1. Introduction

The design of lightweight vehicles and aircrafts, is considered one of the most effective strategies for improving fuel efficiency and reducing anthropogenic climate change. As a result, this area of research has attracted an increasing amount of attention in recent years [

1,

2,

3]. Moreover, the compelling need for lightweight materials is driving the development and motivating a wider spread application of magnesium (Mg) alloys, the ultra-lightweight materials with low density, a high strength-to-weight ratio, and superior damping capacity [

1,

4]. However, some inherent weaknesses, such as low absolute strength and stiffness, low wear resistance, and inferior creep resistance often restrict the scope of their applications. The addition of discontinuous reinforcements, especially nano-sized particles, into the magnesium matrix can significantly improve the physical, mechanical, and damping properties of magnesium alloys beyond the limits dominated by traditional alloying [

5,

6].

Carbon nanotubes (CNTs) have been considered an ideal reinforcement for metal matrix composites since Sumio Iijima discovered them in 1991, due to their excellent mechanical and physical properties [

7,

8]. The incorporation of a small amount of CNTs into the Mg matrix to form nanocomposites can significantly enhance mechanical properties [

9,

10]. Besides, with the development of the synthesis technology of CNTs, their price point is becoming more and more acceptable, making them available to be extensively used in Mg matrix nanocomposites [

11]. These lightweight nanocomposites with good mechanical properties have huge potential in the aerospace, automobile, and transportation industries. Thus, it is essential to investigate CNT-reinforced Mg matrix nanocomposites.

Over the past few years, CNT-reinforced Mg matrix composites have received much attention, and several methods have been proposed to fabricate these composites with a uniform distribution of CNTs in the matrix, including powder metallurgy with ball milling [

12], stir casting with ultrasonic vibration [

13], disintegrated melt deposition technique (DMD) [

14], infiltration method [

15], and so on [

16]. Many previous works have proved that a powder metallurgy method can incorporate more CNTs into the Mg matrix and achieve a more uniform distribution than stir casting and DMD [

17,

18]. What’s more, nanocomposites fabricated by powder metallurgy usually have superior mechanical properties than other methods due to their finer grains [

17]. Shimizu et al. [

19] demonstrated that a 1 wt. % short and straight CNT-reinforced AZ91 matrix fabricated by powder metallurgy could achieve a uniform distribution of CNTs and significantly enhance the tensile strength of the matrix (from 315 MPa to 388 MPa). Gupta et al. [

11] fabricated Al+CNT-reinforced Mg nanocomposites using a powder metallurgy method involving microwave-assisted rapid sintering and hot extrusion, and achieved significant grain refinement and minimal porosity compared with monolithic Mg. Yuan et al. [

20] coated magnesium oxide nanoparticles on the surface of CNTs to increase the interfacial bonding strength, and fabricated CNTs/MgO-reinforced AZ91 matrix nanocomposites using a powder metallurgy method. This way, both the yield strength and ductility of the composites were significantly enhanced. All of these research studies were focused on mechanical properties, especially strength and ductility, but wear property has never been studied. However, it is also essential for to examine wider applications for these magnesium matrix composites fabricated by powder metallurgy method [

15].

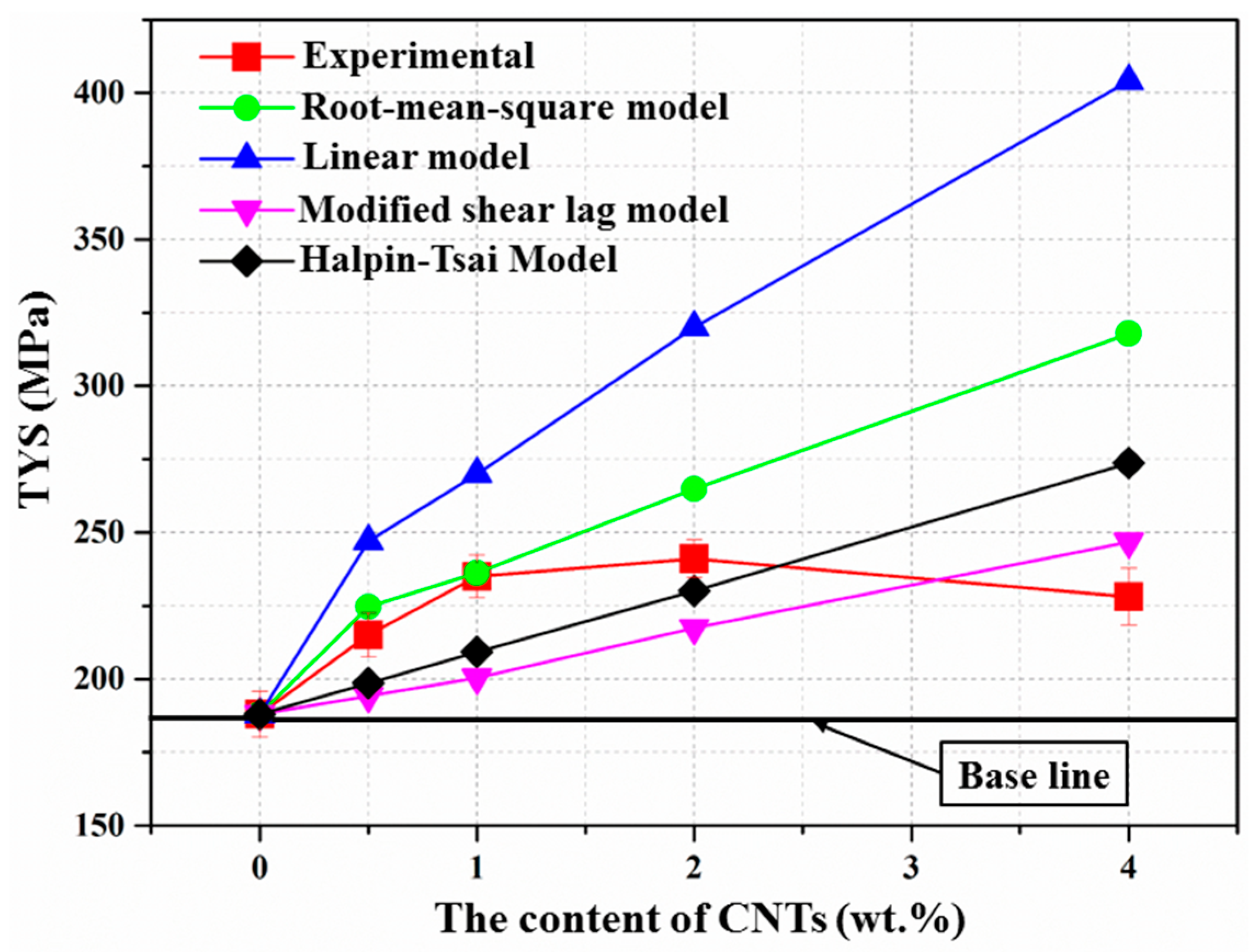

As for strengthening mechanisms, the previous works generally considered (i) the load transfer mechanism, (ii) the generation of dislocations by the mismatch in the coefficient of thermal expansions (CTE) between the matrix and reinforcements, (iii) Orowan looping, and (iv) Hall–Petch strengthening by grain refinement [

5,

21,

22,

23].

The basis of the load transfer mechanism is the shear lag model, which was initially proposed by Kelly and Tyson [

24]. The applied stress can be transferred from the matrix to reinforcements (e.g., CNTs) through interfacial shear stresses, and the resulting increase in the yield strength of the composites due to load transfer can be expressed as the following equation [

20]:

where

σym is the yield strength of the matrix,

l is the average length of the CNTs,

d is the average diameter of the CNTs, and

VCNT is the volume fraction of the CNTs.

The increase in the yield strength of the composites caused by thermal mismatch depends on the difference in the CTE between the matrix and reinforcements; the higher the difference, the higher the increase of the strength that can be obtained. Geoge et al. [

25] attributed the strength improvement to the “prismatic punching” of dislocations at the surface, which can promote the work hardening of the matrix. The improvements to the yield strength due to thermal mismatch can be written as [

26]:

where

α is a constant (1.25 in our case) [

27],

Gm is the shear modulus of the matrix (1.66 × 104 MPa),

b is the Burgers vector of the matrix (3.21 × 10

−10 m) [

28], Δ

T is the range of temperature from tensile test to fabrication process (375 K), Δ

C is the difference in CTE between the matrix and CNTs (the CET for Mg and CNTs is 2.5 × 10

−5 K

−1 and 1 × 10

−6 K

−1, respectively) [

29].

VCNT and

d are the same as defined earlier.

Orowan looping can significantly influence the strengthening of nanoparticle-reinforced metal matrix nanocomposites, because nano-sized CNTs can inhibit the dislocation motion, leading to the “dislocation bending” between the CNTs [

30]. Zhan and Chen [

31] first took the Orowan strengthening effect into account to propose an analytical model for predicting the yield strength of metal matrix nanocomposites, and found that the prediction was in good agreement with the experiment data reported in the literature. The increase of the composites caused by Orowan looping can be given by [

20]:

where

M is the Taylor factor (3.0 for Mg), and

Gm,

b,

d, and

VCNT are the same as defined above.

The decrease of grain size can also enhance yield strength, according to the Hall-Petch relationship, and its contribution can be described by the following equation [

21]:

where

dcom and

dalloy are the average grain sizes of the composite and alloy, respectively, and

K is the Hall–Petch coefficient of the Mg alloy (0.1 MPa m

1/2).

However, some other factors, such as the CNTs’ distribution, texture, interfacial bonding, and porosity in composites fabricated by a powder metallurgy method, will influence the strength of the composites significantly, and thus should also be taken into account.

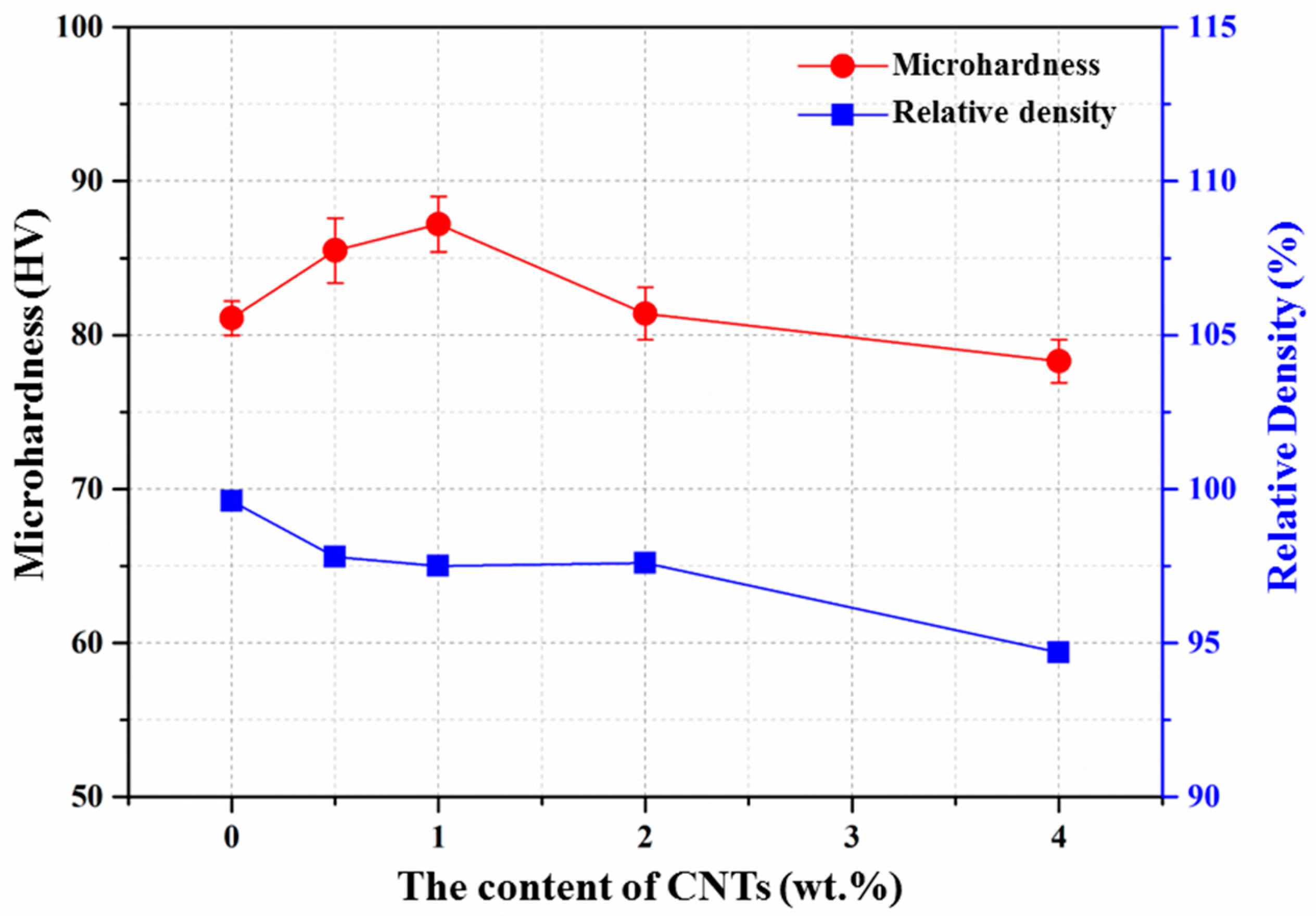

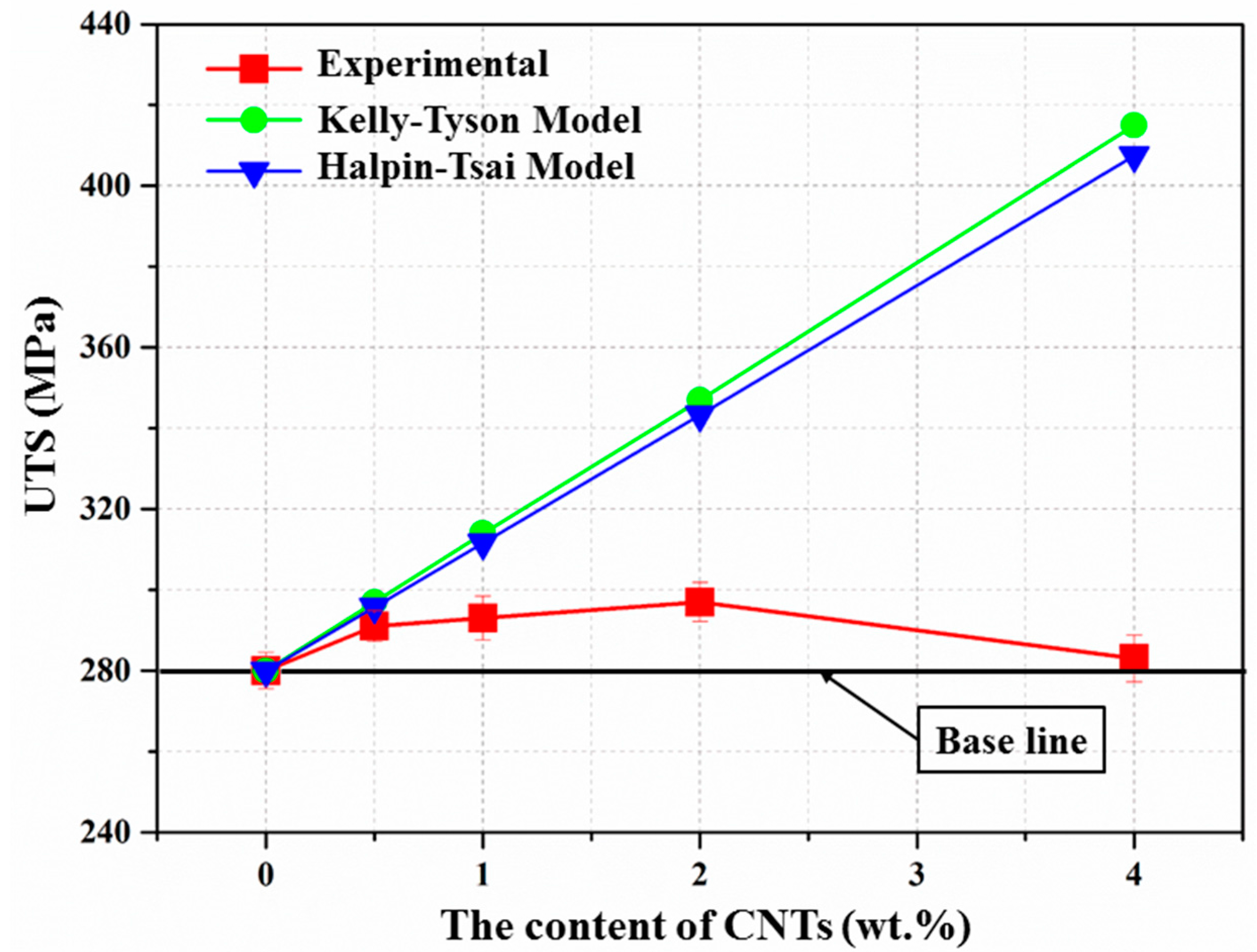

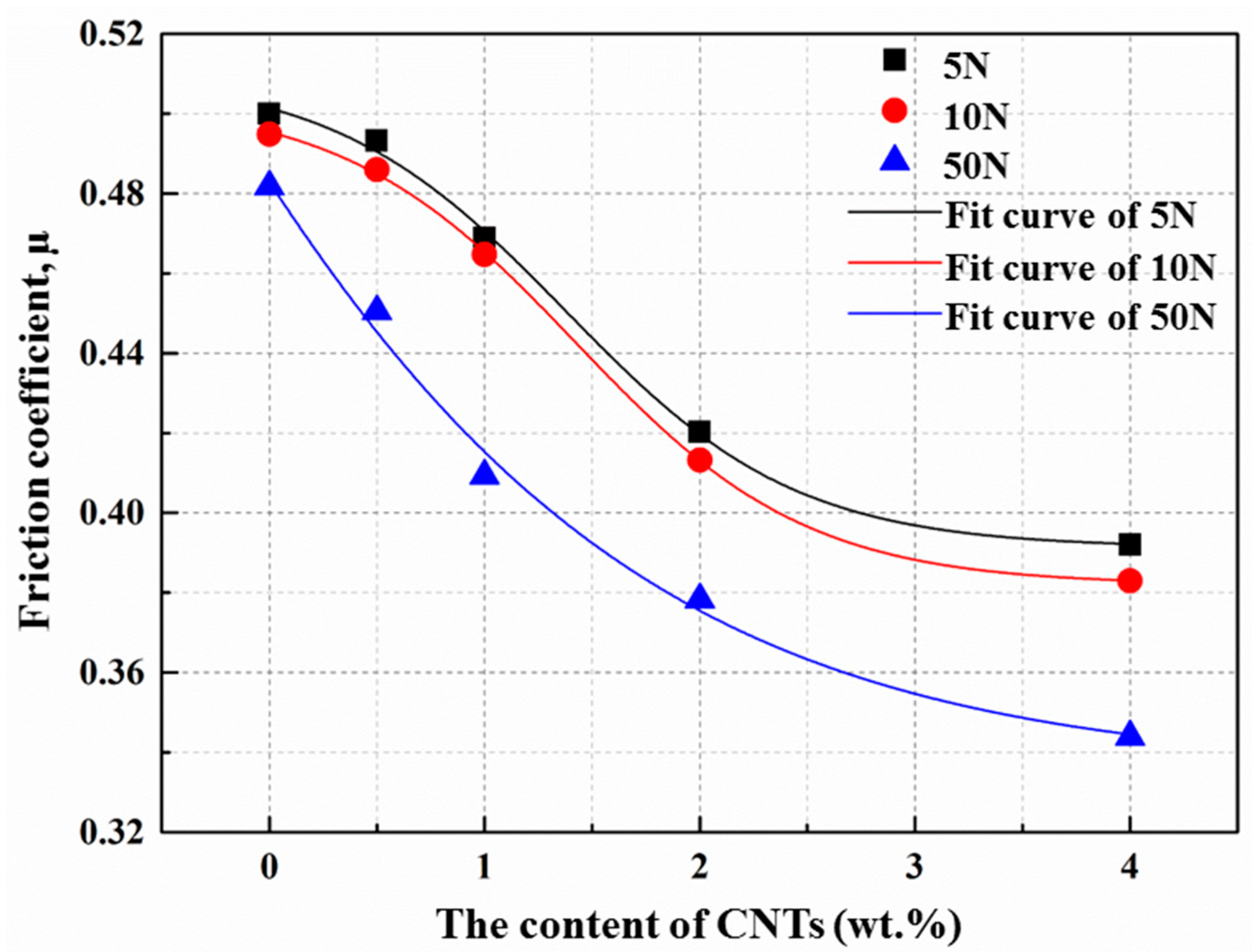

In this study, we examined AZ31 magnesium alloy matrix nanocomposites reinforced with varying amounts of CNTs that were fabricated by a powder metallurgy method followed by hot extrusion. The effects of the amount of CNTs on the microstructure, mechanical properties, and fracture characteristics of AZ31 matix nanocomposites were systematically investigated. The strengthening mechanisms were also discussed in detail. In addition, the relationships between the CNTs’ content, the friction coefficient, and the weight loss of the nanocomposites were studied, and the prediction equations were also established by nonlinear fitting.

2. Materials and Methods

2.1. Materials

AZ31 magnesium alloy with the composition of 3.0 wt. % Al and 1.0 wt. % Zn was used as the raw material, and was prepared by the metal powders of Mg, Al, and Zn, which were purchased from CHINO New Material Technology Co., Ltd., Zhuzhou, China. The specifications of these metal powders are shown in

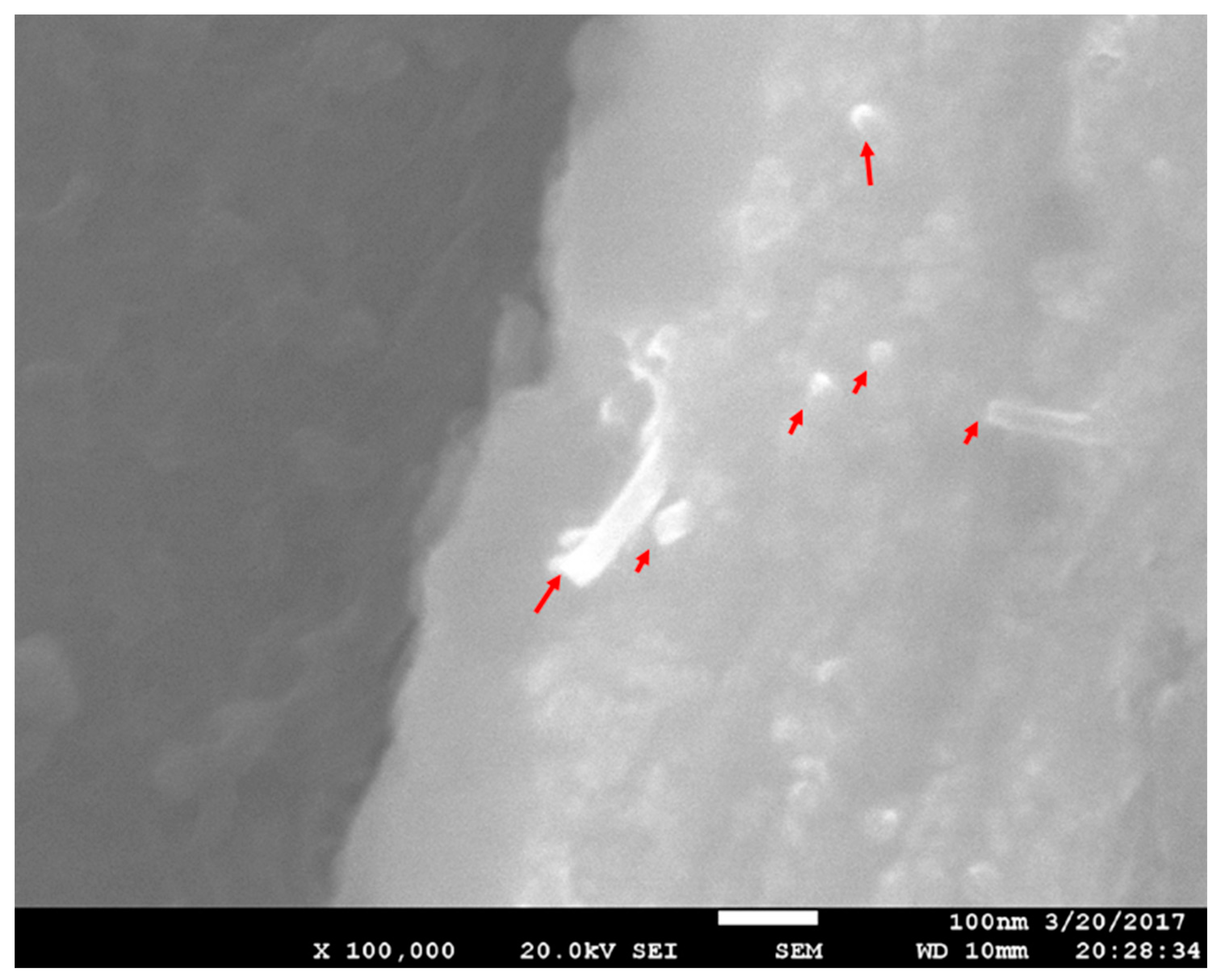

Table 1. The reinforcements, multi-walled CNTs (30–50 nm in outer diameter, 1–2 μm in length, and 98% purity) were supplied by Chengdu Organic Chemistry Co., Ltd., Chengdu, China.

2.2. Fabrication of AZ31–CNTs Composites

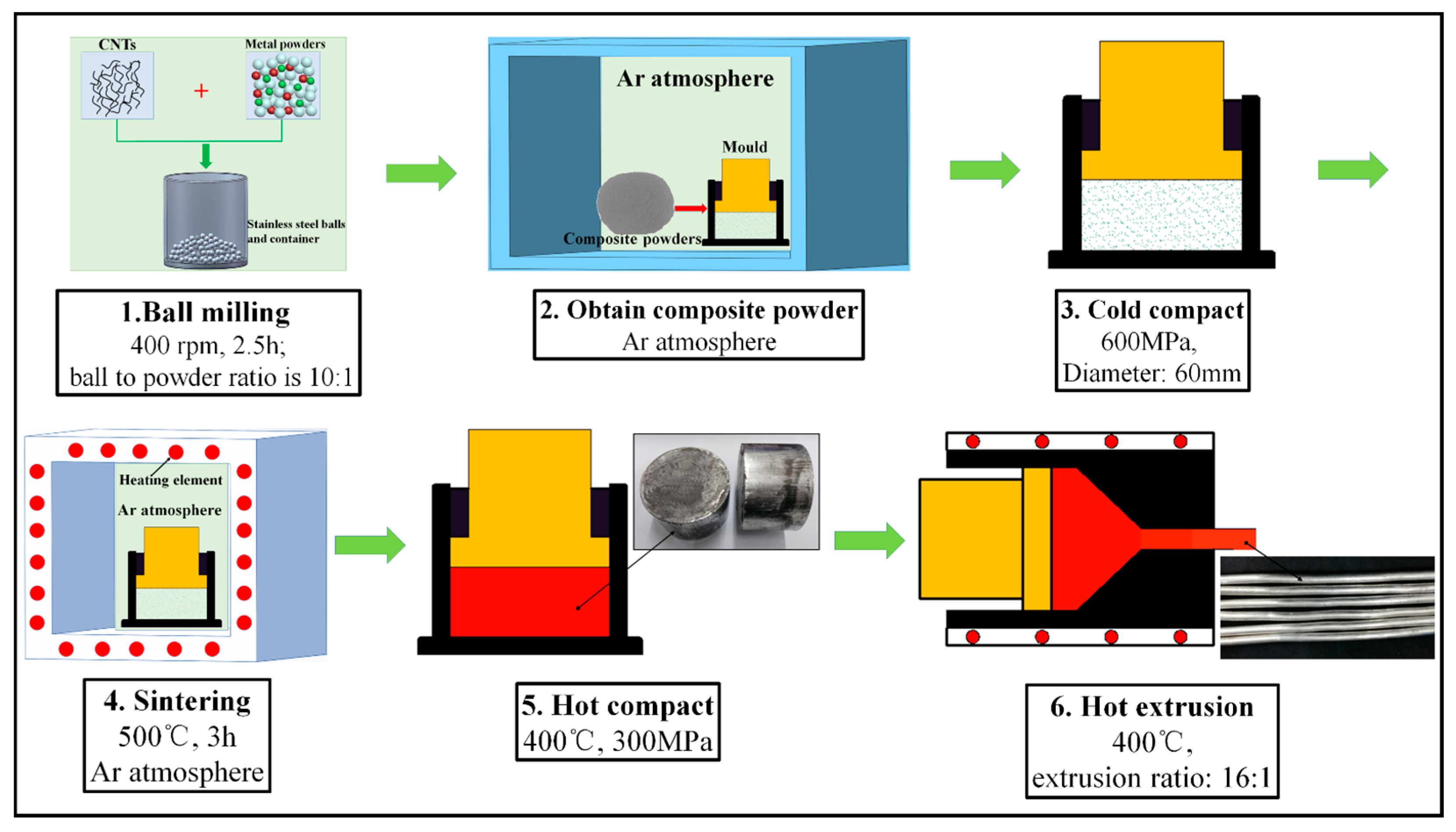

The composites and matrix were fabricated by powder metallurgy method (as shown in

Figure 1). The nano-reinforcements (0.5 wt. %, 1.0 wt. %, 2.0 wt. %, and 4.0 wt. % CNTs, respectively) and 99 wt. % metal powders (AZ31) were added into a stainless steel container and mixed under the protection of argon atmosphere in a glove box to minimize the oxidation. The mixture was then milled in a PBM-4A planetary mill (ZOOKIN, Changsha, China) at 400 rpm for 2.5 h at room temperature using stainless steel balls of 5 mm and 10 mm as the grinding medium, and a ball to powder ratio of 10:1. The planetary mill was turned off for 8 m after every 20 m of work to prevent overheating. To avoid the excessive cold welding of the powders during milling, 0.3 wt. % of stearic acid of analytical reagent grade purity was added into the container as the process control agent. The milled mixture powders were taken out and put into a cylindrical steel die of 60 mm inner diameter in the glove box. The powders were then cold compacted by slowly increasing the pressure up to 600 MPa, and sintered for 3 h at 500 °C under the protection of argon atmosphere without demold. After the temperature of the die decreased to 400 °C, the compacts were hot pressed at a pressure of 300 MPa to obtain the resulting compacts with 45 mm height and 60 mm diameter. Finally, all of the resulting compacts were extruded at 400 °C with an extrusion ratio of 16:1 to obtain rod samples with a diameter of 15 mm. For comparison, the AZ31 matrix samples were prepared by the same conditions.

2.3. Characterization

The density of the polished samples was measured based on the Archimedean principle using an electronic density meter (ESJ182-4, Longteng, Shenyang, China) with an accuracy of 0.1 mg, and distilled water as an immersion fluid. Three samples were randomly selected from extruded rods and weighed both in air and while immersed in distilled water. Theoretical densities of the samples were calculated using the rule-of-mixture principle and assuming that there was no Mg/Al–CNTs interfacial reaction. The phases of the samples were examined by X-ray diffraction (XRD, PANalytical, B.V., Almelo, Holland) using Cu Kα radiation for a 10~90° range (scan step size 0.033°, time per step 12 s, and scan type was continuous). The samples were cut from the extrusion bars, ground on the 2000# SiC abrasive papers, polished to a mirror-like finish, and etched using 4% nitric acid alcohol solution. The microstructure of the samples was characterized using an optic microscope (OM, ZEISS, Oberkochen, Germany) and a scanning electron microscope (SEM, FEI, Hillsboro, OR, USA). The average grain size, G, was calculated using intercept line methods (G = L × 1.73; L, the average length of intercept line). Three tensile specimens with a diameter of 5 mm and a gauge length of 25 mm were machined from each material by electro-discharge cutting parallel to the extrusion direction. The tensile tests were carried out on an MTS-CMT5105 universal testing machine (SANS, Shenzhen, China) at room temperature with an initial strain rate of 0.001 s−1 (according to ASTM: E8/E8M-11 standards). The hardness was tested using Vickers hardness tester (Aiceyi, Dongguan, China) at a load of 1000 gf with a dwell time of 15 s. The wear behavior of the matrix and composites were investigated by using ball-on disk-wear test equipment (CETR UMT-2, Wode, Beijing, China) under air and dry sliding conditions. A high-carbon chromium-bearing steel ball with 10 mm diameter and a hardness of HRC57 was used as the counter material. The tests were conducted under the applied loads of 5 N, 10 N, and 50 N, respectively. The linear reciprocating frequency, displacement amplitude, and friction time were 0.5 HZ, 1000 μm, and 40 min, respectively. The test samples with 15 mm diameter and 5 mm height were cut from the extrusion bars, ground, polished, and cleaned using ultrasonic cleaning in ethanol before the test. Mass loss was measured with an electronic density meter (ESJ182-4, Longteng, Shenyang, China) with an accuracy of 0.1 mg. The coefficients of friction were obtained by measuring the friction torque between the ball and the disk. Three samples were tested for each load and material, and the average of three readings was considered as the results of weight loss and the coefficients of friction.