Investigation on Indentation Cracking-Based Approaches for Residual Stress Evaluation

Abstract

:1. Introduction

2. Analytical Models

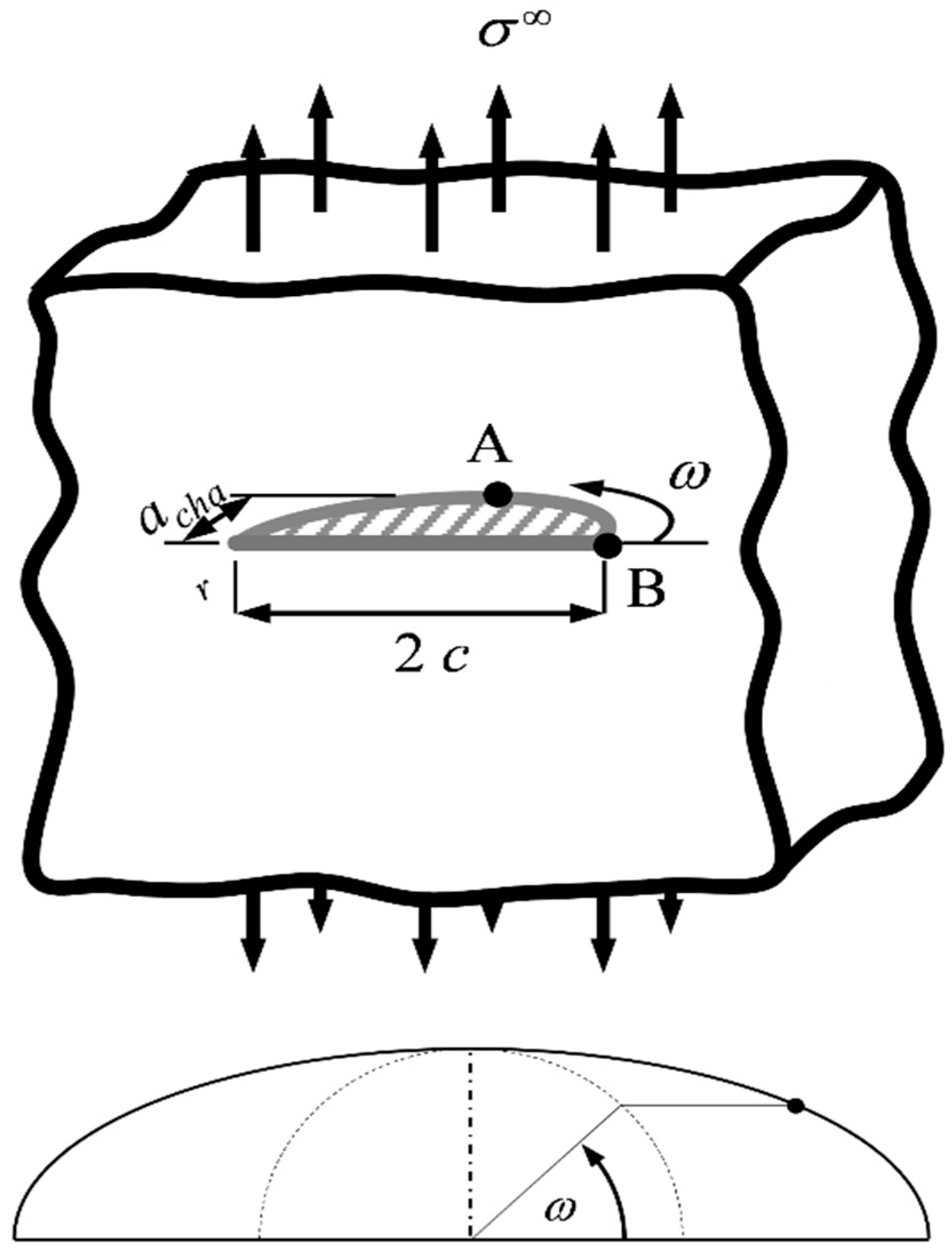

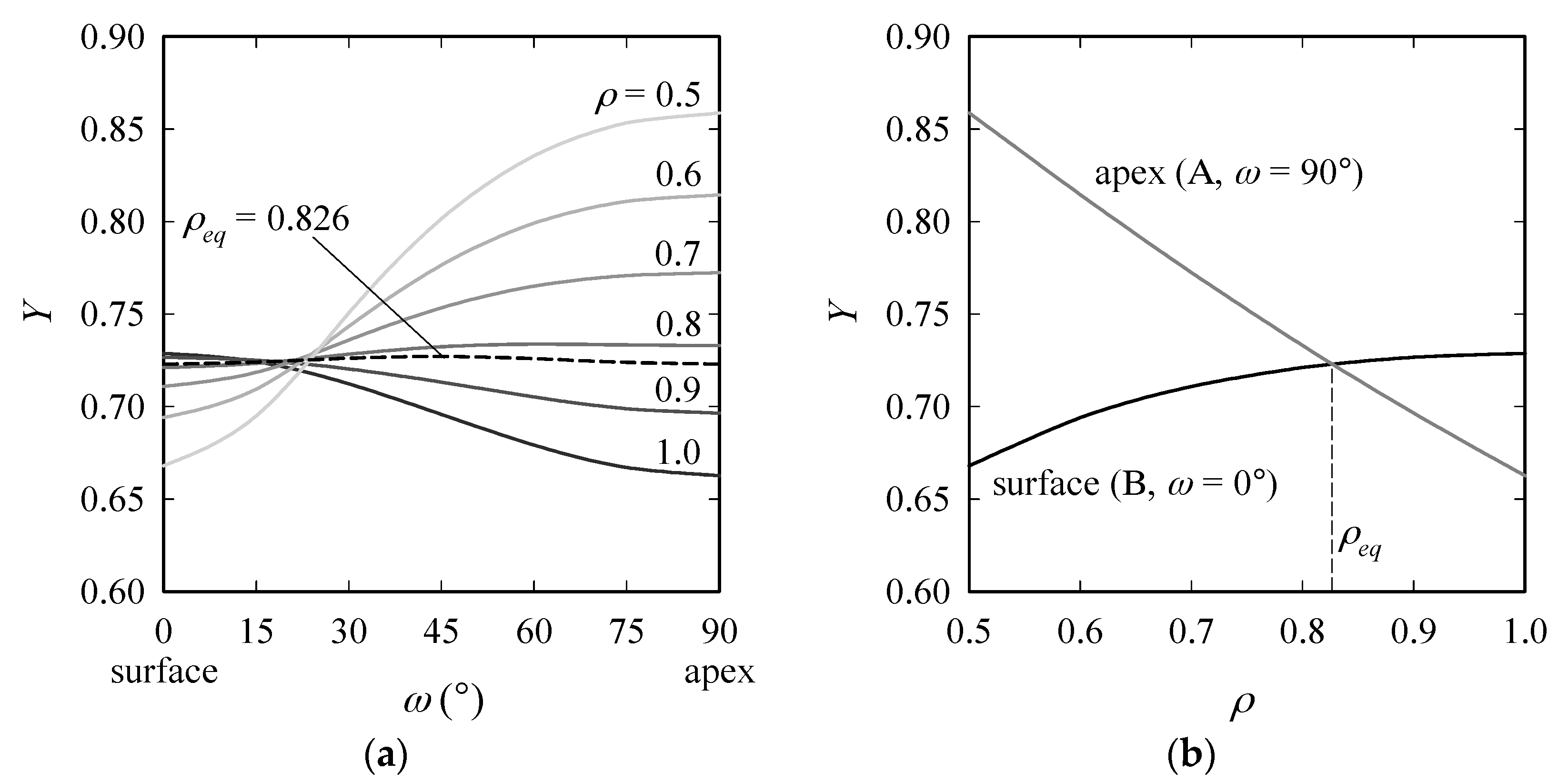

2.1. Shape Factor for a Semi-Elliptical Surface Crack Subject to Remote Tension

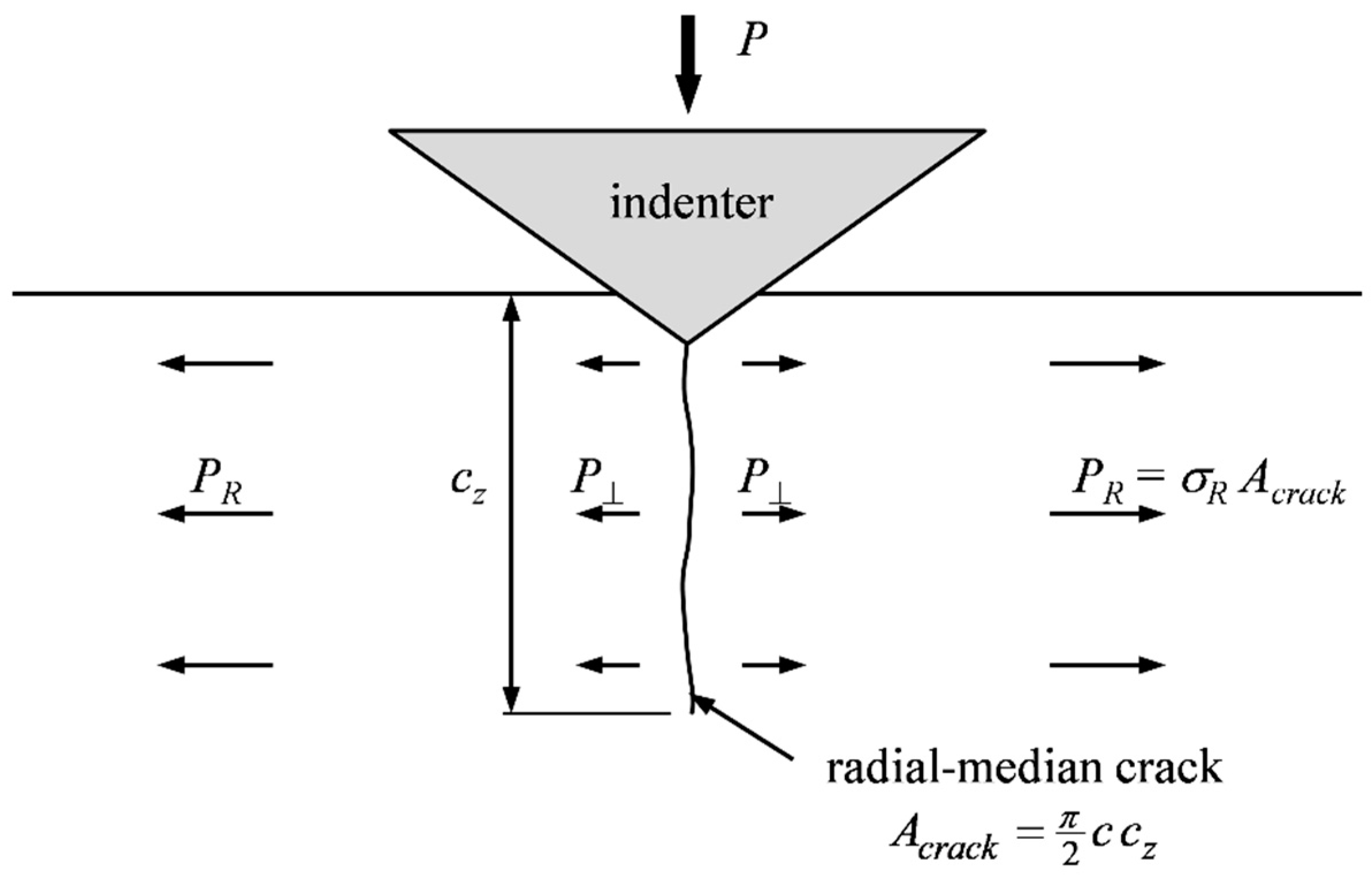

2.2. Previous Approaches

2.3. Generalized Analytical Model

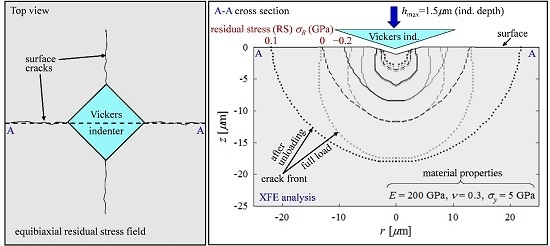

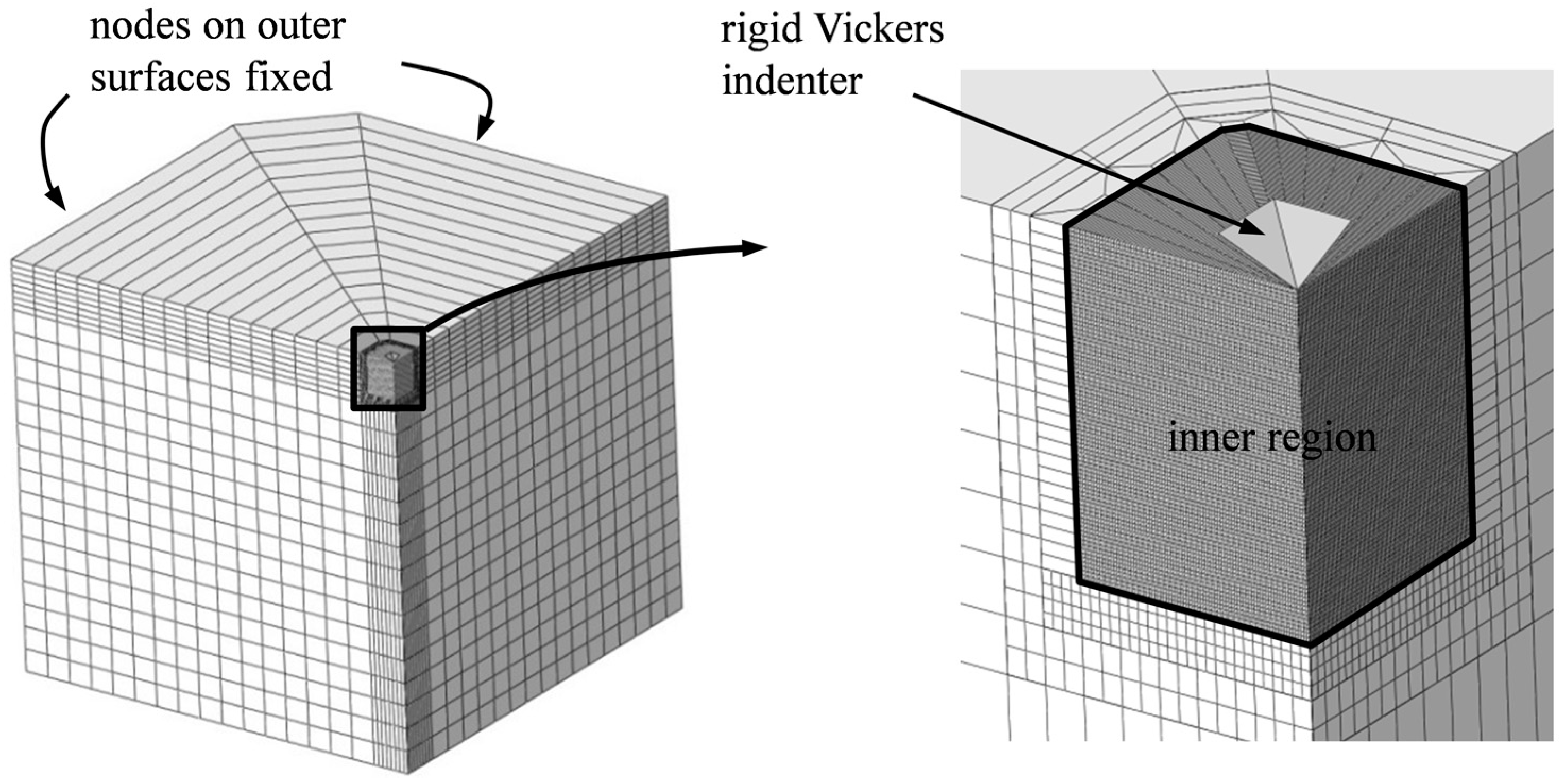

3. FE Model and Imposition of Equibiaxial RS

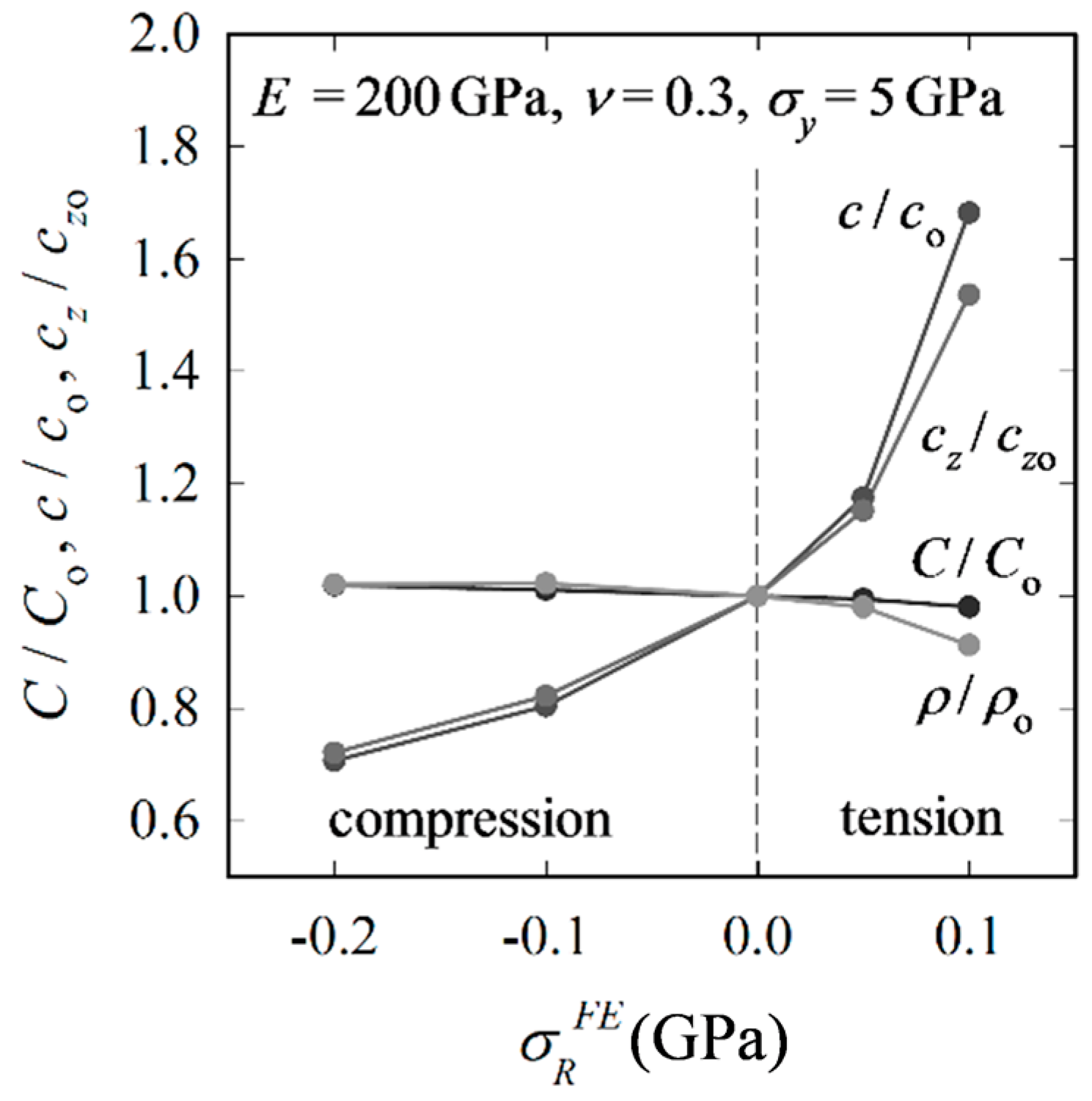

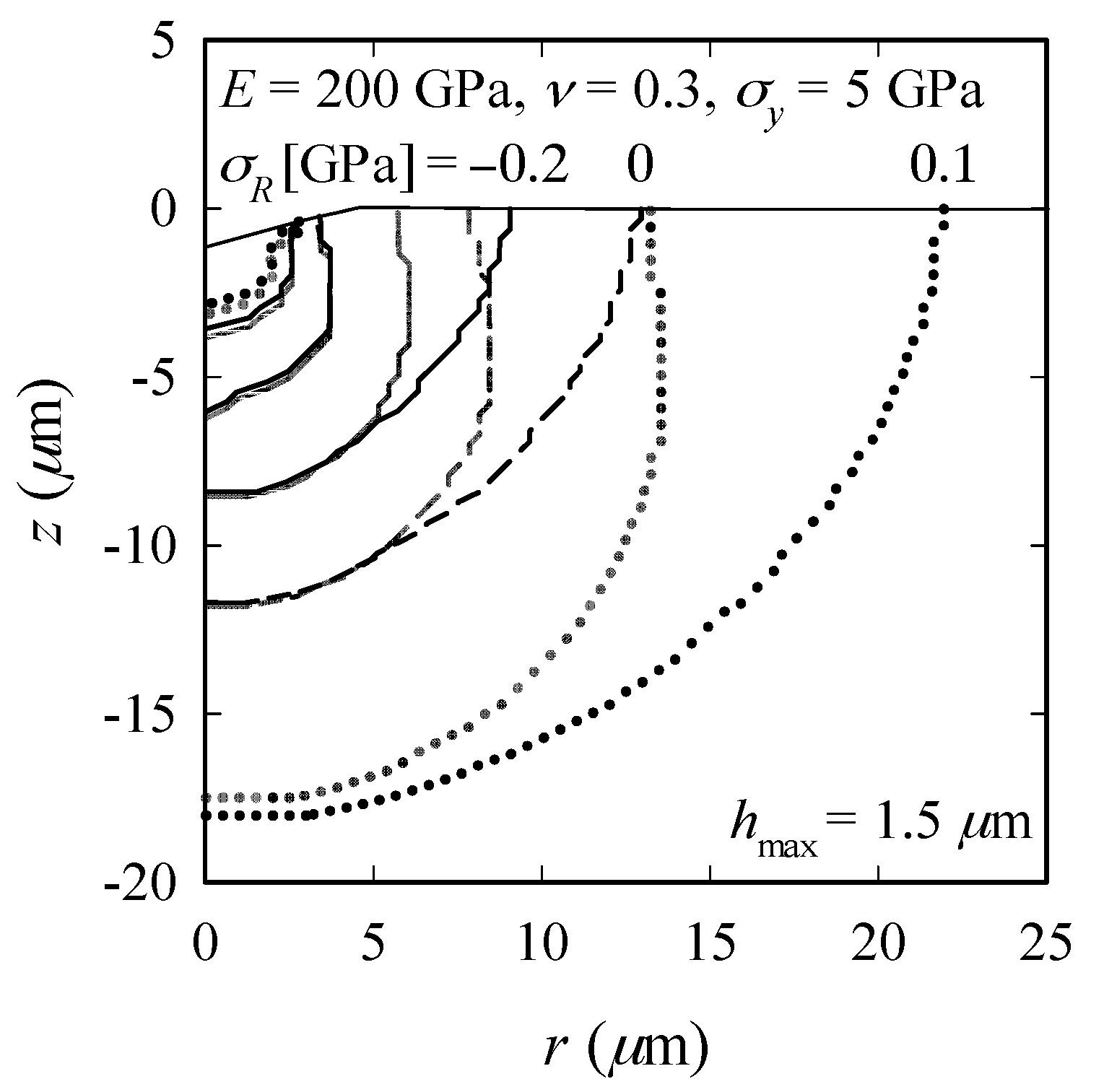

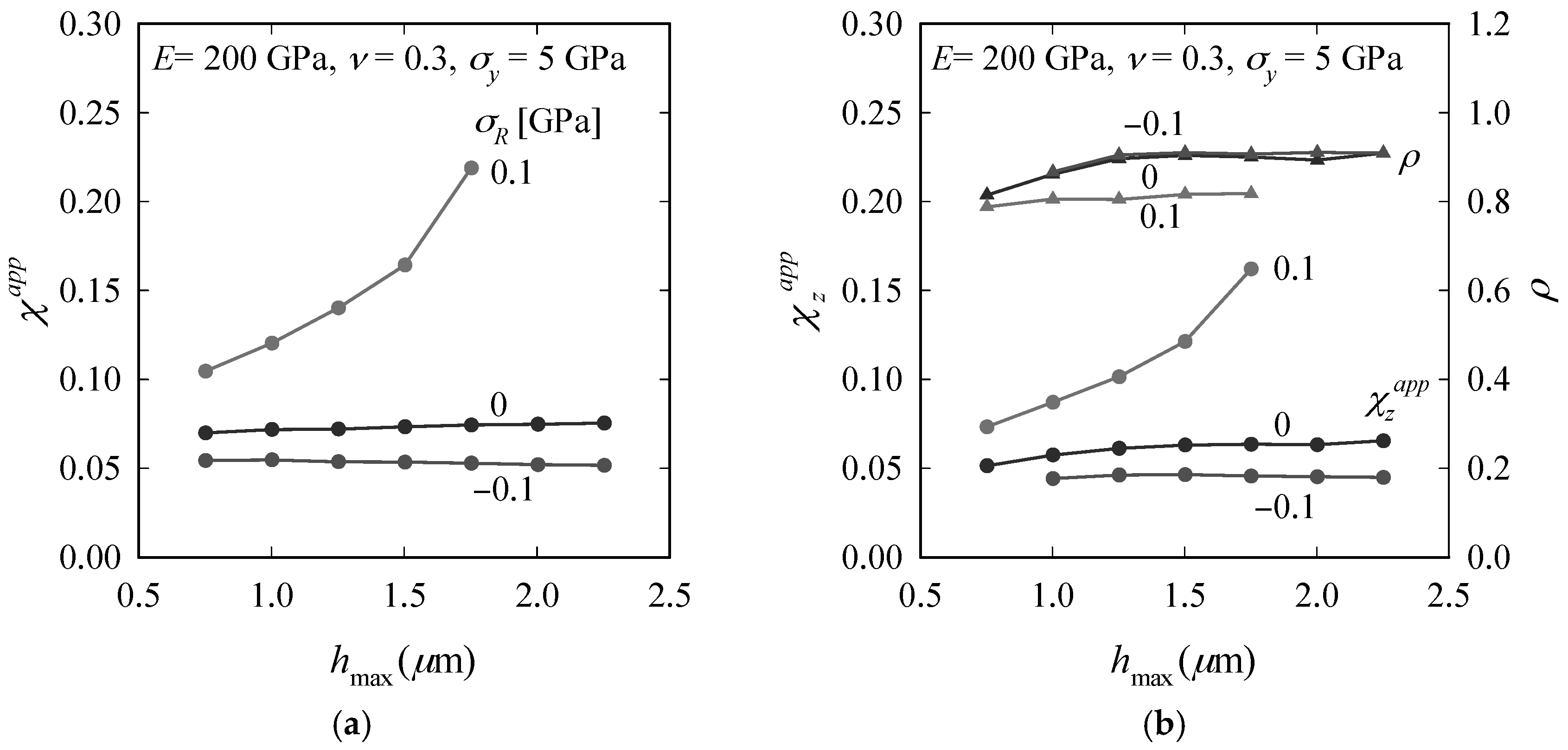

4. FE Results and Observations for Equibiaxial RS

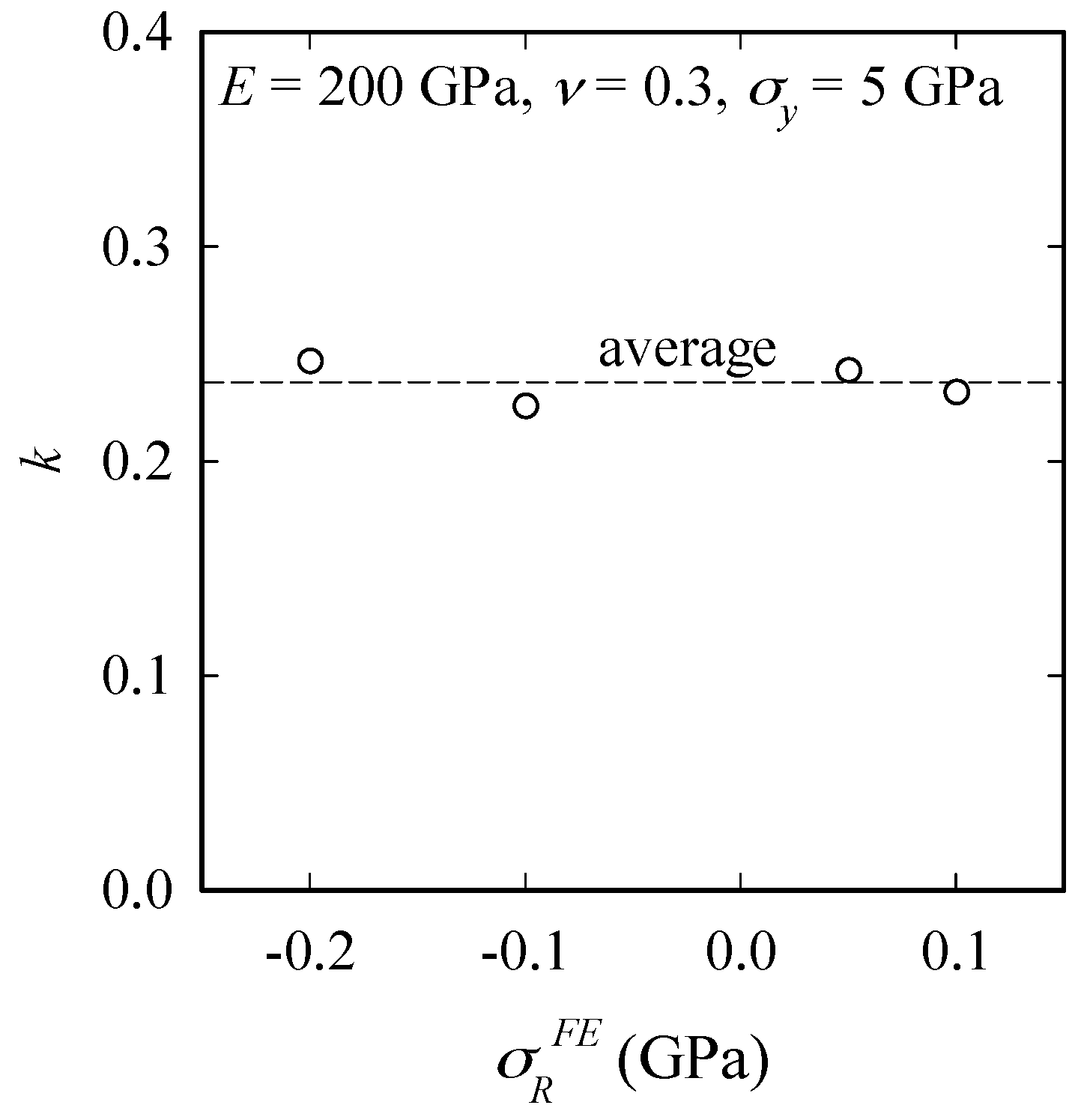

4.1. Observations Made for Reference Material

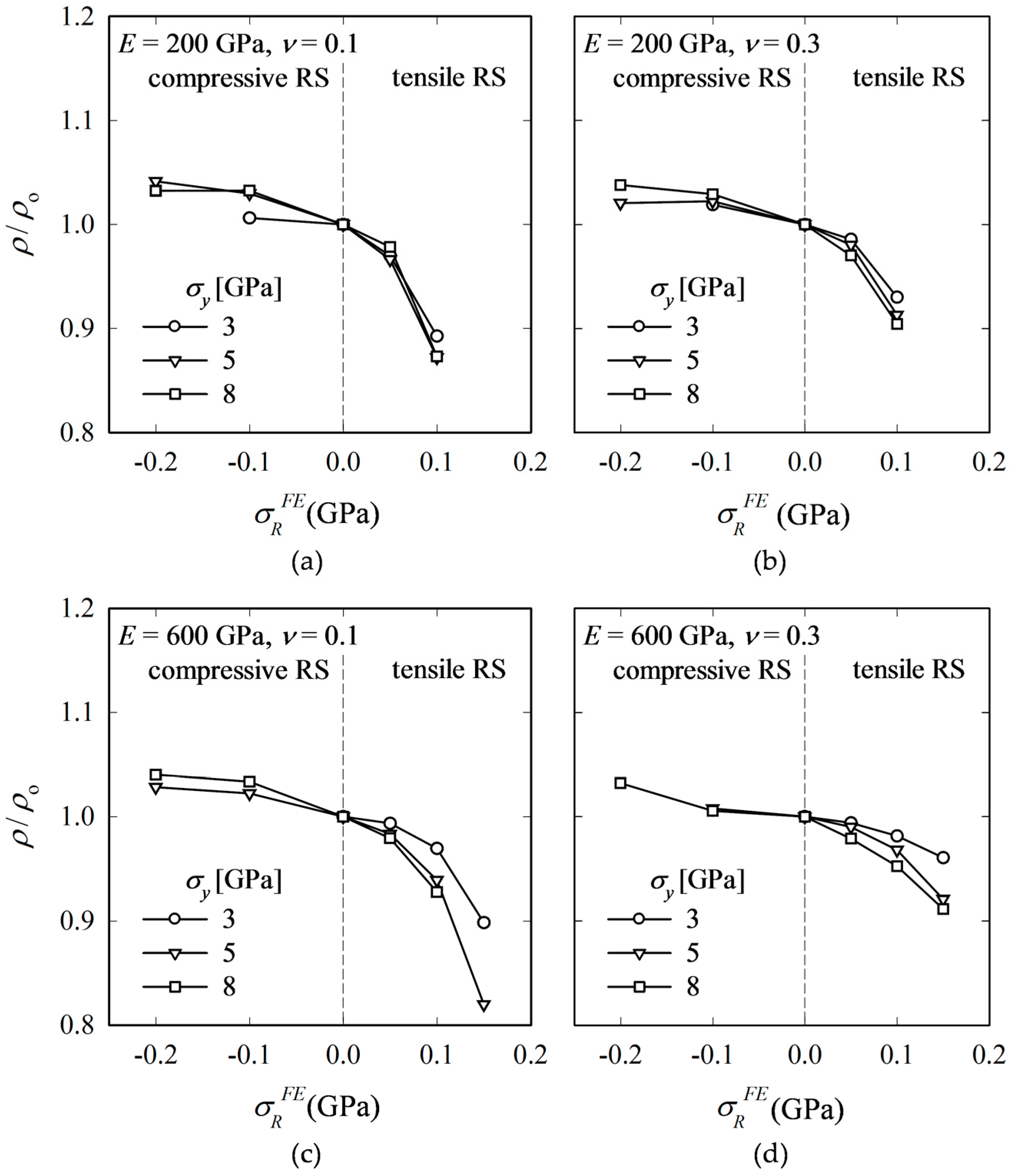

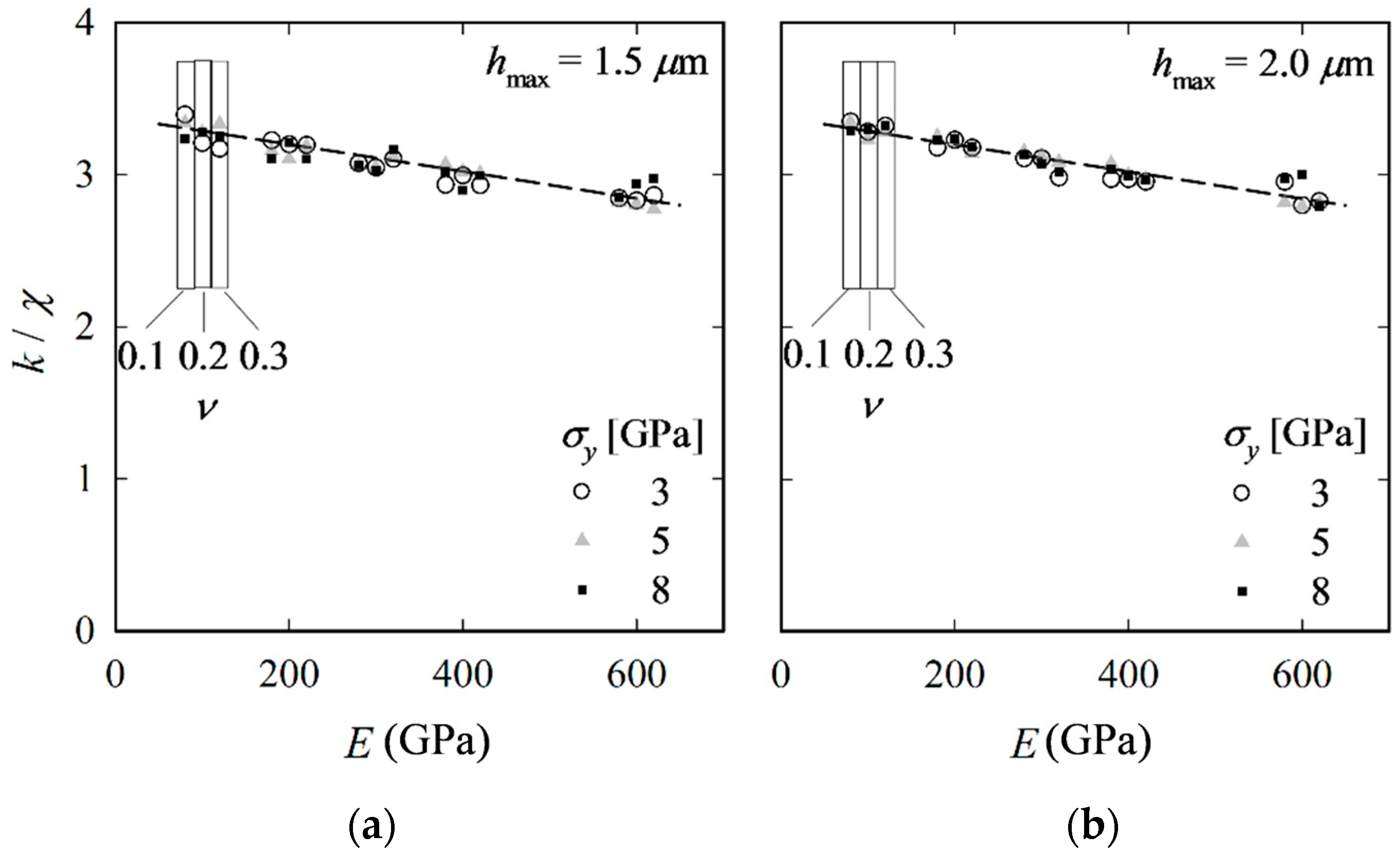

4.2. Influence of Material Properties

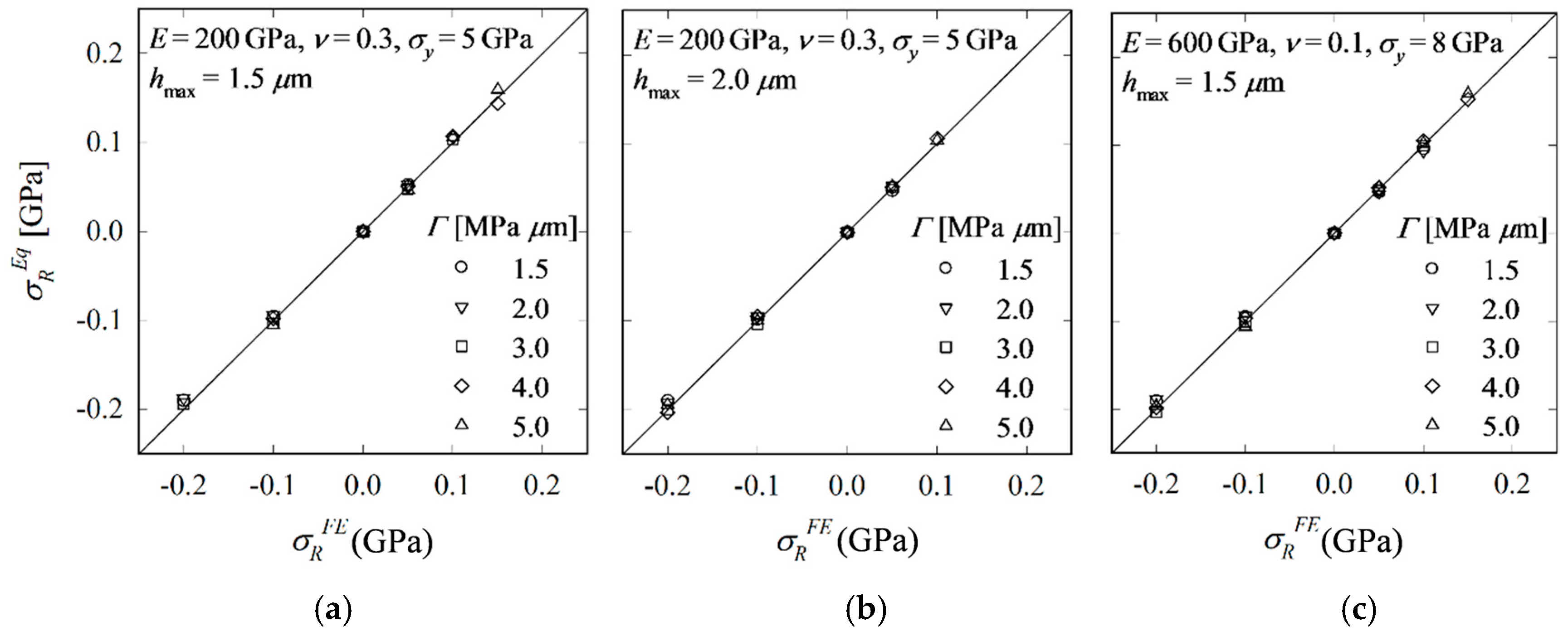

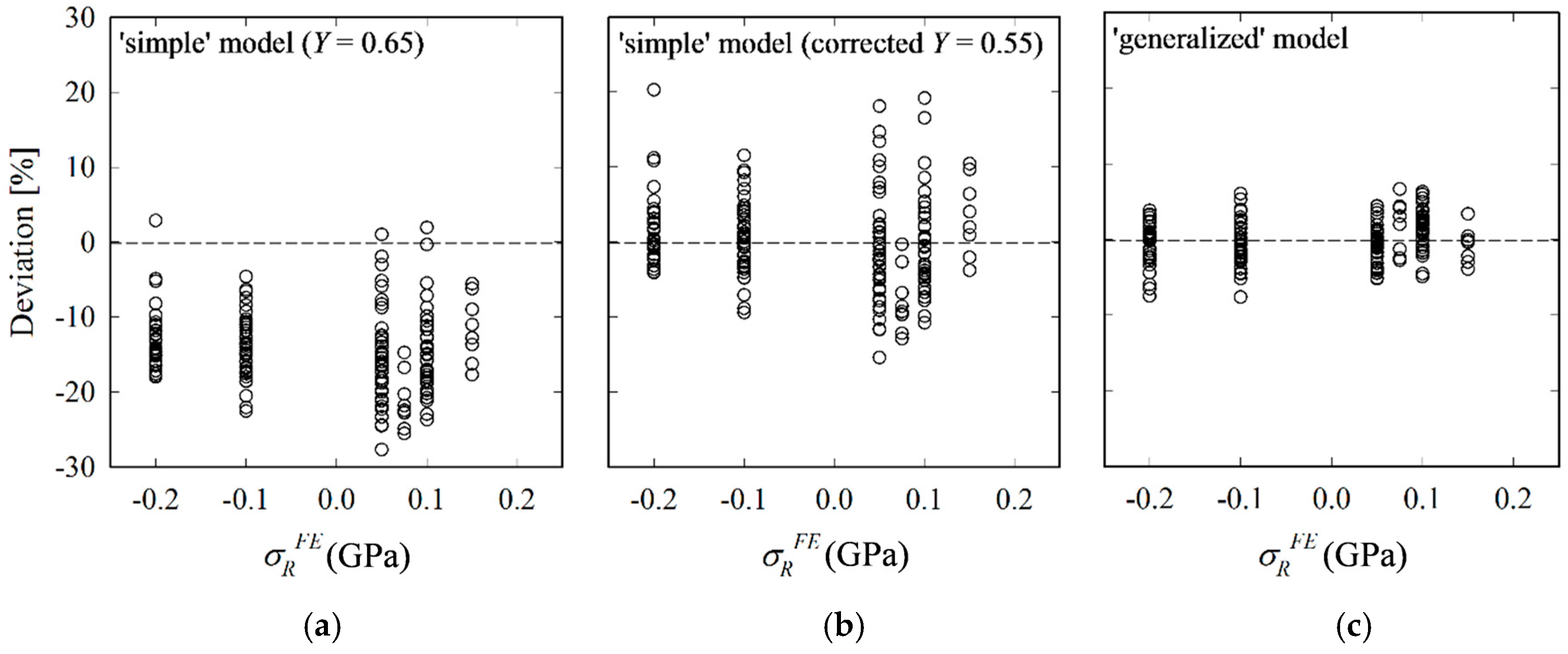

4.3. Comparison of Analytical Models and Conclusion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Warren, A.W.; Guo, Y.B.; Weaver, M.L. The influence of machining induced residual stress and phase transformation on the measurement of subsurface mechanical behavior using nanoindentation. Surf. Coat. Technol. 2006, 200, 3459–3467. [Google Scholar] [CrossRef]

- Golovin, Y.I. Nanoindentation and mechanical properties of solids in submicrovolumes, thin near-surface layers, and films: A Review. Phys. Solid State 2008, 50, 2205–2236. [Google Scholar] [CrossRef]

- Groth, B.P.; Langan, S.M.; Haber, R.A.; Mann, A.B. Relating residual stresses to machining and finishing in silicon carbide. Ceram. Int. 2016, 42, 799–807. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, C.; Cai, F.; Zhao, Y.; Zhu, K.; Chai, Z. Effect of shot peening on the residual stresses and microstructure of tungsten cemented carbide. Mater. Des. 2016, 95, 159–164. [Google Scholar] [CrossRef]

- Rossini, N.S.; Dassisti, M.; Benyounis, K.Y.; Olabi, A.G. Methods of measuring residual stresses in components. Mater. Des. 2012, 35, 572–588. [Google Scholar] [CrossRef]

- Skouras, A.; Paradowska, A.; Peel, M.J.; Flewitt, P.E.J.; Pavier, M.J. Residual stress measurements in a ferritic steel/In625 superalloy dissimilar metal weldment using neutron diffraction and deep-hole drilling. Int. J. Press. Vessel. Pip. 2013, 101, 143–153. [Google Scholar] [CrossRef]

- Hauk, V. Structural and Residual Stress Analysis by Nondestructive Methods: Evaluation-Application-Assessment; Elsevier Science B.V.: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Kandill, F.A.; Lord, D.J.; Fry, A.T.; Grant, P.V. A Review of Residual Stress Measurement Methods: A Guide to Technique Selection; NPL Report/MATC/A: NPL Report; National Physical Laboratory: Teddington, UK, 2001. [Google Scholar]

- Jannotti, P.; Subhash, G. Measurement of residual stresses in B4C-SiC-Si ceramics using Raman spectroscopy. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems, Volume 9. In Proceedings of the 2015 Annual Conference on Experimental and Applied Mechanics, Costa Mesa, CA, USA, 8–11 June 2015; Bossuyt, S., Schajer, G., Carpinteri, A., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 341–345. [Google Scholar]

- Jang, J.I. Estimation of residual stress by instrumented indentation: A review. J. Ceram. Process. Res. 2009, 10, 391–400. [Google Scholar]

- Rickhey, F.; Lee, J.H.; Lee, H. A contact size-independent approach to the estimation of biaxial residual stresses by Knoop indentation. Mater. Des. 2015, 84, 300–312. [Google Scholar] [CrossRef]

- Sebastiani, M.; Bemporad, E.; Carassiti, F.; Schwarzer, N. Residual stress measurement at the micrometer scale: Focused ion beam (FIB) milling and nanoindentation testing. Philos. Mag. 2011, 91, 1121–1136. [Google Scholar] [CrossRef]

- Rickhey, F.; Kim, M.; Lee, H. XFEM simulation of radial-median crack formation in brittle medium underneath sharp indenters. In Proceedings of the KSME 2014 Spring Annual Meeting, Ansan, Korea, 22–23 May 2014; The Korean Society of Mechanical Engineers: Seoul, Korea, 2014; pp. 2143–2148. [Google Scholar]

- Lawn, B.; Wilshaw, R. Indentation fracture: Principles and applications. J. Mater. Sci. 1975, 10, 1049–1081. [Google Scholar] [CrossRef]

- Chaudhri, M.M.; Phillips, M.A. Quasi-static indentation cracking of thermally tempered soda lime glass with spherical and Vickers indenters. Philos. Mag. A 1990, 62, 1–27. [Google Scholar] [CrossRef]

- Roberts, S.G.; Lawrence, C.W.; Bisrat, Y.; Warren, P.D.; Hills, D.A. Determination of surface residual stresses in brittle materials by Hertzian indentation: Theory and experiment. J. Am. Ceram. Soc. 1999, 82, 1809–1816. [Google Scholar] [CrossRef]

- Petit, F.; Sartieaux, A.C.; Gonon, M.; Cambier, F. Fracture toughness and residual stress measurements in tempered glass by Hertzian indentation. Acta Mater. 2007, 55, 2765–2774. [Google Scholar] [CrossRef]

- Chandrasekar, S.; Chaudhri, M.M. Indentation cracking in soda-lime glass and Ni-Zn ferrite under Knoop and conical indenters and residual stress measurements. Philos. Mag. A 1993, 67, 1187–1218. [Google Scholar] [CrossRef]

- Kese, K.; Rowcliffe, D.J. Nanoindentation method for measuring residual stress in brittle materials. J. Am. Ceram. Soc. 2003, 86, 811–816. [Google Scholar] [CrossRef]

- Scares, P.C.; Lepienski, C.M. Residual stress determination on lithium disilicate glass-ceramic by nanoindentation. J. Non. Cryst. Solids 2004, 348, 139–143. [Google Scholar]

- Ahn, Y.; Chandrasekar, S.; Farris, T.N. Determination of surface residual stresses in machined ceramics using indentation fracture. J. Manuf. Sci. Eng. 1996, 118, 483–489. [Google Scholar] [CrossRef]

- Malzbender, J.; de With, G.; den Toonder, J.M. Elastic modulus, indentation pressure and fracture toughness of hybrid coatings on glass. Thin Solid Films 2000, 366, 139–149. [Google Scholar] [CrossRef]

- Tandon, R.; Cook, R.E. Indentation Crack Initiation and Propagation in Tempered Glass. J. Am. Ceram. Soc. 1993, 76, 885–889. [Google Scholar] [CrossRef]

- Koike, A.; Akiba, S.; Sakagami, T.; Hayashi, K.; Ito, S. Difference of cracking behavior due to Vickers indentation between physically and chemically tempered glasses. J. Non. Cryst. Solids 2012, 358, 3438–3444. [Google Scholar] [CrossRef]

- Zeng, K.; Rowcliffe, D. Experimental measurement of residual stress field around sharp indentation in glass. J. Am. Ceram. Soc. 1994, 77, 524–530. [Google Scholar] [CrossRef]

- Zeng, K.; Giannakopoulos, A.E.; Rowcliffe, D.J. Vickers indentations in glass-II. Comparison of finite element analysis and experiments. Acta Metall. Mater. 1995, 43, 1945–1954. [Google Scholar] [CrossRef]

- Peitl, O.; Serbena, F.C.; Mastelaro, V.R.; Zanotto, E.D. Internal residual stress measurements in a bioactive glass–ceramic using Vickers indentation. J. Am. Ceram. Soc. 2010, 93, 2359–2368. [Google Scholar] [CrossRef]

- Bisrat, Y.; Roberts, S.G. Residual stress measurement by Hertzian indentation. Mater. Sci. Eng. A 2000, 288, 148–153. [Google Scholar] [CrossRef]

- Serbena, F.C.; Zanotto, E.D. Internal residual stresses in glass-ceramics: A review. J. Non. Cryst. Solids 2012, 358, 975–984. [Google Scholar] [CrossRef]

- Rodríguez-López, S.; Comesaña, R.; del Val, J.; Durán, A.; Justo, V.M.; Serbena, F.C.; Pascual, M.J. Laser cladding of glass-ceramic sealants for SOFC. J. Eur. Ceram. Soc. 2015, 35, 4475–4484. [Google Scholar] [CrossRef]

- Taskonak, B.; Mecholsky, J.J.; Anusavice, K.J. Residual stresses in bilayer dental ceramics. Biomaterials 2005, 26, 3235–3241. [Google Scholar] [CrossRef] [PubMed]

- Fischer, H.; Hemelik, M.; Telle, R.; Marx, R. Influence of annealing temperature on the strength of dental glass ceramic materials. Dent. Mater. 2005, 21, 671–677. [Google Scholar] [CrossRef] [PubMed]

- Anunmana, C.; Anusavice, K.J.; Mecholsky, J.J. Residual stress in glass: Indentation crack and fractography approaches. Dent. Mater. 2009, 25, 1453–1458. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.E.; Waddell, J.N.; Swain, M.V. Pressed ceramics onto zirconia. Part 2: Indentation fracture and influence of cooling rate on residual stresses. Dent. Mater. 2011, 27, 1111–1118. [Google Scholar] [CrossRef] [PubMed]

- Baldassarri, M.; Stappert, C.F.J.; Wolff, M.S.; Thompson, V.P.; Zhang, Y. Residual stresses in porcelain-veneered zirconia prostheses. Dent. Mater. 2012, 28, 873–879. [Google Scholar] [CrossRef] [PubMed]

- Al-Amleh, B.; Neil Waddell, J.; Lyons, K.; Swain, M.V. Influence of veneering porcelain thickness and cooling rate on residual stresses in zirconia molar crowns. Dent. Mater. 2014, 30, 271–280. [Google Scholar] [CrossRef] [PubMed]

- Wendler, M.; Belli, R.; Petschelt, A.; Lohbauer, U. Characterization of residual stresses in zirconia veneered bilayers assessed via sharp and blunt indentation. Dent. Mater. 2015, 31, 948–957. [Google Scholar] [CrossRef] [PubMed]

- Pfeiffer, W.; Frey, T. Strengthening of ceramics by shot peening. J. Eur. Ceram. Soc. 2006, 26, 2639–2645. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Newman, J.C.; Raju, I.S. An empirical stress-intensity factor equation for the surface crack. Eng. Fract. Mech. 1981, 15, 185–192. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Marshall, D.B.; Lawn, B.R. An indentation technique for measuring stresses in tempered glass surfaces. J. Am. Ceram. Soc. 1977, 60, 86–87. [Google Scholar] [CrossRef]

- Swain, M.V.; Hagan, J.T.; Field, J.E. Determination of the surface residual stresses in tempered glasses by indentation fracture mechanics. J. Mater. Sci. 1977, 12, 1914–1917. [Google Scholar] [CrossRef]

- Lawn, B.R.; Evans, A.G.; Marshall, D.B. Elastic/plastic indentation damage in ceramics: The median/radial crack system. J. Am. Ceram. Soc. 1980, 63, 574–581. [Google Scholar] [CrossRef]

- Rickhey, F.; Lee, J.H.; Lee, H. XFEM investigation on Knoop indentation cracking: Fracture toughness and aspect-ratio of radial-median cracks. Mater. Des. 2016, 107, 393–405. [Google Scholar] [CrossRef]

- Abaqus User’s Manual-Version 6.14, Dassault Systems Simulia Corp: Providence, RI, USA, 2014.

- Francois, P.; Lefebvre, A.; Vanderschaeve, G. Low temperature plasticity of brittle materials. A new device for compressive testing under confining pressure. Phys. Status Solidi 1988, 109, 187–192. [Google Scholar] [CrossRef]

- Lee, J.H.; Gao, Y.F.; Johanns, K.E.; Pharr, G.M. Cohesive interface simulations of indentation cracking as a fracture toughness measurement method for brittle materials. Acta Mater. 2012, 60, 5448–5467. [Google Scholar] [CrossRef]

- Sines, G.; Carlson, R. Hardness measurements for determination of residual stresses. ASTM Bull. 1952, 180, 35–37. [Google Scholar]

- Suresh, S.; Giannakopoulos, A.E. A new method for estimating residual stresses by instrumented sharp indentation. Acta Mater. 1998, 46, 5755–5767. [Google Scholar] [CrossRef]

- Cuadrado, N.; Seuba, J.; Casellas, D.; Anglada, M.; Jiménez-Piqué, E. Geometry of nanoindentation cube-corner cracks observed by FIB tomography: Implication for fracture resistance estimation. J. Eur. Ceram. Soc. 2015, 35, 2949–2955. [Google Scholar] [CrossRef]

| Material Properties | Values |

|---|---|

| E (GPa) | 100, 200, 300, 400, 600 |

| ν | 0.1, 0.2, 0.3 |

| σy (GPa) | 3, 5, 8 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rickhey, F.; Marimuthu, K.P.; Lee, H. Investigation on Indentation Cracking-Based Approaches for Residual Stress Evaluation. Materials 2017, 10, 404. https://doi.org/10.3390/ma10040404

Rickhey F, Marimuthu KP, Lee H. Investigation on Indentation Cracking-Based Approaches for Residual Stress Evaluation. Materials. 2017; 10(4):404. https://doi.org/10.3390/ma10040404

Chicago/Turabian StyleRickhey, Felix, Karuppasamy Pandian Marimuthu, and Hyungyil Lee. 2017. "Investigation on Indentation Cracking-Based Approaches for Residual Stress Evaluation" Materials 10, no. 4: 404. https://doi.org/10.3390/ma10040404