Laser Cladding of Ultra-Thin Nickel-Based Superalloy Sheets

Abstract

:1. Introduction

2. Materials and Methods

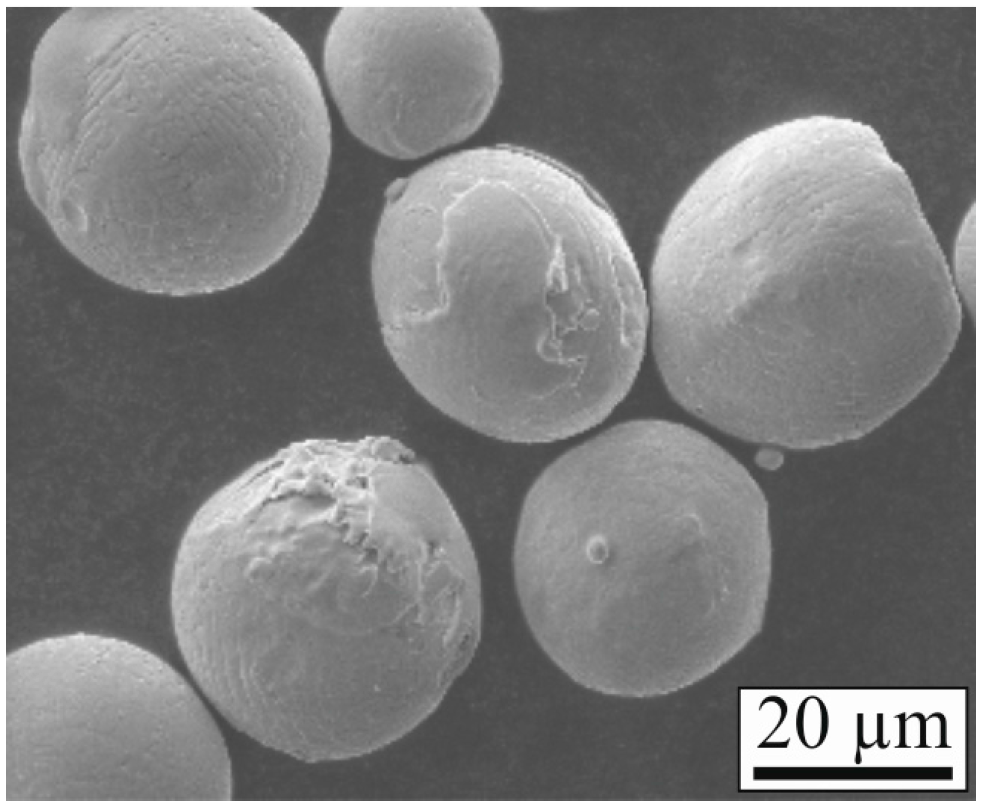

2.1. Materials

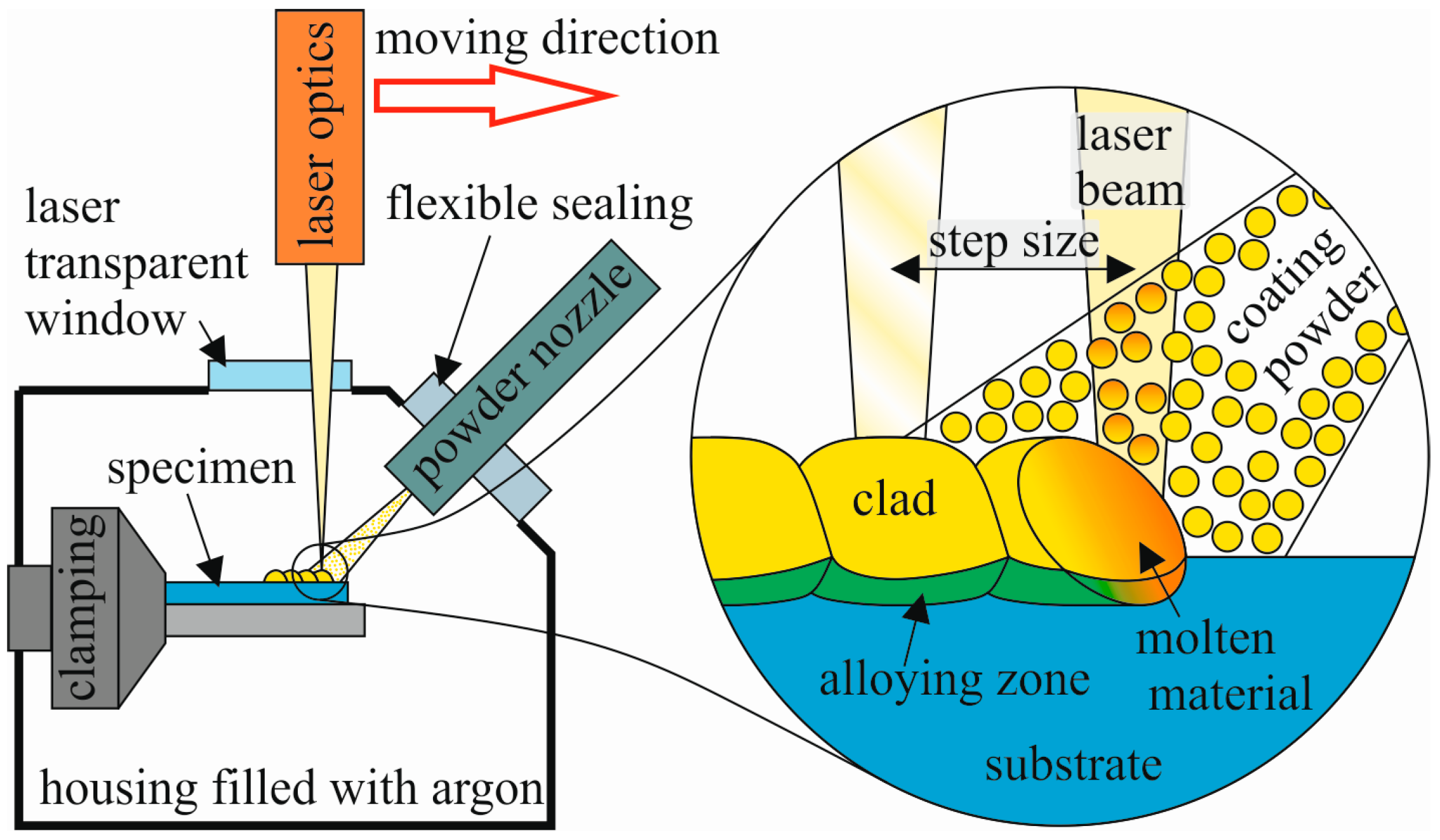

2.2. Laser Cladding Setup and Process

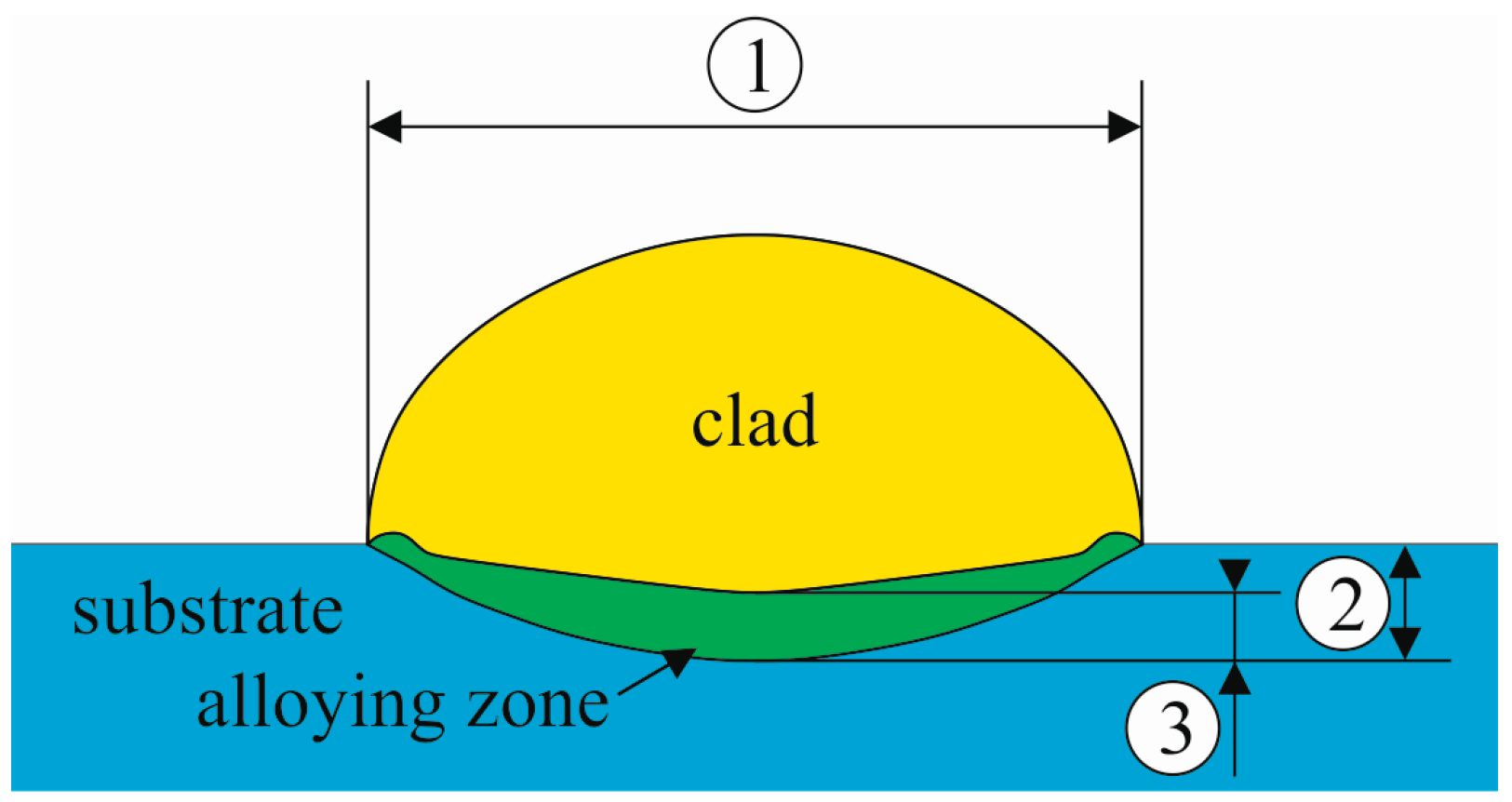

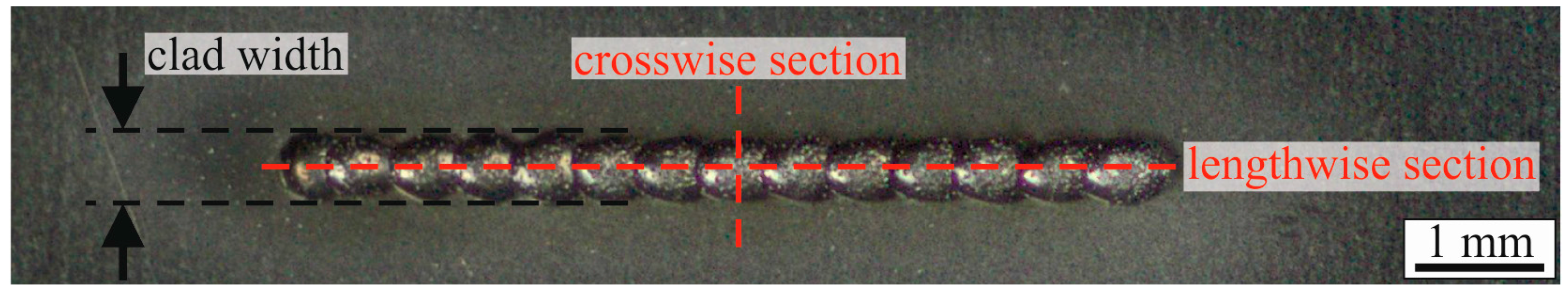

2.3. Characterization Methods and Specimen Preparation

3. Results and Discussion

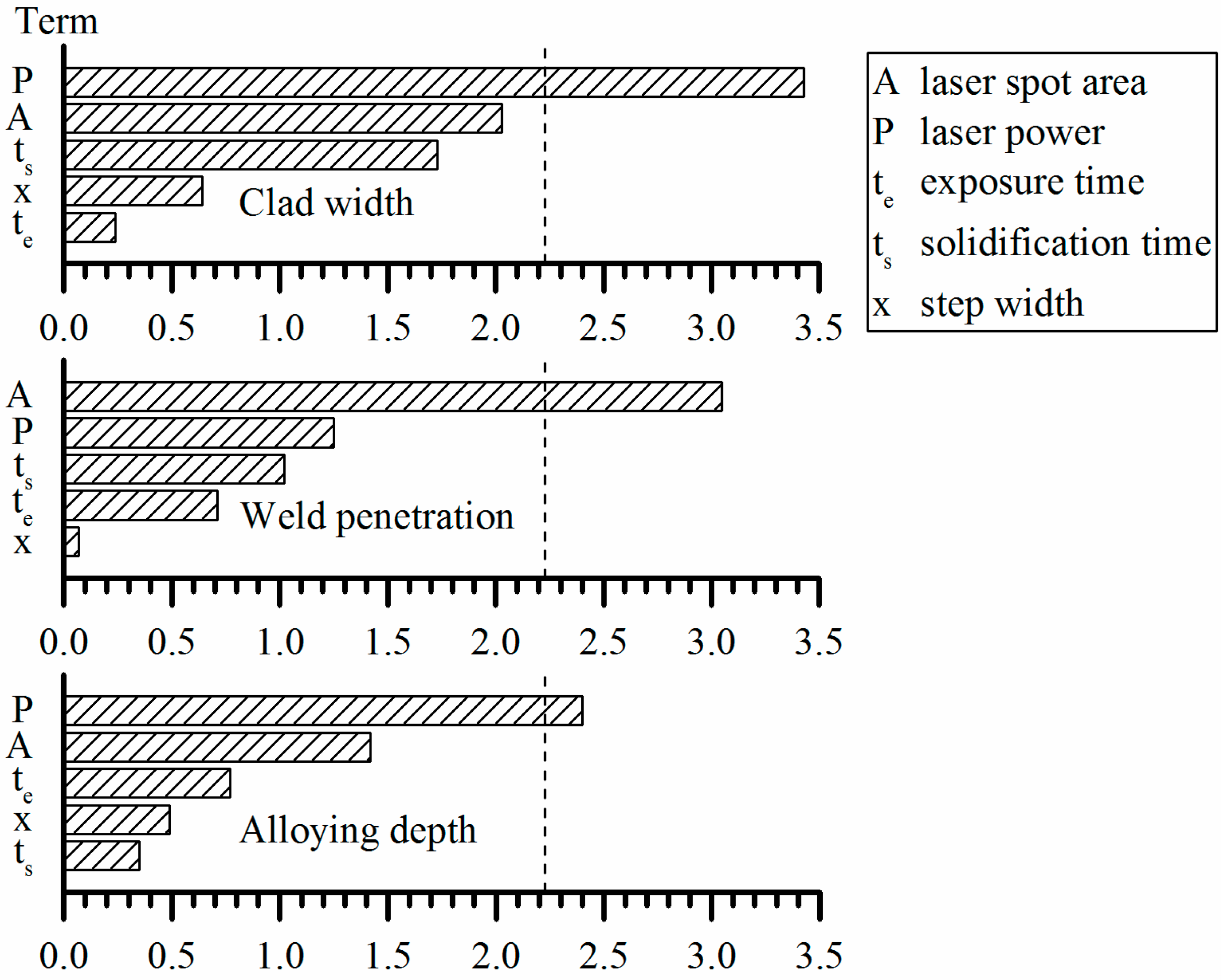

3.1. Quantitative and Statistical Results

- with respect to the clad width: the laser power

- with respect to the weld penetration: the laser spot area

- with respect to the alloying depth: the laser power

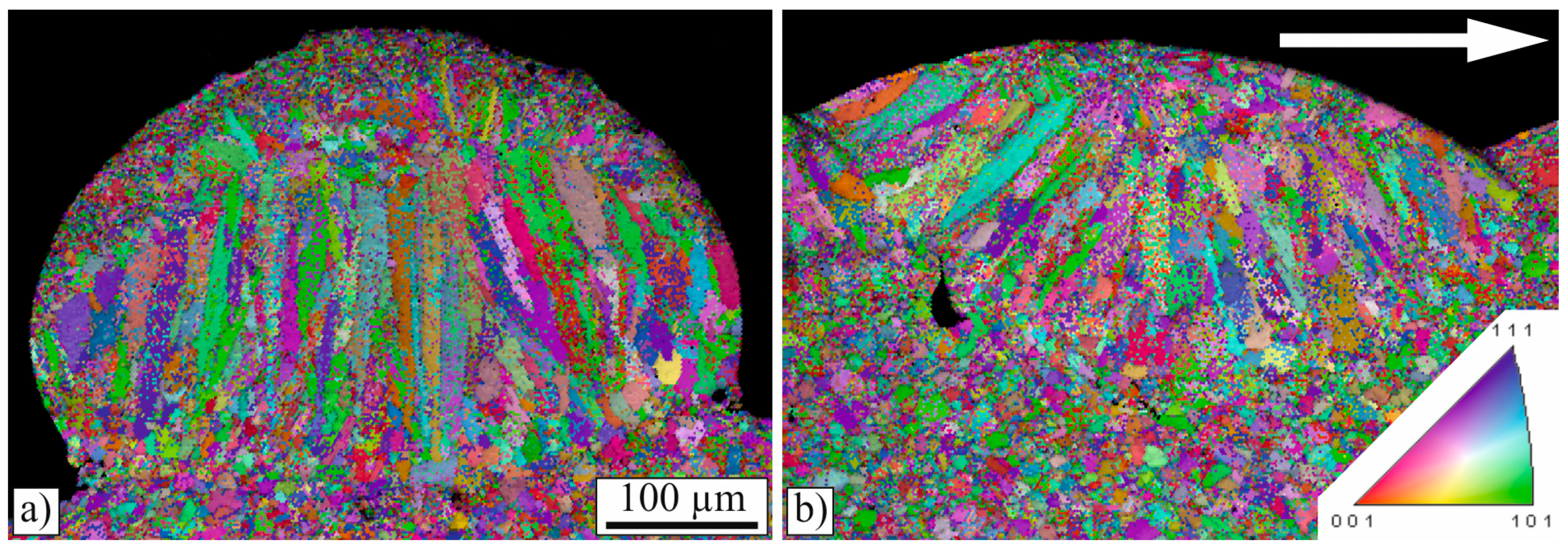

3.2. Microstructural Analysis

4. Conclusions

- The 200 µm thin substrates were coated successfully. Optima for the laser power, the laser spot area, the step size, the exposure time, and the solidification time were found.

- The microstructure of well-fabricated clads looks very similar over all of the process parameters. It is comparable to that of clads of thick substrates described in the literature. Five different areas can be identified:

- Substrate without changes and no distinct heat affected zone.

- Molten and solidified material with a composition close to the substrate material. The grains are smaller and the grain boundaries are enriched with Nb. This Nb enrichment is identified as a Laves phase.

- Slightly elongated grains, orientated perpendicularly to the solidification front.

- Highly elongated grains, orientated perpendicularly to the solidification front. Inter- and intragranular enrichment of Si and Cr, supposed to be Cr3Si.

- Very fine grains with enrichment of Si and Cr at the grain boundaries, also supposed to be Cr3Si.

- In general, the influence of the process parameters is comparable to laser cladding of thicker substrates. The main effects are:

- the clad width increases with increasing laser power

- the weld penetration increases with decreasing laser spot area

- the alloying depth increases with increasing laser power

- The process is very sensitive to the process parameters. It turned out that the minimum laser power used in this work is close to the lower limit to generate well-cladded coatings at all. Therefore, another test series with higher laser powers will be planned for future work. More replications of every parameter set will be considered in this test series for more meaningful statistical analysis.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Sexton, L.; Lavin, S.; Byrne, G.; Kennedy, A. Laser cladding of aerospace materials. J. Mater. Process. Technol. 2002, 122, 63–68. [Google Scholar] [CrossRef]

- Vilar, R.; Santos, E.; Ferreira, P.; Franco, N.; Da Silva, R. Structure of NiCrAlY coatings deposited on single-crystal alloy turbine blade material by laser cladding. Acta Mater. 2009, 57, 5292–5302. [Google Scholar] [CrossRef]

- Shepeleva, L.; Medres, B.; Kaplan, W.; Bamberger, M.; Weisheit, A. Laser cladding of turbine blades. Surf. Coat. Technol. 2000, 125, 45–48. [Google Scholar] [CrossRef]

- Ocelík, V.; Furár, I.; De Hosson, J.T.M. Microstructure and properties of laser clad coatings studied by orientation imaging microscopy. Acta Mater. 2010, 58, 6763–6772. [Google Scholar] [CrossRef]

- De Oliveira, U.; Ocelik, V.; De Hosson, J.T.M. Residual stress analysis in Co-based laser clad layers by laboratory X-rays and synchrotron diffraction techniques. Surf. Coat. Technol. 2006, 201, 533–542. [Google Scholar] [CrossRef]

- Cottam, R.; Brandt, M. Laser cladding of Ti–6Al–4V powder on Ti–6Al–4V substrate: Effect of laser cladding parameters on microstructure. Phys. Procedia 2011, 12, 323–329. [Google Scholar] [CrossRef]

- Zhou, C.; Zhao, S.; Wang, Y.; Liu, F.; Gao, W.; Lin, X. Mitigation of pores generation at overlapping zone during laser cladding. J. Mater. Process. Technol. 2015, 216, 369–374. [Google Scholar] [CrossRef]

- Del Val, J.; Comesaña, R.; Lusquiños, F.; Boutinguiza, M.; Riveiro, A.; Quintero, F.; Pou, J. Laser cladding of Co-based superalloy coatings: Comparative study between Nd: YAG laser and fibre laser. Surf. Coat. Technol. 2010, 204, 1957–1961. [Google Scholar] [CrossRef]

- Farnia, A.; Ghaini, F.M.; Ocelík, V.; De Hosson, J.T.M. Microstructural characterization of Co-based coating deposited by low power pulse laser cladding. J. Mater. Sci. 2013, 48, 2714–2723. [Google Scholar] [CrossRef]

- Corbin, S.; Toyserkani, E.; Khajepour, A. Cladding of an Fe-aluminide coating on mild steel using pulsed laser assisted powder deposition. Mater. Sci. Eng. A 2003, 354, 48–57. [Google Scholar] [CrossRef]

- Burmester, I.; Zhong, M.; Becker, H.; von Alvensleben, F.; Liu, W.; Haferkamp, H. Precision Nd: YAG laser cladding with coaxial powder feeding on very thin sheet. In Proceedings of the Laser Processing of Materials and Industrial Applications II, Beijing, China, 16 September 1998; Volume 3550, pp. 269–275.

- Rommel, D.; Terock, M.; Scherm, F.; Kuttner, C.; Glatzel, U. Direct metal deposition of abrasive tracks—Potentials concerning geometry and materials. In Proceedings of the 35th International Congress on Applications of Lasers and Electro-Optics, San Diego, CA, USA, 16–20 October 2016; Paper 504.

- Strӧßner, J.; Terock, M.; Glatzel, U. Mechanical and Microstructural Investigation of Nickel-Based Superalloy IN718 Manufactured by Selective Laser Melting (SLM). Adv. Eng. Mater. 2015, 17, 1099–1105. [Google Scholar] [CrossRef]

- Trosch, T.; Strӧßner, J.; Vӧlkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Mathews, P.G. Design of Experiments with MINITAB; ASQ Quality Press: Milwaukee, WI, USA, 2005. [Google Scholar]

- Weisheit, A.; Gasser, A.; Backes, G.; Jambor, T.; Pirch, N.; Wissenbach, K. Direct Laser Cladding, Current Status and Future Scope of Application. In Laser-Assisted Fabrication of Materials; Majumdar, J.D., Manna, I., Eds.; Springer: Heidelberg, Germany, 2012; pp. 221–240. [Google Scholar]

- Zhong, M.; Liu, W. Laser surface cladding: The state of the art and challenges. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2010, 224, 1041–1060. [Google Scholar] [CrossRef]

- Radhakrishna, C.; Rao, K.P.; Srinivas, S. Laves phase in superalloy 718 weld metals. J. Mater. Sci. Lett. 1995, 14, 1810–1812. [Google Scholar] [CrossRef]

- Vincent, R. Precipitation around welds in the nickel-base superalloy, Inconel 718. Acta Metall. 1985, 33, 1205–1216. [Google Scholar] [CrossRef]

- Radhakrishna, C.; Rao, K.P. The formation and control of Laves phase in superalloy 718 welds. J. Mater. Sci. 1997, 32, 1977–1984. [Google Scholar] [CrossRef]

- Wang, H.M.; Duan, G. Microstructure and wear resistance of a laser clad reinforced Cr3Si metal silicide composite coating. Mater. Sci. Eng. A 2002, 336, 117–123. [Google Scholar] [CrossRef]

| Elements in wt. % | Ni | Cr | C | Mo | Nb | Ti | Fe | Co | W | Si |

|---|---|---|---|---|---|---|---|---|---|---|

| Substrate | 50–55 | 17–21 | 0.08 (max.) | 2.8–3.3 | 4.75–5.5 | 0.65–1.15 | 14–24 (bal.) | - | - | - |

| Coating | - | 28 | - | - | <1 | - | - | 60.5 | 9 | 1.5 |

| Process Parameter | Value | Adjustable | Note | |

|---|---|---|---|---|

| Min. | Max. | |||

| Laser power (W) | 64 | 82 | x | Varied |

| Working distance (mm) | 10 | 14 | x | Varied |

| Laser spot diameter (mm) | 0.7 | 0.9 | Derivative | |

| Laser spot area (mm2) | 0.38 | 0.64 | Derivative | |

| Energy density (J/mm2) | 10.00 | 43.16 | Derivative | |

| Step size (mm) | 0.4 | 0.5 | x | Varied |

| Exposure time (s) | 0.1 | 0.2 | x | Varied |

| Solidification time (s) | 0.2 | 0.8 | x | Varied |

| Traverse speed (mm/s) | 0.4 | 1.67 | Derivative | |

| Powder feed rate (g/min) | 8 | x | Fix | |

| Shielding gas flow rate (L/min) | 4 | x | Fix | |

| Distance nozzle to surface (mm) | 10 | x | Fix | |

| Angle between nozzle and surface (°) | 45 | x | Fix | |

| Powder nozzle diameter (mm) | 0.85 | Fix | ||

| Laser beam parameter product (mm·mrad) | 0.35 | Fix | ||

| Source | Clad Width | Weld Penetration | Alloying Depth | |||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| te | 0.06 | 0.813 | 0.51 | 0.492 | 0.59 | 0.459 |

| x | 0.41 | 0.535 | 0.01 | 0.943 | 0.24 | 0.635 |

| ts | 2.99 | 0.115 | 1.05 | 0.329 | 0.12 | 0.733 |

| A | 4.13 | 0.069 | 9.34 | 0.012 | 2.02 | 0.185 |

| P | 11.75 | 0.006 | 1.57 | 0.239 | 5.77 | 0.037 |

| Laser Power (W) | Clad Width (µm) | Alloying Depth (µm) | Laser Spot Area (mm2) | Weld Penetration (µm) |

|---|---|---|---|---|

| 64 | 330 (193) | 28 (17) | 0.38 | 39 (13) |

| 82 | 558 (38) | 47 (9) | 0.64 | 17 (13) |

| Predicted Optimum | C4 | ||

|---|---|---|---|

| Parameters | Laser power (W) | 82 | 82 |

| Laser spot area (mm2) | 0.64 | 0.38 | |

| Step size (mm) | 0.5 | 0.5 | |

| Exposure time (s) | 0.2 | 0.2 | |

| Solidification time (s) | 0.2 | 0.5 | |

| Results | Clad width (µm) | 577 | 602 |

| Weld penetration (µm) | 23 | 57 | |

| Alloying depth (µm) | 47 | 60 | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gabriel, T.; Rommel, D.; Scherm, F.; Gorywoda, M.; Glatzel, U. Laser Cladding of Ultra-Thin Nickel-Based Superalloy Sheets. Materials 2017, 10, 279. https://doi.org/10.3390/ma10030279

Gabriel T, Rommel D, Scherm F, Gorywoda M, Glatzel U. Laser Cladding of Ultra-Thin Nickel-Based Superalloy Sheets. Materials. 2017; 10(3):279. https://doi.org/10.3390/ma10030279

Chicago/Turabian StyleGabriel, Tobias, Daniel Rommel, Florian Scherm, Marek Gorywoda, and Uwe Glatzel. 2017. "Laser Cladding of Ultra-Thin Nickel-Based Superalloy Sheets" Materials 10, no. 3: 279. https://doi.org/10.3390/ma10030279