Biocompatibility and Inflammatory Potential of Titanium Alloys Cultivated with Human Osteoblasts, Fibroblasts and Macrophages

Abstract

:1. Introduction

2. Materials and Methods

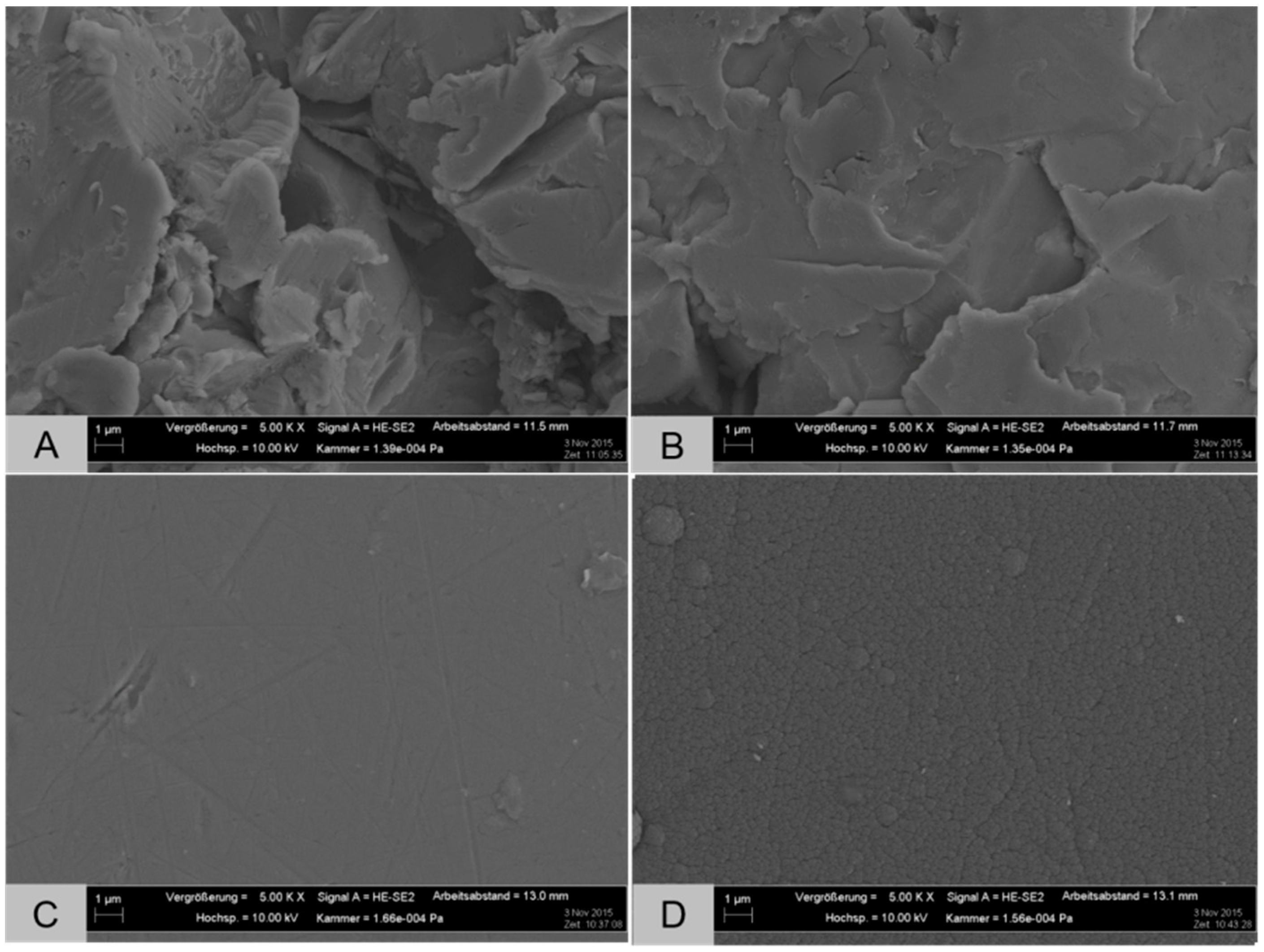

2.1. Test Samples

2.2. Cell Isolation

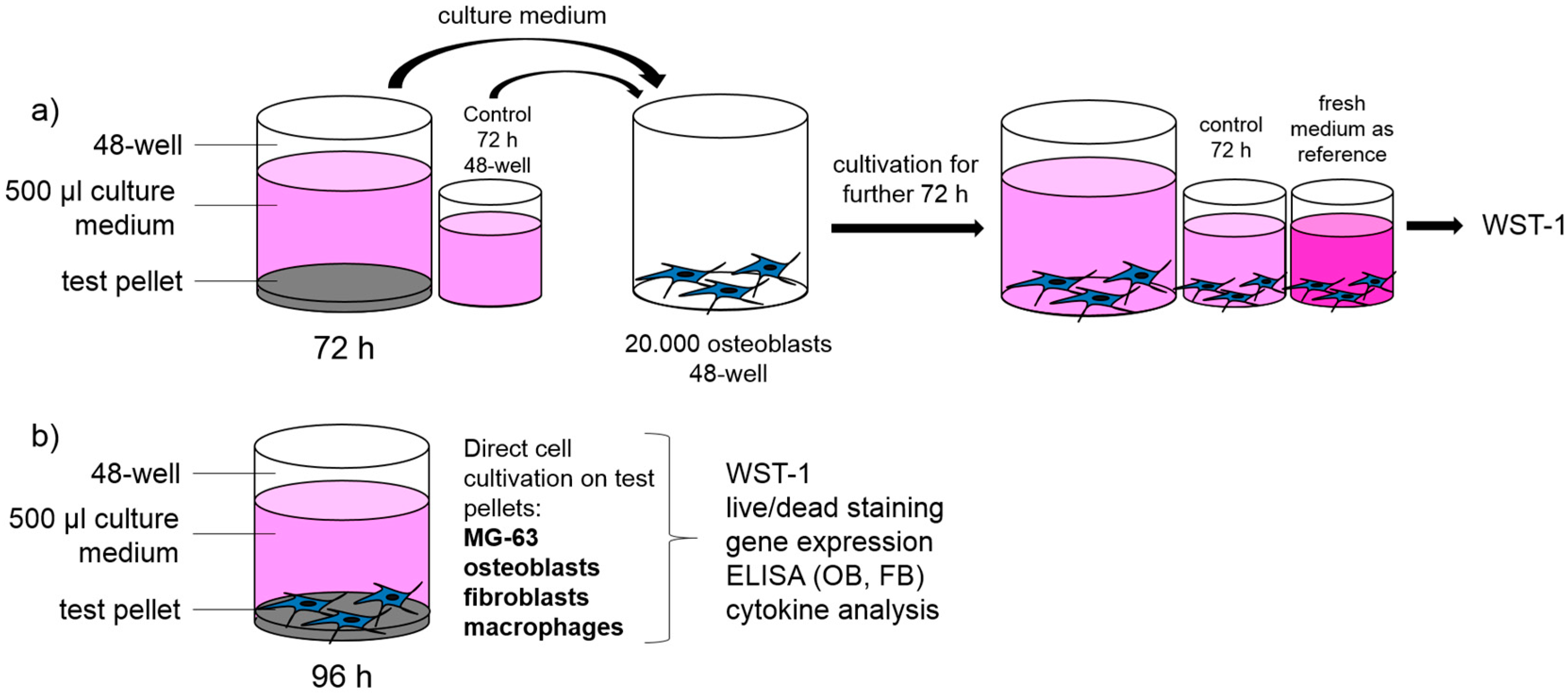

2.3. Cell Biological Testing

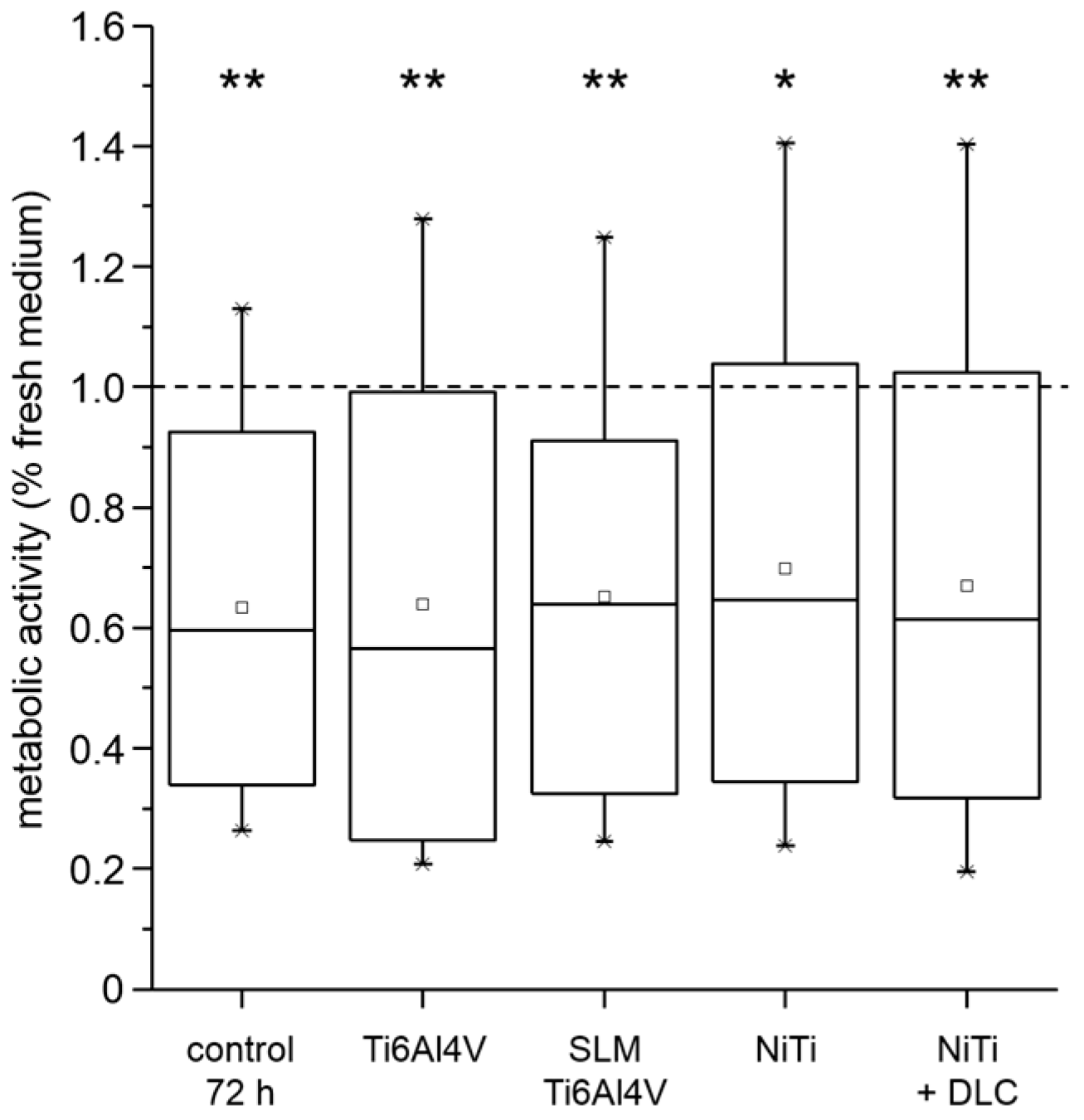

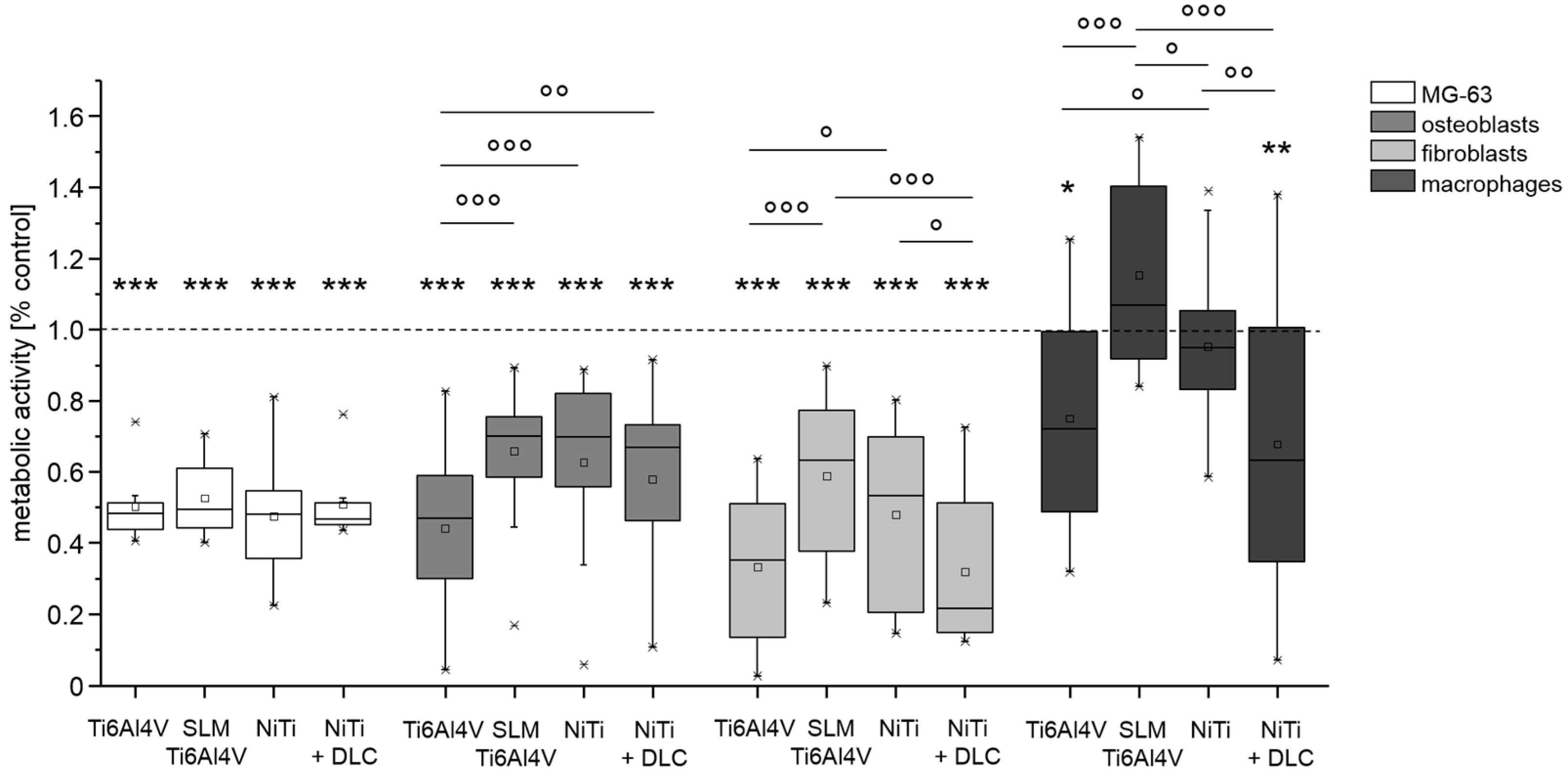

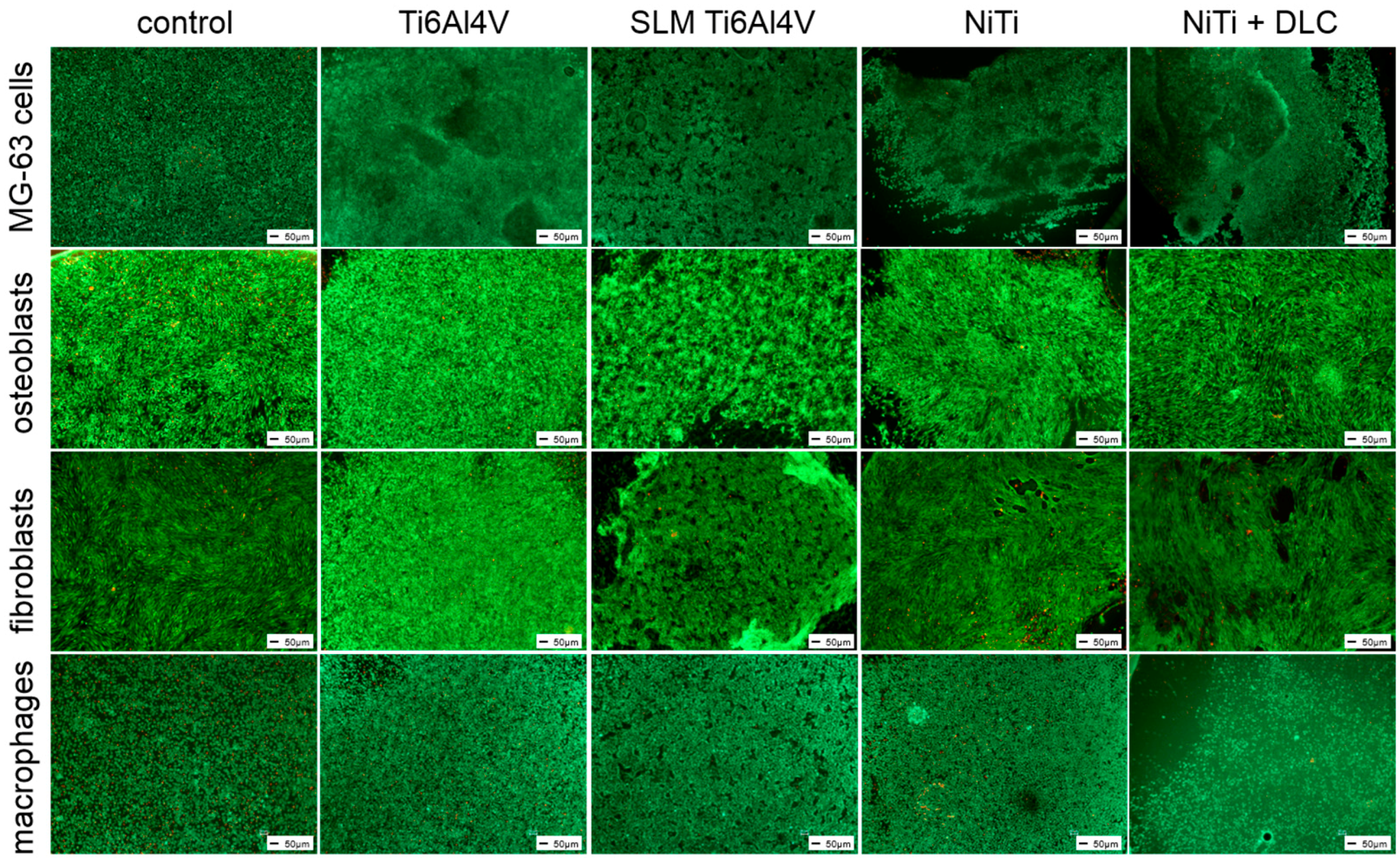

2.3.1. Metabolic Activity and Live/Dead Staining

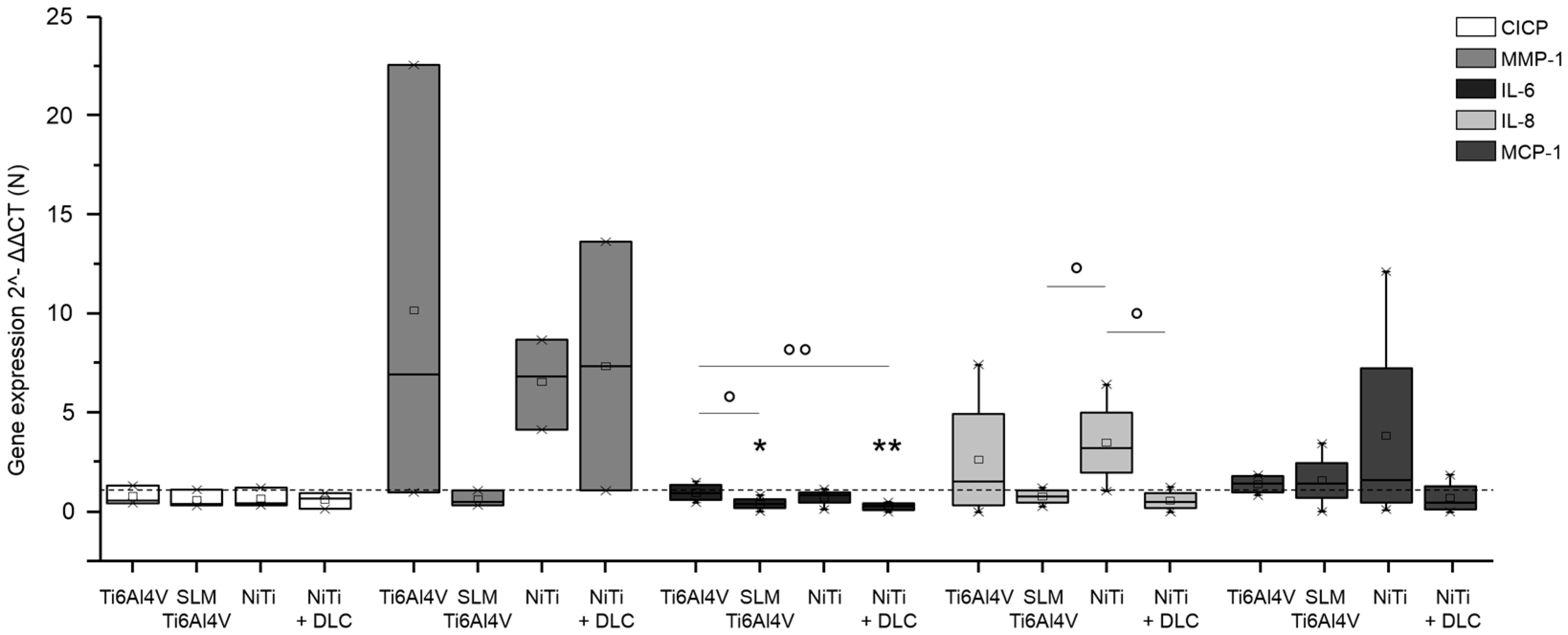

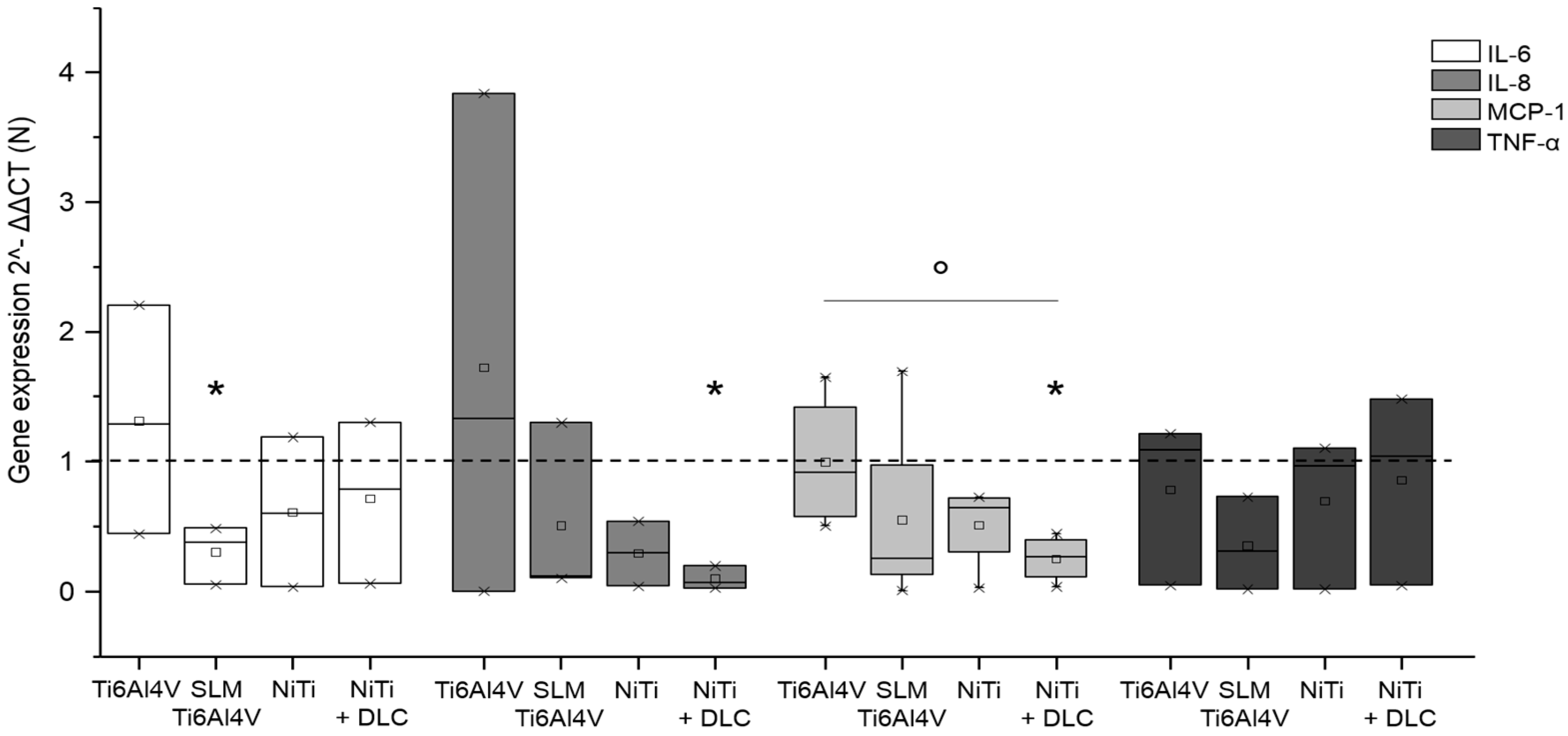

2.3.2. Gene Expression Analysis

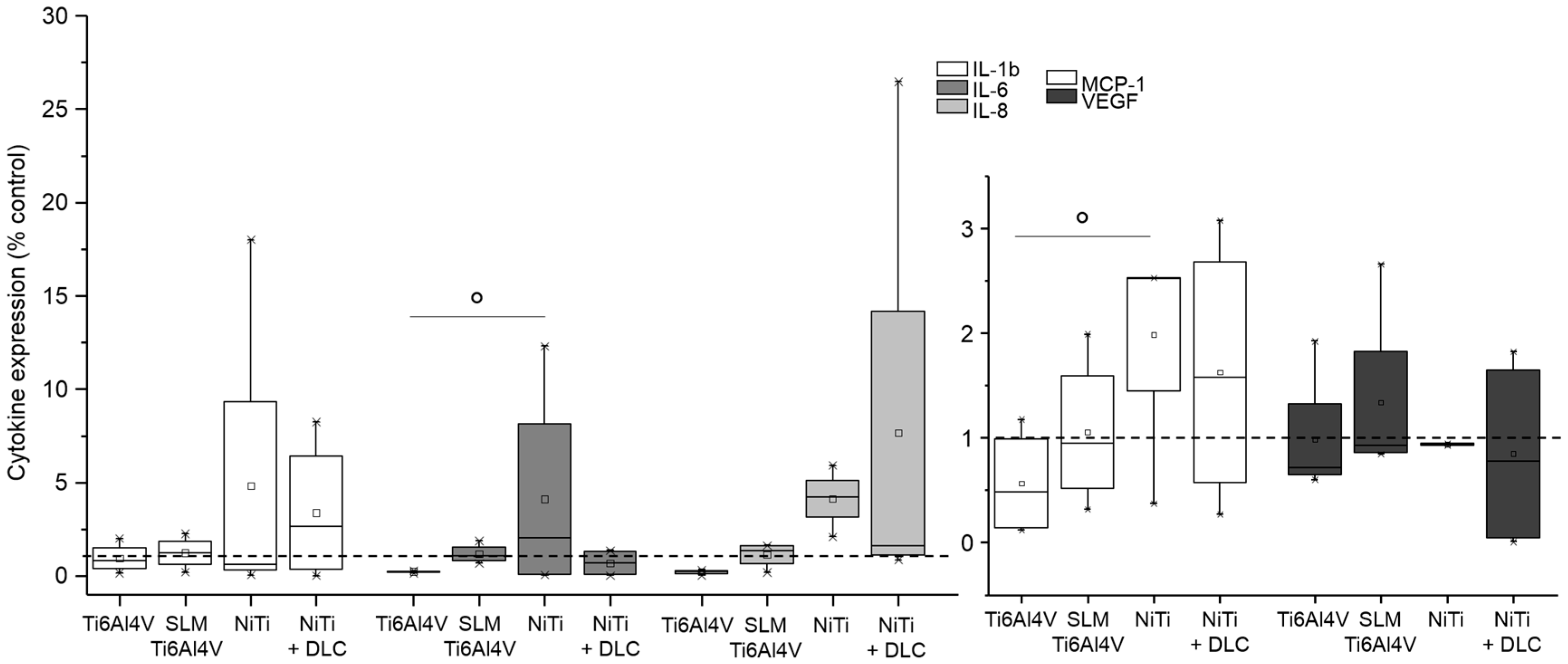

2.3.3. Enzyme-Linked Immunosorbent Assays

2.3.4. Cytokine Analysis

2.3.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Davis, J.R. (Ed.) Handbook of Materials for Medical Devices, 4th ed.; ASM International: Novelty, OH, USA, 2006.

- Lewallen, E.A.; Riester, S.M.; Bonin, C.A.; Kremers, H.M.; Dudakovic, A.; Kakar, S.; Cohen, R.C.; Westendorf, J.J.; Lewallen, D.G.; van Wijnen, A.J. Biological strategies for improved osseointegration and osteoinduction of porous metal orthopedic implants. Tissue Eng. Part B Rev. 2015, 21, 218–230. [Google Scholar] [CrossRef] [PubMed]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Kulkarni, M.; Mazare, A.; Schmuki, P.; Iglic, A. (Eds.) Biomaterial surface modification of titanium and titanium alloys for medical applications. In Nanomedicine; One Central Press: Manchester, UK, 2014.

- Niinomi, M.; Narushima, T.; Nakai, M. Advances in Metallic Biomaterials; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- De Vasconcellos, L.M.R.; Rodarte, Y.; do Prado, R.F.; de Vasconcellos, L.G.O.; Alencastro Graa, M.L.D.; Alves Cairo, C.A. Porous titanium by powder metallurgy for biomedical application: Characterization, cell citotoxity and in vivo tests of osseointegration. In Biomedical Engineering—Technical Applications in Medicine; Hudak, R., Ed.; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Niinomi, M.; Nakai, M.; Hieda, J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012, 8, 3888–3903. [Google Scholar] [CrossRef] [PubMed]

- Cremasco, A.; Messias, A.D.; Esposito, A.R.; Eliana Aparecida de Rezende, D.; Caram, R. Effects of alloying elements on the cytotoxic response of titanium alloys. Mater. Sci. Eng. C 2011, 31, 833–839. [Google Scholar] [CrossRef]

- Goyenvalle, E.; Aguado, E.; Cognet, R.; Bourges, X.; Daculsi, G. Calcium phosphate ceramic blasting on titanium surface improve bone ingrowth. KEM 2008, 361, 1351–1354. [Google Scholar] [CrossRef]

- Chan, C.W.; Hussain, I.; Waugh, D.G.; Lawrence, J.; Man, H.C. Effect of laser treatment on the attachment and viability of mesenchymal stem cell responses on shape memory NiTi alloy. Mater. Sci. Eng. C 2014, 42, 254–263. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fage, S.W.; Muris, J.; Jakobsen, S.S.; Thyssen, J.P. Titanium: A review on exposure, release, penetration, allergy, epidemiology, and clinical reactivity. Contact Dermat. 2016, 74, 323–345. [Google Scholar] [CrossRef] [PubMed]

- Tabish, T.A.; Butt, M.T.; Ali, M. Biocompatibility behavior and biomedical applications of Ti-Ni based shape memory alloys: A brief review. J. Fac. Eng. Technol. 2006, 19, 135–140. [Google Scholar]

- Fonte, M.; Saigal, A. Crystallographic texture of nitinol and its effects on macrophage. In Proceedings of the ASME 2010 International Mechanical Engineering Congress and Exposition, Vancouver, BC, Canada, 12–18 November 2010; pp. 1–8.

- Bernard, S.A.; Balla, V.K.; Davies, N.M.; Bose, S.; Bandyopadhyay, A. Bone cell-materials interactions and Ni ion release of anodized equiatomic NiTi alloy. Acta Biomater. 2011, 7, 1902–1912. [Google Scholar] [CrossRef] [PubMed]

- Elahinia, M.H.; Hashemi, M.; Tabesh, M.; Bhaduri, S.B. Manufacturing and processing of NiTi implants: A review. Prog. Mater. Sci. 2012, 57, 911–946. [Google Scholar] [CrossRef]

- Alvarez, K.; Nakajima, H. Metallic scaffolds for bone regeneration. Materials 2009, 2, 790–832. [Google Scholar] [CrossRef]

- Bansiddhi, A.; Sargeant, T.D.; Stupp, S.I.; Dunand, D.C. Porous NiTi for bone implants: A review. Acta Biomater. 2008, 4, 773–782. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.; Chung, C.; Lin, P.; Wang, S. Fabrication of porous NiTi shape memory alloy for hard tissue implants by combustion synthesis. Mater. Sci. Eng. A 2004, 366, 114–119. [Google Scholar] [CrossRef]

- Biesiekierski, A.; Wang, J.; Abdel-Hady Gepreel, M.; Wen, C. A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 2012, 8, 1661–1669. [Google Scholar] [CrossRef] [PubMed]

- Branzoi, I.V.; Iordoc, M.; Branzoi, F.; Vasilescu-Mirea, R.; Sbarcea, G. Influence of diamond-like carbon coating on the corrosion resistance of the NITINOL shape memory alloy. Surf. Interface Anal. 2010, 42, 502–509. [Google Scholar] [CrossRef]

- Chrzanowski, W.; Neel, E.A.A.; Armitage, D.A.; Zhao, X.; Knowles, J.C.; Salih, V. In vitro studies on the influence of surface modification of Ni-Ti alloy on human bone cells. J. Biomed. Mater. Res. 2009, 9999, 1596–1608. [Google Scholar]

- Li, Q.; Zhang, Q.; Sun, Z. The study on biocompatibility of diamond-like carbon coated nickel-titanium shape memory alloy with osteoblasts cultured in vitro. Chin. J. Repar. Reconstr. Surg. 2006, 20, 5–8. [Google Scholar]

- Arciniegas, M.; Pena, J.; Gil, F.J.; Manero, J.M. In vitro response of preosteoblastic MG63 cells on Ni-free Ti shape memory substrates. J. Biomed. Mater. Res. Part B Appl. Biomater. 2013, 101, 709–720. [Google Scholar] [CrossRef] [PubMed]

- Sahu, S.C. Toxicogenomics: Toxicogenomics; John Wiley & Sons: Chichester, UK, 2008. [Google Scholar]

- Florencio-Silva, R.; Sasso, G.R.; Sasso-Cerri, E.; Simoes, M.J.; Cerri, P.S. Biology of bone tissue: Structure, function, and factors that influence bone cells. BioMed Res. Int. 2015, 2015, 421746. [Google Scholar] [CrossRef] [PubMed]

- Slany, A.; Meshcheryakova, A.; Beer, A.; Ankersmit, H.J.; Paulitschke, V.; Gerner, C. Plasticity of fibroblasts demonstrated by tissue-specific and function-related proteome profiling. Clin. Proteom. 2014, 11, 41. [Google Scholar] [CrossRef] [PubMed]

- Roy, R.K.; Lee, K.-R. Biomedical applications of diamond-like carbon coatings: A review. J. Biomed. Mater. Res. Part B Appl. Biomater. 2007, 83, 72–84. [Google Scholar] [CrossRef] [PubMed]

- Ziegler-Heitbrock, L.; Ancuta, P.; Crowe, S.; Dalod, M.; Grau, V.; Hart, D.N.; Leenen, P.J.; Liu, Y.J.; MacPherson, G.; Randolph, G.J.; et al. Nomenclature of monocytes and dendritic cells in blood. Blood 2010, 116, 80. [Google Scholar] [CrossRef] [PubMed]

- Lochner, K.; Fritsche, A.; Jonitz, A.; Hansmann, D.; Mueller, P.; Mueller-Hilke, B.; Bader, R. The potential role of human osteoblasts for periprosthetic osteolysis following exposure to wear particles. Int. J. Mol. Med. 2011, 28, 1055–1063. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New developments of Ti-based alloys for biomedical applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef]

- Fili, P.; Lausmaa, J.; Musialek, J.; Mazanec, K. Structure and surface of TiNi human implants. Biomaterials 2001, 22, 2131–2138. [Google Scholar] [CrossRef]

- Es-Souni, M.; Fischer-Brandies, H. Assessing the biocompatibility of NiTi shape memory alloys used for medical applications. Anal. Bioanal. Chem. 2005, 381, 557–567. [Google Scholar] [CrossRef] [PubMed]

- Es-Souni, M.; Fischer-Brandies, H.; Es-Souni, M. Human gingival fibroblast response to electropolished NiTi surfaces. J. Biomed. Mater. Res. Part A 2007, 80, 159–166. [Google Scholar] [CrossRef] [PubMed]

- Cortizo, M.C.; De Mele, M.F.; Cortizo, A.M. Metallic dental material biocompatibility in osteoblastlike cells: Correlation with metal ion release. Biol. Trace Elem. Res. 2004, 100, 151–168. [Google Scholar] [CrossRef]

- Ponsonnet, L.; Tréheux, D.; Lissac, M.; Jaffrezic, N.; Grosgogeat, B. Review of in vitro studies on the biocompatibility of NiTi alloys. Int. J. Appl. Electromagn. Mech. 2006, 23, 147–151. [Google Scholar]

- Huang, H. Ion release from NiTi orthodontic wires in artificial saliva with various acidities. Biomaterials 2003, 24, 3585–3592. [Google Scholar] [CrossRef]

- Hahn, A.; Fuhlrott, J.; Loos, A.; Barcikowski, S. Cytotoxicity and ion release of alloy nanoparticles. J. Nanoparticle Res. Interdiscip. Forum Nanoscale Sci. Technol. 2012, 14, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Hang, R.; Liu, Y.; Liu, S.; Bai, L.; Gao, A.; Zhang, X.; Huang, X.; Tang, B.; Chu, P.K. Size-dependent corrosion behavior and cytocompatibility of Ni–Ti–O nanotubes prepared by anodization of biomedical NiTi alloy. Corros. Sci. 2016, 103, 173–180. [Google Scholar] [CrossRef]

- Li, Q.; Xia, Y.-Y.; Tang, J.-C.; Wang, R.-Y.; Bei, C.-Y.; Zeng, Y. In vitro and in vivo biocompatibility investigation of diamond-like carbon coated nickel-titanium shape memory alloy. Artif. Cells Blood Substit. Immobil. Biotechnol. 2011, 39, 137–142. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Wang, L.-P.; Wang, M.; Tong, H.-W.; Lu, W.W. Characteristics and in vitro biological assessment of (Ti, O, N)/Ti composite coating formed on NiTi shape memory alloy. Thin Solid Films 2011, 519, 4623–4628. [Google Scholar] [CrossRef]

- Mikulewicz, M.; Chojnacka, K. Cytocompatibility of medical biomaterials containing nickel by osteoblasts: A systematic literature review. Biol. Trace Elem. Res. 2011, 142, 865–889. [Google Scholar] [CrossRef] [PubMed]

- Michiardi, A.; Engel, E.; Aparicio, C.; Planell, J.A.; Gil, F.J. Oxidized NiTi surfaces enhance differentiation of osteoblast-like cells. J. Biomed. Mater. Res. Part A 2008, 85, 108–114. [Google Scholar] [CrossRef] [PubMed]

- Shabalovskaya, S.; Anderegg, J.; van Humbeeck, J. Critical overview of Nitinol surfaces and their modifications for medical applications. Acta Biomater. 2008, 4, 447–467. [Google Scholar] [CrossRef] [PubMed]

- Kapanen, A.; Kinnunen, A.; Ryhanen, J.; Tuukkanen, J. TGF-beta1 secretion of ROS-17/2.8 cultures on NiTi implant material. Biomaterials 2002, 23, 3341–3346. [Google Scholar] [CrossRef]

- Kapanen, A.; Ilvesaro, J.; Danilov, A.; Ryhanen, J.; Lehenkari, P.; Tuukkanen, J. Behaviour of nitinol in osteoblast-like ROS-17 cell cultures. Biomaterials 2002, 23, 645–650. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S.; Yeung, K.W.K.; Chan, Y.L.; Hu, T.; Xu, Z.; Liu, X.; Chung, J.C.Y.; Cheung, K.M.C.; Chu, P.K. Relationship between osseointegration and superelastic biomechanics in porous NiTi scaffolds. Biomaterials 2011, 32, 330–338. [Google Scholar] [CrossRef] [PubMed]

- Ryhanen, J.; Niemi, E.; Serlo, W.; Niemela, E.; Sandvik, P.; Pernu, H.; Salo, T. Biocompatibility of nickel-titanium shape memory metal and its corrosion behavior in human cell cultures. J. Biomed. Mater. Res. 1997, 35, 451–457. [Google Scholar] [CrossRef]

- Cui, Z.D.; Chen, M.F.; Zhang, L.Y.; Hu, R.X.; Zhu, S.L.; Yang, X.J. Improving the biocompatibility of NiTi alloy by chemical treatments: An in vitro evaluation in 3T3 human fibroblast cell. Mater. Sci. Eng. C 2008, 28, 1117–1122. [Google Scholar] [CrossRef]

- Gotman, I.; Ben-David, D.; Unger, R.E.; Bose, T.; Gutmanas, E.Y.; Kirkpatrick, C.J. Mesenchymal stem cell proliferation and differentiation on load-bearing trabecular Nitinol scaffolds. Acta Biomater. 2013, 9, 8440–8448. [Google Scholar] [CrossRef] [PubMed]

- Fleischmann, L.; Crismani, A.; Falkensammer, F.; Bantleon, H.-P.; Rausch-Fan, X.; Andrukhov, O. Behavior of osteoblasts on TI surface with two different coating designed for orthodontic devices. J. Mater. Sci. Mater. Med. 2015, 26, 5335. [Google Scholar] [CrossRef] [PubMed]

- Kapanen, A.; Ryhanen, J.; Danilov, A.; Tuukkanen, J. Effect of nickel-titanium shape memory metal alloy on bone formation. Biomaterials 2001, 22, 2475–2480. [Google Scholar] [CrossRef]

- Ryhanen, J.; Kallioinen, M.; Tuukkanen, J.; Lehenkari, P.; Junila, J.; Niemela, E.; Sandvik, P.; Serlo, W. Bone modeling and cell-material interface responses induced by nickel-titanium shape memory alloy after periosteal implantation. Biomaterials 1999, 20, 1309–1317. [Google Scholar] [CrossRef]

- McMahon, R.E.; Ma, J.; Verkhoturov, S.V.; Munoz-Pinto, D.; Karaman, I.; Rubitschek, F.; Maier, H.J.; Hahn, M.S. A comparative study of the cytotoxicity and corrosion resistance of nickel-titanium and titanium-niobium shape memory alloys. Acta Biomater. 2012, 8, 2863–2870. [Google Scholar] [CrossRef] [PubMed]

- Ponsonnet, L.; Comte, V.; Othmane, A.; Lagneau, C.; Charbonnier, M.; Lissac, M.; Jaffrezic, N. Effect of surface topography and chemistry on adhesion, orientation and growth of fibroblasts on nickel–titanium substrates. Mater. Sci. Eng. C 2002, 21, 157–165. [Google Scholar] [CrossRef]

- Rongo, R.; Valletta, R.; Bucci, R.; Rivieccio, V.; Galeotti, A.; Michelotti, A.; D’Anto, V. In vitro biocompatibility of nickel-titanium esthetic orthodontic archwires. Angle Orthod. 2016, 86, 789–795. [Google Scholar] [CrossRef] [PubMed]

- Bogdanski, D.; Koller, M.; Bram, M.; Stover, D.; Buchkremer, H.P.; Choi, J.; Epple, M.; Muhr, G. Rapid analysis of biocompatibility with graded test samples exemplified by Ni-NiTi-Ti. Biomed. Technik. Biomed. Eng. 2002, 47, 500–502. [Google Scholar] [CrossRef]

- Man, H.C.; Zhang, S.; Cheng, F.T.; Guo, X. Laser fabrication of porous surface layer on NiTi shape memory alloy. Mater. Sci. Eng. A 2005, 404, 173–178. [Google Scholar] [CrossRef]

- Rocher, P.; El Medawar, L.; Hornez, J.-C.; Traisnel, M.; Breme, J.; Hildebrand, H. Biocorrosion and cytocompatibility assessment of NiTi shape memory alloys. Scripta Mater. 2004, 50, 255–260. [Google Scholar] [CrossRef]

- Armitage, D.A.; Parker, T.L.; Grant, D.M. Biocompatibility and hemocompatibility of surface-modified NiTi alloys. J. Biomed. Mater. Res. Part A 2003, 66, 129–137. [Google Scholar] [CrossRef] [PubMed]

- Waugh, D.G.; Lawrence, J.; Chan, C.W.; Hussain, I.; Man, H.C. Laser melting of NiTi and its effects on in vitro mesenchymal stem cell responses. In Laser Surface Engineering; Elsevier: Cambridge, UK, 2015; pp. 653–676. [Google Scholar]

- Liu, X.M.; Wu, S.L.; Chan, Y.L.; Chu, P.K.; Chung, C.Y.; Chu, C.L.; Yeung, K.W.K.; Lu, W.W.; Cheung, K.M.C.; Luk, K.D.K. Surface characteristics, biocompatibility, and mechanical properties of nickel-titanium plasma-implanted with nitrogen at different implantation voltages. J. Biomed. Mater. Res. Part A 2007, 82, 469–478. [Google Scholar] [CrossRef] [PubMed]

- Strauss, S.; Neumeister, A.; Barcikowski, S.; Kracht, D.; Kuhbier, J.W.; Radtke, C.; Reimers, K.; Vogt, P.M. Adhesion, vitality and osteogenic differentiation capacity of adipose derived stem cells seeded on nitinol nanoparticle coatings. PLoS ONE 2013, 8, e53309. [Google Scholar] [CrossRef] [PubMed]

- Fini, M.; Giardino, R.; Borsari, V.; Torricelli, P.; Rimondini, L.; Giavaresi, G.; Nicoli Aldini, N. In vitro behaviour of osteoblasts cultured on orthopaedic biomaterials with different surface roughness, uncoated and fluorohydroxyapatite-coated, relative to the in vivo osteointegration rate. Int. J. Artif. Organs 2003, 26, 520–528. [Google Scholar] [PubMed]

- Chrzanowski, W.; Neel, E.A.A.; Armitage, D.A.; Knowles, J.C. Effect of surface treatment on the bioactivity of nickel–titanium. Acta Biomater. 2008, 4, 1969–1984. [Google Scholar] [CrossRef] [PubMed]

- Maleki-Ghaleh, H.; Khalil-Allafi, J.; Sadeghpour-Motlagh, M.; Shakeri, M.S.; Masoudfar, S.; Farrokhi, A.; Beygi Khosrowshahi, Y.; Nadernezhad, A.; Siadati, M.H.; Javidi, M.; et al. Effect of surface modification by nitrogen ion implantation on the electrochemical and cellular behaviors of super-elastic NiTi shape memory alloy. J. Mater. Sci. Mater. Med. 2014, 25, 2605–2617. [Google Scholar] [CrossRef] [PubMed]

- Wirth, C.; Grosgogeat, B.; Lagneau, C.; Jaffrezic-Renault, N.; Ponsonnet, L. Biomaterial surface properties modulate in vitro rat calvaria osteoblasts response: Roughness and or chemistry? Mater. Sci. Eng. C 2008, 28, 990–1001. [Google Scholar] [CrossRef]

- Kunzler, T.P.; Drobek, T.; Schuler, M.; Spencer, N.D. Systematic study of osteoblast and fibroblast response to roughness by means of surface-morphology gradients. Biomaterials 2007, 28, 2175–2182. [Google Scholar] [CrossRef] [PubMed]

- Wirth, C.; Comte, V.; Lagneau, C.; Exbrayat, P.; Lissac, M.; Jaffrezic-Renault, N.; Ponsonnet, L. Nitinol surface roughness modulates in vitro cell response: A comparison between fibroblasts and osteoblasts. Mater. Sci. Eng. C 2005, 25, 51–60. [Google Scholar] [CrossRef]

- Kapanen, A.; Danilov, A.; Lehenkari, P.; Ryhanen, J.; Jamsa, T.; Tuukkanen, J. Effect of metal alloy surface stresses on the viability of ROS-17/2.8 osteoblastic cells. Biomaterials 2002, 23, 3733–3740. [Google Scholar] [CrossRef]

- Lohmann, C.H.; Bonewald, L.F.; Sisk, M.A.; Sylvia, V.L.; Cochran, D.L.; Dean, D.D.; Boyan, B.D.; Schwartz, Z. Maturation state determines the response of osteogenic cells to surface roughness and 1,25-dihydroxyvitamin D3. J. Bone Miner. Res. 2000, 15, 1169–1180. [Google Scholar] [CrossRef] [PubMed]

- Refai, A.K.; Textor, M.; Brunette, D.M.; Waterfield, J.D. Effect of titanium surface topography on macrophage activation and secretion of proinflammatory cytokines and chemokines. J. Biomed. Mater. Res. Part A 2004, 70, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Soskolne, W.A.; Cohen, S.; Shapira, L.; Sennerby, L.; Wennerberg, A. The effect of titanium surface roughness on the adhesion of monocytes and their secretion of TNF-alpha and PGE2. Clin. Oral. Implants Res. 2002, 13, 86–93. [Google Scholar] [CrossRef] [PubMed]

| Test Pellet | Dimensions (mm2) | Rz (µm) Mean ± SD | Ra (µm) Mean ± SD |

|---|---|---|---|

| Ti6Al4V | 10 × 2 | 15.71 ± 1.27 | 2.38 ± 0.15 |

| Ti6Al4V SLM | 10 × 2 | 68.82 ± 10.59 | 13.53 ± 2.55 |

| NiTi | 10 × 1 | 1.12 ± 0.26 | 0.15 ± 0.03 |

| NiTi + DLC | 10 × 1 | 1.13 ± 0.32 | 0.15 ± 0.02 |

| Human Cells | Donors | Gender | Average Age |

|---|---|---|---|

| Osteoblasts | n = 8 | 4 ♂/4 ♀ | 71.88 ± 7.88 |

| Fibroblasts | n = 4 | − ♂/2 ♀ (2 n/a) | 40 ± 7.07 (2 n/a) |

| Macrophages | n = 4 | n/a | n/a |

| Primer | Primer Sequence |

|---|---|

| β-Actin | Forward primer: 5′-CTTCCTGGGCATGGAGTC-3′ |

| Reverse primer: 5′-AGCACTGTGTTGGCGTACAG-3′ | |

| Collagen I | Forward primer: 5′-ACGAAGACATCCCACCAATC-3′ |

| Reverse primer 5′-AGATCACGTCATCGCACAAC-3′ | |

| HPRT | Forward primer: 5′-CCCTGGCGTCGTGATTAGTG-3′ |

| Reverse primer: 5′-TCGAGCAAGACGTTCAGTCC-3′ | |

| IL-6 | Forward primer: 5′-TGGATTCAATGAGGAGACTTGCC-3′ |

| Reverse primer: 5′-CTGGCATTTGTGGTTGGGTC-3′ | |

| IL-8 | Forward primer: 5′-TCTGTGTGAAGGTGCAGTTTTG-3′ |

| Reverse primer: 5′-ATTTCTGTGTTGGCGCAGTG-3′ | |

| MCP-1 | Forward primer: 5′-CCGAGAGGCTGAGACTAACC-3′ |

| Reverse primer: 5′-GGCATTGATTGCATCTGGCTG-3′ | |

| MMP-1 | Forward primer: 5′-AGAGCAGATGTGGACCATGC-3′ |

| Reverse primer 5′-TCCCGATGATCTCCCCTGAC-3′ | |

| TNF-α | Forward primer: 5′-GTTGTAGCAAACCCTCAAGCTG-3′ |

| Reverse primer: 5′-GAGGTACAGGCCCTCTGATG-3′ |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markhoff, J.; Krogull, M.; Schulze, C.; Rotsch, C.; Hunger, S.; Bader, R. Biocompatibility and Inflammatory Potential of Titanium Alloys Cultivated with Human Osteoblasts, Fibroblasts and Macrophages. Materials 2017, 10, 52. https://doi.org/10.3390/ma10010052

Markhoff J, Krogull M, Schulze C, Rotsch C, Hunger S, Bader R. Biocompatibility and Inflammatory Potential of Titanium Alloys Cultivated with Human Osteoblasts, Fibroblasts and Macrophages. Materials. 2017; 10(1):52. https://doi.org/10.3390/ma10010052

Chicago/Turabian StyleMarkhoff, Jana, Martin Krogull, Christian Schulze, Christian Rotsch, Sandra Hunger, and Rainer Bader. 2017. "Biocompatibility and Inflammatory Potential of Titanium Alloys Cultivated with Human Osteoblasts, Fibroblasts and Macrophages" Materials 10, no. 1: 52. https://doi.org/10.3390/ma10010052