Microstructure Characterization and Wear-Resistant Properties Evaluation of an Intermetallic Composite in Ni–Mo–Si System

Abstract

:1. Introduction

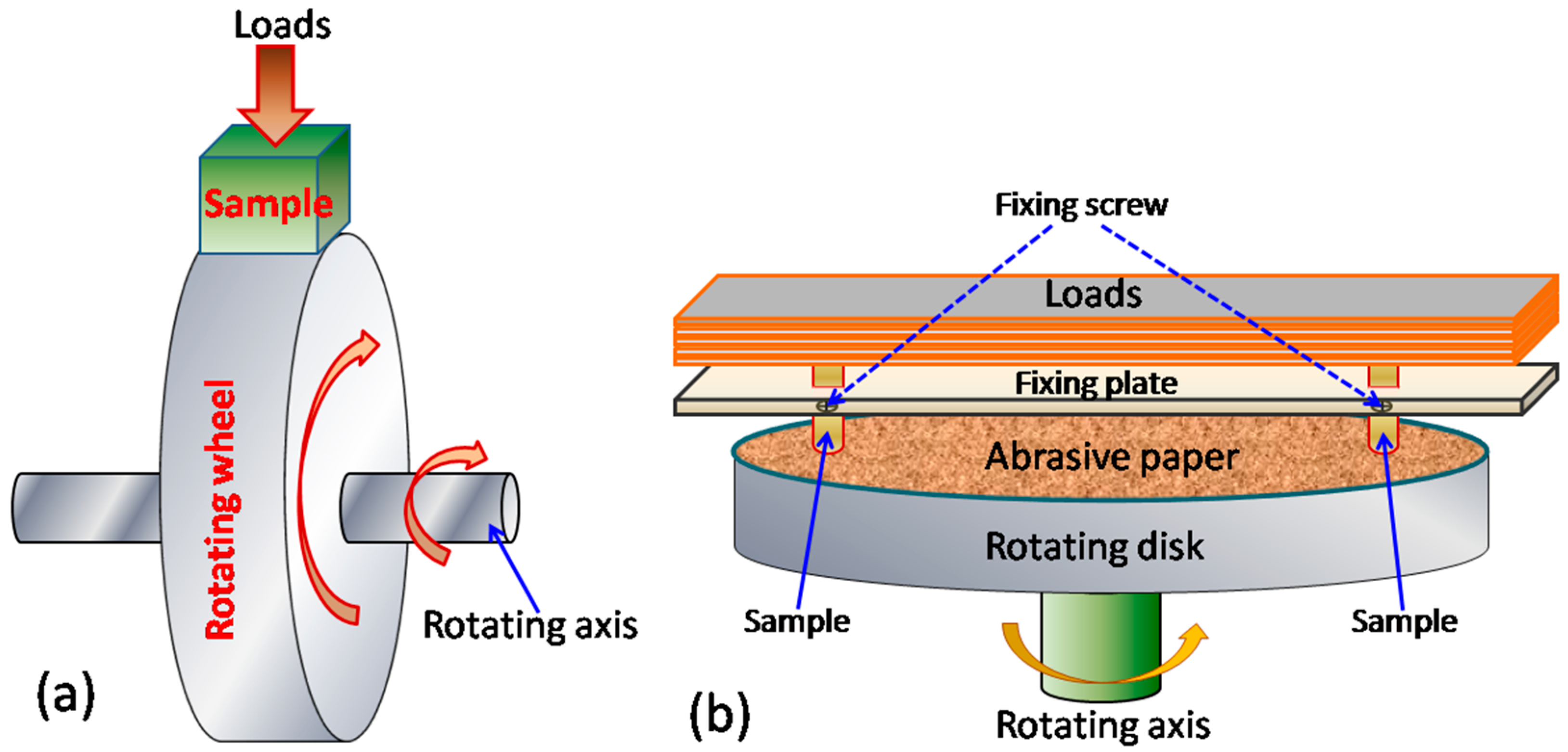

2. Experimental Procedures

3. Results and Discussion

4. Conclusions

- (1)

- A wear-resistant 45Ni–40Mo–15Si intermetallic composite was designed based on the Ni–Mo–Si ternary alloy diagram and was manufactured successfully by an arc-melting route with pure nickel, molybdenum, and silicon powder blends as starting materials.

- (2)

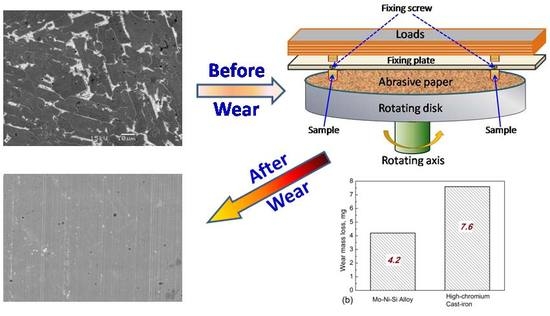

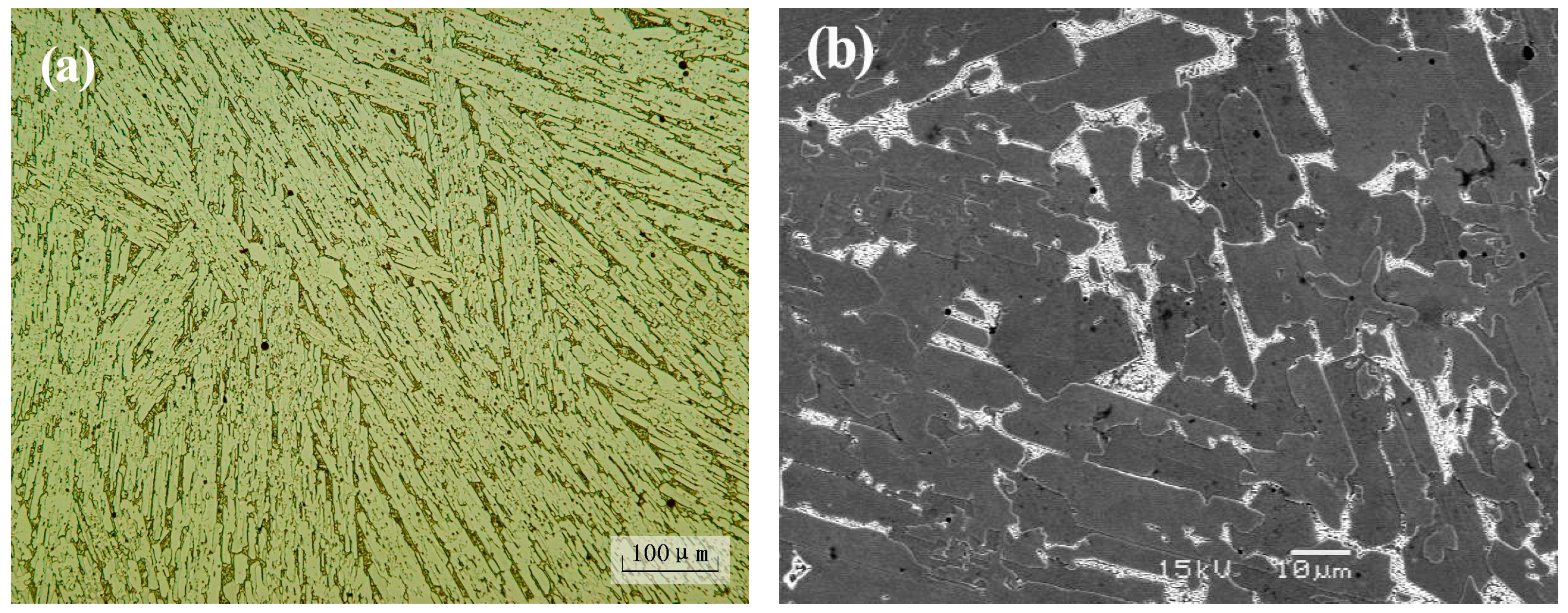

- Microstructural characterization revealed that the new intermetallic composite had a dense and uniform microstructure, and the main constituent phases were binary intermetallic compound NiMo and ternary metal silicide Mo2Ni3Si.

- (3)

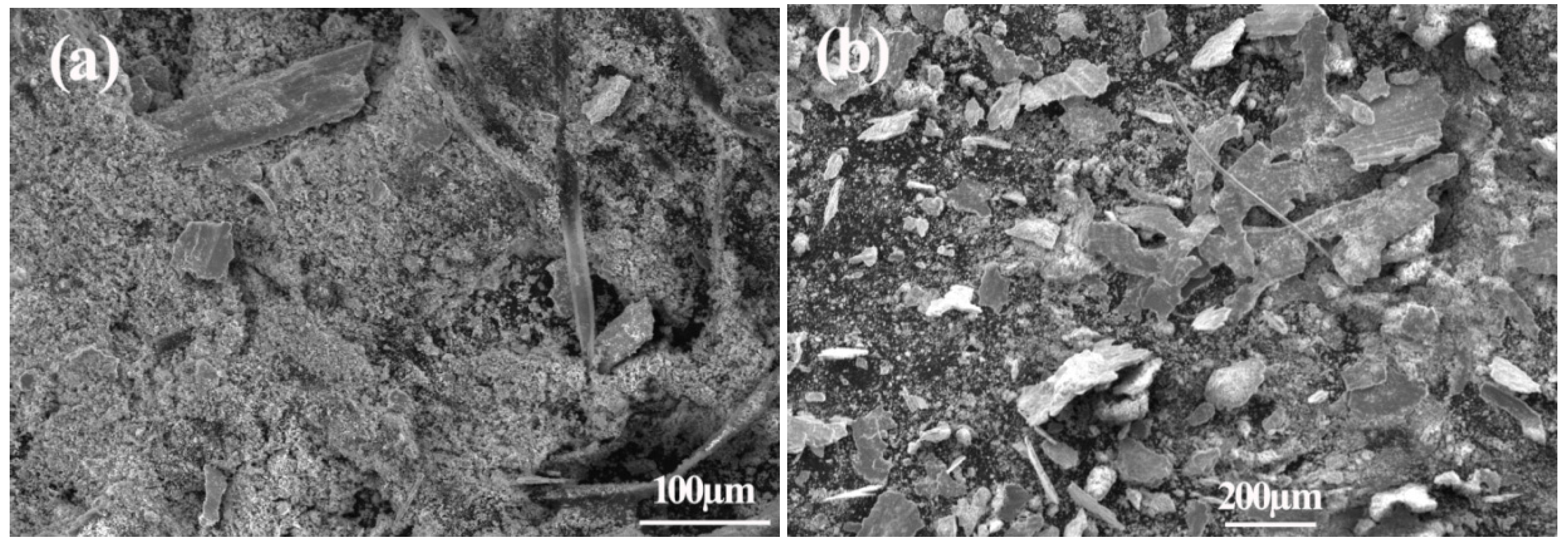

- The Ni–Mo–Si ternary intermetallic composite exhibited better wear-resistant properties compared to traditional engineering steel materials under the same room-temperature dry-sliding and abrasive wear test conditions, which implies its potential in various wear environments.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sigolo, E.; Soyama, J.; Zepon, G.; Kiminami, C.S.; Botta, W.J.; Bolfarini, C. Wear resistant coatings of boron-modified stainless steels deposited by plasma transferred arc. Surf. Coat. Technol. 2016, 302, 255–264. [Google Scholar] [CrossRef]

- Jung, S.; Sohn, S.S.; Jo, Y.H.; Choi, W.-M.; Lee, B.-J.; Oh, Y.-J.; Kim, G.-Y.; Jang, S.; Lee, S. Effects of Cr and Nb addition on high-temperature tensile properties in austenitic cast steels used for turbo-charger application. Mater. Sci. Eng. A 2016, 677, 316–324. [Google Scholar] [CrossRef]

- Chen, T.-C.; Chou, C.-C.; Yung, T.-Y.; Tsai, K.-C.; Huang, J.-Y. Wear behavior of thermally sprayed Zn/15Al, Al and Inconel 625 coatings on carbon steel. Surf. Coat. Technol. 2016, 303, 78–85. [Google Scholar] [CrossRef]

- Itoi, T.; Mineta, S.; Kimura, H.; Yoshimi, K.; Hirohashi, M. Fabrication and wear properties of Fe3Al-based composites. Intermetallics 2010, 18, 2169–2177. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Wang, J. In-situ reactive fabrication and effect of phosphorus on microstructure evolution of Ni/Ni–Al intermetallic composite coating by laser cladding. Mater. Des. 2016, 105, 171–178. [Google Scholar] [CrossRef]

- Wagle, S.; Kaneno, Y.; Nishimura, R.; Takasugi, T. Evaluation of the wear properties of dual two-phase Ni3Al/Ni3V intermetallic alloys. Tribol. Int. 2013, 66, 234–240. [Google Scholar] [CrossRef]

- Li, X.; Guo, X.-P.; Qiao, Y.-Q. Friction and wear behaviors of Nb–Ti–Si–Cr based ultrahigh temperature alloy and its Zr–Y jointly modified silicide coatings. Trans. Nonferrous Met. Soc. Chin. 2016, 26, 1892–1901. [Google Scholar] [CrossRef]

- Gao, F.; Wang, H.-M. Abrasive wear property of laser melting/deposited Ti2Ni/TiNi intermetallic alloy. Trans. Nonferrous Met. Soc. Chin. 2007, 17, 1358–1362. [Google Scholar] [CrossRef]

- Yu, Y.; Zhou, J.; Ren, S.; Wang, L.; Xin, B.; Cao, S. Tribological properties of laser cladding NiAl intermetallic compound coatings at elevated temperatures. Tribol. Int. 2016, 104, 321–327. [Google Scholar] [CrossRef]

- Hwang, K.S.; Huang, H.S. Identification of the segregation layer and its effects on the activated sintering and ductility of Ni-doped molybdenum. Acta. Mater. 2003, 51, 3915–3926. [Google Scholar] [CrossRef]

- Panek, J.; Kubisztal, J.; Bierska-Piech, B. Ni50Mo40Ti10alloy prepared by mechanical alloying as electroactive material for hydrogen evolution reaction. Surf. Interface Anal. 2014, 46, 716–720. [Google Scholar] [CrossRef]

- Navarro-Flores, E.; Chong, Z.; Omanovic, S. Characterization of Ni, NiMo, NiW and NiFe electroactive coatings as electrocatalysts for hydrogen evolution in an acidic medium. J. Mol. Catal. A Chem. 2005, 226, 179–197. [Google Scholar] [CrossRef]

- Gui, Y.L.; Song, C.Y.; Yang, L.; Qin, X.L. Microstructure and tribological properties of NiMo/Mo2Ni3Si intermetallic “in-situ” composites. J. Alloys Compd. 2011, 509, 4987–4991. [Google Scholar]

- Gui, Y.L.; Song, C.Y.; Wang, S.H.; Zhao, D.G. Elevated-temperature wear behaviors of NiMo/Mo2Ni3Si intermetallic “in situ” composites. J. Mater. Res. 2016, 31, 66–75. [Google Scholar] [CrossRef]

- Song, C.Y.; Gui, Y.L.; Kuang, S.B.; Wang, S.H.; Zhao, D.G. Microstructure and wear resistance of a novel Mo–Ni–Si system intermetallic composite with ductile Mo phase. Mater. Trans. 2016, 57, 721–725. [Google Scholar] [CrossRef]

- Mandal, P.; Thom, A.J.; Kramer, M.J.; Behrani, V.; Akinc, M. Oxidation behavior of Mo–Si–B alloys in wet air. Mater. Sci. Eng. A Struct. 2004, 371, 335–342. [Google Scholar] [CrossRef]

- Ma, C.L.; Li, J.G.; Tan, Y.; Tanaka, R.; Hanada, S. Microstructure and mechanical properties of Nb/Nb5Si3 in situ composites in Nb–Mo–Si and Nb–W–Si systems. Mater. Sci. Eng. A Struct. 2004, 386, 375–383. [Google Scholar] [CrossRef]

- Kim, J.H.; Tabaru, T.; Sakamoto, M.; Hanada, S. Mechanical properties and fracture behavior of an NbSS/NbSS/Nb5Si3 in-situ composite modified by Mo and Hf alloying. Mater. Sci. Eng. A Struct. 2004, 372, 137–144. [Google Scholar] [CrossRef]

- Gui, Y.L.; Qi, X.J.; Song, C.Y. Metallic tribological compatibility of MoSS-toughened Mo2Ni3Si metal silicide alloys. Mater. Sci. Forum 2012, 704, 1068–1072. [Google Scholar]

- Lu, X.D.; Wang, H.M. Corrosive sliding wear behavior of laser clad Mo2Ni3Si/NiSi intermetallic coating. Appl. Surf. Sci. 2005, 245, 346–352. [Google Scholar] [CrossRef]

- Xu, Y.W.; Wang, H.M. Room-temperature dry sliding wear behavior of γ-Ni/Mo2Ni3Si metal silicide “in situ” composites. J. Alloys Compd. 2007, 440, 101–107. [Google Scholar] [CrossRef]

- Nieh, T.G.; Wang, J.G.; Liu, C.T. Deformation of a multiphase Mo–9.4Si–13.8B alloy at elevated temperatures. Intermetallics 2001, 9, 73–79. [Google Scholar] [CrossRef]

- Murakami, T.; Hibi, Y.; Mano, H.; Matsuzaki, K.; Inui, H. Friction and wear properties of Fe–Si intermetallic compounds in ethyl alcohol. Intermetallics 2012, 20, 68–75. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Mordike, B.L.; Roy, S.K.; Manna, I. High-temperature oxidation behavior of laser-surface-alloyed Ti with Si and Si plus Al. Oxid. Met. 2002, 57, 473–498. [Google Scholar] [CrossRef]

- Schneibel, J.H.; Kramer, M.J.; Easton, D.S. A Mo–Si–B intermetallic alloy with a continuous alpha-Mo matrix. Scr. Mater. 2002, 46, 217–221. [Google Scholar] [CrossRef]

- Maglia, F.; Milanese, C.; Anselmi-Tamburini, U.; Munir, Z.A. Self-propagating high-temperature synthesis microalloying of MoSi2 with Nb and V. J. Mater. Res. 2003, 18, 1842–1848. [Google Scholar] [CrossRef]

- Ha, S.H.; Yoshimi, K.; Nakamura, J.; Kaneko, T.; Maruyama, K.; Tu, R.; Goto, T. Experimental study of MoSS-T2, MoSS-Mo3Si-T2, and Mo3Si-T2 eutectic reactions in Mo-rich Mo–Si–B alloys. J. Alloys Compd. 2014, 594, 52–59. [Google Scholar] [CrossRef]

| Test Materials | Wear Mass Loss (mg) | Wear Volume Loss (mm3) | ||

|---|---|---|---|---|

| Sample | Counterpart | Sample | Counterpart | |

| 45Ni–40Mo–15Si | 6.0 | 24.6 | 0.66 | 3.14 |

| Hardened 1.0% C–1.5% Cr Bearing Steel | 25.1 | 73.7 | 3.21 | 9.40 |

| Hardened 0.45% C Steel | 39.4 | 135.7 | 5.03 | 17.32 |

| Austenitic 1Cr18Ni9Ti Stainless Steel | 92.2 | 266.3 | 11.74 | 33.98 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, B.; Song, C.; Liu, Y.; Gui, Y. Microstructure Characterization and Wear-Resistant Properties Evaluation of an Intermetallic Composite in Ni–Mo–Si System. Materials 2017, 10, 130. https://doi.org/10.3390/ma10020130

Huang B, Song C, Liu Y, Gui Y. Microstructure Characterization and Wear-Resistant Properties Evaluation of an Intermetallic Composite in Ni–Mo–Si System. Materials. 2017; 10(2):130. https://doi.org/10.3390/ma10020130

Chicago/Turabian StyleHuang, Boyuan, Chunyan Song, Yang Liu, and Yongliang Gui. 2017. "Microstructure Characterization and Wear-Resistant Properties Evaluation of an Intermetallic Composite in Ni–Mo–Si System" Materials 10, no. 2: 130. https://doi.org/10.3390/ma10020130