Quantification of Wear and Deformation in Different Configurations of Polyethylene Acetabular Cups Using Micro X-ray Computed Tomography

Abstract

:1. Introduction

2. Materials and Methods

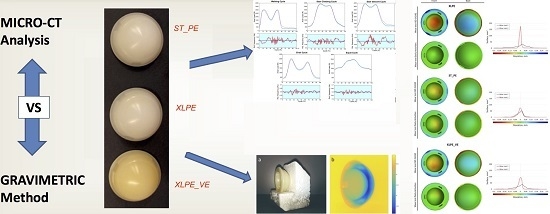

2.1. Materials

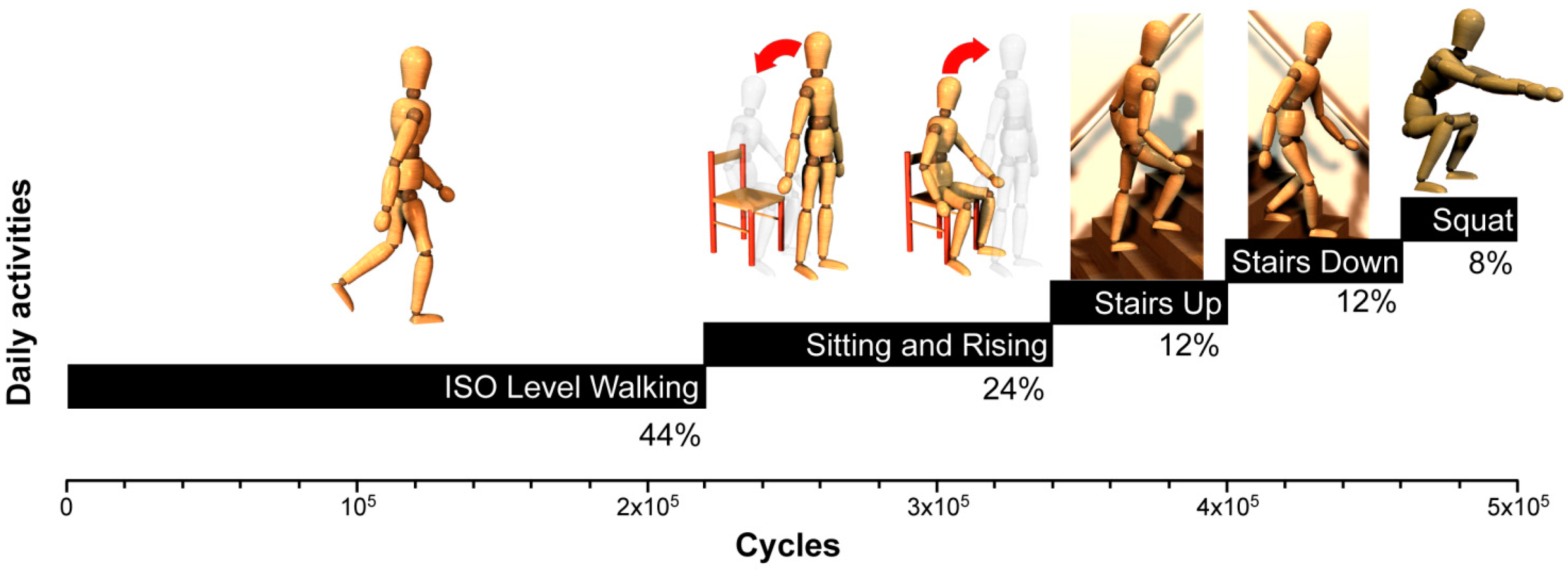

2.2. Kinematics and Load Waveforms

2.3. Wear Test Details and Weight Loss Evaluation

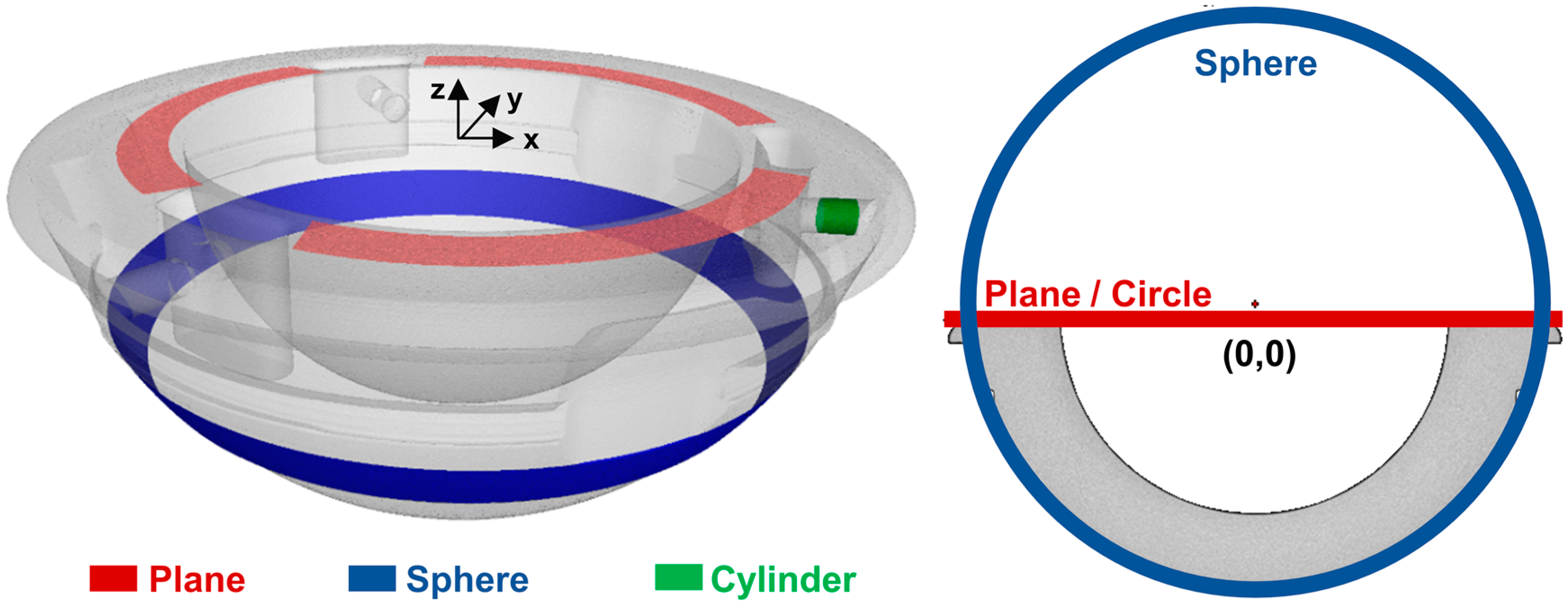

2.4. μCT Wear and Deformation Assessment

- (1)

- Preliminary rough alignment: registration of each single component according to a primary, a secondary, and a tertiary datum reference. For each step, a geometrical element was defined and the axis/origin coordinate specified by that geometrical element was chosen.

- (2)

- Fine adjustment of the previous alignment based on the current position of the objects.

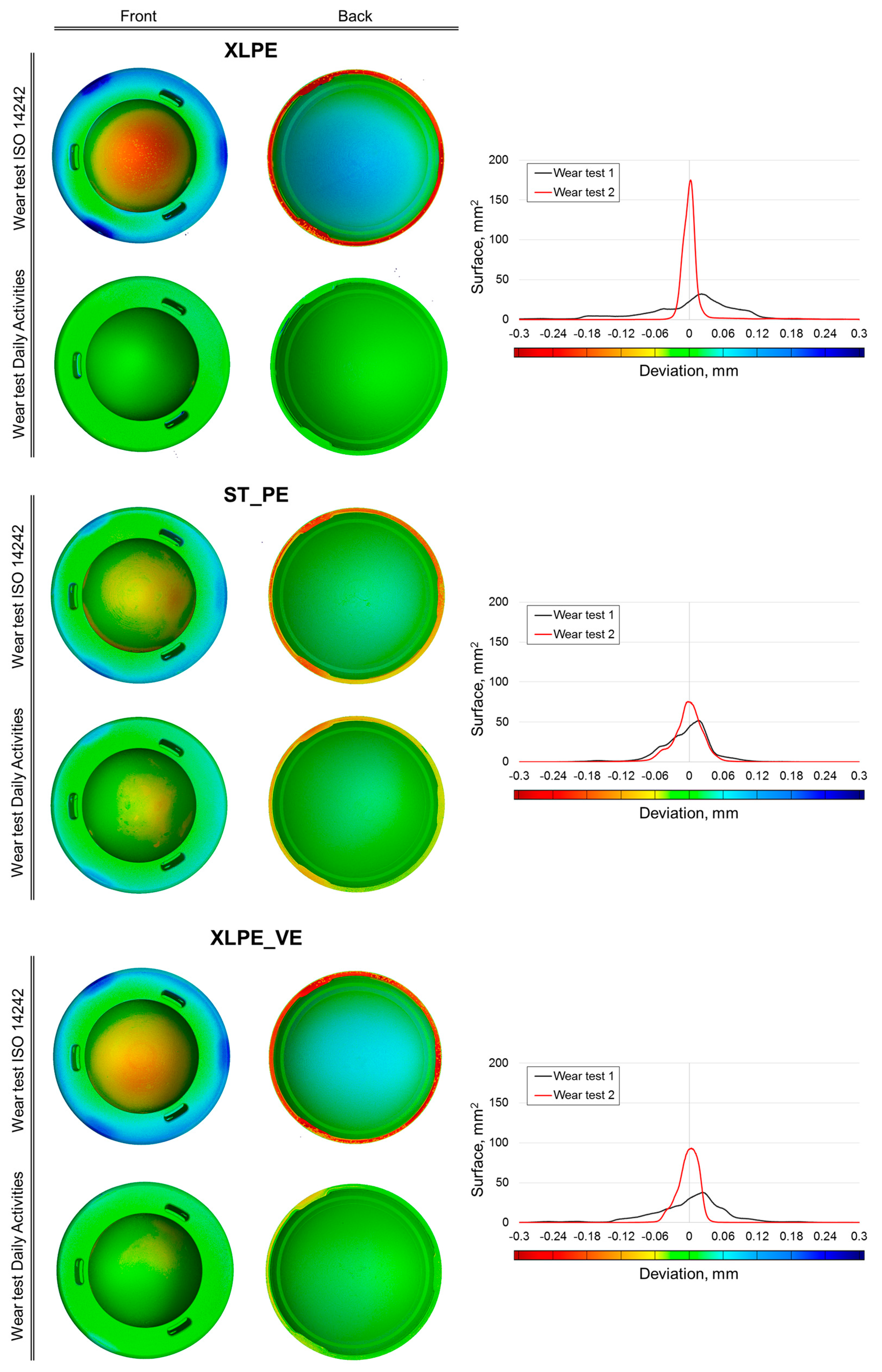

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Affatato, S.; Bracco, P.; Costa, L.; Villa, T.; Quaglini, V.; Toni, A. In vitro wear performance of standard, crosslinked, and vitamin-E-blended UHMWPE. J. Biomed. Mater. Res. A 2012, 100, 554–560. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Traina, F.; Ruggeri, O.; Toni, A. Wear of metal-on-metal hip bearings: Metallurgical considerations after hip simulator studies. Int. J. Artif. Organs 2011, 34, 1155–1164. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Freccero, N.; Taddei, P. The biomaterials challenge: A comparison of polyethylene wear using a hip joint simulator. J. Mech. Behav. Biomed. Mater. 2016, 53, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Ruggiero, A.; Merola, M. Advanced biomaterials in hip joint arthroplasty. A review on polymer and ceramics composites as alternative bearings. Compos. Part B Eng. 2015, 83, 276–283. [Google Scholar] [CrossRef]

- Affatato, S.; Traina, F.; De Fine, M.; Carmignato, S.; Toni, A. Alumina-on-alumina hip implants: A wear study of retrieved components. J. Bone Jt. Surg. Br. 2012, 94, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Carmignato, S.; Balcon, M.; Zanini, F. Investigation on the accuracy of CT measurements for wear testing of prosthetic joint components. In Proceedings of the Conference on Industrial Computed Tomography (ICT) 2014, Wels, Austria, 25–28 February 2014.

- McKellop, H.A.; D’Lima, D. How have wear testing and joint simulator studies helped to discriminate among materials and designs? J. Am. Acad. Orthop. Surg. 2008, 16, S111–S119. [Google Scholar] [CrossRef] [PubMed]

- Grupp, T.M.; Yue, J.J.; Garcia, R.; Basson, J.; Schwiesau, J.; Fritz, B.; Blömer, W. Biotribological evaluation of artificial disc arthroplasty devices: Influence of loading and kinematic patterns during in vitro wear simulation. Eur. Spine J. 2009, 18, 98–108. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization ISO 14242-1. 2012-Implants for surgery—Wear of total hip-joint prostheses—Part 1: Loading and displacement parameters for wear-testing machines and corresponding environmental conditions for test. In Proceedings of the 12th Conference on Retroviruses Opportunistic Infections, Boston, MA, USA, 22–25 February 2005.

- Bragdon, C.R.; Jasty, M.; Muratoglu, O.K.; O’Connor, D.O.; Harris, W.H. Third-body wear of highly cross-linked polyethylene in a hip simulator. J. Arthroplast. 2003, 18, 553–561. [Google Scholar] [CrossRef]

- Bragdon, C.R.; Jasty, M.; Muratoglu, O.K.; Harris, W.H. Third-body wear testing of a highly cross-linked acetabular liner: The effect of large femoral head size in the presence of particulate poly(methyl-methacrylate) debris. J. Arthroplast. 2005, 20, 379–385. [Google Scholar] [CrossRef]

- Wang, A.; Essner, A. Three-body wear of UHMWPE acetabular cups by PMMA particles against CoCr, alumina and zirconia heads in a hip joint simulator. Wear 2001, 250, 212–216. [Google Scholar] [CrossRef]

- Affatato, S.; Salvatore, J.; Mattia, D.; Bracco, P.; Pavoni, E.; Taddei, P. Does cyclic stress and accelerated ageing influence the wear behavior of highly crosslinked polyethylene? J. Mech. Behav. Biomed. Mater. 2016, 59, 418–429. [Google Scholar] [CrossRef] [PubMed]

- Morrison, J.B. The mechanics of the knee joint in relation to normal walking. J. Biomech. 1970, 3, 51–61. [Google Scholar] [CrossRef]

- Morrison, J. Function of the knee joint in various activities. Biomed. Eng. 1969, 4, 573–580. [Google Scholar] [PubMed]

- Abdel-Jaber, S.; Belvedere, C.; De Mattia, J.S.; Leardini, A.; Affatato, S. A new protocol for wear testing of total knee prostheses from real joint kinematic data: Towards a scenario of realistic simulations of daily living activities. J. Biomech. 2016, 49, 2925–2931. [Google Scholar] [CrossRef] [PubMed]

- Battaglia, S.; Belvedere, C.; Jaber, S.A.; Affatato, S.; D’Angeli, V.; Leardini, A. A new protocol from real joint motion data for wear simulation in total knee arthroplasty: Stair climbing. Med. Eng. Phys. 2014, 36, 1605–1610. [Google Scholar] [CrossRef] [PubMed]

- Battaglia, S.; Taddei, P.; Tozzi, S.; Sudanese, A.; Affatato, S. Toward the interpretation of the combined effect of size and body weight on the tribological performance of total knee prostheses. Int. Orthop. 2014, 38, 1183–1190. [Google Scholar] [CrossRef] [PubMed]

- Abdel Jaber, S.; Taddei, P.; Tozzi, S.; Sudanese, A.; Affatato, S.; Jaber, S.A.; Taddei, P.; Tozzi, S.; Sudanese, A.; Affatato, S. In vitro effects on mobile polyethylene insert under highly demanding daily activities: Stair climbing. Int. Orthop. 2015, 39, 1433–1440. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Jaber, S.; Belvedere, C.; Leardini, A.; Affatato, S.; Abdel Jaber, S.; Belvedere, C.; Leardini, A.; Affatato, S. Wear simulation of total knee prostheses using load and kinematics waveforms from stair climbing. J. Biomech. 2015, 48, 3830–3836. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Zanini, F.; Carmignato, S. Micro X-ray computed tomography mass loss assessment of different UHMWPE: A hip joint simulator study on standard vs. cross-linked polyethylene. PLoS ONE 2017, 12, e0170263. [Google Scholar] [CrossRef] [PubMed]

- Kruth, J.P.; Bartscher, M.; Carmignato, S.; Schmitt, R.; De Chiffre, L.; Weckenmann, A. Computed tomography for dimensional metrology. CIRP Ann. Manuf. Technol. 2011, 60, 821–842. [Google Scholar] [CrossRef]

- Affatato, S.; Bersaglia, G.; Rocchi, M.; Taddei, P.; Fagnano, C.; Toni, A. Wear behaviour of cross-linked polyethylene assessed in vitro under severe conditions. Biomaterials 2005, 26, 3259–3267. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, G.; Graichen, F.; Rohlmann, A.; Bender, A.; Heinlein, B.; Duda, G.N.; Heller, M.O.; Morlock, M.M. Realistic loads for testing hip implants. Biomed. Mater. Eng. 2010, 20, 65–75. [Google Scholar] [PubMed]

- Bassett, D.R.; Wyatt, H.R.; Thompson, H.; Peters, J.C.; James, O. Pedometer-Measured Physical Activity and Health Behaviors in United States Adults. Med. Sci. Sports Exerc. 2011, 42, 1819–1825. [Google Scholar] [CrossRef] [PubMed]

- Wimmer, M.A.; Nechtow, W.; Schwenke, T.; Moisio, K.C. Knee Flexion and Daily Activities in Patients following Total Knee Replacement: A Comparison with ISO Standard 14243. BioMed Res. Int. 2015, 2015, 157541. [Google Scholar] [CrossRef] [PubMed]

- Morlock, M.; Schneider, E.; Bluhm, A.; Vollmer, M.; Bergmann, G.; Müller, V.; Honl, M. Duration and frequency of every day activities in total hip patients. J. Biomech. 2001, 34, 873–881. [Google Scholar] [CrossRef]

- Carmignato, S.; Dreossi, D.; Mancini, L.; Marinello, F.; Tromba, G.; Savio, E. Testing of X-ray microtomography systems using a traceable geometrical standard. Meas. Sci. Technol. 2009, 20, 84021. [Google Scholar] [CrossRef]

- Carmignato, S. Accuracy of industrial computed tomography measurements: Experimental results from an international comparison. CIRP Ann. Manuf. Technol. 2012, 61, 491–494. [Google Scholar] [CrossRef]

- Grillini, L.; Affatato, S. How to measure wear following total hip arthroplasty. Hip Int. 2013, 23, 233–242. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Frigo, M.; Toni, A. An in vitro investigation of Diamond-Like Carbon as a femoral head coating. J. Biomed. Mater. Res. (Appl. Biomater.) 2000, 53, 221–226. [Google Scholar] [CrossRef]

- Taddei, P.; Tozzi, S.; Carmignato, S.; Affatato, S. May the surface roughness of the retrieved femoral head influence the wear behavior of the polyethylene liner. J. Biomed. Mater. Res. B (Appl. Biomater.) 2016, 104, 1374–1385. [Google Scholar] [CrossRef]

- Affatato, S.; Spinelli, M.; Zavalloni, M.; Traina, F.; Carmignato, S.; Toni, A. Ceramic-on-metal for total hip replacement: Mixing and matching can lead to high wear. Artif. Organs 2010, 34, 319–323. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Modena, E.; Carmignato, S.; Grupp, T.M.; Taddei, P. Quantification of wear rates and plastic deformation on mobile unicompartmental UHMWPE tibial knee inserts. Tribol. Lett. 2013, 52, 57–65. [Google Scholar] [CrossRef]

- Spinelli, M.; Carmignato, S.; Affatato, S.; Viceconti, M. CMM-based procedure for polyethylene non-congruous unicompartmental knee prosthesis wear assessment. Wear 2009, 267, 753–756. [Google Scholar] [CrossRef]

- Teeter, M.G.; Naudie, D.D.R.; McErlain, D.D.; Brandt, J.-M.M.; Yuan, X.; MacDonald, S.J.; Holdsworth, D.W. In vitro quantification of wear in tibial inserts using microcomputed tomography. Clin. Orthop. Relat. Res. 2011, 469, 107–112. [Google Scholar] [CrossRef] [PubMed]

- Dumbleton, J.H.; D’Antonio, J.A.; Manley, M.T.; Capello, W.N.; Wang, A. The basis for a second-generation highly cross-linked UHMWPE. Clin. Orthop. Relat. Res. 2006, 453, 265–271. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Zavalloni, M.; Taddei, P.; Di Foggia, M.; Fagnano, C.; Viceconti, M. Comparative study on the wear behaviour of different conventional and cross-linked polyethylenes for total hip replacement. Tribol. Int. 2008, 41, 813–822. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Medel, F.J.; Manley, M. (iii) Wear in highly crosslinked polyethylenes. Curr. Orthop. 2008, 22, 392–399. [Google Scholar] [CrossRef]

- Jedenmalm, A.; Nilsson, F.; Noz, M.E.; Green, D.D.; Gedde, U.W.; Clarke, I.C.; Stark, A.; Maguire, G.Q.; Zeleznik, M.P.; Olivecrona, H. Validation of a 3D CT method for measurement of linear wear of acetabular cups. Acta Orthop. 2011, 82, 35–41. [Google Scholar] [CrossRef] [PubMed]

- Engh, C.A., Jr.; Zimmerman, R.L.; Hopper, R.H., Jr.; Engh, G.A. Can microcomputed tomography measure retrieved polyethylene wear? Comparing fixed-bearing and rotating-platform knees. Clin. Orthop. Relat. Res. 2013, 471, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Parrilli, A.; Falcioni, S.; Fini, M.; Affatato, S. Is micro-computed tomography useful for wear assessment of ceramic femoral heads? A preliminary evaluation of volume measurements. J. Appl. Biomater. Funct. Mater. 2016, 14, e483–e489. [Google Scholar] [CrossRef] [PubMed]

| Activity | Min Load (N) | Max Load (N) | Frequency (Hz) |

|---|---|---|---|

| Level walking | ISO 14242-3 | ISO 14242-3 | 1.1 |

| Chair sitting and rising | 351.20 | 2776.4 | 0.7 |

| Stair climbing | 546 | 3951.3 | 1.0 |

| Stair descending | 611.7 | 4082.2 | 1.0 |

| Deep squatting | 1339.1 | 2505.8 | 0.7 |

| Parameter | Value |

|---|---|

| Voltage | 194 kV |

| Current | 46 μA |

| Exposure time | 1415 ms |

| Projections | 1500 |

| Scanning time | 35 min |

| Voxel size | 31 μm |

| Physical filtering | No |

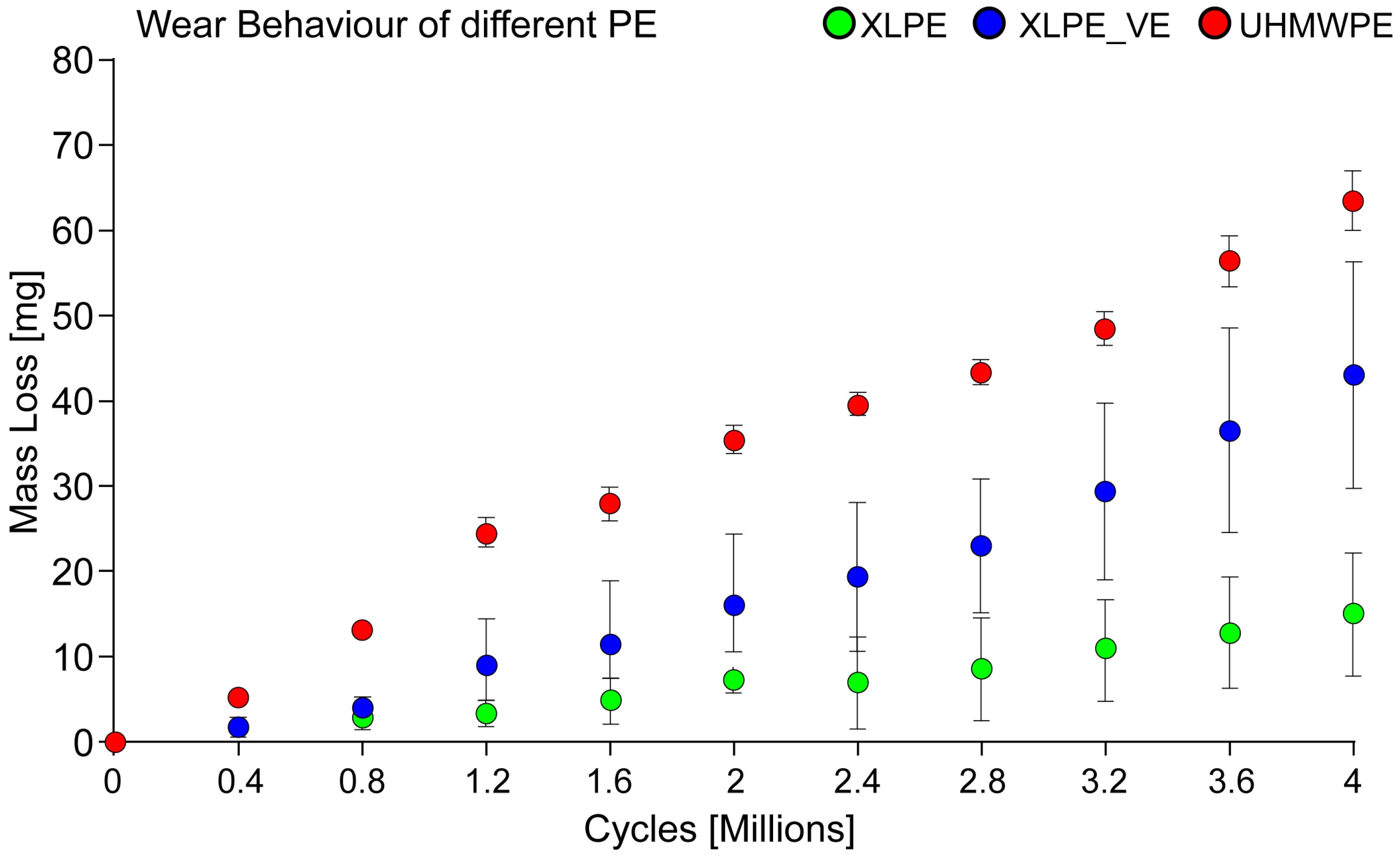

| Cycles (Mc) | Mean (mg) ± Standard Deviation | K–W Test (p-Value) | LSD Post Hoc Test (p-Value) | ||||

|---|---|---|---|---|---|---|---|

| XLPE | XLPE_VE | STD_PE | XLPE vs. XLPE_VE | XLPE vs. STD_PE | XLPE_VE vs. STD_PE | ||

| 2 | 6.5 ± 4.0 | 16.1 ± 8.2 | 35.4 ± 0.6 | 0.039 | NS | 0.034 | NS |

| 2.4 | 6.9 ± 5.3 | 19.3 ± 8.7 | 39.6 ± 0.3 | 0.031 | NS | 0.026 | NS |

| 2.8 | 8.6 ± 6.0 | 23.0 ± 7.9 | 43.3 ± 1.5 | 0.027 | NS | 0.022 | NS |

| 3.2 | 10.8 ± 6.0 | 29.3 ± 10.4 | 48.4 ± 1.9 | 0.027 | NS | 0.022 | NS |

| 3.6 | 12.9 ± 6.5 | 36.5 ± 12.0 | 56.3 ± 2.9 | 0.027 | NS | 0.022 | NS |

| 4 | 15.0 ± 7.1 | 43.0 ± 13.3 | 63.4 ± 3.6 | 0.027 | NS | 0.022 | NS |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Affatato, S.; Zanini, F.; Carmignato, S. Quantification of Wear and Deformation in Different Configurations of Polyethylene Acetabular Cups Using Micro X-ray Computed Tomography. Materials 2017, 10, 259. https://doi.org/10.3390/ma10030259

Affatato S, Zanini F, Carmignato S. Quantification of Wear and Deformation in Different Configurations of Polyethylene Acetabular Cups Using Micro X-ray Computed Tomography. Materials. 2017; 10(3):259. https://doi.org/10.3390/ma10030259

Chicago/Turabian StyleAffatato, Saverio, Filippo Zanini, and Simone Carmignato. 2017. "Quantification of Wear and Deformation in Different Configurations of Polyethylene Acetabular Cups Using Micro X-ray Computed Tomography" Materials 10, no. 3: 259. https://doi.org/10.3390/ma10030259