Study on the Ingredient Proportions and After-Treatment of Laser Sintering Walnut Shell Composites

Abstract

:1. Introduction

2. Materials and Methods

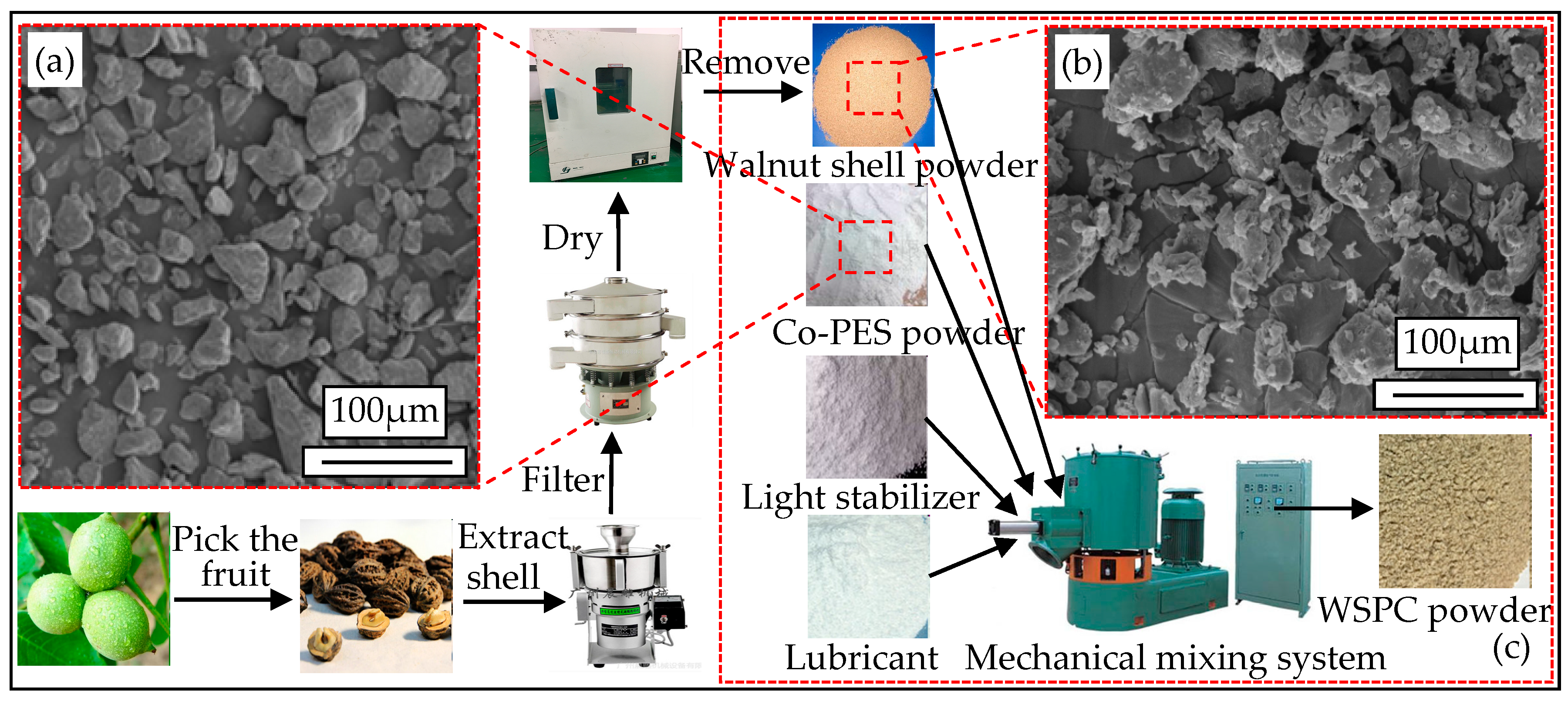

2.1. Experimental Materials

2.2. WSPC Powder Preparation

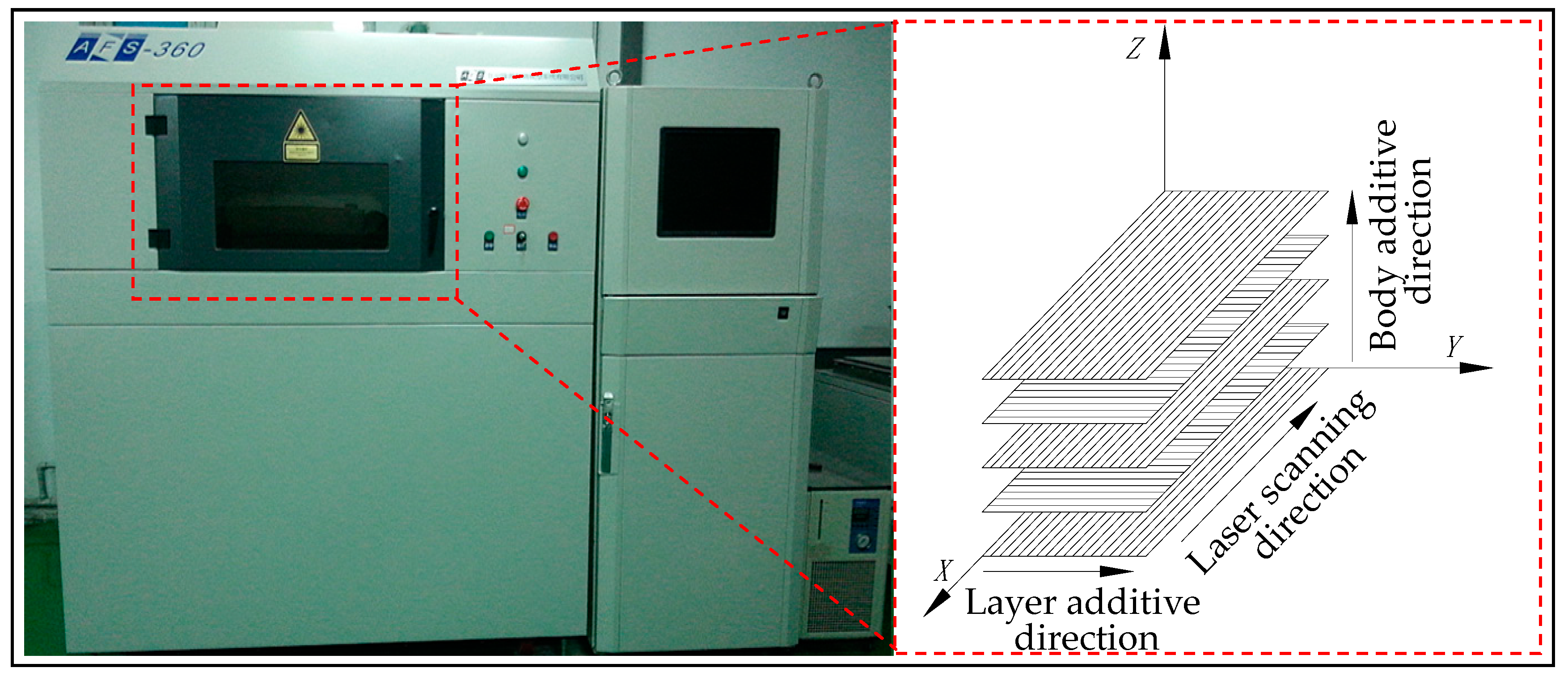

2.3. SLS Experiments and Post Processing

2.4. Characterization

3. Results and Discussion

3.1. Thermal Analysis

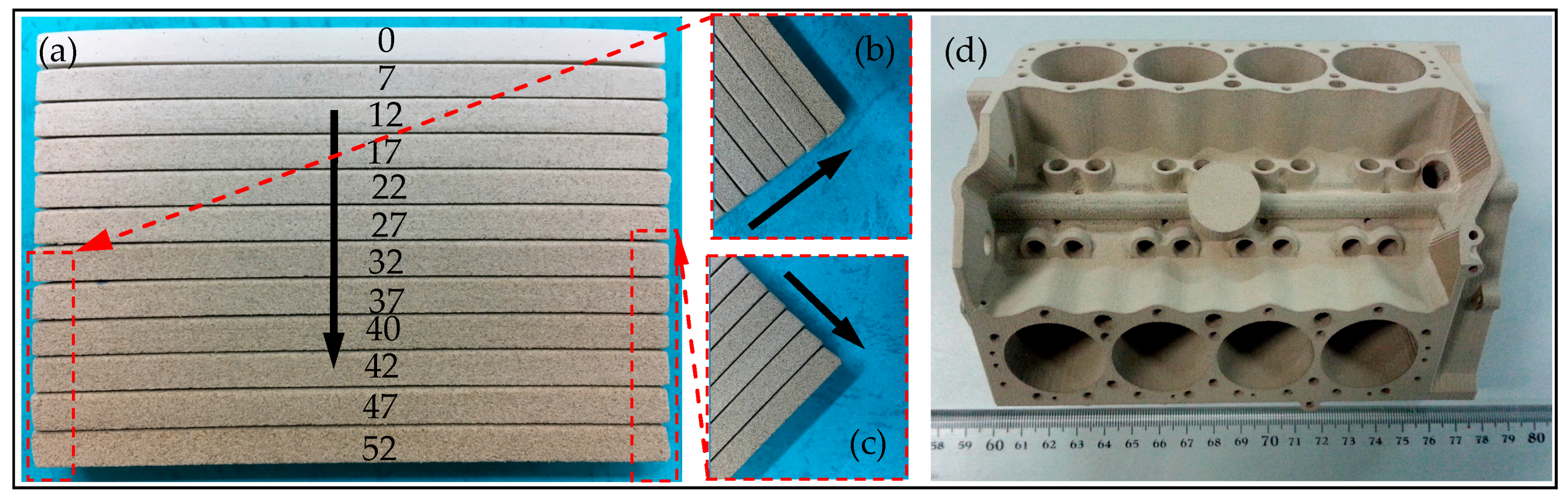

3.2. Laser Sintering Experiments

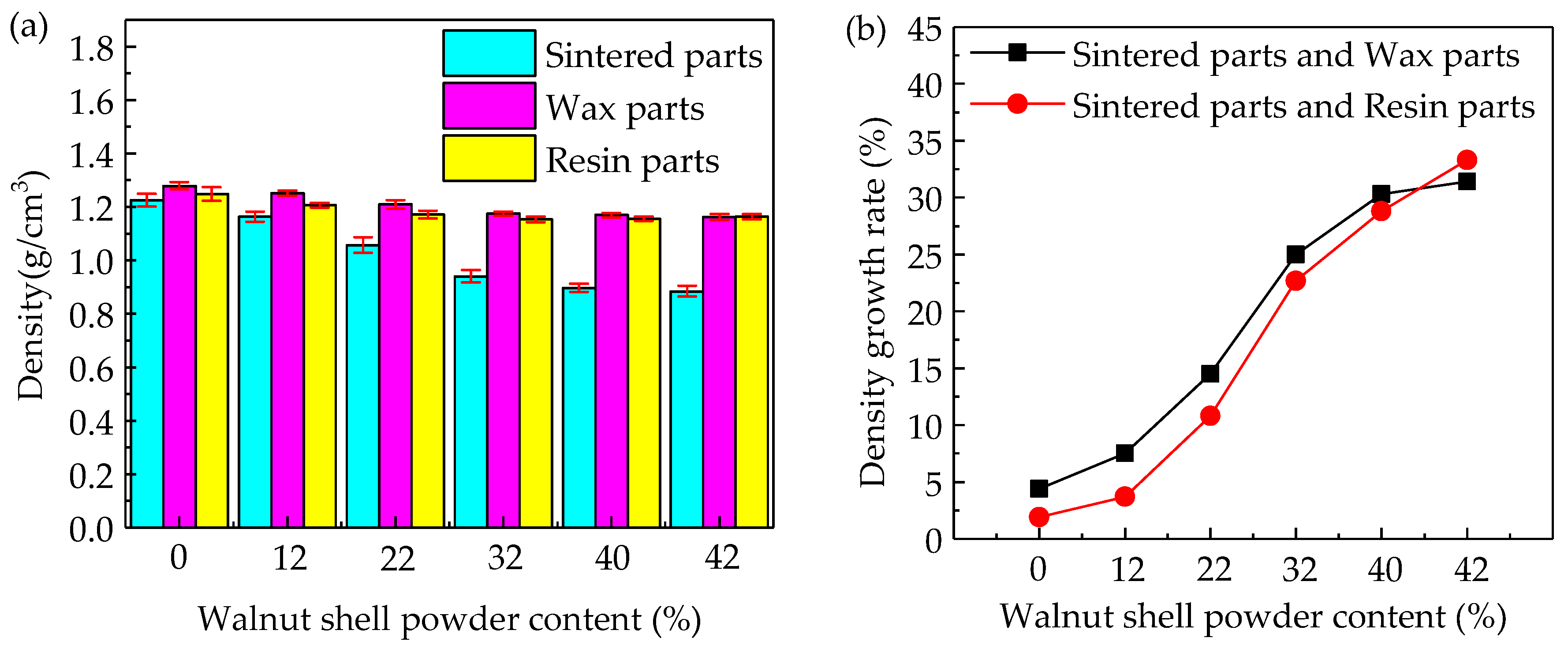

3.3. Density of Parts

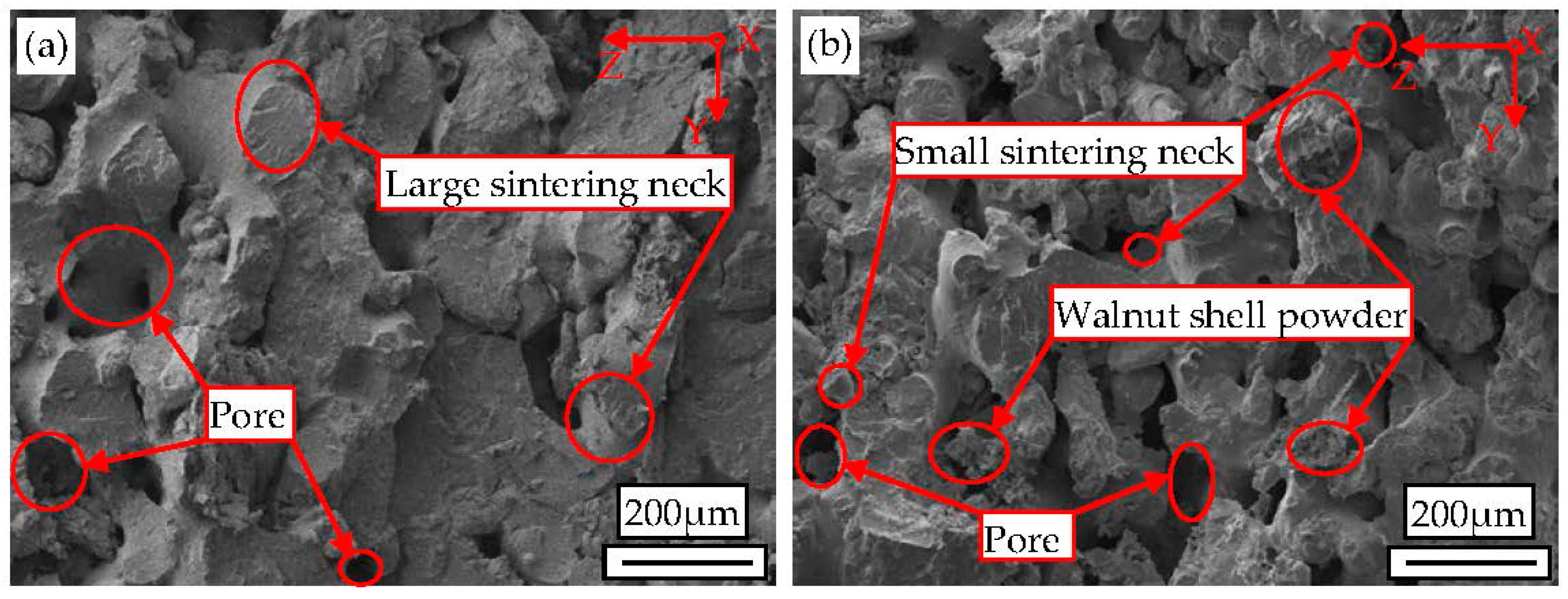

3.4. Microstructure

3.5. Surface Quality

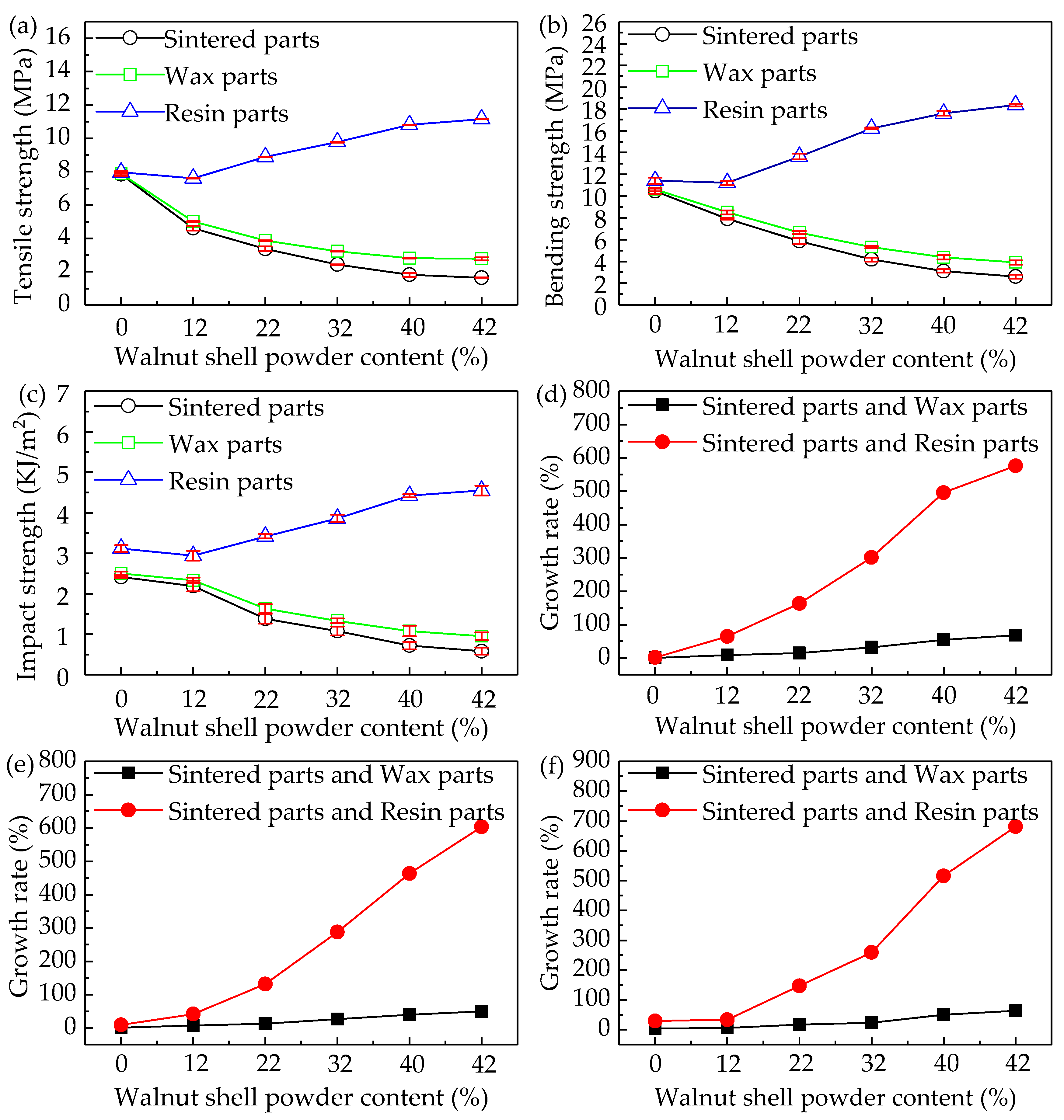

3.6. Mechanical Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Guessasma, S.; Belhabib, S.; Nouri, H. Significance of pore percolation to drive anisotropic effects of 3D printed polymers revealed with X-ray µ-tomography and finite element computation. Polymer 2015, 81, 29–36. [Google Scholar] [CrossRef]

- Guessasma, S.; Nouri, H.; Roger, F. Microstructural and mechanical implications of microscaled assembly in droplet-based multi-material additive manufacturing. Polymers 2017, 9, 372. [Google Scholar] [CrossRef]

- Liu, T.; Guessasma, S.; Zhu, J.H.; Zhang, W.H.; Nouri, H.; Belhabib, S. Microstructural defects induced by stereolithography and related compressive behaviour of polymers. J. Mater. Process. Technol. 2018, 251, 37–46. [Google Scholar] [CrossRef]

- Cao, S.; Qiu, Y.; Wei, X.F.; Zhang, H.H. Experimental and theoretical investigation on ultra-thin powder layering in three dimensional printing (3DP) by a novel double-smoothing mechanism. J. Mater. Process. Technol. 2015, 220, 231–242. [Google Scholar] [CrossRef]

- Krinitcyn, M.; Fu, Z.W.; Harris, J.; Kostikov, K.; Pribytkov, G.A.; Greil, P.; Travitzky, N. Laminated object manufacturing of in-situ, synthesized MAX-phase composites. Ceram. Int. 2017, 43, 9241–9245. [Google Scholar] [CrossRef]

- Deckard, C.R. Selective Laser Sintering. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 1988. [Google Scholar]

- Jia, L.B.; Wang, X.C.; Wang, X.J.; Xu, B.; Wei, J. The research and application progress of selected laser sintering technology. Inf. Technol. Informatiz. 2015, 11, 172–175. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. The additive manufacturing (AM) of titanium alloys. Met. Power Rep. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Mangano, F.; Bazzoli, M.; Tettamanti, L.; Farronato, D.; Maineri, M.; Macchi, M.; Mangano, C. Custom-made, selective laser sintering (SLS) blade implants as a non-conventional solution for the prosthetic rehabilitation of extremely atrophied posterior mandible. Lasers Med. Sci. 2013, 28, 1241–1247. [Google Scholar] [CrossRef] [PubMed]

- Bourell, D.L. Sintering in laser sintering. JOM 2016, 68, 885–889. [Google Scholar] [CrossRef]

- Barrioberovila, P.; Gussone, J.; Haubrich, J.; Sandlöbes, S.; Silva, J.; Cloetens, P.; Schell, N.; Requena, G. Inducing Stable α + β Microstructures during Selective Laser Melting of Ti-6Al-4V Using Intensified Intrinsic Heat Treatments. Materials 2017, 10, 268. [Google Scholar] [CrossRef] [PubMed]

- Pace, M.L.; Guarnaccio, A.; Dolce, P.; Mollica, D.; Parisi, G.P.; Lettino, A.; Medici, L.; Summa, V.; Ciancio, R.; Santagata, A. 3D additive manufactured 316L components microstructural features and changes induced by working life cycles. Appl. Surf. Sci. 2017, 418, 437–445. [Google Scholar] [CrossRef]

- Maszybrocka, J.; Stwora, A.; Gapiński, B.; Skrabalak, G.; Karolus, M. Morphology and surface topography of Ti6Al4V lattice structure fabricated by selective laser sintering. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 85–92. [Google Scholar] [CrossRef]

- Shahzad, K.; Deckers, J.; Zhang, Z.Y.; Kruth, J.; Vleugels, J. Additive manufacturing of zirconia parts by indirect selective laser sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89. [Google Scholar] [CrossRef]

- Stašić, J.; Trtica, M.; Rajković, V.; Ružić, J.; Božić, D. Laser sintering of Cu-Zr-ZrB2 composite. Appl. Surf. Sci. 2014, 321, 353–357. [Google Scholar] [CrossRef]

- Warnakula, A.; Singamneni, S. Selective Laser Sintering of Nano Al2O3 Infused Polyamide. Materials 2017, 10, 864. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.F.; Liu, Y.H.; Zhu, X.G.; Li, C.G.; Sun, J.; Cheng, L.Y.; Guo, L.J.; Yu, Z.S. Investigation on the mechanical properties of PA6 by SLS. Appl. Laser 2016, 36, 136–140. [Google Scholar] [CrossRef]

- Bai, J.; Zhang, B.; Song, J.; Bi, G.J.; Wang, P.; Wei, J. The effect of treatment conditions on the mechanical properties of polyethylene produced by selective laser sintering. Polym. Test. 2016, 52, 89–93. [Google Scholar] [CrossRef]

- Qi, F.W.; Chen, N.; Wang, Q. Preparation of PA11/BaTiO3, nanocomposite powders with improved processability, dielectric and piezoelectric properties for use in selective laser sintering. Mater. Des. 2017, 131, 135–143. [Google Scholar] [CrossRef]

- Guo, Y.L.; Jiang, K.Y.; Yu, Z.X.; Xin, Z.S.; Zeng, W.L. The preparation technology and forming properties of wood-plastic composite powder used in selective laser sintering. J. Shanghai Jiaotong Univ. 2011, 45, 1327–13311. [Google Scholar]

- Zeng, W.L.; Guo, Y.L.; Jiang, K.Y.; Yu, Z.X.; Liu, Y. Preparation and selective laser sintering of rice husk-plastic composite powder and post treatment. Dig. J. Nanomater. Biostruct. 2012, 7, 1063–1070. [Google Scholar]

- Zeng, W.L.; Guo, Y.L.; Jiang, K.Y.; Yu, Z.X.; Liu, Y.; Shen, Y.D.; Deng, J.R.; Wang, P.X. Laser intensity effect on mechanical properties of wood-plastic composite parts fabricated by selective laser sintering. J. Thermoplast. Compos. Mater. 2012, 26, 125–136. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, Y.L.; Zhao, D.J.; Yu, Z.X. Preparation and selective laser sintering of Pine/Polyether sulfone composite. J. Northeast For. Univ. 2014, 11. [Google Scholar] [CrossRef]

- Zhao, D.J.; Guo, Y.L.; Song, W.L.; Jiang, K.Y. Preparation and forming characteristics of bamboo powder/co-polyamide laser sintering composite materials. J. Northeast For. Univ. 2015, 43, 107–109, 115. [Google Scholar] [CrossRef]

- Yu, Y.Q.; Guo, Y.L.; Jiang, T.; Jiang, K.Y.; Guo, S. Laser sintering and post-processing of a walnut shell/Co-PES composite. RSC Adv. 2017, 7, 23176–23181. [Google Scholar] [CrossRef]

| Serial Number | Walnut Shell Powder (%) | Co-PES Powder (%) | Micro-Additive (%) |

|---|---|---|---|

| 1 | 0 | 98 | 2 |

| 2 | 7 | 91 | 2 |

| 3 | 12 | 86 | 2 |

| 4 | 17 | 81 | 2 |

| 5 | 22 | 76 | 2 |

| 6 | 27 | 71 | 2 |

| 7 | 32 | 66 | 2 |

| 8 | 37 | 61 | 2 |

| 9 | 40 | 58 | 2 |

| 10 | 42 | 56 | 2 |

| 11 | 47 | 51 | 2 |

| 12 | 52 | 46 | 2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.; Guo, Y.; Jiang, T.; Li, J.; Jiang, K.; Zhang, H. Study on the Ingredient Proportions and After-Treatment of Laser Sintering Walnut Shell Composites. Materials 2017, 10, 1381. https://doi.org/10.3390/ma10121381

Yu Y, Guo Y, Jiang T, Li J, Jiang K, Zhang H. Study on the Ingredient Proportions and After-Treatment of Laser Sintering Walnut Shell Composites. Materials. 2017; 10(12):1381. https://doi.org/10.3390/ma10121381

Chicago/Turabian StyleYu, Yueqiang, Yanling Guo, Ting Jiang, Jian Li, Kaiyi Jiang, and Hui Zhang. 2017. "Study on the Ingredient Proportions and After-Treatment of Laser Sintering Walnut Shell Composites" Materials 10, no. 12: 1381. https://doi.org/10.3390/ma10121381