Computational Modelling of Materials for Wind Turbine Blades: Selected DTU Wind Energy Activities

Abstract

1. Introduction

- ○

- Understanding the degradation mechanisms of wind blades as a function of their structures, and the prediction of the lifetime and performance of wind blades. For this, we estimate the loads on the wind blades (Section 2), and develop the micromechanical models of wind blade composite degradation at the level of fibers and bundles under tensile (Section 3) and compressive (Section 4) loading.

- ○

- Exploring the promising ways to optimize the wind blade performance by tailoring the materials’ structures. Here, we develop computational models of hybrid and nanoengineered composites (Section 5) and estimate the effect of these structures on the composite performance and lifetime.

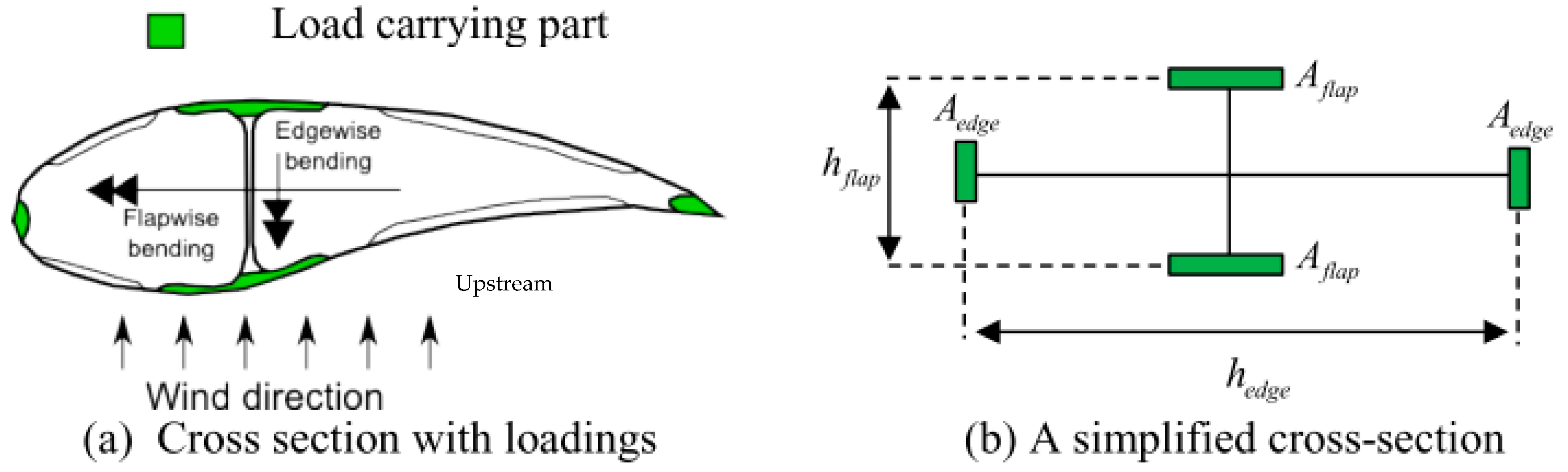

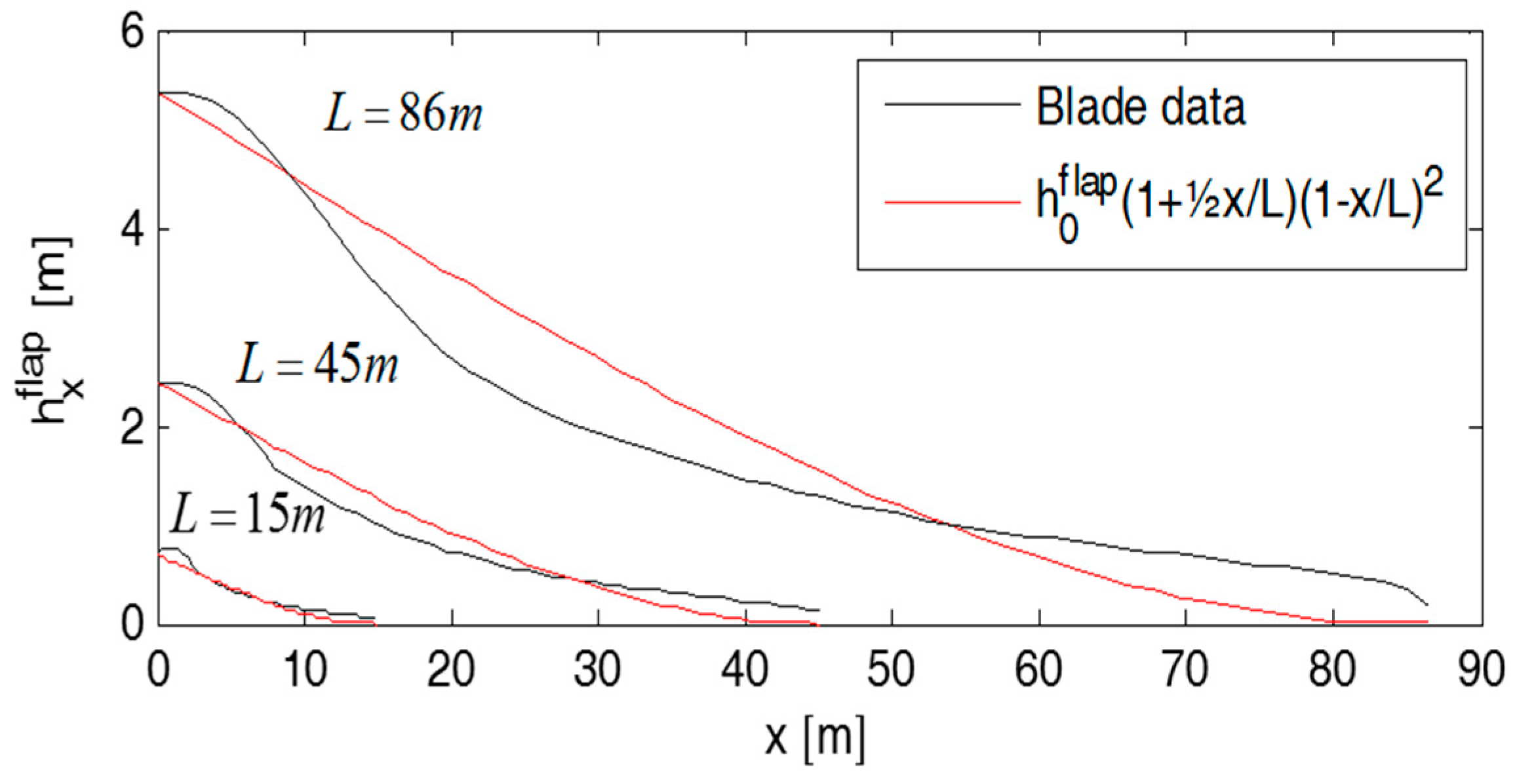

2. Loads on the Wind Blades and Stresses in the Material

2.1. Loads on a Wind Blade

2.2. Stresses in a Wind Blade

3. Three Dimensional Modelling of Composite Degradation under Tensile Loading

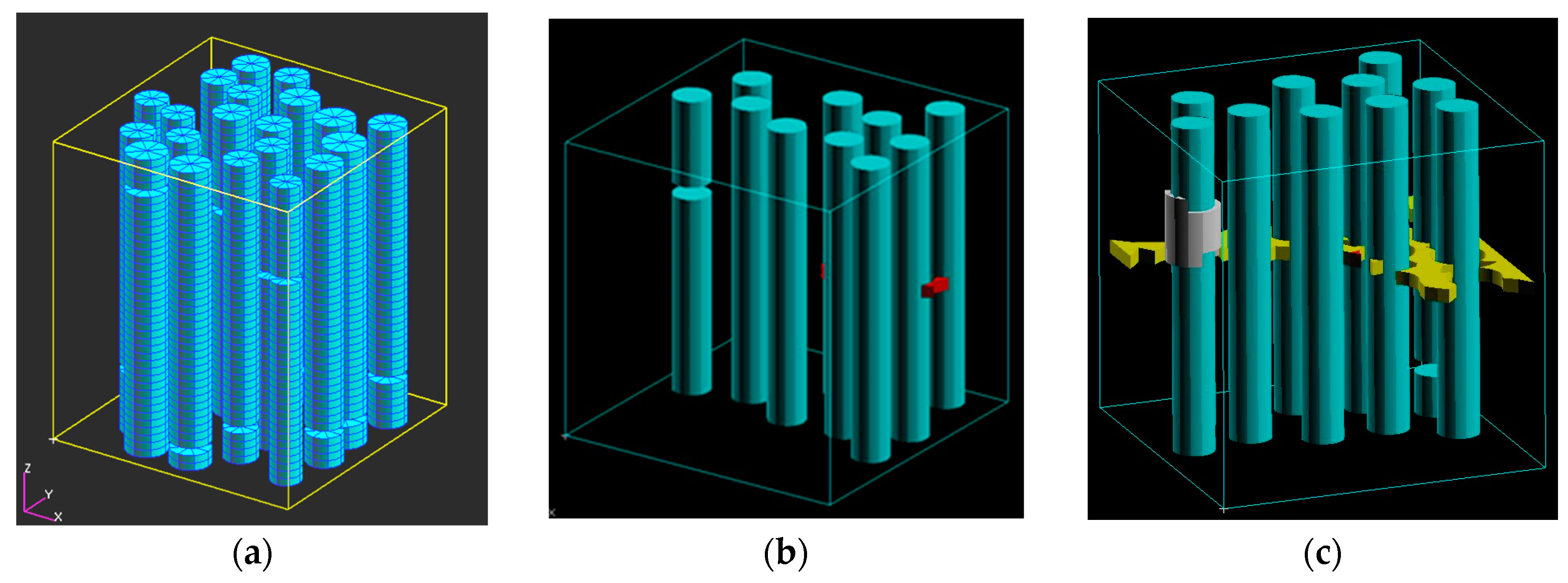

3.1. Computational Modelling of Micromechanisms of Degradation of Wind Blade Composites

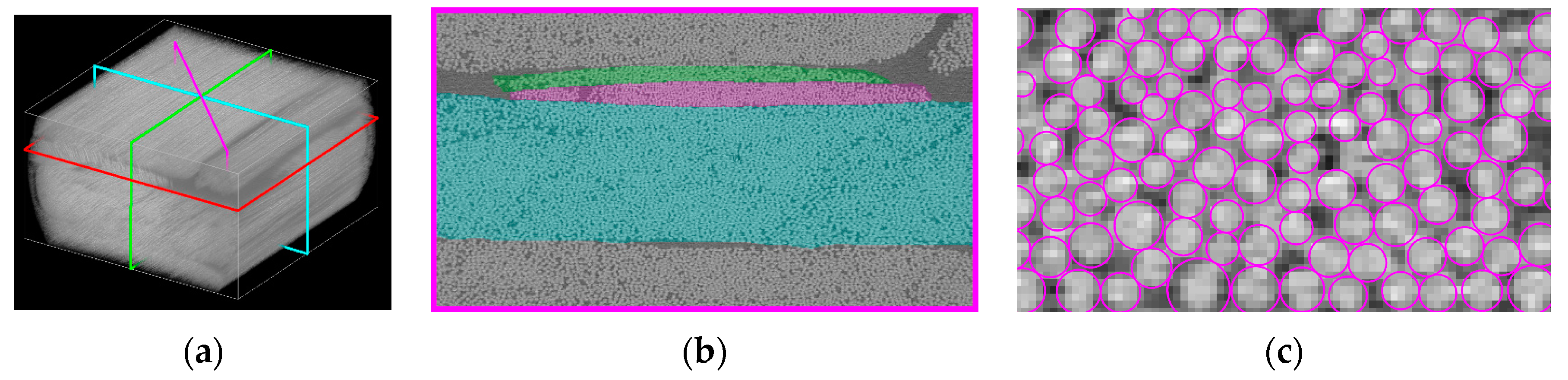

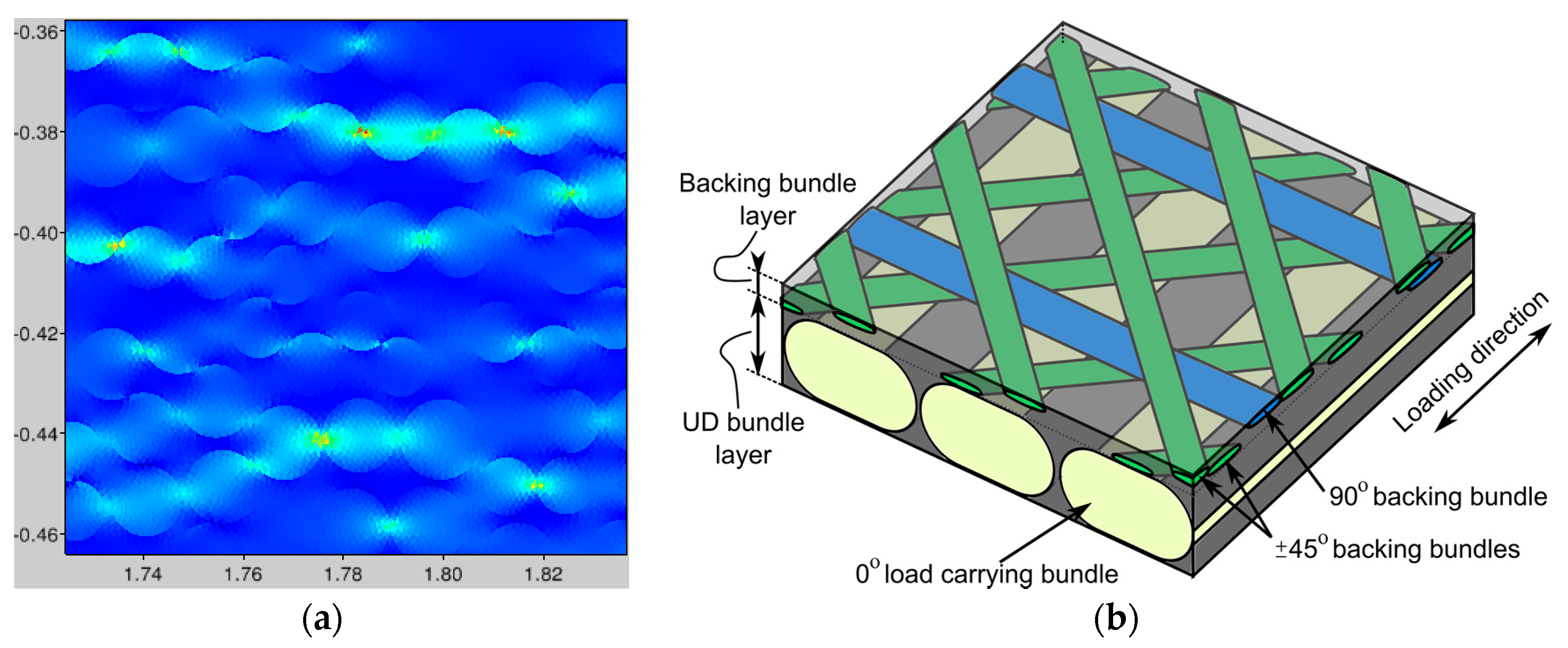

3.2. Fiber Bundle Modelling with an Experimentally-Determined Fiber Distribution

4. Compressive Strength of Wind Turbine Composites

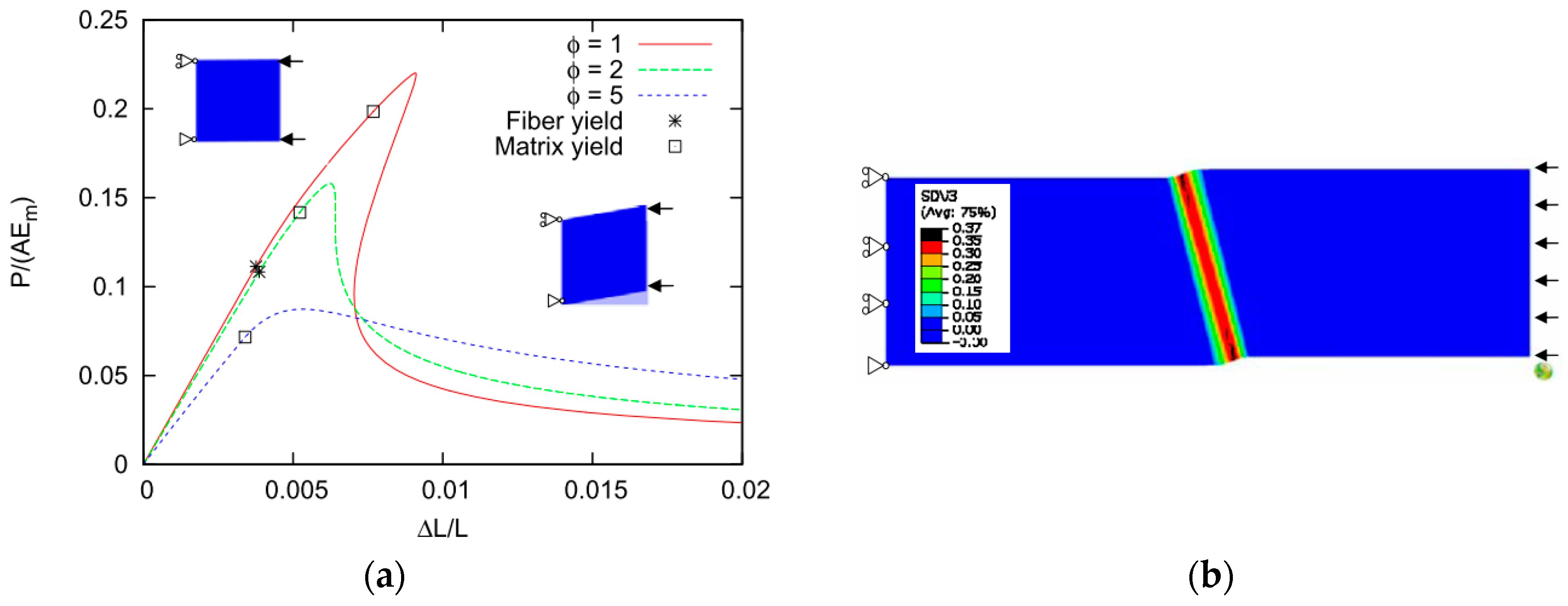

4.1. Statistical Model of Compressive Damage Evolution

4.2. Effect of Local Fiber Misalignment and Wrinkles on Compression Strength of the Composite

5. Computational Modelling of Hybrid and Hierarchical Composites

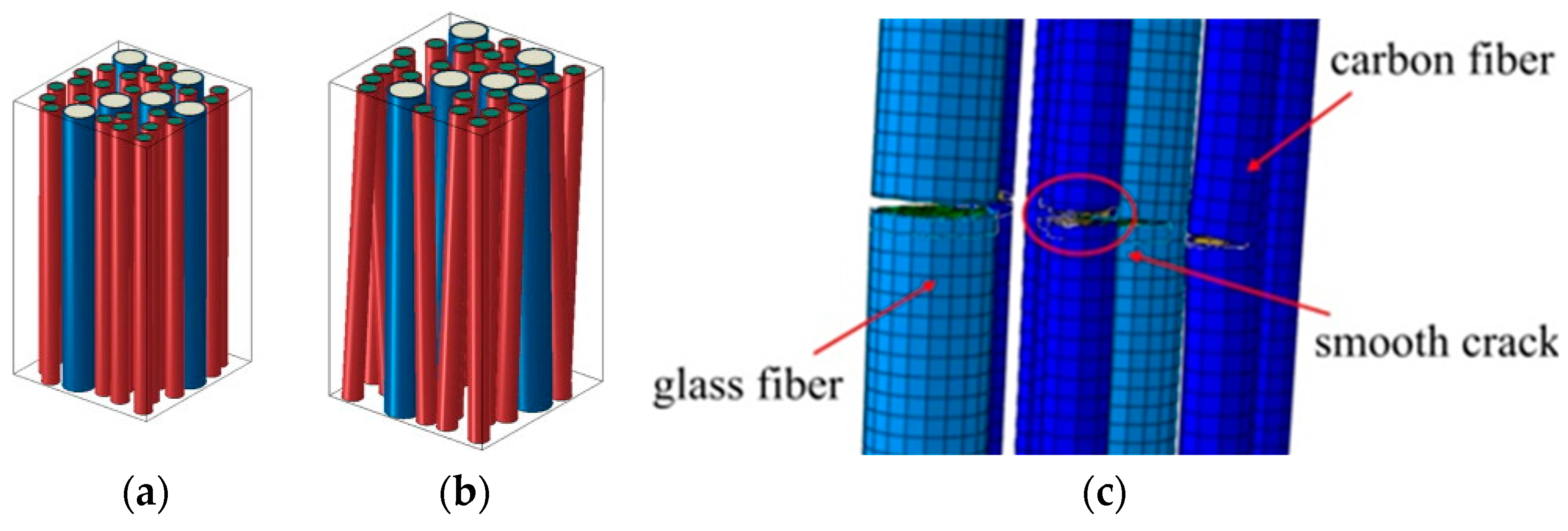

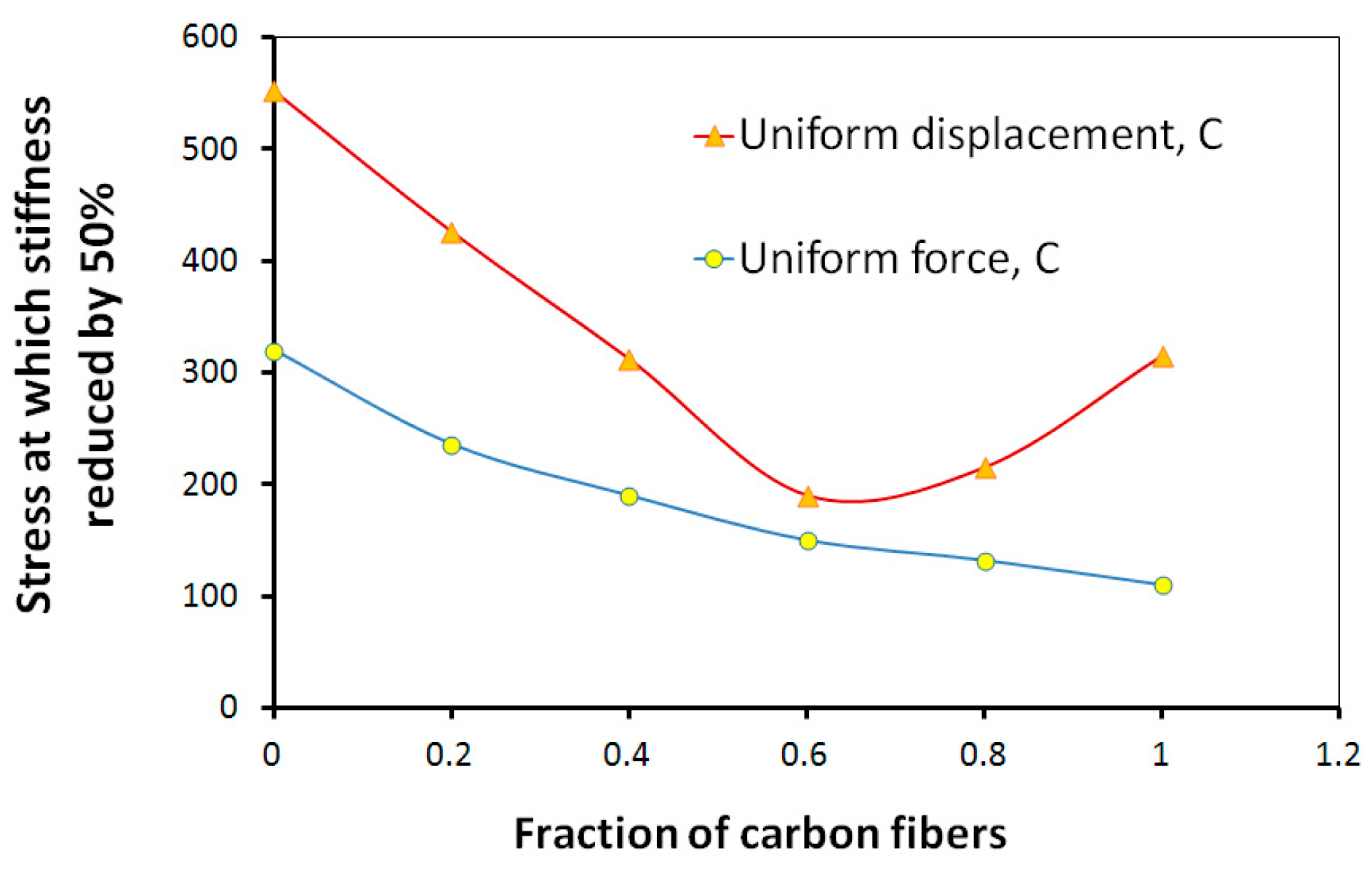

5.1. Modellling of Hybrid Composites

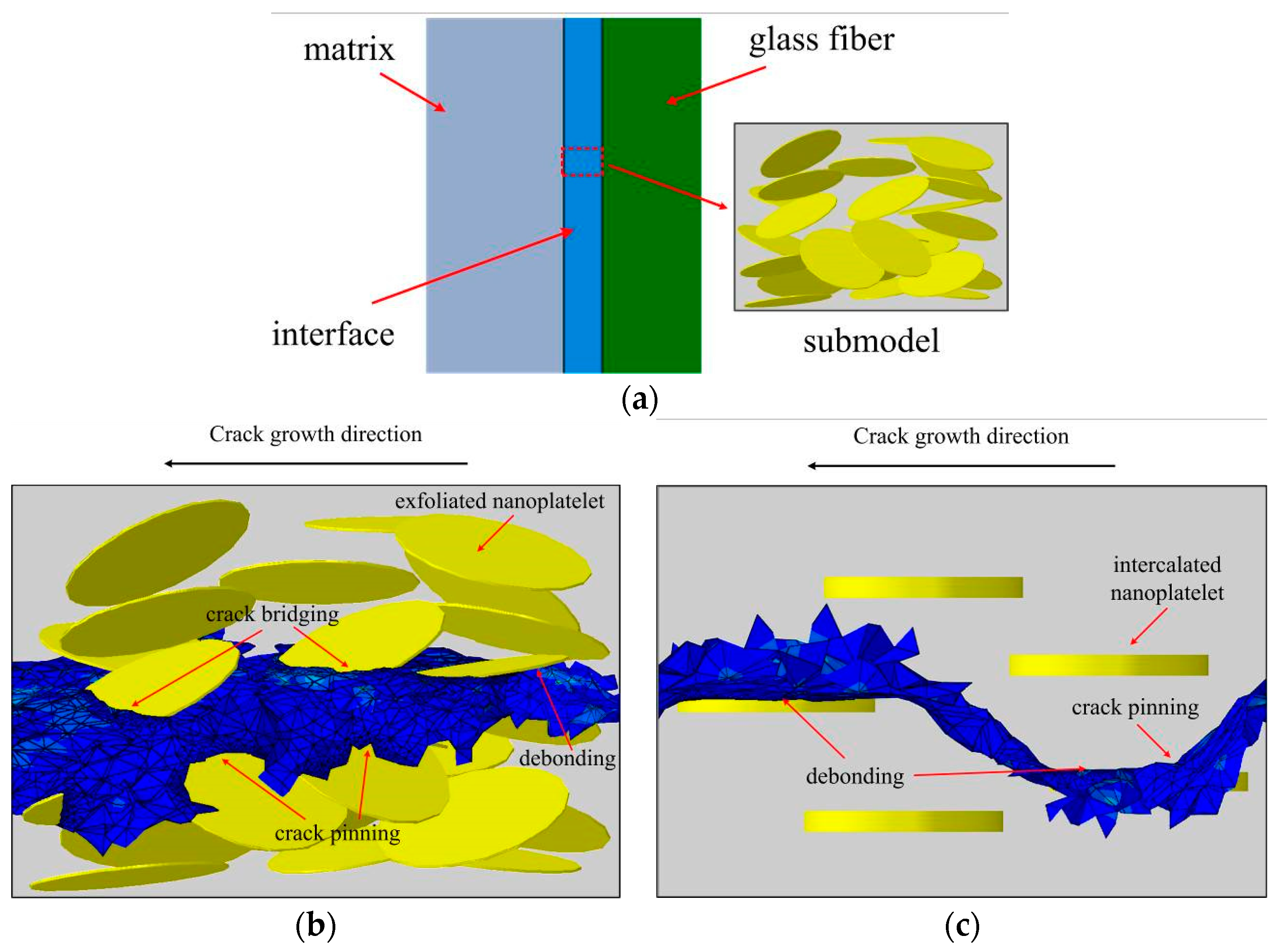

5.2. Nanoengineered Composites

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mishnaevsky, L., Jr.; Brøndsted, P.; Nijssen, R.; Lekou, D.J.; Philippidis, T.P. Materials of large wind turbine blades: Recent results in testing and modelling. Wind Energy 2012, 15, 83–97. [Google Scholar] [CrossRef]

- Veers, P.S.; Butterfield, S. Extreme load estimation for wind turbines: Issues and opportunities for improved practice. In Proceedings of the 2001 ASME Wind Energy Symposium, Reno, NV, USA, 11–14 January 2001. [Google Scholar]

- Del Campo, V.; .Ragni, D.; Micallef, D.; Diez, F.J.; Simão Ferreira, C.J. Estimation of loads on a horizontal axis wind turbine operating in yawed flow conditions. Wind Energy 2015, 18, 1875–1891. [Google Scholar] [CrossRef]

- Tran, T.T.; Kim, D.H.; Bae, K.S. Extreme Load Estimation for a Large Wind Turbine Using CFD and Unsteady BEM. In Lecture Notes in Computer Science, Proceedings of the Computational Science and Its Applications (ICCSA 2013), Ho Chi Minh City, Vietnam, 24–27 June 2013; Murgante, B., Misra, S., Carlini, M., Torre, C.M., Nguyen, H.-Q., Taniar, D., Apduhan, B.O., Gervasi, O., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 7975. [Google Scholar]

- Muskulus, M. Simplified rotor load models and fatigue damage estimates for offshore wind turbines. Philos. Trans. R. Soc. A 2015, 373. [Google Scholar] [CrossRef] [PubMed]

- Mikkelsen, L.P. A simplified model predicting the weight of the load carrying beam in a wind turbine blade. IOP Conf. Ser. Mater. Sci. Eng. 2016, 139, 012038. [Google Scholar] [CrossRef]

- Blasques, J.P.; Stolpe, M. Multi-material topology optimization of laminated composite beam cross sections. Compos. Struct. 2012, 94, 3278–3289. [Google Scholar] [CrossRef]

- Bak, C.; Zahle, F.; Bitsche, R.; Yde, A.; Henriksen, L.C.; Nataraja, A.; Hansen, M.H. Description of the DTU 10 MW Reference Wind Turbine; DTU Wind Energy Report-I-0092; DTU: Roskilde, Denmark, 2013. [Google Scholar]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 73–79. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Phoenix, S.L. Stress concentrations around multiple fiber breaks in an elastic matrix with local yielding or debonding using quadratic influence superposition. J. Mech. Phys. Solids 1996, 44, 1997–2039. [Google Scholar] [CrossRef]

- Xia, Z.; Curtin, W.A.; Okabe, T. Green’s function vs. shear-lag models of damage and failure in fiber composites. Compos. Sci. Technol. 2002, 62, 1279–1288. [Google Scholar] [CrossRef]

- Ibnabdeljalil, M.; Curtin, W.A. Strength and reliability of fiber-reinforced composites: Localized load-sharing and associated size effects. Int. J. Solids Struct. 1997, 34, 2649–2668. [Google Scholar] [CrossRef]

- Daniels, H.E. The Statistical Theory of the Strength of Bundles of Threads. I. Proc. R. Soc. Lond. A 1945, 183, 405. [Google Scholar] [CrossRef]

- Kun, F.; Zapperi, S.; Herrmann, H.J. Damage in fiber bundle models. Eur. Phys. J. 2000, B17, 269–279. [Google Scholar] [CrossRef]

- Marshall, D.B.; Cox, B.N.; Evans, A.G. The Mechanics of Matrix Cracking in Brittle-Matrix Fiber Composites. Acta Metall. 1985, 33, 2013–2021. [Google Scholar] [CrossRef]

- Budiansky, J.W. Hutchinson and A.G. Evans, Matrix fracture in fiber-reinforced ceramics. J. Mech. Phys. Solids 1986, 34, 167–189. [Google Scholar] [CrossRef]

- McCartney, L.N. Mechanics of matrix cracking in brittle-matrix fiber-reinforced composites. Proc. R. Soc. Lond. A 1987, 409, 329–350. [Google Scholar] [CrossRef]

- Allen, D.H.; Harris, C.E.; Groves, S.E. A thermomechanical constitutive theory for elastic composites with distributed damage-1, theoretical development. Int. J. Solids Struct. 1987, 23, 1301–1318. [Google Scholar] [CrossRef]

- Burr, A.; Hild, F.; Leckie, F. Continuum description of damage in ceramic-matrix composites. Eur. J. Mech. A/Solids 1997, 16, 53–78. [Google Scholar]

- Brockenborough, J.R.; Suresh, S.; Wienecke, H.A. Deformation of metal-matrix composites with continuous fibers: Geometrical effects of fiber distribution and shape. Acta Metall. Mater. 1991, 39, 735–752. [Google Scholar] [CrossRef]

- Böhm, H.J.; Rammerstorfer, F.G. Micromechanical models for investigating fibre arrangements in MMC’s. In Proceedings of the International Seminar on Micromechanics of Materials (MECAMAT), Fontainebleau, France, 6–8 July 1993; pp. 383–394. [Google Scholar]

- Babuška, I.; Andersson, B.; Smith, P.J.; Levinb, K. Damage analysis of fiber composites Part I: Statistical analysis on fiber scale. Comput. Methods Appl. Mech. Eng. 1999, 172, 27–77. [Google Scholar] [CrossRef]

- Gonzalez, C.; LLorca, J. Multiscale modeling of fracture in fiber-reinforced composites. Acta Mater. 2006, 54, 4171–4181. [Google Scholar] [CrossRef]

- Asp, L.E.; Berglund, L.A.; Talreja, R. Effects of fiber and interphase on matrixinitiated transverse failure in polymer composites. Compos. Sci. Technol. 1996, 56, 657–665. [Google Scholar] [CrossRef]

- Curtin, W.A. Advances in Applied Mechanics; Book Series; Academic Press: London, UK, 1999; Volume 36, pp. 163–253. [Google Scholar]

- Mishnaevsky, L., Jr.; Brøndsted, P. Micromechanical modeling of damage and fracture of unidirectional fiber reinforced composites: A review. Comput. Mater. Sci. 2009, 44, 1351–1359. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Schmauder, S. Continuum mesomechanical finite element modeling in materials development: A state-of-the-art review. Appl. Mech. Rev. 2001, 54, 49–69. [Google Scholar] [CrossRef]

- Qian, C. Multi-Scale Modelling of Fatigue of Wind Turbine Rotor Blade Composites. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2013. [Google Scholar]

- Mishnaevsky, L., Jr.; Brøndsted, P. Micromechanisms of damage in unidirectional fiber reinforced composites: 3D computational analysis. Compos. Sci. Technol. 2009, 69, 1036–1044. [Google Scholar] [CrossRef]

- Llorca, J.; Gonzalez, C. Microstructural factors controlling the strength and ductility of particle reinfoced metal matrix composites. J. Mech. Phys. Solids 1998, 46, 1–28. [Google Scholar] [CrossRef]

- Mikkelsen, L.P.; Emerson, M.J.; Jespersen, K.M.; Dahlv, A.; Conradsen, K.; Dahl, A.B. X-ray Based Micromechanical Finite Element Modeling Of Composite Materials. In Proceedings of the 29th Nordic Seminar on Computational Mechanics (NSCM-29), Göteborg, Sweden, 26–28 October 2016; Larsson, R., Ed.; Volume 244480. [Google Scholar]

- Emerson, M.J.; Jespersen, K.M.; Dahl, A.B.; Conradsen, K.; Mikkelsen, L.P. Individual fibre segmentation from 3D X-ray computed tomography to study the misalignment in unidirectional composite materials. Compos. Part A Appl. Sci. Manuf. 2017, 97, 83–92. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Zhou, H.W.; Yi, H.Y.; Gui, L.L.; Peng, R.D.; Wang, H.W. Microscale damage mechanisms and degradation of fiber reinforced composites for wind energy applications: Results of Danish-Chinese collaborative investigations. J. Compos. Mater. 2014, 48, 2977–2991. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Brøndsted, P. Statistical modelling of compression and fatigue damage of unidirectional fiber reinforced composites. Compos. Sci. Technol. 2009, 69, 477–484. [Google Scholar] [CrossRef]

- Manikarnika, K. Compression Strength of Wrinkled Composite Laminate. DTU Wind Energy-M-0068. Master’s Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, August 2016. [Google Scholar]

- Sørensen, K.D.; Mikkelsen, L.P.; Jensen, H.M. User subroutine for compressive failure of composites. In Proceedings of the 2009 Simulia Customer Conference, London, UK, 18–21 May 2009; pp. 618–632. [Google Scholar]

- Gautheron, E. Prediction of the Compression Strength of Composite Materials with Local Wrinkles. DTU Wind Energy-M-0145. Master’s Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, June 2017. [Google Scholar]

- Ong, C.-H.; Tsai, S.W. The Use of Carbon Fibers in Wind Turbine Blade Design: A SERI-8 Blade Example SAND2000-0478; Sandia National Laboratories Contractor Report; Sandia: Albuquerque, NM, USA, 2000. [Google Scholar]

- Chiang, M.Y.M.; Wang, X.F.; Schultheisz, C.R.; He, J.M. Prediction and three-dimensional Monte-Carlo simulation for tensile properties of unidirectional hybrid composites. Compos. Sci. Technol. 2005, 65, 1719–1727. [Google Scholar] [CrossRef]

- Gutans, J.; Tamuzs, V. Strength probability of unidirectional hybrid composites. Theor. Appl. Fract. Mech. 1987, 7, 193–200. [Google Scholar] [CrossRef]

- Yao, L.N.; Chou, T.W. Analysis of hybrid effect in unidirectional composites under longitudinal compression. Compos. Struct. 1989, 12, 27–37. [Google Scholar] [CrossRef]

- Summerscales, J.; Short, D. Carbon fibre and glass fibre hybrid reinforced plastics. Composites 1978, 9, 157–166. [Google Scholar] [CrossRef]

- Sonparote, P.W.; Lakkad, S.C. Mechanical properties of carbon/glass fibre reinforced hybrids. Fibre Sci. Technol. 1982, 16, 309–312. [Google Scholar] [CrossRef]

- Brune, D.A.; Bicerano, J. Micromechanics of nanocomposites: Comparison of tensile and compressive elastic moduli, and prediction of effects of incomplete exfoliation and imperfect alignment on modulus. Polymer 2002, 43, 369–387. [Google Scholar] [CrossRef]

- Fornes, T.D.; Paul, D.R. Modeling properties of nylon 6/clay nanocomposites using composite theories. Polymer 2003, 44, 4993–5013. [Google Scholar] [CrossRef]

- Luo, J.J.; Daniel, I.M. Characterization and modeling of mechanical behavior of polymer/clay nanocomposites. Compos. Sci. Technol. 2003, 63, 1607–1616. [Google Scholar] [CrossRef]

- Li, K.; Saigal, S. Micromechanical modeling of stress transfer in carbon nanotube reinforced polymer composites. Mater. Sci. Eng. A 2007, 457, 44–57. [Google Scholar] [CrossRef]

- Park, J.Y.; Fay, T.A.; Sullivan, P.S. Mathematical Modeling of Nanocomposite Properties Considering Nanoclay/Epoxy Debonding. J. Reinf. Plast. Compos. 2010, 29, 1230–1247. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Rafiee, R. Prediction of Young’s modulus of graphene sheets and carbon nanotubes using nanoscale continuum mechanics approach. Mater. Des. 2010, 31, 790–795. [Google Scholar] [CrossRef]

- Ashrafi, B.; Hubert, P. Modeling the elastic properties of carbon nanotube array/polymer composites. Compos. Sci. Technol. 2006, 66, 387–396. [Google Scholar] [CrossRef]

- Tsai, J.; Sun, C.T. Effect of platelet dispersion on the load transfer efficiency in nanoclay composites. J. Compos. Mater. 2004, 38, 567–579. [Google Scholar] [CrossRef]

- Odegard, G.M.; Gates, T.S.; Wise, K.E.; Park, C.; Siochi, E.J. Constitutive modeling of nanotube–reinforced polymer composites. Compos. Sci. Technol. 2003, 63, 1671–1687. [Google Scholar] [CrossRef]

- Sheng, N.; Boyce, M.C.; Parks, D.M.; Rutledge, G.C.; Abes, J.I.; Cohen, R.E. Multiscale micromechanical modeling of polymer/clay nanocomposites and the effective clay particle. Polymer 2004, 45, 487–506. [Google Scholar] [CrossRef]

- De Villoria, R.G.; Miravete, A. Mechanical model to evaluate the effect of the dispersion in nanocomposites. Acta Mater. 2007, 55, 3025–3031. [Google Scholar] [CrossRef]

- Xu, W.; Zeng, Q.; Yu, A.; Paul, D.R. Determination of Interphase Thickness and Mechanical Properties of Effective Nanofillers in Polymer Nanocomposites by Molecular Dynamic Simulation. Mater. Sci. Forum 2010, 654–656, 1654–1657. [Google Scholar] [CrossRef]

- Adam, L.; Delaere, K.; Kaszacs, M.; Gerard, J.S.; Assaker, R.; Doghri, I. Multi-Scale Modeling of Polymer Nanocomposites. In Proceedings of the Nanotech Conference & Expo 2009, Nanotechnology 2009: Life Sciences, Medicine, Diagnostics, Biomaterials and Composites, Houston, TX, USA, 3–7 May 2009; Volume 2, pp. 515–518. [Google Scholar]

- Mishnaevsky, L., Jr.; Dai, G.M. Hybrid carbon/glass fiber composites: Micromechanical analysis of structure-damage resistance relationship. Comput. Mater. Sci. 2014, 81, 630–640. [Google Scholar] [CrossRef]

- Dai, G.M.; Mishnaevsky, L., Jr. Fatigue of hybrid carbon/glass composites: 3D Computational modelling. Compos. Sci. Technol. 2014, 94, 71–79. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Pontefisso, A.; Dai, G. Hierarchical nanoreinforced composites: Computational analysis of damage mechanisms. In Proceedings of the 37th Risø Symposium Understanding Performance of Composite Materials, Roskilde, Denmark, 5–8 September 2016. [Google Scholar]

- Prabhakaran, D.; Andersen, T.L.; Markussen, C.M.; Madsen, B.; Lilholt, H. Tensile and compression properties of hybrid composites—A comparative study. In Proceedings of the 19th International Conference on Composite Materials (ICCM19), Montréal, QC, Canada, 28 July–2 August 2013; pp. 1029–1035. [Google Scholar]

- Mishnaevsky, L., Jr. Nanostructured interfaces for enhancing mechanical properties of materials: Computational micromechanical studies. Compos. Part B 2015, 68, 75–84. [Google Scholar] [CrossRef]

- Dai, G.M.; Mishnaevsky, L., Jr. Carbone nanotube reinforced hybrid composites: Computational modelling of environmental fatigue and their usability for wind blades. Compos. B 2015, 78, 349–360. [Google Scholar] [CrossRef]

- Peng, R.D.; Zhou, H.W.; Wang, H.W.; Mishnaevsky, L., Jr. Modeling of nano-reinforced polymer composites: Microstructure effect on the Young’s modulus. Comput. Mater. Sci. 2012, 60, 19–31. [Google Scholar] [CrossRef]

- Dai, G.M.; Mishnaevsky, L., Jr. Graphene monolayer nanocomposites: 3D simulation of damage and fracture. Comput. Mater. Sci. 2014, 95, 684–692. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Dai, G. Hybrid and hierarchical nanoreinforced polymer composites: Computational modelling of structure-properties relationships. Compos. Struct. 2014, 117, 156–168. [Google Scholar] [CrossRef]

- Dai, G.M.; Mishnaevsky, L., Jr. Fatigue of multiscale composites with secondary nanoplatelet reinforcement: 3D computational analysis. Compos. Sci. Technol. 2014, 91, 71–81. [Google Scholar] [CrossRef]

- Pontenfisso, A.; Mishnaevsky, L., Jr. Nanomorphology of graphene and CNT reinforced polymer and its effect on damage: Micromechanical numerical study. Compos. Part B 2016, 96, 338–349. [Google Scholar] [CrossRef]

| Bundle | Number of Fibers | Average Fiber Diameter | Total Bundle Area | Total Fiber Area | Local Fiber Volume Fraction | Estimate Tex-Value |

|---|---|---|---|---|---|---|

| 0° | 5954 | 15.8 µm | 1.926 mm2 | 1.197 mm2 | 0.62 | 3113 |

| 45° | 794 | 14.9 µm | 0.245 mm2 | 0.142 mm2 | 0.58 | 369 |

| 90° | 375 | 15.4 µm | 0.125 mm2 | 0.071 mm2 | 0.57 | 185 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikkelsen, L.P.; Mishnaevsky Jr., L. Computational Modelling of Materials for Wind Turbine Blades: Selected DTU Wind Energy Activities. Materials 2017, 10, 1278. https://doi.org/10.3390/ma10111278

Mikkelsen LP, Mishnaevsky Jr. L. Computational Modelling of Materials for Wind Turbine Blades: Selected DTU Wind Energy Activities. Materials. 2017; 10(11):1278. https://doi.org/10.3390/ma10111278

Chicago/Turabian StyleMikkelsen, Lars Pilgaard, and Leon Mishnaevsky Jr. 2017. "Computational Modelling of Materials for Wind Turbine Blades: Selected DTU Wind Energy Activities" Materials 10, no. 11: 1278. https://doi.org/10.3390/ma10111278

APA StyleMikkelsen, L. P., & Mishnaevsky Jr., L. (2017). Computational Modelling of Materials for Wind Turbine Blades: Selected DTU Wind Energy Activities. Materials, 10(11), 1278. https://doi.org/10.3390/ma10111278