Sparse and Dispersion-Based Matching Pursuit for Minimizing the Dispersion Effect Occurring when Using Guided Wave for Pipe Inspection

Abstract

:1. Introduction

2. Matching Pursuit

- (1)

- Calculate the inner product between the residue rn−1(t) and all atoms in D excluding the ones that were already selected in the previous iterations.

- (2)

- Select an atom a that produces the maximum inner product with rn−1(t):where 0 < ρ ≤ 1 is some number independent of n.

- (3)

- Compute the new residue:

- (4)

- The new approximation of the signal x(t) with n atoms can be represented as:

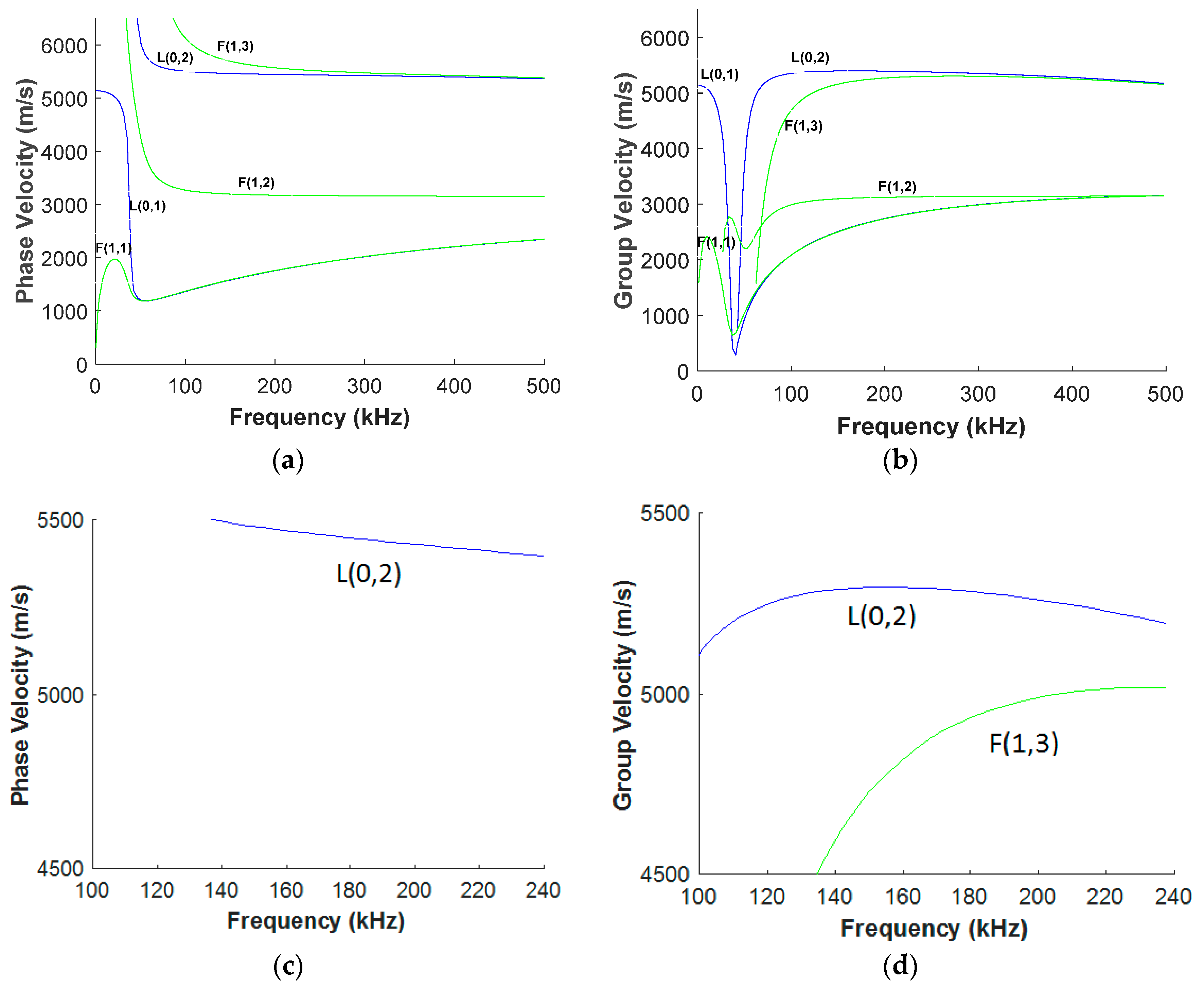

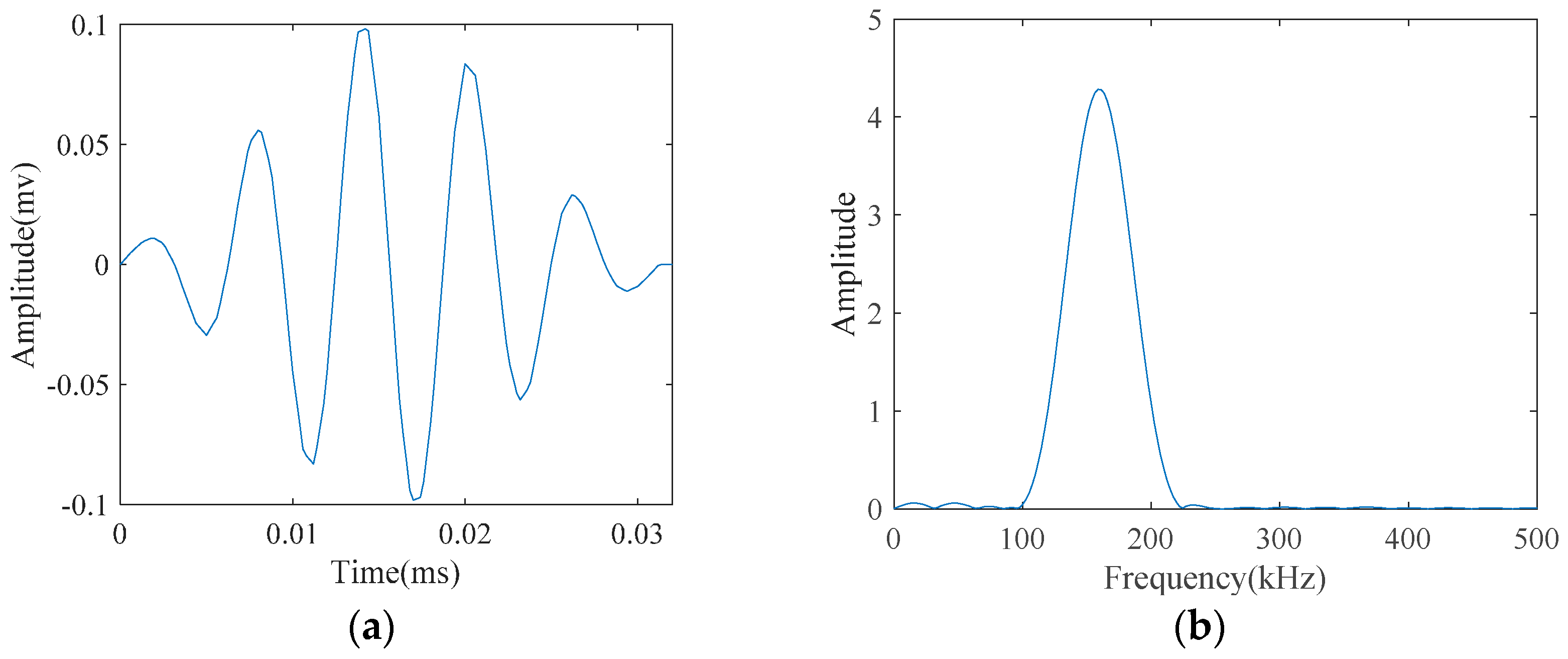

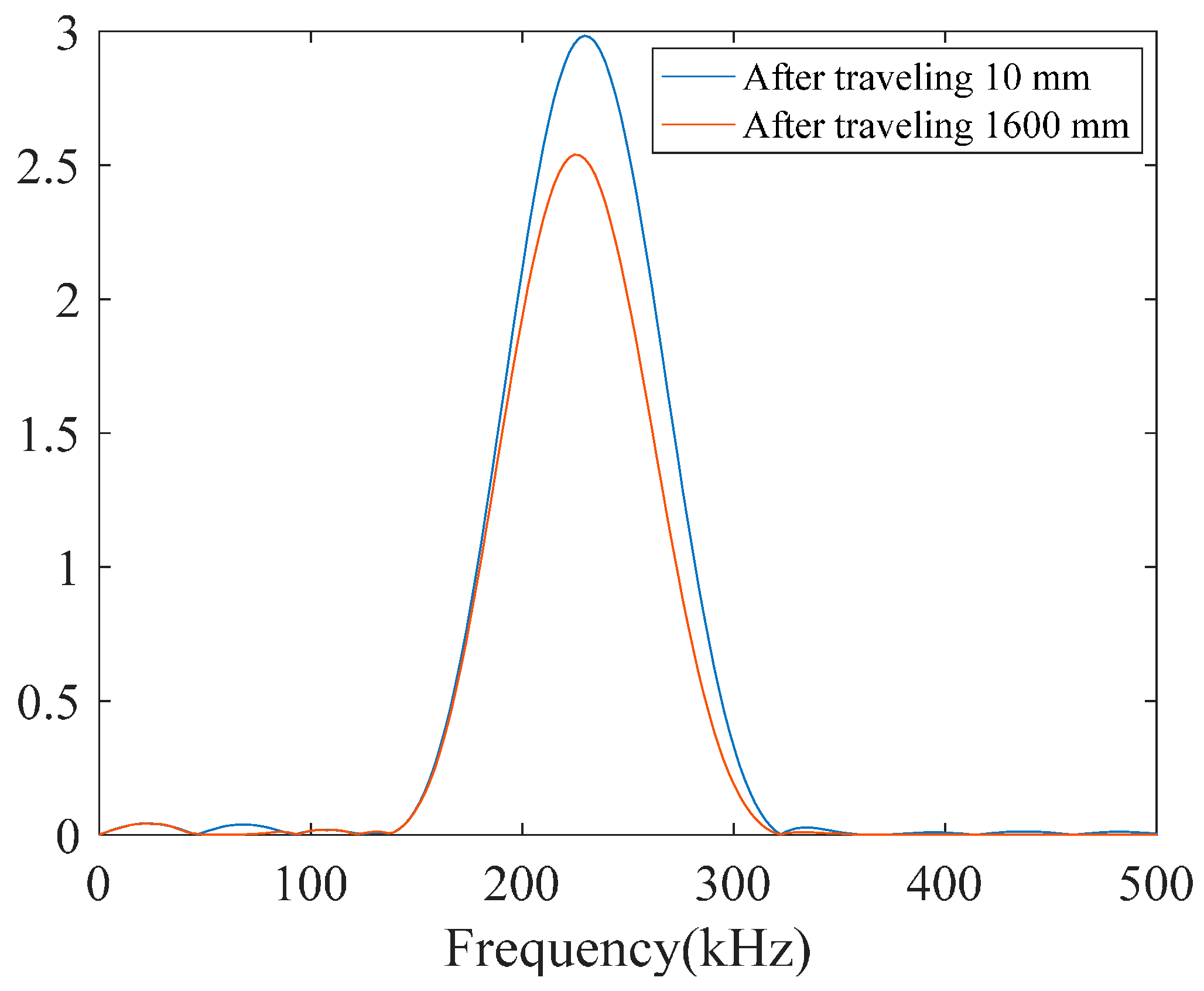

3. Dictionary Design for Guided Wave Inspection

4. Proposed SDMP Algorithm for Sparse Representation

- Phase I.

- (1)

- Initialize the iteration counter n = 0 and the residue rn(t) = x(t).

- (2)

- Calculate the inner product between the current residue rn(t) and all atoms in D excluding ones that were already selected in the previous iterations.

- (3)

- Select all atoms whose inner product with rn(t) are above a specific threshold Th1 value:

- (4)

- Calculate the next residual signal rn+1(t) for each atom selected in the previous Step (3):

- (5)

- Choose the atom that minimizes the robust support and put it in Â:

- (6)

- Update the residue based on the chosen atom.

- (7)

- If the residue energy then stop, otherwise n = n + 1 and jump to Step (2).

- Phase II. Increasing Sparsity.

- (8)

- Calculate the FFT of the atoms in Â:

- (9)

- Calculate the absolute cross-correlation c between the atoms in B and the atom in D’ representing excitation signal at the center frequency (bfc).

- (10)

- Discard the atoms in  whose absolute cross-correlation in the frequency domain with bfc is smaller than a predefined threshold Th2.

5. Demonstration of the SDMP Capabilities

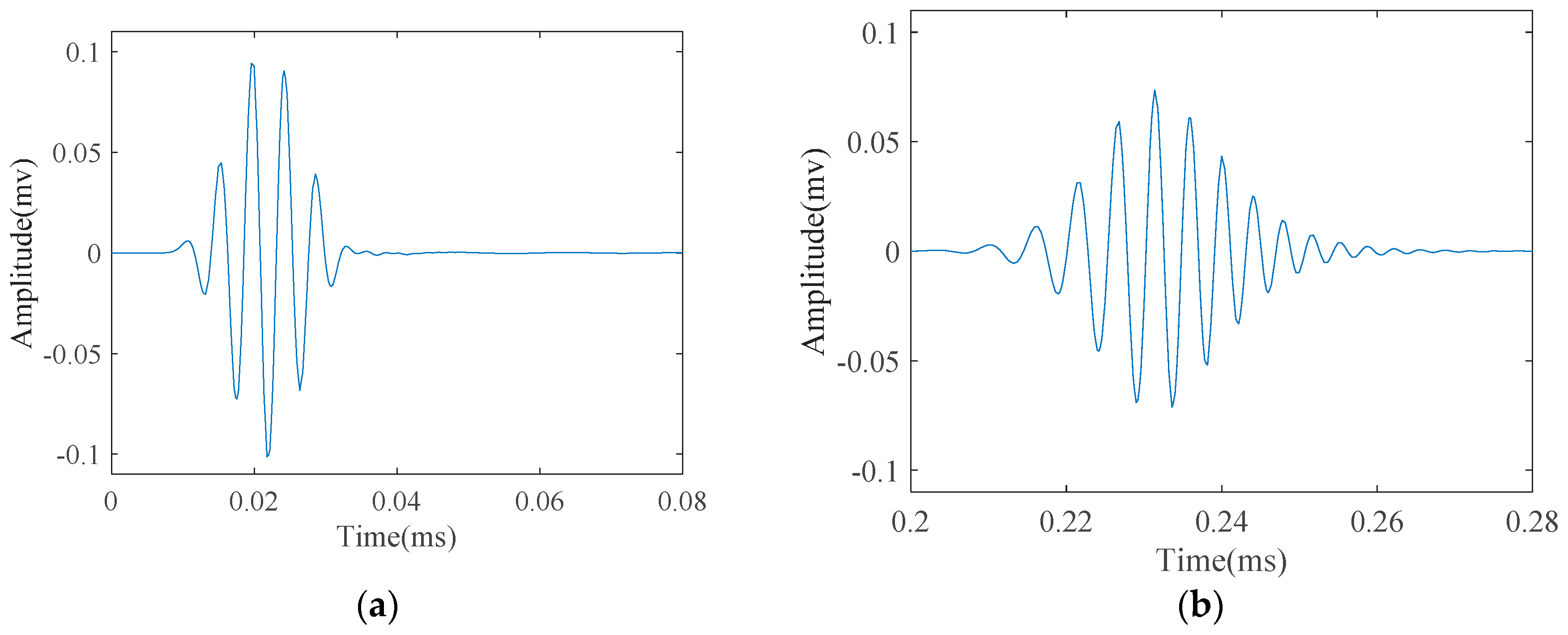

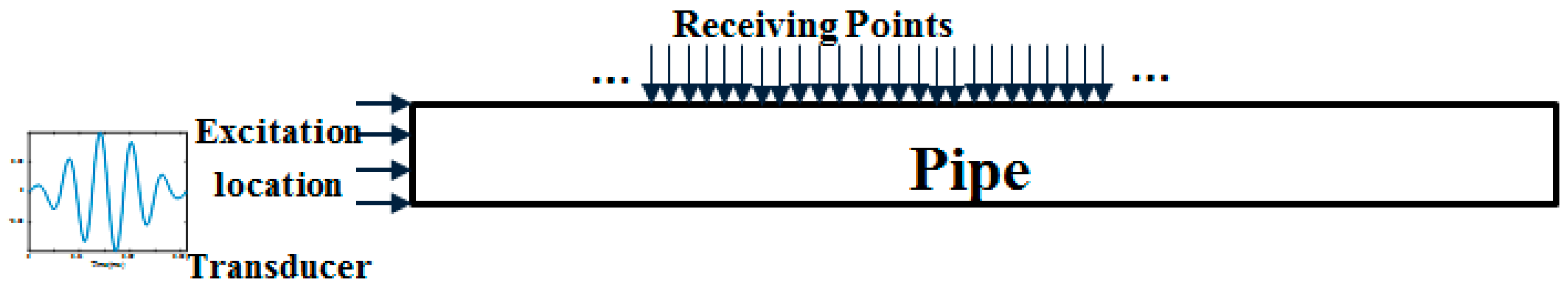

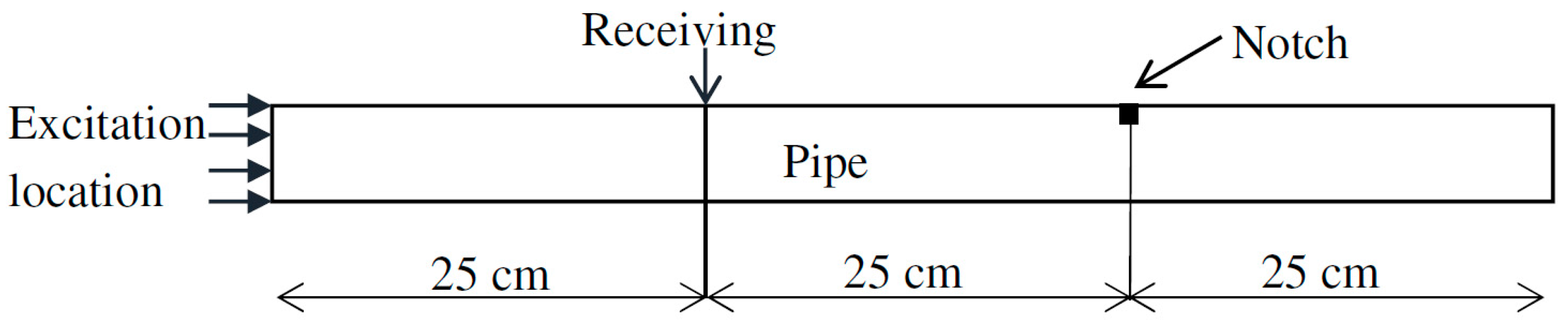

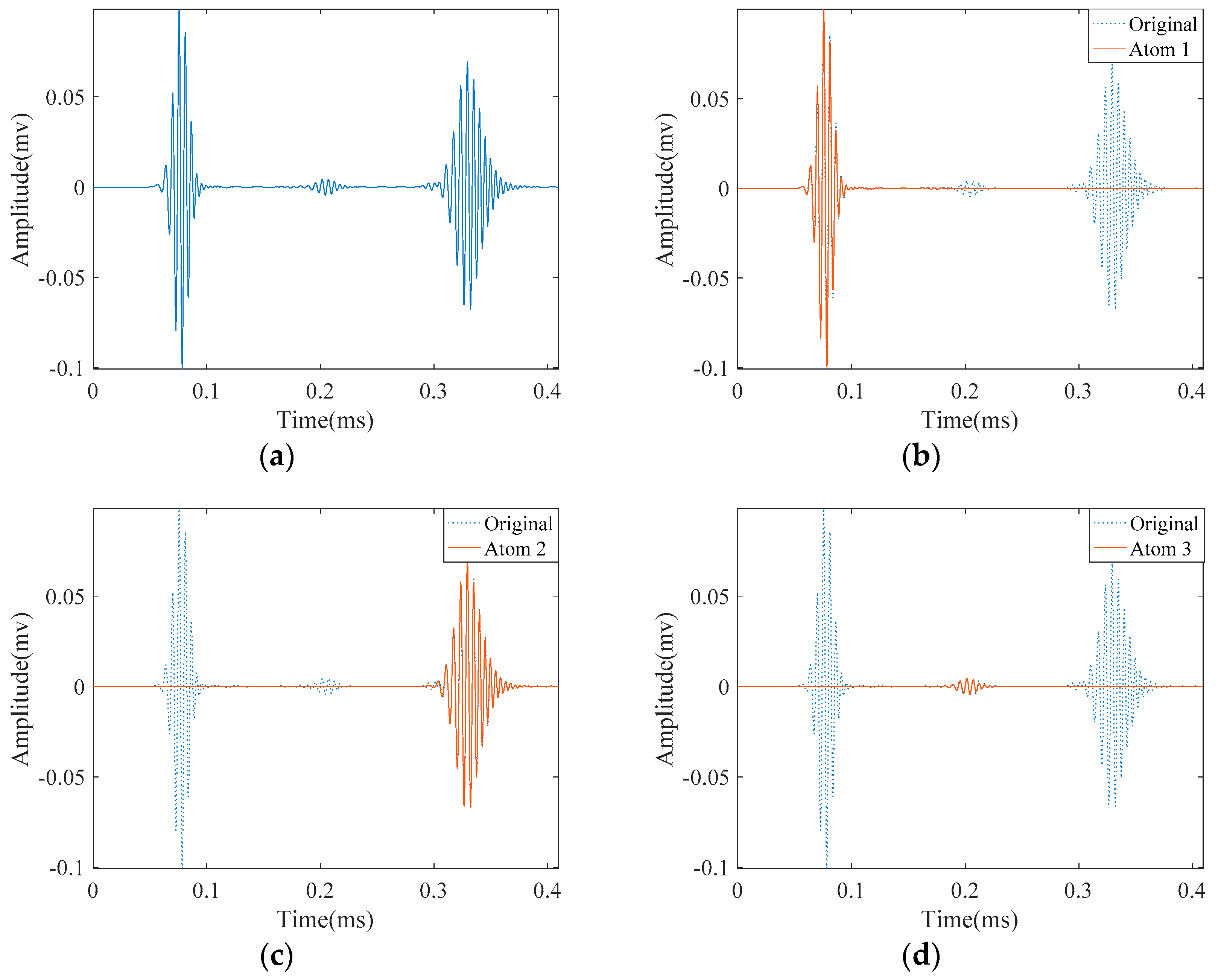

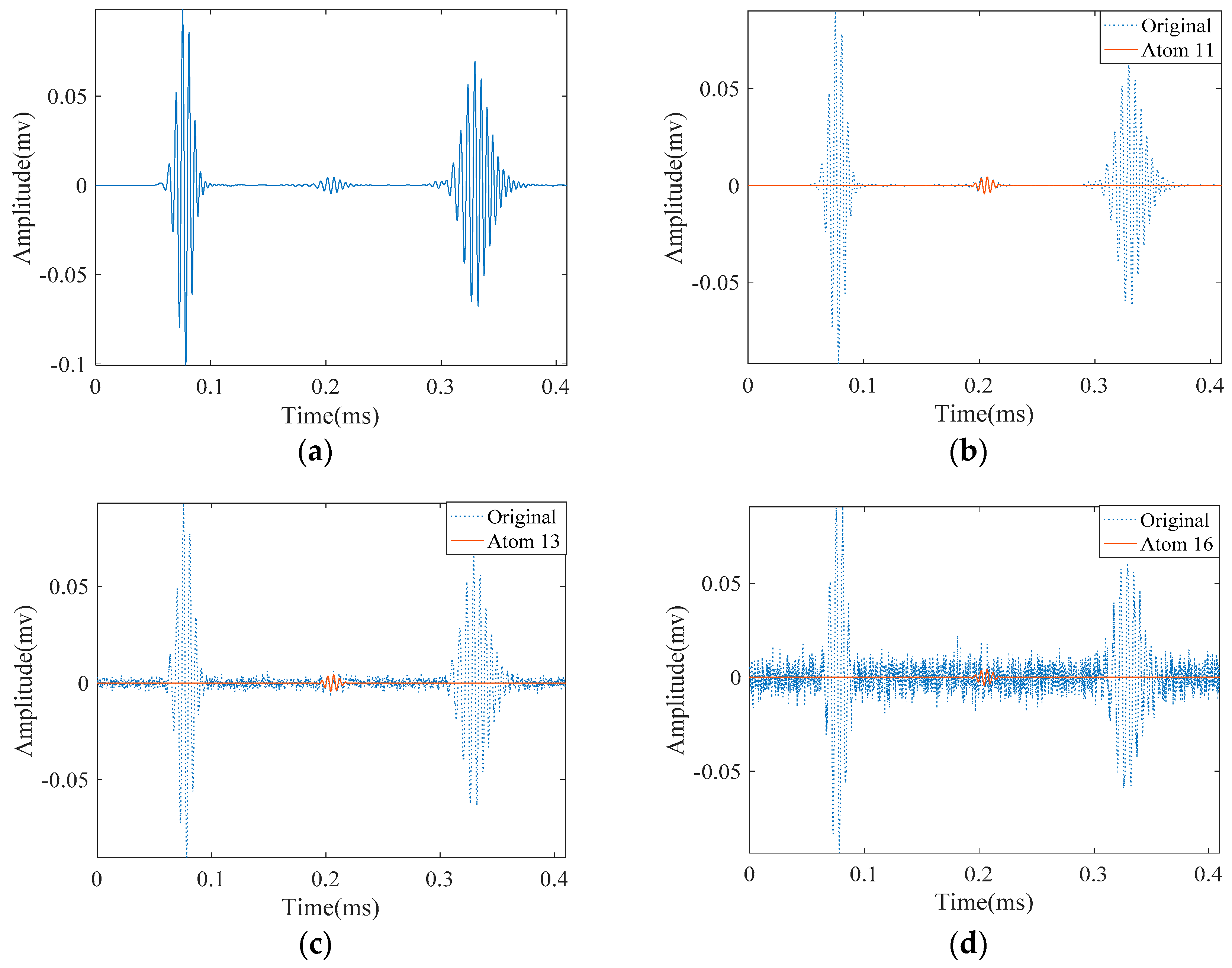

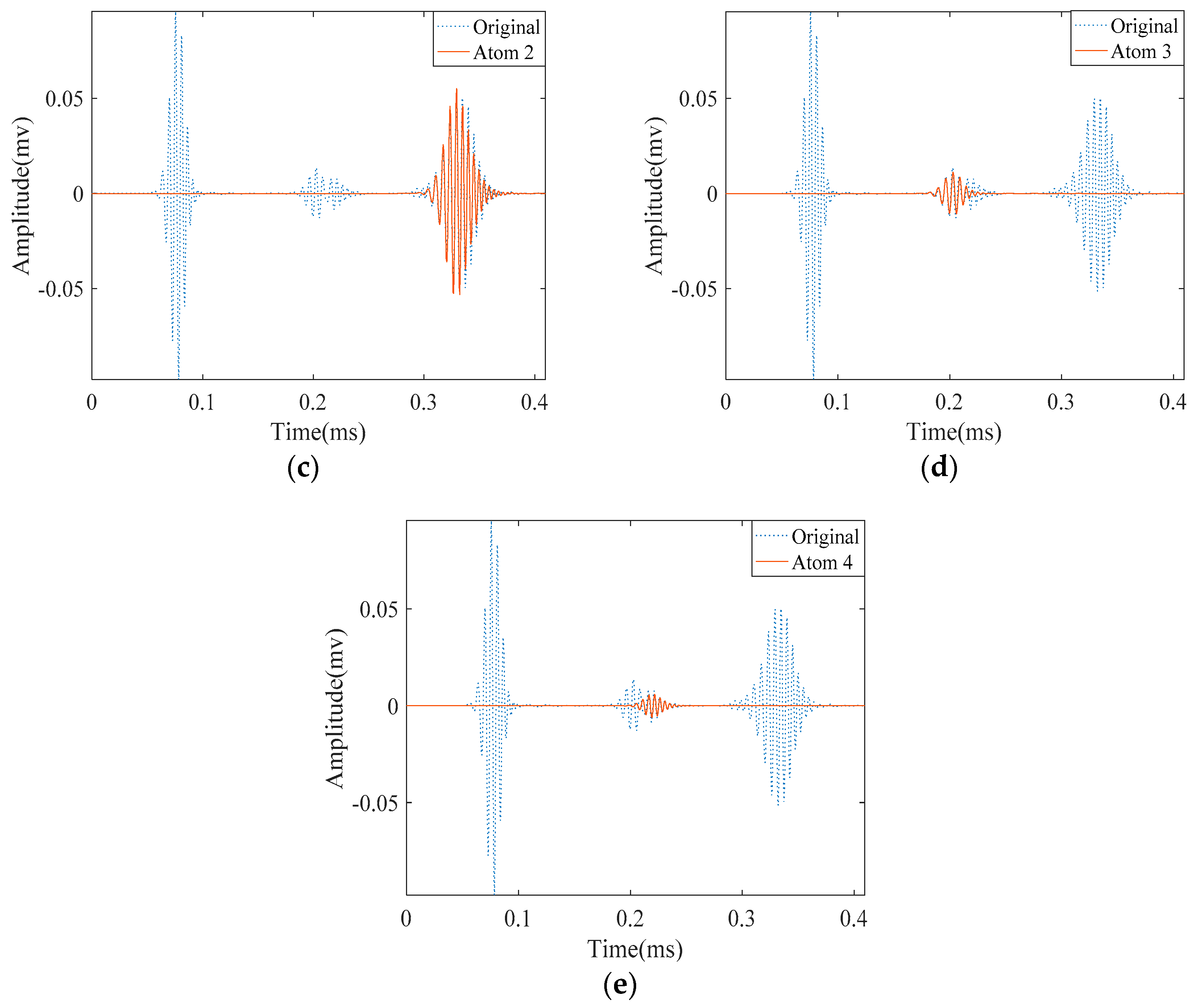

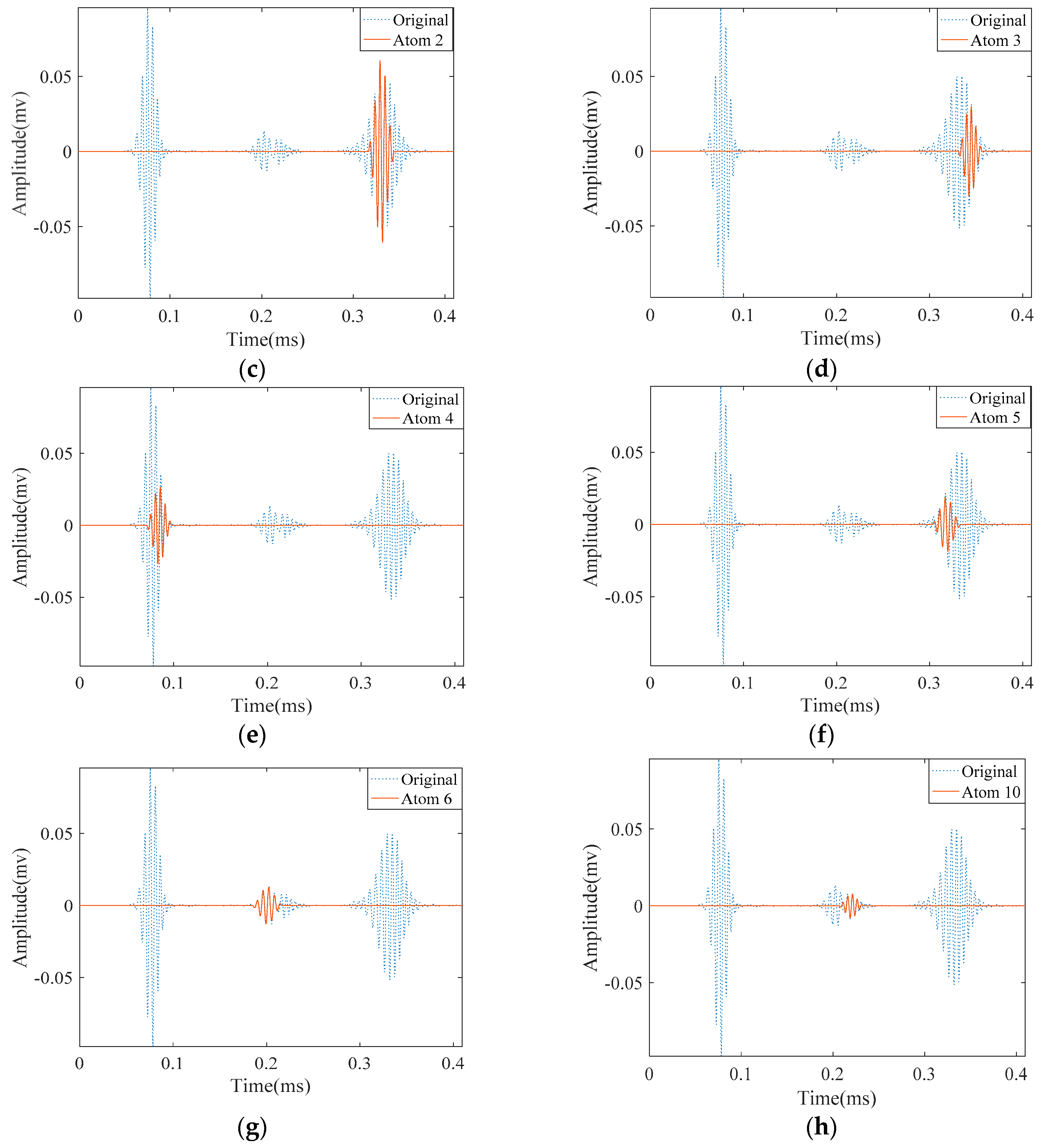

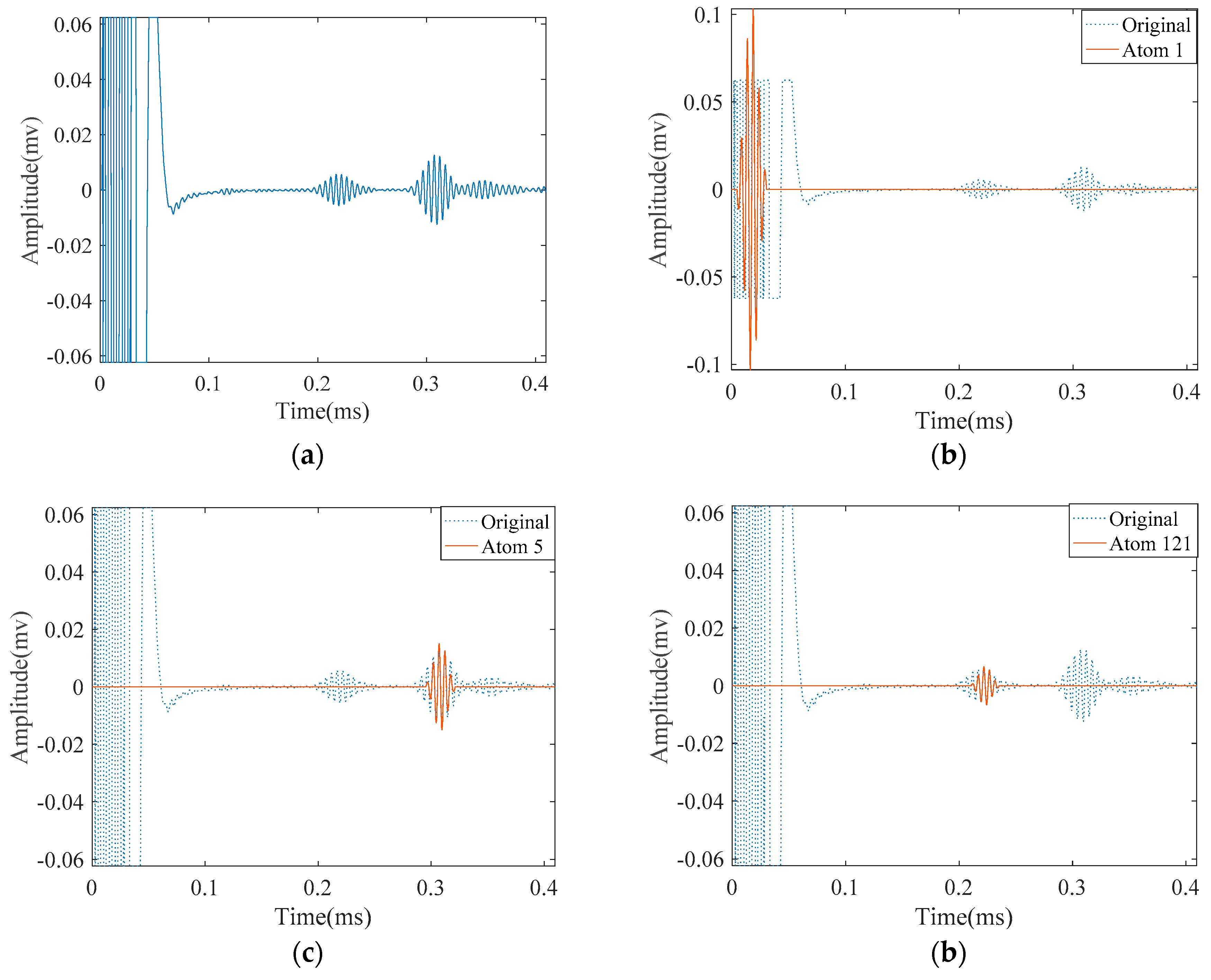

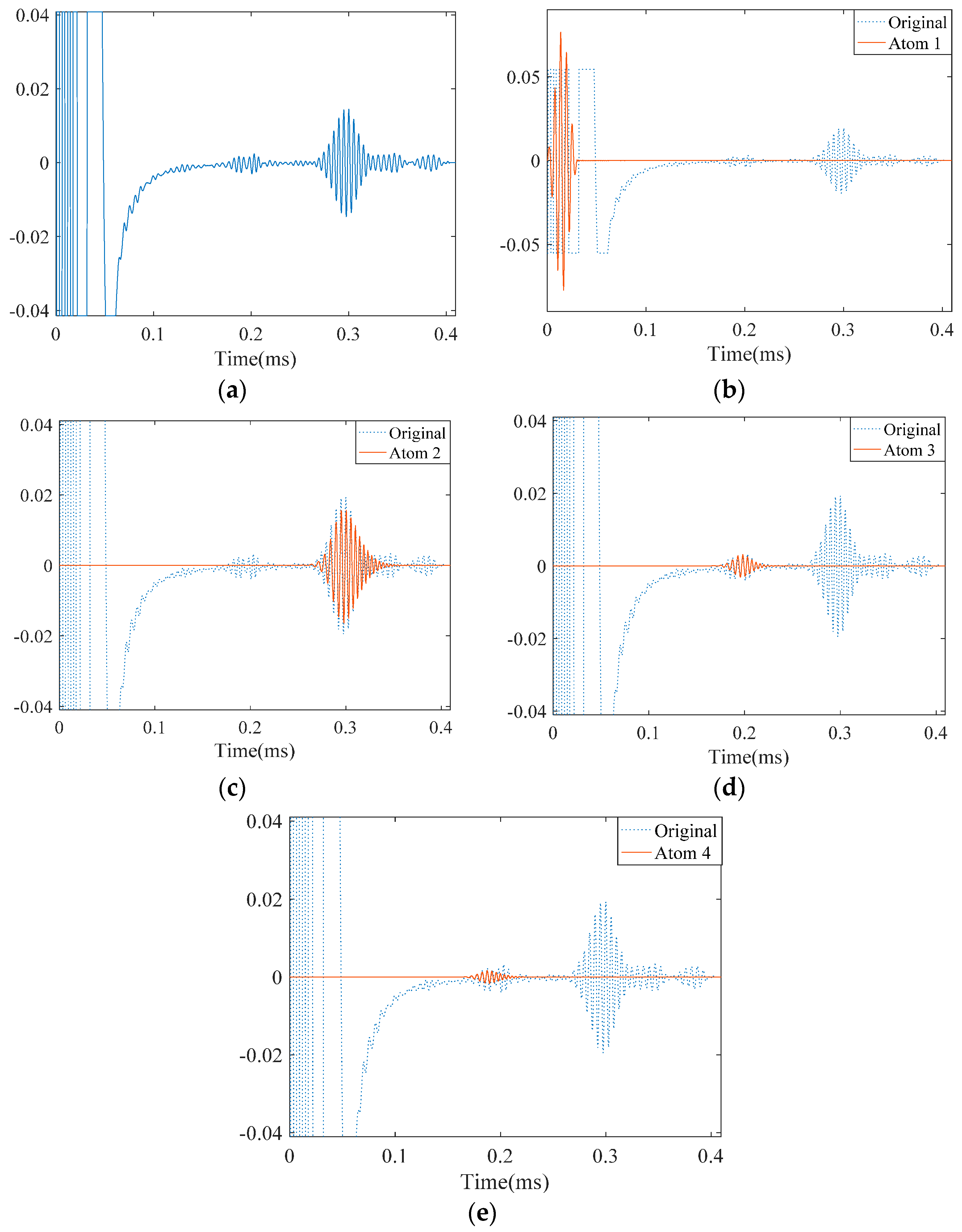

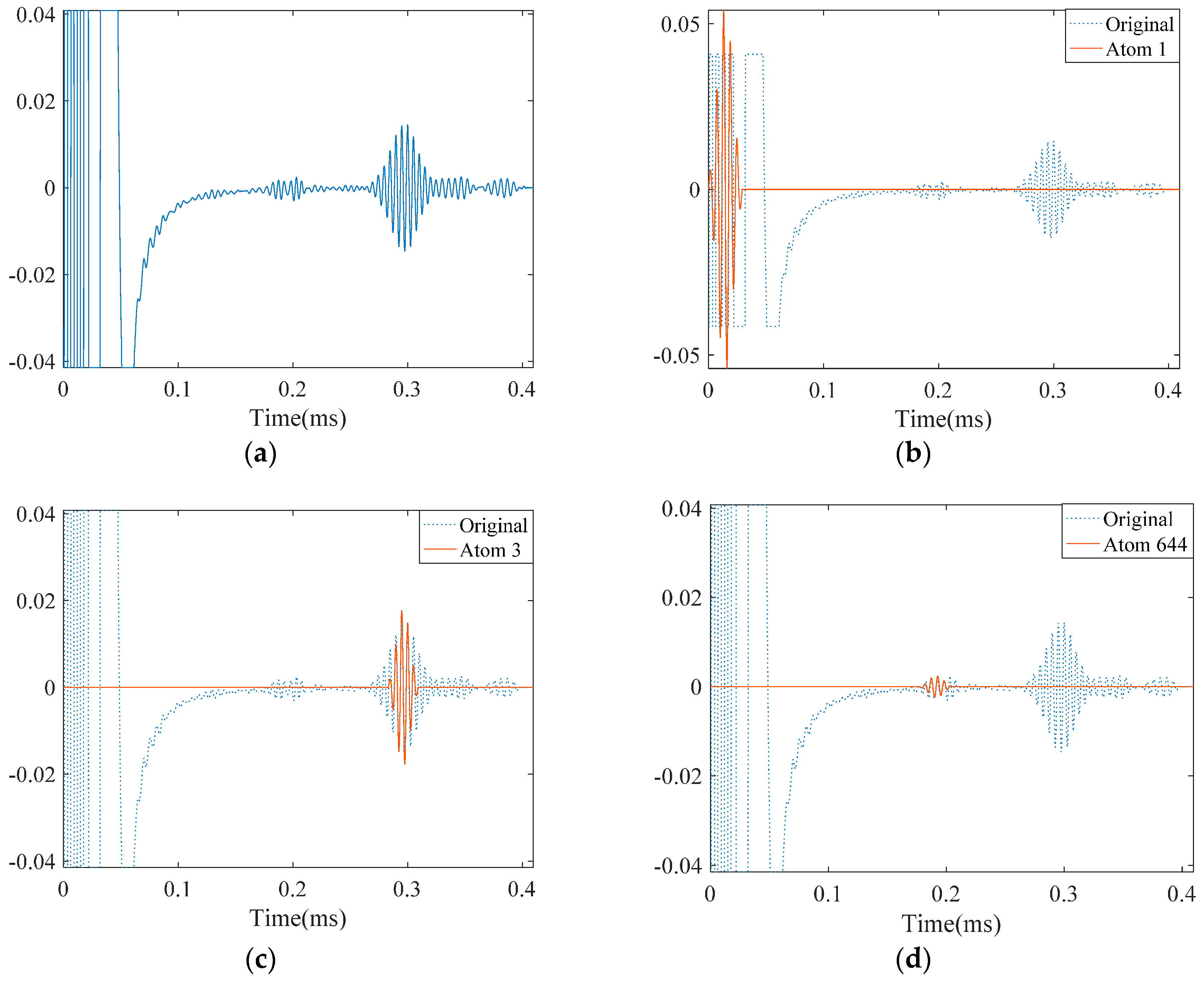

5.1. FEM Simulation

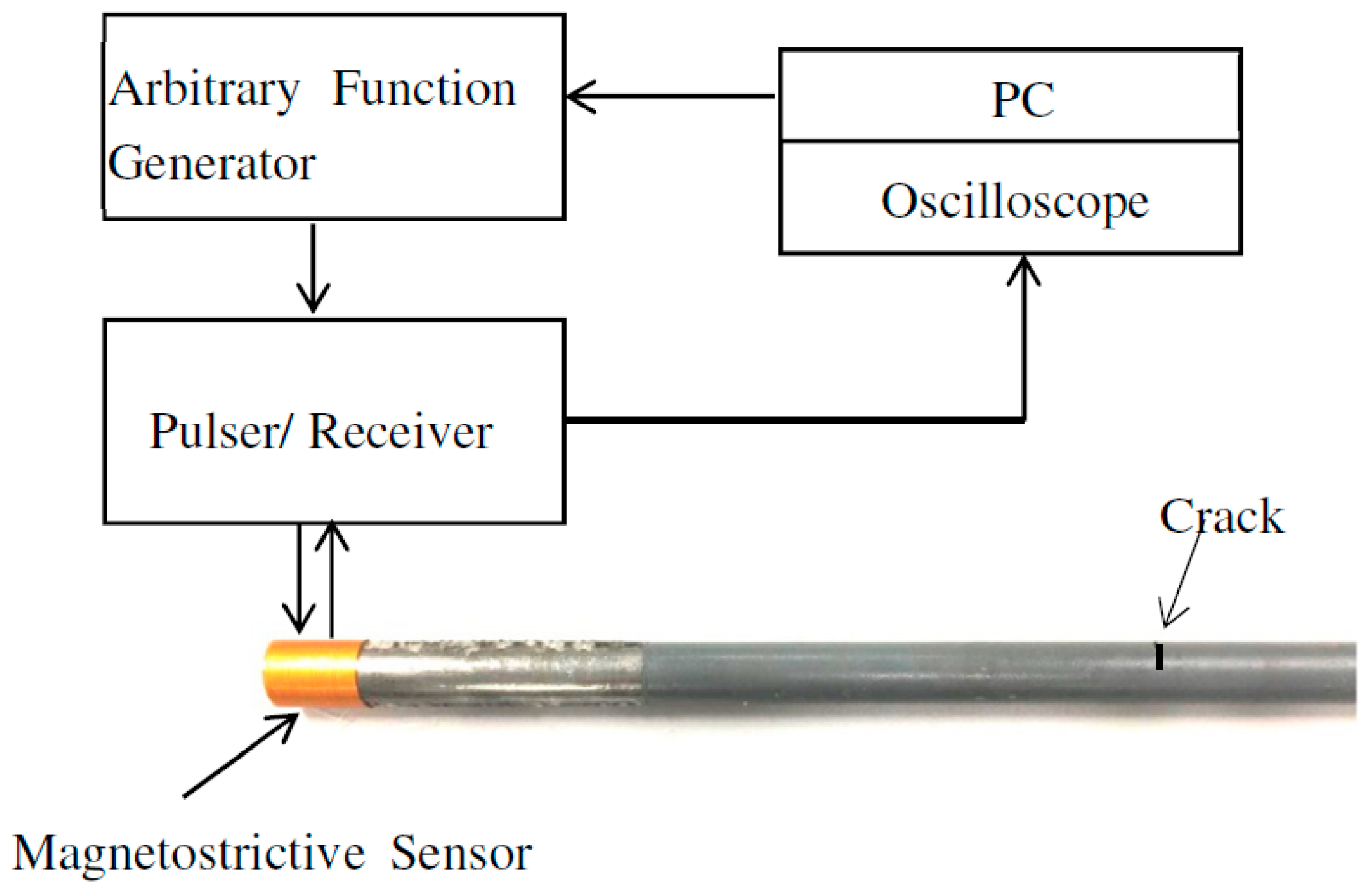

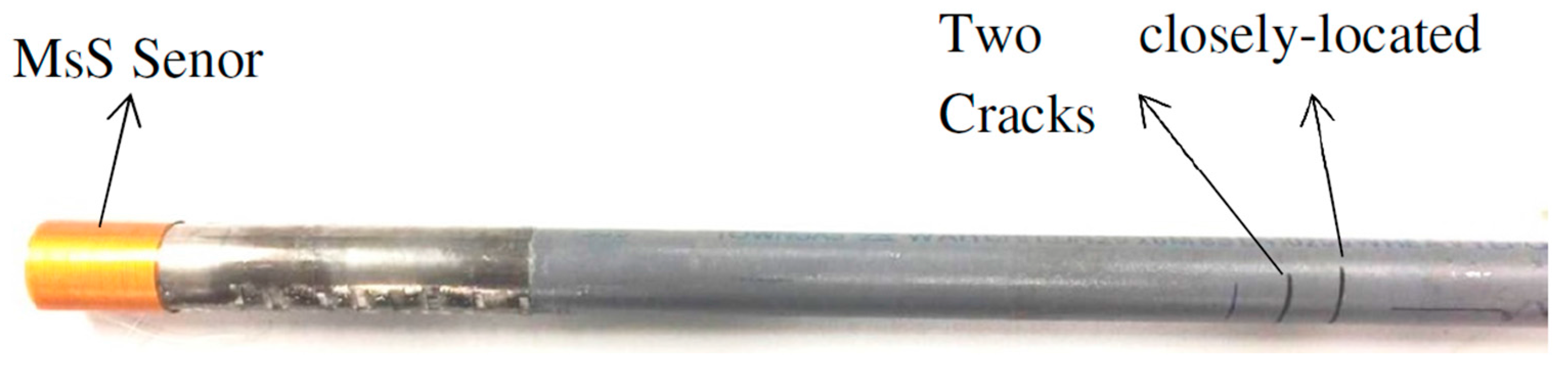

5.2. Experimental Results

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Carandente, R.; Lovstad, A.; Cawley, P. The influence of sharp edges in corrosion profiles on the reflection of guided waves. NDT E Int. 2012, 52, 57–68. [Google Scholar] [CrossRef]

- Yang, F.; Jing, L.; Zhang, W.; Yan, Y.; Ma, H. Experimental and numerical studies of the oblique defects in the pipes using a chaotic oscillator based on ultrasonic guided waves. J. Sound Vib. 2015, 347, 218–231. [Google Scholar] [CrossRef]

- Leinov, E.; Lowe, M.J.S.; Cawley, P. Ultrasonic isolation of buried pipes. J. Sound Vib. 2016, 363, 225–239. [Google Scholar] [CrossRef]

- Kim, C.-Y.; Park, K.-J. Mode separation and characterization of torsional guided wave signals reflected from defects using chirplet transform. NDT E Int. 2015, 74, 15–23. [Google Scholar] [CrossRef]

- Lowe, M.J.S.; Cawley, P. Long Range Guided Wave Inspection Usage—Current Commercial Capabilities and Research Directions; Department of Mechanical Engineering, Imperial College London: London, UK, 2006. [Google Scholar]

- Vogelaar, B.; Golombok, M. Dispersion and attenuation by transmission, reflection, and mode conversion in welded pipes. Appl. Acoust. 2016, 110, 1–8. [Google Scholar] [CrossRef]

- Baravelli, E.; De Marchi, L.; Speciale, N.; Ruzzene, M. Bimodal warped frequency transformation for guided wave mode conversion characterization. In Proceedings of the Health Monitoring of Structural and Biological Systems 2012, San Diego, CA, USA, 11–15 March 2012. [Google Scholar]

- Soleimanpour, R.; Ng, C. Mode conversion and scattering analysis of guided waves at delaminations in laminated composite beams. Struct. Monit. Maint. 2015, 2, 213–236. [Google Scholar] [CrossRef]

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Cai, J.; Yuan, S.; Wang, T. Signal Construction-Based Dispersion Compensation of Lamb Waves Considering Signal Waveform and Amplitude Spectrum Preservation. Materials 2017, 10, 4. [Google Scholar] [CrossRef]

- Wilcox, P.D. A rapid signal processing technique to remove the effect of dispersion from guided wave signals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2003, 50, 419–427. [Google Scholar] [CrossRef] [PubMed]

- Su, Z.; Ye, L. Identification of Damage Using Lamb Waves; Springer Science & Business Media: New York, NY, USA, 2009; Volume 48. [Google Scholar]

- Gan, T.H.; Hutchins, D.A.; Billson, D.R.; Schindel, D.W. The use of broadband acoustic transducers and pulse-compression techniques for air-coupled ultrasonic imaging. Ultrasonics 2001, 39, 181–194. [Google Scholar] [CrossRef]

- Gaal, M.; Bartusch, J.; Dohse, E.; Schadow, F.; Köppe, E. Focusing of ferroelectret air-coupled ultrasound transducers. In Proceedings of the 42nd Annual Review of Progress in Quantitative Nondestructive Evaluation: Incorporating the 6th European-American Workshop on Reliability of NDE, Minneapolis, MN, USA, 26–31 July 2015; AIP Publishing: Melville, NY, USA, 2016. [Google Scholar]

- Uhrig, M.P.; Kim, J.-Y.; Jacobs, L.J. Development of a 3D finite element model evaluating air-coupled ultrasonic measurements of nonlinear Rayleigh waves. In Proceedings of the 42nd Annual Review of Progress in Quantitative Nondestructive Evaluation: Incorporating the 6th European-American Workshop on Reliability of NDE, Minneapolis, MN, USA, 26–31 July 2015; AIP Publishing: Melville, NY, USA, 2016. [Google Scholar]

- Longo, R.; Vanlanduit, S.; Vanherzeele, J.; Guillaume, P. A method for crack sizing using Laser Doppler Vibrometer measurements of Surface Acoustic Waves. Ultrasonics 2010, 50, 76–80. [Google Scholar] [CrossRef] [PubMed]

- Mitra, M.; Gopalakrishnan, S. Guided wave based structural health monitoring: A review. Smart Mater. Struct. 2016, 25, 53001. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, J.; Hu, Y.; He, C.; Wu, B. Torsional mode magnetostrictive patch transducer array employing a modified planar solenoid array coil for pipe inspection. NDT E Int. 2015, 69, 9–15. [Google Scholar] [CrossRef]

- Xu, J.; Wu, X.; Kong, D.; Sun, P. A Guided Wave Sensor Based on the Inverse Magnetostrictive Effect for Distinguishing Symmetric from Asymmetric Features in Pipes. Sensors 2015, 15, 5151–5162. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.Y.; Kwon, Y.E. Review of magnetostrictive patch transducers and applications in ultrasonic nondestructive testing of waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef] [PubMed]

- Yoo, B.; Na, S.-M.; Flatau, A.B.; Pines, D.J. Directional magnetostrictive patch transducer based on Galfenol’s anisotropic magnetostriction feature. Smart Mater. Struct. 2014, 23, 95035. [Google Scholar] [CrossRef]

- Avanesians, P.; Momayez, M. Wave separation: Application for arrival time detection in ultrasonic signals. Ultrasonics 2015, 55, 15–25. [Google Scholar] [CrossRef] [PubMed]

- Farhidzadeh, A.; Salamone, S. Reference-free corrosion damage diagnosis in steel strands using guided ultrasonic waves. Ultrasonics 2015, 9437, 94371F. [Google Scholar] [CrossRef] [PubMed]

- Ng, C.-T. On the selection of advanced signal processing techniques for guided wave damage identification using a statistical approach. Eng. Struct. 2014, 67, 50–60. [Google Scholar] [CrossRef]

- Ahmed Mohamed, E.T.; Kamanyi, A.; von Buttlar, M.; Wannemacher, R.; Hillmann, K.; Ngwa, W.; Grill, W. A Defect Localization Procedure Based on Warped Lamb Waves. Acoust. Imaging 2011, 30, 125–134. [Google Scholar]

- Perelli, A.; De Marchi, L.; Marzani, A.; Speciale, N. Frequency warped cross-wavelet multiresolution analysis of guided waves for impact localization. Signal Process. 2014, 96, 51–62. [Google Scholar] [CrossRef]

- Hong, J.C.; Sun, K.H.; Kim, Y.Y. Waveguide damage detection by the matching pursuit using the gaussian chirp pulses. In Proceedings of the 2004 IEEE Ultrasonics Symposium, Montreal, QC, Canada, 23–27 August 2004; Volume 3, pp. 2310–2313. [Google Scholar]

- Mor, E.; Azoulay, A.; Aladjem, M. A matching pursuit method for approximating overlapping ultrasonic echoes. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 1996–2004. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Michaels, J.E. Numerical implementation of matching pursuit for the analysis of complex ultrasonic signals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 173–182. [Google Scholar] [PubMed]

- Tse, P.W.; Wang, X. Characterization of pipeline defect in guided-waves based inspection through matching pursuit with the optimized dictionary. NDT E Int. 2013, 54, 171–182. [Google Scholar] [CrossRef]

- Moll, J.; Heftrich, C.; Fritzen, C.-P. Time-varying inverse filtering of narrowband ultrasonic signals. Struct. Heal. Monit. 2010, 10, 403–415. [Google Scholar] [CrossRef]

- Wu, B.; Huang, Y.; Chen, X.; Krishnaswamy, S.; Li, H. Guided-wave signal processing by the sparse Bayesian learning approach employing Gabor pulse model. Struct. Heal. Monit. 2016, 1–16. [Google Scholar] [CrossRef]

- Raghavan, A.; Cesnik, C.E.S. Guided-wave signal processing using chirplet matching pursuits and mode correlation for structural health monitoring. Smart Mater. Struct. 2007, 16, 355–366. [Google Scholar] [CrossRef]

- Hong, J.C.; Sun, K.H.; Kim, Y.Y. Waveguide damage detection by the matching pursuit approach employing the dispersion-based chirp functions. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 592–604. [Google Scholar] [CrossRef] [PubMed]

- Valle, C.; Niethammer, M.; Qu, J.; Jacobs, L.J. Crack characterization using guided circumferential waves. J. Acoust. Soc. Am. 2001, 110, 1282–1290. [Google Scholar] [CrossRef] [PubMed]

- Ghose, B.; Balasubramaniam, K.; Krishnamurthy, C.V.; Rao, A.S. Two Dimensional FEM Simulation of Ultrasonic Wave Propagation in Isotropic Solid Media using COMSOL. In Proceedings of the Comsol Conference, Burlington, MA, USA, 5 April 2010. [Google Scholar]

- Mallat, S.G.; Zhang, Z. Matching pursuits with time-frequency dictionaries. IEEE Trans. Signal Process. 1993, 41, 3397–3415. [Google Scholar] [CrossRef]

- Hong, J.-C.; Sun, K.H.; Kim, Y.Y. The matching pursuit approach based on the modulated Gaussian pulse for efficient guided-wave damage inspection. Smart Mater. Struct. 2005, 14, 548–560. [Google Scholar] [CrossRef]

- Giurgiutiu, V. Tuned Lamb Wave Excitation and Detection with Piezoelectric Wafer Active Sensors for Structural Health Monitoring. J. Intell. Mater. Syst. Struct. 2005, 16, 291–305. [Google Scholar] [CrossRef]

- Lee, B.C.; Staszewski, W.J. Modelling of Lamb waves for damage detection in metallic structures: Part II. Wave interactions with damage. Smart Mater. Struct. 2003, 12, 815–824. [Google Scholar] [CrossRef]

- Willberg, C.; Duczek, S.; Vivar-Perez, J.M.; Ahmad, Z.A.B. Simulation Methods for Guided Wave-Based Structural Health Monitoring: A Review. Appl. Mech. Rev. 2015, 67, 10803. [Google Scholar] [CrossRef]

- Wan, X.; Xu, G.; Zhang, Q.; Tse, P.W.; Tan, H. A quantitative method for evaluating numerical simulation accuracy of time-transient Lamb wave propagation with its applications to selecting appropriate element size and time step. Ultrasonics 2016, 64, 25–42. [Google Scholar] [CrossRef] [PubMed]

- Bhuiyan, M.; Shen, Y.; Giurgiutiu, V. Guided Wave Based Crack Detection in the Rivet Hole Using Global Analytical with Local FEM Approach. Materials 2016, 9, 602. [Google Scholar] [CrossRef]

- Raisutis, R.; Kazys, R.; Mazeika, L.; Samaitis, V.; Zukauskas, E. Propagation of Ultrasonic Guided Waves in Composite Multi-Wire Ropes. Materials 2016, 9, 451. [Google Scholar] [CrossRef]

- Predoi, M.V. Guided waves dispersion equations for orthotropic multilayered pipes solved using standard finite elements code. Ultrasonics 2014, 54, 1825–1831. [Google Scholar] [CrossRef] [PubMed]

- Furukawa, T.; Komura, I. Simulation and visualization of guided wave propagation by large-scale 3D FEM. E-J. Adv. Maint. 2011, 3, 92–101. [Google Scholar]

- Castaings, M.; Bacon, C. Finite element modeling of torsional wave modes along pipes with absorbing materials. J. Acoust. Soc. Am. 2006, 119, 3741. [Google Scholar] [CrossRef]

- Bartoli, I.; Lanza di Scalea, F.; Fateh, M.; Viola, E. Modeling guided wave propagation with application to the long-range defect detection in railroad tracks. NDT E Int. 2005, 38, 325–334. [Google Scholar] [CrossRef]

- Wang, X.; Tse, P.W.; Dordjevich, A. Evaluation of pipeline defect’s characteristic axial length via model-based parameter estimation in ultrasonic guided wave-based inspection. Meas. Sci. Technol. 2011, 22, 25701. [Google Scholar] [CrossRef]

- Boßmann, F.; Plonka, G.; Peter, T.; Nemitz, O.; Schmitte, T. Sparse deconvolution methods for ultrasonic NDT: Application on TOFD and wall thickness measurements. J. Nondestruct. Eval. 2012, 31, 225–244. [Google Scholar] [CrossRef]

- Demirli, R.; Saniie, J. Model-based estimation pursuit for sparse decomposition of ultrasonic echoes. IET Signal Process. 2012, 6, 313. [Google Scholar] [CrossRef]

- Shi, G.; Chen, C.; Lin, J.; Xie, X.; Chen, X. Narrowband ultrasonic detection with high range resolution: Separating echoes via compressed sensing and singular value decomposition. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 2237–2253. [Google Scholar] [PubMed]

- Wei, L.; Huang, Z.-Y.; Que, P.-W. Sparse deconvolution method for improving the time-resolution of ultrasonic NDE signals. NDT E Int. 2009, 42, 430–434. [Google Scholar] [CrossRef]

- Li, X.; Li, X.; Liang, W.; Chen, L. ℓ0-Norm regularized minimum entropy deconvolution for ultrasonic NDT & E. NDT E Int. 2012, 47, 80–87. [Google Scholar]

- Zhang, G.-M.; Harvey, D.M.; Braden, D.R. Signal denoising and ultrasonic flaw detection via overcomplete and sparse representations. J. Acoust. Soc. Am. 2008, 124, 2963–2972. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.-M.; Zhang, C.-Z.; Harvey, D.M. Sparse signal representation and its applications in ultrasonic NDE. Ultrasonics 2012, 52, 351–363. [Google Scholar] [CrossRef] [PubMed]

- Hurley, N.P.; Rickard, S.T. Comparing Measures of Sparsity. IEEE Trans. Inf. Theory 2008, 55, 4723–4741. [Google Scholar] [CrossRef]

- Tse, P.W.; Liu, X.C.; Liu, Z.H.; Wu, B.; He, C.F.; Wang, X.J. An innovative design for using flexible printed coils for magnetostrictive-based longitudinal guided wave sensors in steel strand inspection. Smart Mater. Struct. 2011, 20, 55001. [Google Scholar] [CrossRef]

- Kim, H.W.; Kwon, Y.E.; Lee, J.K.; Kim, Y.Y. Higher torsional mode suppression in a pipe for enhancing the first torsional mode by using magnetostrictive patch transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2013, 60, 562–572. [Google Scholar] [PubMed]

- Jung Kim, H.; Seung Lee, J.; Woong Kim, H.; Sun Lee, H.; Young Kim, Y. Numerical simulation of guided waves using equivalent source model of magnetostrictive patch transducers. Smart Mater. Struct. 2015, 24, 15006. [Google Scholar] [CrossRef]

| Density (ρ) | Young’s Modulus () | Poisson’s Ratio () |

|---|---|---|

| 7800 kg/m3 | 200 GPa | 0.33 |

| Method | q | α | Th2 |

|---|---|---|---|

| SDMP | 0.1 | 0.95 | 0.8 |

| MP | 0.1 | 1 | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rostami, J.; Tse, P.W.T.; Fang, Z. Sparse and Dispersion-Based Matching Pursuit for Minimizing the Dispersion Effect Occurring when Using Guided Wave for Pipe Inspection. Materials 2017, 10, 622. https://doi.org/10.3390/ma10060622

Rostami J, Tse PWT, Fang Z. Sparse and Dispersion-Based Matching Pursuit for Minimizing the Dispersion Effect Occurring when Using Guided Wave for Pipe Inspection. Materials. 2017; 10(6):622. https://doi.org/10.3390/ma10060622

Chicago/Turabian StyleRostami, Javad, Peter W.T Tse, and Zhou Fang. 2017. "Sparse and Dispersion-Based Matching Pursuit for Minimizing the Dispersion Effect Occurring when Using Guided Wave for Pipe Inspection" Materials 10, no. 6: 622. https://doi.org/10.3390/ma10060622