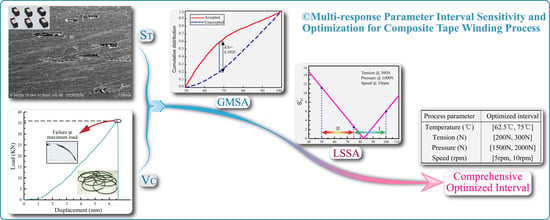

Multi-Response Parameter Interval Sensitivity and Optimization for the Composite Tape Winding Process

Abstract

:1. Introduction

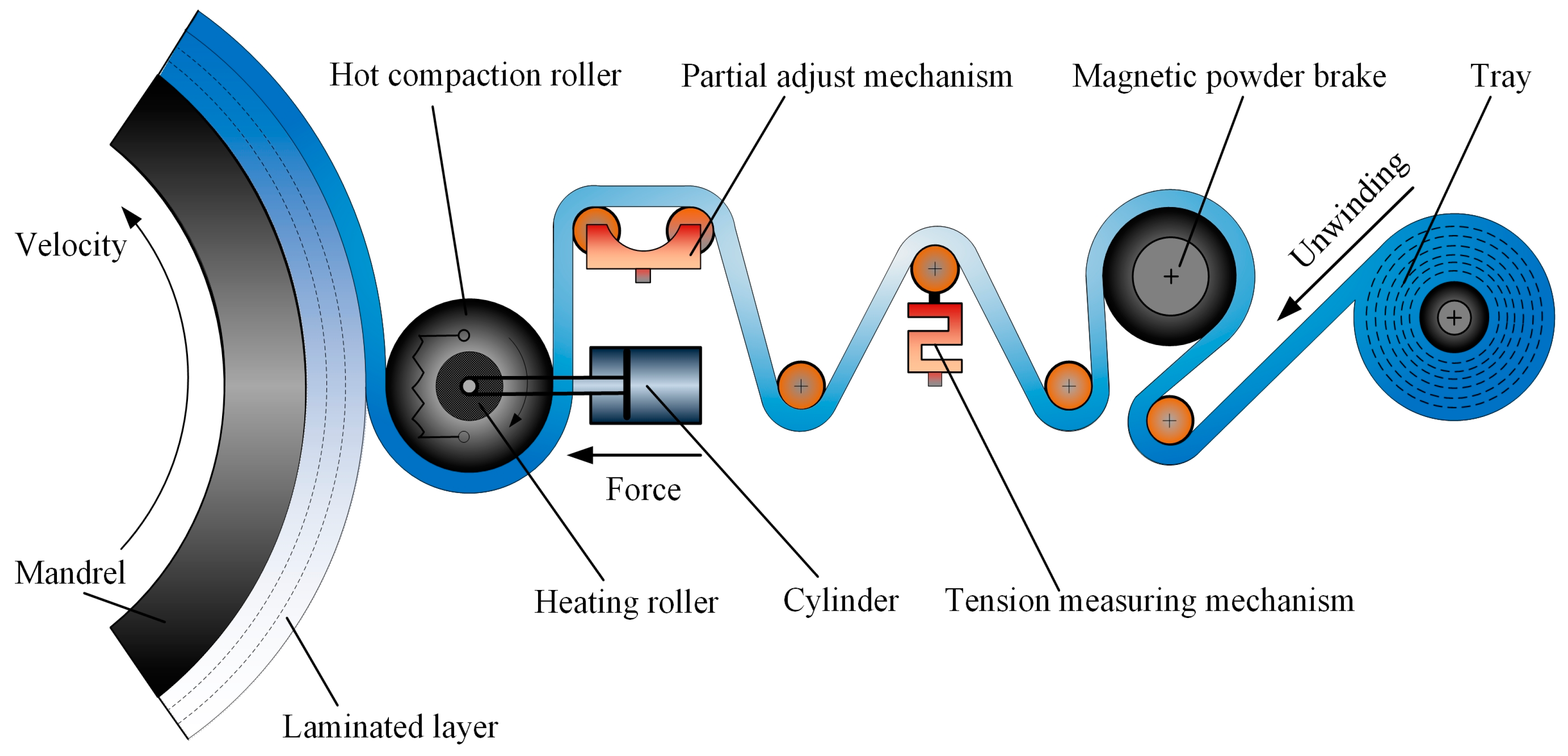

2. Tape Winding Process

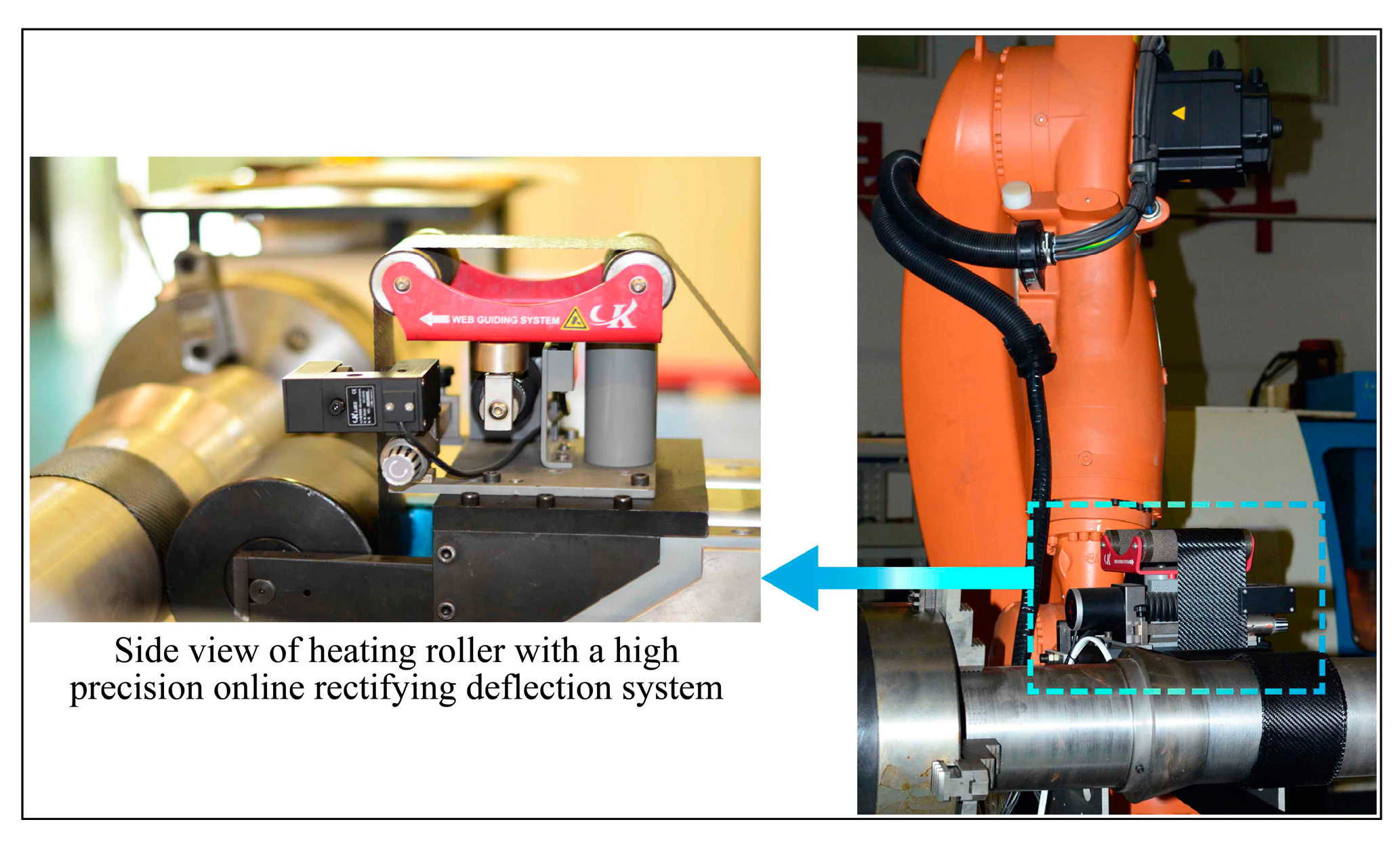

2.1. Composite Prepreg Tape Winding Process

2.2. Tensile Strength and Void Content Model

3. Experiment Procedure and Results

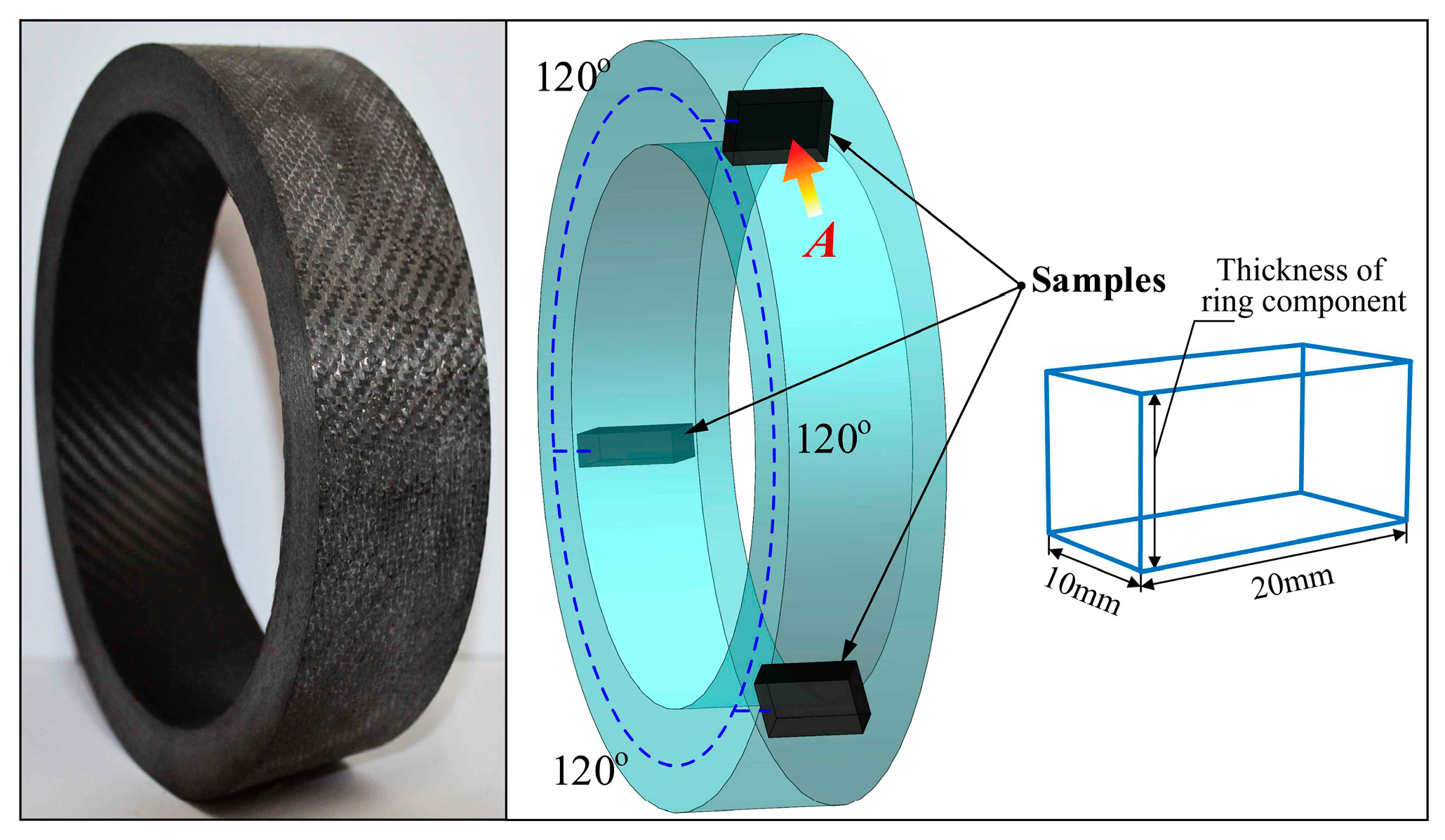

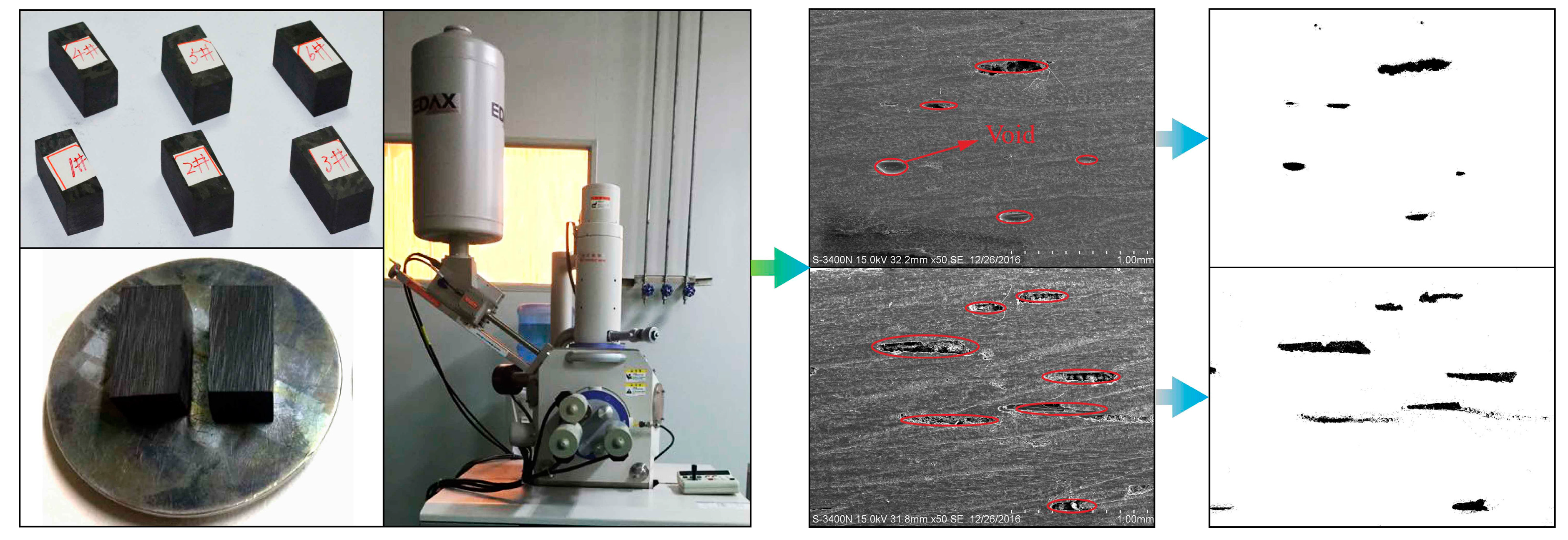

3.1. Experiment Design and Sample Preparation

3.2. Measurement Method

3.2.1. Tensile Strength

3.2.2. Void Content

3.3. Experiment Results

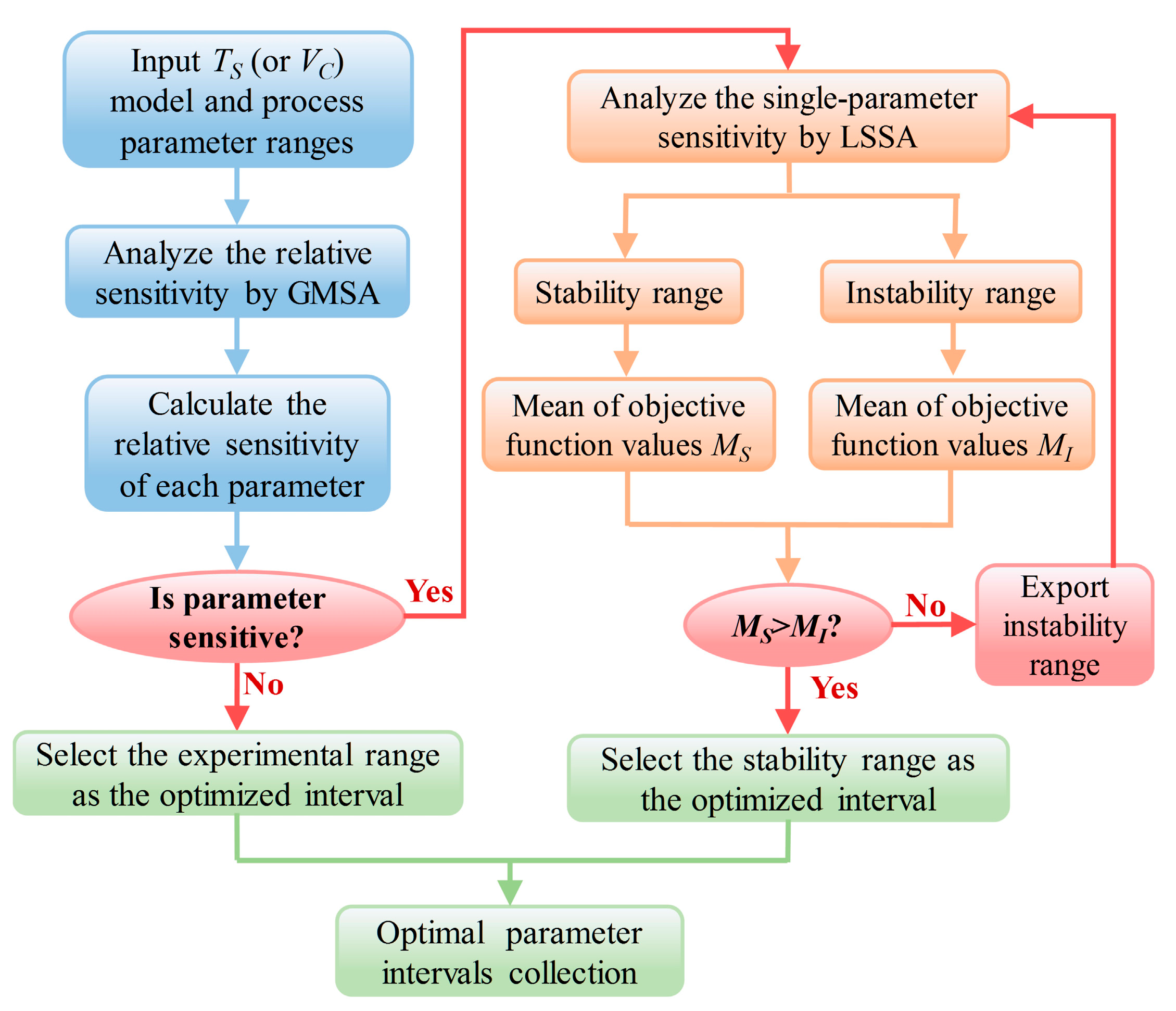

4. Sensitivity Analysis Method

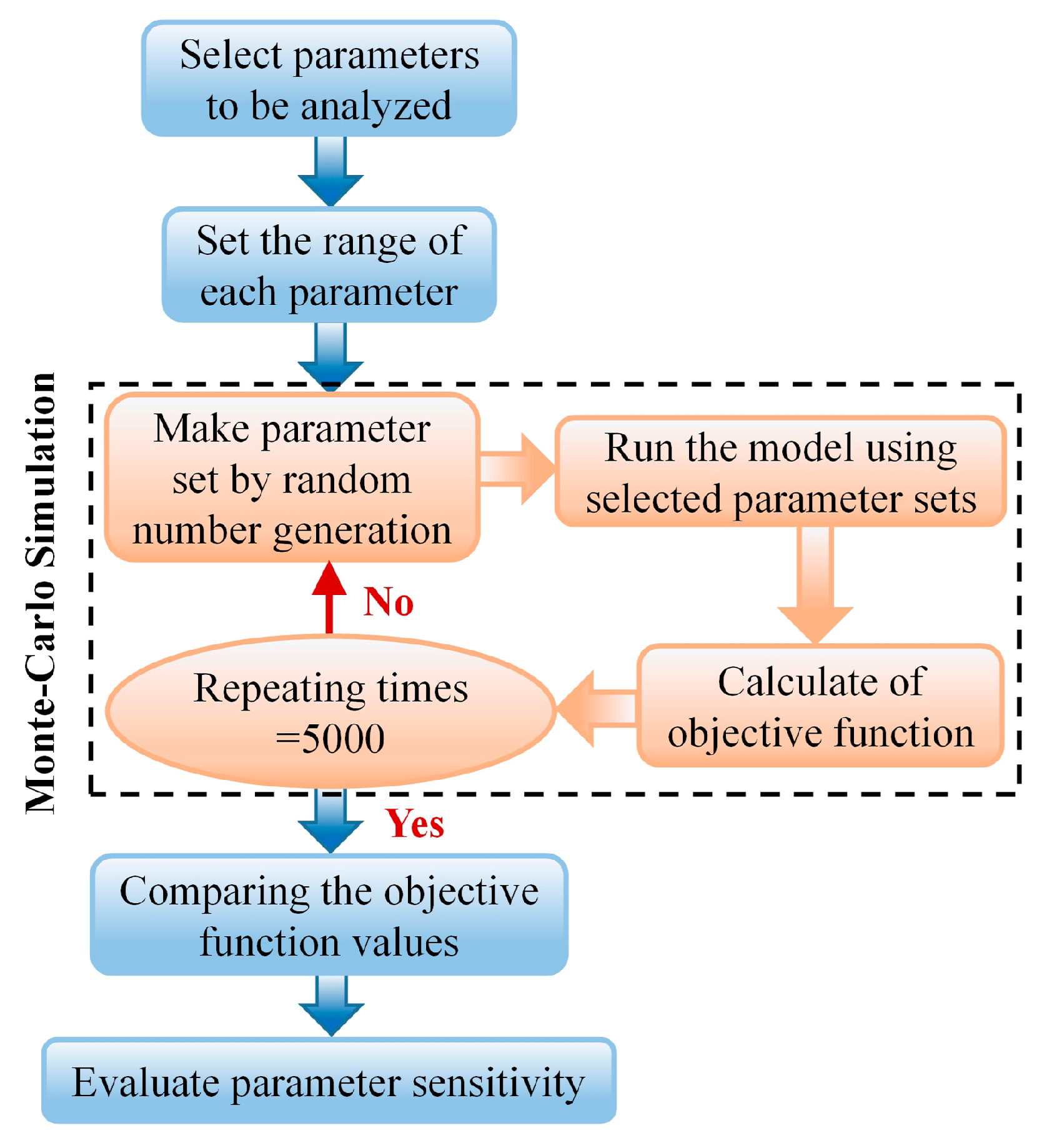

4.1. Global Multi-Parameter Sensitivity Analysis

- Select the parameters x1, x2, …, xn to be tested respectively.

- Set the range of each parameter based on the practical production experience.

- To every parameter, generate a series of N independent random numbers xi,j (j = 1, 2, 3, …, N) with a uniform distribution within the defined range.

- Operating the model using selected parameter sets and calculate the objective function values yi. The objective function values can be calculated from the modeled values.

- Determine whether the parameter sets are ‘acceptable’ or ‘unacceptable’ by comparing the objective function values to a given criterion (R). Here, the criterion R is given by:

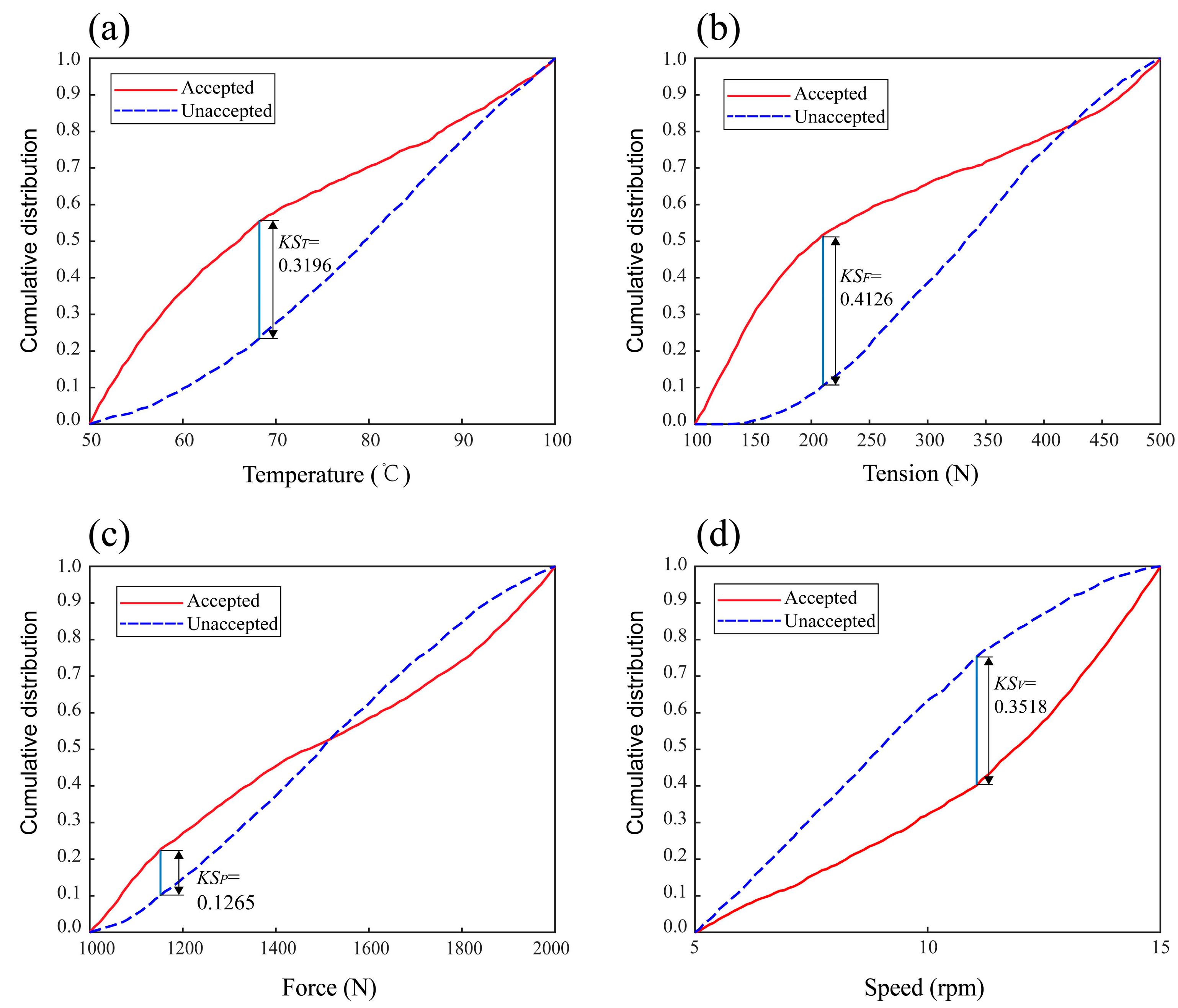

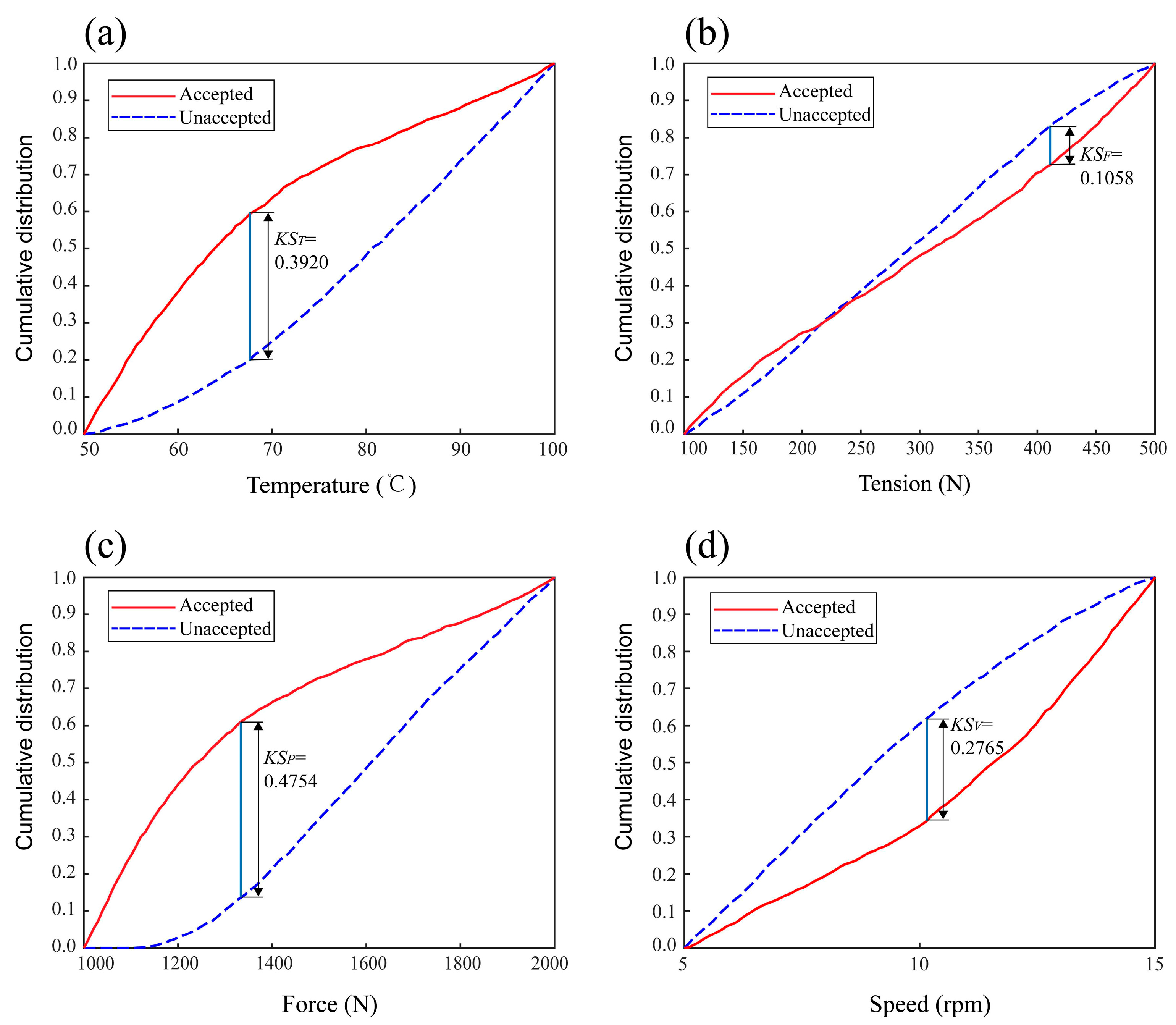

- For each parameter, calculate the cumulative frequency of ‘acceptable’ or ‘unacceptable’ cases, and illustrate the cumulative frequency curves. Evaluate the separated degree Kolmogorov Smirnov distance (KS) of the two cumulative frequency distributions curves. For a certain parameter, the larger the value of KS, the more sensitive is the corresponding parameter. The KS can be written as:

4.2. Local Single-Parameter Sensitivity Analysis

5. Sensitivity Analysis Results

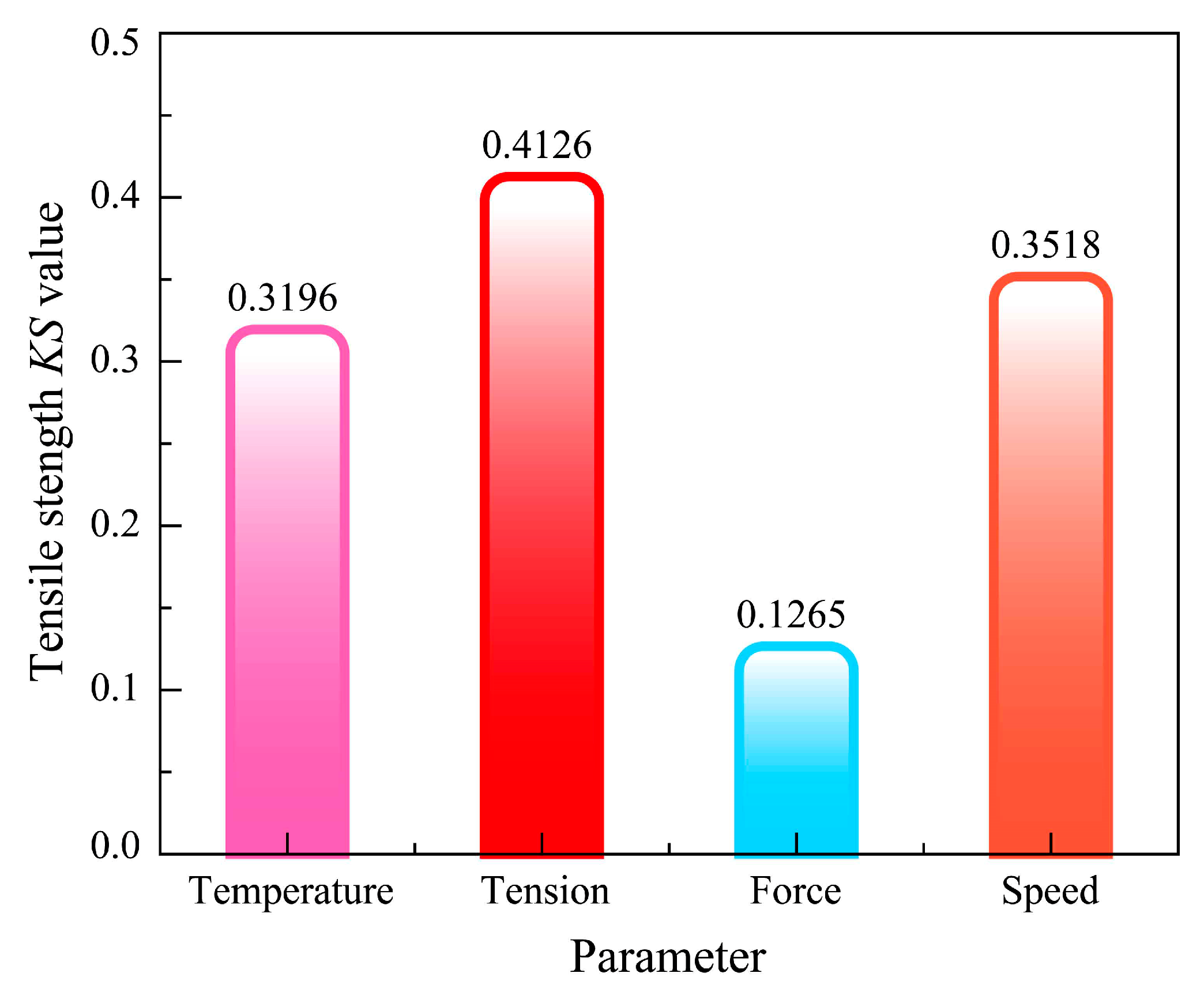

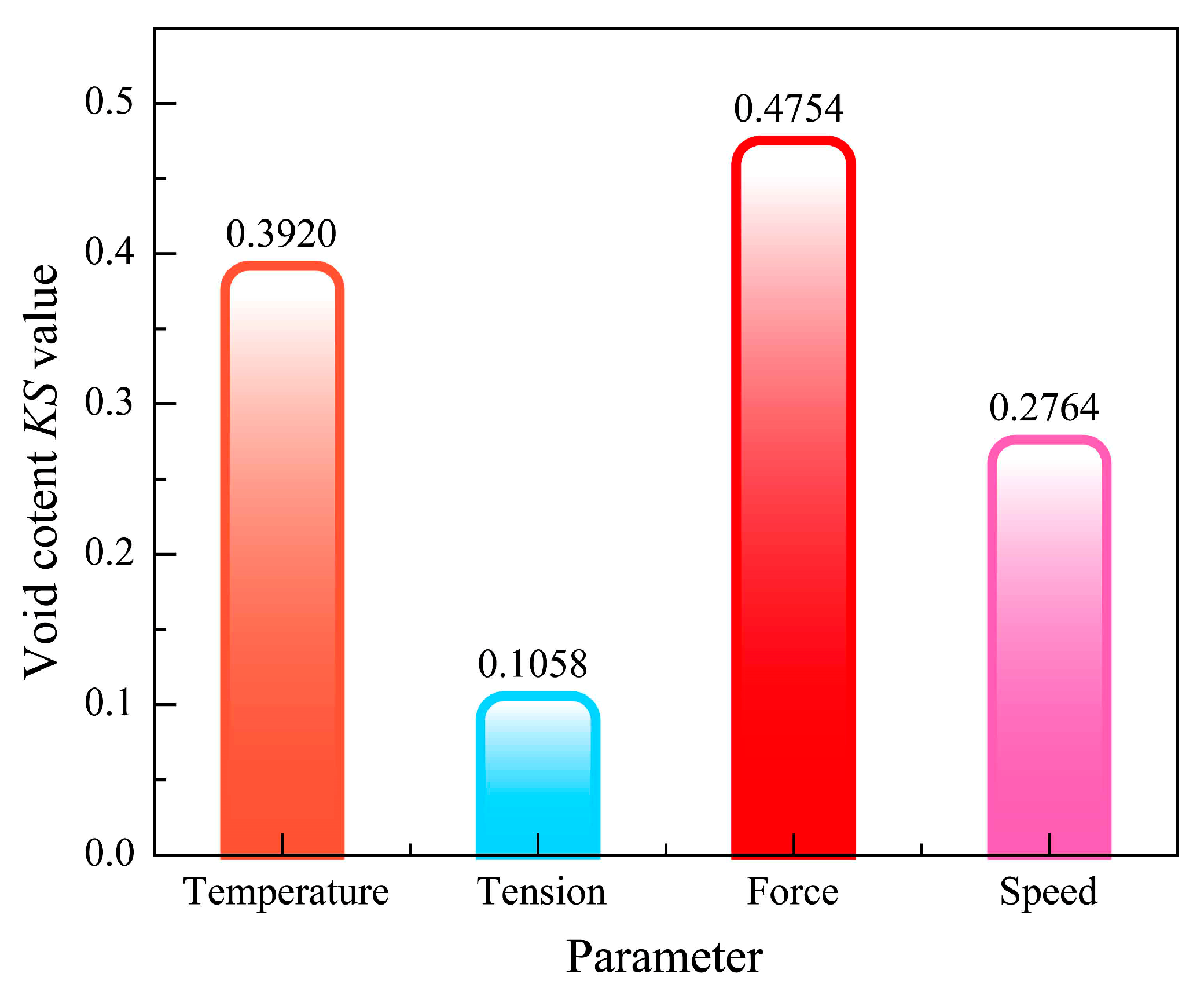

5.1. Global Multi-Parameter Sensitivity Analysis Results

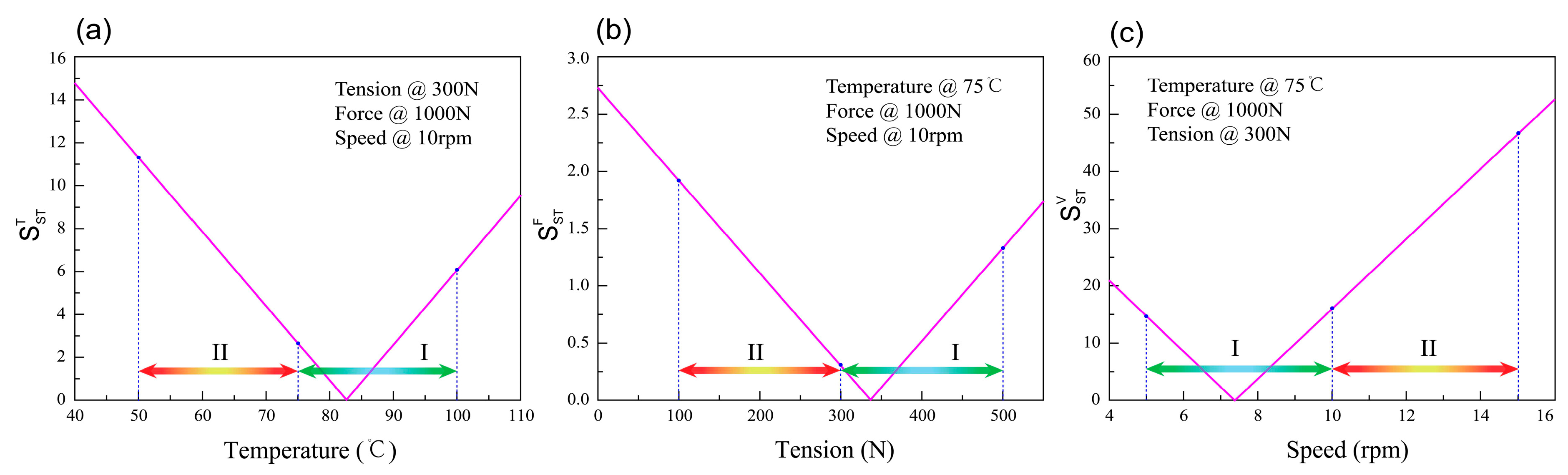

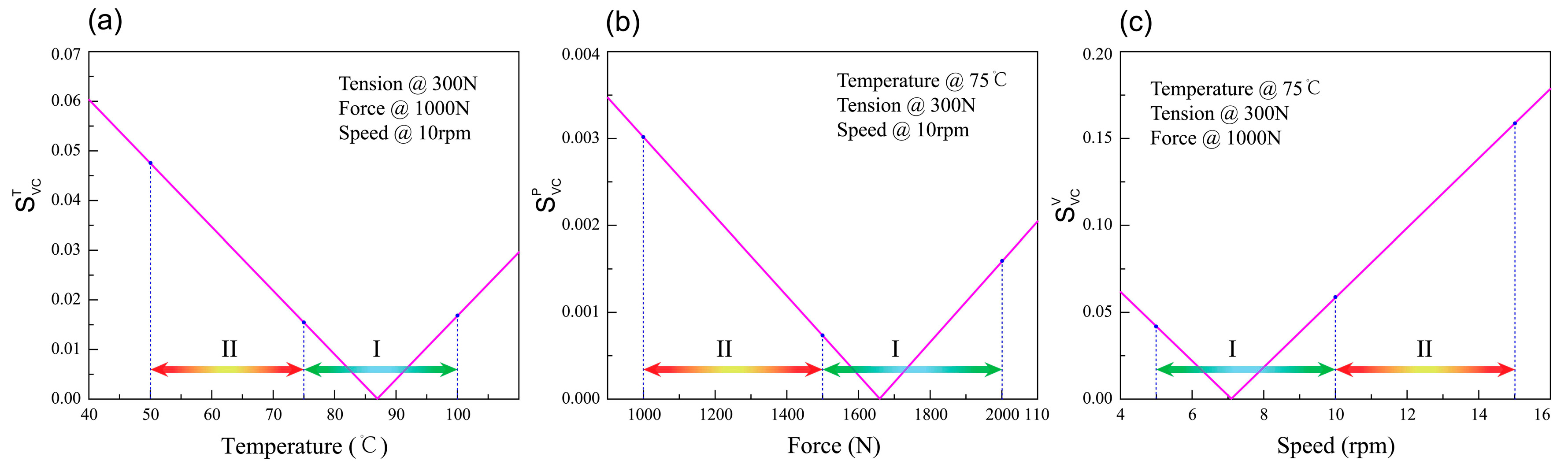

5.2. Local Single-Parameter Sensitivity Analysis

5.3. Stability and Instability Interval Division

6. Interval Optimization

6.1. Tensile Strength Model

6.2. Void Content Model

6.3. Comprehensive Optimized Interval of Winding Parameters

6.4. Experimental Verification

7. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zaami, A.; Baran, I.; Akkerman, R. Numerical modeling of laser assisted tape winding process. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017; p. 180004. [Google Scholar]

- Tannous, M.; Barasinski, A.; Binetruy, C.; Courtemanche, B. Contribution of thermo-mechanical parameters and friction to the bonding of thermoplastic tapes in the tape winding process. J. Mater. Process. Technol. 2016, 229, 587–595. [Google Scholar] [CrossRef]

- Nimdum, P.; Patamaprohm, B.; Renard, J.; Villalonga, S. Experimental method and numerical simulation demonstrate non-linear axial behaviour in composite filament wound pressure vessel due to thermal expansion effect. Int. J. Hydrogen Energy 2015, 40, 13231–13241. [Google Scholar] [CrossRef]

- Rafiee, R. Experimental and theoretical investigations on the failure of filament wound GRP pipes. Compos. Part B Eng. 2013, 45, 257–267. [Google Scholar] [CrossRef]

- Schlottermöller, M.; Schledjewski, R.; Mitschang, P. Influence of process parameters on residual stress in thermoplastic filament-wound parts. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2004, 218, 157–164. [Google Scholar] [CrossRef]

- Guzman-Maldonado, E.; Hamila, N.; Naouar, N.; Moulin, G.; Boisse, P. Simulation of thermoplastic prepreg thermoforming based on a visco-hyperelastic model and a thermal homogenization. Mater. Des. 2016, 93, 431–442. [Google Scholar] [CrossRef]

- Grünewald, J.; Parlevliet, P.; Altstädt, V. Definition of process parameters for manufacturing of thermoplastic composite sandwiches—Part A: Modelling. J. Thermoplast. Compos. Mater. 2016, 1–22. [Google Scholar] [CrossRef]

- Guest, D.A. Manufacturing Process Modeling for Composite Materials. Ph.D. Thesis, Montana State University-Bozeman, Bozeman, MT, USA, 2013. [Google Scholar]

- Sonmez, F.O.; Hahn, H.T. Analysis of the on-line consolidation process in thermoplastic composite tape placement. J. Thermoplast. Compos. Mater. 1997, 10, 543–572. [Google Scholar] [CrossRef]

- Lu, H.; Schlottermuller, M.; Himmel, N.; Schledjewski, R. Effects of tape tension on residual stress in thermoplastic composite filament winding. J. Thermoplast. Compos. Mater. 2005, 18, 469–487. [Google Scholar] [CrossRef]

- Schlottermuller, M.; Lu, H.; Roth, Y.; Himmel, N.; Schledjewski, R.; Mitschang, P. Thermal residual stress simulation in thermoplastic filament winding process. J. Thermoplast. Compos. Mater. 2003, 16, 497–519. [Google Scholar] [CrossRef]

- Polini, W.; Sorrentino, L. Influence of winding speed and winding trajectory on tension in robotized filament winding of full section parts. Compos. Sci. Technol. 2005, 65, 1574–1581. [Google Scholar] [CrossRef]

- Chinesta, F.; Leygue, A.; Bognet, B.; Ghnatios, C.; Poulhaon, F.; Bordeu, F.; Barasinski, A.; Poitou, A.; Chatel, S.; Maison-Le-Poec, S. First steps towards an advanced simulation of composites manufacturing by automated tape placement. Int. J. Mater. Form. 2014, 7, 81–92. [Google Scholar] [CrossRef]

- Cui, Y.Q.; Yin, Z.W.; Li, H.L. Influence of tension in t300/epoxy prepreg winding process on the performance of the bearing composites. J. Reinf. Plast. Compos. 2017, 36, 1099–1115. [Google Scholar] [CrossRef]

- Cheng, J.; Zhao, D.; Liu, K.; Wang, Y. Process modeling and parameter optimization based on assumed inherent sensor inversion for composite automated placement. J. Reinf. Plast. Compos. 2017, 36, 226–238. [Google Scholar] [CrossRef]

- Khan, M.A.; Mitschang, P.; Schledjewski, R. Identification of some optimal parameters to achieve higher laminate quality through tape placement process. Adv. Polym. Technol. 2010, 29, 98–111. [Google Scholar] [CrossRef]

- Grouve, W.; Warnet, L.; Rietman, B.; Visser, H.; Akkerman, R. Optimization of the tape placement process parameters for carbon—PPS composites. Compos. Part A Appl. Sci. Manuf. 2013, 50, 44–53. [Google Scholar] [CrossRef]

- Khan, M.A.; Mitschang, P.; Schledjewski, R. Parametric study on processing parameters and resulting part quality through thermoplastic tape placement process. J. Compos. Mater. 2013, 47, 485–499. [Google Scholar] [CrossRef]

- Nath, N.K. Optimization of tape winding process parameters to enhance the performance of solid rocket nozzle throat back up liners using Taguchi’s robust design methodology. J. Inst. Eng. Ser. C 2017, 98, 479–484. [Google Scholar] [CrossRef]

- Khan, M.A. Tracing the void content development and identification of its effecting parameters during in situ consolidation of thermoplastic tape material. Polym. Polym. Compos. 2010, 18, 1–15. [Google Scholar]

- Paciornik, S.; d’Almeida, J. Digital microscopy and image analysis applied to composite materials characterization. Matéria 2010, 15, 172–181. [Google Scholar] [CrossRef]

- Fedulov, B.; Antonov, F.; Safonov, A.; Ushakov, A.; Lomov, S.V. Influence of fibre misalignment and voids on composite laminate strength. J. Compos. Mater. 2015, 49, 2887–2896. [Google Scholar] [CrossRef]

- Croft, K.; Lessard, L.; Pasini, D.; Hojjati, M.; Chen, J.; Yousefpour, A. Experimental study of the effect of automated fiber placement induced defects on performance of composite laminates. Compos. Part A Appl. Sci. Manuf. 2011, 42, 484–491. [Google Scholar] [CrossRef]

- Okuya, T.; Nakada, M.; Miyano, Y. Reliable test method for tensile strength in longitudinal direction of unidirectional carbon fiber-reinforced plastics. J. Reinf. Plast. Compos. 2013, 32, 1579–1585. [Google Scholar] [CrossRef]

- Deng, B.; Shi, Y. Modeling and simulation of voids in composite tape winding process based on domain superposition technique. Appl. Compos. Mater. 2017, 1–18. [Google Scholar] [CrossRef]

- Devanathan, S.; Koch, P.N. Comparison of Meta-Modeling Approaches for Optimization. In Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition, Denver, CO, USA, 11–17 November 2011; pp. 827–835. [Google Scholar]

- Standardization Administration of the People’s Republic of China. Test Method for Mechanical Properties of Ring of Filament-Winding Reinforced Plastics; Standardization Administration of the People’s Republic of China: Beijing, China, 2008; GT/B 1458-2008. [Google Scholar]

- Paciornik, S.; d’Almeida, J. Measurement of void content and distribution in composite materials through digital microscopy. J. Compos. Mater. 2009, 43, 101–112. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, B.; Li, D.; Zhang, D.; Chen, Y. Influence of voids on the tensile performance of carbon/epoxy fabric laminates. J. Mater. Sci. Technol. 2011, 27, 69–73. [Google Scholar] [CrossRef]

- Nikishkov, Y.; Airoldi, L.; Makeev, A. Measurement of voids in composites by X-ray computed tomography. Compos. Sci. Technol. 2013, 89, 89–97. [Google Scholar] [CrossRef]

- Standardization Administration of the People’s Republic of China. Carbon Fiber Reinforced Plastics-Determination of Void Content and Fiber Volume Content; Standardization Administration of the People’s Republic of China: Beijing, China, 2008; GT/B 3365-2008. [Google Scholar]

- Zhao, D.; Dou, M.; Zhou, D.; Gao, F. Study of the modeling parameter effects on the polarization characteristics of the PEM fuel cell. Int. J. Hydrogen Energy 2016, 41, 22316–22327. [Google Scholar] [CrossRef]

- Huangfu, Y.; Gao, F.; Abbas-Turki, A.; Bouquain, D.; Miraoui, A. Transient dynamic and modeling parameter sensitivity analysis of 1d solid oxide fuel cell model. Energy Convers. Manag. 2013, 71, 172–185. [Google Scholar] [CrossRef]

- Sarma, U.; Gade, P.M.; Saha, B. A mathematical model for dynamics of cd40 clustering. Syst. Synth. Biol. 2013, 7, 197–208. [Google Scholar] [CrossRef] [PubMed]

- Ramnauth, J.D.; Mudhoo, A.; Mohee, R. Methane emissions reduction from organic wastewater and solid waste co-composting: Parameter estimation and sensitivity analysis. Int. J. Glob. Environ. Issues 2012, 12, 1–35. [Google Scholar] [CrossRef]

- Hoseinnia, S.; Sadeghzadeh, S.M.; Fathi, A.H.; Nasiri, M. Evaluating one of renewable electricity generation technologies: PEM fuel cells. In Proceedings of the 2010 IEEE Electric Power and Energy Conference (EPEC), Halifax, NS, Canada, 25–27 August 2010; pp. 1–6. [Google Scholar]

- Zhou, D.; Zhang, K.; Ravey, A.; Gao, F.; Miraoui, A. Parameter sensitivity analysis for fractional-order modeling of lithium-ion batteries. Energies 2016, 9, 123. [Google Scholar] [CrossRef]

- Choi, J.; Harvey, J.W.; Conklin, M.H. Use of Multi-Parameter Sensitivity Analysis to Determine Relative Importance of Factors Influencing Natural Attenuation of Mining Contaminants; U.S. Department of Geological Survey: Reston, VA, USA, 1999.

- Ingalls, B. Sensitivity analysis: From model parameters to system behaviour. Essays Biochem. 2008, 45, 177–194. [Google Scholar] [CrossRef] [PubMed]

- Dresch, J.M.; Liu, X.; Arnosti, D.N.; Ay, A. Thermodynamic modeling of transcription: Sensitivity analysis differentiates biological mechanism from mathematical model-induced effects. BMC Syst. Biol. 2010, 4, 142. [Google Scholar] [CrossRef] [PubMed]

- Peralta, J.M.; Meza, B.R.E.; Zorrilla, S.E. Mathematical modeling of a dip-coating process using a generalized newtonian fluid. 2. Model validation and sensitivity analysis. Ind. Eng. Chem. Res. 2014, 53, 6533–6543. [Google Scholar] [CrossRef]

- Perumal, T.M.; Gunawan, R. Pathpsa: A dynamical pathway-based parametric sensitivity analysis. Ind. Eng. Chem. Res. 2014, 53, 9149–9157. [Google Scholar] [CrossRef]

- Perumal, T.M.; Gunawan, R. Understanding dynamics using sensitivity analysis: Caveat and solution. BMC Syst. Biol. 2011, 5, 41. [Google Scholar] [CrossRef] [PubMed]

- Zi, Z. Sensitivity analysis approaches applied to systems biology models. IET Syst. Biol. 2011, 5, 336–346. [Google Scholar] [CrossRef] [PubMed]

| No. | Process Parameters | Objective Value | ||||

|---|---|---|---|---|---|---|

| Temperature T (°C) | Tension F (N) | Force P (N) | Speed V (rpm) | Tensile Strength (MPa) | Void Content (%) | |

| 1 | 75 | 300 | 1000 | 15 | 896.92 | 1.64 |

| 2 | 50 | 300 | 2000 | 10 | 942.36 | 1.19 |

| 3 | 100 | 300 | 2000 | 10 | 1012.24 | 0.25 |

| 4 | 75 | 500 | 1500 | 15 | 951.33 | 1.26 |

| 5 | 75 | 300 | 1500 | 10 | 1215.31 | 0.13 |

| 6 | 75 | 300 | 2000 | 5 | 1123.47 | 0.35 |

| 7 | 100 | 500 | 1500 | 10 | 1062.27 | 0.73 |

| 8 | 50 | 500 | 1500 | 10 | 920.61 | 1.45 |

| 9 | 75 | 300 | 1500 | 10 | 1212.53 | 0.15 |

| 10 | 75 | 300 | 1500 | 10 | 1209.32 | 0.17 |

| 11 | 75 | 500 | 1000 | 10 | 1029.13 | 1.39 |

| 12 | 75 | 100 | 1500 | 5 | 967.14 | 0.95 |

| 13 | 75 | 500 | 2000 | 10 | 1018.74 | 0.71 |

| 14 | 100 | 100 | 1500 | 10 | 951.72 | 0.87 |

| 15 | 75 | 100 | 2000 | 10 | 866.58 | 0.59 |

| 16 | 75 | 300 | 1500 | 10 | 1213.24 | 0.14 |

| 17 | 75 | 300 | 1500 | 10 | 1210.68 | 0.15 |

| 18 | 100 | 300 | 1500 | 15 | 1130.29 | 0.28 |

| 19 | 50 | 100 | 1500 | 10 | 823.21 | 0.79 |

| 20 | 75 | 100 | 1500 | 15 | 876.68 | 0.38 |

| 21 | 75 | 100 | 1000 | 10 | 846.43 | 1.68 |

| 22 | 50 | 300 | 1500 | 5 | 1116.38 | 0.31 |

| 23 | 50 | 300 | 1500 | 15 | 783.26 | 2.19 |

| 24 | 75 | 300 | 2000 | 15 | 911.07 | 1.16 |

| 25 | 100 | 300 | 1500 | 5 | 1134.81 | 0.27 |

| 26 | 100 | 300 | 1000 | 10 | 997.85 | 1.06 |

| 27 | 75 | 500 | 1500 | 5 | 1053.11 | 0.73 |

| 28 | 50 | 300 | 1000 | 10 | 921.39 | 2.12 |

| 29 | 75 | 300 | 1000 | 5 | 1106.54 | 0.79 |

| Process Parameter | Stability Interval | Instability Interval |

|---|---|---|

| Temperature (°C) | (75 °C, 100 °C) | (50 °C, 75 °C) |

| Tension (N) | (300 N, 500 N) | (100 N, 300 N) |

| Force (N) | (1000 N, 2000 N) | |

| Speed (rpm) | (5 rpm, 10 rpm) | (10 rpm, 15 rpm) |

| Process Parameter | Stability Interval | Instability Interval |

|---|---|---|

| Temperature (°C) | (75 °C, 100 °C) | (50 °C, 75 °C) |

| Tension (N) | (100 N, 500 N) | |

| Force (N) | (1500 N, 2000 N) | (1000 N, 1500 N) |

| Speed (rpm) | (5 rpm, 10 rpm) | (10 rpm, 15 rpm) |

| Parameters | Range Division | Mean Objective Value (%) | Stability |

|---|---|---|---|

| The First Round of Optimization (5000 times) | |||

| Temperature | (50 °C, 75 °C) | 1035.333 | instability range |

| (75 °C, 100 °C) | 961.699 | ||

| Tension | (100 N, 300 N) | 1054.731 | instability range |

| (300 N, 500 N) | 944.352 | ||

| Speed | (5 rpm, 10 rpm) | 1014.125 | stability range |

| (10 rpm, 15 rpm) | 983.493 | ||

| The Second Round of Optimization (5000 times) | |||

| Tension | (100 N, 200 N) | 1045.158 | |

| (200 N, 300 N) | 1057.711 | stability range | |

| Temperature | (50 °C, 62.5 °C) | 1023.512 | |

| (62.5 °C, 75 °C) | 1049.634 | stability range | |

| Process Parameter | Optimized Interval |

|---|---|

| Temperature (°C) | (62.5 °C, 75 °C) |

| Tension (N) | (200N, 300N) |

| Force (N) | (1000 N, 2000 N) |

| Speed (rpm) | (5 rpm, 10 rpm) |

| Parameters | Range Division | Mean Objective Value (%) | Stability |

|---|---|---|---|

| The First Round of Optimization (5000 times) | |||

| Temperature | (50 °C, 75 °C) | 0.5207 | instability range |

| (75 °C, 100 °C) | 0.8418 | ||

| Force | (1000 N, 1500 N) | 0.8782 | |

| (1500 N, 2000 N) | 0.5518 | stability range | |

| Speed | (5 rpm, 10 rpm) | 0.5235 | stability range |

| (10 rpm, 15 rpm) | 0.8951 | ||

| The Second Round of Optimization (5000 times) | |||

| Temperature | (50 °C, 62.5 °C) | 0.6918 | |

| (62.5 °C, 75 °C) | 0.4807 | stability range | |

| Process Parameter | Optimized Interval |

|---|---|

| Temperature (°C) | (62.5 °C, 75 °C) |

| Tension (N) | (100 N, 500 N) |

| Force (N) | (1500 N, 2000 N) |

| Speed (rpm) | (5 rpm, 10 rpm) |

| Process Parameter | Optimized Interval |

|---|---|

| Temperature (°C) | (62.5 °C, 75 °C) |

| Tension (N) | (200 N, 300 N) |

| Force (N) | (1500 N, 2000 N) |

| Speed (rpm) | (5 rpm, 10 rpm) |

| No. | T (°C) | F (N) | P (N) | V (rpm) | Tensile Strength (MPa) | Void Content (%) | ||

|---|---|---|---|---|---|---|---|---|

| Simulation | Experiment | Simulation | Experiment | |||||

| 1 | 65 | 252 | 1621 | 6.8 | 1190.81 | 1220.57 | 0.139 | 0.14 |

| 2 | 69 | 235 | 1580 | 9.1 | 1167.96 | 1138.42 | 0.168 | 0.18 |

| 3 | 72 | 284 | 1874 | 7.2 | 1159.43 | 1195.61 | 0.148 | 0.16 |

| 4 | 58 | 373 | 1275 | 12.5 | 998.69 | 1002.84 | 1.427 | 1.38 |

| 5 | 79 | 169 | 1480 | 13.7 | 1012.48 | 996.70 | 0.523 | 0.57 |

| 6 | 92 | 452 | 1341 | 14.5 | 1032.12 | 1021.39 | 0.876 | 0.95 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, B.; Shi, Y.; Yu, T.; Kang, C.; Zhao, P. Multi-Response Parameter Interval Sensitivity and Optimization for the Composite Tape Winding Process. Materials 2018, 11, 220. https://doi.org/10.3390/ma11020220

Deng B, Shi Y, Yu T, Kang C, Zhao P. Multi-Response Parameter Interval Sensitivity and Optimization for the Composite Tape Winding Process. Materials. 2018; 11(2):220. https://doi.org/10.3390/ma11020220

Chicago/Turabian StyleDeng, Bo, Yaoyao Shi, Tao Yu, Chao Kang, and Pan Zhao. 2018. "Multi-Response Parameter Interval Sensitivity and Optimization for the Composite Tape Winding Process" Materials 11, no. 2: 220. https://doi.org/10.3390/ma11020220