Exploiting Process-Related Advantages of Selective Laser Melting for the Production of High-Manganese Steel

Abstract

:1. Introduction

2. Experimental Procedure

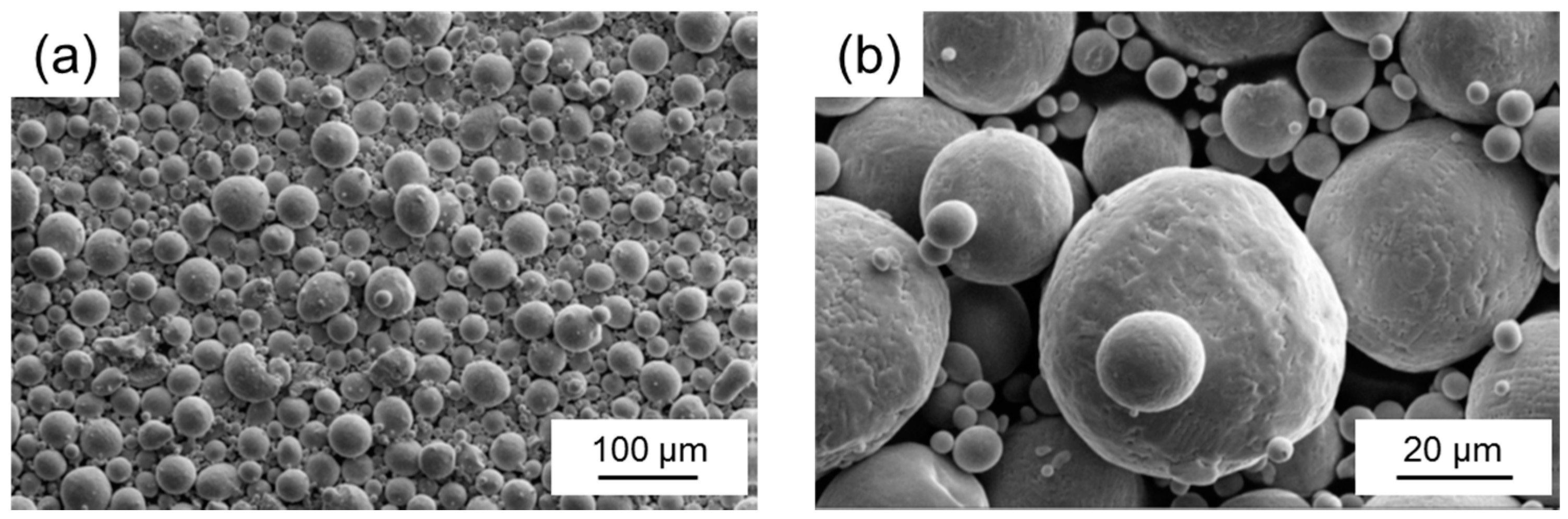

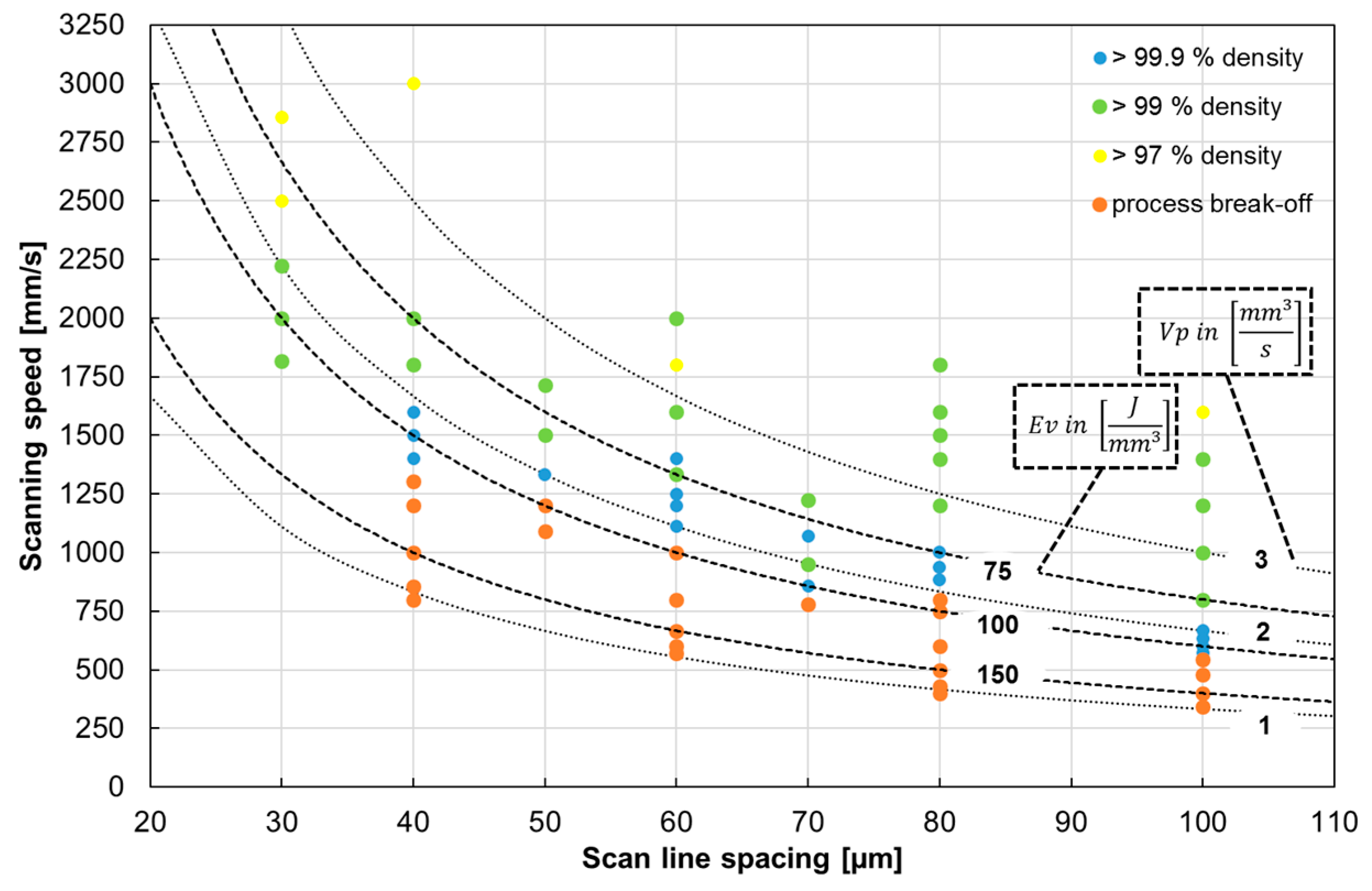

2.1. Material Chemistry and Processing

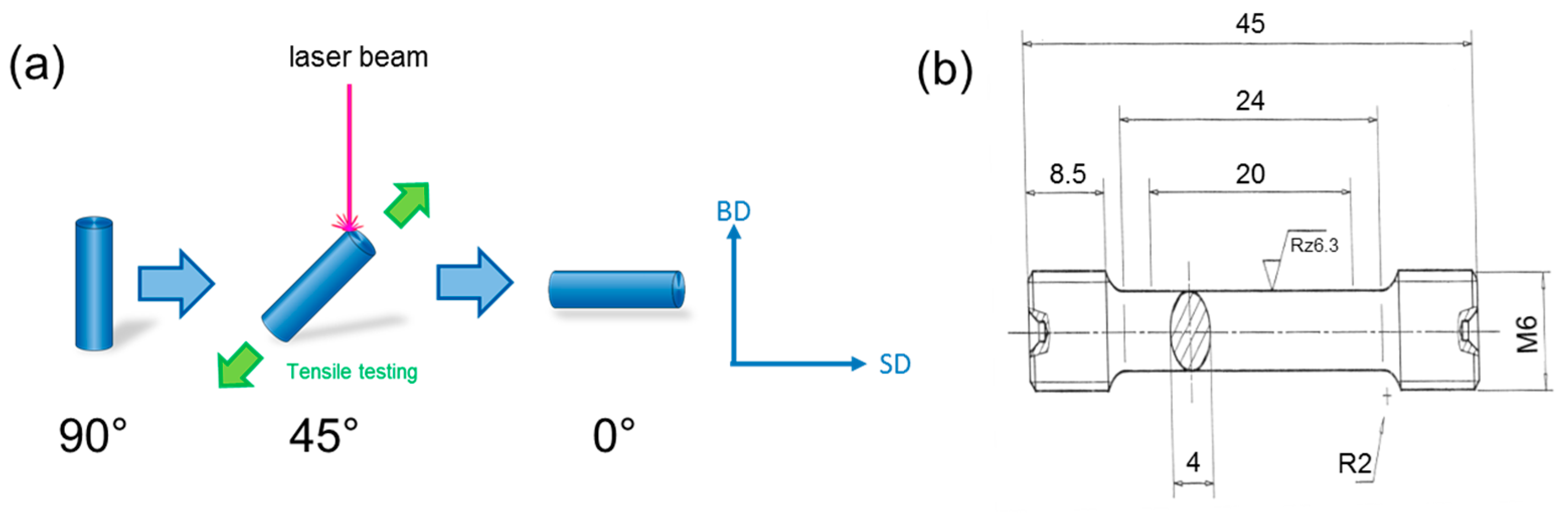

2.2. Specimens and Characterization Techniques

3. Results and Discussion

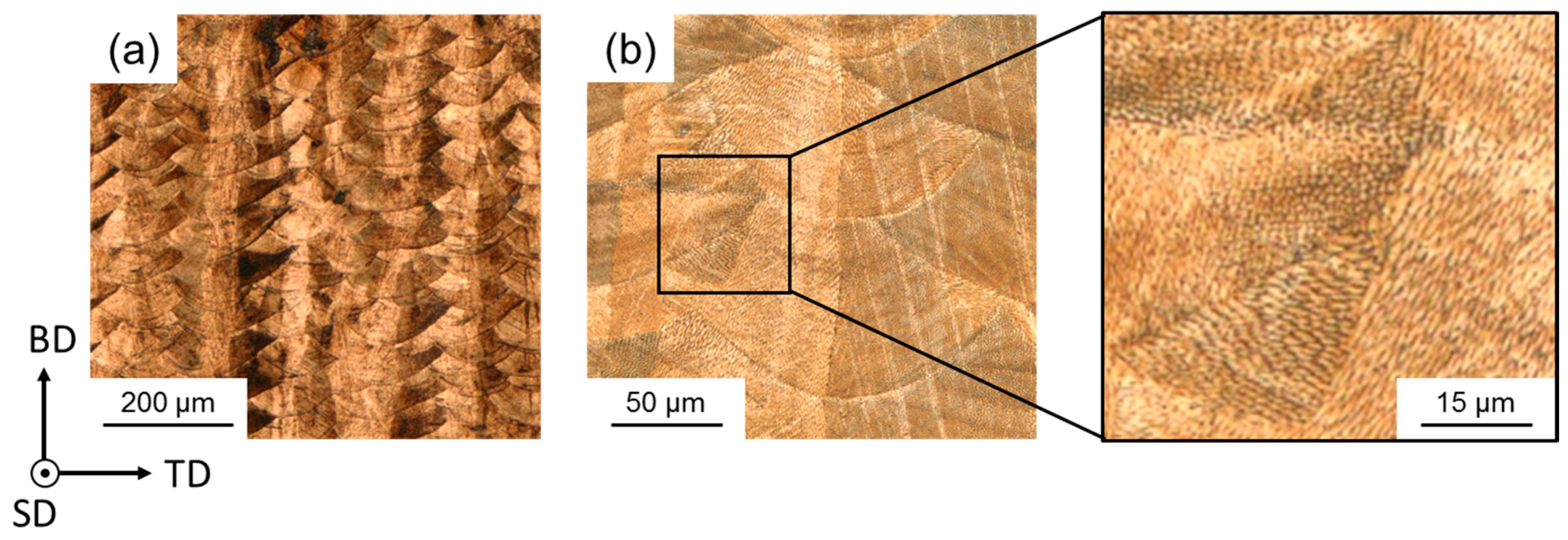

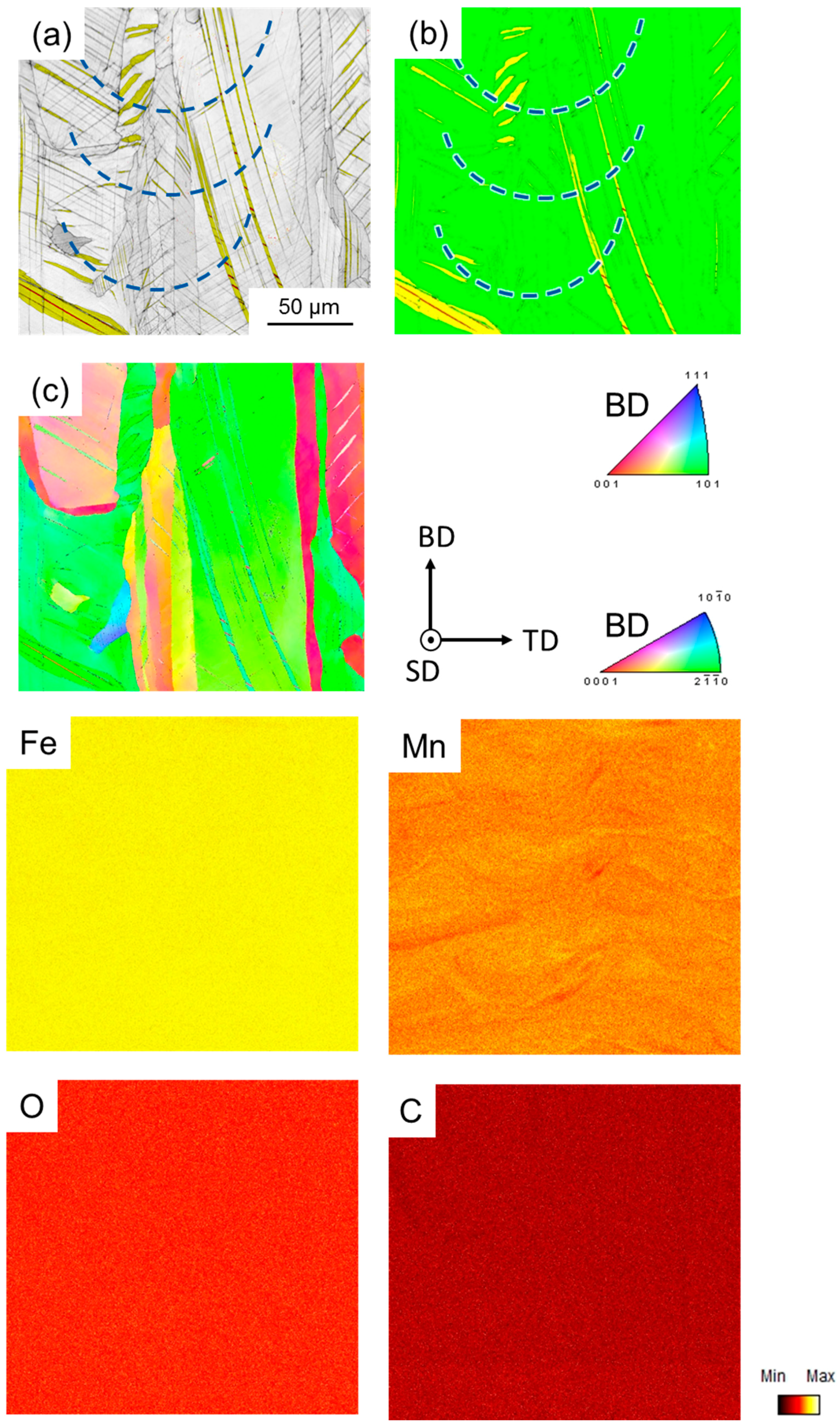

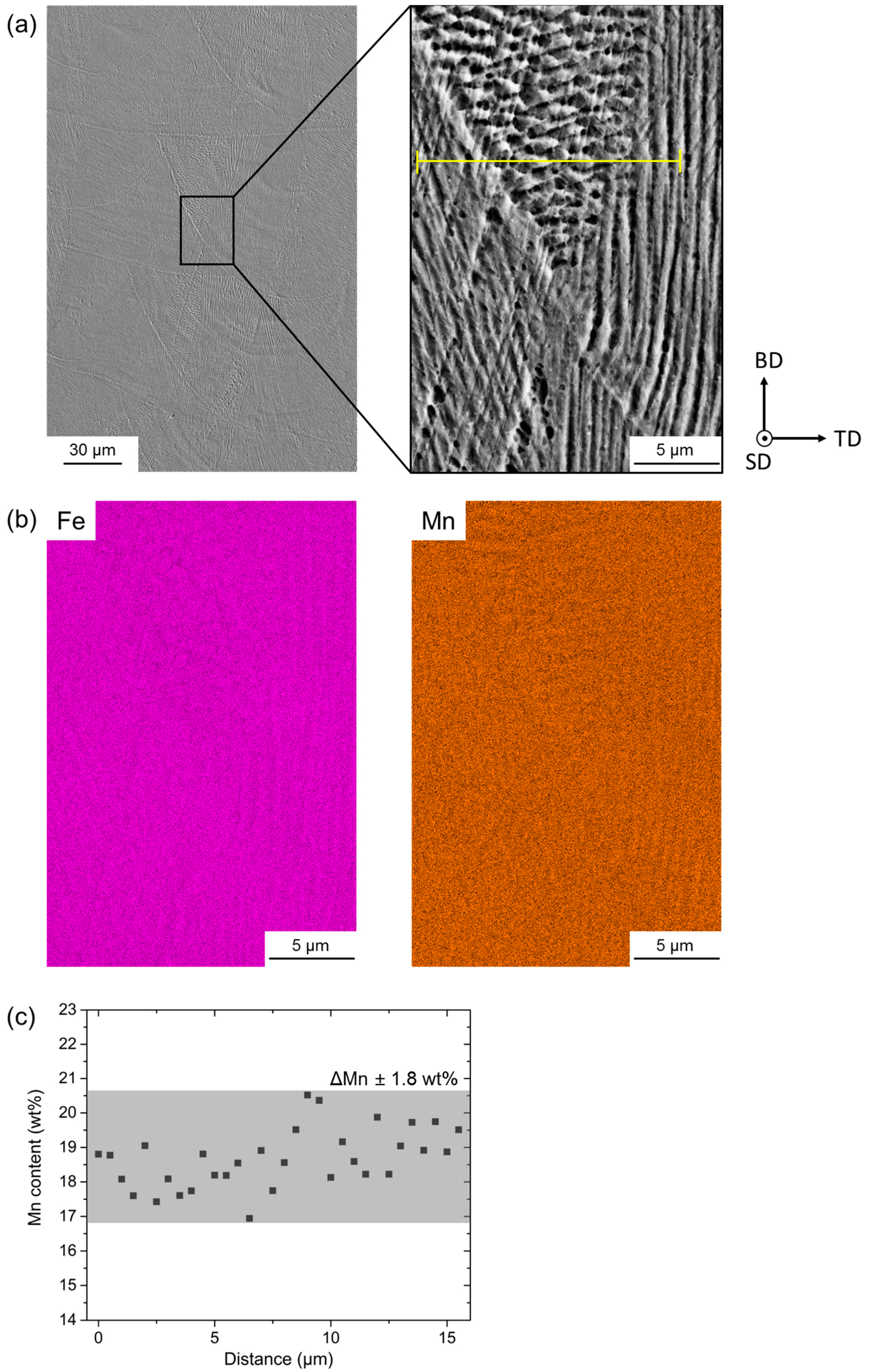

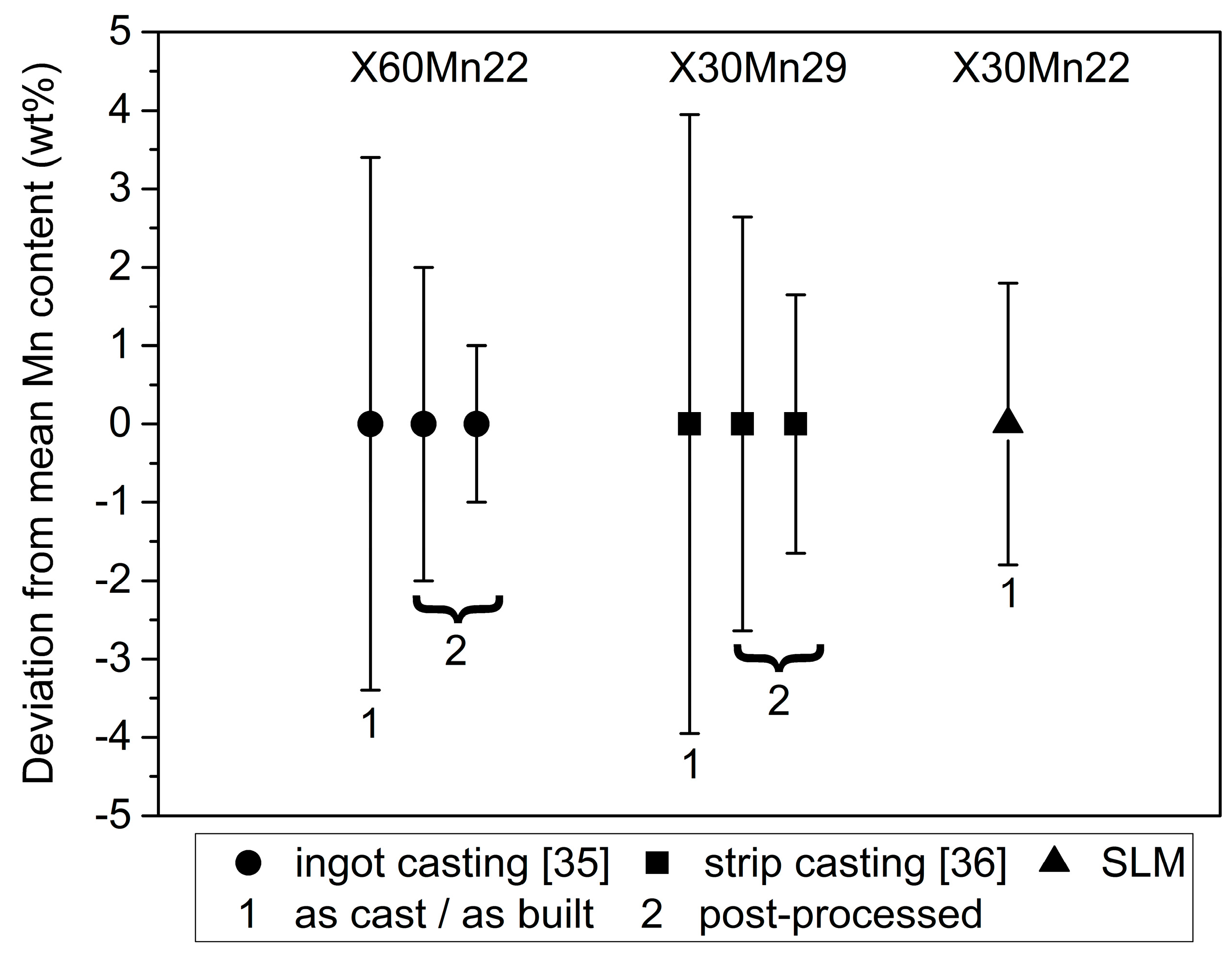

3.1. Solidification Behavior

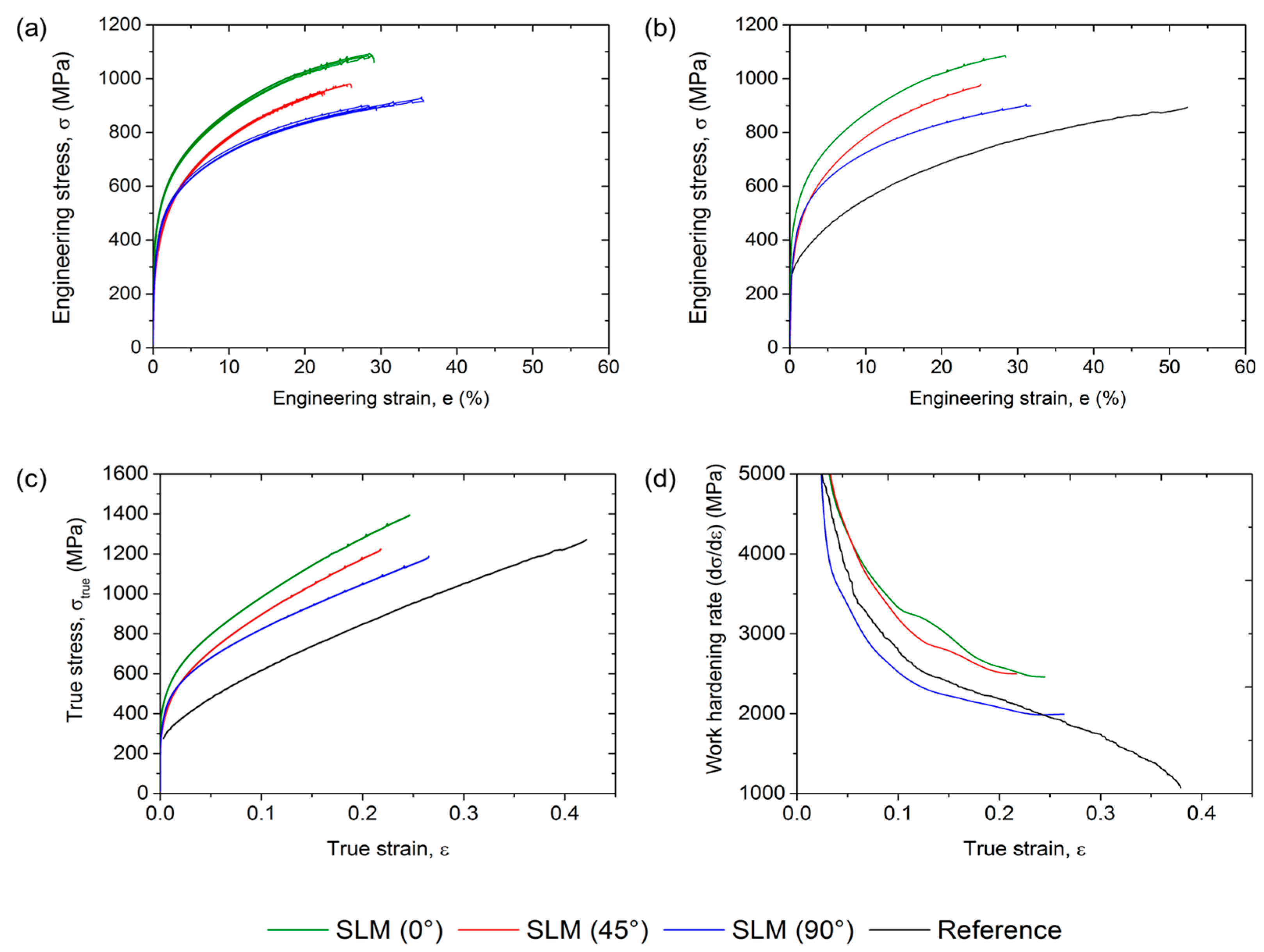

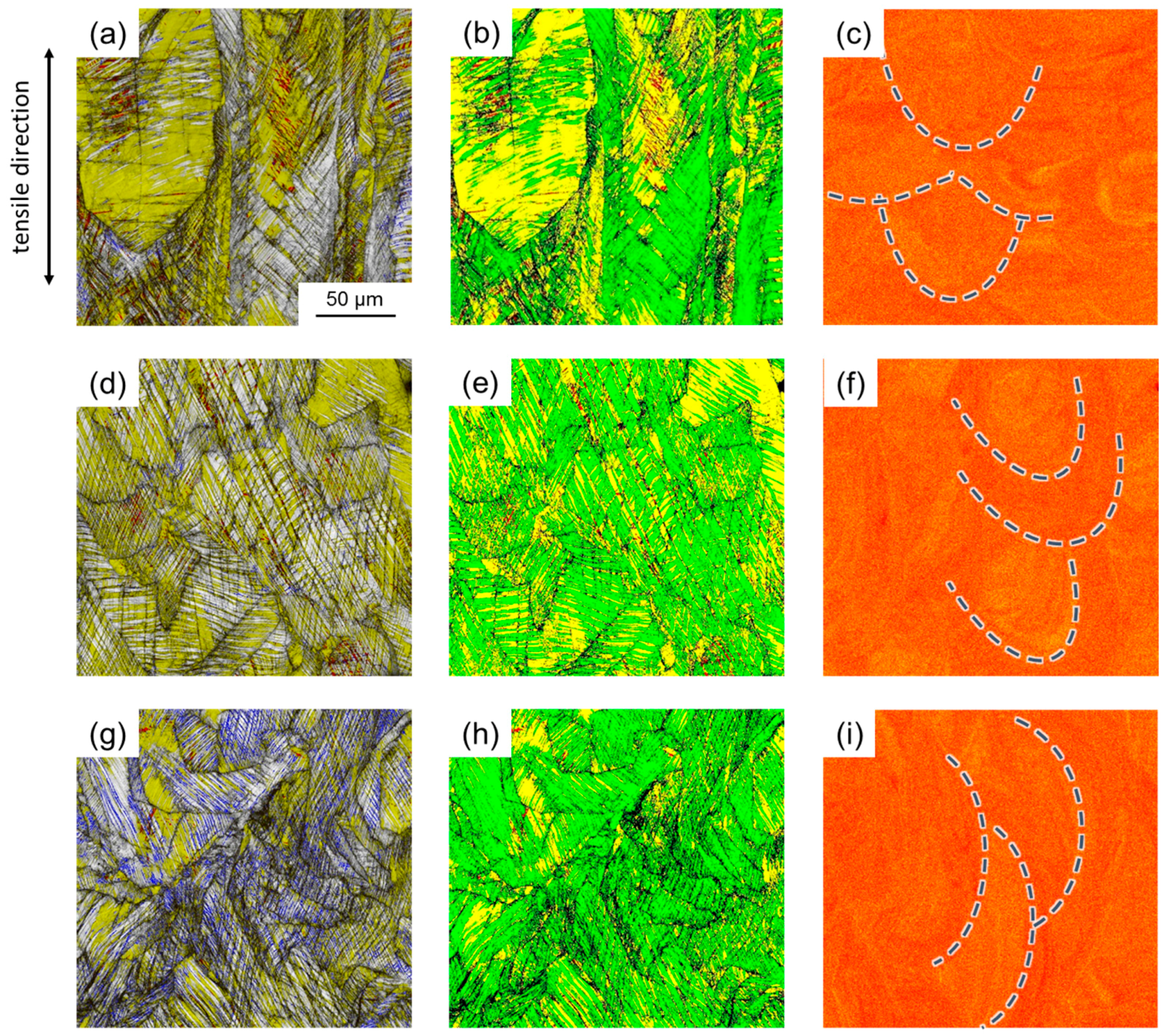

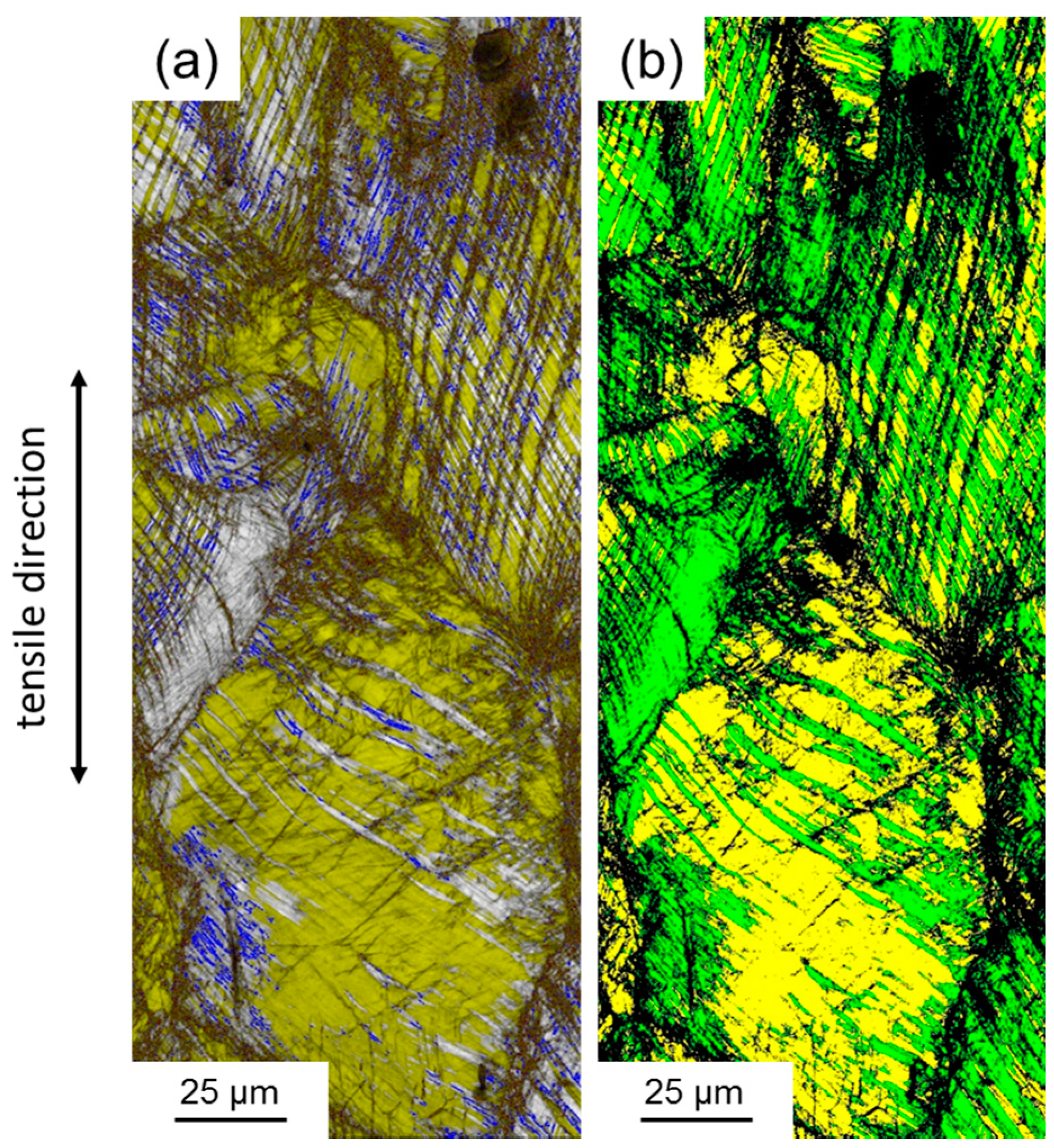

3.2. Deformation Behavior

4. Conclusions

- The high cooling rates that are associated with the SLM process facilitated the production of HMnS with reduced elemental segregation compared to ingot- and strip-cast material. Therefore, energy-intensive post processing may be avoided and makes HMnS a promising candidate material to ideally use process-specific peculiarities.

- Whereas the orientation of laser-melted tracks was found to have no influence on the material properties, the morphological and crystallographic texture due to directional solidification affected the mechanical behavior significantly. Especially the anisotropy of the grain size and the varying contribution of deformation twinning depending on the angle between scan direction and tensile direction defined the work hardening of the steel.

- The SLM-produced samples obtained superior strength but reduced formability with high reproducibility. As well as in conventionally produced HMnS, TRIP and TWIP effects were activated in the additively manufactured HMnS and allowed for the beneficial work hardening of this class of steels.

- The as-built state already contained ε- and α’-martensite, induced as a result of the very fast cooling during SLM. The initial martensite fraction and dislocation density can be varied depending on the cooling rate and, thus, may be used to tailor the yield strength.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bourell, D.L. Perspectives on Additive Manufacturing. Ann. Rev. Mater. Res. 2016, 46, 1–18. [Google Scholar] [CrossRef]

- Gordon, R.; Harrop, J. 3D Printing Materials 2016–2026: Status, Opportunities, Market Forecasts; IDTechEx: Cambridge, UK, 2016. [Google Scholar]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Ann. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Schleifenbaum, H.; Theis, J.; Meiners, W.; Wissenbach, K.; Diatlov, A.; Bültmann, J.; Voswinckel, H. High Power Selective Laser Melting (HP SLM)—Upscaling the Productivity of Additive Metal Manufacturing towards Factor 10. In Proceedings of the 2010 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010; Bourell, D.L., Ed.; pp. 216–229.

- Niendorf, T.; Brenne, F. Steel showing twinning-induced plasticity processed by selective laser melting—An additively manufactured high performance material. Mater. Charact. 2013, 85, 57–63. [Google Scholar] [CrossRef]

- Niendorf, T.; Brenne, F.; Hoyer, P.; Schwarze, D.; Schaper, M.; Grothe, R.; Wiesener, M.; Grundmeier, G.; Maier, H.J. Processing of New Materials by Additive Manufacturing: Iron-Based Alloys Containing Silver for Biomedical Applications. Metall. Mater. Trans. A 2015, 46, 2829–2833. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Chin, K.G.; Kim, J. High Mn TWIP Steels for Automotive Applications. In New Trends and Developments in Automotive System Engineering; Chiaberge, M., Ed.; InTech: Rijeka, Croatia, 2011; pp. 101–128. [Google Scholar]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the Calculated Stacking Fault Energy and the Plasticity Mechanisms in Fe–Mn–C Alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Sato, K.; Ichinose, M.; Hirotsu, Y.; Inoue, Y. Effects of Deformation Induced Phase Transformation and Twinning on the Mechanical Properties of Austenitic Fe-Mn-Al Alloys. ISIJ Int. 1989, 29, 868–877. [Google Scholar] [CrossRef]

- Grässel, O.; Frommeyer, G.; Derder, C.; Hofmann, H. Phase Transformations and Mechanical Properties of Fe-Mn-Si-Al TRIP-Steels. J. Phys. 1997, 7, 383–388. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High Manganese Austenitic Twinning Induced Plasticity Steels: A Review of the Microstructure Properties Relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Haase, C.; Barrales-Mora, L.A.; Molodov, D.A.; Gottstein, G. Tailoring the Mechanical Properties of a Twinning-Induced Plasticity Steel by Retention of Deformation Twins During Heat Treatment. Metall. Mater. Trans. A 2013, 44, 4445–4449. [Google Scholar] [CrossRef]

- Haase, C.; Barrales-Mora, L.A.; Roters, F.; Molodov, D.A.; Gottstein, G. Applying the Texture Analysis for Optimizing Thermomechanical Treatment of High Manganese Twinning-Induced Plasticity Steel. Acta Mater. 2014, 80, 327–340. [Google Scholar] [CrossRef]

- Haase, C.; Kremer, O.; Hu, W.; Ingendahl, T.; Lapovok, R.; Molodov, D.A. Equal-channel angular pressing and annealing of a twinning-induced plasticity steel: Microstructure, texture, and mechanical properties. Acta Mater. 2016, 107, 239–253. [Google Scholar] [CrossRef]

- Haase, C.; Zehnder, C.; Ingendahl, T.; Bikar, A.; Tang, F.; Hallstedt, B.; Hu, W.; Bleck, W.; Molodov, D.A. On the deformation behavior of κ -carbide-free and κ -carbide-containing high-Mn lightweight steel. Acta Mater. 2017, 122, 332–343. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mosecker, L.; Schwedt, A.; Bleck, W. Characterization and Prediction of Flow Behavior in High-Manganese Twinning Induced Plasticity Steels: Part I. Mechanism Maps and Work-Hardening Behavior. Metall. Mater. Trans. A 2011, 43, 1688–1704. [Google Scholar] [CrossRef]

- Field, D.P. Recent advances in the application of orientation imaging. Ultramicroscopy 1997, 67, 1–9. [Google Scholar] [CrossRef]

- Glicksman, M.E. Rapid Solidification Processing. In Principles of Solidification: An Introduction to Modern Casting and Crystal Growth Concepts; Springer: New York, NY, USA, 2011; pp. 427–446. [Google Scholar]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Yuan, P.; Gu, D. Molten pool behaviour and its physical mechanism during selective laser melting of TiC/AlSi10Mg nanocomposites: Simulation and experiments. J. Phys. D Appl. Phys. 2015, 48, 035303. [Google Scholar] [CrossRef]

- Collins, P.C.; Brice, D.A.; Samimi, P.; Ghamarian, I.; Fraser, H.L. Microstructural Control of Additively Manufactured Metallic Materials. Ann. Rev. Mater. Res. 2016, 46, 63–91. [Google Scholar] [CrossRef]

- Ferraiuolo, A.; Smith, A.; Sevillano, J.G.; de las Cuevas, F.; Karjalainen, P.; Pratolongo, G.; Gouveia, H.; Rodrigues, M.M. Metallurgical Design of High Strength Austenitic Fe-C-Mn Steels with Excellent Formability (Metaldesign); European Union: Luxembourg, 2012; p. 162. [Google Scholar]

- Li, Y.; Gu, D. Thermal behavior during selective laser melting of commercially pure titanium powder: Numerical simulation and experimental study. Addit. Manuf. 2014, 1–4, 99–109. [Google Scholar] [CrossRef]

- Murr, L.E. Metallurgy of additive manufacturing: Examples from electron beam melting. Addit. Manuf. 2015, 5, 40–53. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Deng, S.; Liao, H.; Coddet, C. Microstructure and tensile properties of iron parts fabricated by selective laser melting. Opt. Laser Technol. 2014, 56, 451–460. [Google Scholar] [CrossRef]

- Humbert, M.; Petit, B.; Bolle, B.; Gey, N. Analysis of the γ–ɛ–α′ variant selection induced by 10% plastic deformation in 304 stainless steel at −60 °C. Mater. Sci. Eng. A 2007, 454–455, 508–517. [Google Scholar] [CrossRef]

- Takaki, S.; Nakatsu, H.; Tokunaga, Y. Effects of Austenite Grain Size on ε Martensitic Transformation in Fe-15mass%Mn Alloy. Mater. Trans. JIM 1993, 34, 489–495. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Choi, C. Driving force for γ→ε martensitic transformation and stacking fault energy of γ in Fe-Mn binary system. Metall. Mater. Trans. A 2000, 31, 355–360. [Google Scholar] [CrossRef]

- Haase, C.; Barrales-Mora, L.A.; Molodov, D.A.; Gottstein, G. Texture Evolution of a Cold-Rolled Fe-28Mn-0.28C TWIP Steel During Recrystallization. Mater. Sci. Forum 2013, 753, 213–216. [Google Scholar] [CrossRef]

- Wietbrock, B.; Bambach, M.; Seuren, S.; Hirt, G. Homogenization Strategy and Material Characterization of High-Manganese TRIP and TWIP Steels. Mater. Sci. Forum 2010, 638–642, 3134–3139. [Google Scholar] [CrossRef]

- Daamen, M.; Haase, C.; Dierdorf, J.; Molodov, D.A.; Hirt, G. Twin-roll strip casting: A competitive alternative for the production of high-manganese steels with advanced mechanical properties. Mater. Sci. Eng. A 2015, 627, 72–81. [Google Scholar] [CrossRef]

- Daamen, M.; Wietbrock, B.; Richter, S.; Hirt, G. Strip Casting of a High-Manganese Steel (FeMn22C0.6) Compared with a Process Chain Consisting of Ingot Casting and Hot Forming. Steel Res. Int. 2011, 82, 70–75. [Google Scholar] [CrossRef]

- Haase, C.; Ingendahl, T.; Güvenç, O.; Bambach, M.; Bleck, W.; Molodov, D.A.; Barrales Mora, L.A. On the Applicability of Recovery-Annealed Twinning-Induced Plasticity Steels: Potential and Limitations. Mater. Sci. Eng. A 2016, 649, 74–84. [Google Scholar] [CrossRef]

- Haase, C.; Kühbach, M.; Barrales-Mora, L.A.; Wong, S.L.; Roters, F.; Molodov, D.A.; Gottstein, G. Recrystallization Behavior of a High-Manganese Steel: Experiments and Simulations. Acta Mater. 2015, 100, 155–168. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly Anisotropic Steel Processed by Selective Laser Melting. Metall. Mater. Trans. B 2013, 44, 794–796. [Google Scholar] [CrossRef]

- Kunze, K.; Etter, T.; Grässlin, J.; Shklover, V. Texture, anisotropy in microstructure and mechanical properties of IN738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2015, 620, 213–222. [Google Scholar] [CrossRef]

- Haase, C.; Chowdhury, S.G.; Barrales-Mora, L.A.; Molodov, D.A.; Gottstein, G. On the Relation of Microstructure and Texture Evolution in an Austenitic Fe-28Mn-0.28C TWIP Steel During Cold Rolling. Metall. Mater. Trans. A 2013, 44, 911–922. [Google Scholar] [CrossRef]

- Byun, T.S. On the Stress Dependence of Partial Dislocation Separation and Deformation Microstructure in Austenitic Stainless Steels. Acta Mater. 2003, 51, 3063–3071. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Dahmoun, D.; Bouaziz, O. Modeling of mechanical twinning in a high manganese content austenitic steel. Mater. Sci. Eng. A 2004, 387–389, 272–276. [Google Scholar] [CrossRef]

| State | Fe | Mn | C | Al | Si | S | P |

|---|---|---|---|---|---|---|---|

| Ingot-cast | bal. | 21.67 | 0.293 | 0.003 | 0.05 | 0.0085 | 0.01 |

| After SLM | bal. | 20.15 | 0.274 | 0.014 | 0.05 | 0.0105 | 0.01 |

| State | YS (MPa) | UTS (MPa) | epl (%) |

|---|---|---|---|

| SLM (0°) | 416 ± 9 | 1085 ± 6 | 27.4 ± 1.2 |

| SLM (45°) | 302 ± 16 | 966 ± 14 | 23.8 ± 1.6 |

| SLM (90°) | 329 ± 3 | 906 ± 11 | 31.2 ± 2.9 |

| Reference | 275 | 894 | 52 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haase, C.; Bültmann, J.; Hof, J.; Ziegler, S.; Bremen, S.; Hinke, C.; Schwedt, A.; Prahl, U.; Bleck, W. Exploiting Process-Related Advantages of Selective Laser Melting for the Production of High-Manganese Steel. Materials 2017, 10, 56. https://doi.org/10.3390/ma10010056

Haase C, Bültmann J, Hof J, Ziegler S, Bremen S, Hinke C, Schwedt A, Prahl U, Bleck W. Exploiting Process-Related Advantages of Selective Laser Melting for the Production of High-Manganese Steel. Materials. 2017; 10(1):56. https://doi.org/10.3390/ma10010056

Chicago/Turabian StyleHaase, Christian, Jan Bültmann, Jan Hof, Stephan Ziegler, Sebastian Bremen, Christian Hinke, Alexander Schwedt, Ulrich Prahl, and Wolfgang Bleck. 2017. "Exploiting Process-Related Advantages of Selective Laser Melting for the Production of High-Manganese Steel" Materials 10, no. 1: 56. https://doi.org/10.3390/ma10010056