Rheology–Microstructure Relationships in Melt-Processed Polylactide/Poly(vinylidene Fluoride) Blends

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing

2.3. Rheometry

2.4. Determination of Continuous Relaxation Spectra

2.5. Morphological Analysis

2.6. Dynamic Mechanical Analysis

3. Results

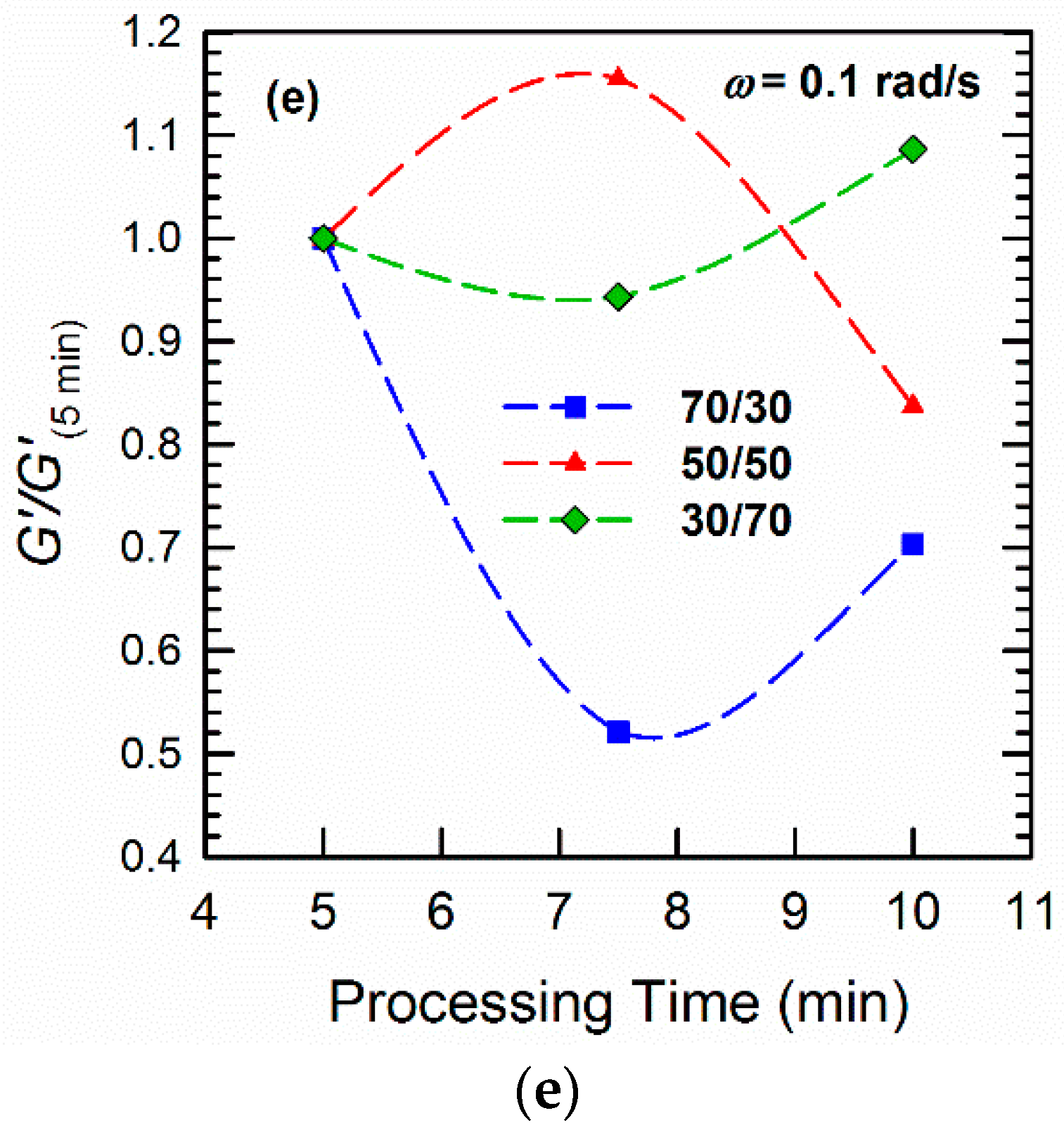

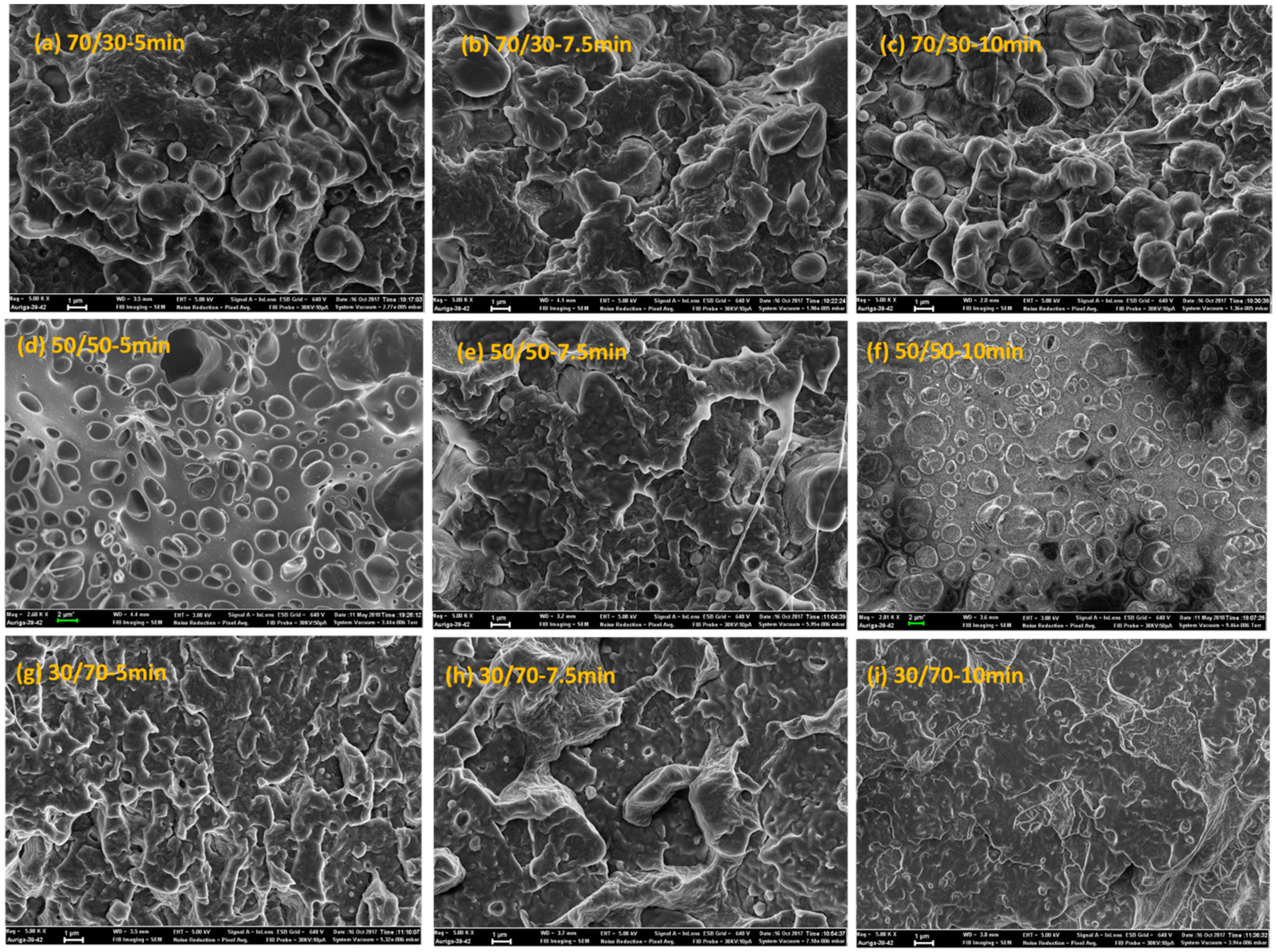

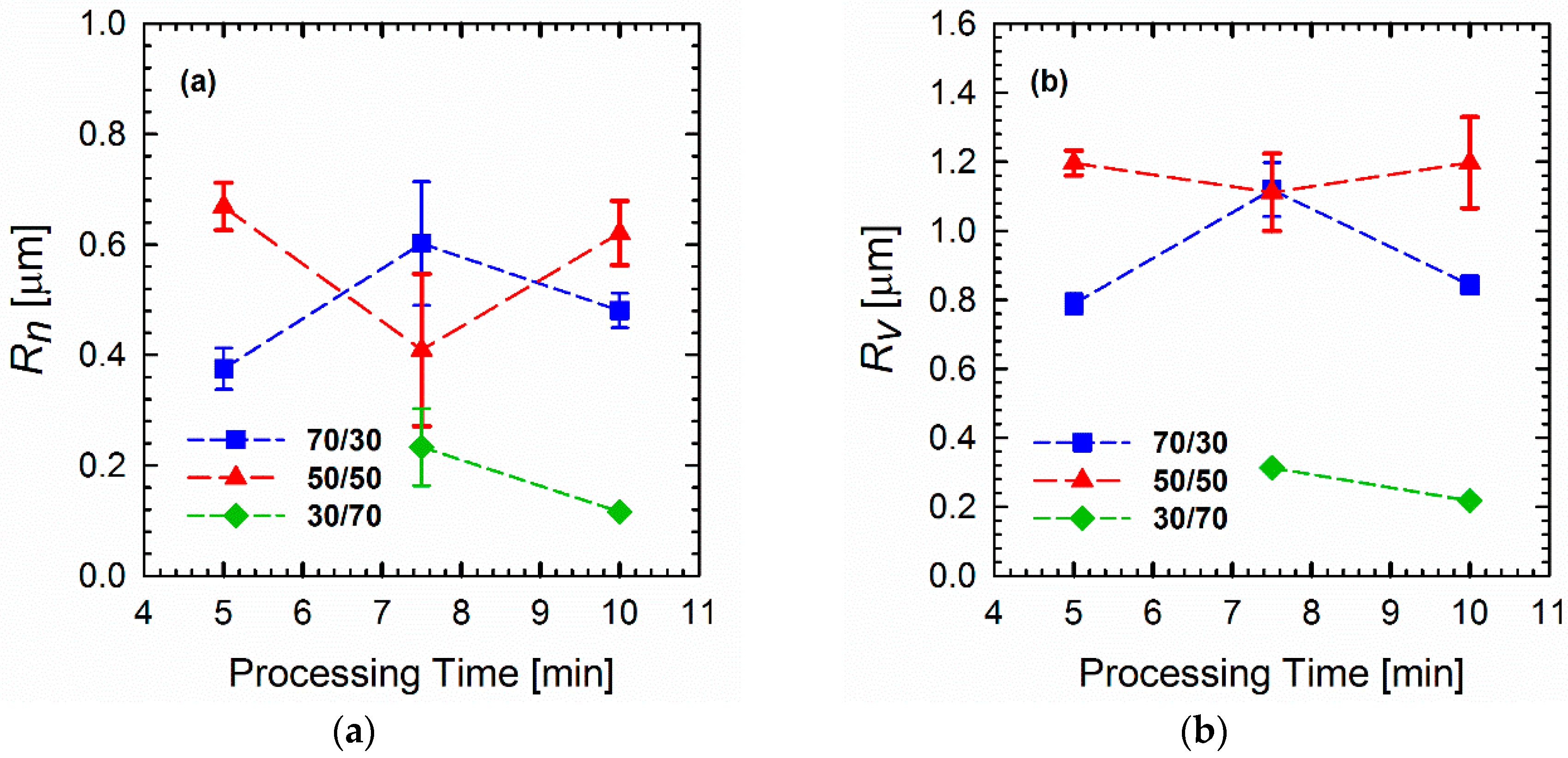

3.1. Small Amplitude Oscillatory Shear Tests

3.2. Van Gurp–Palmen Plots

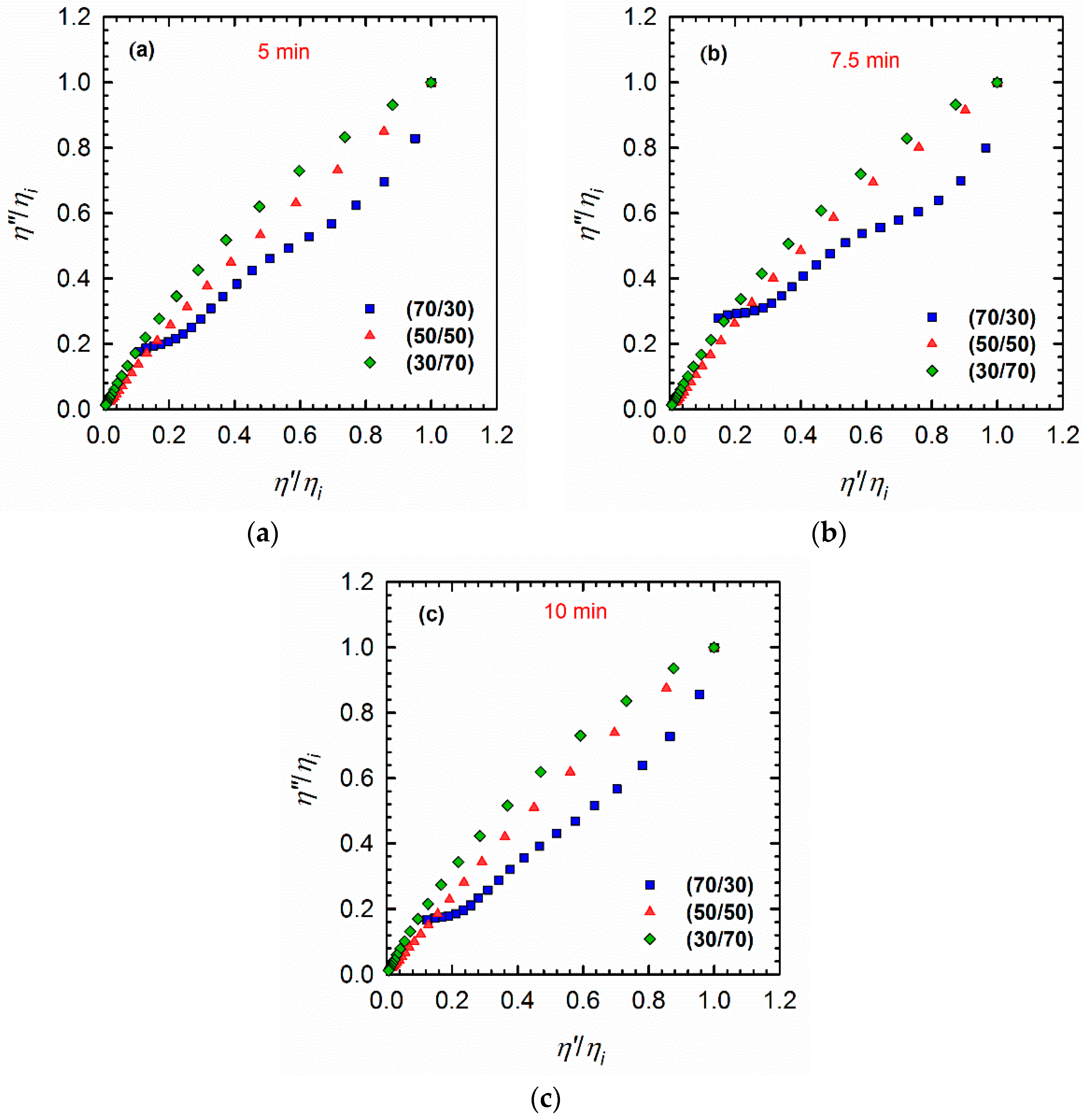

3.3. Cole–Cole Plots

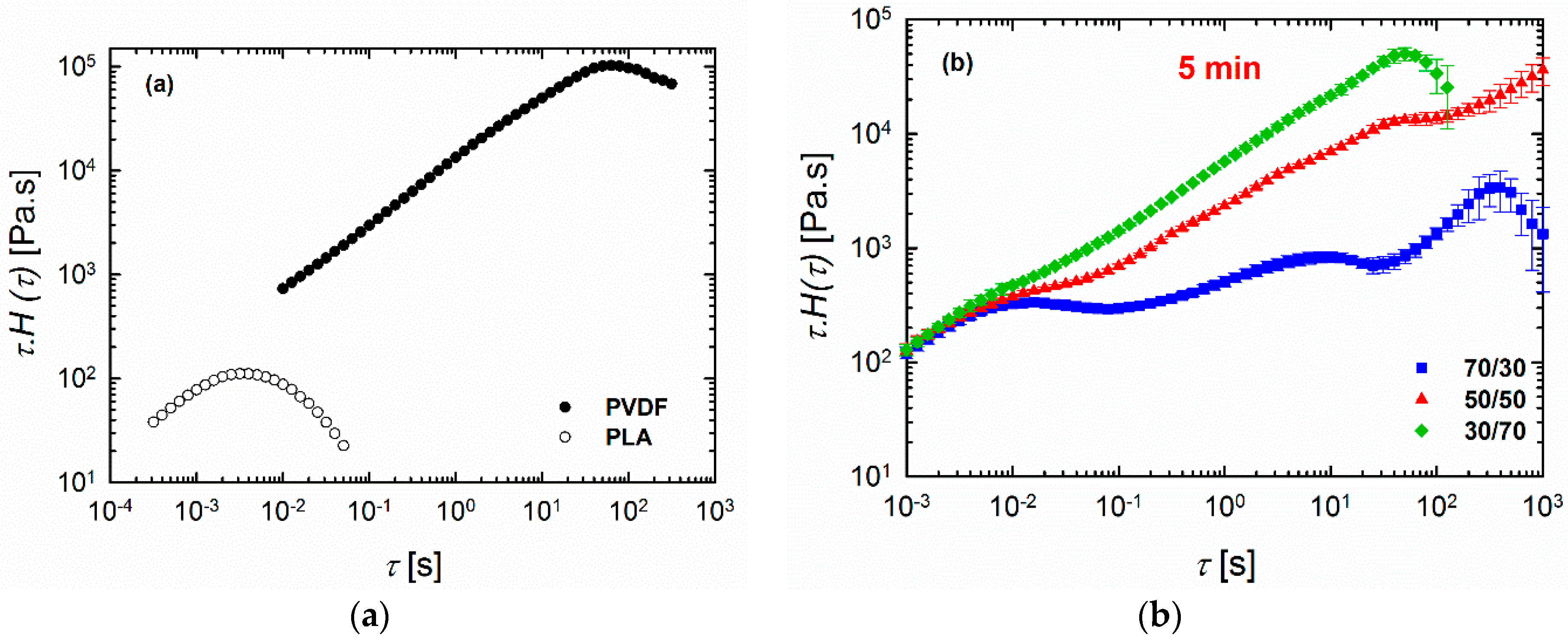

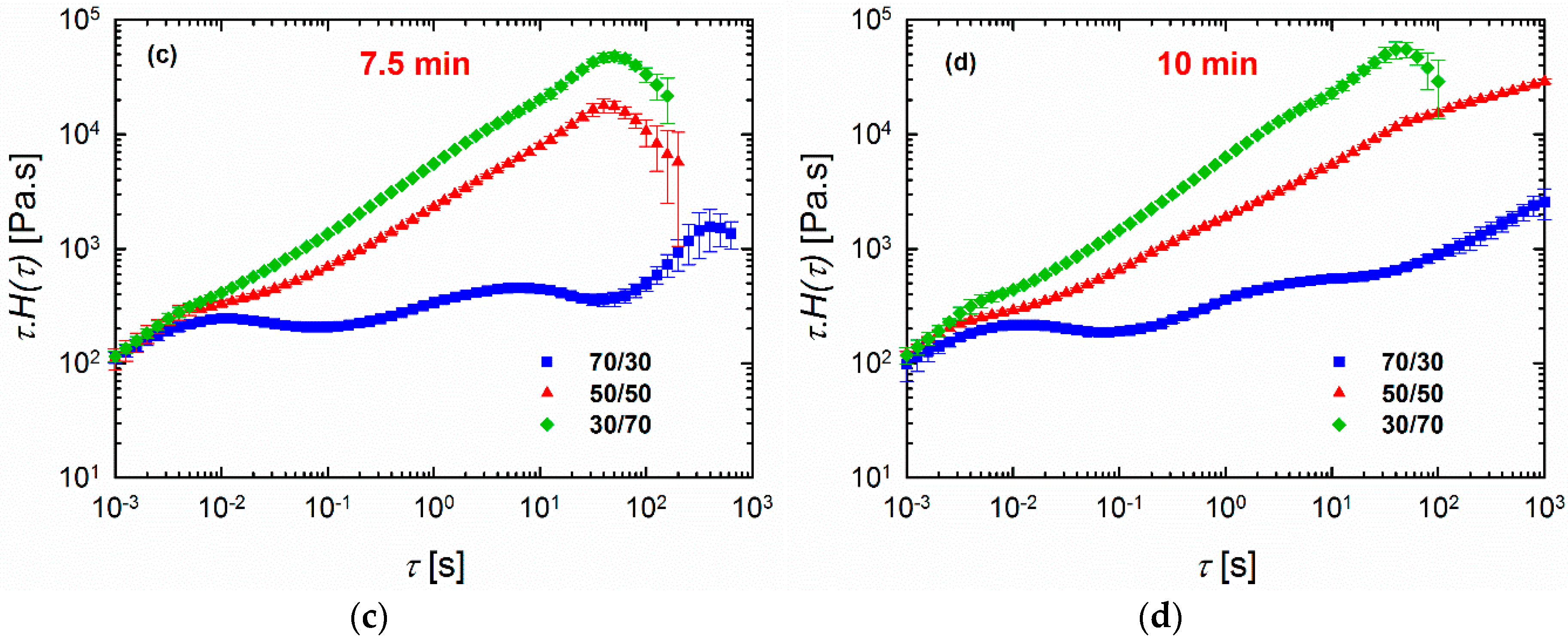

3.4. Relaxation Spectra

3.5. Interfacial Tension Analysis

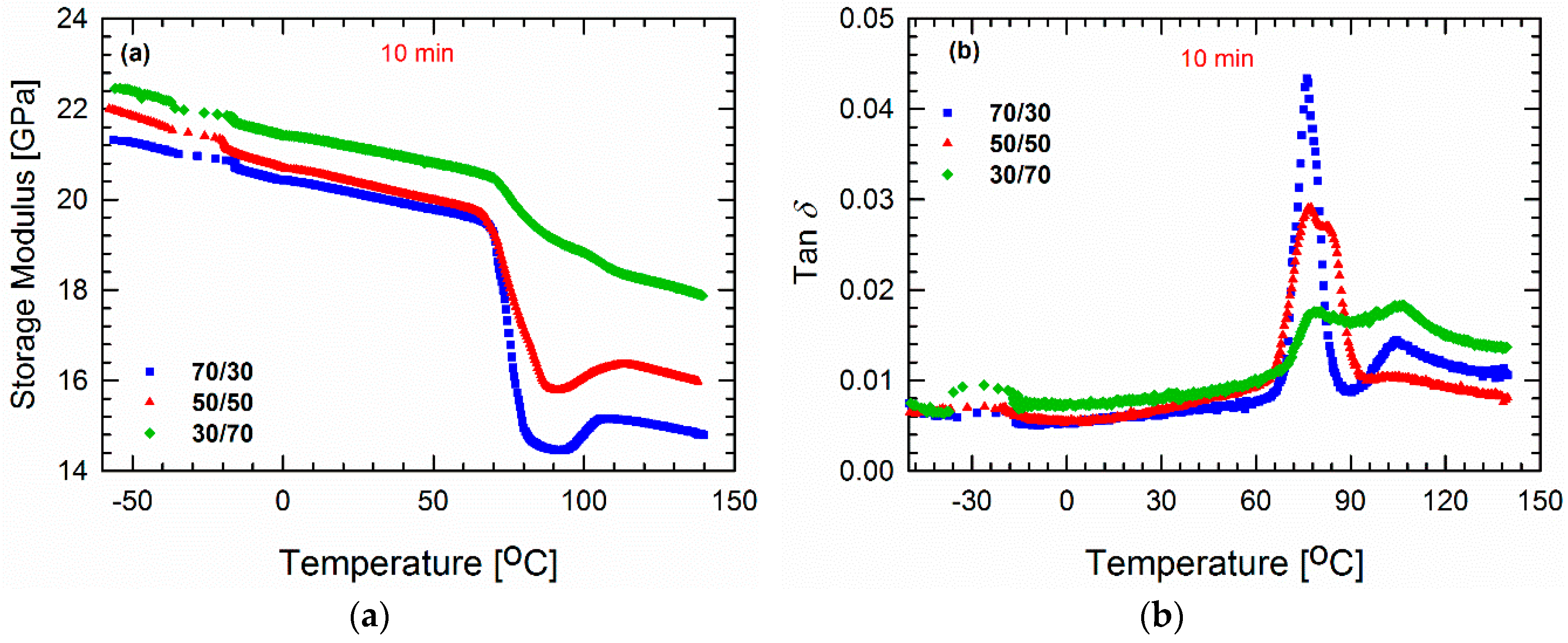

3.6. Dynamic Mechanical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Paul, D.; Walsh, D.; Higgins, J. Polymer Blends and Mixtures; Springer: Berlin, Germany, 1985. [Google Scholar]

- Salehiyan, R.; Song, H.Y.; Hyun, K. Nonlinear behavior of PP/PS blends with and without clay under large amplitude oscillatory shear (LAOS) flow. Korea. Aust. Rheol. J. 2015, 27, 95–103. [Google Scholar] [CrossRef]

- Ziegler, V.; Wolf, B.A. Viscosity and morphology of the two-phase system PDMS/P (DMS-ran-MPS). J. Rheol. 1999, 43, 1033–1045. [Google Scholar] [CrossRef]

- Jafari, S.-H.; Hesabi, M.-N.; Khonakdar, H.A.; Asl-Rahimi, M. Correlation of rheology and morphology and estimation of interfacial tension of immiscible COC/EVA blends. J. Polym. Res. 2011, 18, 821–831. [Google Scholar] [CrossRef]

- Utracki, L. On the viscosity-concentration dependence of immiscible polymer blends. J. Rheol. 1991, 35, 1615–1637. [Google Scholar] [CrossRef]

- Van Puyvelde, P.; Moldenaers, P. Rheology and morphology development in immiscible polymer blends. Rheol. Rev. 2005, 2005, 101. [Google Scholar]

- Khalili, R.; Jafari, S.H.; Saeb, M.R.; Khonakdar, H.A.; Wagenknecht, U.; Heinrich, G. Toward in situ compatibilization of polyolefin ternary blends through morphological manipulations. Macromol. Mater. Eng. 2014, 299, 1197–1212. [Google Scholar] [CrossRef]

- Yousfi, M.; Soulestin, J.; Vergnes, B.; Lacrampe, M.F.; Krawczak, P. Compatibilization of immiscible polymer blends by organoclay: Effect of nanofiller or organo-modifier? Macromol. Mater. Eng. 2013, 298, 757–770. [Google Scholar] [CrossRef]

- Salehiyan, R.; Choi, W.J.; Lee, J.H.; Hyun, K. Effects of mixing protocol and mixing time on viscoelasticity of compatibilized PP/PS blends. Korea Aust. Rheol. J. 2014, 26, 311–318. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Q.; Fu, Q. Compatibilization of immiscible poly (propylene)/polystyrene blends using clay. Macromol. Rapid Commun. 2003, 24, 231–235. [Google Scholar] [CrossRef]

- Cho, S.; Hong, J.S.; Lee, S.J.; Ahn, K.H.; Covas, J.A.; Maia, J.M. Morphology and rheology of polypropylene/polystyrene/clay nanocomposites in batch and continuous melt mixing processes. Macromol. Mater. Eng. 2011, 296, 341–348. [Google Scholar] [CrossRef]

- Jiang, G.; Huang, H.-X.; Chen, Z.-K. Rheological responses and morphology of polylactide/linear low density polyethylene blends produced by different mixing type. Polym. Plast. Technol. Eng. 2011, 50, 1035–1039. [Google Scholar] [CrossRef]

- Salehiyan, R.; Ray, S.S. Influence of nanoclay localization on structure-property relationships of polylactide-based biodegradable blend nanocomposites. Macromol. Mater. Eng. 2018, 303, 1800134. [Google Scholar] [CrossRef]

- Nofar, M.; Maani, A.; Sojoudi, H.; Heuzey, M.C.; Carreau, P.J. Interfacial and rheological properties of PLA/PBAT and PLA/PBSA blends and their morphological stability under shear flow. J. Rheol. 2015, 59, 317–333. [Google Scholar] [CrossRef]

- Nam, J.Y.; Okamoto, M.; Okamoto, H.; Nakano, M.; Usuki, A.; Matsuda, M. Morphology and crystallization kinetics in a mixture of low-molecular weight aliphatic amide and polylactide. Polymer 2006, 47, 1340–1347. [Google Scholar] [CrossRef]

- Nofar, M.; Heuzey, M.C.; Carreau, P.J.; Kamal, M.R. Effects of nanoclay and its localization on the morphology stabilization of PLA/PBAT blends under shear flow. Polymer 2016, 98, 353–364. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, Y.; Zhang, M.; Zhou, W. Phase behavior and its viscoelastic response of polylactide/poly(ε-caprolactone) blend. Eur. Polym. J. 2008, 44, 2171–2183. [Google Scholar] [CrossRef]

- Bai, L.; He, S.; Fruehwirth, J.W.; Stein, A.; Macosko, C.W.; Cheng, X. Localizing graphene at the interface of cocontinuous polymer blends: Morphology, rheology, and conductivity of cocontinuous conductive polymer composites. J. Rheol. 2017, 61, 575–587. [Google Scholar] [CrossRef]

- Deng, Y.; Thomas, N.L. Blending poly (butylene succinate) with poly (lactic acid): Ductility and phase inversion effects. Eur. Polym. J. 2015, 71, 534–546. [Google Scholar] [CrossRef] [Green Version]

- Salehiyan, R.; Ray, S.S.; Bandyopadhyay, J.; Ojijo, V. The distribution of nanoclay particles at the interface and their influence on the microstructure development and rheological properties of reactively processed biodegradable polylactide/poly(butylene succinate) blend nanocomposites. Polymers 2017, 9, 350. [Google Scholar] [CrossRef]

- Salehiyan, R.; Ray, S.S.; Ojijo, V. Process Driven Morphology Developement and Crystallization Behaviour of Immiscible Polylactic acid/Polyvinylidene fluoride (PLA/PVDF) blends. Macromol. Mater. Eng. 2018, 1800349. [Google Scholar] [CrossRef]

- Xie, Q.; Ke, K.; Jiang, W.R.; Yang, W.; Liu, Z.Y.; Xie, B.H.; Yang, M.B. Role of poly (lactic acid) in the phase transition of poly (vinylidene fluoride) under uniaxial stretching. J. Appl. Polym. Sci. 2013, 129, 1686–1696. [Google Scholar] [CrossRef]

- Wang, H.; Yang, X.; Fu, Z.; Zhao, X.; Li, Y.; Li, J. Rheology of nanosilica-compatibilized immiscible polymer blends: Formation of a “heterogeneous network” facilitated by interfacially anchored hybrid nanosilica. Macromolecules 2017, 50, 9494–9506. [Google Scholar] [CrossRef]

- Stadler, F.J.; Bailly, C. A new method for the calculation of continuous relaxation spectra from dynamic-mechanical data. Rheol. Acta 2009, 48, 33–49. [Google Scholar] [CrossRef]

- Baumgaertel, M.; Winter, H.H. Determination of discrete relaxation and retardation time spectra from dynamic mechanical data. Rheol. Acta 1989, 28, 511–519. [Google Scholar] [CrossRef]

- Stadler, F.J. Effect of incomplete datasets on the calculation of continuous relaxation spectra from dynamic-mechanical data. Rheol. Acta 2010, 49, 1041–1057. [Google Scholar] [CrossRef]

- Kong, M.; Huang, Y.; Lv, Y.; Wang, S.; Yang, Q.; Li, G. Flow-induced morphological instability in nanosilica-filled polyamide 6/polystyrene blends. Polymer 2014, 55, 4348–4357. [Google Scholar] [CrossRef]

- Fenouillot, F.; Cassagnau, P.; Majesté, J.C. Uneven distribution of nanoparticles in immiscible fluids: Morphology development in polymer blends. Polymer 2009, 50, 1333–1350. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Nunez, R.; Favis, B.; Carreau, P.; Lavallee, C. Factors influencing the formation of elongated morphologies in immiscible polymer blends during melt processing. Polym. Eng. Sci. 1993, 33, 851–859. [Google Scholar] [CrossRef]

- Li, R.; Yu, W.; Zhou, C. Rheological characterization of droplet-matrix versus co-continuous morphology. J. Macromol. Sci. B 2006, 45, 889–898. [Google Scholar] [CrossRef]

- López-Barrón, C.R.; Macosko, C.W. Rheology of compatibilized immiscible blends with droplet-matrix and cocontinuous morphologies during coarsening. J. Rheol. 2014, 58, 1935–1953. [Google Scholar] [CrossRef]

- Liu, D.; Li, W.; Zhang, N.; Huang, T.; Yang, J.; Wang, Y. Graphite oxide-driven miscibility in PVDF/PMMA blends: Assessment through dynamic rheology method. Eur. Polym. J. 2017, 96, 232–247. [Google Scholar] [CrossRef]

- Ajji, A.; Choplin, L.; Prud Homme, R.E. Rheology of polystyrene/poly(vinyl methyl ether)blends near the phase transition. J. Polym. Sci. B Polym. Phys. 1991, 29, 1573–1578. [Google Scholar] [CrossRef]

- Ding, Y.; Lu, B.; Wang, P.; Wang, G.; Ji, J. PLA-PBAT-PLA tri-block copolymers: Effective compatibilizers for promotion of the mechanical and rheological properties of pla/pbat blends. Polym. Degrad. Stab. 2018, 147, 41–48. [Google Scholar] [CrossRef]

- López-Barrón, C.R.; Macosko, C.W. Rheological and morphological study of cocontinuous polymer blends during coarsening. J. Rheol. 2012, 56, 1315–1334. [Google Scholar] [CrossRef]

- Soo Cho, K.; Woo Park, G. Fixed-point iteration for relaxation spectrum from dynamic mechanical data. J. Rheol. 2013, 57, 647–678. [Google Scholar] [CrossRef]

- Saito, H.; Takahashi, M.; Inoue, T. Cooperative chain relaxation in miscible polymer blends. J. Polym. Sci. B Polym. Phys. 1988, 26, 1761–1768. [Google Scholar] [CrossRef]

- Saito, H.; Takahashi, M.; Inoue, T. Chain relaxation behavior in single-phase mixtures of dissimilar polymers. Macromolecules 1991, 24, 6536–6538. [Google Scholar] [CrossRef]

- Saito, H.; Miyashita, H.; Inoue, T. Cooperative chain relaxation in a single-phase mixture of dissimilar polymers: Definition and implication of the cooperativity. Macromolecules 1992, 25, 1824–1827. [Google Scholar] [CrossRef]

- Mijovic, J.; Sy, J.-W.; Kwei, T. Reorientational dynamics of dipoles in poly (vinylidene fluoride)/poly (methyl methacrylate)(PVDF/PMMA) blends by dielectric spectroscopy. Macromolecules 1997, 30, 3042–3050. [Google Scholar] [CrossRef]

- Bousmina, M. Effect of interfacial tension on linear viscoelastic behavior of immiscible polymer blends. Rheol. Acta 1999, 38, 251–254. [Google Scholar] [CrossRef]

- Graebling, D.; Muller, R.; Palierne, J. Linear viscoelasticity of incompatible polymer blends in the melt in relation with interfacial properties. J. Phys. IV 1993, 3, 1525–1534. [Google Scholar] [CrossRef]

- Gramespacher, H.; Meissner, J. Interfacial tension between polymer melts measured by shear oscillations of their blends. J. Rheol. 1992, 36, 1127–1141. [Google Scholar] [CrossRef]

- Palierne, J. Linear rheology of viscoelastic emulsions with interfacial tension. Acta. 1990, 29, 204–214. [Google Scholar] [CrossRef]

- Gui, Z.Y.; Wang, H.R.; Gao, Y.; Lu, C.; Cheng, S.J. Morphology and melt rheology of biodegradable poly (lactic acid)/poly (butylene succinate adipate) blends: effect of blend compositions. Iran. Polym. J. 2012, 21, 81–89. [Google Scholar] [CrossRef]

- Kwon, M.K.; Cho, K.S. Analysis of the Palierne model by relaxation time spectrum. Korea Aust. Rheol. J. 2016, 28, 23–31. [Google Scholar] [CrossRef]

- Maani, A.; Blais, B.; Heuzey, M.C.; Carreau, P.J. Rheological and morphological properties of reactively compatibilized thermoplastic olefin (TPO) blends. J. Rheol. 2012, 56, 625–647. [Google Scholar] [CrossRef]

- Wang, H.; Dong, W.; Li, Y. Compatibilization of immiscible polymer blends using in situ formed janus nanomicelles by reactive blending. ACS Macro Lett. 2015, 4, 1398–1403. [Google Scholar] [CrossRef]

- Wang, H.; Fu, Z.; Dong, W.; Li, Y.; Li, J. Formation of interfacial janus nanomicelles by reactive blending and their compatibilization effects on immiscible polymer blends. J. Phys. Chem. B 2016, 120, 9240–9252. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Fu, Z.; Zhao, X.; Li, Y.; Li, J. Reactive nanoparticles compatibilized immiscible polymer blends: Synthesis of reactive SiO2 with long poly (methyl methacrylate) chains and the in situ formation of janus SiO2 nanoparticles anchored exclusively at the interface. ACS Appl. Mater. Interfaces 2017, 9, 14358–14370. [Google Scholar] [CrossRef] [PubMed]

- Pawde, S.; Bhat, N. Thermal analysis of poly (vinylidene fluoride)(PVDF) in composites with polypyrrole (PPY). J. Appl. Polym. Sci. 1994, 54, 201–205. [Google Scholar] [CrossRef]

- Sencadas, V.; Lanceros-Mendez, S.; Mano, J. Characterization of poled and non-poled β-pvdf films using thermal analysis techniques. Thermochim. Acta 2004, 424, 201–207. [Google Scholar] [CrossRef] [Green Version]

- Vidhate, S.; Shaito, A.; Chung, J.; D’Souza, N.A. Crystallization, mechanical, and rheological behavior of polyvinylidene fluoride/carbon nanofiber composites. J. Appl. Polym. Sci. 2009, 112, 254–260. [Google Scholar] [CrossRef]

- Mano, J.; Sencadas, V.; Costa, A.M.; Lanceros-Méndez, S. Dynamic mechanical analysis and creep behaviour of β-pvdf films. Mater. Sci. Eng. A 2004, 370, 336–340. [Google Scholar] [CrossRef] [Green Version]

- Mofokeng, T.G.; Luyt, A.S.; Pavlović, V.P.; Pavlović, V.B.; Dudić, D.; Vlahović, B.; Djoković, V. Ferroelectric nanocomposites of polyvinylidene fluoride/polymethyl methacrylate blend and batio3 particles: Fabrication of β-crystal polymorph rich matrix through mechanical activation of the filler. J. Appl. Phys. 2014, 115, 084109. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Salehiyan, R.; Yussuf, A.A.; Hanani, N.F.; Hassan, A.; Akbari, A. Polylactic acid/polycaprolactone nanocomposite: Influence of montmorillonite and impact modifier on mechanical, thermal, and morphological properties. J. Elastomers Plast. 2015, 47, 69–87. [Google Scholar] [CrossRef]

- Okamoto, N.; Oguni, M. Discovery of crystal nucleation proceeding much below the glass transition temperature in a supercooled liquid. Solid State Commun. 1996, 99, 53–56. [Google Scholar] [CrossRef]

- Hikima, T.; Hanaya, M.; Oguni, M. Microscopic observation of a peculiar crystallization in the glass transition region and β-process as potentially controlling the growth rate in triphenylethylene. J. Mol. Struct. 1999, 479, 245–250. [Google Scholar] [CrossRef]

| Blend | * | * | D | |||

|---|---|---|---|---|---|---|

| (70/30) | 14.44 | 86.27 | 5 | 0.84 ± 0.03 | 0.48 ± 0.04 | 1.76 ± 0.17 |

| (50/50) | 25.57 | 72.80 | 50 | 1.19 ± 0.18 | 0.62 ± 0.08 | 1.93 ± 0.21 |

| (30/70) | 5.12 | 9.86 | 50 | 0.21 ± 0.00 | 0.11 ± 0.00 | 1.86 ± 0.12 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salehiyan, R.; Ray, S.S.; Stadler, F.J.; Ojijo, V. Rheology–Microstructure Relationships in Melt-Processed Polylactide/Poly(vinylidene Fluoride) Blends. Materials 2018, 11, 2450. https://doi.org/10.3390/ma11122450

Salehiyan R, Ray SS, Stadler FJ, Ojijo V. Rheology–Microstructure Relationships in Melt-Processed Polylactide/Poly(vinylidene Fluoride) Blends. Materials. 2018; 11(12):2450. https://doi.org/10.3390/ma11122450

Chicago/Turabian StyleSalehiyan, Reza, Suprakas Sinha Ray, Florian J. Stadler, and Vincent Ojijo. 2018. "Rheology–Microstructure Relationships in Melt-Processed Polylactide/Poly(vinylidene Fluoride) Blends" Materials 11, no. 12: 2450. https://doi.org/10.3390/ma11122450