Interacting Effects Induced by Two Neighboring Pits Considering Relative Position Parameters and Pit Depth

Abstract

:1. Introduction

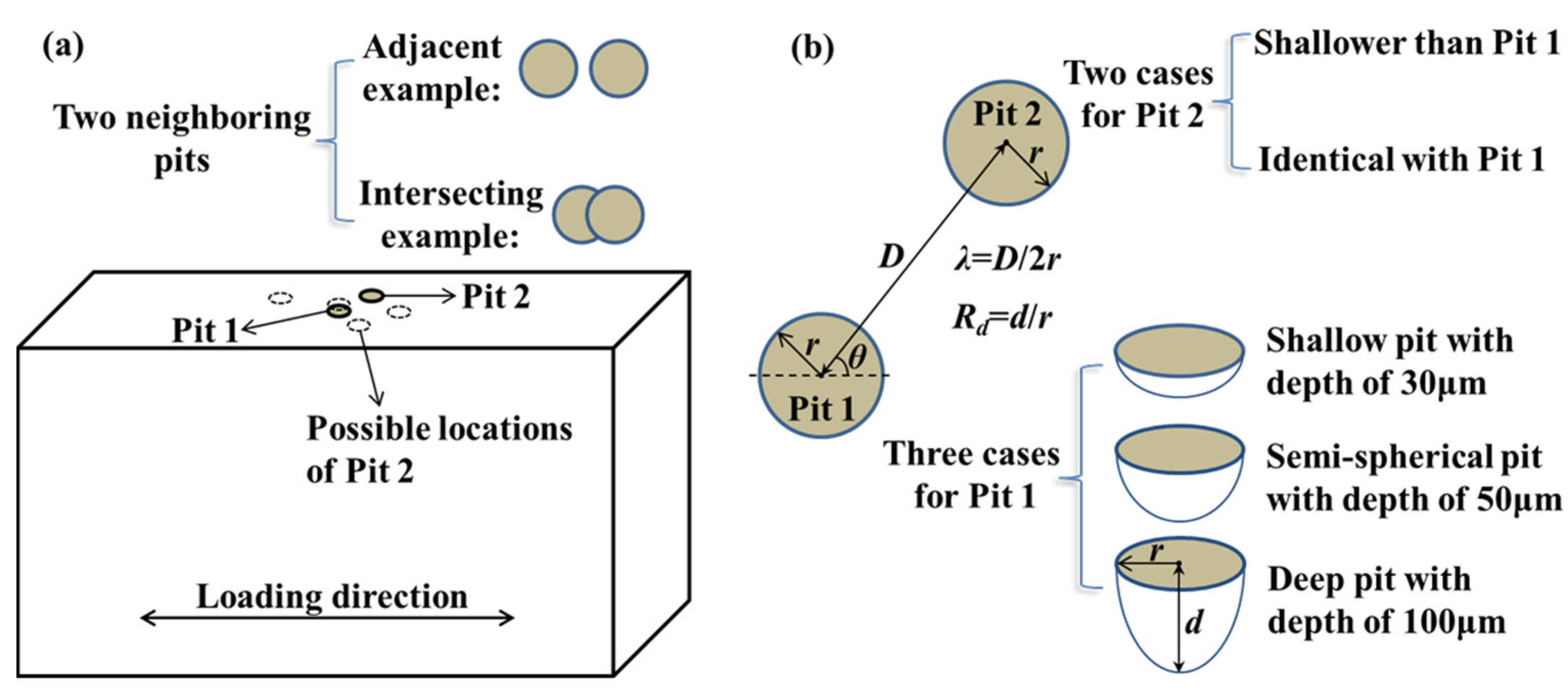

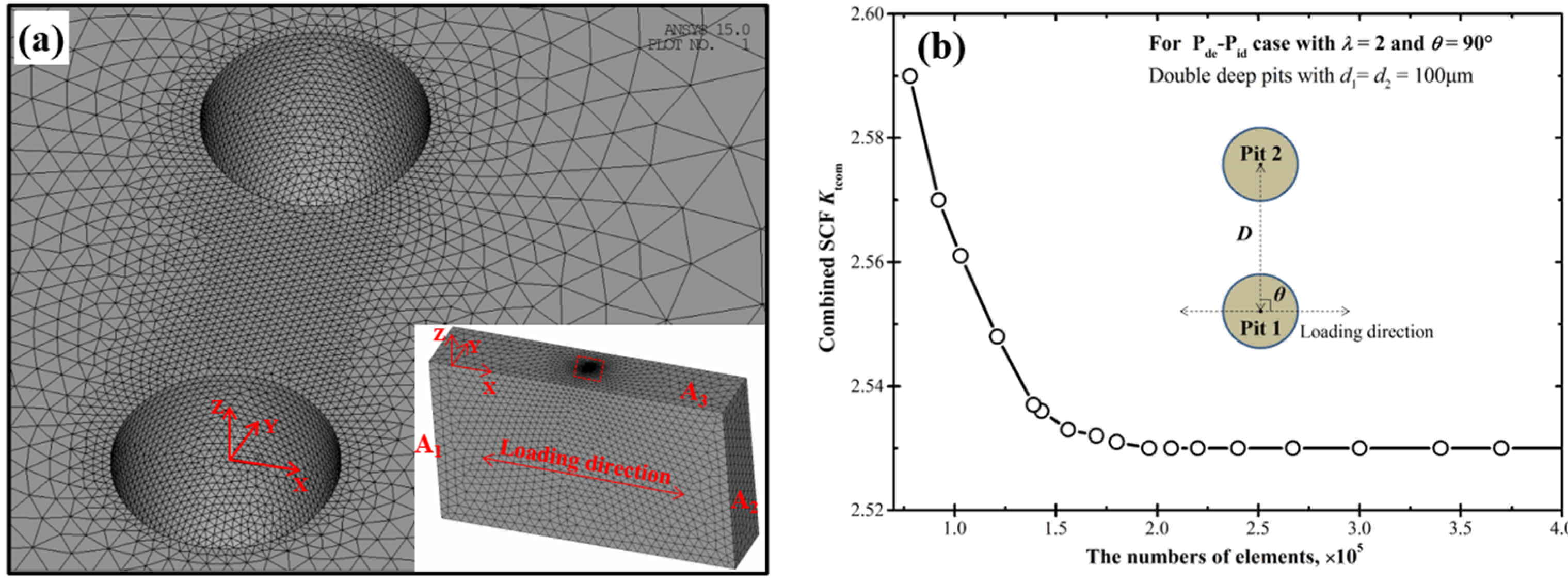

2. Finite Element Model

3. Results and Discussion

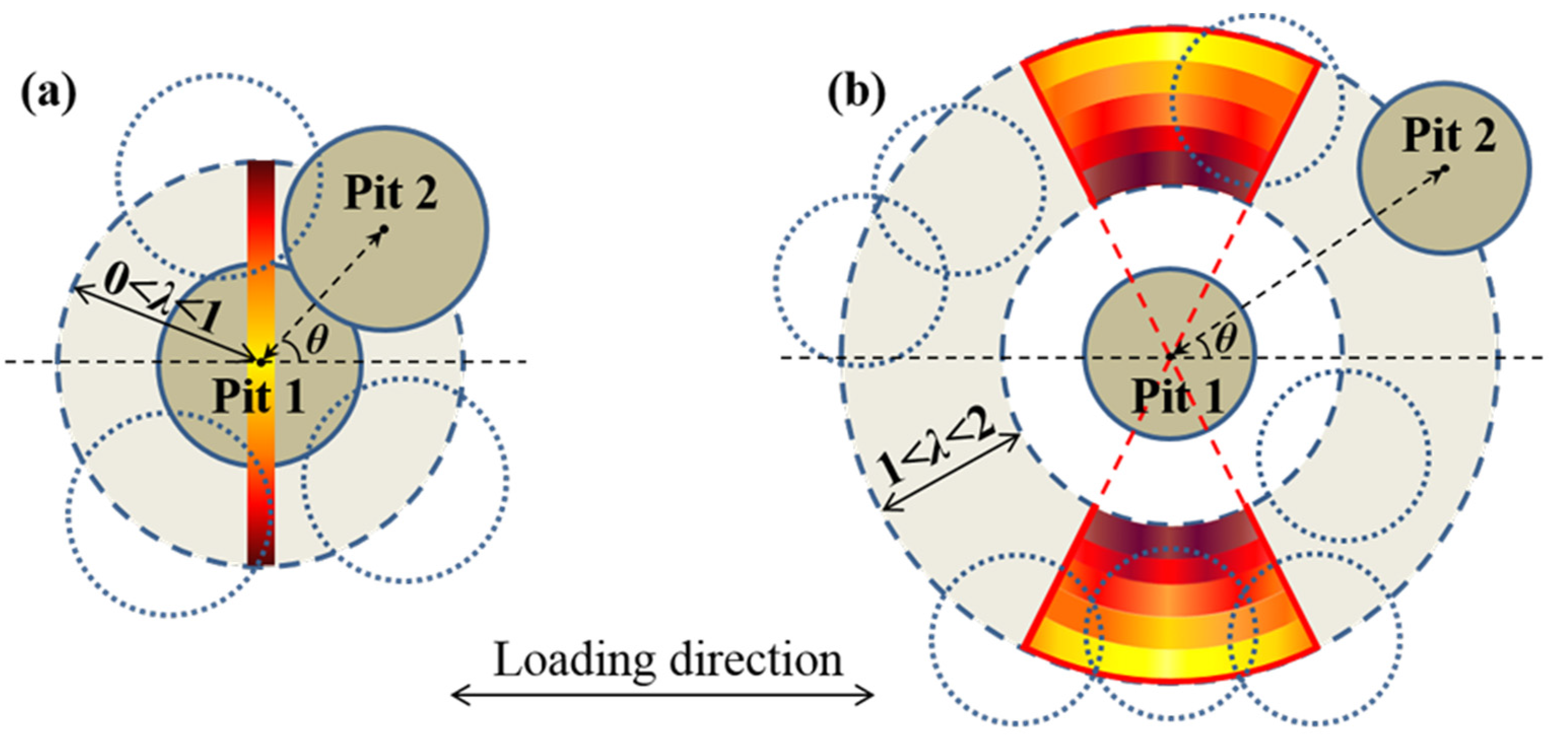

3.1. The Influence of the Relative Position Parameters

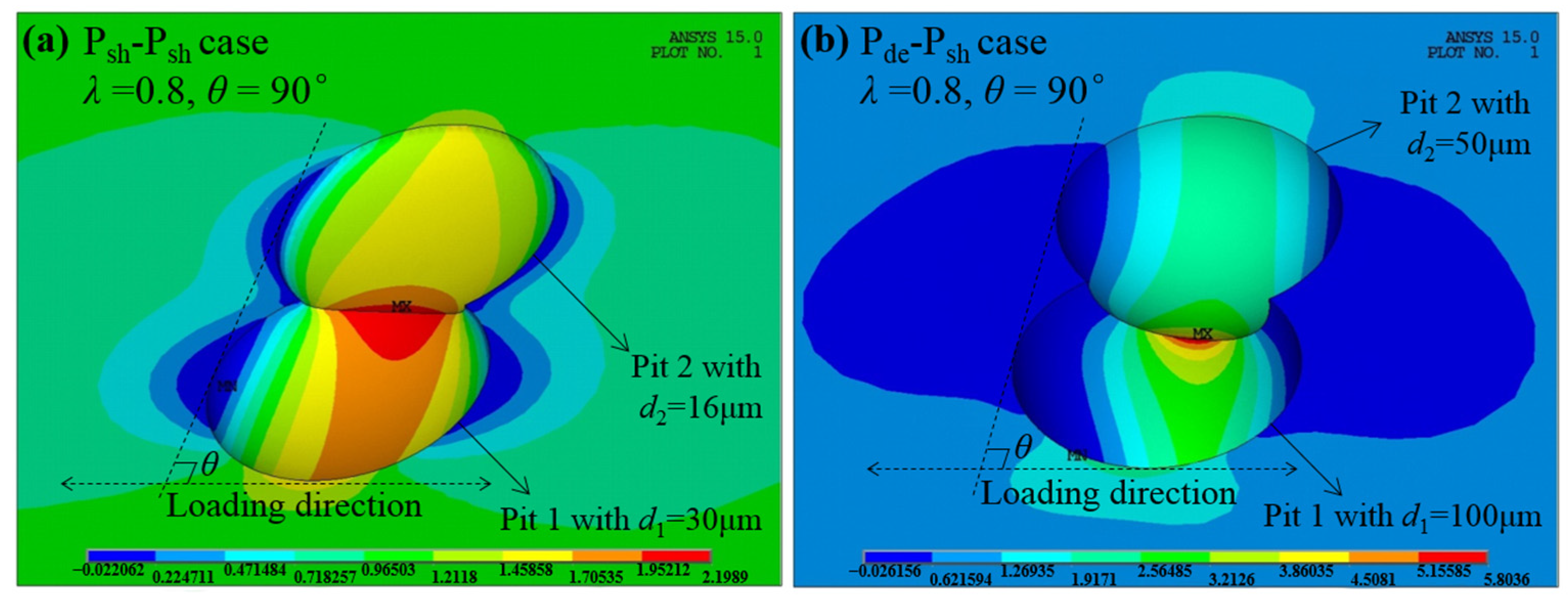

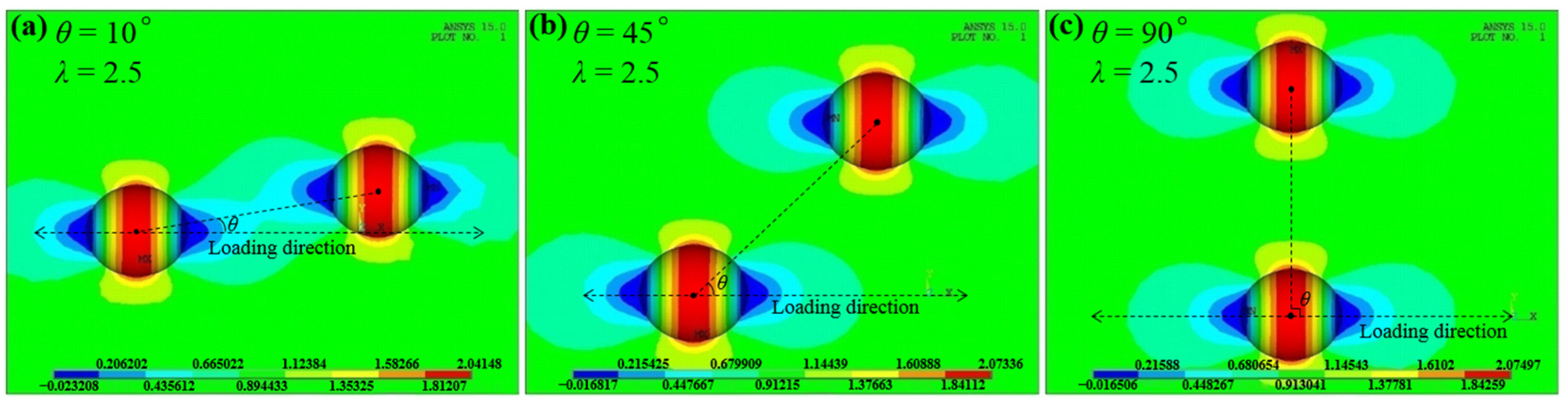

3.1.1. Two Intersecting Pits

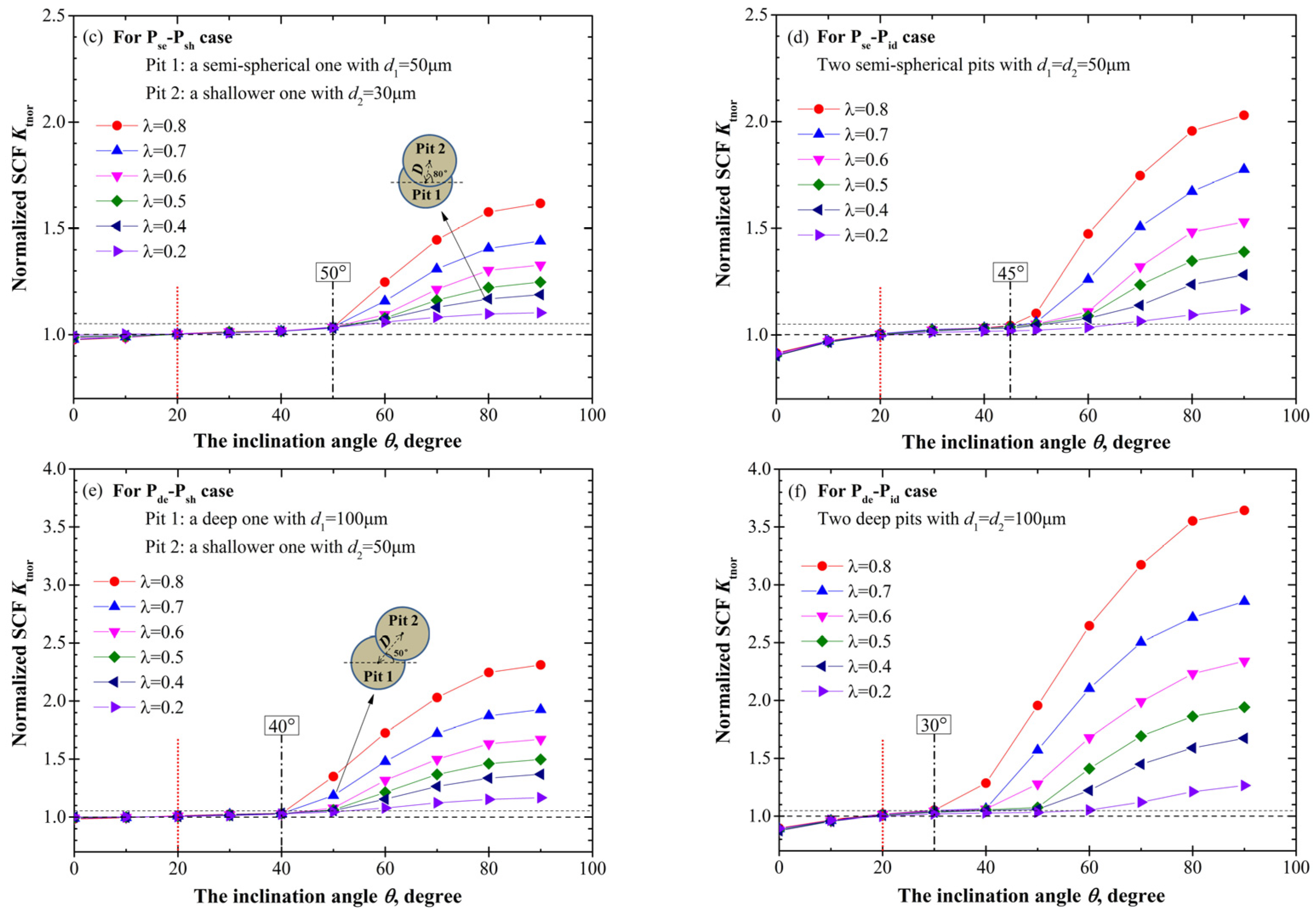

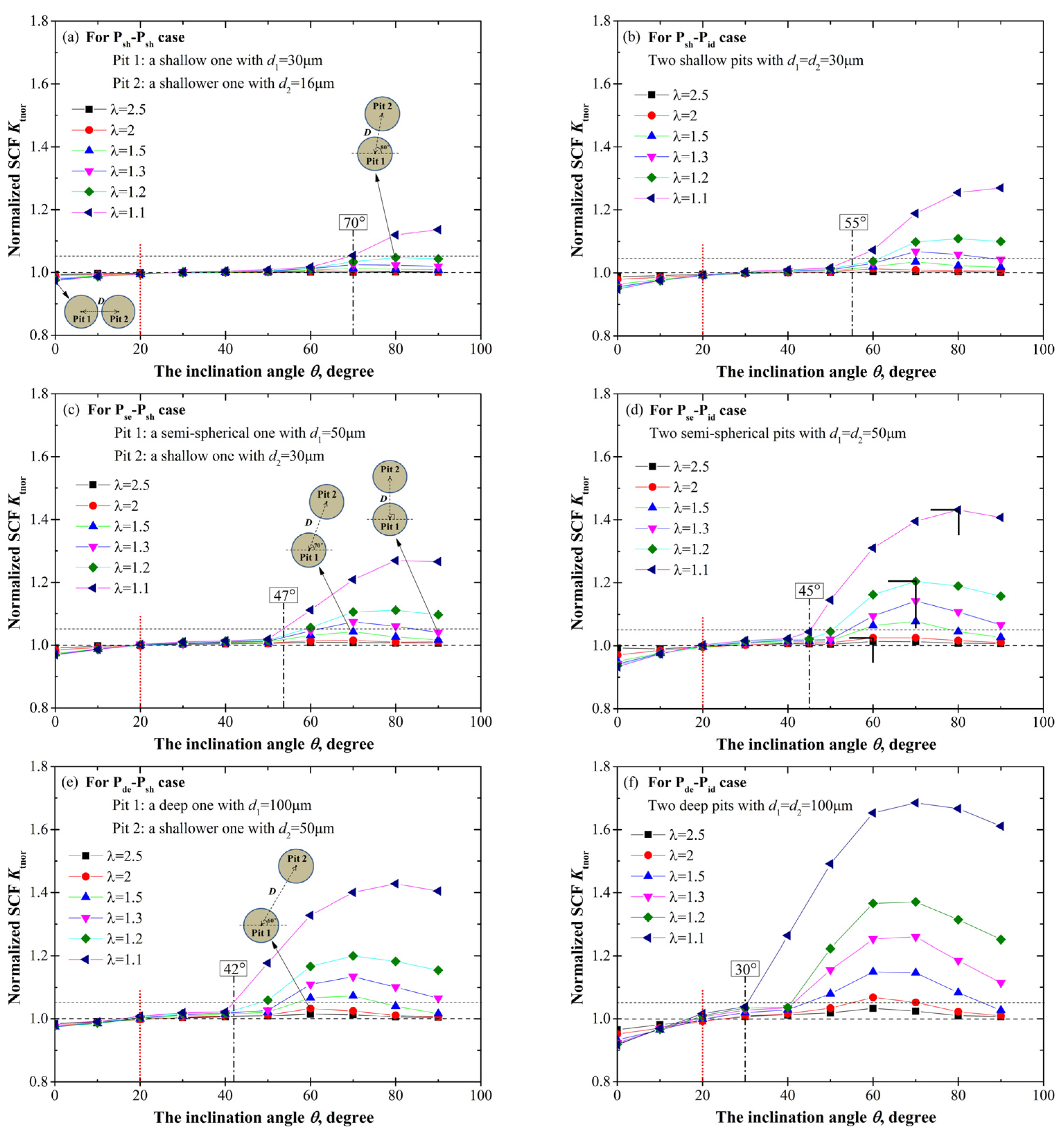

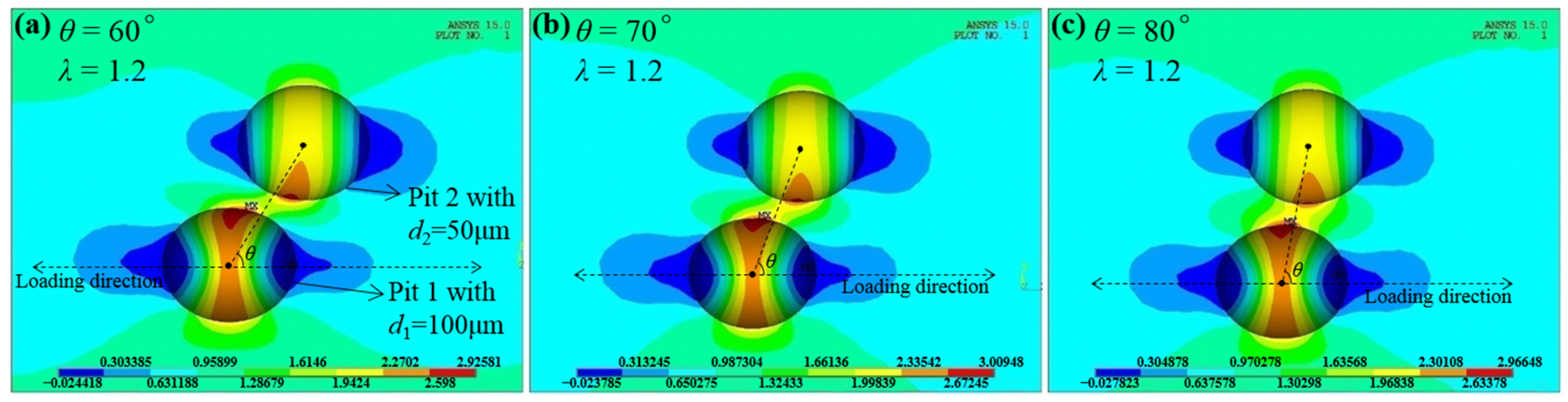

3.1.2. Two Adjacent Pits

3.1.3. The Critical Corrosion Region

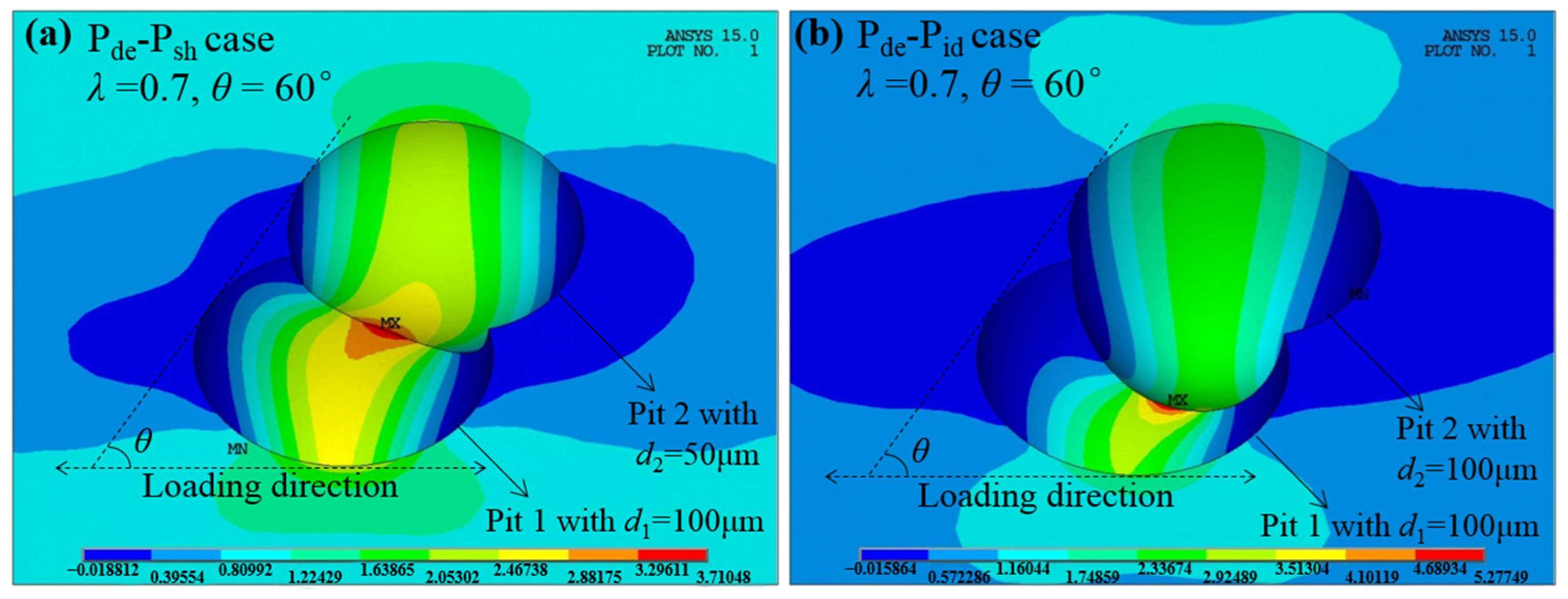

3.2. The Influence of Pit Depth

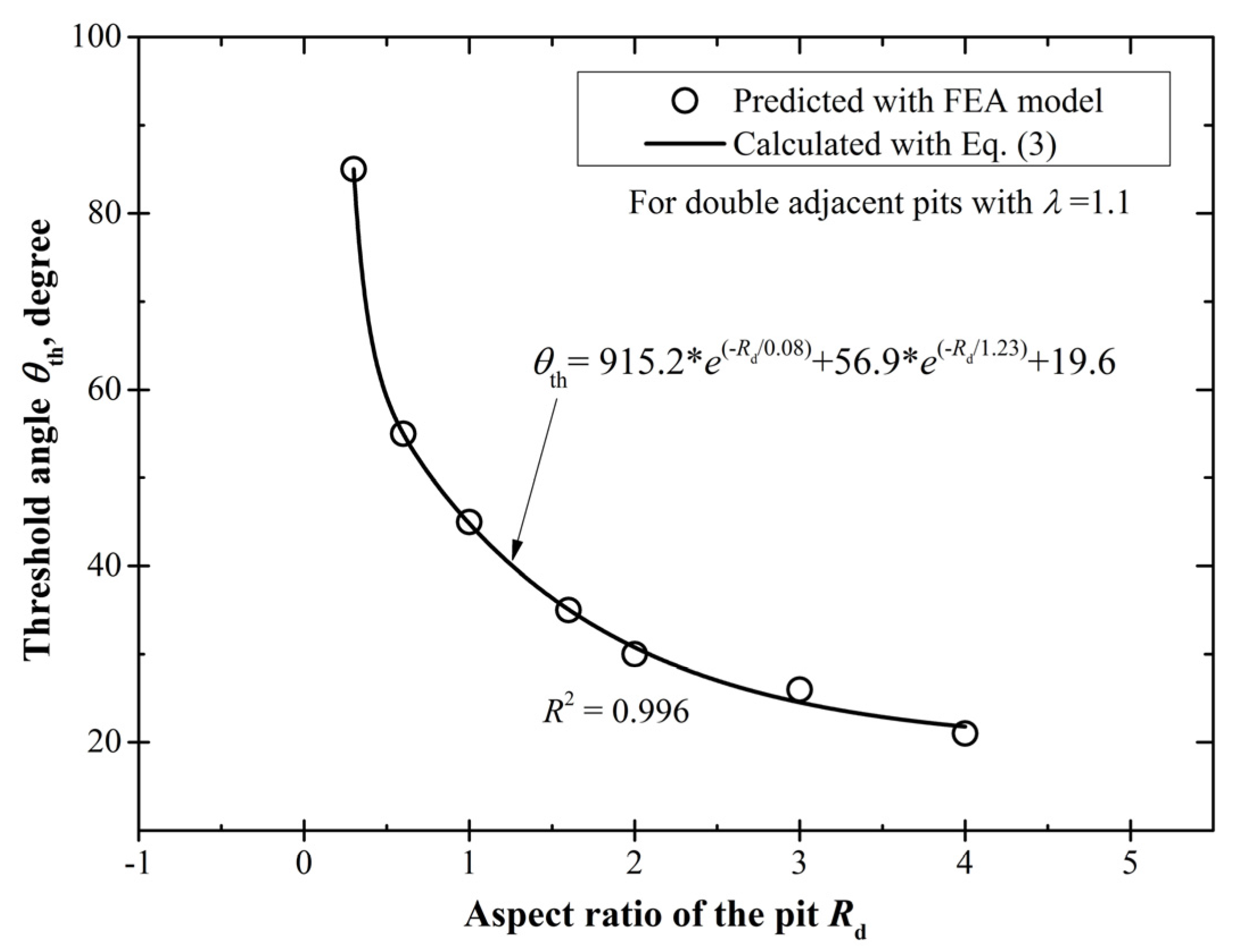

3.2.1. The Relationship between θth and Pit Depth

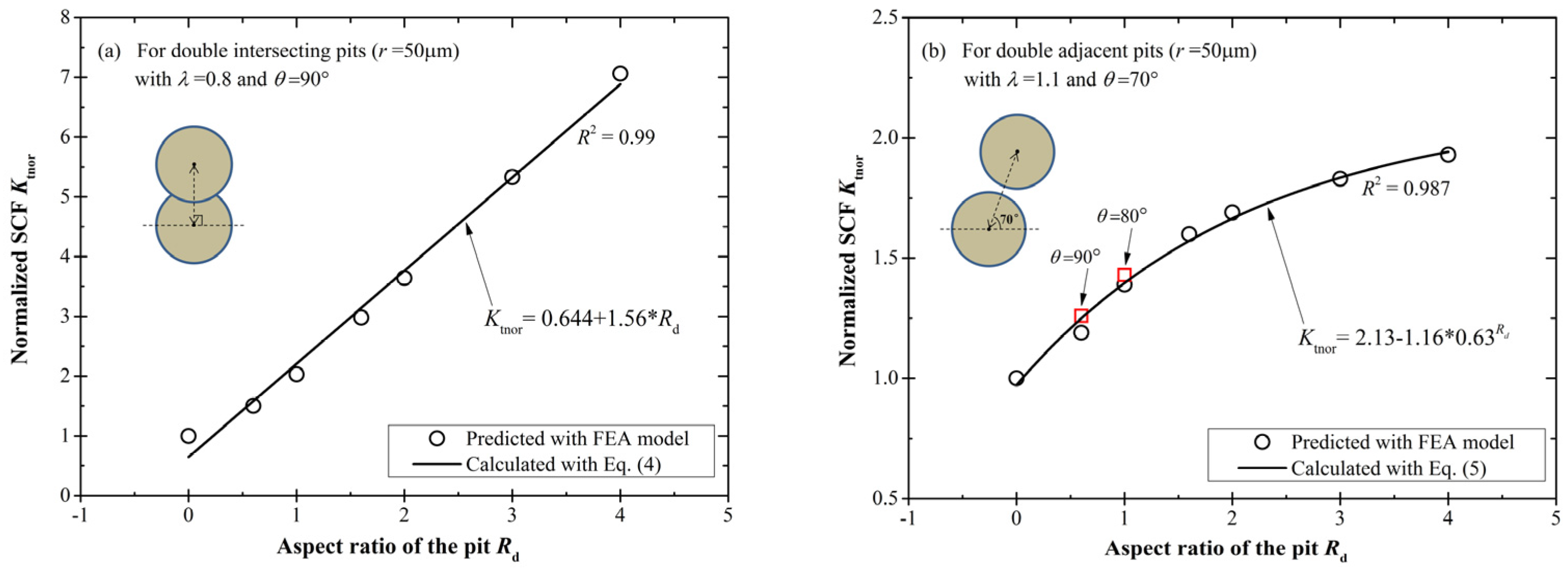

3.2.2. The Relationship between Ktnor and Pit Depth

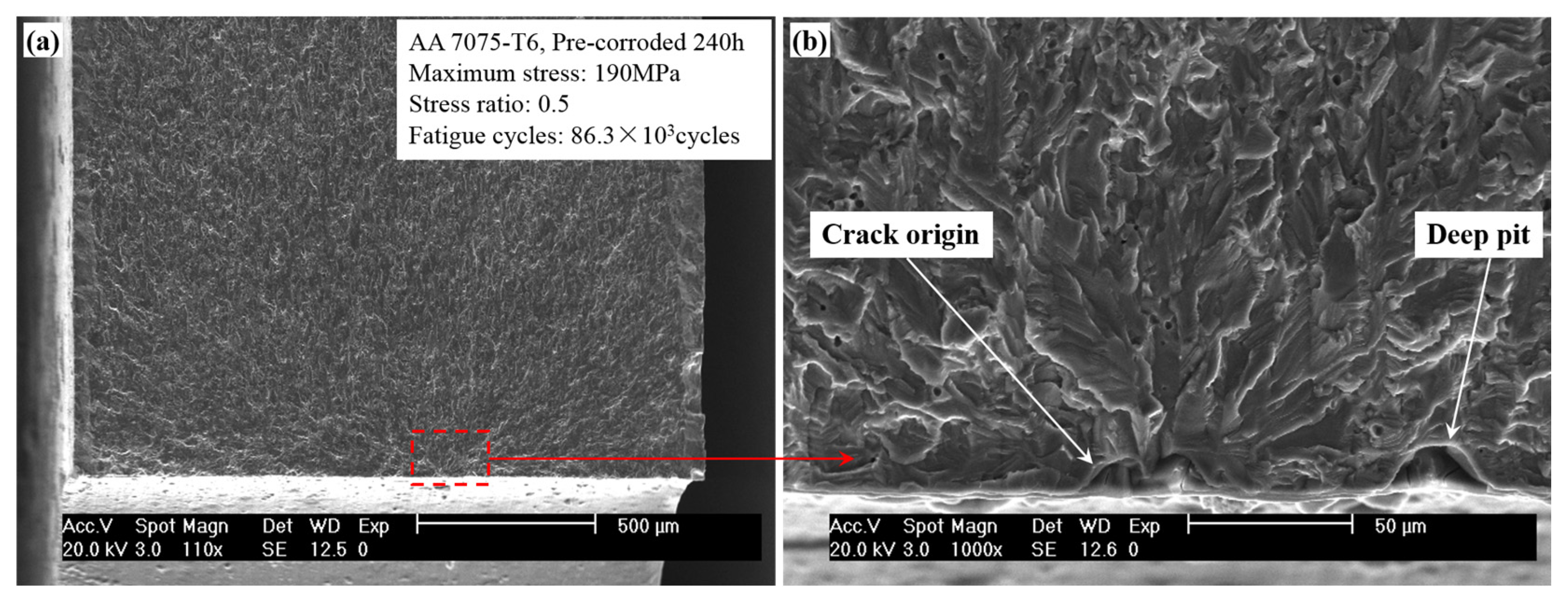

4. Application

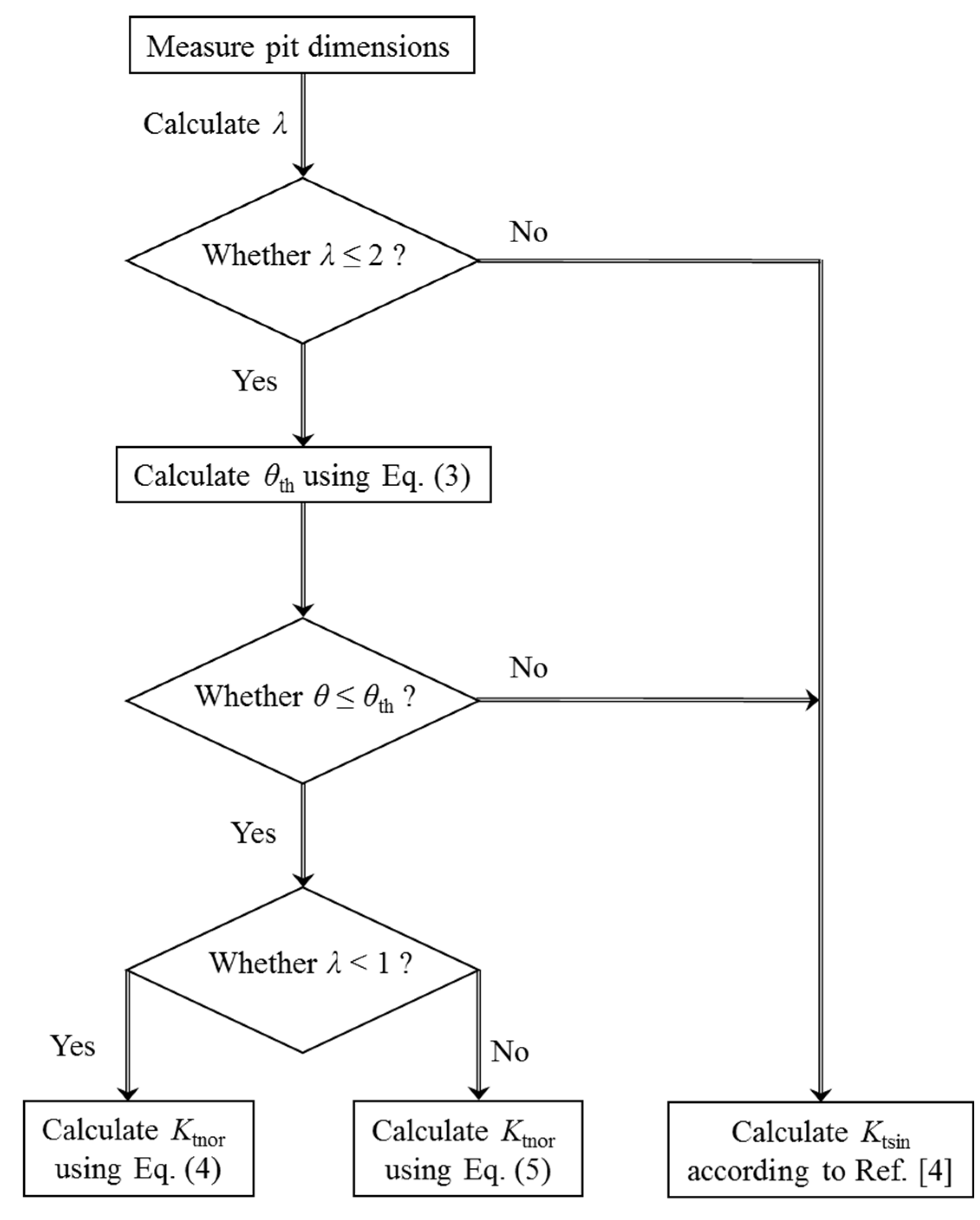

4.1. Estimation Procedure for the C-SCF

4.2. Application Example

5. Conclusions

- (1)

- For two intersecting pits, the combined SCF Ktcom increases with the increase of the relative position parameters θ and λ, and Ktcom always reaches its maximum at the symmetric location (θ = 90°) in the range of 0 < λ <1.

- (2)

- For two adjacent pits, the combined SCF Ktcom decreases with the increase of λ, and when λ > 2, the interacting effects have little contribution to the combined SCF, thus Ktcom ≈ Ktsin. The maximum C-SCF occurs at the asymmetric location of 60° ≤ θcri ≤ 90°. Meanwhile, θcri decreases with the increase of λ from 1 to 2, and θcri = 60° can be regarded as the limiting angle of this asymmetric feature.

- (3)

- The threshold angle θth exponentially decreases with the aspect ratio Rd (Equation (3)), which implies that the interacting effects induced by two neighboring pits exert influence in a larger scope for the deeper pits.

- (4)

- The normalized SCF generally increases with the pit depth, and follows a linear and an exponential relationship with Rd for two intersecting and adjacent pits, respectively. For the most disadvantageous configurations (i.e., the high stress concentration) of the relative position parameters, the empirical formulas (Equations (4) and (5)) are proposed to conservatively estimate the combined SCF and are validated via a practical example with the estimation error factor of 1.37.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jones, K.; Hoeppner, D.W. Prior corrosion and fatigue of 2024-T3 aluminum alloy. Corros. Sci. 2006, 48, 3109–3122. [Google Scholar] [CrossRef]

- Kazempour-Liacy, H.; Mehdizadeh, M.; Akbari-Garakani, M.; Abouali, S. Corrosion and fatigue failure analysis of a forced draft fan blade. Eng. Fail. Anal. 2011, 18, 1193–1202. [Google Scholar] [CrossRef]

- Sharma, M.M.; Zeimian, C.W. Pitting and stress corrosion cracking susceptibility of nanostructured Al–Mg alloys in natural and artificial environments. J. Mater. Eng. Perform 2008, 1059, 94–95. [Google Scholar] [CrossRef]

- Huang, Y.F.; Wei, C.; Chen, L.J.; Li, P.F. Quantitative correlation between geometric parameters and stress concentration of corrosion pits. Eng. Fail. Anal. 2014, 44, 168–178. [Google Scholar] [CrossRef]

- Cerit, M. Numerical investigation on torsional stress concentration factor at the semi elliptical corrosion pit. Corros. Sci. 2013, 67, 225–232. [Google Scholar] [CrossRef]

- Burns, J.T.; Larsen, J.M.; Gangloff, R.P. Driving forces for localized corrosion-to-fatigue crack transition in Al–Zn–Mg–Cu. Fatigue Fract. Eng. Mater. Struct. 2011, 34, 745–773. [Google Scholar] [CrossRef]

- Turnbull, A.; Wright, L.; Crocker, L. New insight into the pit-to-crack transition from finite element analysis of the stress and strain distribution around a corrosion pit. Corros. Sci. 2010, 52, 1492–1498. [Google Scholar] [CrossRef]

- Cerit, M.; Genel, K.; Eksi, S. Numerical investigation on stress concentration of corrosion pit. Eng. Fail. Anal. 2009, 16, 2467–2472. [Google Scholar] [CrossRef]

- Pidaparti, R.M.; Patel, R.R. Correlation between corrosion pits and stresses in Al alloys. Mater. Lett. 2008, 62, 4497–4499. [Google Scholar] [CrossRef]

- Pao, P.S.; Gill, S.J.; Feng, C.R. On fatigue crack initiation from corrosion pits in 7075-T7351 aluminum alloy. Scr. Mater. 2000, 43, 391–396. [Google Scholar] [CrossRef]

- Domínguez Almaraz, G.M.; Mercada Lemus, V.H.; Villalón López, J.J. Effect of proximity and dimension of two artificial pitting holes on the fatigue endurance of aluminum alloy AISI 6061-T6 under rotating bending fatigue tests. Metall. Mater. Trans. A 2011, 43, 2271–2776. [Google Scholar] [CrossRef]

- Han, C.J.; Zhang, H.; Zhang, J. Failure pressure analysis of the pipe with inner corrosion defects by FEM. Int. J. Electrochem. Sci. 2016, 11, 5046–5062. [Google Scholar] [CrossRef]

- Kolios, A.; Srikanth, S.; Salonitis, K. Numerical simulation of material strength deterioration due to pitting corrosion. Procedia CIRP 2014, 13, 230–236. [Google Scholar] [CrossRef]

- Hou, J.; Song, L. Numerical investigation on stress concentration of tension steel bars with one or two corrosion pits. Adv. Mater. Sci. Eng. 2015, 1–7. [Google Scholar] [CrossRef]

- Pidaparti, R.M.; Rao, A.S. Analysis of pits induced stresses due to metal corrosion. Corros. Sci. 2008, 50, 1932–1938. [Google Scholar] [CrossRef]

- Xu, Y.D. The Corrosion characteristics and tensile behavior of reinforcement under coupled carbonation and static loading. Materials 2015, 8, 8561–8577. [Google Scholar] [CrossRef]

- Huang, Y.F.; Ye, X.B.; Hu, B.R.; Chen, L.J. Equivalent crack size model for pre-corrosion fatigue life prediction of aluminum alloy 7075-T6. Int. J. Fatigue 2016, 88, 217–226. [Google Scholar] [CrossRef]

- Huang, Y.F. Fatigue Testing and Life Prediction for Pre-Corroded Aluminum Alloy 7075-T6. Ph.D. Thesis, Xiamen University, Xiamen, China, 2014. (In Chinese). [Google Scholar]

- Van der Walde, K. Corrosion-Nucleated Fatigue Crack Growth. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2005. [Google Scholar]

- Huang, Y.F.; Chen, L.J.; Ye, X.B. Statistical analysis of pit dimensions for pre-corroded AA7075-T6. Adv. Mater. Res. 2014, 906, 259–262. [Google Scholar] [CrossRef]

- Pistorius, P.C.; Burstein, G.T. Metastable pitting corrosion of stainless steel and the transition to stability. Phil. Trans. R. Soc. Lond. A 1992, 341, 531–559. [Google Scholar] [CrossRef]

- Medved, J.J.; Breton, A.M.; Irving, P.E. Corrosion pit size distributions and fatigue lives—A study of the EIFS technique for fatigue design in the presence of corrosion. Int. J. Fatigue 2004, 26, 71–80. [Google Scholar] [CrossRef]

- Kishimoto, K.; Soboyejo, W.O.; Smith, R.A.; Knott, J.F. A numerical investigation of the interaction and coalescence of twin coplanar semi-elliptical fatigue cracks. Int. J. Fatigue 1989, 11, 91–96. [Google Scholar] [CrossRef]

- Noda, N.-A.; Kobayashi, K.; Oohashi, T. Variation of the stress intensity factor along the crack front of interacting semi-elliptical surface cracks. Arch. Appl. Mech. 2001, 71, 43–52. [Google Scholar] [CrossRef]

- Kachanov, M. Elastic solids with many cracks and related problems. In Advances in Applied Mechanics; Hutchinson, J.W., Wu, T.Y., Eds.; Academic Press: New York, NY, USA, 1993; Volume 3, pp. 259–445. [Google Scholar]

- Tsukrov, I.; Kachanov, M. Stress concentrations and microfracturing patterns in a brittle-elastic solid with interacting pores of diverse shapes. Int. J. Solids Struct. 1997, 34, 2887–2904. [Google Scholar] [CrossRef]

- Medina, H.; Hinderliter, B. Where do random rough surfaces fail? Part I: Fracture loci safety envelopes at early stages of degradation. J. Energy Power Eng. 2013, 7, 907–916. [Google Scholar]

- Kim, S.; Burns, J.T.; Gangloff, R.P. Fatigue crack formation and growth from localized corrosion in Al-Zn-Mg-Cu. Eng. Fract. Mech. 2009, 76, 651–667. [Google Scholar] [CrossRef]

- Crawford, B.R.; Sharp, P.K. Equivalent Crack Size Modelling of Corrosion Pitting in an AA7050-T7451 Aluminium Alloy and Its Implications for Aircraft Structural Integrity; Technical Report; DSTO-TR-2745: Melbourne, Victoria, Australia, 2012. [Google Scholar]

- Gruenberg, K.M.; Craig, B.A.; Hillberry, B.M.; Bucci, R.J.; Hinkle, A.J. Predicting fatigue life of pre-corroded 2024-T3 aluminum. Int. J. Fatigue 2004, 26, 629–640. [Google Scholar] [CrossRef]

| Definition | Pit 2 (μm) | ||

|---|---|---|---|

| Shallower | Identical | ||

| Pit 1 (μm) | Shallow | Psh-Psh (d1 = 30, d2 = 16) | Psh-Pid (d1 = 30, d2 = 30) |

| Hemi-spherical | Pse-Psh (d1 = 50, d2 = 30) | Pse-Pid (d1 = 50, d2 = 50) | |

| Deep | Pde-Psh (d1 = 100, d2 = 50) | Pde-Pid (d1 = 100, d2 = 100) | |

| d (μm) | Rd | Ktsin | Ktnor | θ |

|---|---|---|---|---|

| 15 | 0.3 | 1.53 | 1.051 | 86° |

| 1.047 | 85° | |||

| 30 | 0.6 | 1.76 | 1.05 | 55° |

| 50 | 1 | 2.06 | 1.05 | 45° |

| 80 | 1.6 | 2.37 | 1.057 | 36° |

| 1.033 | 35° | |||

| 100 | 2 | 2.51 | 1.05 | 30° |

| 150 | 3 | 2.72 | 1.051 | 27° |

| 1.048 | 26° | |||

| 200 | 4 | 2.82 | 1.052 | 22° |

| 1.046 | 21° |

| d (μm) | Rd | Ktsin | Ktnor |

|---|---|---|---|

| 30 | 0.6 | 1.76 | 1.49 |

| 50 | 1 | 2.06 | 2.03 |

| 80 | 1.6 | 2.37 | 2.98 |

| 100 | 2 | 2.51 | 3.64 |

| 150 | 3 | 2.72 | 5.33 |

| 200 | 4 | 2.82 | 7.062 |

| d (μm) | Rd | Ktsin | Ktnor | θ |

|---|---|---|---|---|

| 30 | 0.6 | 1.76 | 1.27 | 90° |

| 1.19 | 70° | |||

| 50 | 1 | 2.06 | 1.43 | 80° |

| 1.39 | 70° | |||

| 80 | 1.6 | 2.37 | 1.591 | 75° |

| 1.602 | 70° | |||

| 1.561 | 65° | |||

| 100 | 2 | 2.51 | 1.69 | 70° |

| 150 | 3 | 2.72 | 1.782 | 72° |

| 1.83 | 70° | |||

| 1.786 | 65° | |||

| 200 | 4 | 2.82 | 1.89 | 72° |

| 1.934 | 70° | |||

| 1.877 | 65° |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Y.; Gang, T.; Chen, L. Interacting Effects Induced by Two Neighboring Pits Considering Relative Position Parameters and Pit Depth. Materials 2017, 10, 398. https://doi.org/10.3390/ma10040398

Huang Y, Gang T, Chen L. Interacting Effects Induced by Two Neighboring Pits Considering Relative Position Parameters and Pit Depth. Materials. 2017; 10(4):398. https://doi.org/10.3390/ma10040398

Chicago/Turabian StyleHuang, Yongfang, Tieqiang Gang, and Lijie Chen. 2017. "Interacting Effects Induced by Two Neighboring Pits Considering Relative Position Parameters and Pit Depth" Materials 10, no. 4: 398. https://doi.org/10.3390/ma10040398