The Mechanical Behavior of HAVAR Foils Using the Small Punch Technique

Abstract

:1. Introduction

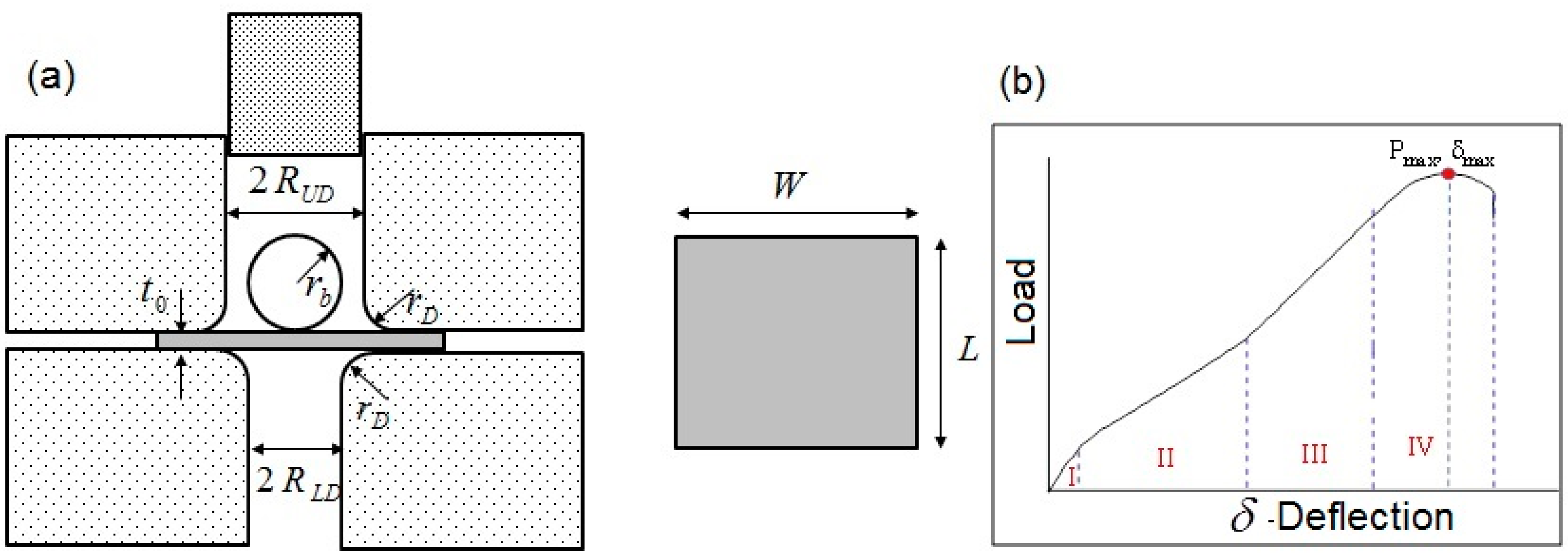

2. Experimental Procedure

3. Results and Discussion

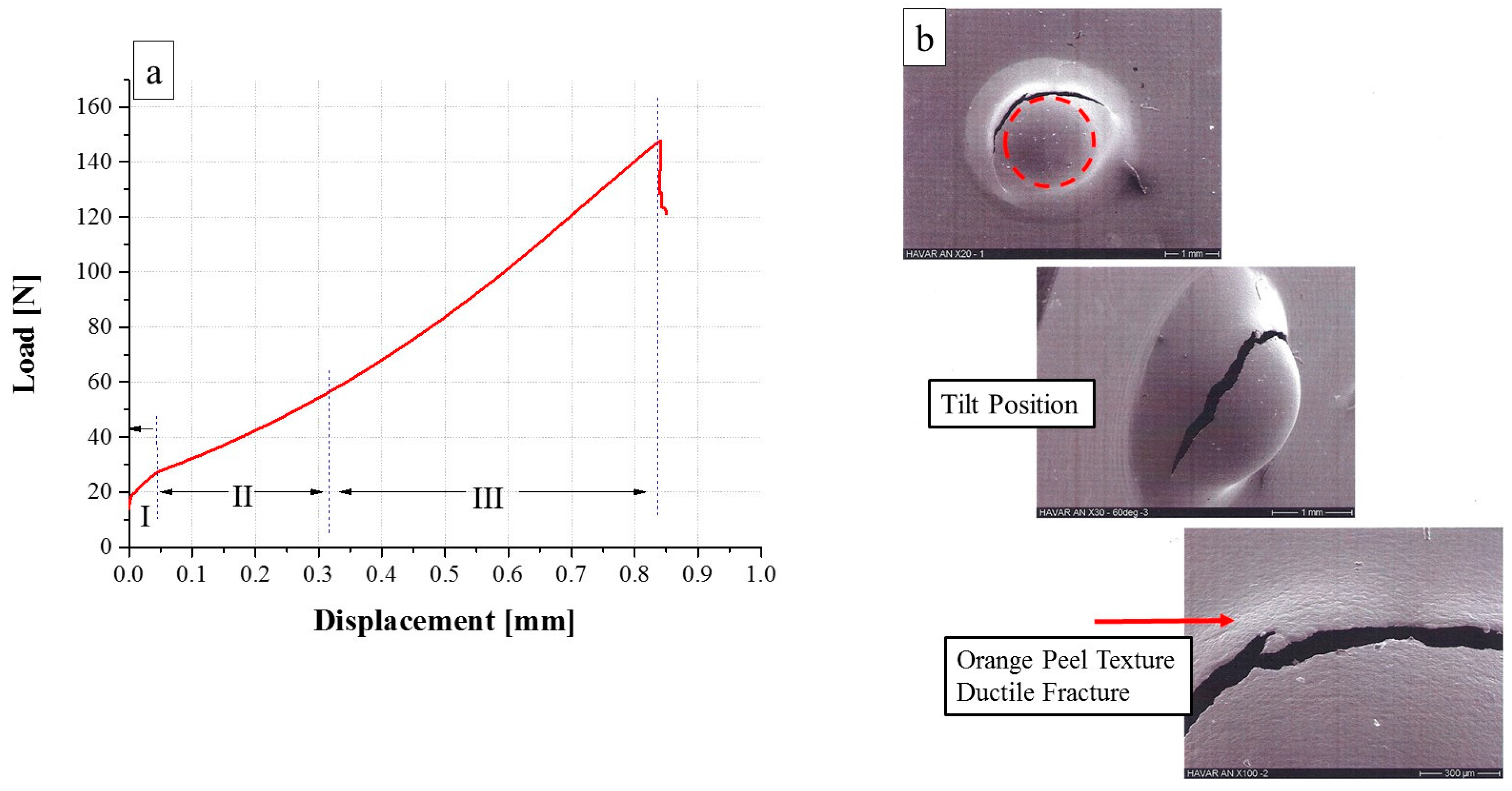

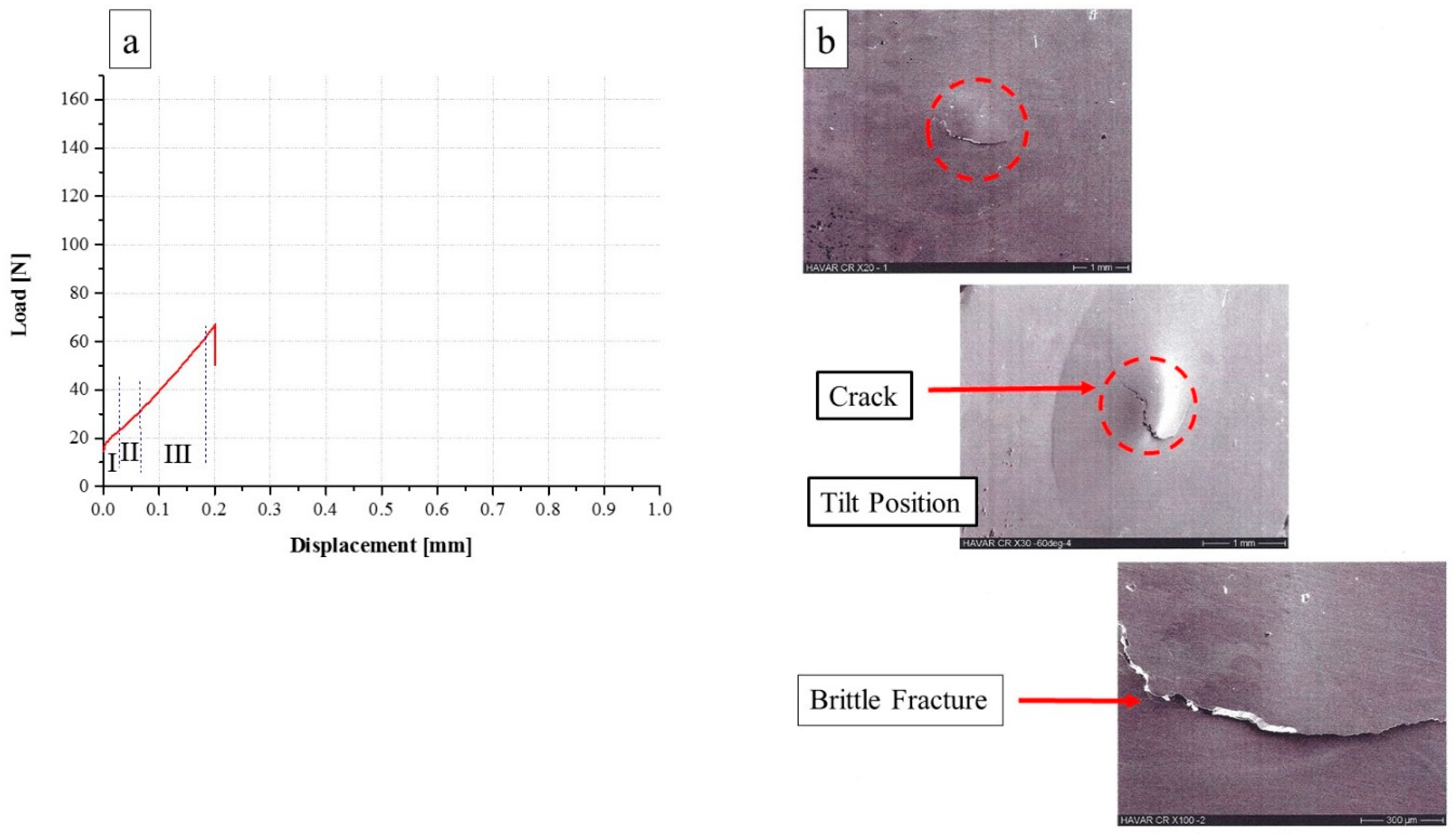

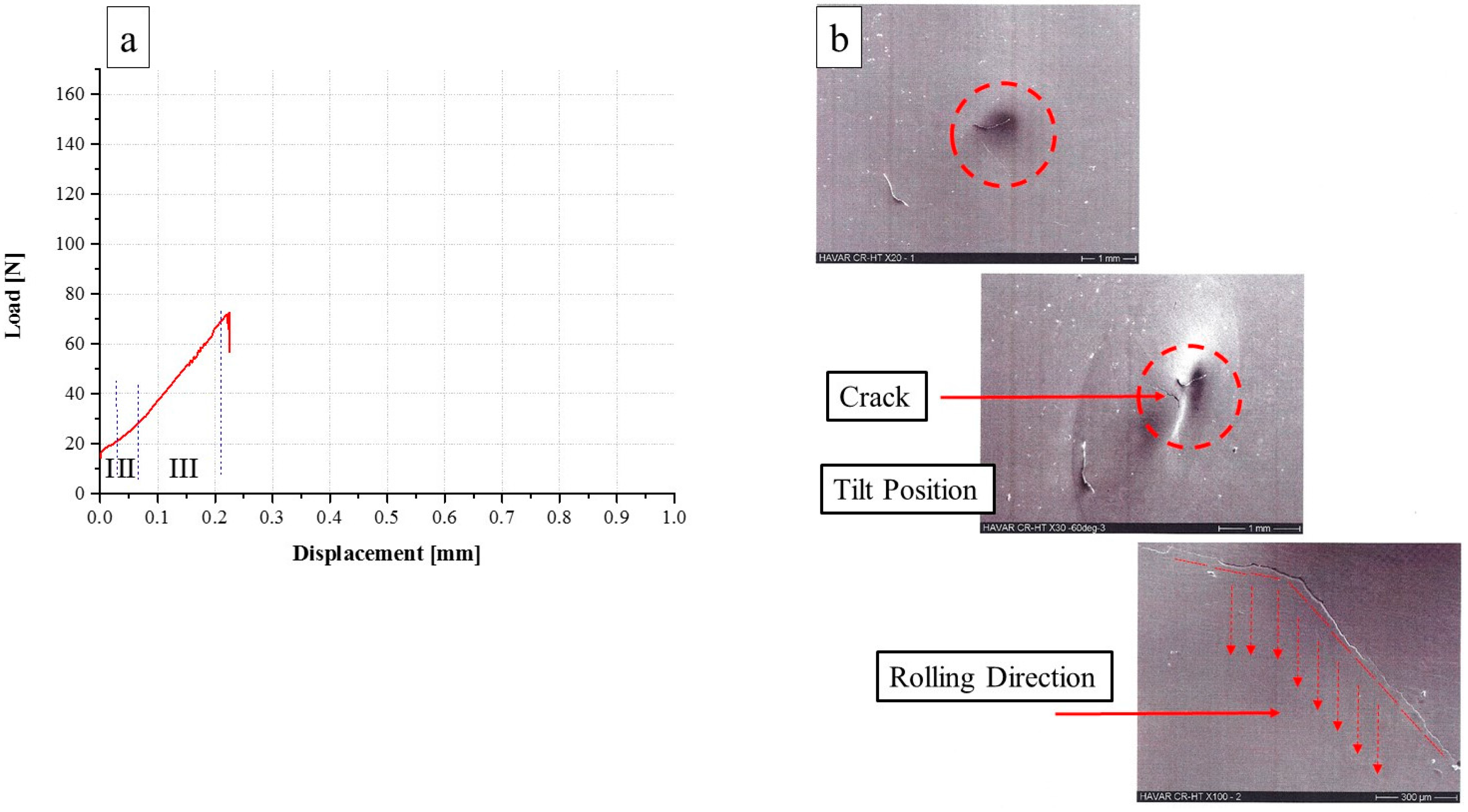

3.1. Small Punch Test

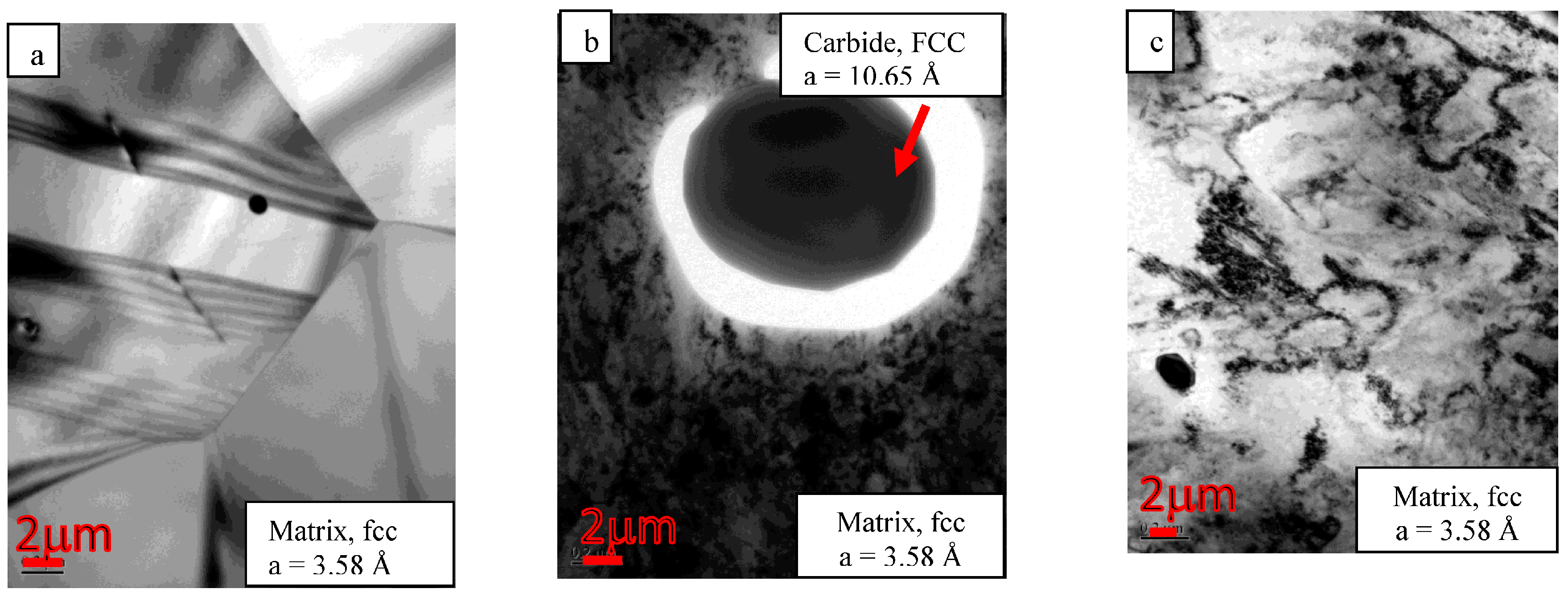

3.2. Crystallographic Structure

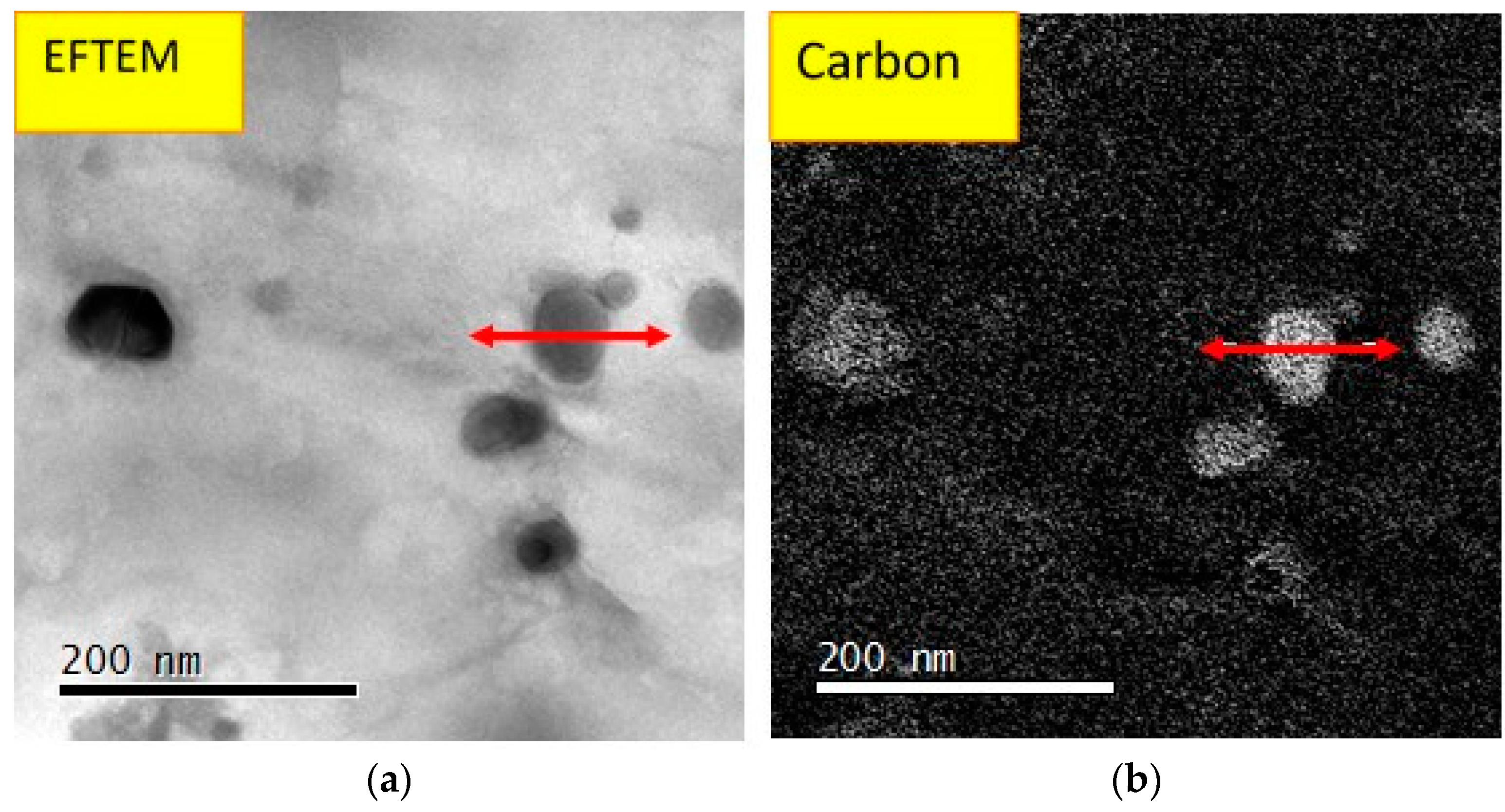

3.3. TEM Observation

4. Conclusions

Author Contributions

Conflicts of Interest

References

- Lucas, G. The development of small specimen mechanical test techniques. J. Nucl. Mater. 1983, 117, 327–339. [Google Scholar] [CrossRef]

- Guduru, R.K.; Darling, K.A.; Kishore, R.; Scattergood, R.O.; Koch, C.C.; Murty, K.L. Evaluation of mechanical properties using shear–punch testing. Mater. Sci. Eng. A 2005, 395, 307–314. [Google Scholar] [CrossRef]

- Guduru, R.K.; Wong, P.Z.; Darling, K.A.; Koch, C.C.; Murty, K.L.; Scattergood, R.O. Determination of activation volume in nanocrystalline Cu using the shear punch test. Adv. Eng. Mater. 2007, 9, 855–859. [Google Scholar] [CrossRef]

- Hamilton, M.; Toloczko, M. Effect of low temperature irradiation on the mechanical properties of ternary V–Cr–Ti alloys as determined by tensile tests and shear punch tests. J. Nucl. Mater. 2000, 283, 488–491. [Google Scholar] [CrossRef]

- Toloczko, M.B.; Kurtz, R.J.; Hasegawa, A.; Abe, K. Shear punch tests performed using a new low compliance test fixture. J. Nucl. Mater. 2002, 307, 1619–1623. [Google Scholar] [CrossRef]

- Hankin, G.L.; Toloczko, M.B.; Hamilton, M.L.; Garner, F.A.; Faulkner, R.G. Shear punch testing of 59 Ni isotopically-doped model austenitic alloys after irradiation in FFTF at different He/dpa ratios. J. Nucl. Mater. 1998, 258, 1657–1663. [Google Scholar] [CrossRef]

- Goyal, S.; Karthik, V.; Kasiviswanathan, K.V.; Valsan, M.; Rao, K.B.; Raj, B. Finite element analysis of shear punch testing and experimental validation. Mater. Des. 2010, 31, 2546–2552. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Ball Punch Deformation of Metallic Sheet Material; ASTM-E643; American Society for Testing and Materials: West Conshohocken, PA, USA, 1987; pp. 885–888. [Google Scholar]

- García, T.E.; Rodríguez, C.; Belzunce, F.J.; Suárez, C. Estimation of the mechanical properties of metallic materials by means of the small punch test. J. Alloys Compd. 2014, 582, 708–717. [Google Scholar] [CrossRef]

- Baik, J.-M.; Kameda, J.; Buck, O. Development of small punch tests for ductile-brittle transition temperature measurement of temper embrittled Ni-Cr steels. In The Use of Small-Scale Specimens for Testing Irradiated Material; Corwin, W.R., Lucas, G.E., Eds.; ASTM-STP 888; American Society for Testing and Materials: West Conshohocken, PA, USA, 1983; pp. 92–111. [Google Scholar]

- Mao, X.; Takahashi, H. Development of a further-miniaturized specimen of 3 mm diameter for tem disk (ø 3 mm) small punch tests. J. Nucl. Mater. 1987, 150, 42–52. [Google Scholar] [CrossRef]

- Klein, M.; Hadrboletz, A.; Weiss, B.; Khatibi, G. The ‘size effect’ on the stress–strain, fatigue and fracture properties of thin metallic foils. Mater. Sci. Eng. A 2001, 319, 924–928. [Google Scholar] [CrossRef]

- Matoca, K.; Hurst, R. The European Code of Practice for Small Punch testing—Where do we go from here. In Proceedings of the 1st International Conference on Determination of Mechanical Properties of Materials by Small Punch and other Miniature Testing Techniques, Ostrava, Czech Republic, 30 August–2 September 2010. [Google Scholar]

- Haroush, S.; Priel, E.; Moreno, D.; Busiba, A.; Silverman, I.; Turgeman, A.; Shneck, R.; Gelbstein, Y. Evaluation of the mechanical properties of SS-316L thin foils by small punch testing and finite element analysis. Mater. Des. 2015, 83, 75–84. [Google Scholar] [CrossRef]

- Gagnon, K.; Wilson, J.S.; Sant, E.; Backhouse, C.J.; McQuarrie, S.A. Assessing the performance and longevity of Nb, Pt, Ta, Ti, Zr, and ZrO2-sputtered Havar foils for the high-power production of reactive [18F]F− by proton irradiation of [18O] H2O. Appl. Radiat. Isot. 2011, 69, 1330–1336. [Google Scholar] [CrossRef] [PubMed]

- Shaiju, V.S.; Sharma, S.D.; Kumar, R.; Sarin, B. Target foil rupture scenario and provision for handling different models of medical cyclotrons used in India. J. Med. Phys 2009, 34, 161. [Google Scholar] [PubMed]

- Metals, H.P. HAVAR—Technical Data Sheet; Hamilton Precision Metals: Lancaster, PA, USA, 1991. [Google Scholar]

- Benson, R.B.J. The resistance of selected high strength alloys to embrittlement by a hydrogen environment. In Proceedings of the International Conference on the Effects of Hydrogen on Materials Properties and Selection and Structural Design, Champion, PA, USA, 23–27 September 1973. [Google Scholar]

| Maximal Load Displacement (mm) | Load (Max.) (N) | Alloy |

|---|---|---|

| 0.87 ± 0.01 | 154.19 ± 0.8 | Ann. |

| 0.19 ± 0.01 | 64.83 ± 3.4 | CR |

| 0.22 ± 0.007 | 69.62 ± 3.3 | CR-HT |

| Typical Tensile Mechanical Properties of HAVAR | |||

|---|---|---|---|

| Ann. | CR | CR-HT | |

| SUTS (Mpa) | 960 | 1860 | 2275 |

| S0.2% (Mpa) | 480 | 1725 | 2070 |

| Elongation to Fracture (%) | 40 | 1% | 1% |

| Hardness (HRc) | 25 | 50 | 60 |

| Modulus of Elasticity (Gpa) | 200 | 200 | 200 |

| Element (wt %) | Co | Co | Cr | Ni | Fe | W | Mo | Mn | C |

|---|---|---|---|---|---|---|---|---|---|

| Matrix | 41.68 | 41.68 | 19.49 | 12.5 | 19.5 | 2.78 | 2.19 | 1.56 | 0.20 |

| Particle (carbide) | 12–14 | 12–14 | 53–69 | 3–4 | 7–10 | 5–6 | 7–10 | 1.5–2.5 | Higher than 0.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haroush, S.; Moreno, D.; Silverman, I.; Turgeman, A.; Shneck, R.; Gelbstein, Y. The Mechanical Behavior of HAVAR Foils Using the Small Punch Technique. Materials 2017, 10, 491. https://doi.org/10.3390/ma10050491

Haroush S, Moreno D, Silverman I, Turgeman A, Shneck R, Gelbstein Y. The Mechanical Behavior of HAVAR Foils Using the Small Punch Technique. Materials. 2017; 10(5):491. https://doi.org/10.3390/ma10050491

Chicago/Turabian StyleHaroush, Shlomo, Daniel Moreno, Ido Silverman, Asher Turgeman, Roni Shneck, and Yaniv Gelbstein. 2017. "The Mechanical Behavior of HAVAR Foils Using the Small Punch Technique" Materials 10, no. 5: 491. https://doi.org/10.3390/ma10050491