Strain Amount Dependent Grain Size and Orientation Developments during Hot Compression of a Polycrystalline Nickel Based Superalloy

Abstract

:1. Introduction

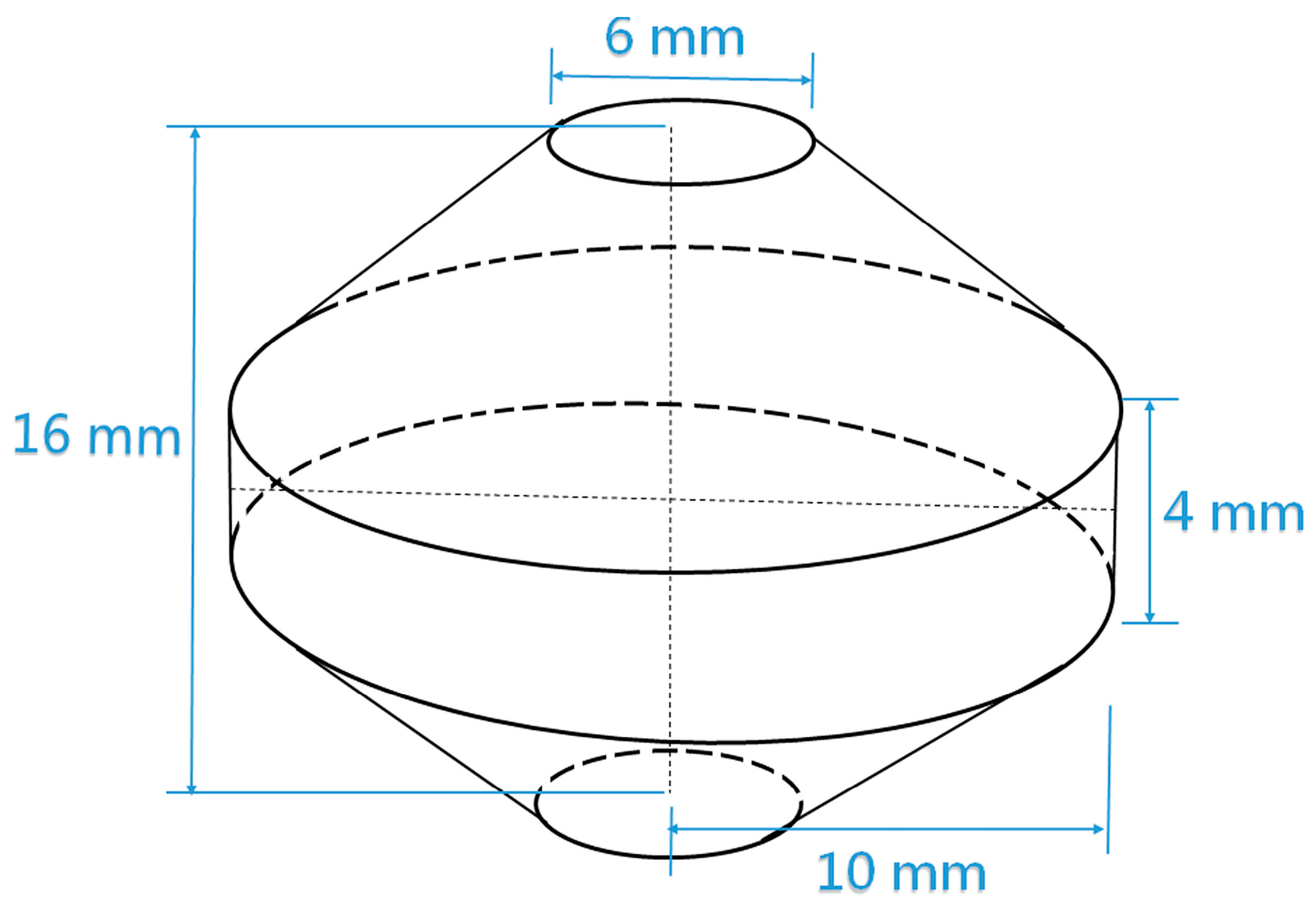

2. Materials and Experimental Procedures

3. Results and Discussion

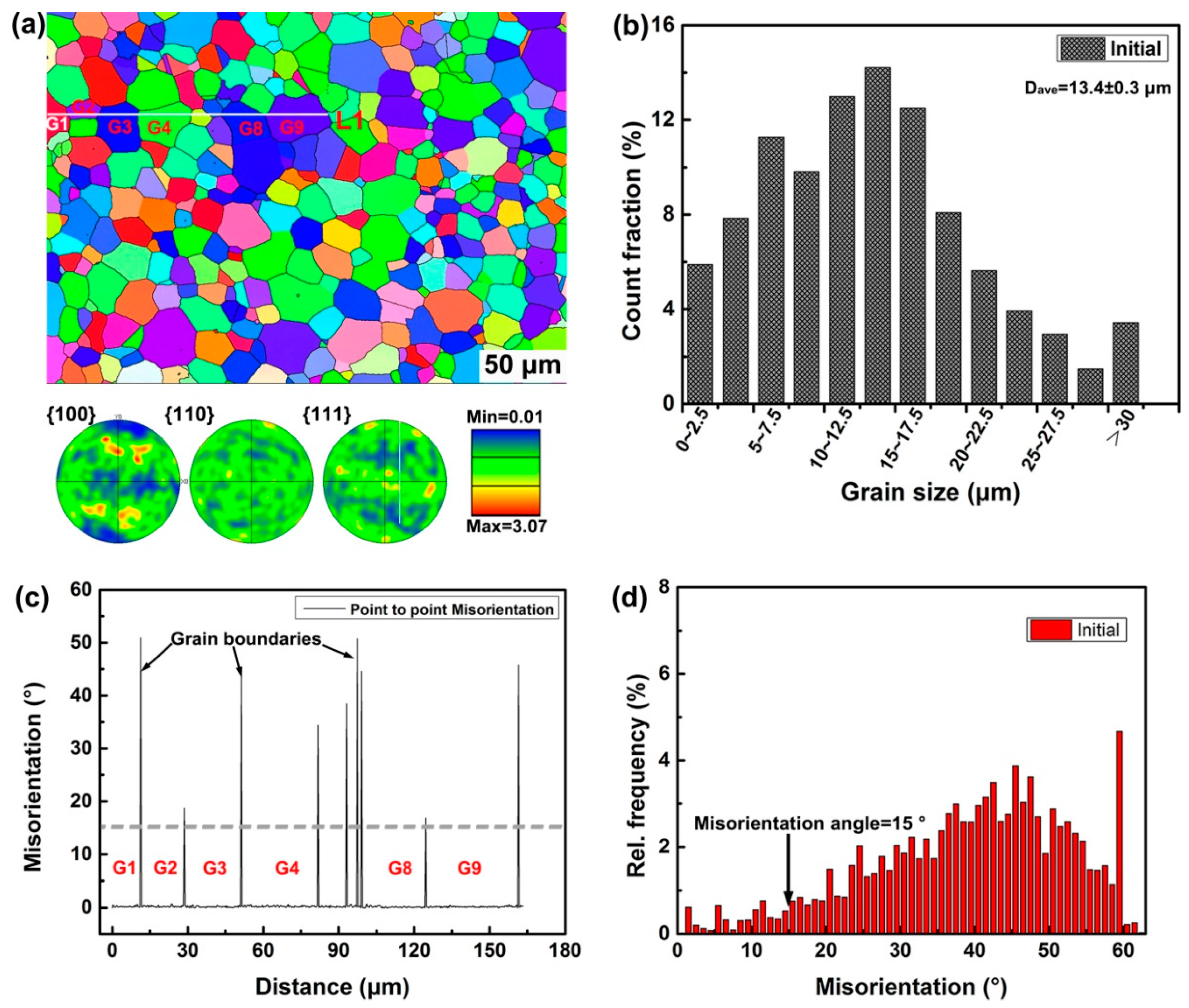

3.1. Pristine Microstructure

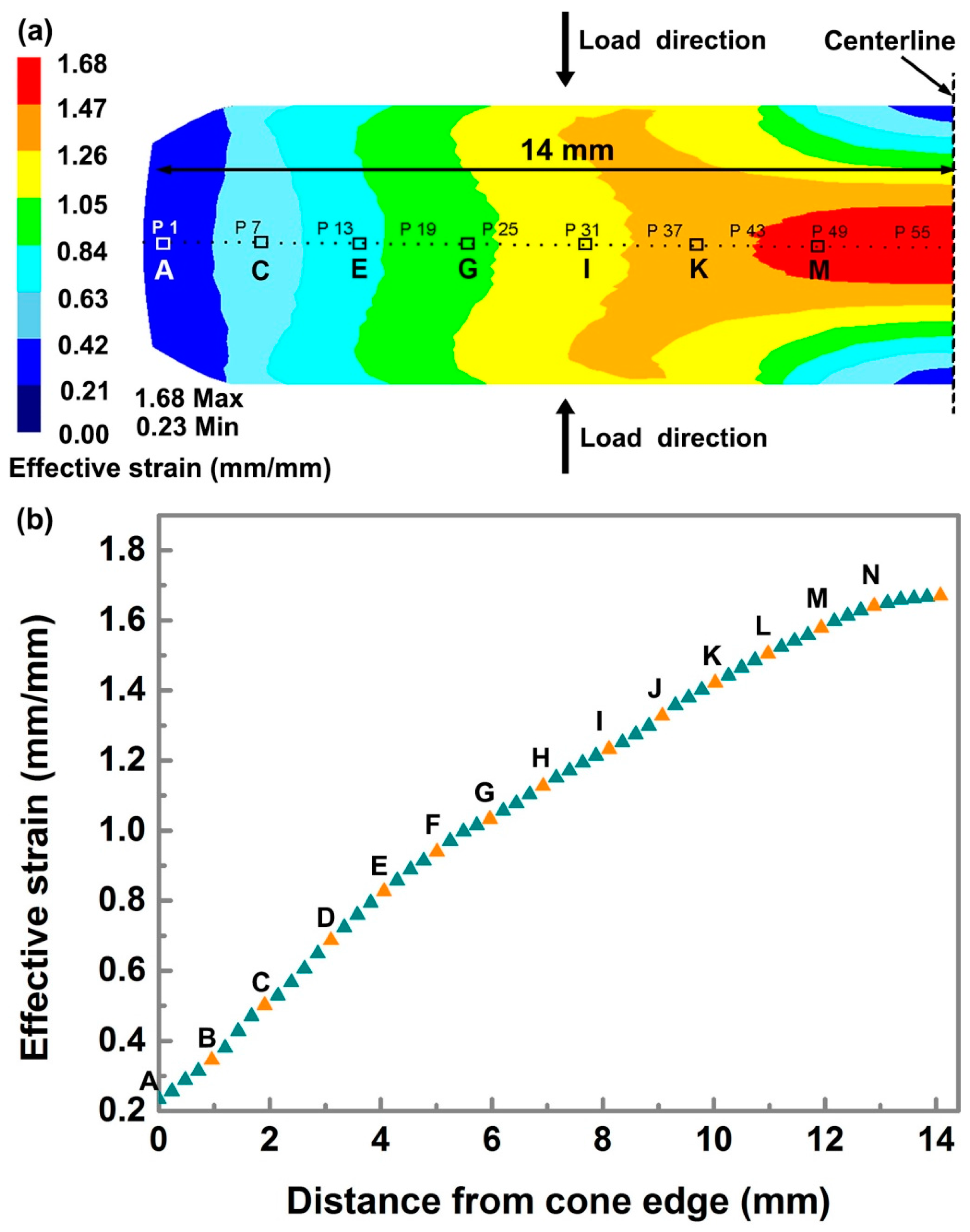

3.2. Deformation Modeling and Strain Distribution

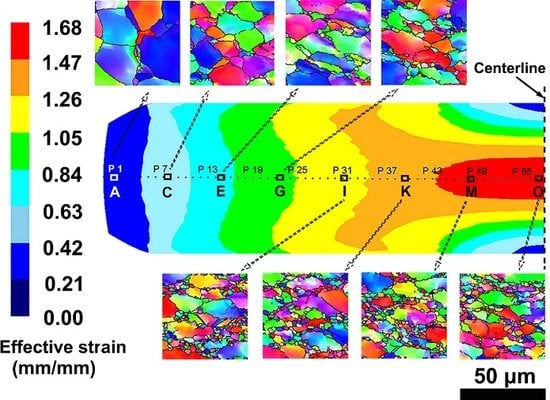

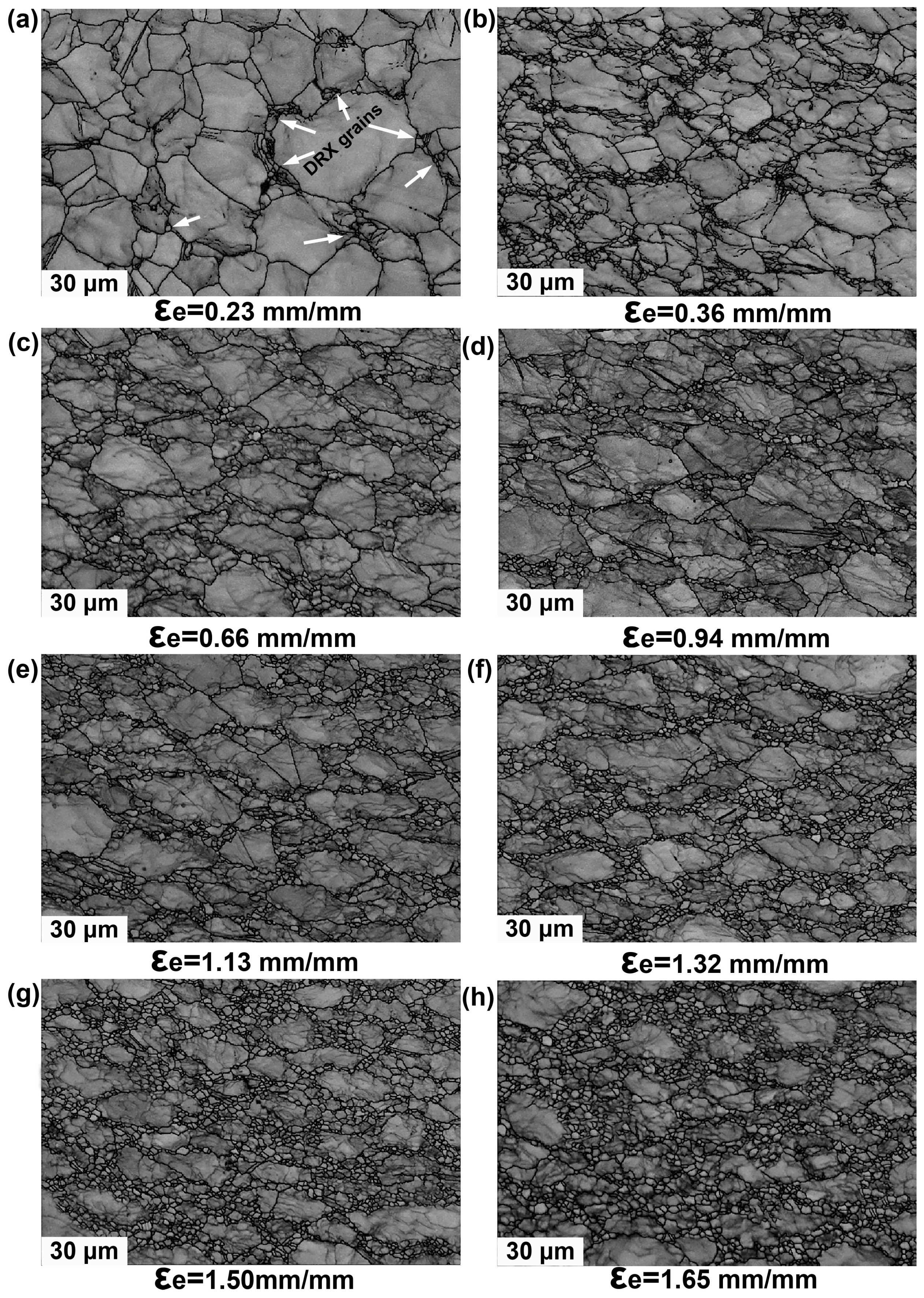

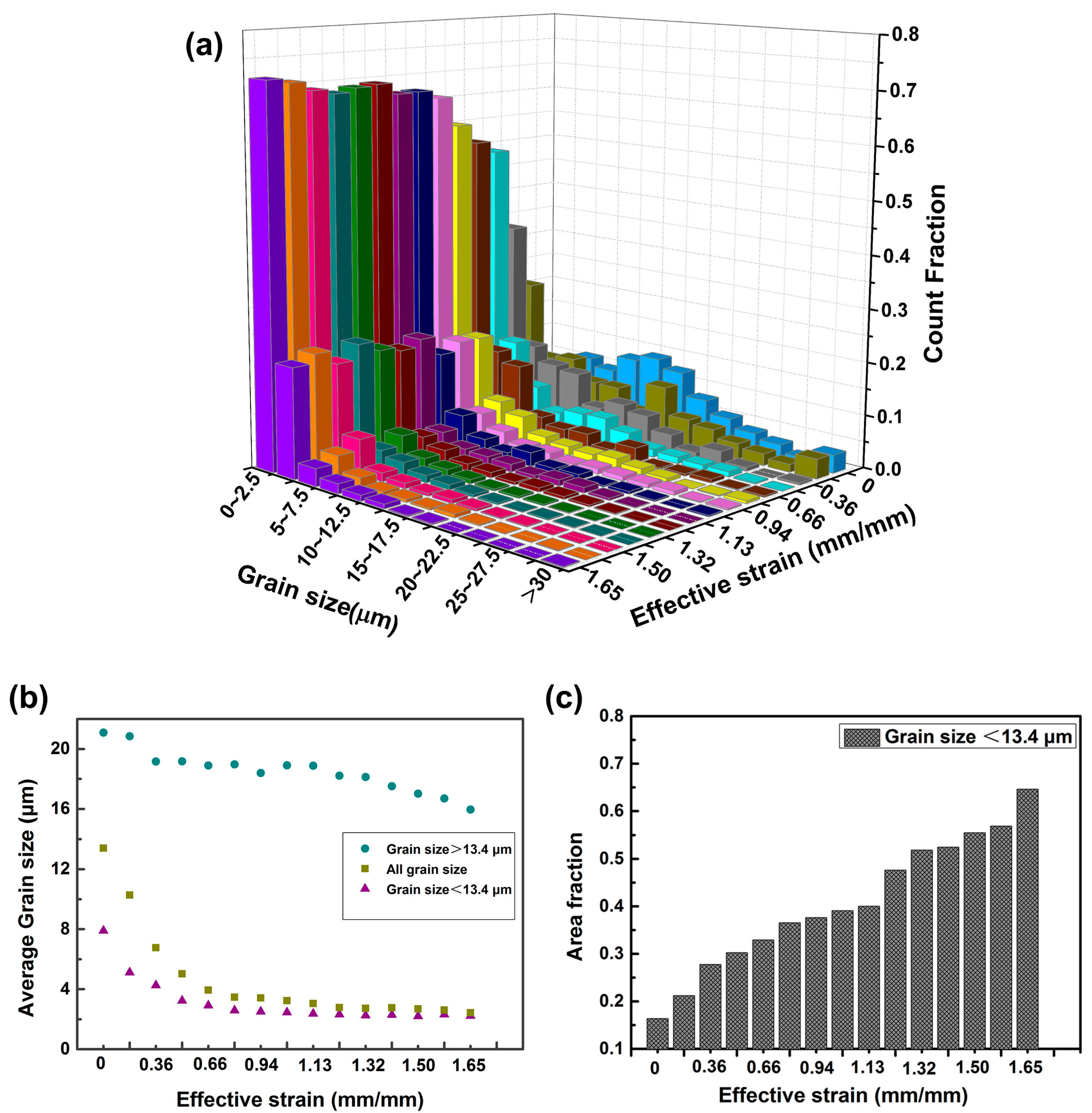

3.3. Microstructure Developments Related to Strain Amount

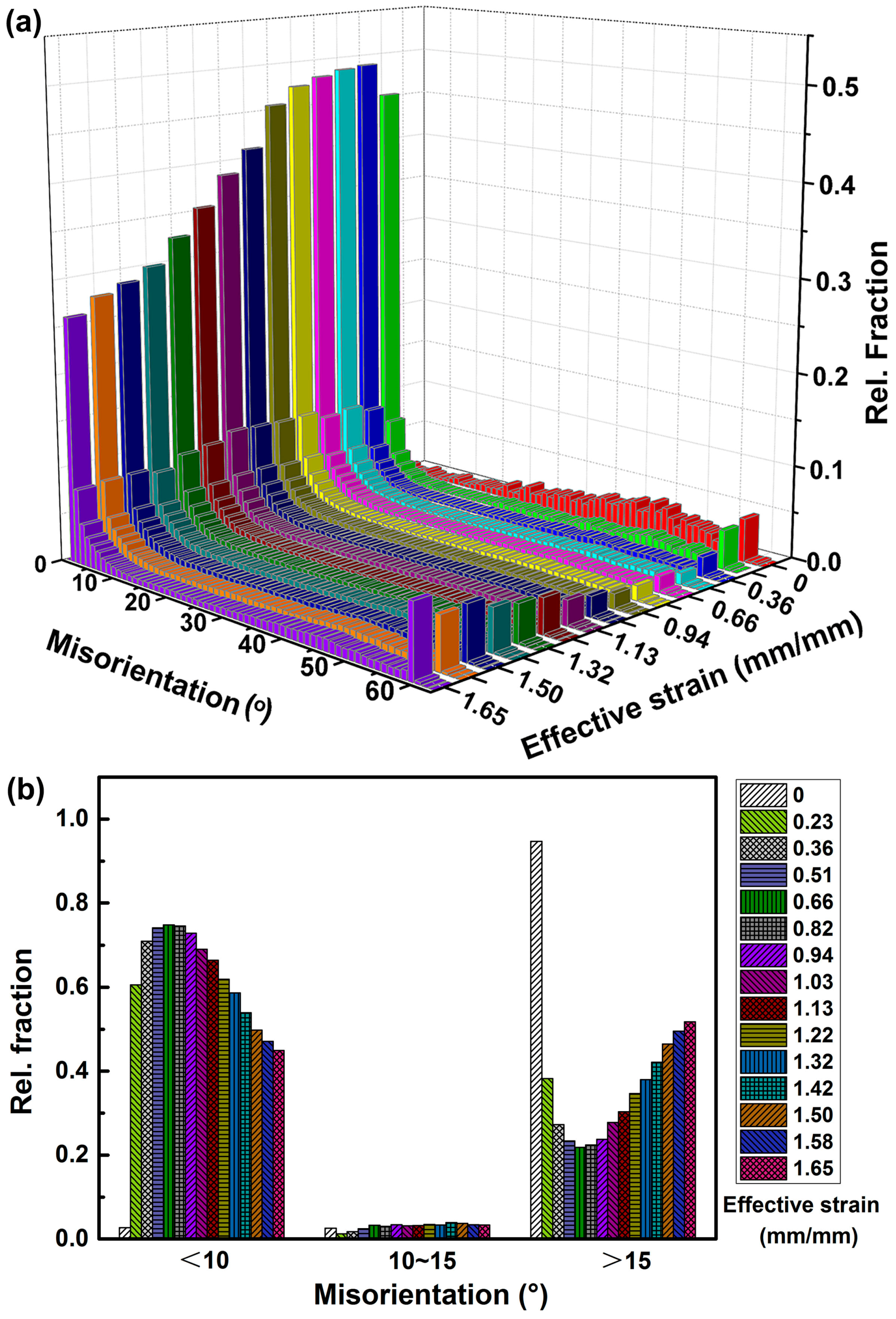

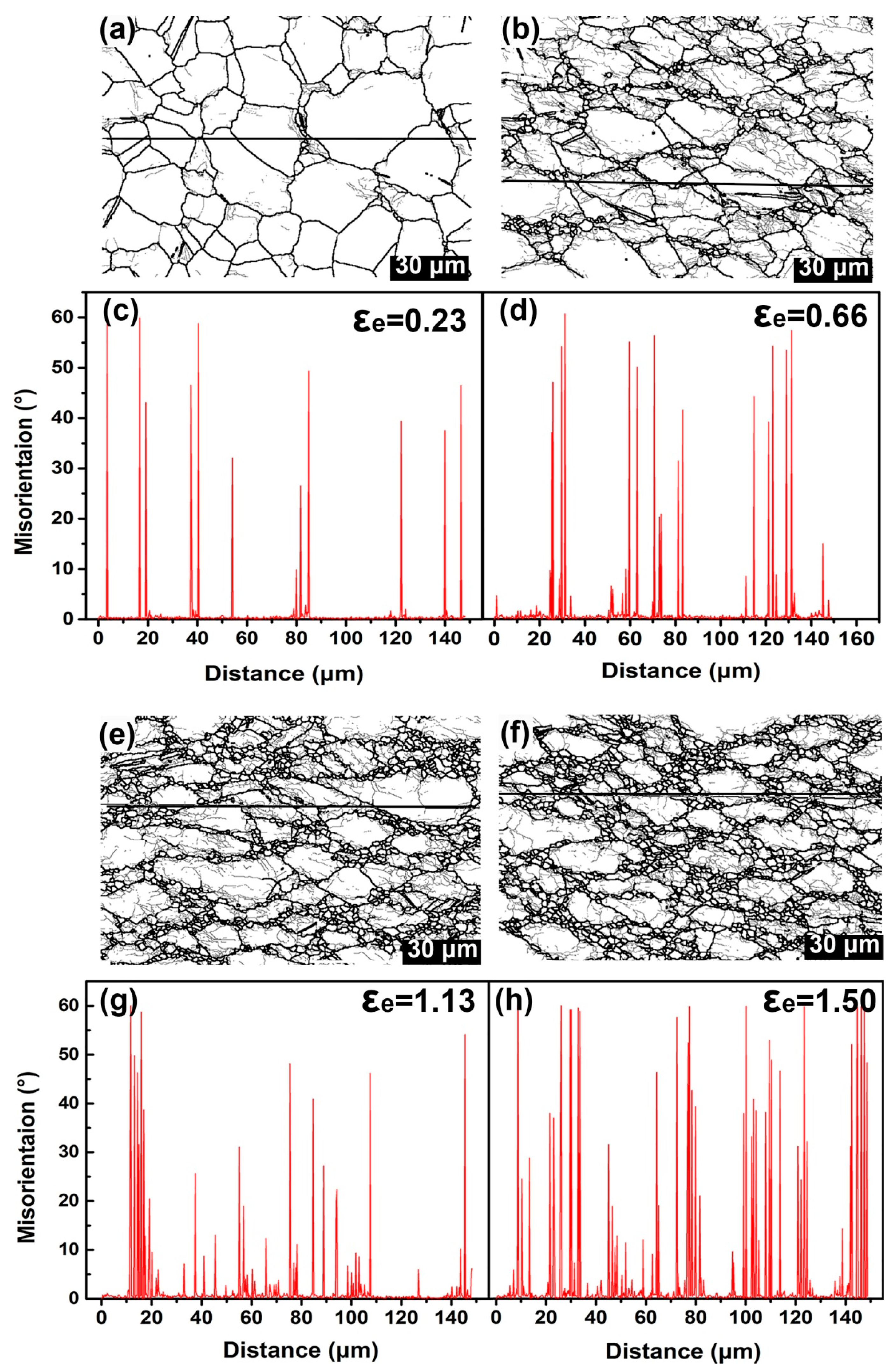

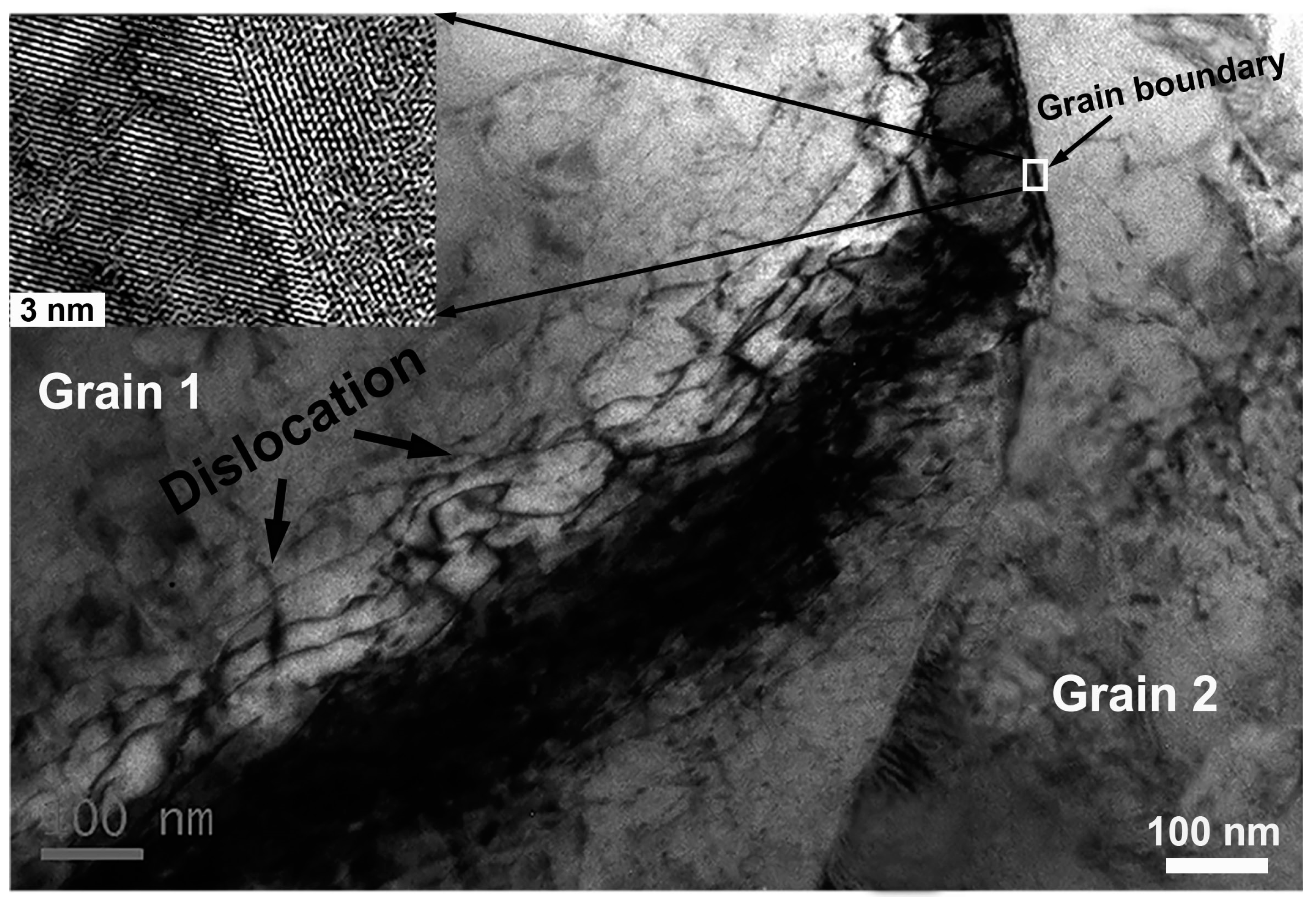

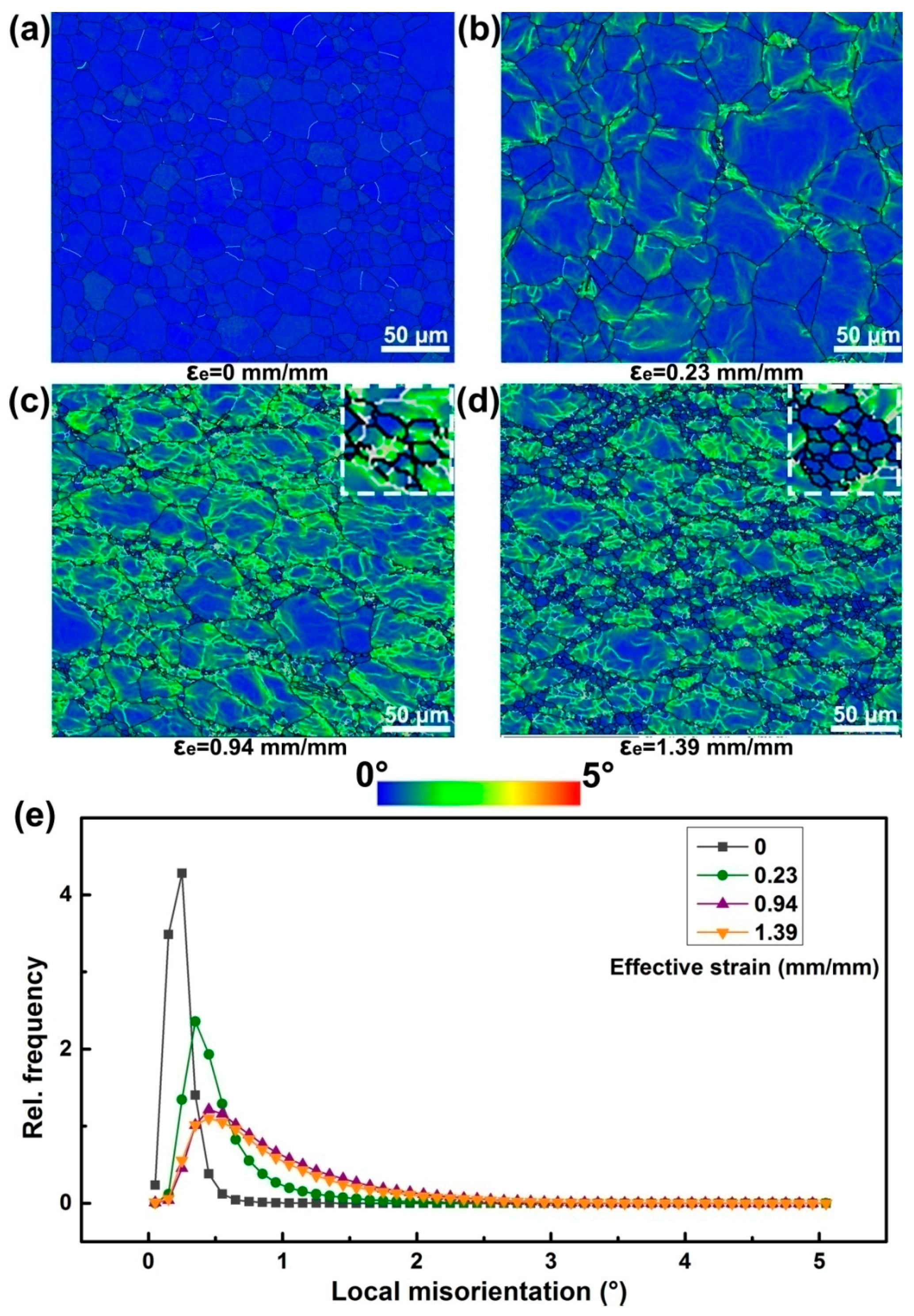

3.4. Grain Boundaries Evolutions Related to Strain Amount

4. Conclusions

- Continuous variations of effective strain ranging from 0.23 to 1.65 across the whole sample were achieved after reaching a reduction of 70%. Gradients of microstructure and grain size were found to exist from the edge to the center of the specimen.

- Grain size was measured to be decreased with increase of effective strain form the edge to the center of specimen. The average grain size decreased dramatically at the initial deformation period and kept at a stable value by balancing the process of DRX and grain growth. The area fraction of fine grains was observed to increase all the way to the end of deformation due to successive DRX process.

- The grain boundaries are the first sites to produce misorientation, which is manifested as the formation of dislocation. Subgrains are proved to be further generated in the higher deformation regions near the grain boundaries, where new DRX grains are inclined to be generated.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propul. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Matthew, J.; Donachie, S.; Donachie, J. Superalloys, A Technical Guide; ASM International: New York, NY, USA, 2002; pp. 192–265. [Google Scholar]

- Kumar, S.S.S.; Raghu, T.; Bhattacharjee, P.P.; Rao, G.A.; Borah, U. Strain rate dependent microstructural evolution during hot deformation of a hot isostatically processed nickel base superalloy. J. Alloys Compd. 2016, 681, 28–42. [Google Scholar] [CrossRef]

- He, G.; Liu, F.; Huang, L.; Huang, Z.; Jiang, L. Microstructure evolutions and nucleation mechanisms of dynamic recrystallization of a powder metallurgy Ni-based superalloy during hot compression. Mater. Sci. Eng. A 2016, 677, 496–504. [Google Scholar] [CrossRef]

- Arısoy, Y.M.; Guo, C.; Kaftanoğlu, B.; Özel, T. Investigations on microstructural changes in machining of Inconel 100 alloy using face turning experiments and 3D finite element simulations. Int. J. Mech. Sci. 2016, 107, 80–92. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Shank, J.M.; Shiveley, A.R.; Saurber, W.M.; Gaussa, E.F.; Pilchak, A.L. The Effect of Forging Variables on the Supersolvus Heat-Treatment Response of Powder-Metallurgy Nickel-Base Superalloys. Metall. Mater. Trans. A 2014, 45, 6231–6251. [Google Scholar] [CrossRef]

- Roy, S.; Suwas, S. The influence of temperature and strain rate on the deformation response and microstructural evolution during hot compression of a titanium alloy Ti–6Al–4V–0.1B. J. Alloys Compd. 2013, 548, 110–125. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, Z.; Ning, Y.; Nan, Y. Effect of deformation temperature and strain rate on dynamic recrystallized grain size of a powder metallurgical nickel-based superalloy. J. Alloys Compd. 2017, 691, 554–563. [Google Scholar] [CrossRef]

- Mejía, I.; Bedolla-Jacuinde, A.; Maldonado, C.; Cabrera, J.M. Determination of the critical conditions for the initiation of dynamic recrystallization in boron microalloyed steels. Mater. Sci. Eng. A 2011, 528, 4133–4140. [Google Scholar] [CrossRef]

- Fang, B.; Ji, Z.; Liu, M.; Tian, G.; Jia, C.; Zeng, T.; Hu, B.; Chang, Y. Critical strain and models of dynamic recrystallization for FGH96 superalloy during two-pass hot deformation. Mater. Sci. Eng. A 2014, 593, 8–15. [Google Scholar] [CrossRef]

- Mirzadeh, H.; Najafizadeh, A. Prediction of the critical conditions for initiation of dynamic recrystallization. Mater. Des. 2010, 31, 1174–1179. [Google Scholar] [CrossRef]

- Semiatin, S.L.; McClary, K.E.; Rollett, A.D.; Roberts, C.G.; Payton, E.J.; Zhang, F.; Gabb, T.P. Plastic Flow and Microstructure Evolution during Thermomechanical Processing of a PM Nickel-Base Superalloy. Metall. Mater. Trans. A 2013, 44, 2778–2798. [Google Scholar] [CrossRef]

- VMiller, M.; Johnson, A.E.; Torbet, C.J.; Pollock, T.M. Recrystallization and the Development of Abnormally Large Grains After Small Strain Deformation in a Polycrystalline Nickel-Based Superalloy. Metall. Mater. Trans. A 2016, 47, 1566–1574. [Google Scholar] [CrossRef]

- Detrois, M.; Helmink, R.C.; Tin, S. Microstructural Stability and Hot Deformation of γ-γ′-δ Ni-Base Superalloys. Metall. Mater. Trans. A 2014, 45, 5332–5343. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, K.; Zhou, H.; Lu, Z.; Zhao, C.; Yang, X. Effect of strain rate on microstructure evolution of a nickel-based superalloy during hot deformation. Mater. Des. 2015, 80, 51–62. [Google Scholar] [CrossRef]

- Chamanfar, A.; Jahazi, M.; Gholipour, J.; Wanjara, P.; Yue, S. Evolution of flow stress and microstructure during isothermal compression of Waspaloy. Mater. Sci. Eng. A 2014, 615, 497–510. [Google Scholar] [CrossRef]

- Buckingham, R.C.; Argyrakis, C.; Hardy, M.C.; Birosca, S. The effect of strain distribution on microstructural developments during forging in a newly developed nickel base superalloy. Mater. Sci. Eng. A 2016, 654, 317–328. [Google Scholar] [CrossRef]

- Huron, E.; Srivatsa, S.; Raymond, E. Control of Grain Size via Forging Strain Rate Limits for R'88DT. In Superalloys 2000, Proceedings of the 9th International Symposium on Superalloys, Champion, PA, USA, 17–21 September 2000; TMS: Warrendale, PA, USA, 2000; pp. 49–58. [Google Scholar]

- Weaver, D.S.; Semiatin, S.L. Recrystallization and grain-growth behavior of a nickel-base superalloy during multi-hit deformation. Scr. Mater. 2007, 57, 1044–1047. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Weaver, D.S.; Kramb, R.C.; Fagin, P.N.; Glavicic, M.G.; Goetz, R.L.; Frey, N.D.; Antony, M.M. Deformation and recrystallization behavior during hot working of a coarse-grain, nickel-base superalloy ingot material. Metall. Mater. Trans. A 2004, 35, 679–693. [Google Scholar] [CrossRef]

- Charpagne, M.-A.; Billot, T.; Franchet, J.-M.; Bozzolo, N. Heteroepitaxial recrystallization: A new mechanism discovered in a polycrystalline γ-γ′ nickel based superalloy. J. Alloys Compd. 2016, 688, 685–694. [Google Scholar] [CrossRef]

- Srinivasan, R.; Ramnarayan, V.; Deshpande, U.; Jain, V.; Weiss, I. Computer simulation of the forging of fine grain IN-718 alloy. Metall. Trans. A 1993, 24, 2061–2069. [Google Scholar] [CrossRef]

- Huang, D.; Wu, W.; Lambert, D.; Semiatin, S. Computer simulation of microstructure evolution during hot forging of Waspaloy and nickel alloy 718. In Microstructure Modeling and Prediction During Thermomechanical Processing; TMS: Warrendale, PA, USA, 2001; pp. 137–147. [Google Scholar]

- Payton, E.; Wang, G.; Ma, N.; Wang, Y.; Mills, M.; Whitis, D.; Mourer, D.; Wei, D. Integration of simulations and experiments for modeling superalloy grain growth. Growth 2008, 11, 12. [Google Scholar]

- Rollett, A.; Humphreys, F.; Rohrer, G.S.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

| Element | Co | Cr | Ti | W | Mo | Al | Nb | Hf | C | B | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt. % | 26 | 13 | 3.7 | 4 | 4 | 3.2 | 0.95 | 0.2 | 0.05 | 0.025 | 0.05 | Bal. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, G.; Tan, L.; Liu, F.; Huang, L.; Huang, Z.; Jiang, L. Strain Amount Dependent Grain Size and Orientation Developments during Hot Compression of a Polycrystalline Nickel Based Superalloy. Materials 2017, 10, 161. https://doi.org/10.3390/ma10020161

He G, Tan L, Liu F, Huang L, Huang Z, Jiang L. Strain Amount Dependent Grain Size and Orientation Developments during Hot Compression of a Polycrystalline Nickel Based Superalloy. Materials. 2017; 10(2):161. https://doi.org/10.3390/ma10020161

Chicago/Turabian StyleHe, Guoai, Liming Tan, Feng Liu, Lan Huang, Zaiwang Huang, and Liang Jiang. 2017. "Strain Amount Dependent Grain Size and Orientation Developments during Hot Compression of a Polycrystalline Nickel Based Superalloy" Materials 10, no. 2: 161. https://doi.org/10.3390/ma10020161