Strengthening Effect of Extruded Mg-8Sn-2Zn-2Al Alloy: Influence of Micro and Nano-Size Mg2Sn Precipitates

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

3.1. The Microstructures Prior to Extrusion

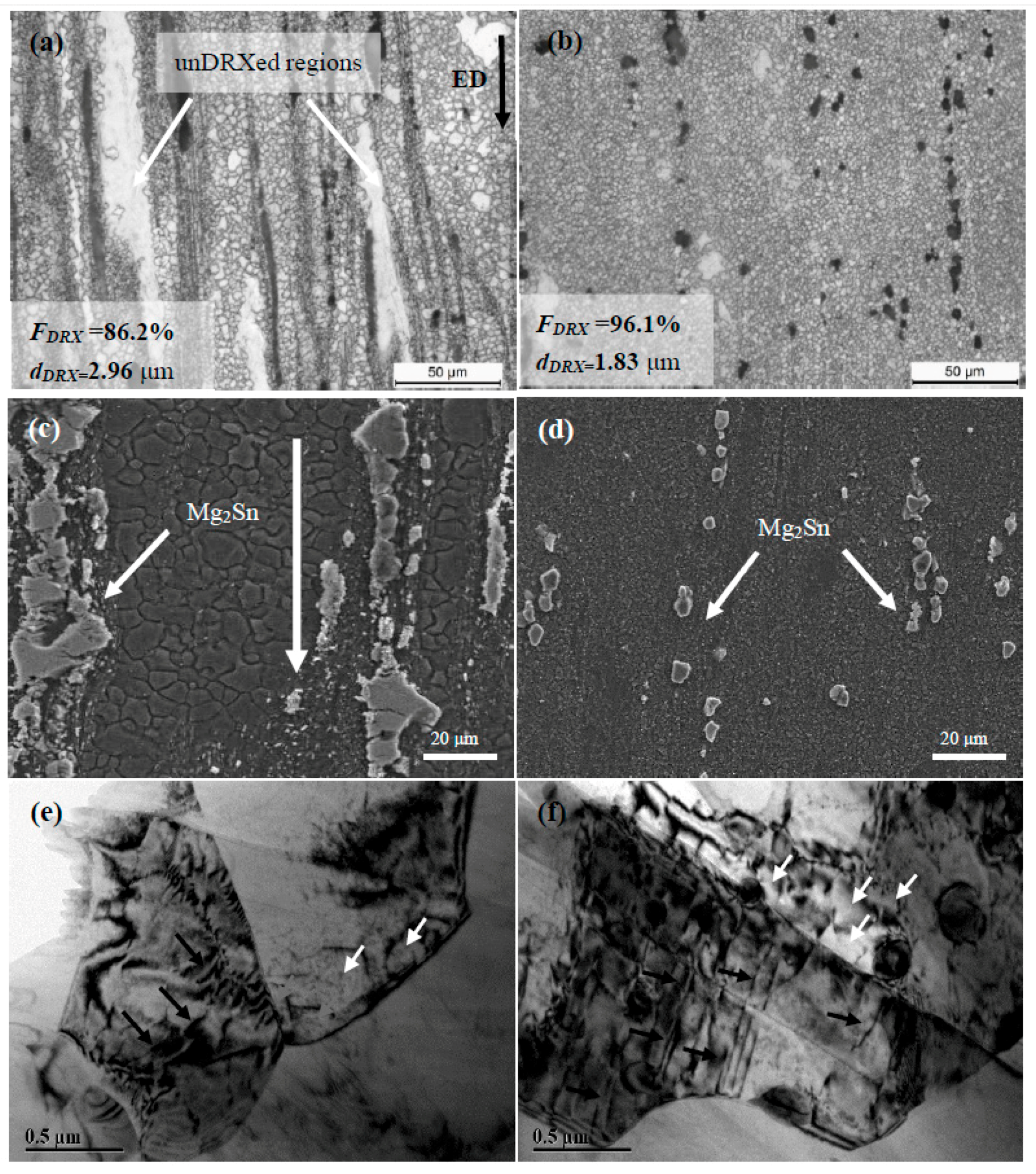

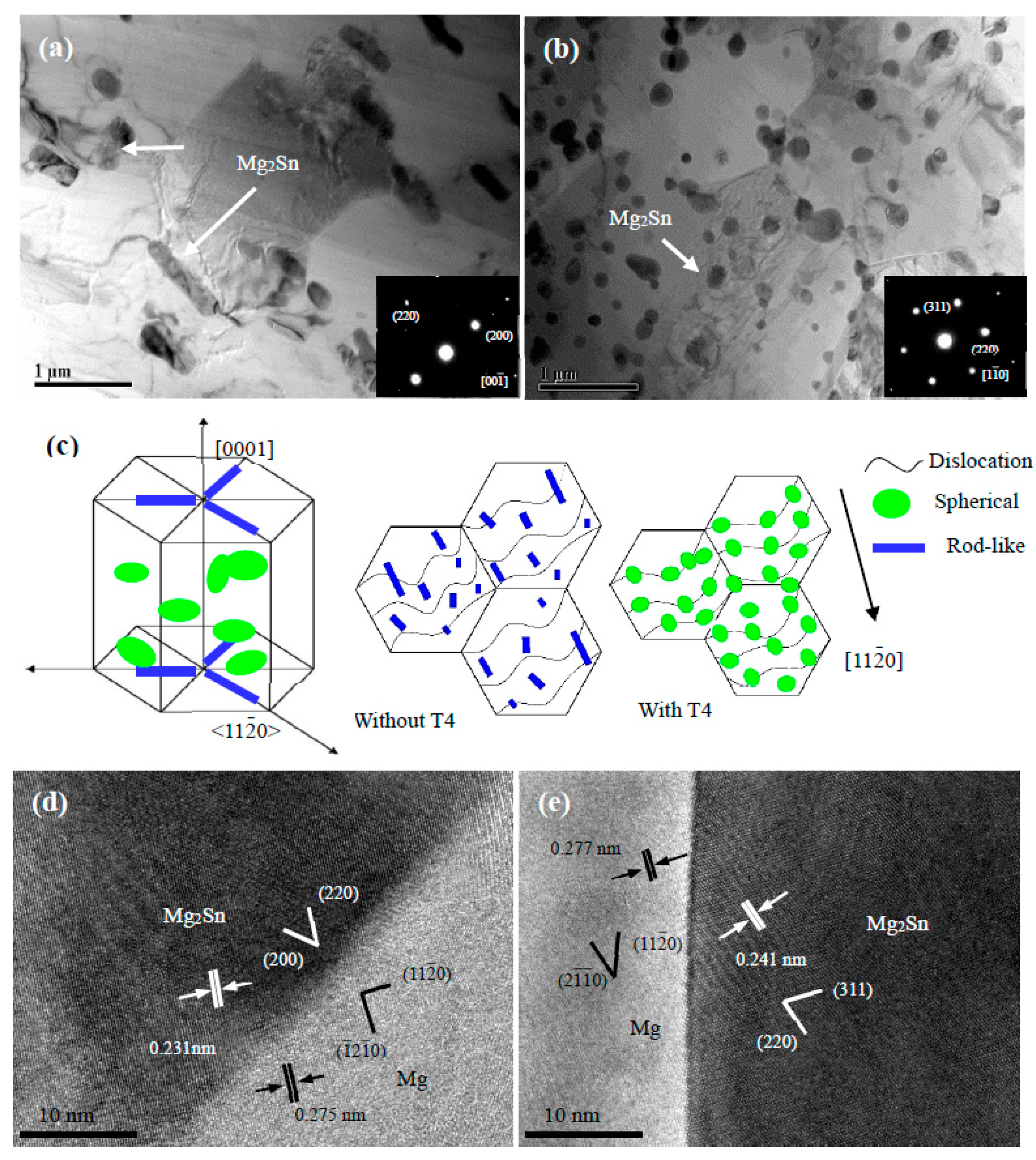

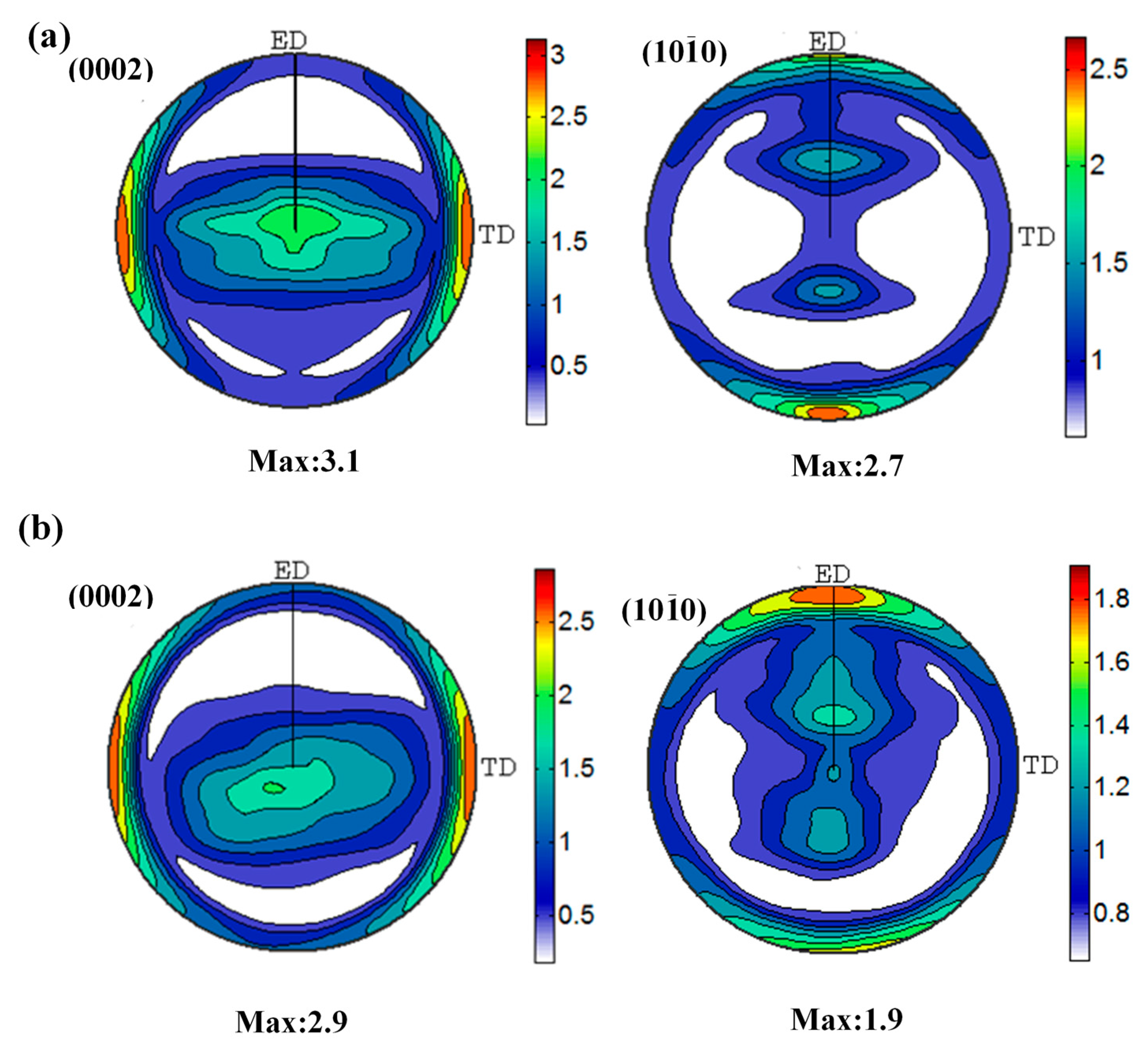

3.2. The Microstructures after Extrusion

3.3. Mechanical Properties of the Extruded Alloys

3.4. Strengthening Effect

4. Conclusions

- (1)

- The morphology of nano-size Mg2Sn precipitates exhibited a significant change in basal plane from rod-like to spherical due to the decrement in the fraction of micro-size particles before extrusion.

- (2)

- The spherical Mg2Sn precipitates provided a much stronger strengthening effect than the rod-like precipitates, which was ascribed to uniform dispersion and refinement of spherical precipitates to effectively hinder basal <a> dislocation slip.

- (3)

- The refined precipitate microstructure led to high TYS of 245 MPa, UTS of 320 MPa and EL of 26.5% while keeping a lower degree of yield asymmetry (R = 0.96) in the extruded TZA822 alloy with T4. The balance of strength and ductility for the studied alloys was comparable to that of RE-containing Mg alloys.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cheng, W.L.; Park, S.S.; You, B.S.; Koo, B.H. Microstructure and mechanical properties of binary Mg-Sn alloys subjected to indirect extrusion. Mater. Sci. Eng. A 2010, 527, 4650–4653. [Google Scholar] [CrossRef]

- Elsayed, F.R.; Sasaki, T.T.; Ohkubo, T.; Takahashi, H.; Xu, S.W.; Kamado, S.; Hono, K. Effect of extrusion conditions on microstructure and mechanical properties of microalloyed Mg-Sn-Al-Zn alloys. Mater. Sci. Eng. A 2013, 588, 318–328. [Google Scholar] [CrossRef]

- Park, S.S.; Tang, W.N.; You, B.S. Microstructure and mechanical properties of indirect-extruded Mg-8Sn-1Al-1Zn alloy. Mater. Lett. 2011, 64, 31–34. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Oh-ishi, K.; Ohkubo, T.; Hono, K. Enhanced age hardening response by the addition of Zn in Mg-Sn alloys. Scr. Mater. 2006, 55, 251–254. [Google Scholar] [CrossRef]

- Mendis, C.L.; Bettles, C.J.; Gibson, M.A.; Hutchinson, C.R. An enhanced age hardening response in Mg-Sn based alloys containing Zn. Mater. Sci. Eng. A 2006, 435–436, 163–171. [Google Scholar] [CrossRef]

- Mendis, C.L.; Bettles, C.J.; Gibson, M.A.; Gorsse, S.; Hutchinson, C.R. Refinement of precipitate distributions in an age-hardenable Mg-Sn alloy through micro-alloying. Philos. Mag. Lett. 2006, 86, 443–456. [Google Scholar] [CrossRef]

- Pan, H.; Qin, G.; Xu, M.; Fu, H.; Ren, Y.; Pan, F.; Gao, Z.; Zhao, C.; Yang, Q.; She, J.; Song, B. Enhancing mechanical properties of Mg-Sn alloys by combining addition of Ca and Zn. Mater. Des. 2015, 83, 736–744. [Google Scholar] [CrossRef]

- Li, W.D.; Huang, X.F.; Huang, W.G. Effects of Ca, Ag addition on the microstructure and age-hardening behavior of a Mg-7Sn (wt %) alloy. Mater. Sci. Eng. A 2016, 692, 75–80. [Google Scholar] [CrossRef]

- Liu, C.Q.; Chen, H.W.; Nie, J.F. Interphase boundary segregation of Zn in Mg-Sn-Zn alloys. Scr. Mater. 2016, 123, 5–8. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, S.H.; Kim, H.S.; Yoon, J.H.; You, B.S. High-speed indirect extrusion of Mg-Sn-Al-Zn alloy and its influence on microstructure and mechanical properties. J. Alloys Compd. 2016, 667, 170–177. [Google Scholar] [CrossRef]

- Sasakia, T.T.; Elsayed, F.R.; Nakata, T.; Ohkubo, T.; Kamado, S.; Hono, K. Strong and ductile heat-treatable Mg-Sn-Zn-Al wrought alloys. Acta Mater. 2015, 99, 176–186. [Google Scholar] [CrossRef]

- Robson, J.D.; Stanford, N.; Barnett, M.R. Effect of precipitate shape on slip and twinning in magnesium alloys. Acta Mater. 2011, 59, 1945–1956. [Google Scholar] [CrossRef]

- Hidalgo-Manrique, P.; Robson, J.D.; Perez-Prado, M.T. Precipitation strengthening and reversed yield stress asymmetry in Mg alloys containing rare-earth elements: A quantitative study. Acta Mater. 2017, 124, 456–467. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, J.H.; Yu, H.; Yoon, J.H.; You, B.S. Effect of cold pre-forging on the microstructure and mechanical properties of extruded Mg-8Sn-1Al-1Zn alloy. Mater. Sci. Eng. A 2014, 612, 197–201. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, Y.C.; Li, J.P.; He, F.; Xia, F.; Liang, M.X. Plastic deformation and dynamic recrystallization behaviors of Mg-5Gd-4Y-0.5Zn-0.5Zr alloy. Mater. Sci. Eng. A 2015, 485, 487–491. [Google Scholar] [CrossRef]

- Tang, L.C.; Liu, C.M.; Chen, Z.Y.; Ji, D.W.; Xiao, H.C. Microstructures and tensile properties of Mg-Gd-Y-Zr alloy during multidirectional forging at 773 K. Mater. Des. 2013, 50, 587–596. [Google Scholar] [CrossRef]

- Cheng, W.; Tian, Q.; Yu, H.; You, B.S.; Wang, H. Optimum parameters and kinetic analysis for hot working of a homogenized Mg-8Sn-1Al-1Zn alloy. Mater. Des. 2015, 85, 762–770. [Google Scholar] [CrossRef]

- Kim, S.H.; You, B.S.; Park, S.H. Effect of billet diameter on hot extrusion behavior of Mg-Al-Zn alloys and its influence on microstructure and mechanical properties. J. Alloys Compd. 2017, 690, 417–423. [Google Scholar] [CrossRef]

- Kim, S.H.; Park, S.H. Influence of Ce addition and homogenization temperature on microstructural evolution and mechanical properties of extruded Mg-Sn-Al-Zn alloy. Mater. Sci. Eng. A 2016, 676, 232–240. [Google Scholar] [CrossRef]

- She, J.; Pan, F.; Zhang, J.; Tang, A.; Luo, S.; Yu, Z.; Song, K.; Rashad, M. Microstructure and mechanical properties of Mg-Al-Sn extruded alloys. J. Alloys Compd. 2016, 657, 893–905. [Google Scholar] [CrossRef]

- Cheng, W.L.; Tian, L.; Wang, H.X.; Bian, L.P.; Yu, H. Improved tensile properties of an equal channel angular pressed (ECAPed) Mg-8Sn-6Zn-2Al alloy by prior aging treatment. Mater. Sci. Eng. A 2017, 687, 148–154. [Google Scholar] [CrossRef]

- Park, S.S.; Kim, Y.J.; Cheng, W.L.; Kim, Y.M.; You, B.S. Tensile properties of extruded Mg-8Sn-1Zn alloys subjected to different heat treatments. Phil. Mag. Lett. 2011, 91, 37–44. [Google Scholar] [CrossRef]

- Li, W.J.; Deng, K.K.; Zhang, X.; Nie, K.B.; Xu, F.J. Effect of ultra-slow extrusion speed on the microstructure and mechanical properties of Mg-4Zn-0.5Ca alloy. Mater. Sci. Eng. A 2016, 677, 367–375. [Google Scholar] [CrossRef]

- Oh-ishi, K.; Hono, K.; Shin, K.S. Effect of pre-aging and Al addition on age-hardening and microstructure in Mg-6wt % Zn alloys. Mater. Sci. Eng. A 2008, 496, 425–433. [Google Scholar] [CrossRef]

- Sasaki, T.T.; Ju, J.D.; Hono, K.; Shin, K.S. Heat-treatable Mg-Sn-Zn wrought alloy. Scr. Mater. 2009, 61, 80–83. [Google Scholar] [CrossRef]

- Wang, L.F.; Mostaed, E.; Cao, X.Q.; Huang, G.S.; Fabrizi, A.; Bonollo, F.; Chi, C.Z.; Vedani, M. Effects of texture and grain size on mechanical properties of AZ80 magnesium alloys at lower temperatures. Mater. Des. 2016, 89, 1–8. [Google Scholar] [CrossRef]

- Qi, F.; Zhang, D.; Zhang, X.; Xu, X. Effects of Mn addition and X-phase on the microstructure and mechanical properties of high-strength Mg-Zn-Y-Mn alloys. Mater. Sci. Eng. A 2014, 593, 70–78. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Liu, X.L.; Wang, Z.K.; Le, Q.C.; Hu, W.Y.; Bao, L.; Cui, J.Z. Effects of phase composition and content on the microstructures and mechanical properties of high strength Mg-Y-Zn-Zr alloys. Mater. Des. 2015, 88, 915–923. [Google Scholar] [CrossRef]

- Meyers, M.A.; Vöhringer, O.; Lubarda, V.A. The onset of twinning in metals: Aconstitutive description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Yu, H.; Park, S.H.; You, B.S. Development of extraordinary high-strength Mg-8Al-0.5Zn alloy via a low temperature and slow speed extrusion. Mater. Sci. Eng. A 2014, 610, 445–449. [Google Scholar] [CrossRef]

- Kang, J.W.; Sun, X.F.; Deng, K.K.; Xu, F.J.; Zhang, X.; Bai, Y. High strength Mg-9Al serial alloy processed by slow extrusion. Mater. Sci. Eng. A 2017, 697, 211–216. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Suh, B.C.; Kim, J.H.; Bae, J.H.; Hwang, J.H.; Shim, M.S.; Kima, N.J. Effect of Sn addition on the microstructure and deformation behavior of Mg-3Al alloy. Acta Mater. 2017, 124, 268–279. [Google Scholar] [CrossRef]

- Park, S.H.; You, B.S. Effect of homogenization temperature on the microstructure and mechanical properties of extruded Mg-7Sn-1Al-1Zn alloy. J. Alloys Compd. 2015, 637, 332–338. [Google Scholar] [CrossRef]

- Tang, W.N.; Park, S.S.; You, B.S. Effect of the Zn content on the microstructure and mechanical properties of indirect-extruded Mg-5Sn-xZn alloys. Mater. Des. 2011, 32, 3537–3543. [Google Scholar] [CrossRef]

| State | Microstructure | Mechanical Properties | |||||||

|---|---|---|---|---|---|---|---|---|---|

| FDRX (%) | dDRX (μm) | Texture Intensity | TYS (MPa) | UTS (MPa) | EL (%) | CYS (MPa) | YR | n | |

| Without T4 | 86.2 ± 3.1 | 2.96 ± 0.34 | 3.1 | 186 ± 3 | 231 ± 4 | 17.6 ± 0.3 | 163 ± 3 | 0.88 | 0.18 |

| With T4 | 96.1 ± 1.8 | 1.83 ± 0.26 | 2.9 | 245 ± 2 | 320 ± 2 | 26.5 ± 0.2 | 234 ± 3 | 0.96 | 0.21 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, W.; Bai, Y.; Wang, L.; Wang, H.; Bian, L.; Yu, H. Strengthening Effect of Extruded Mg-8Sn-2Zn-2Al Alloy: Influence of Micro and Nano-Size Mg2Sn Precipitates. Materials 2017, 10, 822. https://doi.org/10.3390/ma10070822

Cheng W, Bai Y, Wang L, Wang H, Bian L, Yu H. Strengthening Effect of Extruded Mg-8Sn-2Zn-2Al Alloy: Influence of Micro and Nano-Size Mg2Sn Precipitates. Materials. 2017; 10(7):822. https://doi.org/10.3390/ma10070822

Chicago/Turabian StyleCheng, Weili, Yang Bai, Lifei Wang, Hongxia Wang, Liping Bian, and Hui Yu. 2017. "Strengthening Effect of Extruded Mg-8Sn-2Zn-2Al Alloy: Influence of Micro and Nano-Size Mg2Sn Precipitates" Materials 10, no. 7: 822. https://doi.org/10.3390/ma10070822