post-flight investigation of the ASGA solar cell experiment on EURECA. In Proceedings of the 1994 IEEE First World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, 5–9 December1994; pp. 2076–2081. [Google Scholar]

- Harris, I.L.; Chambers, A.R.; Roberts, G.T. Preliminary results of an atomic oxygen spaceflight experiment. Mater. Lett. 1997, 31, 321–328. [Google Scholar] [CrossRef]

- Huang, Y.; Kong, D.Y.; He, F.; Wang, Y.L.; Liu, W.X. Preparation of Mo/Ag laminar composites by using irradiation damage alloying method. Acta Metall. Sin. 2012, 48, 1253–1259. [Google Scholar] [CrossRef]

- Luft, W. Solar cell interconnector design. IEEE Trans. Aerosp. Electron. Syst. 1971, AES-7, 781–791. [Google Scholar] [CrossRef]

- Zhang, P.J.; Xu, G.Q.; Liu, J.Q.; Yi, X.F.; Wu, Y.C.; Chen, J.W. Effect of pretreating technologies on the adhesive strength and anticorrosion property of Zn coated NdFeB specimens. Appl. Surf. Sci. 2015, 363, 499–506. [Google Scholar] [CrossRef]

- Sun, S.Y.; Yang, R.; Han, J.; Guo, H.F.; Xing, L.B. Effect of nickel particles on the interfacial adhesive strength between a Ni-P composite coating and a polymeric composite substrate. Surf. Coat. Technol. 2016, 297, 19–26. [Google Scholar] [CrossRef]

- Wang, Y.H.; Liu, J.; Wu, X.; Yang, B. Adhesion enhancement of indium tin oxide (ITO) coated quartz optical fibers. Appl. Surf. Sci. 2014, 308, 341–346. [Google Scholar] [CrossRef]

- Sharifi, S.; Attar, M.M.; Ramezanzadeh, B. Effects of surface treatment of aluminium alloy 1050 on the adhesion and anticorrosion properties of the epoxy coating. Appl. Surf. Sci. 2015, 345, 360–368. [Google Scholar] [CrossRef]

- Coulon, J.F.; Tournerie, N.; Maillard, H. Adhesion enhancement of Al coatings on carbon/epoxy composite surfaces by atmospheric plasma. Appl. Surf. Sci. 2013, 283, 843–850. [Google Scholar] [CrossRef]

- Martin, L.J.; Wong, C.P. Chemical and mechanical adhesion mechanisms of sputter-deposited metal on epoxy dielectric for high density interconnect printed circuit boards. IEEE Trans. Compon. Packag. Technol. 2001, 24, 416–424. [Google Scholar] [CrossRef]

- Karakoca, S.; Yılmaz, H. Influence of surface treatments on surface roughness, phase transformation, and biaxial flexural strength of Y-TZP ceramics. J. Biomed. Mater. Res. Part B Appl. Biomater. 2009, 91, 930–937. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, L.; Fu, Q.G. Bonding strength, thermal shock and oxidation resistance of interlocking (Zr,Hf)C-SiC/SiC double-layer coating for C/C composites. Surf. Coat. Technol. 2017, 315, 436–442. [Google Scholar] [CrossRef]

- Ding, X.F.; Wu, Y.J.; Yang, L.J.; Xu, C.; Mao, S.D.; Wang, Y.P.; Zheng, D.; Song, Z.L. The properties of chromium oxide coatings on NdFeB magnets by magnetron sputtering with ion beam assisted deposition. Vacuum 2016, 131, 127–134. [Google Scholar] [CrossRef]

- Kakas, D.; Terek, P.; Kovacevic, L.; Miletic, A.; Skoric, B. Influence of interfacial layer thickness and substrate roughness on adhesion of TiN coatings deposited at low temperature by IBAD. Surf. Rev. Lett. 2011, 18, 83–90. [Google Scholar] [CrossRef]

- Funada, Y.; Awazu, K.; Yasui, H.; Sugita, T. Adhesion strength of DLC films on glass with mixing layer prepared by IBAD. Surf. Coat. Technol. 2000, 128, 308–312. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ho, H.P.; Lee, S.T. Development of single- and multi-layered metallic films on diamond by ion beam-assisted deposition. Diam. Relat. Mater. 2001, 10, 1578–1583. [Google Scholar] [CrossRef]

- Choi, J.M.; Kim, H.E.; Lee, I.S. Ion-beam-assisted deposition (IBAD) of hydroxyapatite coating layer on Ti-based metal substrate. Biomaterials 2000, 21, 469–473. [Google Scholar] [CrossRef]

- Rauschenbach, B.; Lotnyk, A.; Neumann, L.; Poppitz, D.; Gerlach, J.W. Ion beam assisted deposition of thin epitaxial GaN films. Materials 2017, 10, 690. [Google Scholar] [CrossRef] [PubMed]

- Cotell, C.M.; Hirvonen, J.K. Effect of ion energy on the mechanical properties of ion beam assisted deposition (IBAD) wear resistant coatings. Surf. Coat. Technol. 1996, 81, 118–125. [Google Scholar] [CrossRef]

- Smidt, F.A. Use of ion beam assisted deposition to modify the microstructure and properties of thin films. Metall. Rev. 1990, 35, 61–128. [Google Scholar] [CrossRef]

- Yan, Z.; Ma, Y.P.; Deng, P.R.; Yu, Z.S.; Liu, C.; Song, Z.T. Ag–N doped ZnO film and its p–n junction fabricated by ion beam assisted deposition. Appl. Surf. Sci. 2010, 256, 2289–2292. [Google Scholar] [CrossRef]

- Tian, L.H.; Tang, B.; Liu, D.X.; Zhu, X.D.; He, J.W. Interfacial reactions during IBAD and their effects on the adhesion of Cr-N coatings on steel. Surf. Coat. Technol. 2005, 191, 149–154. [Google Scholar] [CrossRef]

- Manova, D.; Gerlach, J.W.; Mänd, S. Thin Film Deposition Using Energetic Ions. Materials 2010, 3, 4109–4141. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.J.; Xu, M.; Yang, W.L.; Li, D.Y.; Zhou, L.P.; Fu, L.C. Friction and wear behavior of an Ag–Mo Co-implanted GH4169 alloy via ion-beam-assisted bombardment. Coatings 2017, 7, 191. [Google Scholar] [CrossRef]

- Kim, E.H.; Yang, C.W.; Park, J.W. Improving the delamination resistance of indiumtin oxide (ITO) coatings on polymeric substrates by O2 plasma surface treatment. Curr. Appl. Phys. 2010, 10, S510–S514. [Google Scholar] [CrossRef]

- Chen, D.X.; Zhang, Y.; Bessho, T.; Kudo, T.; Sang, J.; Hirahara, H.; Mori, K.; Kang, Z.X. Ag films with enhanced adhesion fabricated by solution process for solar reflector applications. Sol. Energy Mater. Sol. Cells 2016, 151, 154–161. [Google Scholar] [CrossRef]

- Wei, Q.F.; Wang, H.F.; Deng, B.Y.; Xu, Y. Surface and interface investigation of indium-tin-oxide (ITO) coated nonwoven fabrics. J. Adhes. Sci. Technol. 2010, 24, 135–147. [Google Scholar] [CrossRef]

- Zhu, J.J.; Hu, Y.H.; Xu, M.; Yang, W.L.; Fu, L.C.; Li, D.Y.; Zhou, L.P. Study on silver-plated molybdenum interconnected materials for LEO solar cell array. IOP Conf. Series: Mater. Sci. Eng. 2017, 229, 012010. [Google Scholar] [CrossRef]

- Ellis, E.A.; Chmielus, M.; Lin, M.T.; Joress, H.; Visser, K.; Woll, A.; Vinci, R.P.; Brown, W.L.; Baker, S.P. Driving forces for texture transformation in thin Ag films. Acta Mater. 2016, 105, 495–504. [Google Scholar] [CrossRef]

- Ukahapunyakul, P.; Gridsadanurak, N.; Sapcharoenkun, C.; Treetong, A.; Kasamechonchung, P.; Khemthong, P.; Horprathum, M.; Porntheeraphat, S.; Wongwiriyapan, W.; Nukeaw, J.; et al. Texture orientation of silver thin films grown via gas-timing radio frequency magnetron sputtering and their SERS activity. RSC Adv. 2016, 6, 7661–7667. [Google Scholar] [CrossRef]

- Dong, L.; Srolovitz, D.J. Mechanism of texture development in ion beam assisted deposition. Appl. Phys. Lett. 1999, 75, 584–586. [Google Scholar] [CrossRef]

- Matias, V.; Hammond, R.H. Ion beam induced crystalline texturing during thin film deposition. Surf. Coat. Technol. 2015, 264, 1–8. [Google Scholar] [CrossRef]

- Feng, T.; Jiang, B.Y.; Zhuo, S.; Wang, X.; Liu, X.H. Study on the orientation of silver films by ion beam assisted deposition. Appl. Surf. Sci. 2008, 254, 1565–1568. [Google Scholar] [CrossRef]

- Ma, H.; Zou, Y.; Sologubenko, A.S.; Spolenak, R. Copper thin films by ion beam assisted deposition: Strong texture, superior thermal stability and enhanced hardness. Acta Mater. 2015, 98, 17–28. [Google Scholar] [CrossRef]

- Tsuji, H.; Sakai, N.; Sugahara, H.; Gotoh, Y.; Ishikawa, J. Silver negative-ion implantation to sol-gel TiO2 film for improving photocatalytic property under fluorescent light. Nucl. Instrum. Methods Phys. Res. B 2005, 237, 433–437. [Google Scholar] [CrossRef]

- Tian, X.B.; Peng, P.; Chu, P.K. Numerical simulation of plasma implanted nitrogen depth profiles in iron. Nucl. Instrum. Methods Phys. Res. B 2003, 206, 673–676. [Google Scholar] [CrossRef]

- Yang, J.X.; Cui, F.Z.; Lee, I.S.; Wang, X.M. Plasma surface modification of magnesium alloy for biomedical application. Surf. Coat. Technol. 2010, 205, S182–S187. [Google Scholar] [CrossRef]

- Ran, J.; Zhang, J.Z.; Yao, W.Q.; Wei, Y.T. Properties of Cu film and Ti/Cu film on polyimide prepared by ion beam techniques. Appl. Surf. Sci. 2010, 256, 7010–7017. [Google Scholar] [CrossRef]

- Xu, M.; Zhu, J.J.; Yang, W.L.; Li, D.Y.; Zhou, L.P.; Fu, L.C. Wear behavior of Ag implantation GH4169 alloy by ion beam assisted bombardment. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 2018. [Google Scholar] [CrossRef]

| Element | Al | Ca | Fe | Mg | Ni | Si | C | N | O | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| Content | 0.002 | 0.002 | 0.01 | 0.002 | 0.005 | 0.01 | 0.01 | 0.003 | 0.008 | Bal. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Hu, Y.; Xu, M.; Yang, W.; Fu, L.; Li, D.; Zhou, L. Enhancement of the Adhesive Strength between Ag Films and Mo Substrate by Ag Implanted via Ion Beam-Assisted Deposition. Materials 2018, 11, 762. https://doi.org/10.3390/ma11050762

Zhu J, Hu Y, Xu M, Yang W, Fu L, Li D, Zhou L. Enhancement of the Adhesive Strength between Ag Films and Mo Substrate by Ag Implanted via Ion Beam-Assisted Deposition. Materials. 2018; 11(5):762. https://doi.org/10.3390/ma11050762

Chicago/Turabian StyleZhu, Jiajun, Yuhao Hu, Meng Xu, Wulin Yang, Licai Fu, Deyi Li, and Lingping Zhou. 2018. "Enhancement of the Adhesive Strength between Ag Films and Mo Substrate by Ag Implanted via Ion Beam-Assisted Deposition" Materials 11, no. 5: 762. https://doi.org/10.3390/ma11050762