Giant Strain and Induced Ferroelectricity in Amorphous BaTiO3 Films under Poling

Abstract

:1. Introduction

2. Experimental

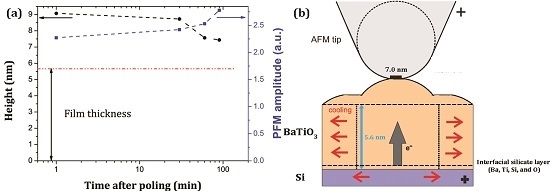

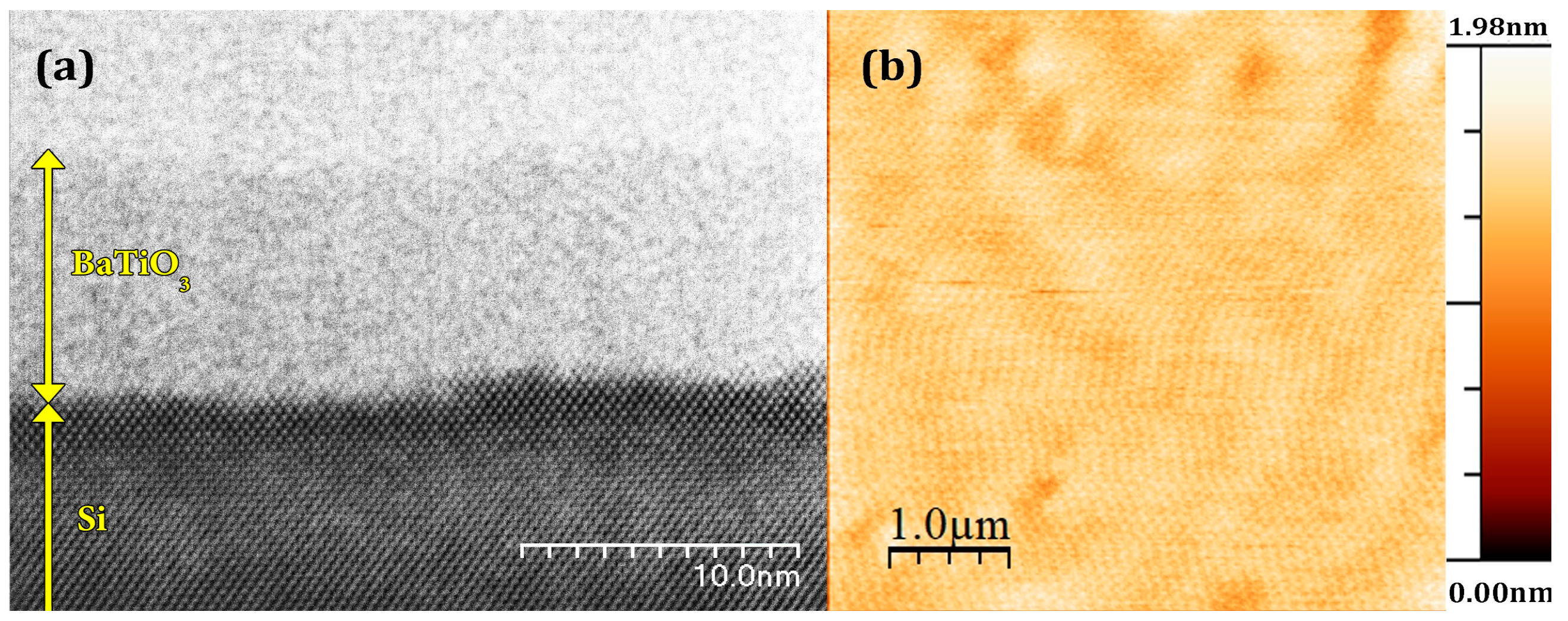

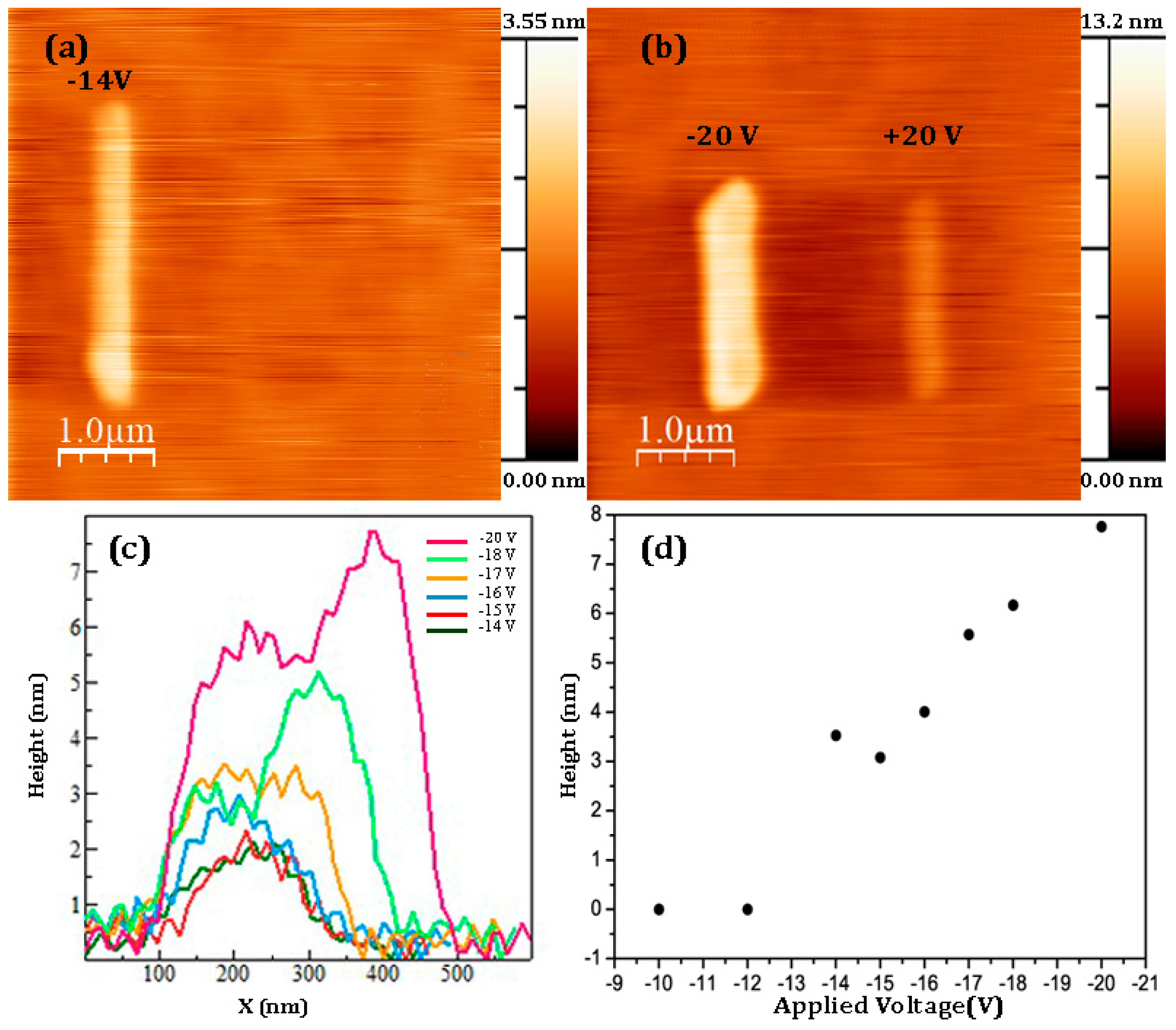

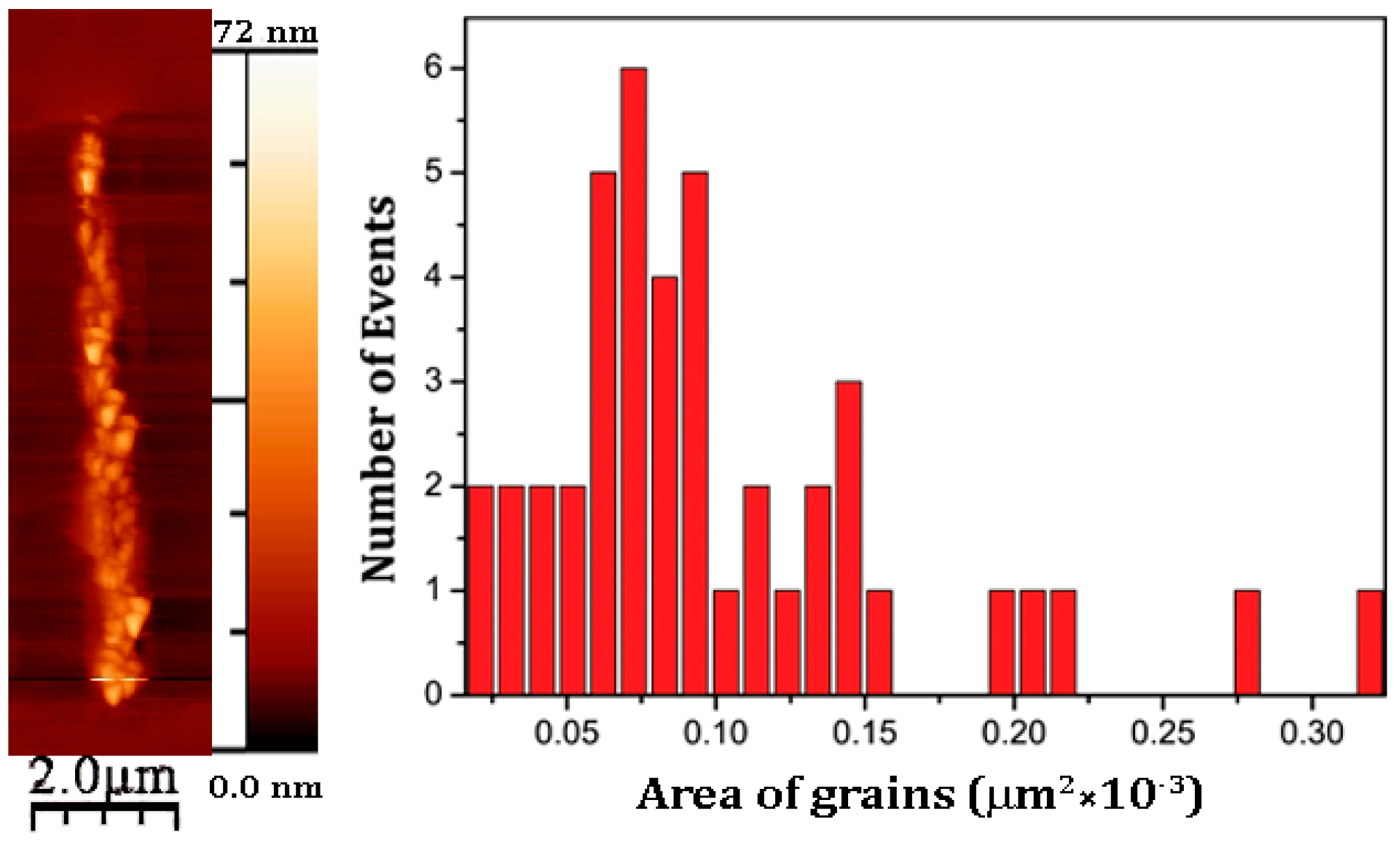

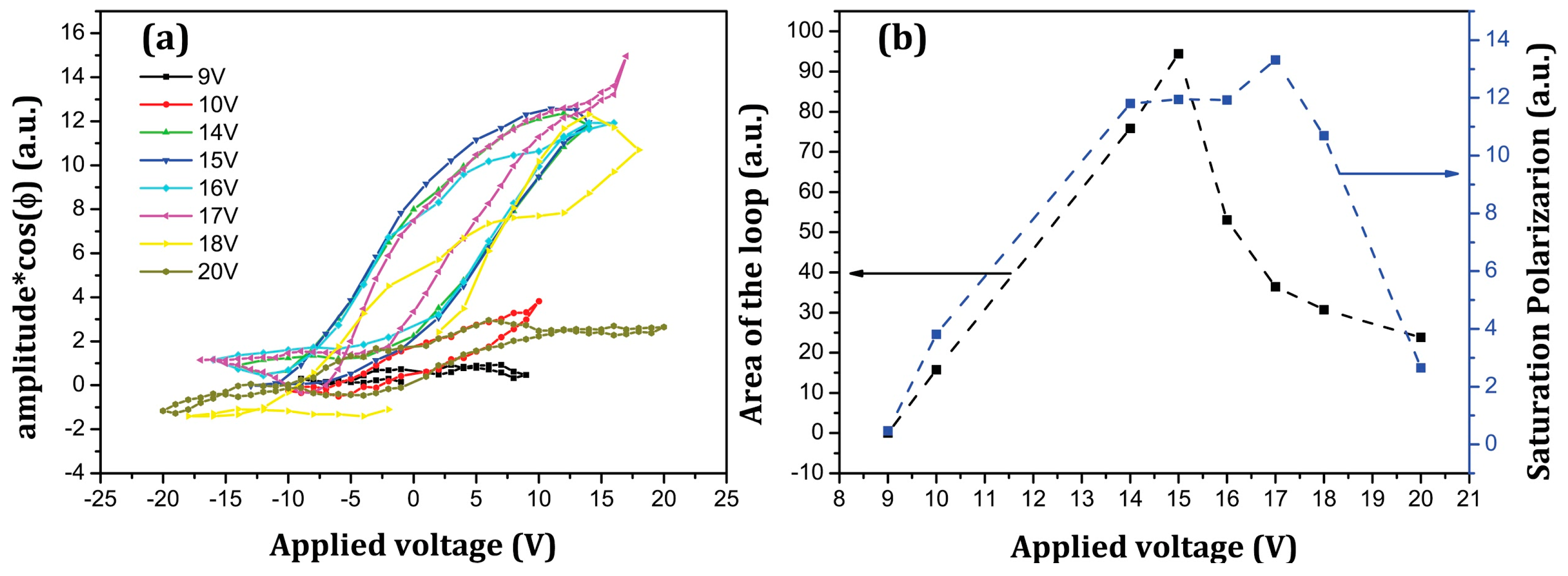

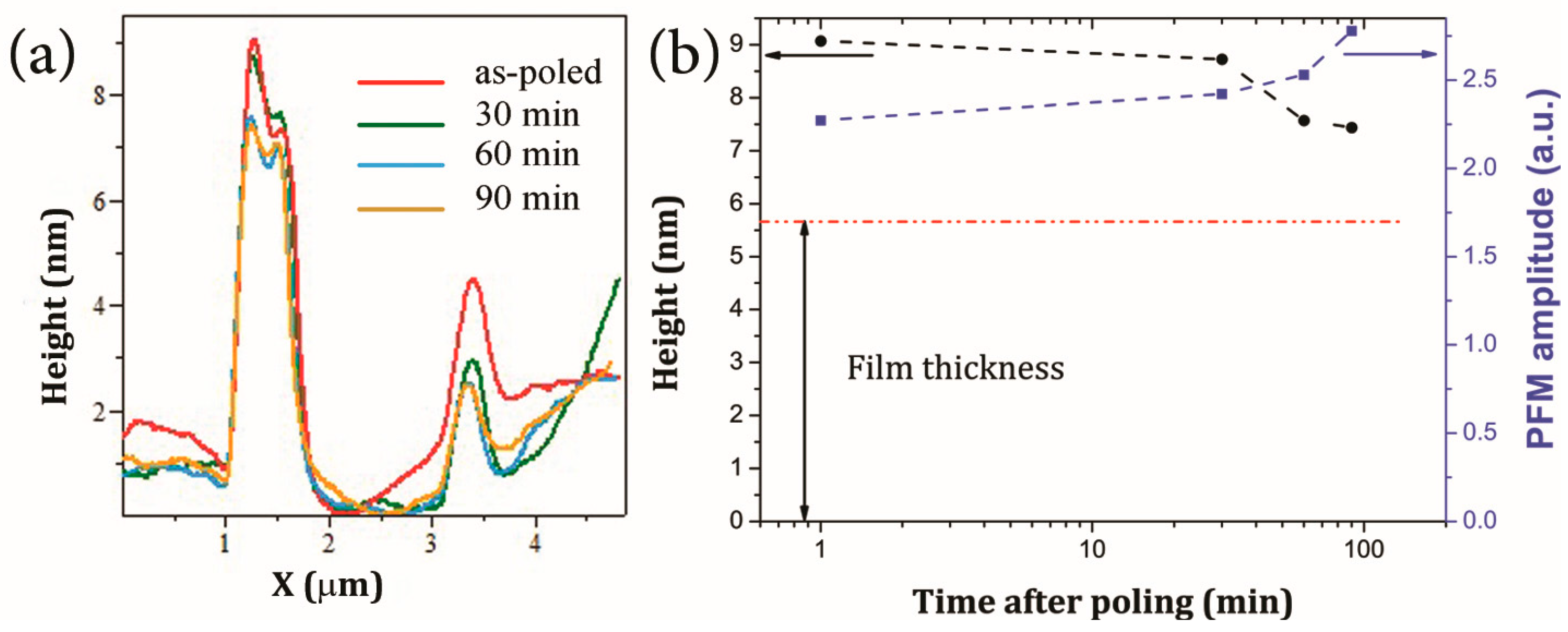

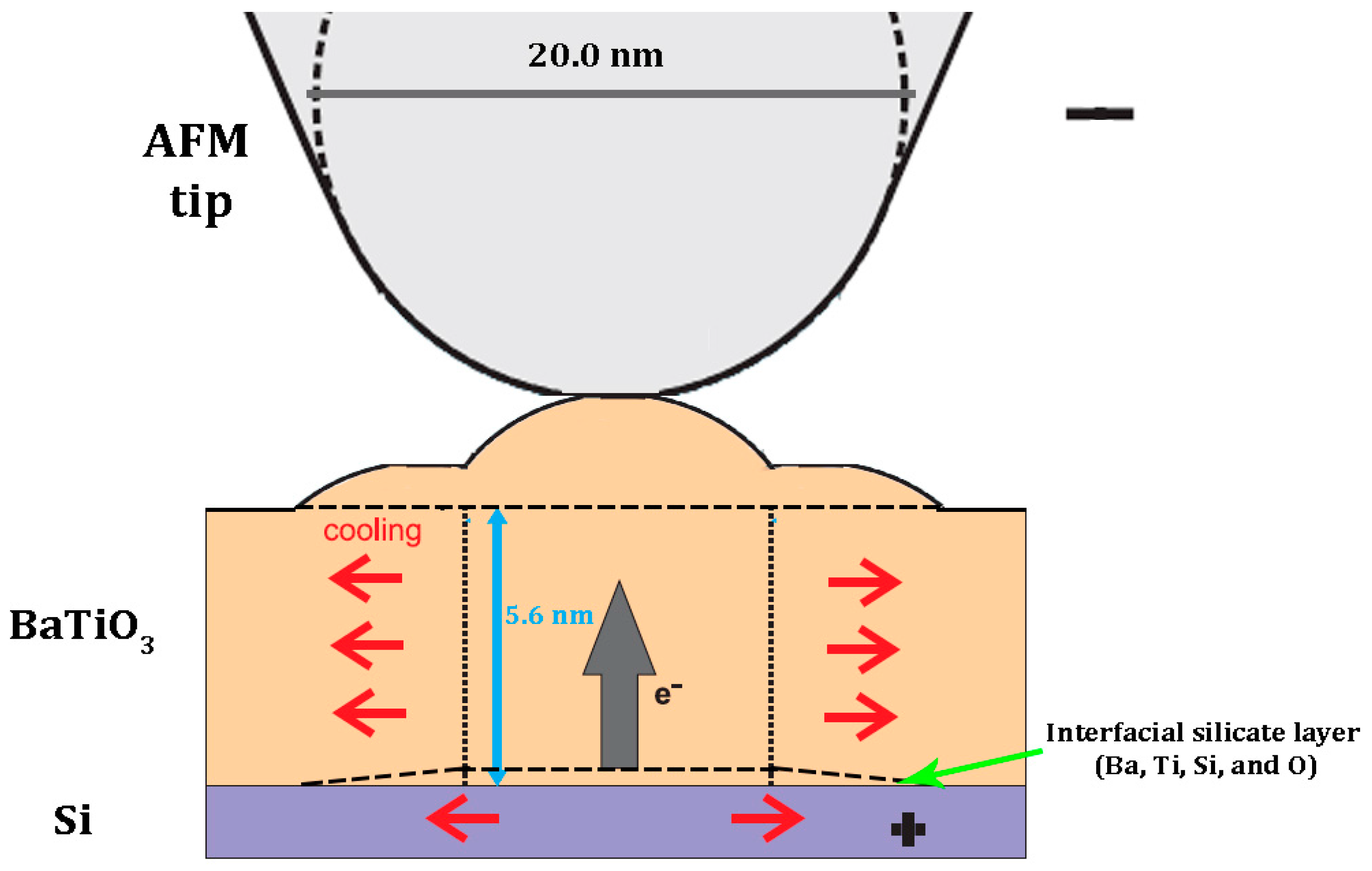

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gates, B.D.; Xu, Q.B.; Love, J.C.; Wolfe, D.B.; Whitesides, G.M. Unconventional nanofabrication. Ann. Rev. Mater. Res. 2004, 34, 339–372. [Google Scholar] [CrossRef]

- Gates, B.D.; Xu, Q.B.; Stewart, M.; Ryan, D.; Willson, C.G.; Whitesides, G.M. New approaches to nanofabrication: Molding, printing, and other techniques. Chem. Rev. 2005, 105, 1171–1196. [Google Scholar] [CrossRef] [PubMed]

- Cavallini, M.; Biscarini, F.; Leon, S.; Zerbetto, F.; Bottari, G.; Leigh, D.A. Information storage using supramolecular surface patterns. Science 2003, 299, 531. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luthi, R.; Schlittler, R.R.; Brugger, J.; Vettiger, P.; Welland, M.E.; Gimzewski, J.K. Parallel nanodevice fabrication using a combination of shadow mask and scanning probe methods. Appl. Phys. Lett. 1999, 75, 1314–1316. [Google Scholar] [CrossRef]

- Yan, X.M.; Contreras, A.M.; Koebel, M.M.; Liddle, J.A.; Somorjai, G.A. Parallel fabrication of sub-50-nm uniformly sized nanoparticles by deposition through a patterned silicon nitride nanostencil. Nano Lett. 2005, 5, 1129–1134. [Google Scholar] [CrossRef] [PubMed]

- Ginger, D.S.; Zhang, H.; Mirkin, C.A. The evolution of dip-pen nanolithography. Angew. Chem. Int. Ed. 2004, 43, 30–45. [Google Scholar] [CrossRef] [PubMed]

- Piner, R.D.; Zhu, J.; Xu, F.; Hong, S.H.; Mirkin, C.A. “Dip-pen” nanolithography. Science 1999, 283, 661–663. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.N.; Whitesides, G.M. Soft lithography. Angew. Chem. Int. Ed. 1998, 37, 550–575. [Google Scholar] [CrossRef]

- Cedeno, C.C.; Seekamp, J.; Kam, A.P.; Hoffmann, T.; Zankovych, S.; Torres, C.M.S.; Menozzi, C.; Cavallini, M.; Murgia, M.; Ruani, G.; et al. Nanoimprint lithography for organic electronics. Microelectron. Eng. 2002, 61–62, 25–31. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Birkin, P.R.; Ghanem, M.A. Electrochemical deposition of macroporous platinum, palladium and cobalt films using polystyrene latex sphere templates. Chem. Commun. 2000, 17, 1671–1672. [Google Scholar] [CrossRef]

- Haynes, C.L.; Van Duyne, R.P. Fabrication and optical properties of angle-resolved nanostructures. Abstr. Pap. Am. Chem. Soc. 2001, 222, U89. [Google Scholar]

- Hulteen, J.C.; Treichel, D.A.; Smith, M.T.; Duval, M.L.; Jensen, T.R.; Van Duyne, R.P. Nanosphere lithography: Size-tunable silver nanoparticle and surface cluster arrays. J. Phys. Chem. B 1999, 103, 3854–3863. [Google Scholar] [CrossRef]

- Cavallini, M.; Albonetti, C.; Biscarini, F. Nanopatterning soluble multifunctional materials by unconventional wet lithography. Adv. Mater. 2009, 21, 1043–1053. [Google Scholar] [CrossRef]

- Cavallini, M.; Biscarini, F.; Gomez-Segura, J.; Ruiz, D.; Veciana, J. Multiple length scale patterning of single-molecule magnets. Nano Lett. 2003, 3, 1527–1530. [Google Scholar] [CrossRef]

- Si, S.; Hoffmann, M. Consecutive imprinting performance of large area UV nanoimprint lithography using Bi-layer soft stamps in ambient atmosphere. Microelectron. Eng. 2017, 176, 62–70. [Google Scholar] [CrossRef]

- Kim, J.; Chmielak, B.; Lerch, H.; Plachetka, U. Fabrication of photonic integrated circuits in silicon nitride using substrate conformal imprint lithography. Microelectron. Eng. 2017, 176, 11–14. [Google Scholar] [CrossRef]

- Simeone, F.C.; Albonetti, C.; Cavallini, M. Progress in micro- and nanopatterning via electrochemical lithography. J. Phys. Chem. C 2009, 113, 18987–18994. [Google Scholar] [CrossRef]

- Kalinin, S.V.; Bonnell, D.A.; Alvarez, T.; Lei, X.J.; Hu, Z.H.; Shao, R.; Ferris, J.H. Ferroelectric lithography of multicomponent nanostructures. Adv. Mater. 2004, 16, 795–799. [Google Scholar] [CrossRef]

- Zhu, G.; Xu, J.; Zeng, Z.; Zhang, L.; Yan, X.; Li, J. Electric field dependence of topography in ferroelectric P(VDF/TrFE) films. Appl. Surf. Sci. 2006, 253, 2498–2501. [Google Scholar] [CrossRef]

- Kalinin, S.V.; Jesse, S.; Tselev, A.; Baddorf, A.P.; Balke, N. The Role of electrochemical phenomena in scanning probe microscopy of ferroelectric thin films. ACS Nano 2011, 5, 5683–5691. [Google Scholar] [CrossRef] [PubMed]

- Rezek, B.; Sipek, E.; Ledinsky, M.; Stuchlik, J.; Vetushka, A.; Kocka, J. Creating nanocrystals in amorphous silicon using a conductive tip. Nanotechnology 2009, 20. [Google Scholar] [CrossRef] [PubMed]

- Kwak, B.S.; Zhang, K.; Boyd, E.P.; Erbil, A.; Wilkens, B.J. Metalloorganic chemical vapor deposition of BaTiO3 thin films. J. Appl. Phys. 1991, 69, 767–772. [Google Scholar] [CrossRef]

- Zhang, Q.; Cagin, T.; Goddard, W.A.I. The ferroelectric and cubic phases in BaTiO(3) ferroelectrics are also antiferroelectric. Proc. Natl. Acad. Sci. USA 2006, 103, 14695–14700. [Google Scholar] [CrossRef] [PubMed]

- Kholkin, A.L.; Colla, E.L.; Tagantsev, A.K.; Taylor, D.V.; Setter, N. Fatigue of piezoelectric properties in Pb(Zr,Ti)O3 films. Appl. Phys. Lett. 1996, 68, 2577–2579. [Google Scholar] [CrossRef]

- Thomas, R.; Dube, D.C.; Kamalasanan, M.N.; Kumar, N.D. Electrical properties of sol-gel processed amorphous BaTiO3 thin films. J. Sol-Gel Sci. Technol. 1999, 16, 101–107. [Google Scholar] [CrossRef]

- Stawski, T.M.; Vijselaar, W.J.C.; Gobel, O.F.; Veldhuis, S.A.; Smith, B.F.; Blank, D.H.A.; Elshof, J.E. Influence of high temperature processing of sol-gel derived barium titanate thin films deposited on platinum and strontium ruthenate coated silicon wafers. Thin Solid Films 2012, 520, 4394–4401. [Google Scholar] [CrossRef]

- Alexe, M.; Harnagea, C.; Hesse, D.; Gosele, U. Patterning and switching of nanosize ferroelectric memory cells. Appl. Phys. Lett. 1999, 75, 1793–1795. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaghefi, P.M.; Baghizadeh, A.; Lourenço, A.A.C.S.; Amaral, V.S.; Kholkin, A.L. Giant Strain and Induced Ferroelectricity in Amorphous BaTiO3 Films under Poling. Materials 2017, 10, 1107. https://doi.org/10.3390/ma10091107

Vaghefi PM, Baghizadeh A, Lourenço AACS, Amaral VS, Kholkin AL. Giant Strain and Induced Ferroelectricity in Amorphous BaTiO3 Films under Poling. Materials. 2017; 10(9):1107. https://doi.org/10.3390/ma10091107

Chicago/Turabian StyleVaghefi, Pegah Mirzadeh, Ali Baghizadeh, Armando A.C.S. Lourenço, Vitor S. Amaral, and Andre L. Kholkin. 2017. "Giant Strain and Induced Ferroelectricity in Amorphous BaTiO3 Films under Poling" Materials 10, no. 9: 1107. https://doi.org/10.3390/ma10091107