Grain Refinement and Aging Hardening of the Mg-10Gd-3Y-2Ag-0.4Zr Alloy Produced by a Two-Step Forming Process

Abstract

:1. Introduction

2. Experimental Producer

3. Results and Discussion

4. Conclusions

- (1)

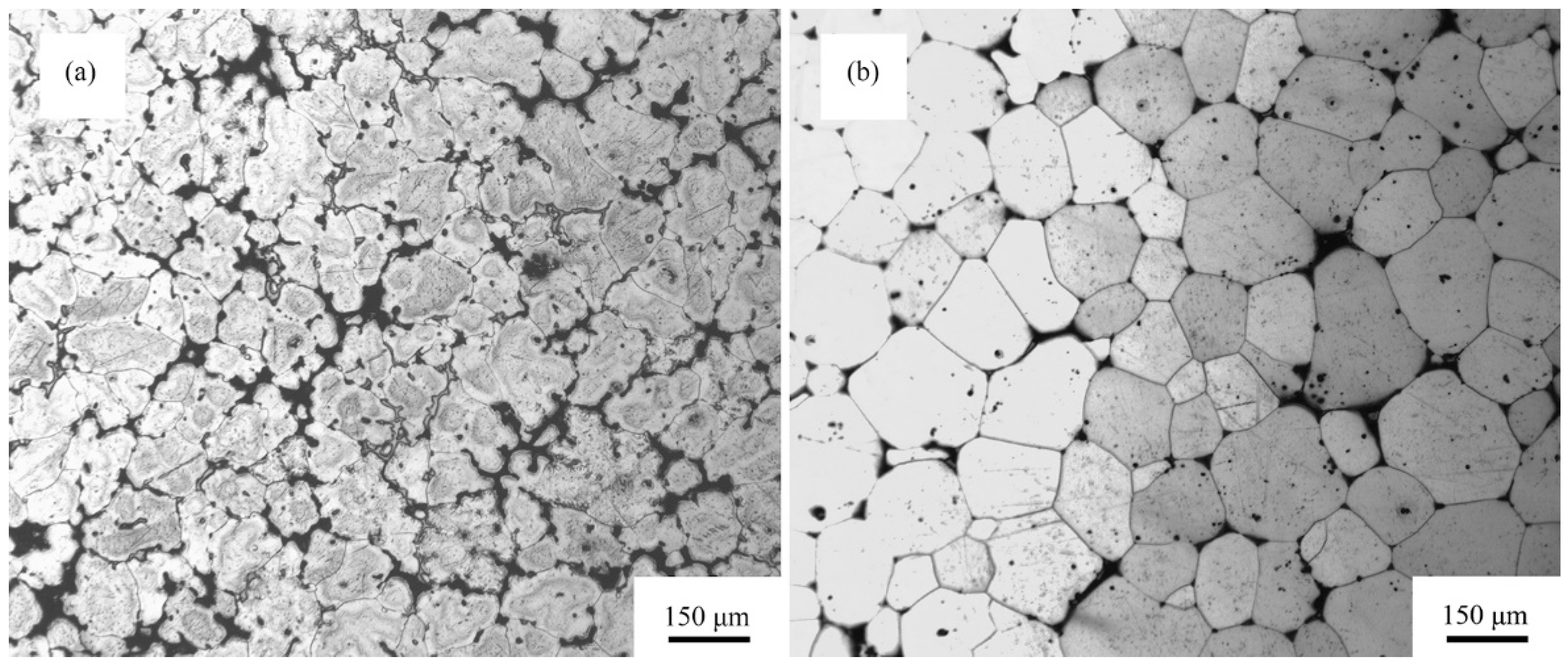

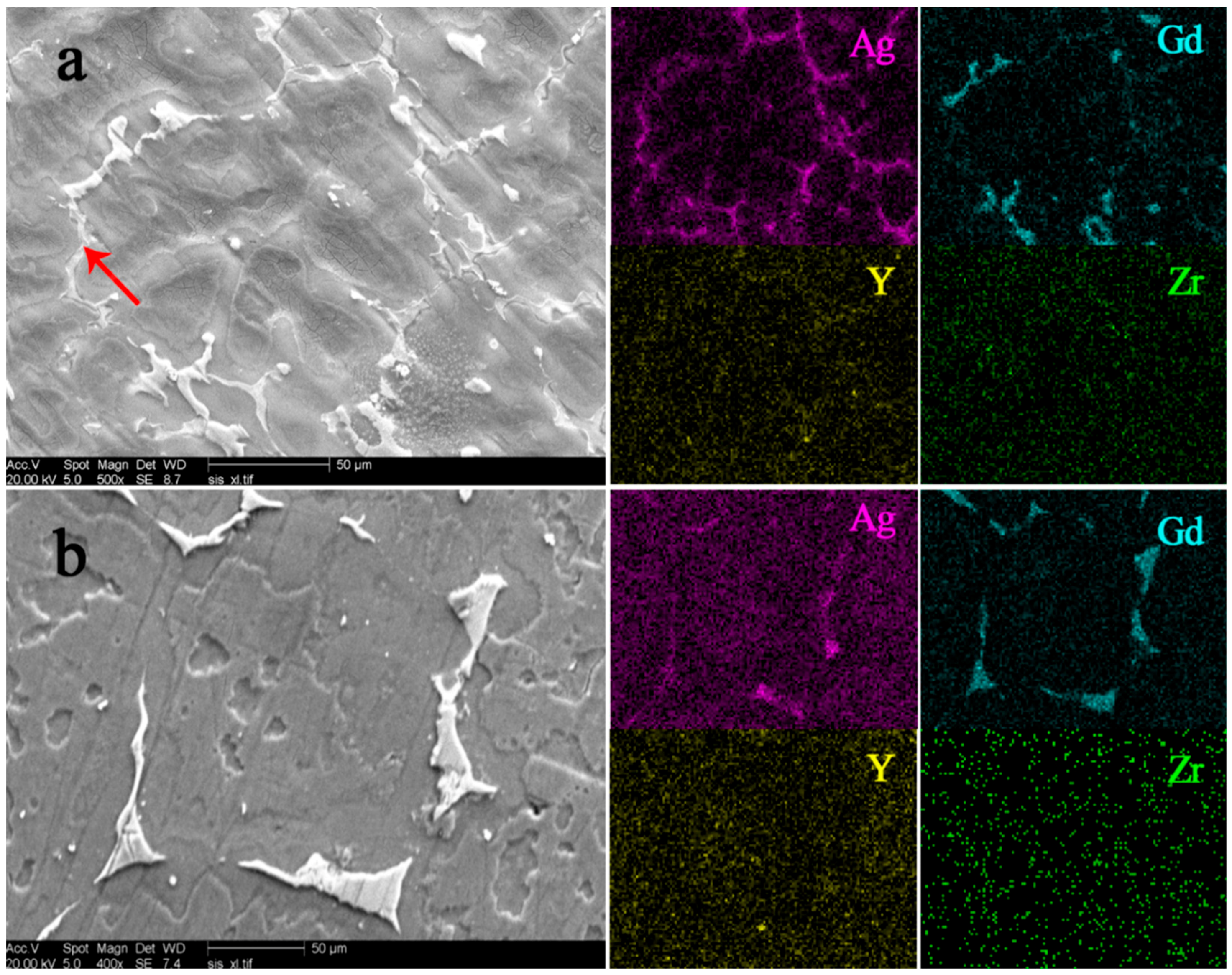

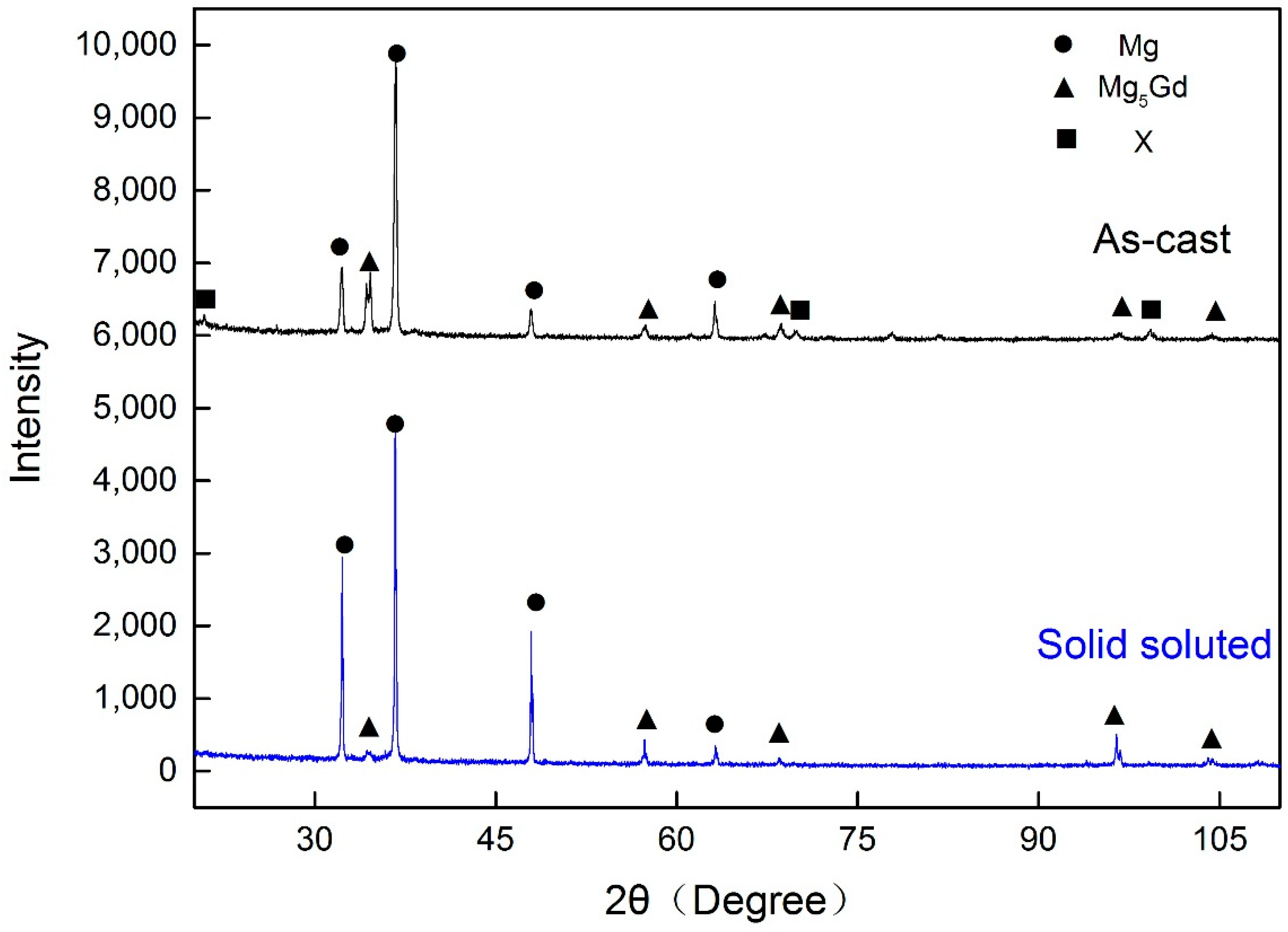

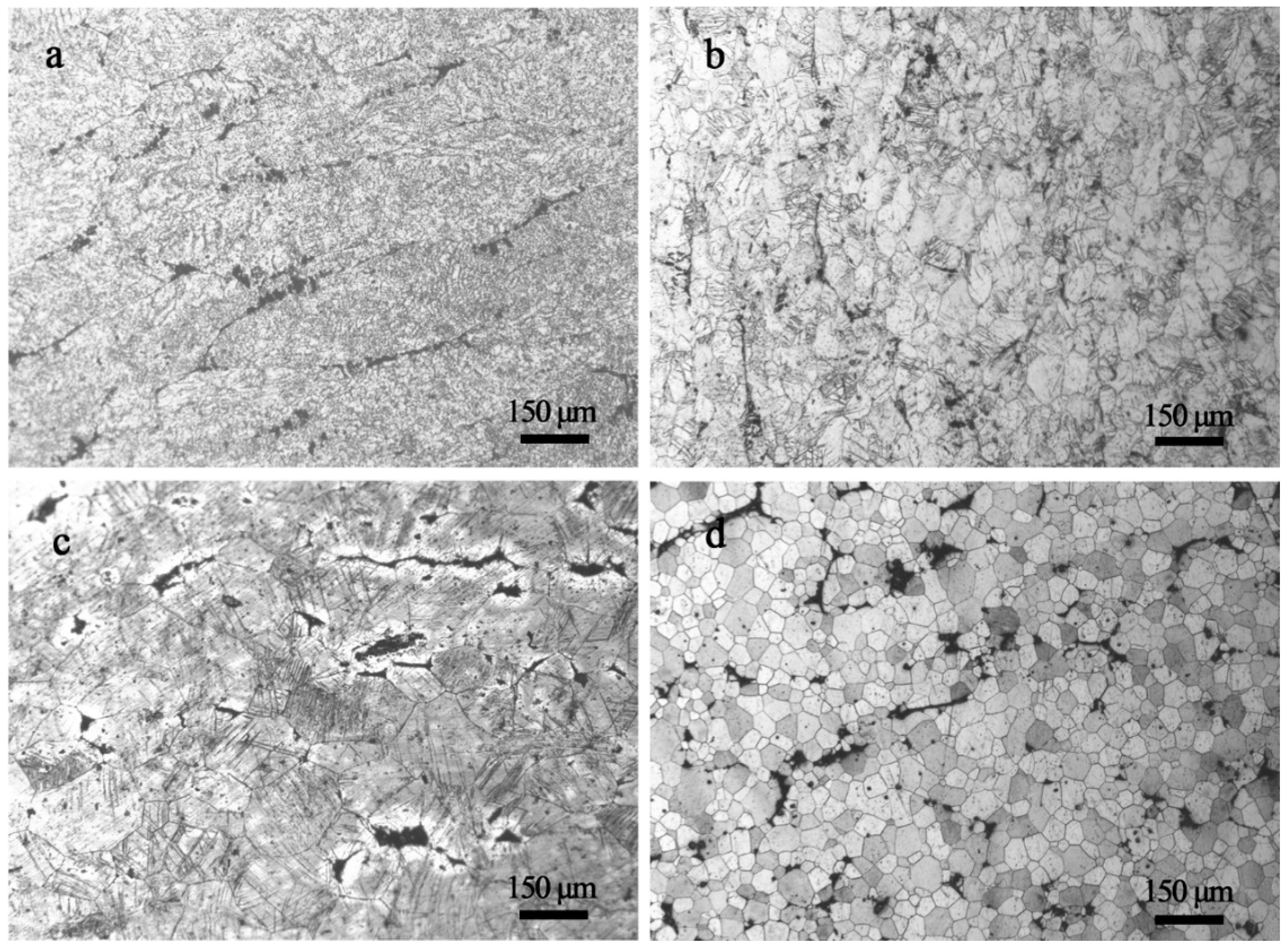

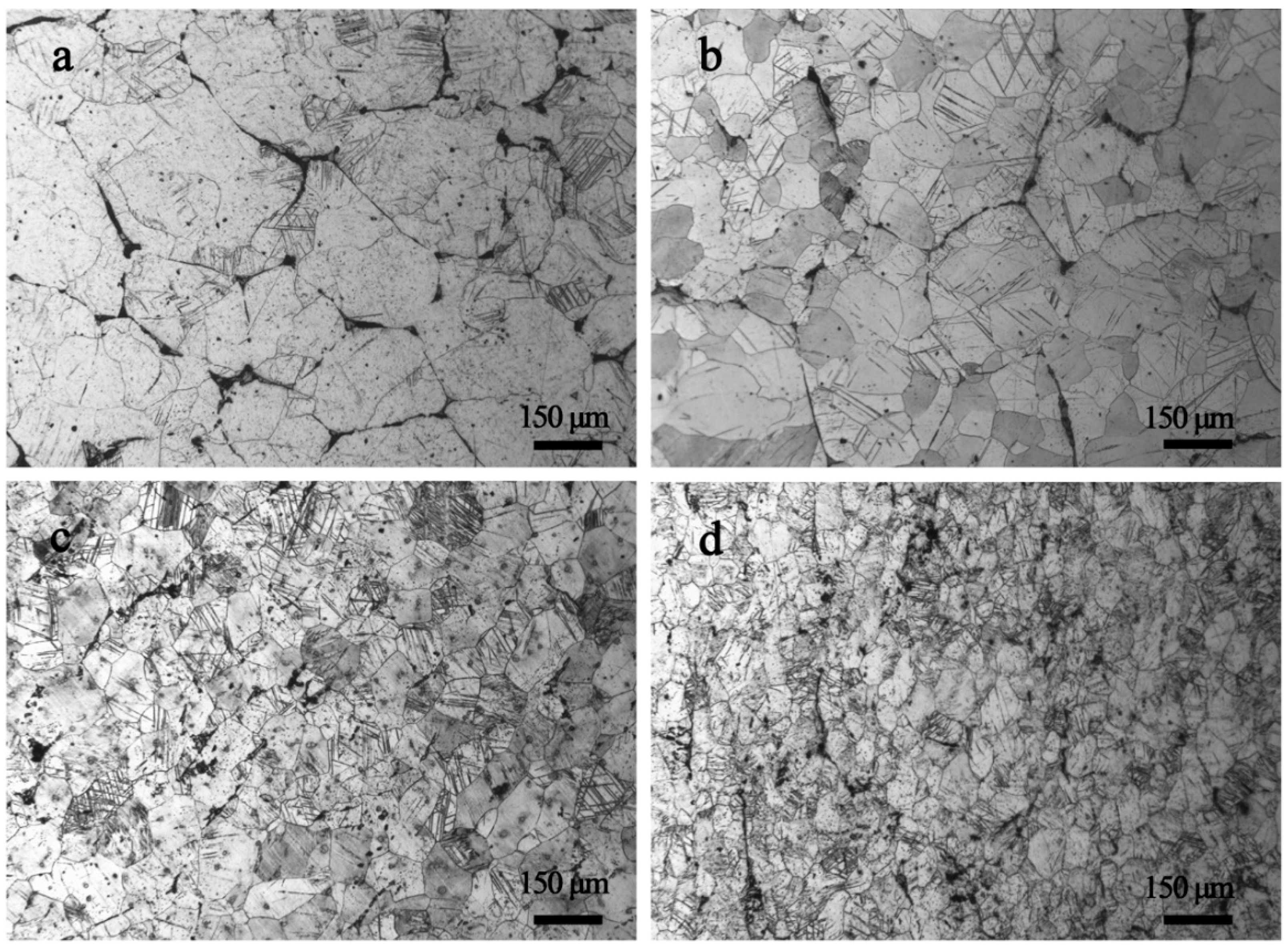

- For Mg-10Gd-3Y-2Ag (GWQ1032K) alloy prepared by cold rolling with 40% reduction and subsequent annealing at 530 °C for 20 s, the grains are refined from 100 μm to 20 μm, which exhibits more effective grain refinement compared with common hot rolling at 450 °C in a thickness reduction of 80% (with refined grains ~30 μm). The hardness results reveal a higher value of 95 HV for Mg alloy fabricated by the two-step forming process than that of the hot-rolled sample (80 HV).

- (2)

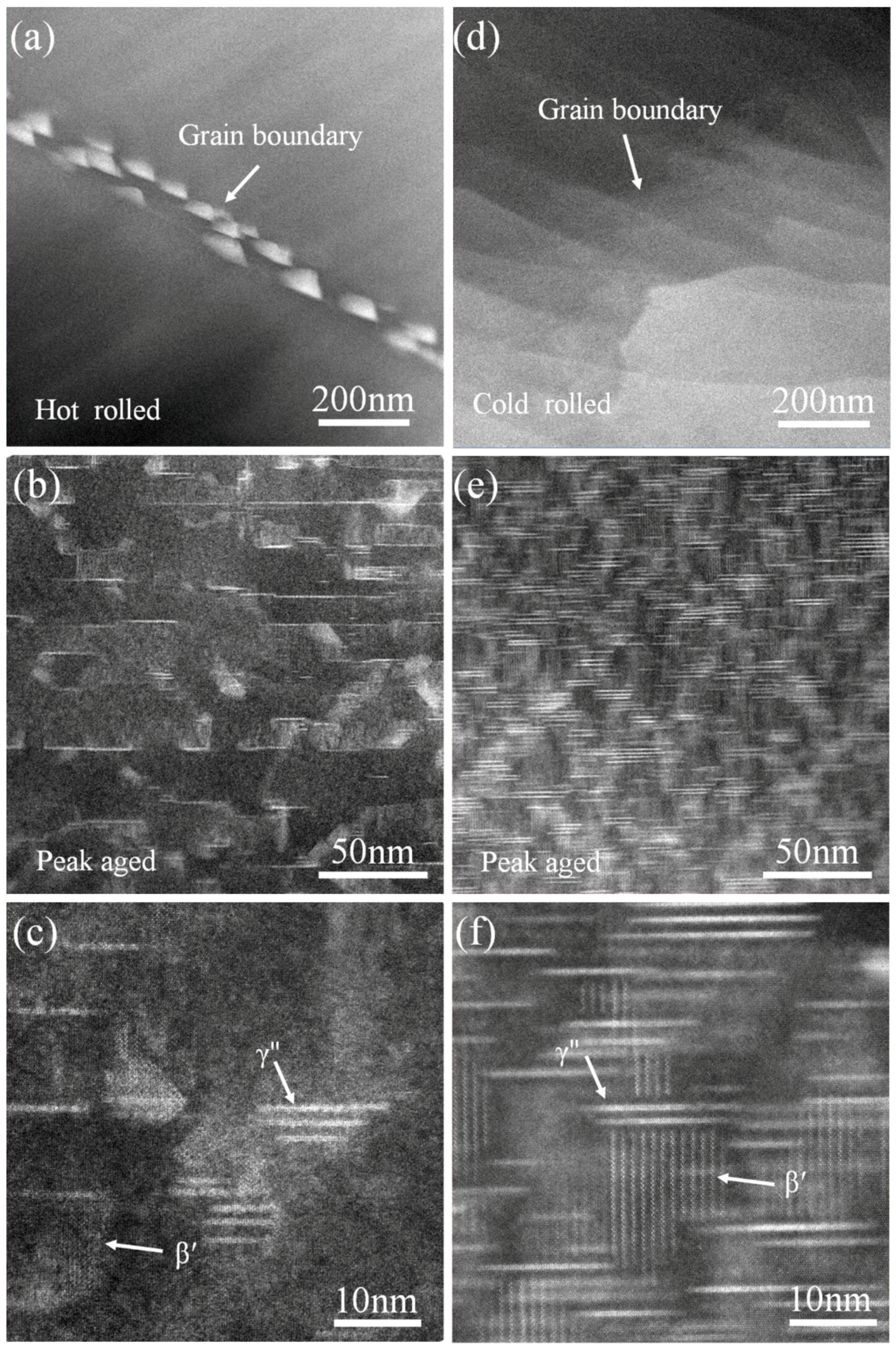

- The sample prepared by the two-step forming process shows more distinct aging hardening, with the hardness amplification of 60 HV, which is twice that of the hot-rolled sample. As a result of the effective suppression of dynamic precipitation by the two-step forming process, the density of precipitation at grain boundary is far less than that in the hot-rolled sample, and after aging, the density of precipitation for Mg alloy from the two-step processing route, in particular of β′ precipitation, is much higher than hot-rolled Mg alloy.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kainer, K. Magnesium Alloys and Technologies; Wiley-VCH Verlag GmbH: Weiheim, Germany, 2003; pp. 1–18. [Google Scholar]

- Zhixin, B.A.; Chen, Y. Research progress on corrosion resistance of hydrotalcite films on magnesium alloys. Mater. Rev. 2017. (In Chinese) [Google Scholar] [CrossRef]

- Yamagata, M.; Katayama, Y.; Miura, T. Electrochemical behavior of samarium, europium, and ytterbium in hydrophobic room-temperature molten salt systems. J. Electrochem. Soc. 2006, 153, E5–E9. [Google Scholar] [CrossRef]

- Pekguleryuz, M.; Celikin, M. Creep resistance in magnesium alloys. Int. Mater. Rev. 2010, 55, 197–217. [Google Scholar] [CrossRef]

- Stanford, N.; Geng, J.; Chun, Y.B.; Davies, C.H.J.; Nie, J.F.; Barnett, M.R. Effect of plate-shaped particle distributions on the deformation behaviour of magnesium alloy AZ91 in tension and compression. Acta Mater. 2012, 60, 218–228. [Google Scholar] [CrossRef]

- Movahedi-Rad, A.; Mahmudi, R. Effect of Ag addition on the elevated-temperature mechanical properties of an extruded high strength Mg-Gd-Y-Zr alloy. Mater. Sci. Eng. A 2014, 614, 62–66. [Google Scholar] [CrossRef]

- Lukyanova, E.A.; Rokhlin, L.L.; Tabachkova, N.Y.; Dobatkina, T.V.; Nikitina, N.I. Reversion after ageing in an Mg-Y-Gd-Zr alloy. J. Alloys Compd. 2015, 635, 173–179. [Google Scholar] [CrossRef]

- Nodooshan, H.J.; Liu, W.; Wu, G.; Rao, Y.; Zhou, C.; He, S.; Ding, W.; Mahmudi, R. Effect of Gd content on microstructure and mechanical properties of Mg-Gd-Y-Zr alloys under peak-aged condition. Mater. Sci. Eng. A 2014, 615, 79–86. [Google Scholar] [CrossRef]

- Liu, Z.J.; Wu, G.H.; Liu, W.C.; Pang, S.; Ding, W.J. Effect of heat treatment on microstructures and mechanical properties of sand-cast Mg-4Y-2Nd-1Gd-0.4Zr magnesium alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 1540–1548. [Google Scholar] [CrossRef]

- Chen, Z.B.; Liu, C.M.; Xiao, H.C.; Wang, J.K.; Chen, Z.Y.; Jiang, S.N.; Su, Z.J. Effect of rolling passes on the microstructures and mechanical properties of Mg–Gd–Y–Zr alloy sheets. Mater. Sci. Eng. A 2014, 618, 232–237. [Google Scholar] [CrossRef]

- Fan, Y.; Peng, Q.; Pan, J.; Bi, G.; Liu, B. Strengthening Precipitate, Thermal Stability, and Mechanical Properties of Melt-Spun Mg-8Gd-3Nd Alloy. J. Mater. Eng. Perform. 2014, 23, 250–254. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, W.Z.; Jian, W.W.; Cheng, G.M.; Ma, X.L.; Guo, W.; Mathaudhu, S.N.; Wang, Q.D.; Zhu, Y.T. A new metastable precipitate phase in Mg-Gd-Y-Zr alloy. Philos. Mag. 2014, 94, 2403–2409. [Google Scholar] [CrossRef]

- Li, R.G.; Nie, J.F.; Huang, G.J.; Xin, Y.C.; Liu, Q. Development of high-strength magnesium alloys via combined processes of extrusion, rolling and ageing. Scr. Mater. 2011, 64, 950–953. [Google Scholar] [CrossRef]

- Cao, T.D.; Yang, X.M. Study on Mechanical Properties at High Temperatures and Microstructure of Mg-12Gd-3Y-0.5Zr Magnesium Alloy. Adv. Mater. Res. 2014, 997, 618–623. [Google Scholar] [CrossRef]

- Lu, F.M.; Ma, A.B.; Jiang, J.H.; Yang, D.H.; Yuan, Y.C.; Zhang, L.Y. Formation of profuse long period stacking ordered microcells in Mg-Gd-Zn-Zr alloy during multipass ECAP process. J. Alloys Compd. 2014, 601, 140–145. [Google Scholar] [CrossRef]

- Xu, C.; Zheng, M.Y.; Xu, S.W.; Wu, K.; Wang, E.D.; Kamado, S.; Wang, G.J.; Lv, X.Y. Microstructure and mechanical properties of rolled sheets of Mg-Gd-Y-Zn-Zr alloy: As-cast versus as-homogenized. J. Alloys Compd. 2012, 528, 40–44. [Google Scholar] [CrossRef]

- Yamasaki, M.; Sasaki, M.; Nishijima, M.; Hiraga, K.; Kawamura, Y. Formation of 14H long period stacking ordered structure and profuse stacking faults in Mg-Zn-Gd alloys during isothermal aging at high temperature. Acta Mater. 2007, 55, 6798–6805. [Google Scholar] [CrossRef]

- Honma, T.; Ohkubo, T.; Kamado, S.; Hono, K. Effect of Zn additions on the age-hardening of Mg-2.0Gd-1.2Y-0.2Zr alloys. Acta Mater. 2007, 55, 4137–4150. [Google Scholar] [CrossRef]

- Zhou, H.; Cheng, G.M.; Ma, X.L.; Xu, W.Z.; Mathaudhu, S.N.; Wang, Q.D.; Zhu, Y.T. Effect of Ag on interfacial segregation in Mg-Gd-Y-(Ag)-Zr alloy. Acta Mater. 2015, 95, 20–29. [Google Scholar] [CrossRef]

- Gao, X.; Nie, J.F. Enhanced precipitation-hardening in Mg-Gd alloys containing Ag and Zn. Scr. Mater. 2008, 58, 619–622. [Google Scholar] [CrossRef]

- Movahedi-Rad, A.; Mahmudi, R.; Wu, G.H.; Nodooshan, H.J. Enhanced superplasticity in an extruded high strength Mg–Gd–Y–Zr alloy with Ag addition. J. Alloys Compd. 2015, 626, 309–313. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, J.; Zhao, Z.; He, S. Microstructure and super high strength of cast Mg-8.5Gd-2.3Y-1.8Ag-0.4Zr alloy. Mater. Sci. Eng. A 2010, 528, 323–328. [Google Scholar] [CrossRef]

- Zhou, H.; Ning, H.Y.; Ma, X.L.; Yin, D.D.; Xiao, L.R.; Sha, X.C.; Yu, Y.D.; Wang, Q.D.; Li, Y.S. Microstructural evolution and mechanical properties of Mg-9.8Gd-2.7Y-0.4Zr alloy produced by repetitive upsetting. J. Mater. Sci. Technol. 2018. [Google Scholar] [CrossRef]

- Alizadeh, R.; Mahmudi, R.; Pereira, P.H.R.; Huang, Y.; Langdon, T.G. Microstructural evolution and superplasticity in an Mg-Gd-Y-Zr alloy after processing by different SPD techniques. Mater. Sci. Eng. A 2017, 682, 577–585. [Google Scholar] [CrossRef]

- Hou, X.; Cao, Z.; Sun, X.; Wang, L.; Wang, L. Twinning and dynamic precipitation upon hot compression of a Mg-Gd-Y-Nd-Zr alloy. J. Alloys Compd. 2012, 525, 103–109. [Google Scholar] [CrossRef]

- Xiao, H.; Tang, B.; Liu, C.; Gao, Y.; Yu, S.; Jiang, S. Dynamic precipitation in a Mg-Gd-Y-Zr alloy during hot compression. Mater. Sci. Eng. A 2015, 645, 241–247. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, Q.; Chen, J.; Ye, B.; Guo, W. Microstructure and mechanical properties of extruded Mg-8.5Gd-2.3Y-0.8Ag-0.4Zr alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 1891–1895. [Google Scholar] [CrossRef]

- Lin, D.; Wang, L.; Liu, Y.; Cui, J.Z.; Le, Q.C. Effects of plastic deformation on precipitation behavior and tensile fracture behavior of Mg-Gd-Y-Zr alloy. Trans. Nonferrous Met. Soc. China 2011, 21, 2160–2167. [Google Scholar] [CrossRef]

- Nie, J.F. Precipitation and Hardening in Magnesium Alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Y.; Peng, L.; Zhang, C. Experimental investigation and thermodynamic assessment of the Mg-Gd-Ag system focused on Mg-rich region. Calphad 2015, 48, 43–54. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.Y.; Rong, J.; Yu, Z.Y.; Zha, M.; Wang, C.; Yang, Z.Z.; Bu, R.Y.; Jiang, Q.C. Tensile properties, texture evolutions and deformation anisotropy of as extruded Mg-6Zn-1Zr magnesium alloy at room and elevated temperatures. Mater. Sci. Eng. A 2017, 697, 149–157. [Google Scholar] [CrossRef]

- Jin, X.; Xu, W.; Shan, D.; Liu, C.; Zhang, Q. Deformation behavior, microstructure evolution and hot workability of Mg-3.7Gd-2.9Y-0.7Zn-0.7Zr alloy. Met. Mater. Int. 2017, 23, 434–443. [Google Scholar] [CrossRef]

- Kim, K.H.; Suh, B.C.; Bae, J.H.; Shim, M.S.; Kim, S.; Kim, N.J. Microstructure and texture evolution of Mg alloys during twin-roll casting and subsequent hot rolling. Scr. Mater. 2010, 63, 716–720. [Google Scholar] [CrossRef]

- Huang, C.X.; Hu, W.P.; Wang, Q.Y.; Wang, C.; Yang, G.; Zhu, Y.T. An ideal ultrafine-grained structure for high strength and high ductility. Mater. Res. Lett. 2015, 3, 88–94. [Google Scholar] [CrossRef]

- Mónica, P.; Bravo, P.M.; Cárdenas, D. Deep cryogenic treatment of HPDC AZ91 magnesium alloys prior to aging and its influence on alloy microstructure and mechanical properties. J. Mater. Process. Technol. 2017, 239, 297–302. [Google Scholar] [CrossRef]

- Yu, D.; Zhang, D.; Sun, J.; Luo, Y.; Xu, J.; Zhang, H.; Pan, F. Improving mechanical properties of ZM61 magnesium alloy by aging before extrusion. J. Alloys Compd. 2017, 690, 553–560. [Google Scholar] [CrossRef]

- Chen, C.; Chen, J.; Yan, H.; Su, B.; Song, M.; Zhu, S. Dynamic precipitation, microstructure and mechanical properties of Mg-5Zn-1Mn alloy sheets prepared by high strain-rate rolling. Mater. Des. 2016, 100, 58–66. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Wu, X.L.; Liao, X.Z.; Narayan, J.; Kecskes, L.J.; Mathaudhu, S.N. Dislocation–twin interactions in nanocrystalline fcc metals. Acta Mater. 2011, 59, 812–821. [Google Scholar] [CrossRef]

- Nie, J.F.; Zhu, Y.M.; Liu, J.Z.; Fang, X.Y. Periodic Segregation of Solute Atoms in Fully Coherent Twin Boundaries. Science 2013, 340, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Nie, J.F. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys. Scr. Mater. 2003, 48, 1009–1015. [Google Scholar] [CrossRef]

- Wang, F.; Bhattacharyya, J.J.; Agnew, S.R. Effect of precipitate shape and orientation on Orowan strengthening of non-basal slip modes in hexagonal crystals, application to magnesium alloys. Mater. Sci. Eng. A 2016, 666, 114–122. [Google Scholar] [CrossRef]

| Element | Gd | Y | Ag | Zr | Mg |

|---|---|---|---|---|---|

| Content wt % | 10 | 3 | 2 | 0.4 | 84.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, H.; Yu, Y.; Gao, B.; Xiao, L.; Wen, L.; Yan, Z.; Li, L.; Chen, X. Grain Refinement and Aging Hardening of the Mg-10Gd-3Y-2Ag-0.4Zr Alloy Produced by a Two-Step Forming Process. Materials 2018, 11, 757. https://doi.org/10.3390/ma11050757

Ning H, Yu Y, Gao B, Xiao L, Wen L, Yan Z, Li L, Chen X. Grain Refinement and Aging Hardening of the Mg-10Gd-3Y-2Ag-0.4Zr Alloy Produced by a Two-Step Forming Process. Materials. 2018; 11(5):757. https://doi.org/10.3390/ma11050757

Chicago/Turabian StyleNing, Huiyan, Yandong Yu, Bo Gao, Lirong Xiao, Lihua Wen, Zehua Yan, Li Li, and Xuefei Chen. 2018. "Grain Refinement and Aging Hardening of the Mg-10Gd-3Y-2Ag-0.4Zr Alloy Produced by a Two-Step Forming Process" Materials 11, no. 5: 757. https://doi.org/10.3390/ma11050757