Machinability of Minor Wooden Species before and after Modification with Thermo-Vacuum Technology

Abstract

:1. Introduction

2. Experimental Section

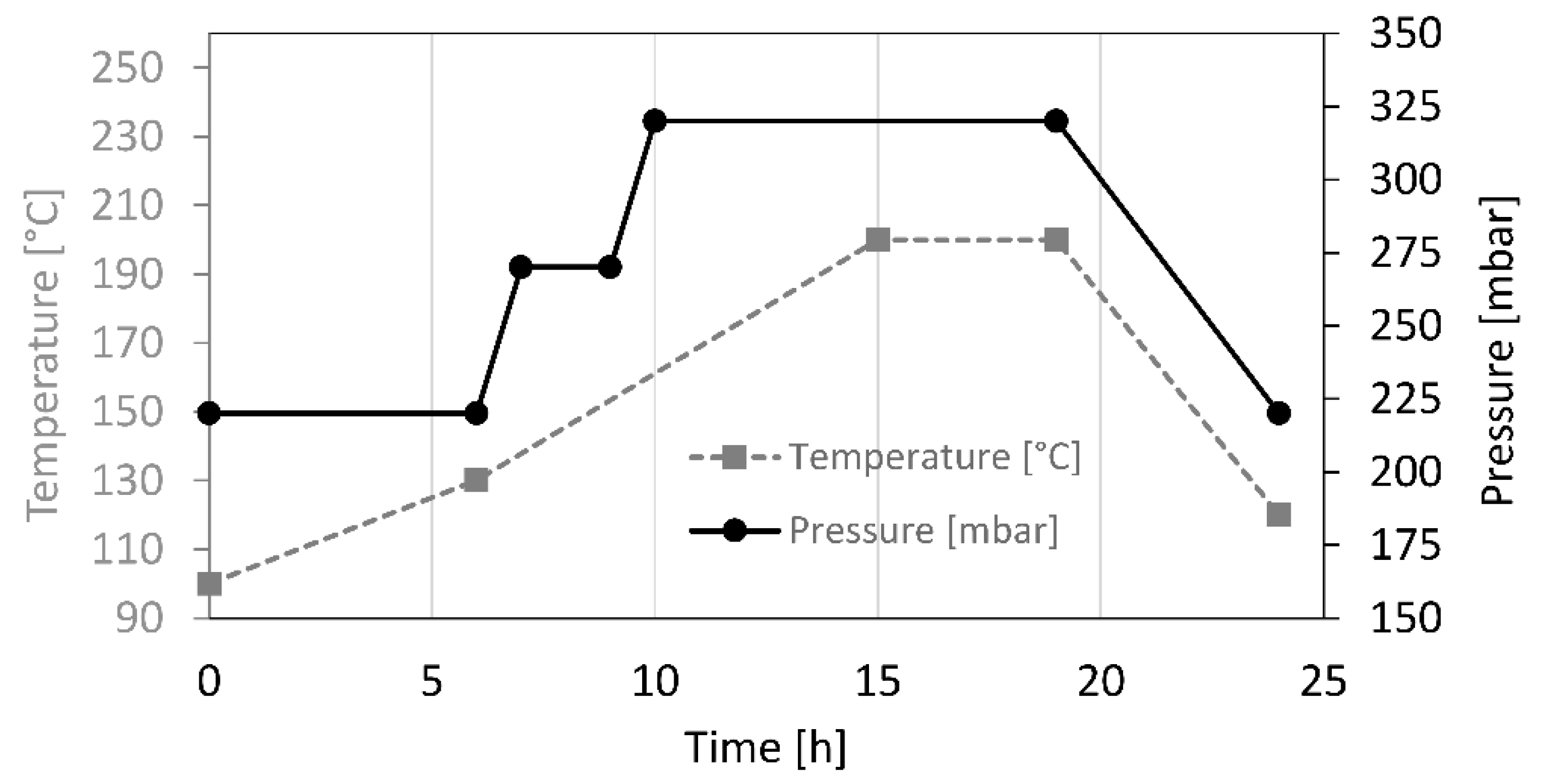

2.1. Thermal Treatment of Experimental Samples

2.2. Wood Machining Test

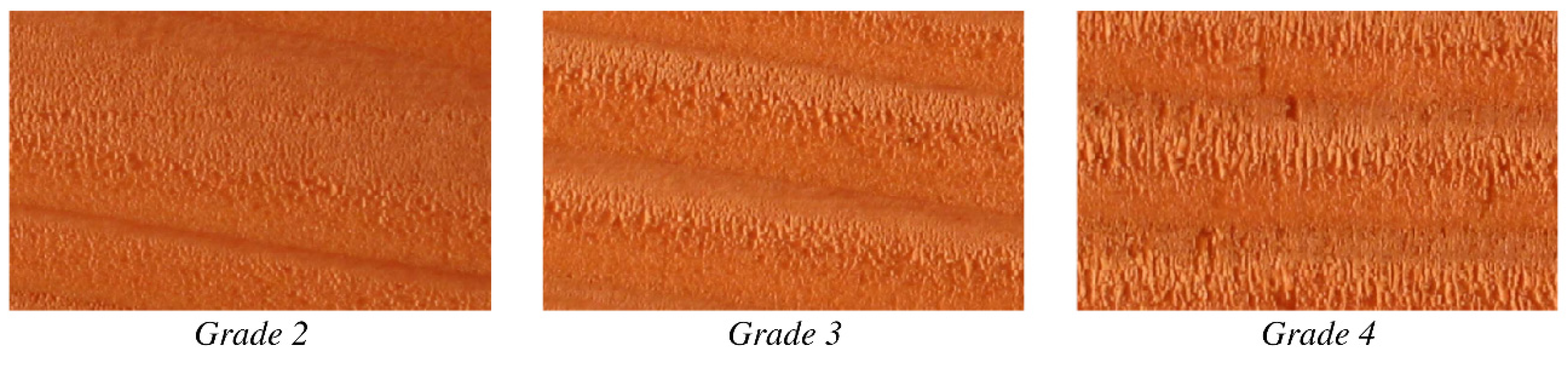

2.3. Visual Assessment of the Surface

2.4. Surface Topography Measurement and Analysis

3. Results and Discussion

3.1. Visual Assessment

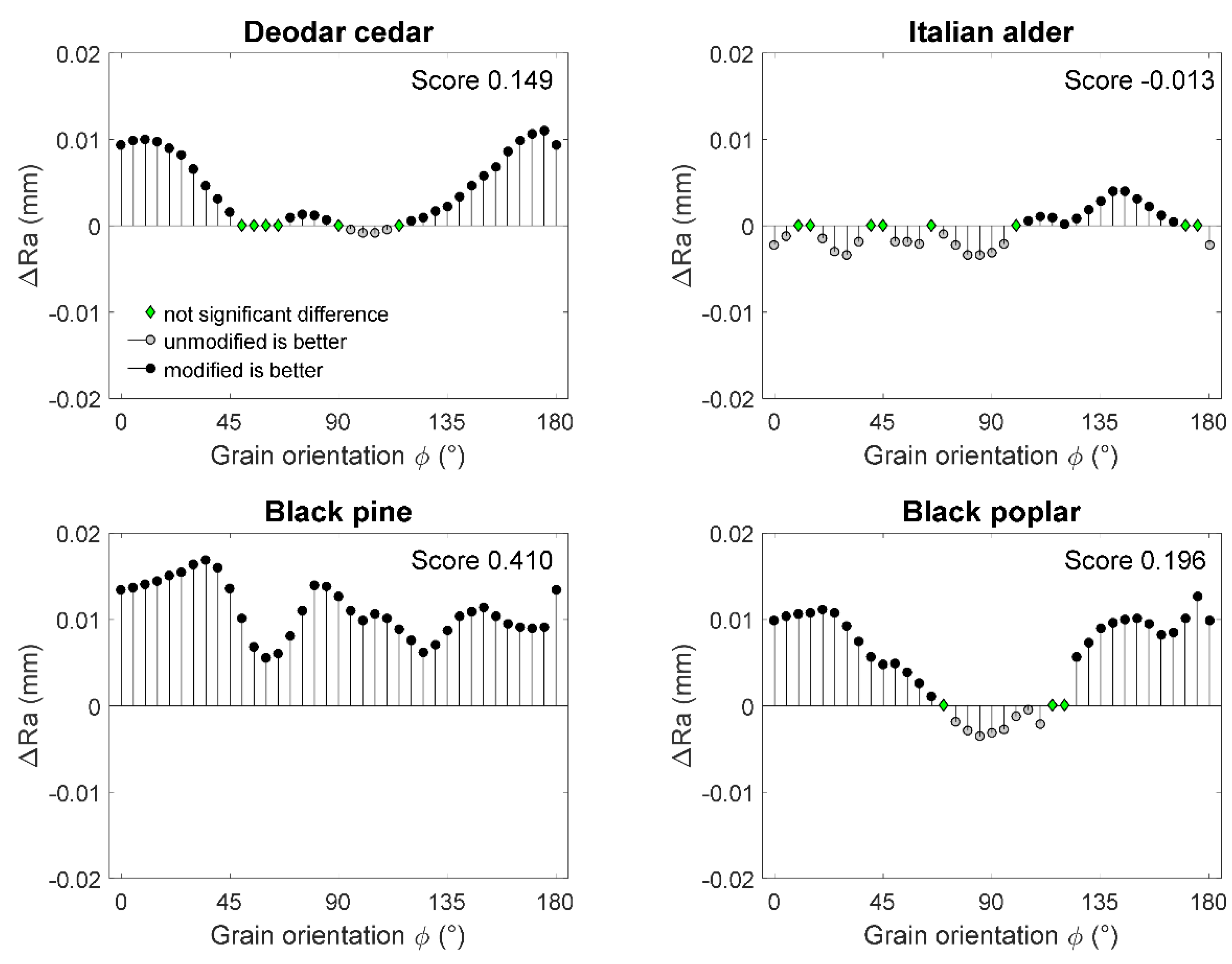

3.2. 3D Surface Topography Analysis

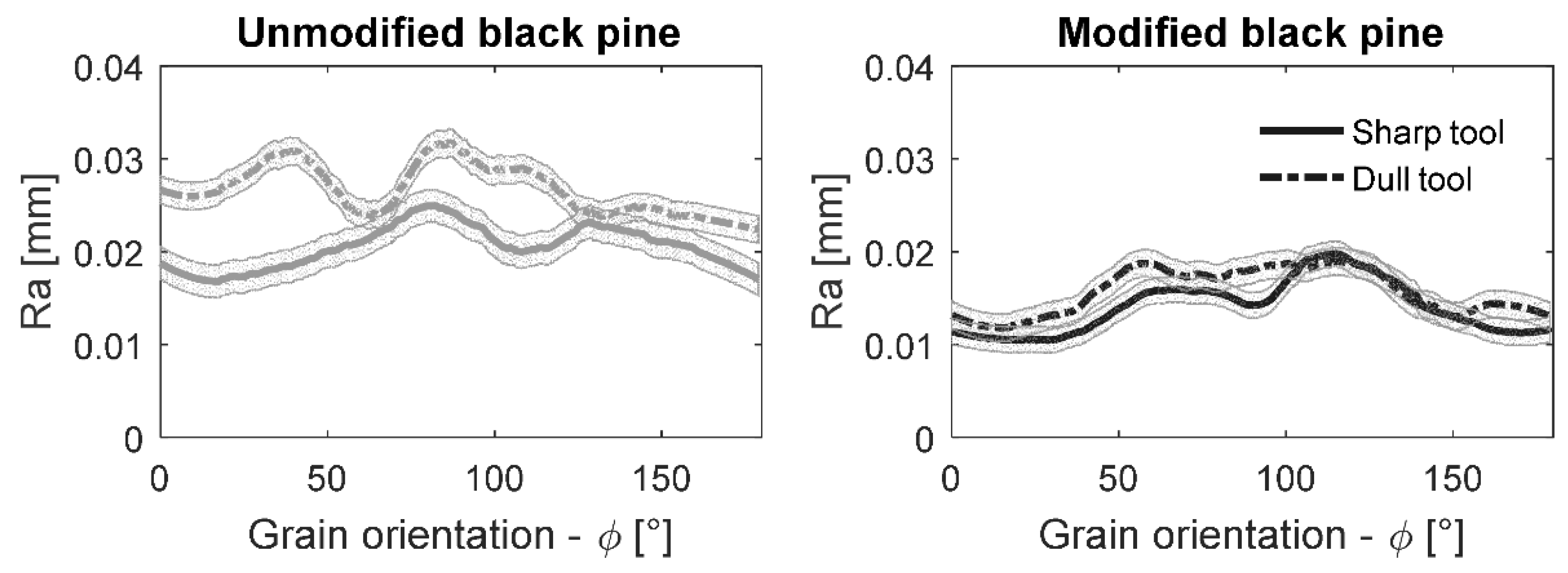

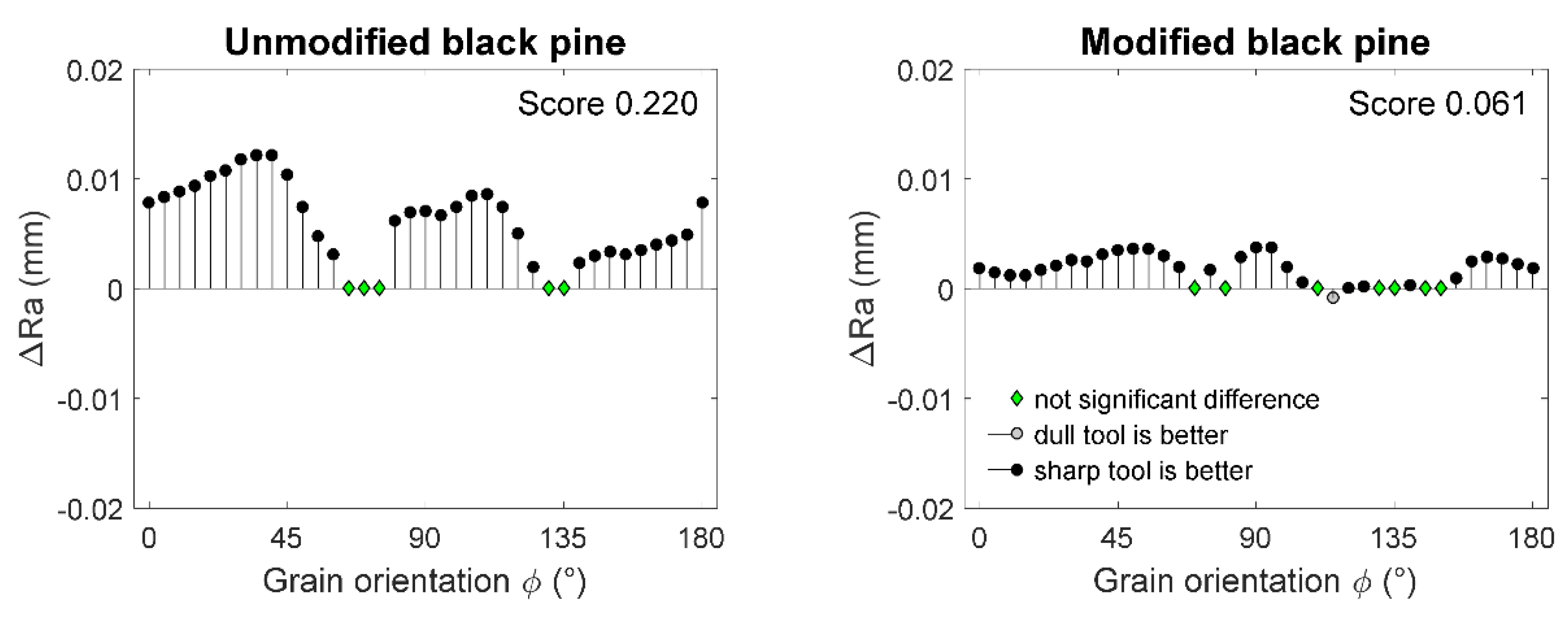

3.3. Influence of the Tool Sharpness on the Final Surface Quality

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hill, C. Wood modification. In Chemical, Thermal and Other Processes; Wiley & Sons Ltd.: Chichester, UK, 2006. [Google Scholar]

- Korkut, D.; Hiziroglu, S. Experimental Test of Heat Treatment Effect on Physical Properties of Red Oak (Quercus falcate Michx.) and Southern Pine (Pinus taeda L.). Materials 2014, 7, 7314–7323. [Google Scholar] [CrossRef]

- Todaro, L.; Zanuttini, R.; Scopa, A.; Moretti, N. Influence of combined hydro-thermal treatments on selected properties of Turkey oak (Quercus cerris L.) wood. Wood Sci. Technol. 2011, 46, 563–578. [Google Scholar] [CrossRef]

- Ferrari, S.; Allegretti, O.; Cuccui, I.; Moretti, N.; Marra, M.; Todaro, L. A revaluation of Turkey oak wood (Quercus Cerris L.) through combined steaming and thermo-vacuum treatments. BioResources 2013, 8, 5051–5066. [Google Scholar] [CrossRef]

- Finnish ThermoWood Association. ThermoWood Handbook; Finnish ThermoWood Association: Helsinki, Finland, 2003. [Google Scholar]

- De Moura, L.F.; Brito, J.O.; Nolasco, A.M.; Uliana, L.R. Effect of thermal rectification on machinability of Eucalyptus grandis and Pinus caribaea var. hondurensis woods. Eur. J. Wood Wood Prod. 2010, 69, 641–648. [Google Scholar] [CrossRef]

- Budakçı, M.; İlçe, A.C.; Gürleyen, T.; Utar, M. Determination of the surface roughness of heat-treated wood materials planed by the cutters of a horizontal milling machine. BioResources 2013, 8, 3189–3199. [Google Scholar] [CrossRef]

- Tu, D.; Liao, L.; Yun, H.; Zhou, Q.; Cao, X.; Huang, J. Effects of heat treatment on the machining properties of Eucalyptus urophylla×E. camaldulensis. BioResources 2014, 9, 2847–2855. [Google Scholar] [CrossRef]

- De Moura Palermo, G.P.; de Figueiredo Latorraca, J.V.; de Moura, L.F.; Nolasco, A.M.; Monteiro de Carvalho, A.; Garcia, R.A. Surface roughness of heat treated Eucalyptus grandis wood. Maderas. Cienc. Tecnol. 2014, 16. [Google Scholar] [CrossRef]

- Palermo, G.P.M.; Latorraca, J.V.F.; Carvalho, A.M.; Garcia, R.A. Surface evaluation of the heat treated wood of Eucalyptus grandis Hill ex Maiden. Ciência Florest. 2015, 25, 145–152. [Google Scholar]

- Goli, G.; Sandak, J. Proposal of a new method for the rapid assessment of wood machinability and cutting tool performance in peripheral milling. Eur. J. Wood Wood Prod. 2016, 74, 867–874. [Google Scholar] [CrossRef]

- Aknouche, H.; Goli, G.; Marchal, R.; Sandak, J.; Zerizer, A.; Butaud, J.-C. Mesure des efforts de défonçage et de la qualité finale en usinant en différents angles du fil: Comparaison entre le pin Douglas et le pin d’ Alep. Bois et Forêts des Tropiques 2012, 313, 85–93. [Google Scholar]

- Allegretti, O.; Brunetti, M.; Cuccui, I.; Ferrari, S.; Nocetti, M.; Terziev, N. Thermo-vacuum modification of spruce (picea abies karst.) and fir (abies alba mill.) wood. BioResources 2012, 7, 3656–3669. [Google Scholar]

- Sandak, A.; Sandak, J.; Allegretti, O. Quality control of vacuum thermally modified wood with near infrared spectroscopy. Vacuum 2015, 114, 44–48. [Google Scholar] [CrossRef]

- ASTM. ASTM D1666-87 (2004), Conducting Machining Tests of Wood and Wood-Base Materials. ASTM 2004, 87, 1–19. [Google Scholar]

- Porankiewicz, B.; Goli, G. Cutting forces by oak and douglas fir machining. Maderas. Cienc. Tecnol. 2014, 16, 199–216. [Google Scholar] [CrossRef]

- Sandak, J. Optical triangulation in wood surface roughness measurement. In Proceedings of the 18th International Wood Machining Seminar, Vancouver, Canada, 7–9 May 2007; Taylor, J., Wong, D., Eds.; FPInnovations–orintek: Vancouver, Canada, 2007; pp. 275–284. [Google Scholar]

- Savitzky, A.; Golay, M.J.E. Smoothing and differentiation of data by simplified least squares procedures. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Caldeirani Filho, J.; Diniz, A.E. Influence of Cutting Conditions on Tool Life, Tool Wear and Surface Finish in the Face Milling Process. J. Braz. Soc. Mech. Sci. 2002, 24, 10–14. [Google Scholar] [CrossRef]

- Bendikiene, R.; Keturakis, G. The effect of tool wear and planing parameters on birch wood surface roughness. Wood Res. 2016, 61, 791–798. [Google Scholar]

| Treatment | Italian Alder | Black Pine | Black Poplar | Deodar Cedar |

|---|---|---|---|---|

| Control | 556 (11) | 475 (10) | 479 (22) | 571 (28) |

| TH | 506 (7) | 461 (36) | 425 (13) | 447 (25) |

| Treatment | Italian Alder | Black Pine | Black Poplar | Deodar Cedar |

|---|---|---|---|---|

| Control | 11.8 (0.6) | 12.6 (0.8) | 11.8 (0.7) | 12.1 (0.6) |

| TH | 7.6 (0.5) | 9.4 (0.9) | 7.6 (0.5) | 7.1 (0.7) |

| Specie | Score |

|---|---|

| Black Pine Control | 21.2 |

| Black Pine TH | 18.9 |

| Black Poplar Control | 20.3 |

| Black Poplar TH | 18.4 |

| Deodar Cedar Control | 16.3 |

| Deodar Cedar TH | 16.0 |

| Italian Alder Control | 18.3 |

| Italian Alder TH | 19.6 |

| Specie | Score (mm) |

|---|---|

| Black Pine Control | 9.586 |

| Black Pine TH | 5.301 |

| Black Poplar Control | 7.012 |

| Black Poplar TH | 5.154 |

| Deodar Cedar Control | 4.279 |

| Deodar Cedar TH | 2.849 |

| Italian Alder Control | 5.009 |

| Italian Alder TH | 5.640 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sandak, J.; Goli, G.; Cetera, P.; Sandak, A.; Cavalli, A.; Todaro, L. Machinability of Minor Wooden Species before and after Modification with Thermo-Vacuum Technology. Materials 2017, 10, 121. https://doi.org/10.3390/ma10020121

Sandak J, Goli G, Cetera P, Sandak A, Cavalli A, Todaro L. Machinability of Minor Wooden Species before and after Modification with Thermo-Vacuum Technology. Materials. 2017; 10(2):121. https://doi.org/10.3390/ma10020121

Chicago/Turabian StyleSandak, Jakub, Giacomo Goli, Paola Cetera, Anna Sandak, Alberto Cavalli, and Luigi Todaro. 2017. "Machinability of Minor Wooden Species before and after Modification with Thermo-Vacuum Technology" Materials 10, no. 2: 121. https://doi.org/10.3390/ma10020121