Effect of Solution Treatment on Precipitation Behaviors, Age Hardening Response and Creep Properties of Elektron21 Alloy Reinforced by AlN Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composite Fabrication

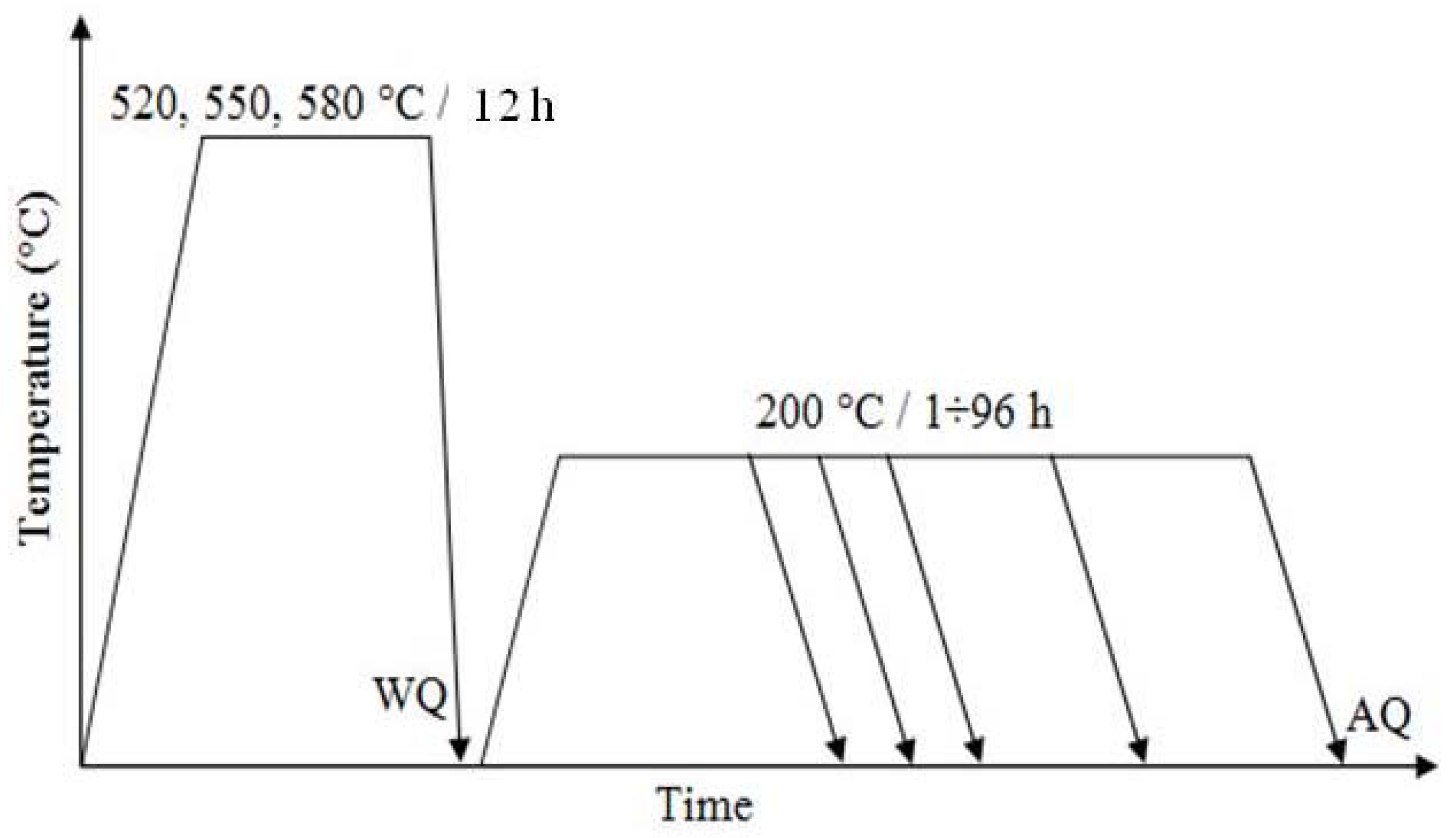

2.2. Heat Treatment

2.3. Characterization

2.3.1. Microstructural Characterization

2.3.2. Mechanical Properties

3. Results and Discussion

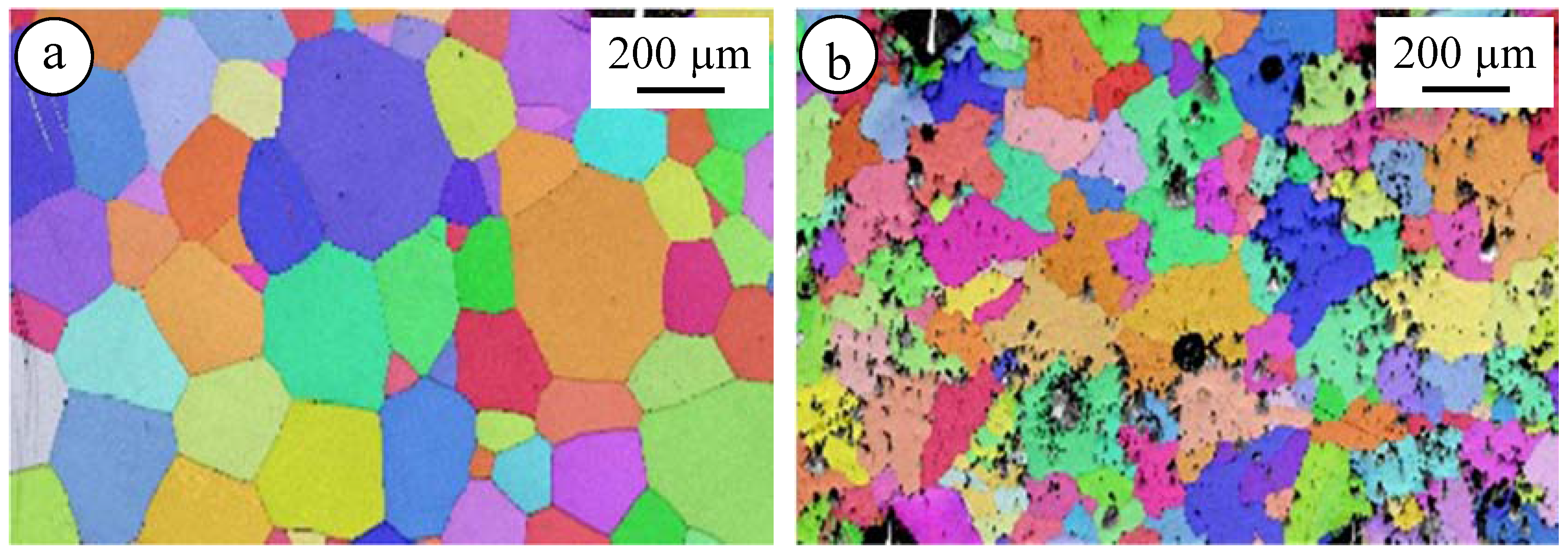

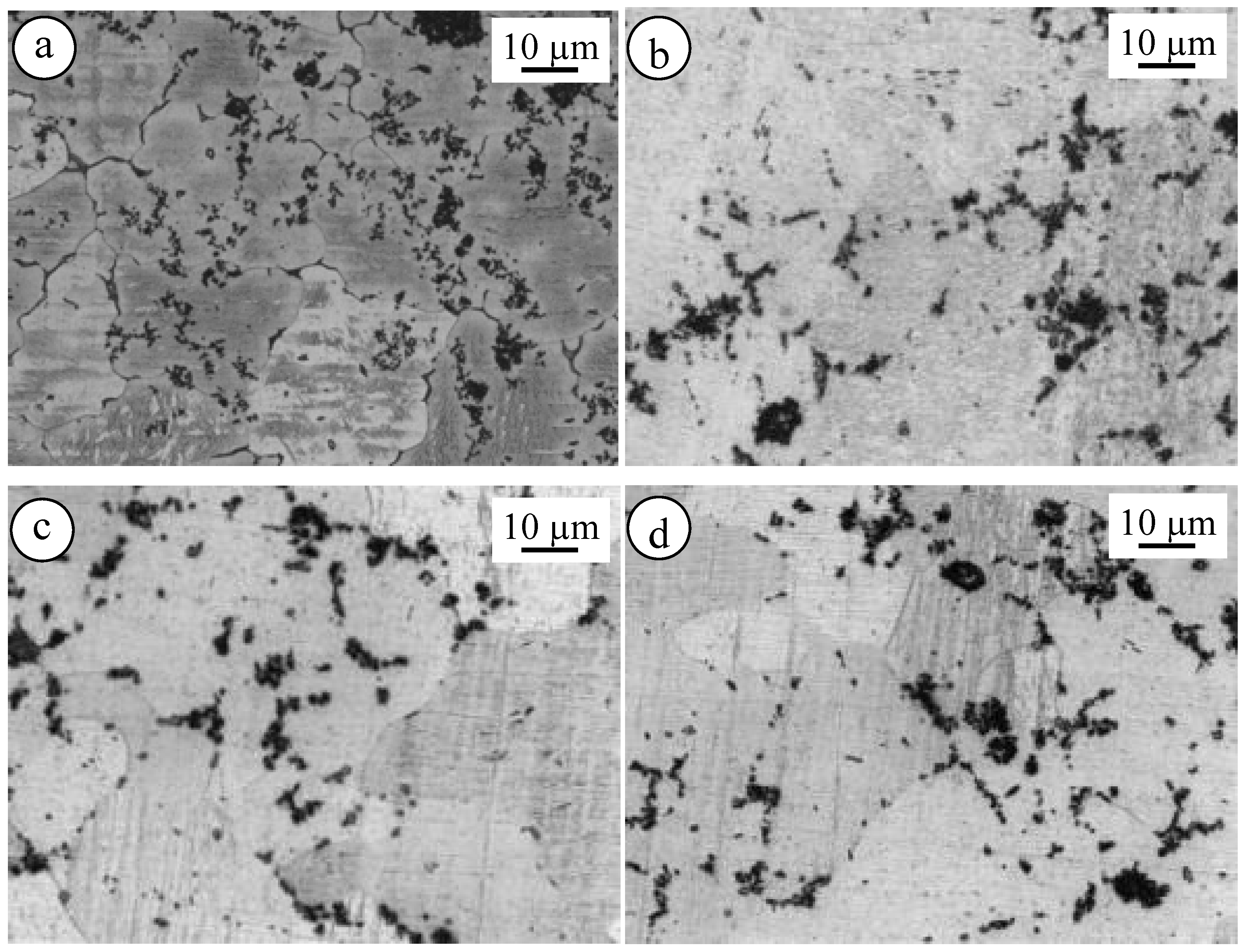

3.1. Elektron21

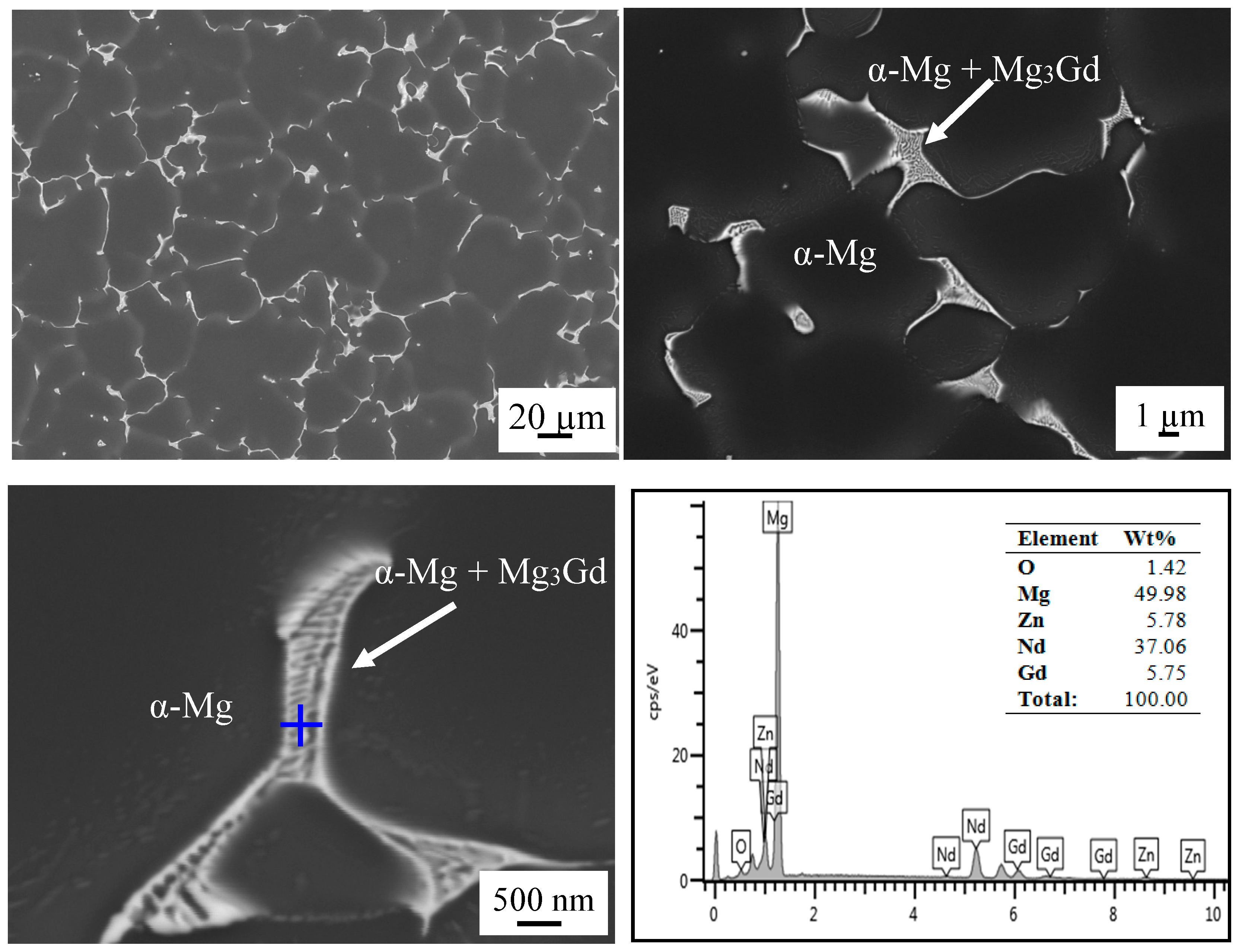

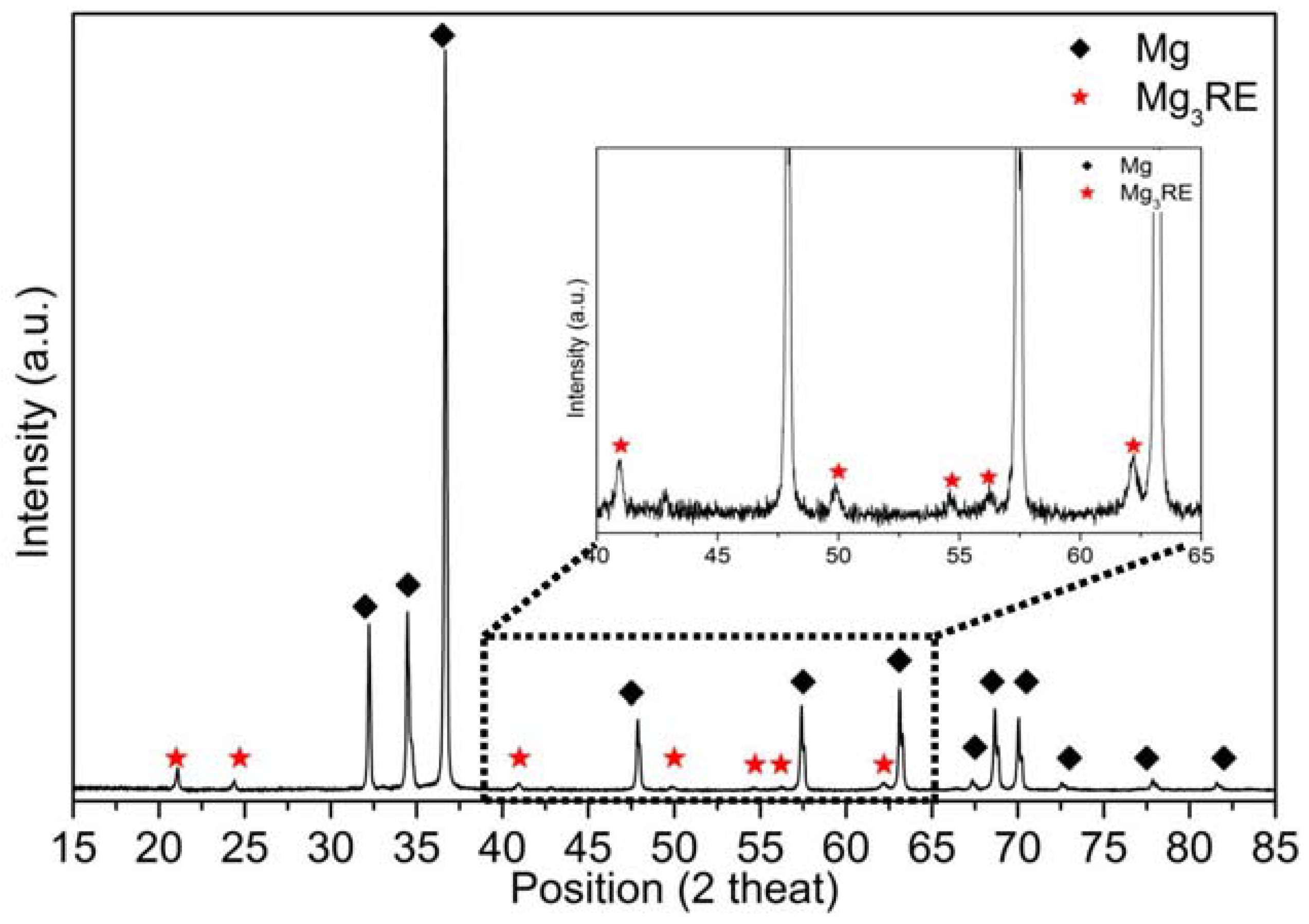

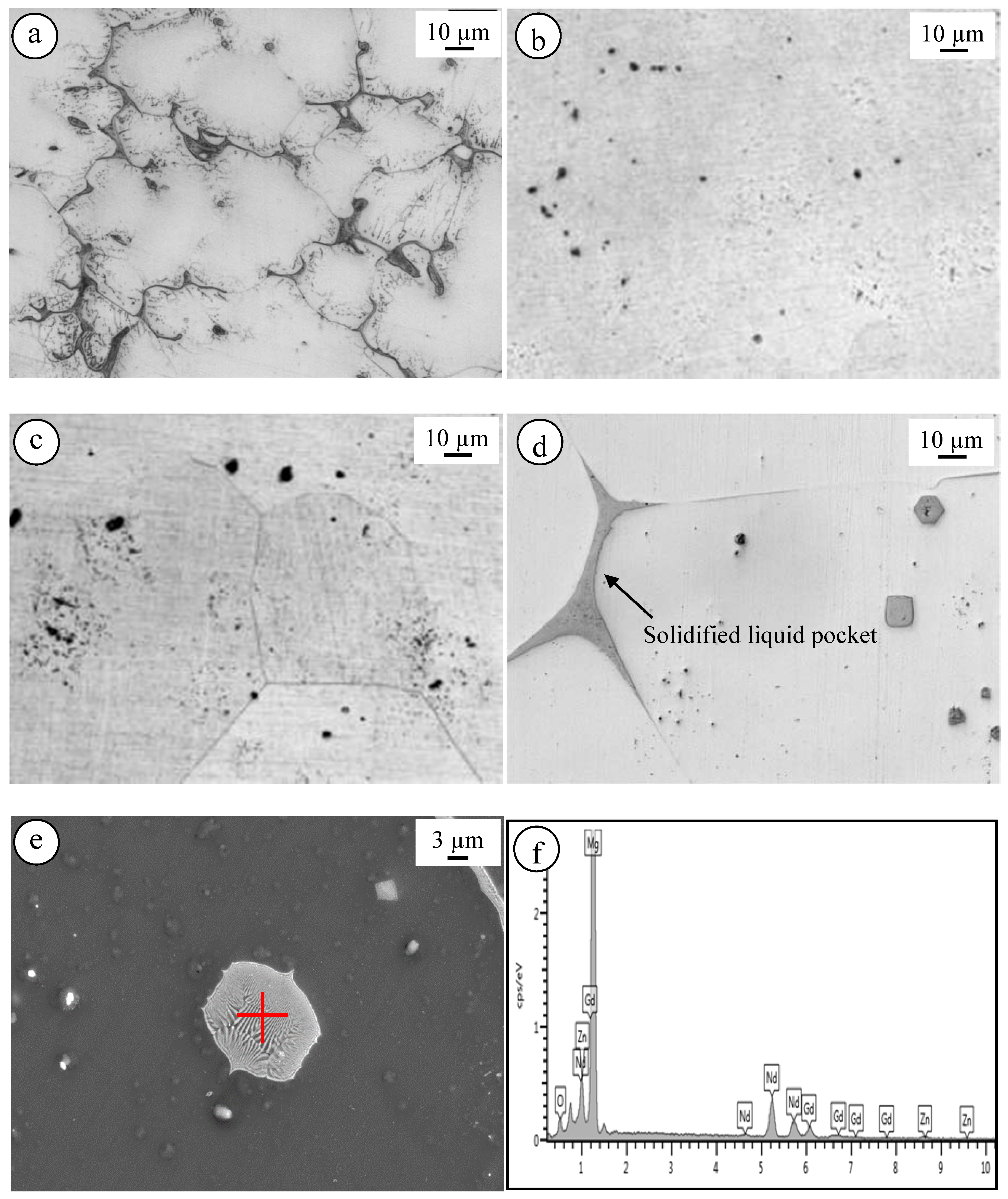

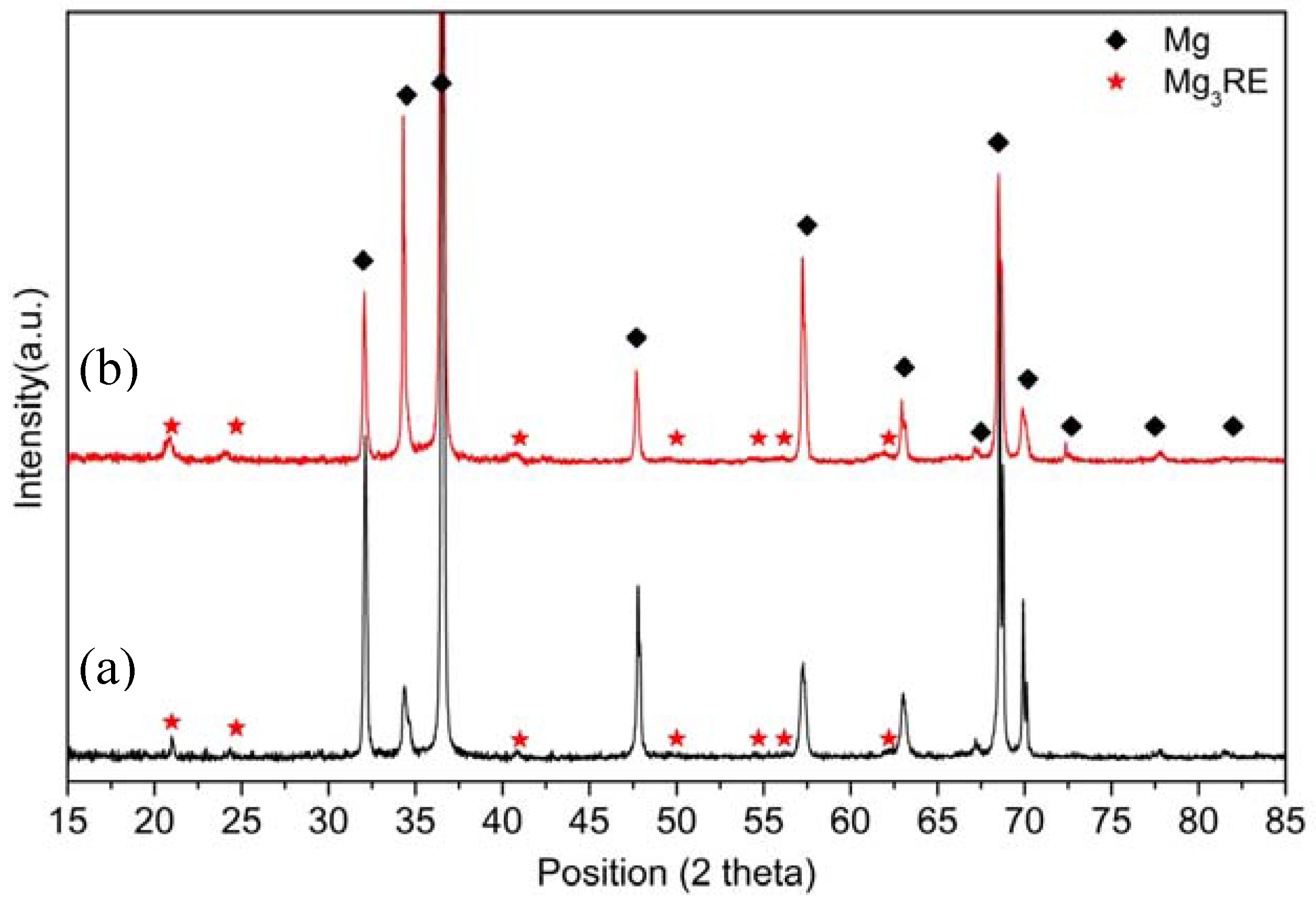

3.1.1. As Cast

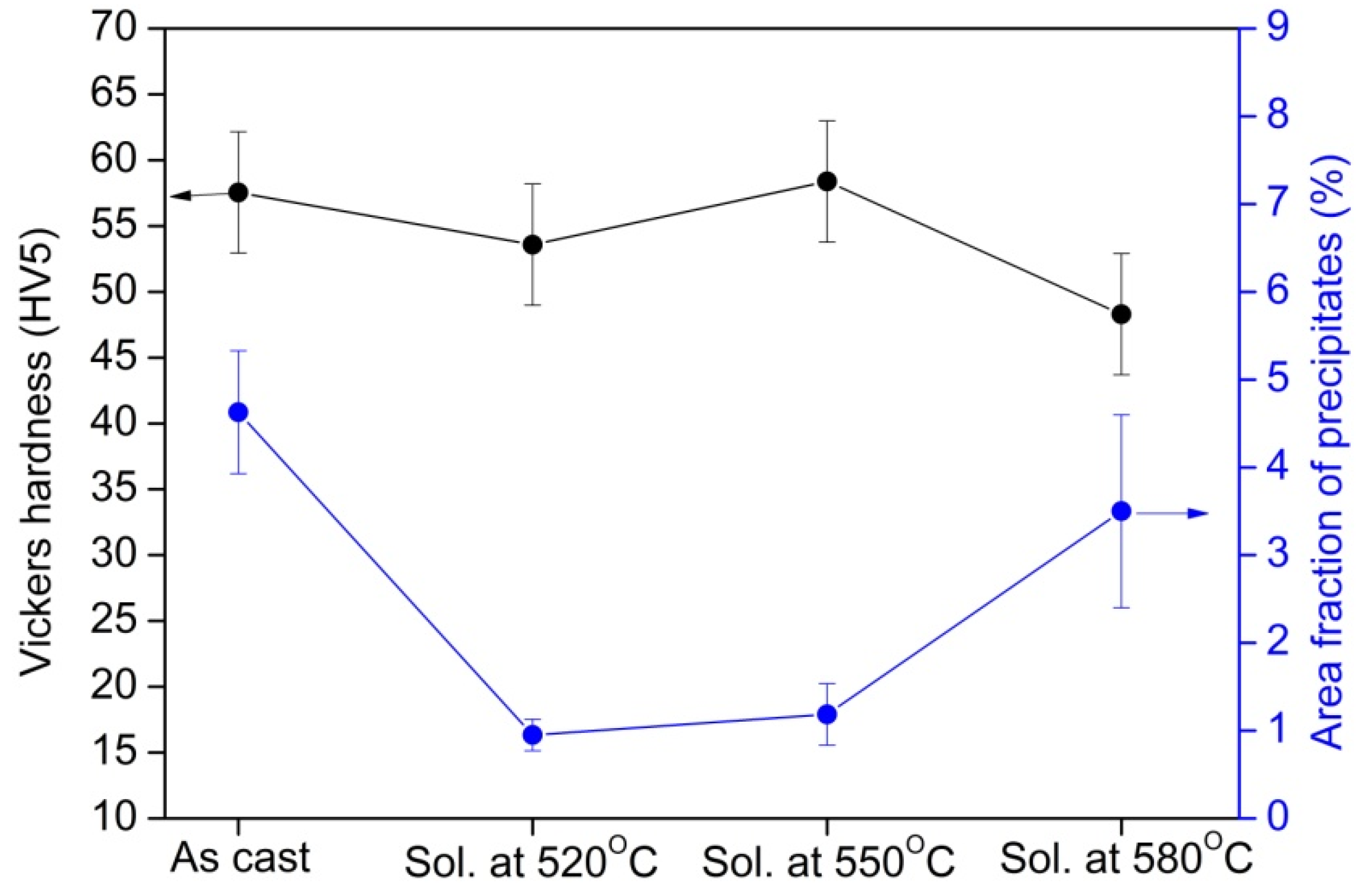

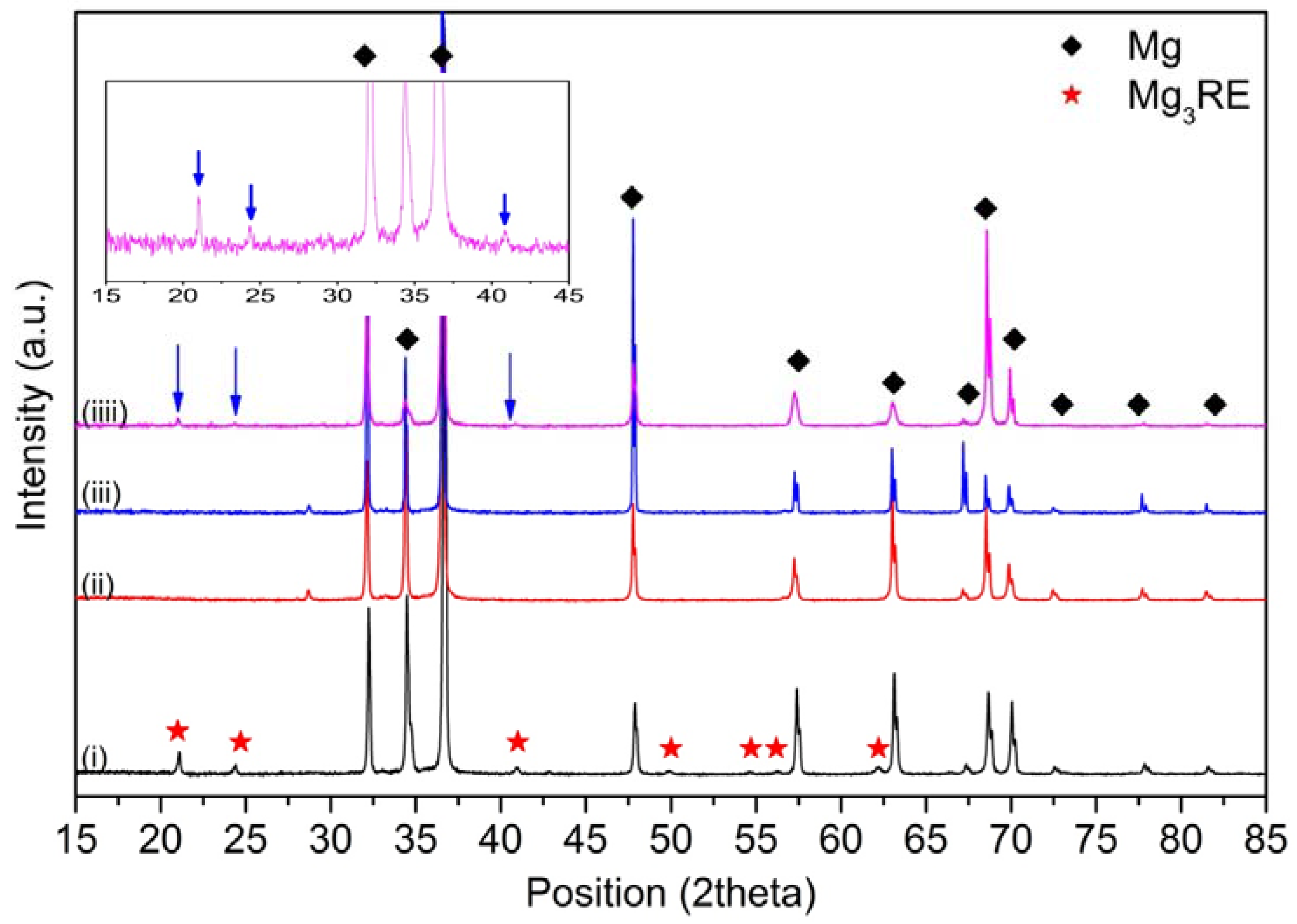

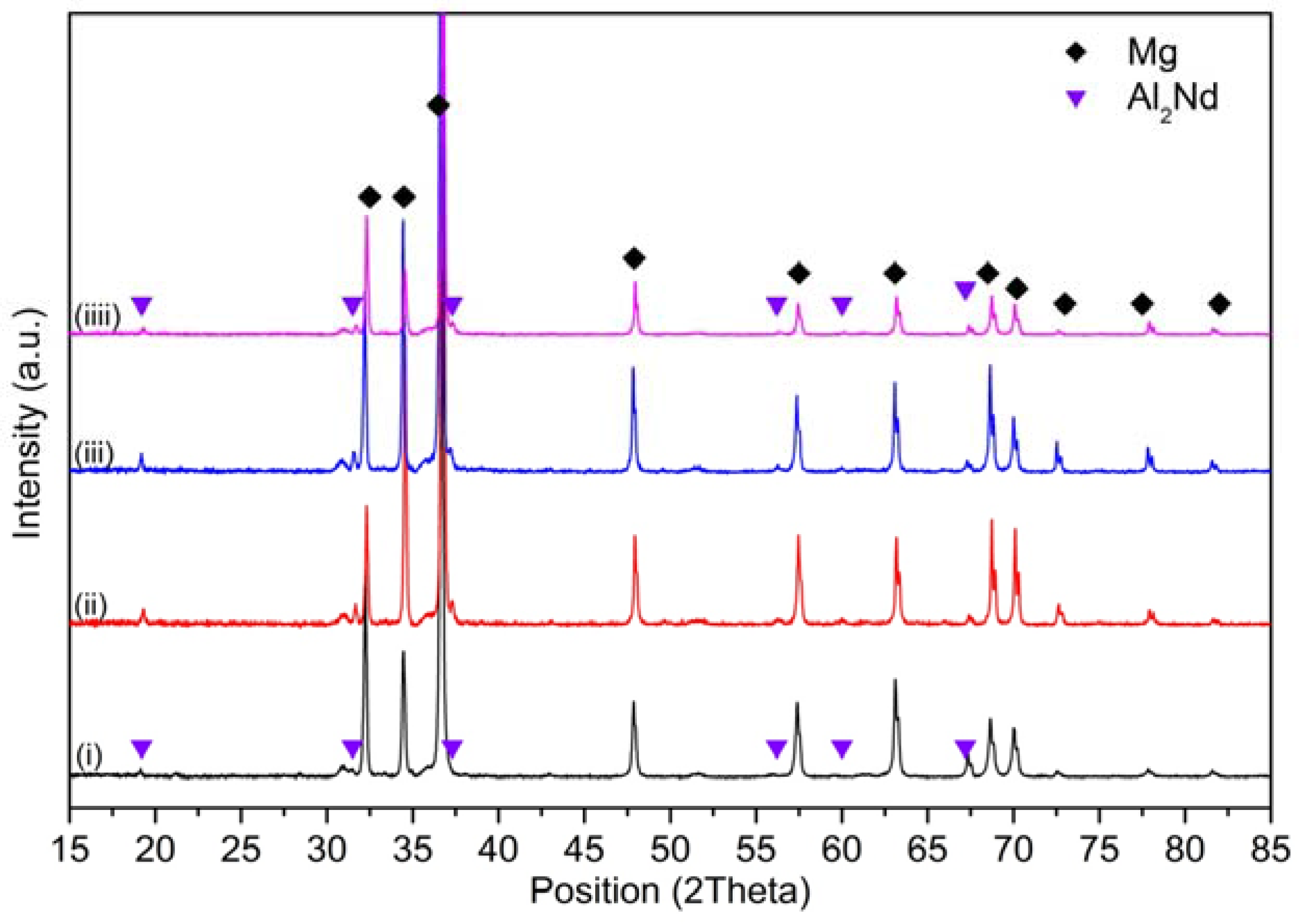

3.1.2. Solution Treatment

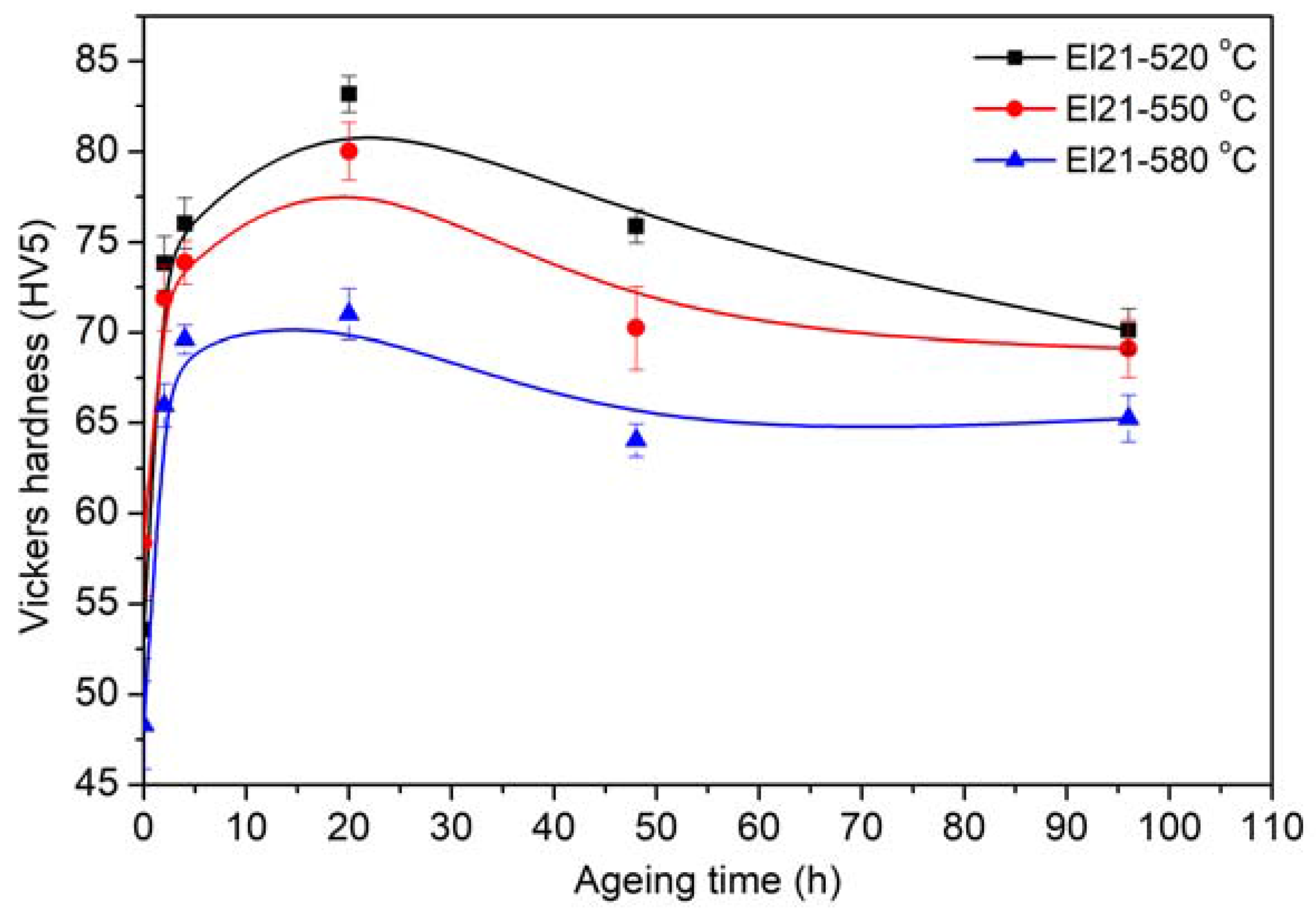

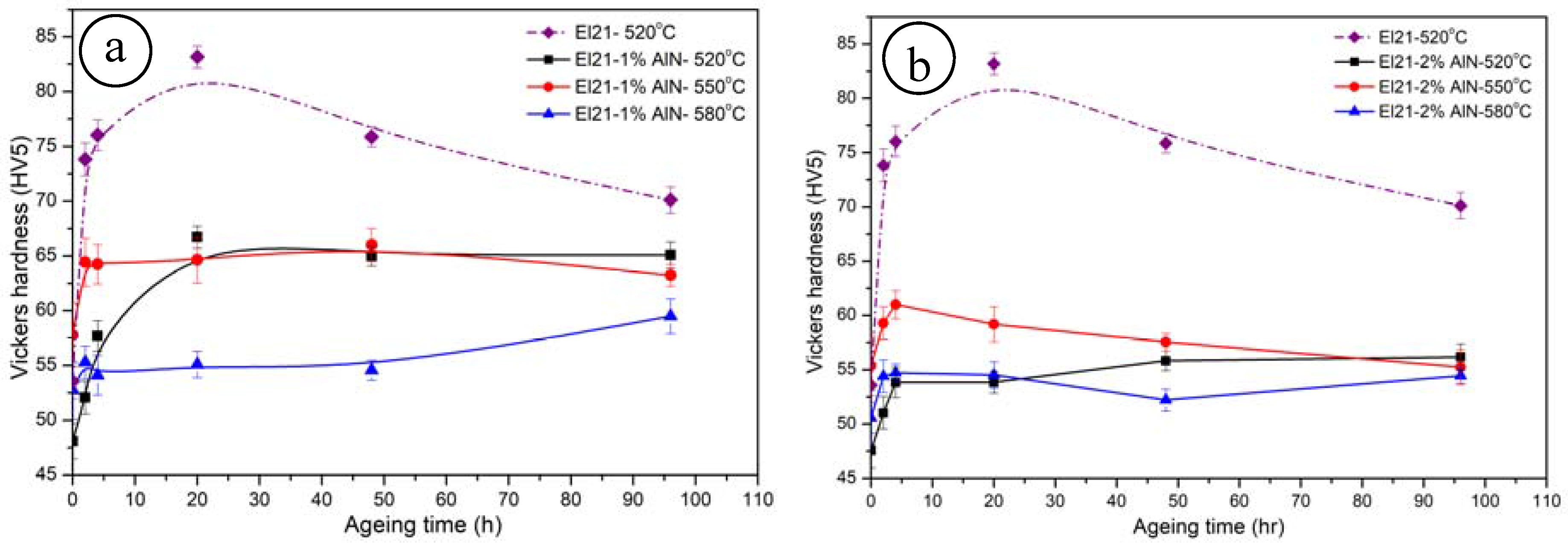

3.1.3. Ageing Treatments

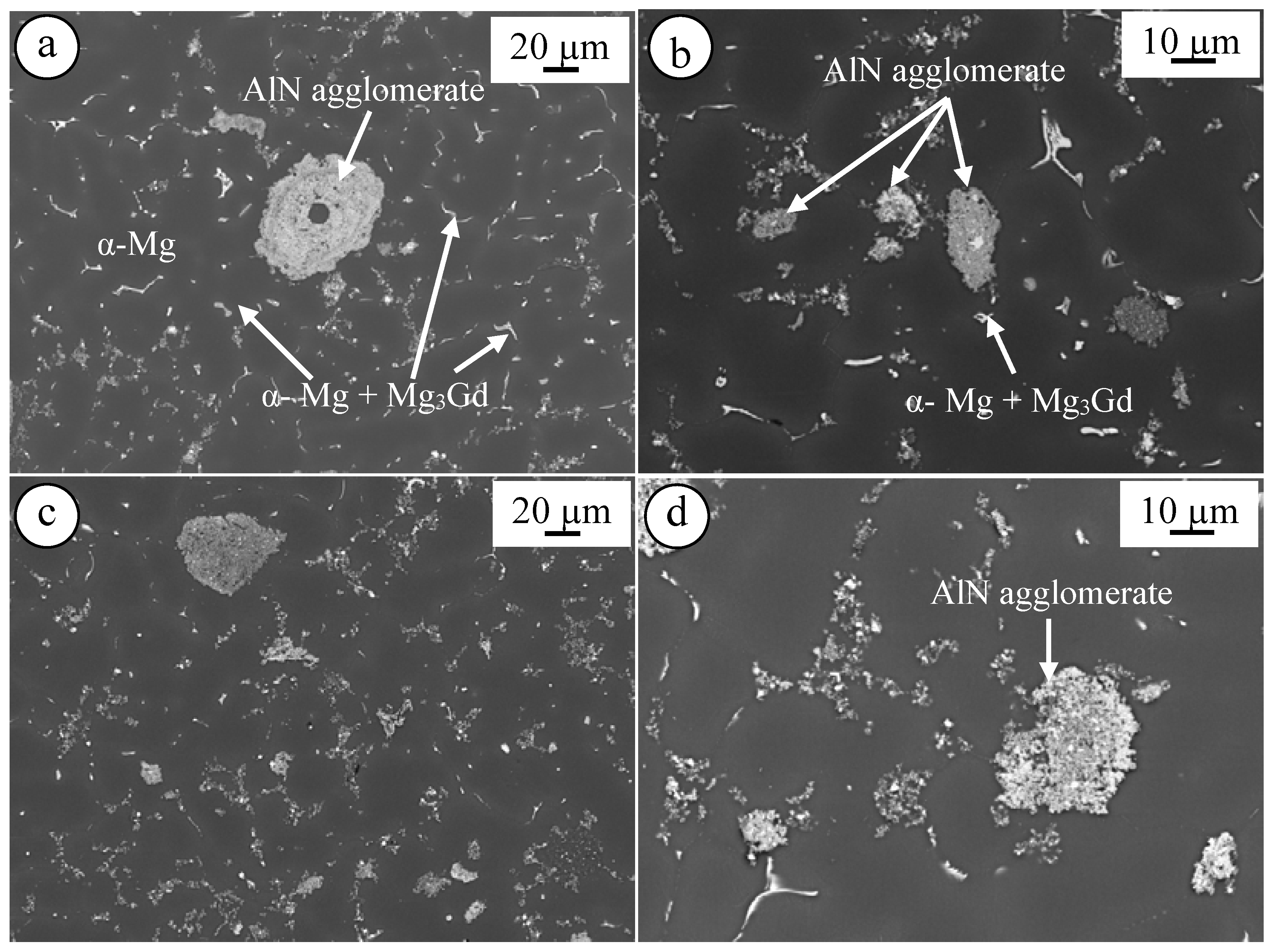

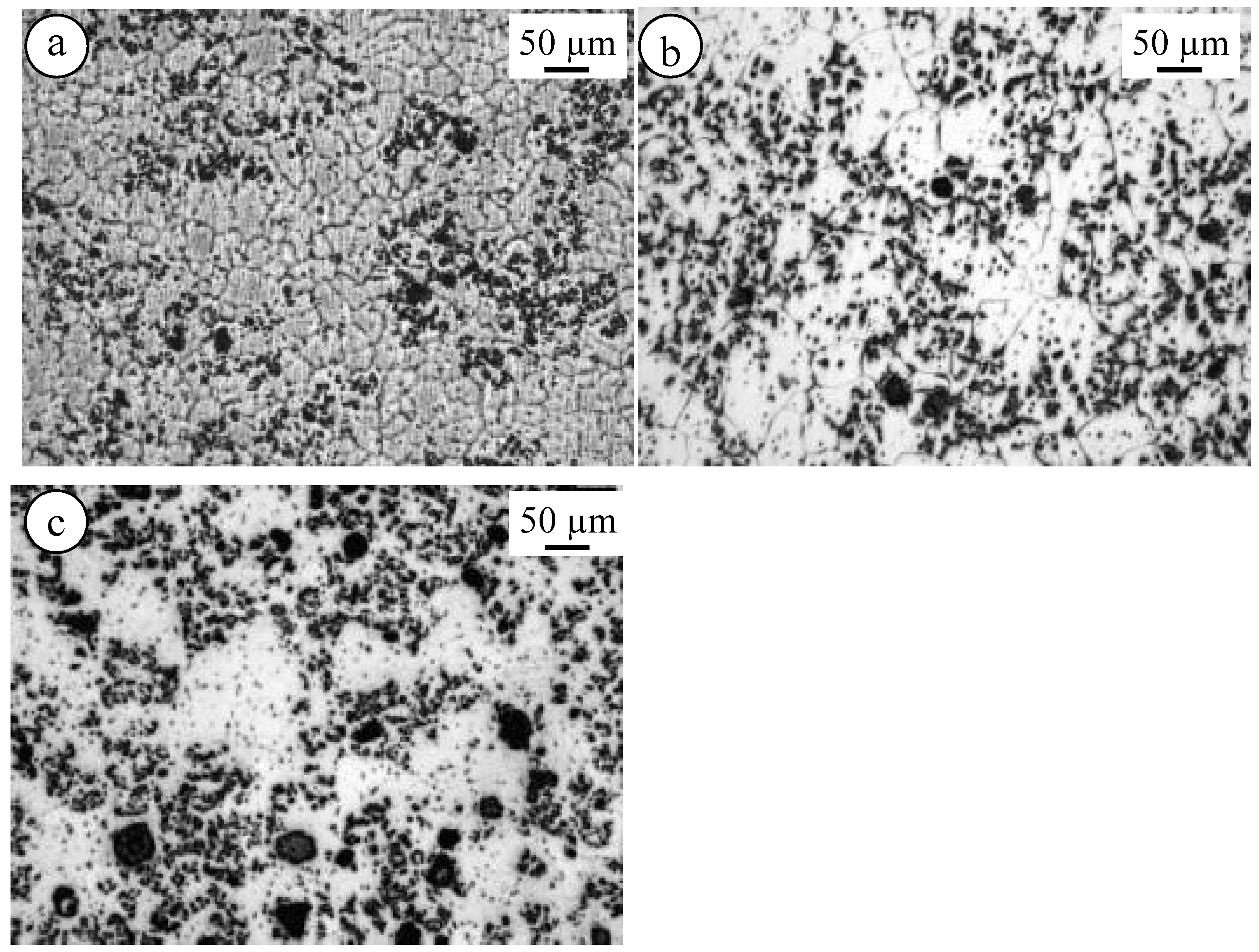

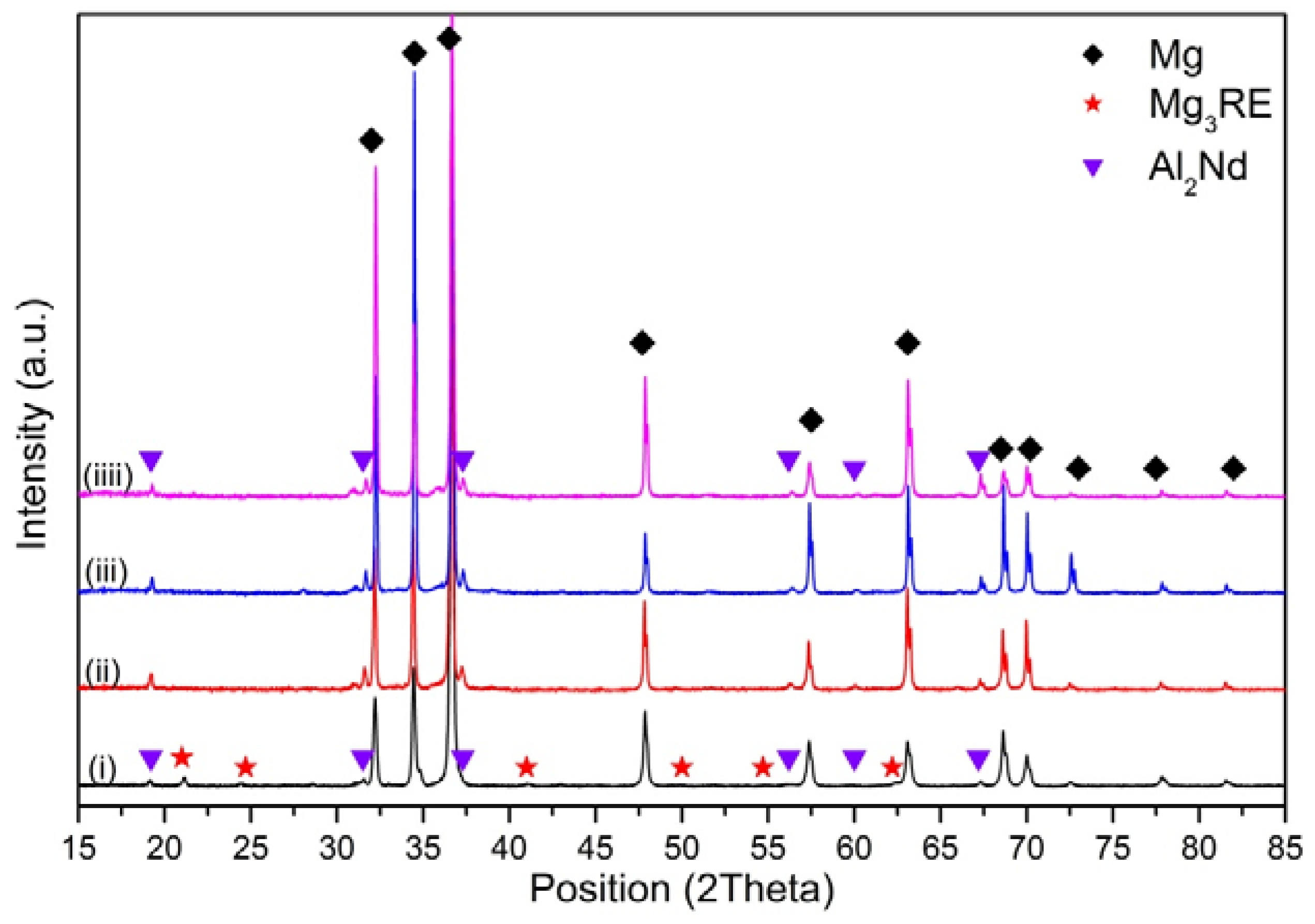

3.2. Elektron21–AlN Composites

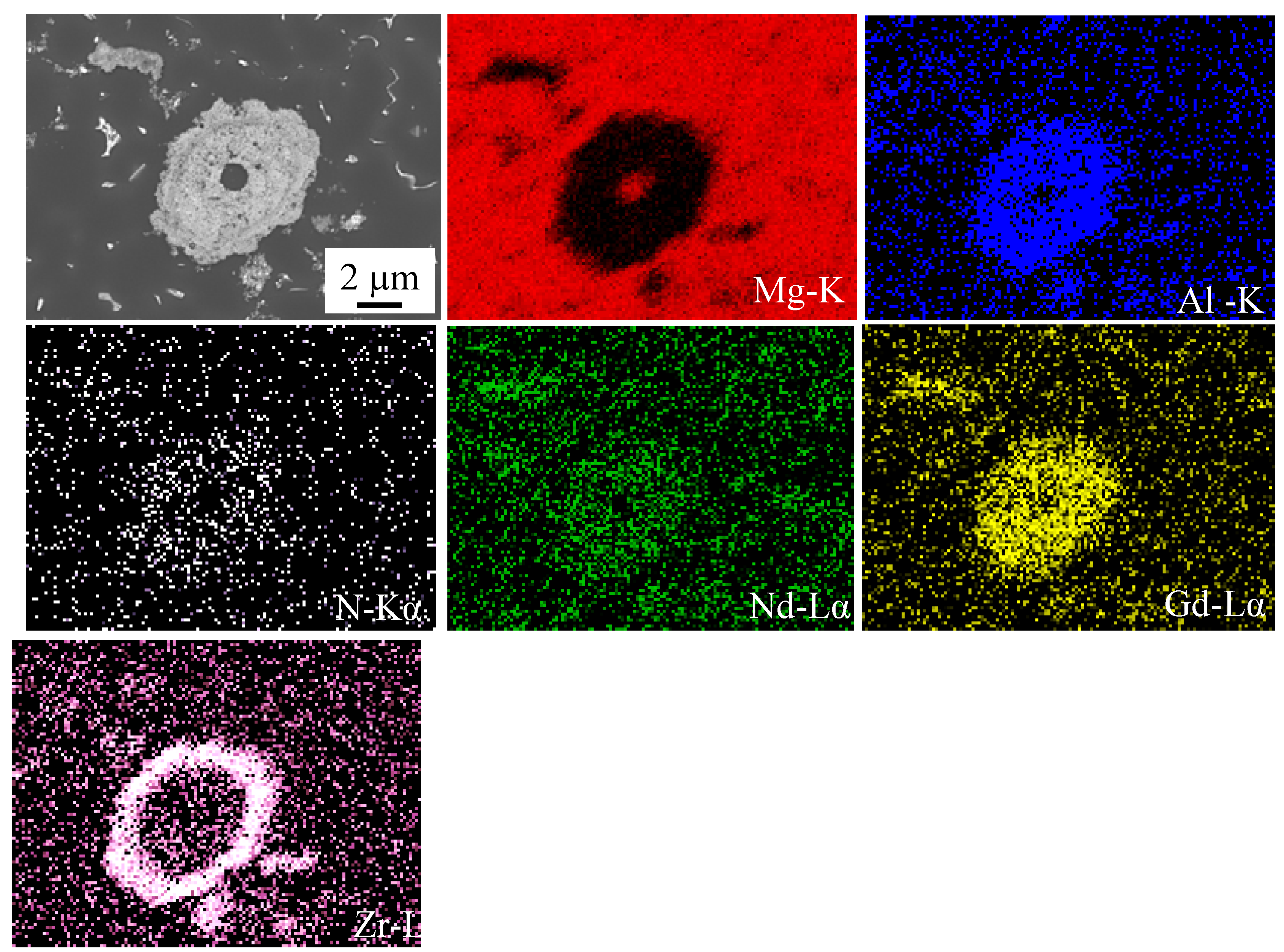

3.2.1. As cast El21–AlN Composites

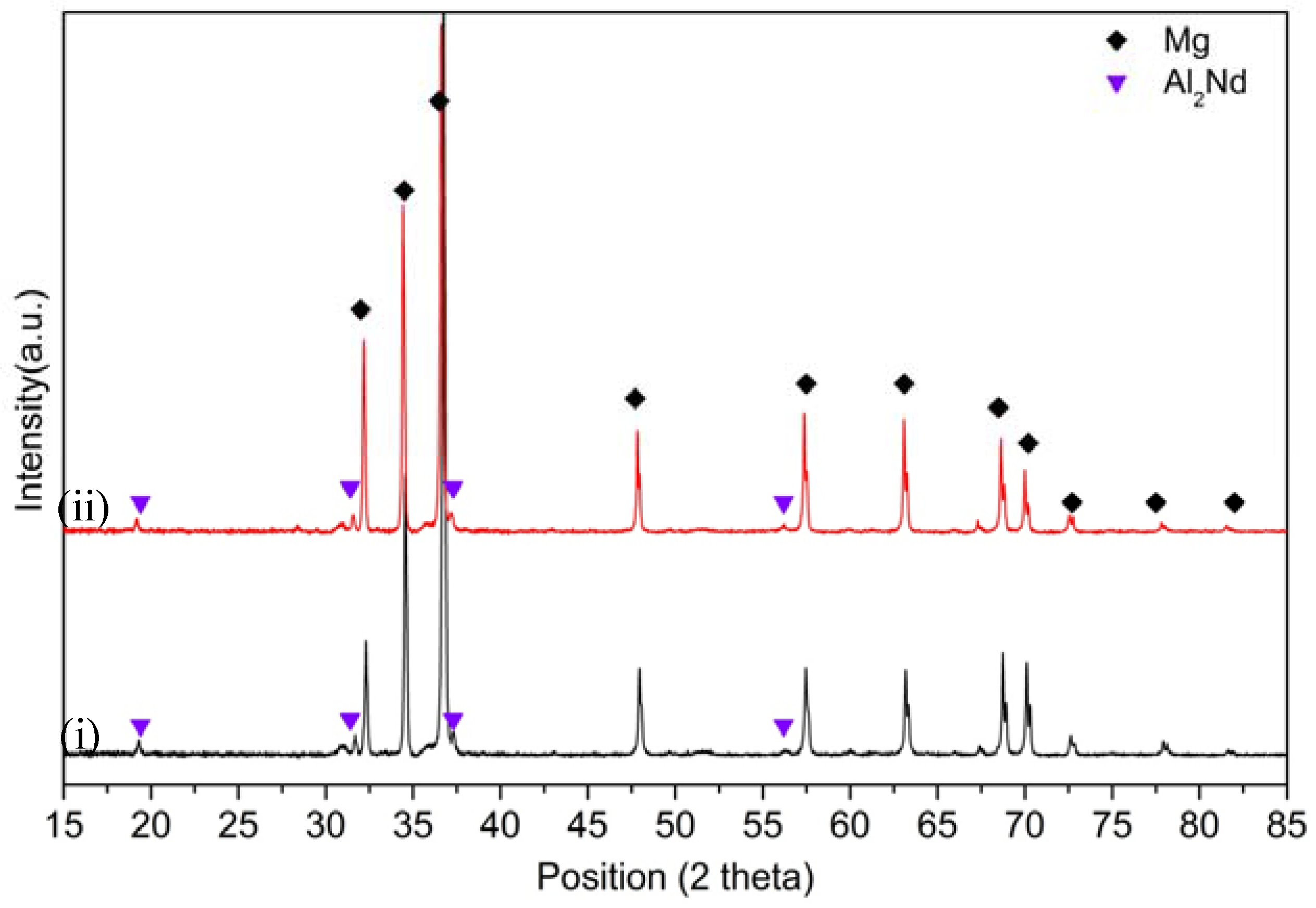

3.2.2. Solution Treatment

3.2.3. Ageing Treatment

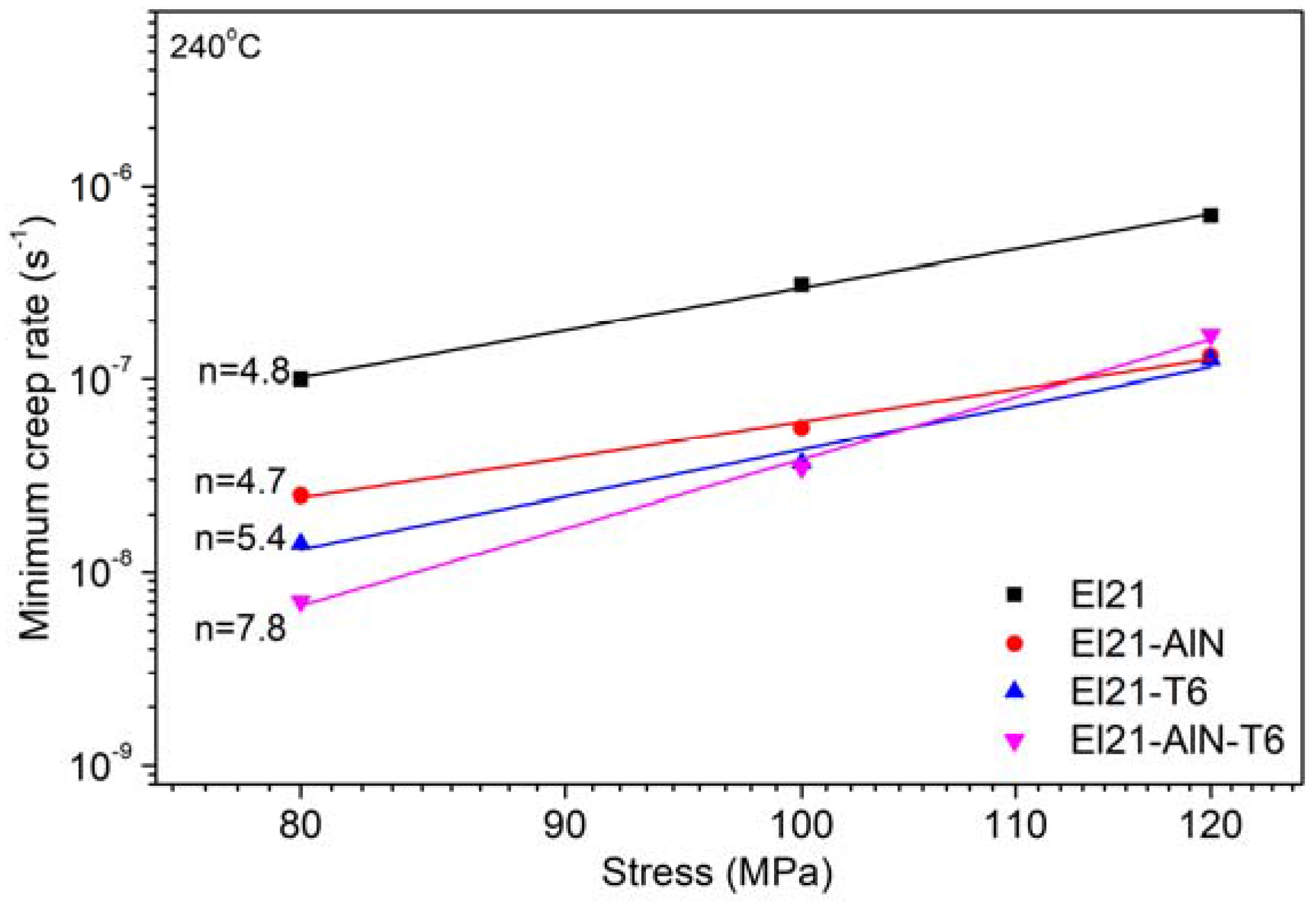

3.3. Creep Properties

4. Conclusions

- (1)

- As-cast El21 showed the typical behavior of age hardening in the magnesium alloys. The best condition for solution treatment and ageing process was solutionizing at 520 °C for 12 h followed by ageing at 200 °C for 20 h.

- (2)

- Solution treatment at very high temperatures (higher than eutectic) brings the microstructure to a point where there are liquid regions at grain triple points as well as within the grains, and consequently kills the precipitation hardening response.

- (3)

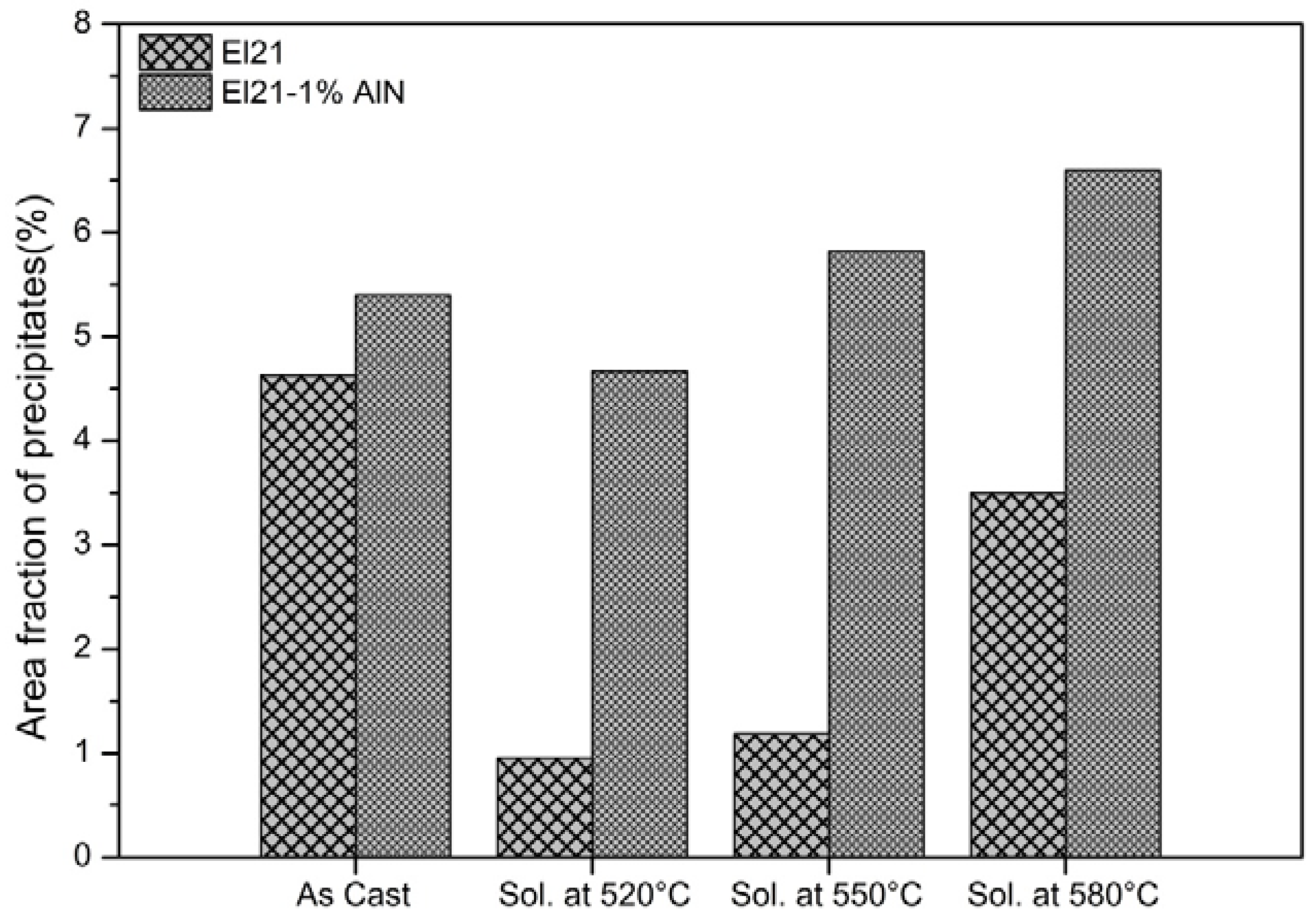

- Through the comparison between as-cast and as-solutionized El21, together with the variation of the area fraction of precipitates, it could be concluded that the complete dissolution of precipitates during the solution treatment was not possible and the residual precipitates grew at higher solution treatment temperatures.

- (4)

- In the case of the El21–AlN nanocomposite, precipitation of Al2Nd was detected in the solutionized case, while, in the case of El21, the only Mg3RE phase was identified as the main intermetallic phase.

- (5)

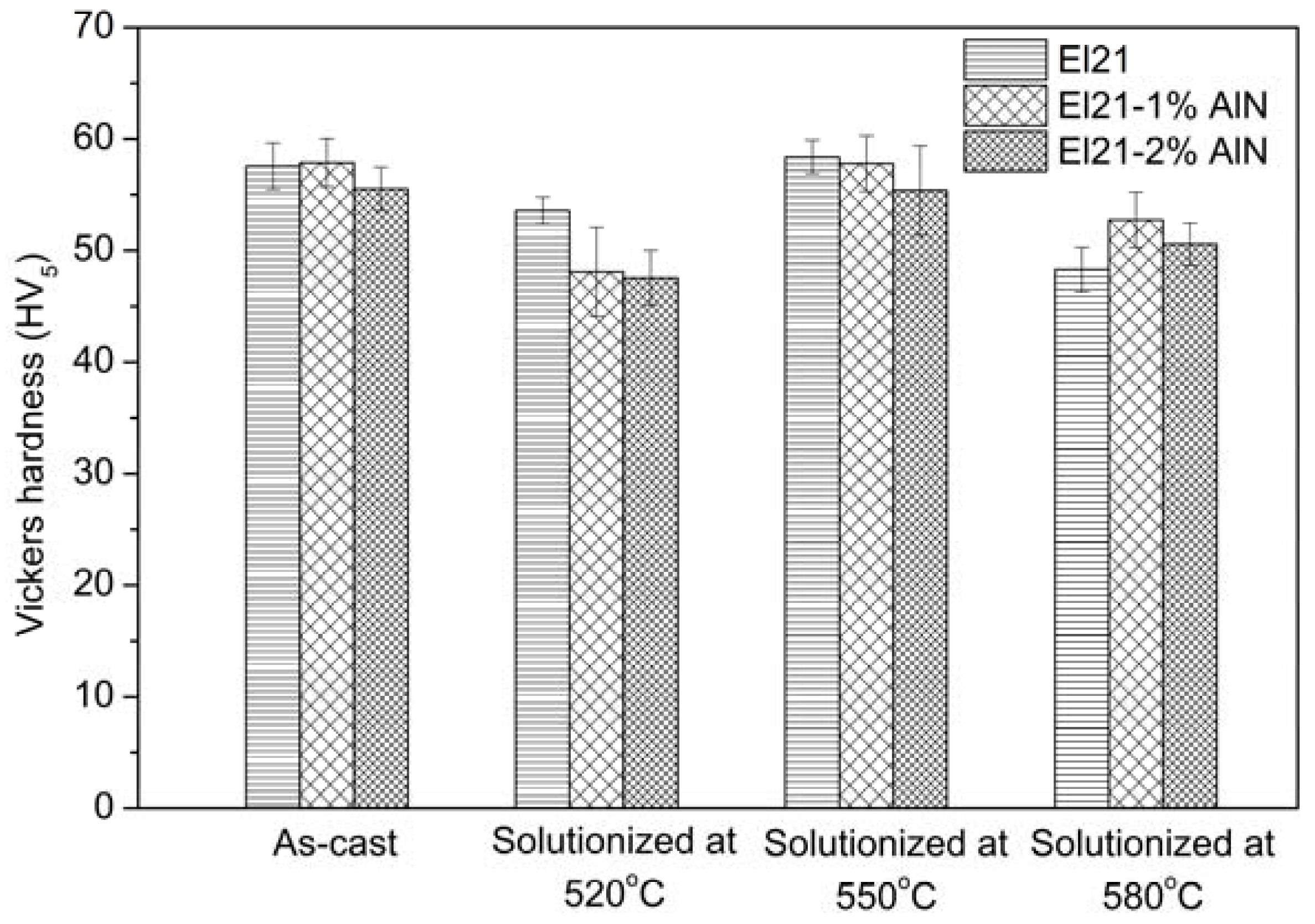

- The El21–AlN composites showed a similar hardness with respect to El21 alloy after solution treatment, but gained a very limited hardness during the early stage of ageing treatment and remained unchanged up to an ageing treatment of 96 h.

- (6)

- By increasing the solutionizing temperature, the maximum hardness decreases, which could be related to the magnesium grain growth and the growth of residual precipitates left after solutionizing with the increasing temperature. In fact, the samples obtained at the higher solutionizing temperatures contain less alloying elements in solid solution, so that their ageing is less effective.

- (7)

- The first creep results confirmed that the addition of nanoparticles could be effective to improve the creep properties, while the results after the T6 treatment showed that the minimum creep rate of T6 El21 was almost equal to the as-cast El21–AlN.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sillekens, W.H.; Jarvis, D.J.; Vorozhtsov, A.; Bojarevics, V.; Badini, C.F.; Pavese, M.; Terzi, S.; Salvo, L.; Katsarou, L.; Dieringa, H. The ExoMet Project: EU/ESA Research on high-performance light-metal alloys and nanocomposites. Metall. Mater. Trans. A 2014, 45, 3349–3361. [Google Scholar] [CrossRef]

- Mortensen, A.; Llorca, J. Metal Matrix Composites. Annu. Rev. Mater. Res. 2010, 40, 243–270. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Microstructure and thermal conductivity of Al-Graphene composites fabricated by powder metallurgy and hot rolling techniques. Acta Metall. Sin. 2017, 30, 675–687. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. Development of Al- and Cu-based nanocomposites reinforced by graphene nanoplatelets: Fabrication and characterization. Front. Mater. Sci. 2017, 11, 171–181. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A Novel Cu—GNPs Nanocomposite with Improved Thermal and Mechanical Properties. Acta Metall. Sin. 2017, 1–5. [Google Scholar] [CrossRef]

- Hu, H.; Yu, A.; Li, N.; Allison, J.E. Potential magnesium alloys for high temperature die cast automotive applications: A Review. Mater. Manuf. Process. 2003, 18, 687–717. [Google Scholar] [CrossRef]

- Kulekci, M.K. Magnesium and its alloys applications in automotive industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Lyon, P.; Syed, I.; Heaney, S. Elektron 21—An aerospace magnesium alloy for sand cast and investment cast applications. Adv. Eng. Mater. 2007, 9, 793–798. [Google Scholar] [CrossRef]

- Musfirah, A.H.; Jaharah, A.G. Magnesium and aluminum alloys in automotive industry. J. Appl. Sci. Res. 2012, 8, 4865–4875. [Google Scholar]

- Polmear, I.J. Magnesium alloys and applications. Mater. Sci. Technol. 1994, 10, 1–16. [Google Scholar] [CrossRef]

- Luo, A.A. Magnesium casting technology for structural applications. J. Magnes. Alloys 2013, 1, 2–22. [Google Scholar] [CrossRef]

- He, S.M.; Zeng, X.Q.; Peng, L.M.; Gao, X.; Nie, J.F.; Ding, W.J. Precipitation in a Mg–10Gd–3Y–0.4Zr (wt.%) alloy during isothermal ageing at 250 °C. J. Alloys Compd. 2006, 421, 309–313. [Google Scholar] [CrossRef]

- Moreno, I.P.; Nandy, T.K.; Jones, J.W.; Allison, J.E.; Pollock, T.M. Microstructural stability and creep of rare-earth containing magnesium alloys. Scr. Mater. 2003, 48, 1029–1034. [Google Scholar] [CrossRef]

- Kielbus, A. Microstructure and properties of elektron 21 magnesium alloy. In Magnesium Alloys—Design, Processing and Properties; Czerwinski, F., Ed.; InTech: London, UK, 2011; pp. 281–296. ISBN 978-953-307-520-4. [Google Scholar]

- Negishi, Y.; Nishimura, T.; Kiryuu, M.; Kamado, S.; Kojima, Y.; Ninomiya, R. Phase diagrams of magnesium-rich portion, aging characteristics and tensile properties of Mg-heavy rare earth metal (Gd, Dy)-Nd alloys. J. Jpn. Inst. Light Met. 1995, 45, 57–63. [Google Scholar] [CrossRef]

- Yao, J.Y.; Edwards, G.A.; Graham, D.A. Precipitation and age-hardening in Al-Si-Cu-Mg-Fe casting alloys. Mater. Sci. Forum 1996, 217–222, 777–782. [Google Scholar] [CrossRef]

- Katsarou, L.; Mounib, M.; Lefebvre, W.; Vorozhtsov, S.; Pavese, M.; Badini, C.; Molina-aldareguia, J.M.; Cepeda, C.; MariaTeresa, P.P.; Dieringa, H. Microstructure, mechanical properties and creep of magnesium alloy Elektron21 reinforced with AlN nanoparticles by ultrasound-assisted stirring. Mater. Sci. Eng. A 2016, 659, 84–92. [Google Scholar] [CrossRef]

- Saboori, A.; Pavese, M.; Badini, C.; Fino, P. A novel approach to enhance the mechanical strength and electrical and thermal conductivity of Cu-GNP nanocomposites. Metall. Mater. Trans. A 2017. [Google Scholar] [CrossRef]

- Dieringa, H. Properties of magnesium alloys reinforced with nanoparticles and carbon nanotubes: A review. J. Mater. Sci. 2011, 46, 289–306. [Google Scholar] [CrossRef]

- Kielbus, A.; Rzychon, T.; Przeliorz, R. DSC and microstructural investigations of the Elektron 21 magnesium alloy. Mater. Sci. Forum 2010, 642, 1447–1452. [Google Scholar] [CrossRef]

- Nie, J.F.; Muddle, B.C. Characterisation of strengthening precipitate phases in a Mg-Y-Nd alloy. Acta Mater. 2000, 48, 1691–1703. [Google Scholar] [CrossRef]

- Antion, C.; Donnadieu, P.; Perrard, F.; Deschamps, A.; Tassin, C.; Pisch, A. Hardening precipitation in a Mg–4Y–3RE alloy. Acta Mater. 2003, 51, 5335–5348. [Google Scholar] [CrossRef]

- Shi, W.; Kobashi, M.; Choh, T. Wettability of molten magnesium on carbon and AlN. J. Jpn. Inst. Met. Mater. 2000, 64, 335–338. [Google Scholar] [CrossRef]

- He, X.; Yang, S.; Du, Y.; Tao, K.; Fan, Y. Reaction layer formation at the interface between Ti or Zr and AlN. Phys. Status Solidi A 1996, 157, 99–106. [Google Scholar] [CrossRef]

- López-pérez, W.; González-hernández, R.; Arbey, J.; Rodríguez, M. Zirconium adsorption and incorporation on a reconstructed Al-T4 AlN(0001) surface. J. Phys. Chem. Solids 2013, 74, 1387–1391. [Google Scholar] [CrossRef]

- García-Cordovilla, C.; Louis, E.; Narciso, J.; Pamies, A. A differential scanning calorimetry study of solid state reactions in AA6061-SiC, AA6061-Al2O3 and A357-SiC composites fabricated by means of compocasting. Mater. Sci. Eng. A 1994, 189, 219–227. [Google Scholar] [CrossRef]

- Kouzeli, M.; Mortensen, A. Size dependent strengthening in particle reinforced aluminium. Acta Mater. 2002, 50, 39–51. [Google Scholar] [CrossRef]

- Kocks, U.F. A statistical theory of flow stress and work-hardening. Philos. Mag. 1966, 13, 541–566. [Google Scholar] [CrossRef]

- Arzt, E.; Rösler, J. The kinetics of dislocation climb over hard particles—II. Effects of an attractive particle-dislocation interaction. Acta Metall. 1988, 36, 1053–1060. [Google Scholar] [CrossRef]

- Li, Y.; Langdon, T.G. A simple procedure for estimating threshold stresses in the creep of metal matrix composites. Scr. Mater. 1997, 36, 1457–1460. [Google Scholar] [CrossRef]

| - | Mg | Nd | Gd | Zr | Zn |

|---|---|---|---|---|---|

| wt.% | Balance | 2.6–3.1 | 1.0–1.7 | 0.49 | 0.2–0.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saboori, A.; Padovano, E.; Pavese, M.; Dieringa, H.; Badini, C. Effect of Solution Treatment on Precipitation Behaviors, Age Hardening Response and Creep Properties of Elektron21 Alloy Reinforced by AlN Nanoparticles. Materials 2017, 10, 1380. https://doi.org/10.3390/ma10121380

Saboori A, Padovano E, Pavese M, Dieringa H, Badini C. Effect of Solution Treatment on Precipitation Behaviors, Age Hardening Response and Creep Properties of Elektron21 Alloy Reinforced by AlN Nanoparticles. Materials. 2017; 10(12):1380. https://doi.org/10.3390/ma10121380

Chicago/Turabian StyleSaboori, Abdollah, Elisa Padovano, Matteo Pavese, Hajo Dieringa, and Claudio Badini. 2017. "Effect of Solution Treatment on Precipitation Behaviors, Age Hardening Response and Creep Properties of Elektron21 Alloy Reinforced by AlN Nanoparticles" Materials 10, no. 12: 1380. https://doi.org/10.3390/ma10121380