A Feed-Forward Control Realizing Fast Response for Three-Branch Interleaved DC-DC Converter in DC Microgrid

Abstract

:1. Introduction

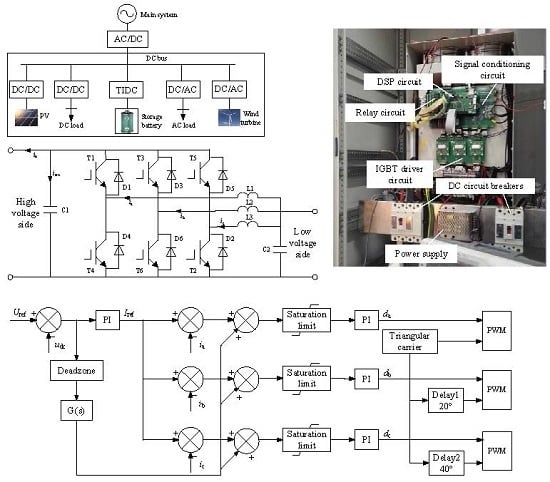

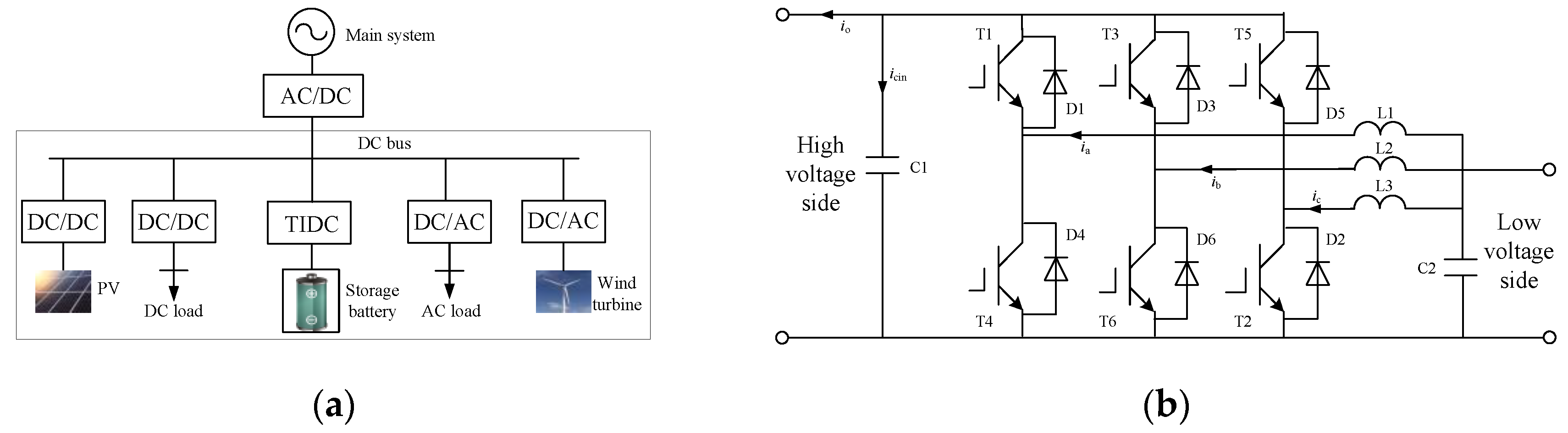

2. Three-Branch Interleaved DC-DC Converter

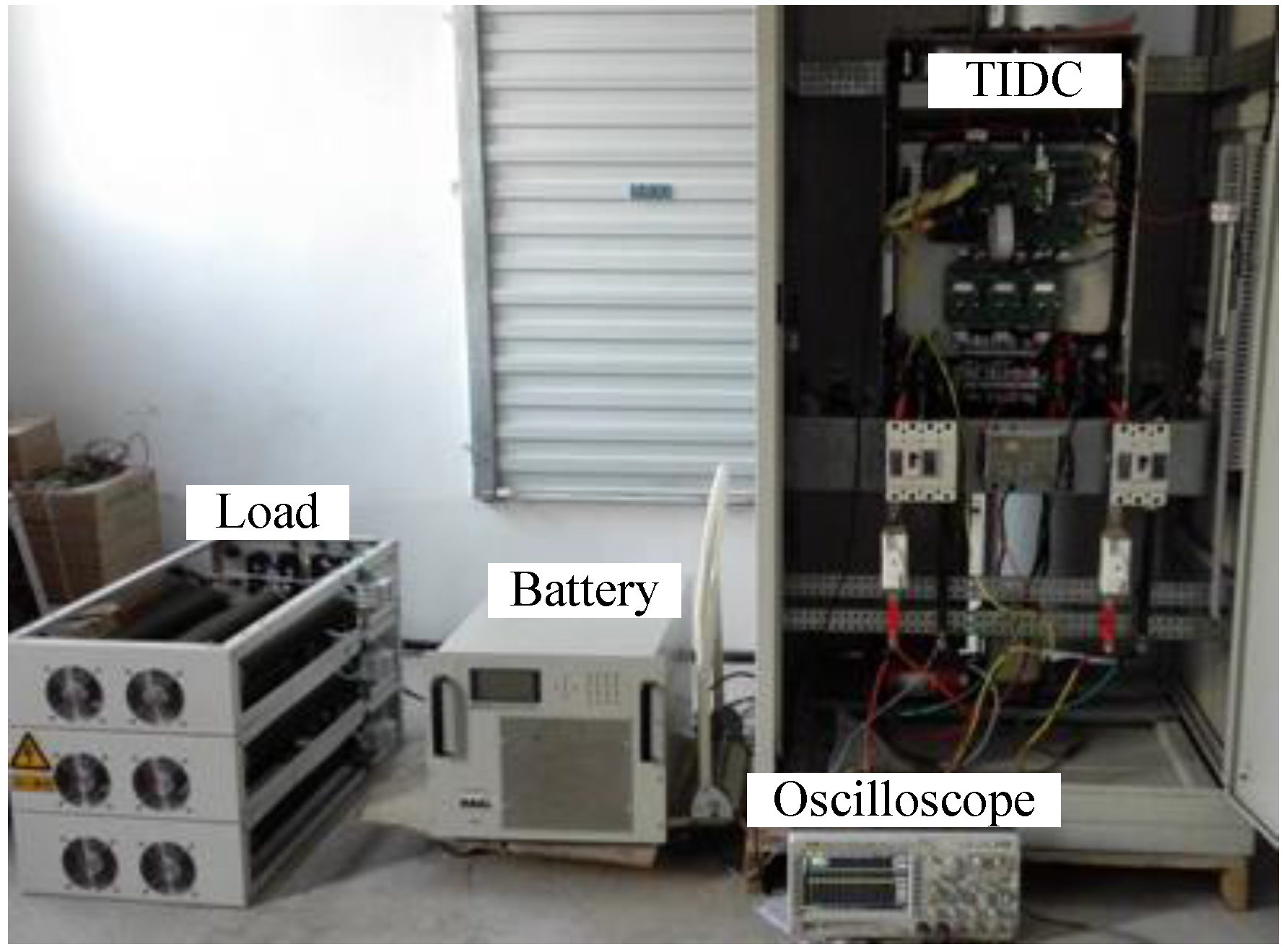

2.1. The Topology of TIDC

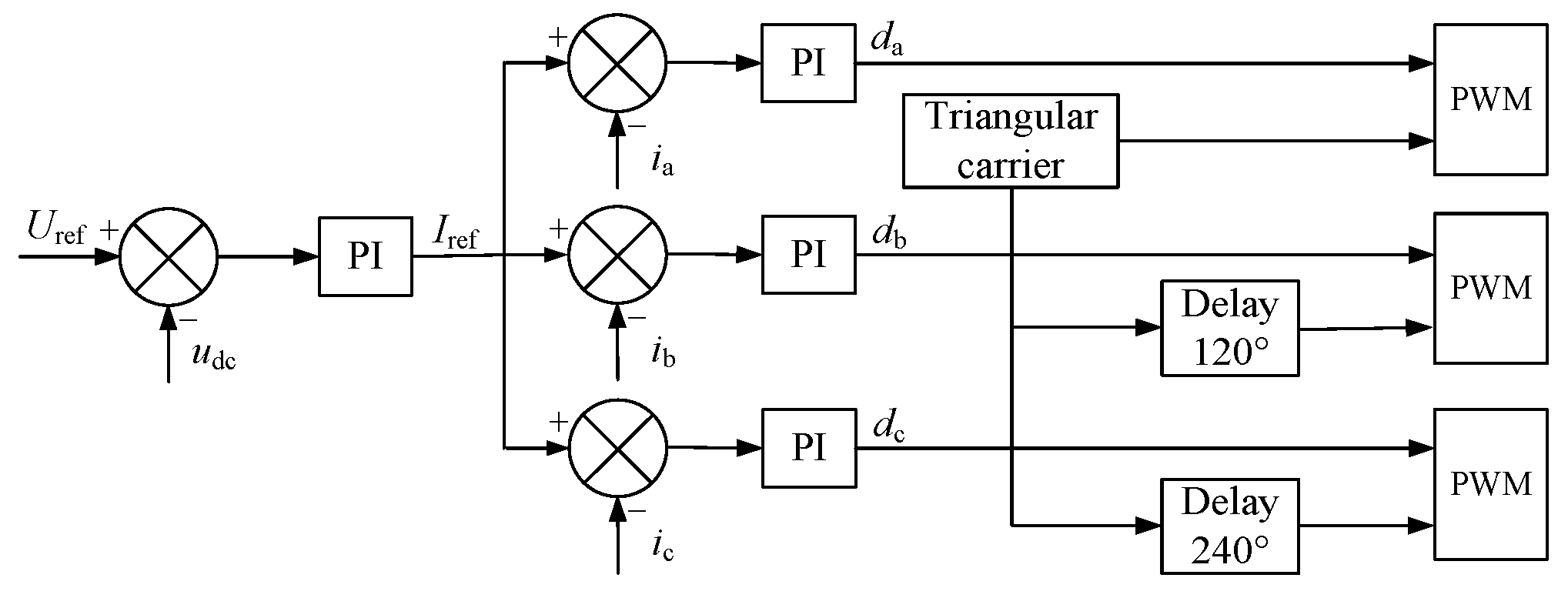

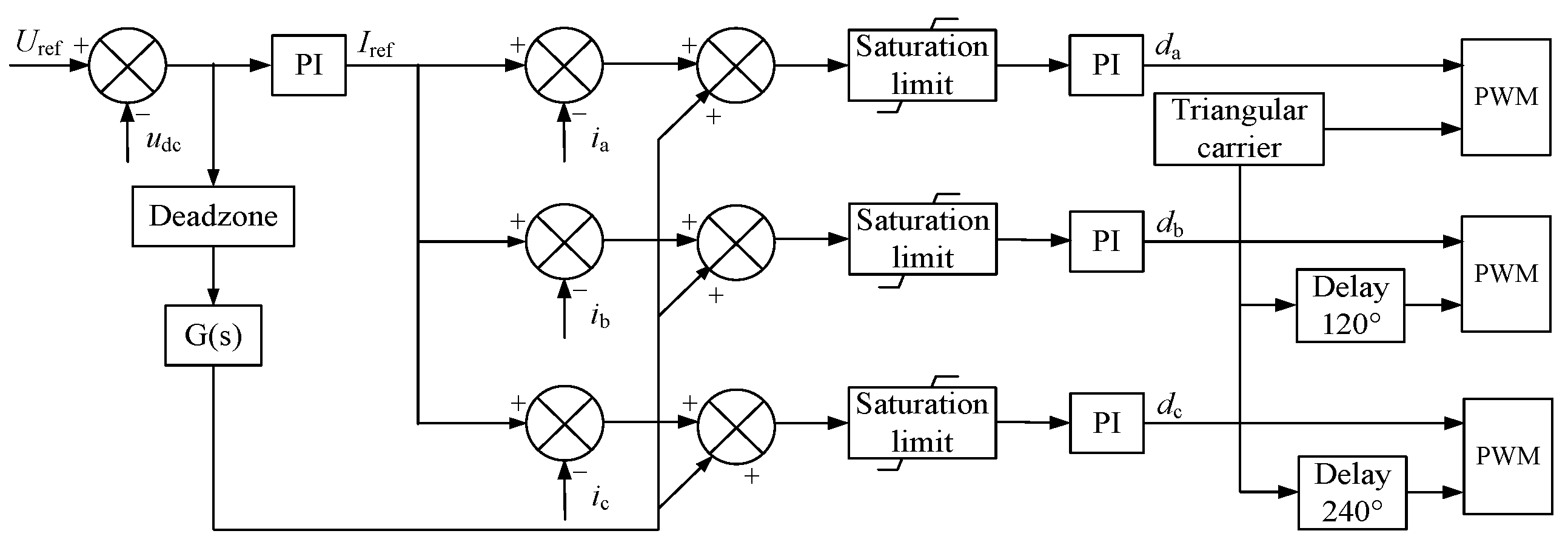

2.2. The Control of TIDC

3. Analysis of Feed-Forward Control

3.1. Presentation of Feed-Forward Control

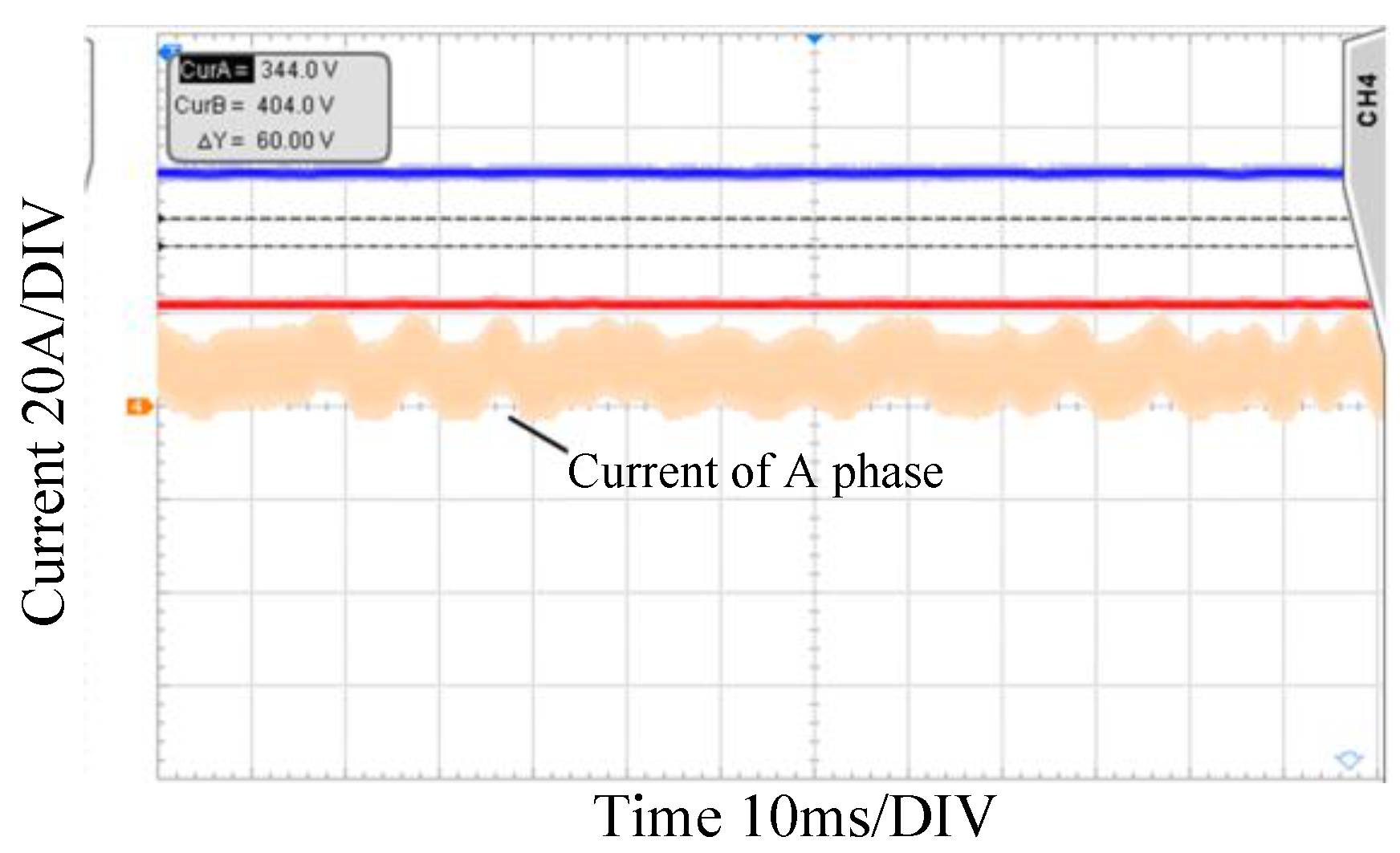

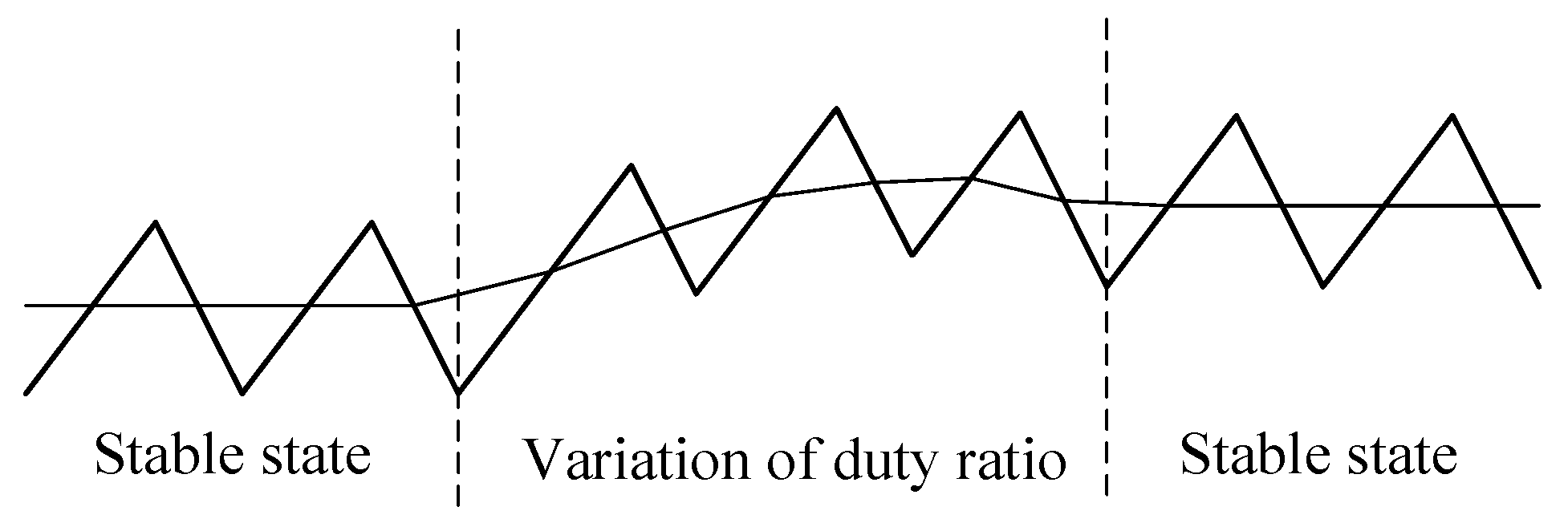

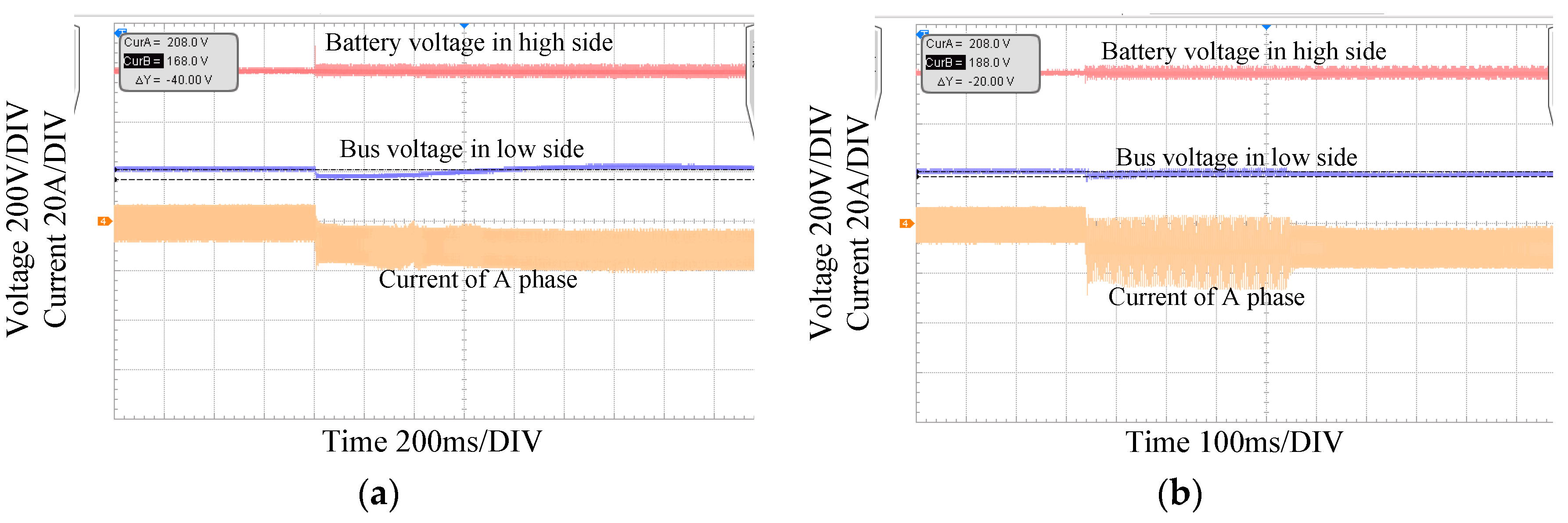

3.2. Defects of Feed-Forward Control and Its Experiment

4. Improvement of the Feed-Forward Control and Its Experiment

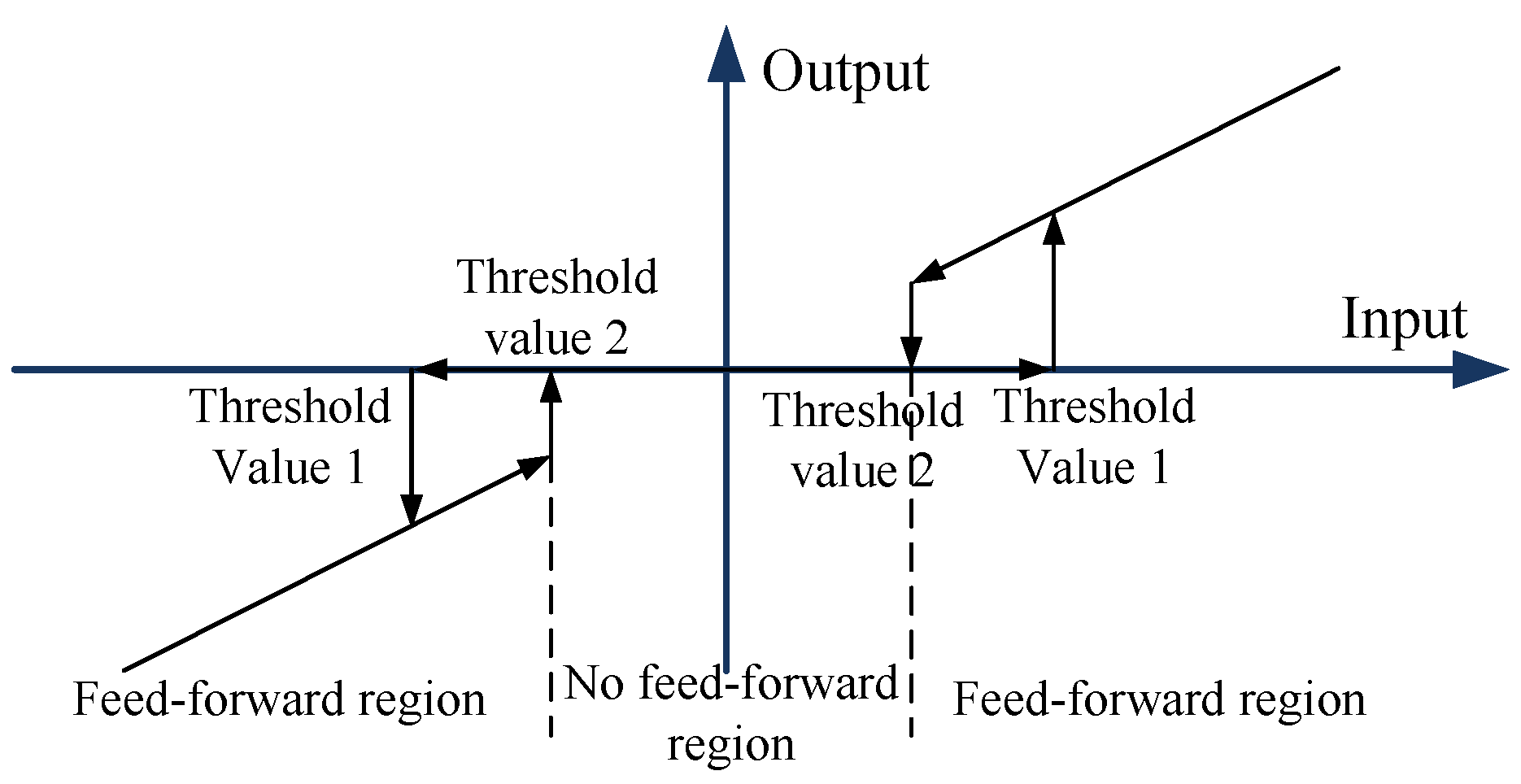

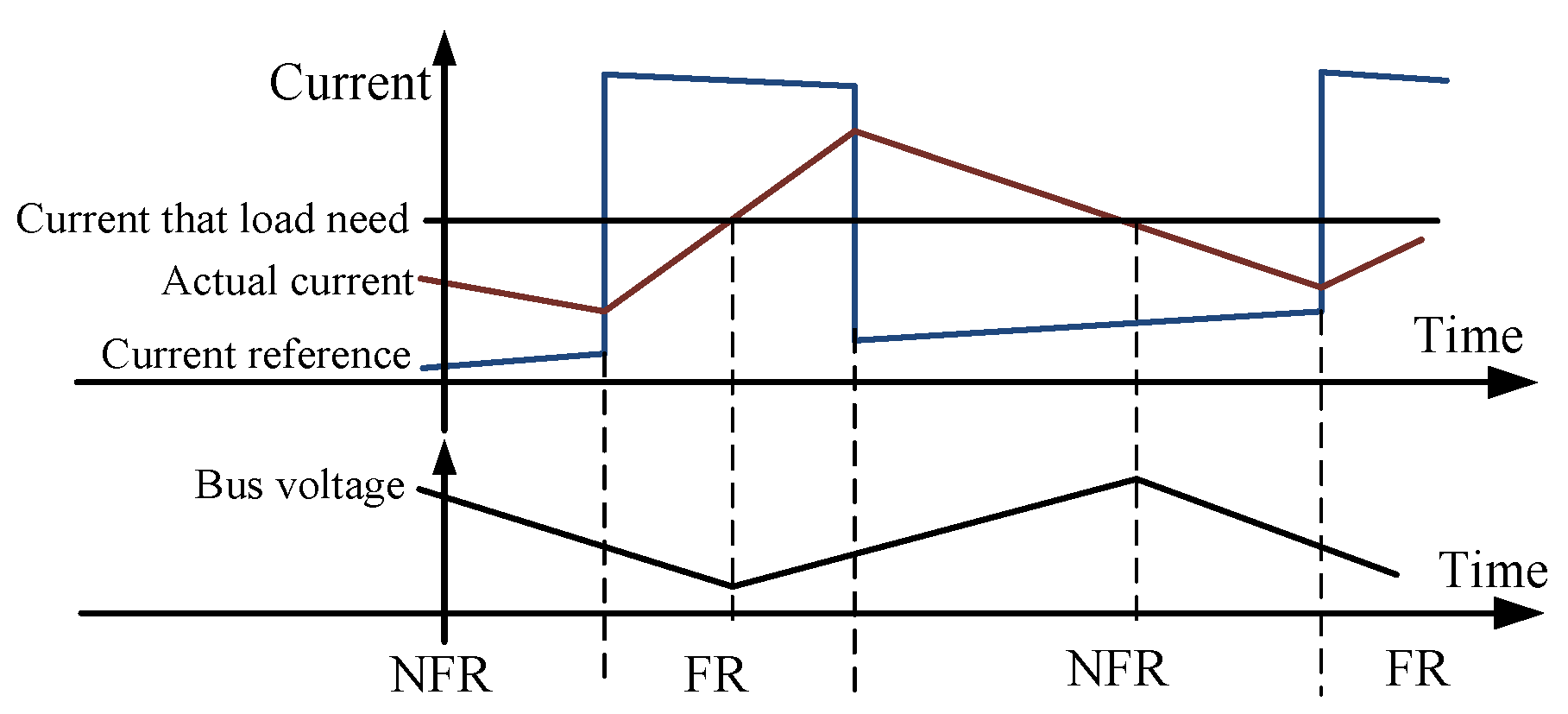

4.1. Improvement of the Feed-Forward Control

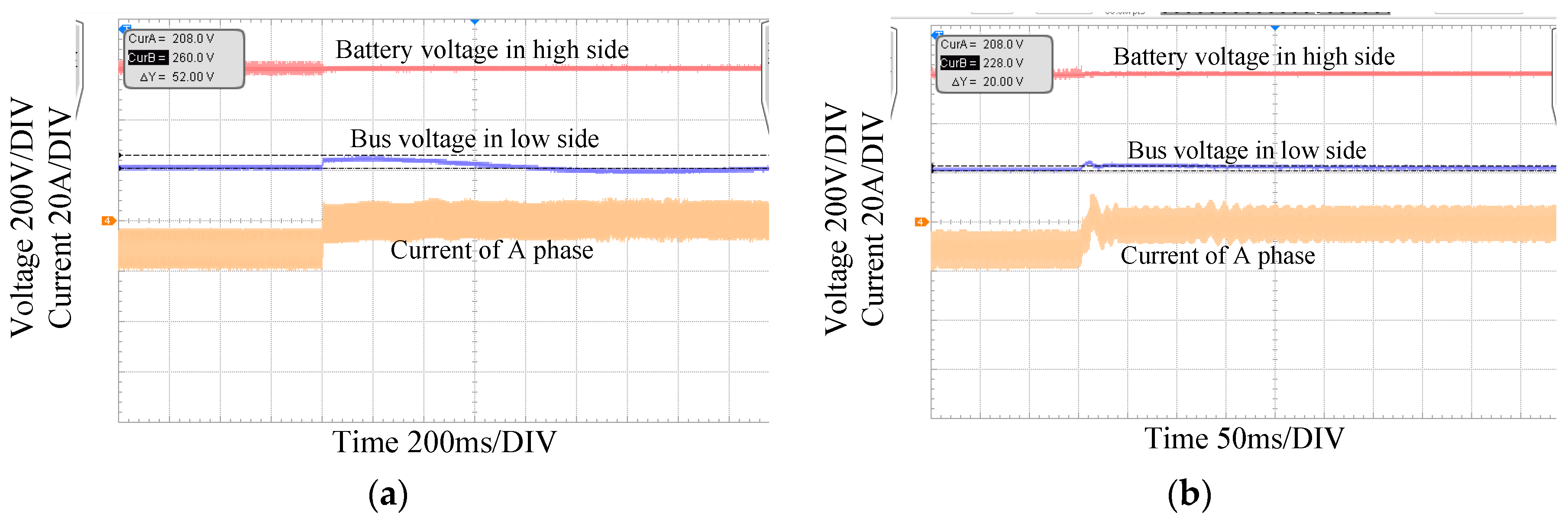

4.2. Experiment of the Improved Feed-Forward Control

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Han, M.; Wang, H. DC micro-grid—the important mode in the field of power supply and consumption. J. Electr. Eng. 2015, 10, 1–9. [Google Scholar]

- Jian, Z.H.; He, Z.Y.; Jia, J.; Xie, Y. A review of control strategies for DC micro-grid. In Proceedings of the 2013 Fourth International Conference on Intelligent Control and Information (ICICIP), Beijing, China, 9–11 June 2013; pp. 666–671.

- Chen, D.; Xu, L. DC microgrid with variable generations and energy storage. In Proceedings of the IET Conference on Renewable Power Generation (RPG 2011), Edinburgh, UK, 6–8 September 2011; pp. 1–6.

- Yu, X.; She, X.; Huang, A. Hierarchical power management for DC microgrid in islanding mode and Solid State transformer enabled mode. In Proceedings of the IECON 2013—39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 1656–1661.

- Veneri, O.; Capasso, C.; Iannuzzi, D. Experimental evaluation of DC charging architecture for fully-electrified low-power two-wheeler. Appl. Energy 2016, 162, 1428–1438. [Google Scholar] [CrossRef]

- Li, S.; Bao, K.; Fu, X.; Zheng, H. Energy management and control of electric vehicle charging stations. Electr. Power Compon. Syst. 2014, 42, 339–347. [Google Scholar] [CrossRef]

- Capasso, C.; Veneri, O. Experimental study of a DC charging station for full electric and plug in hybrid vehicles. Appl. Energy 2015, 152, 131–142. [Google Scholar] [CrossRef]

- Hõimoja, H.; Rufer, A.; Dziechciaruk, G.; Vezzini, A. An ultrafast EV charging station demonstrator. In Proceedings of the 2012 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italia, 20–22 June 2012; pp. 1390–1395.

- Xiao, J.; Wang, P. Multiple modes control of household DC microgrid with integration of various renewable energy sources. In Proceedings of the IECON 2019th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 1773–1778.

- Yuan, J.; Gao, F.; Gao, H. Study on multiple hierarchical DC micro-grid based on photovoltaic generation systems. In Proceedings of the 2012 China International Conference on Electricity Distribution (CICED), Shanghai, China, 10–14 September 2012; pp. 1–5.

- Kranz, C. Complete digital control method for PWM DCDC boost converter. In Proceedings of the 2003 IEEE 34th Annual Power Electronics Specialist Conference, PESC’03, Acapulco, Mexico, 15–19 June 2003; Volume 2, pp. 951–956.

- Zhang, G.; Wu, X.; Zhang, J.; Qian, Z. A Feed-Forward Synchronous-Rectifier Half Bridge DC-DC Converter. Power Electron. 2008, 42, 17–18. [Google Scholar]

- Yao, C.; Ruan, X.; Cao, W.; Chen, P. A two-mode control scheme with input voltage feed-forward for the two-switch buck-boost DC–DC converter. IEEE Trans. Power Electron. 2014, 29, 2037–2048. [Google Scholar] [CrossRef]

- Chae, S.; Hyun, B.; Kim, W.; Cho, B. Digital load current feed-forward control method for a DC-DC converter. In Proceedings of the Twenty-Third Annual IEEE Applied Power Electronics Conference and Exposition, APEC 2008, Austin, TX, USA, 24–28 February 2008; pp. 498–502.

- Chae, S.; Hyun, B.; Agarwal, P.; Kim, W. Digital predictive feed-forward controller for a DC–DC converter in plasma display panel. IEEE Trans. Power Electron. 2008, 23, 627–634. [Google Scholar] [CrossRef]

- Pipolo, S.; Bifaretti, S.; Lidozzi, A.; Solero, L. Feed-forward control of a ZVT Full Bridge DC-DC Converter. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italia, 10–13 June 2015; pp. 1041–1046.

- Lu, Z.; Tang, W.; Zeng, X. Voltage Stability Control of Isolated DC Micro-grid Based on Power Feed Forward. Power Electron. 2015, 49, 32–36. [Google Scholar]

- Kang, R.; Kim, K.; Yang, I.; Jeong, K.; Kang, C.; Kim, G. The use of FPGA in HIL Simulation of three phase interleaved DC-DC Converter. In Proceedings of the 2012 OEEE Vehicle Power and Propulsion Conference, Seoul, Korea, 9–12 October 2012; pp. 772–776.

- Lee, W.; Han, B.M.; Cha, H. Battery ripple current reduction in a three-phase interleaved dc-dc converter for 5kW battery charger. In Proceedings of the 2011 IEEE Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 17–22 September 2011; pp. 3535–3540.

- Gavriluta, C.; Citro, C.; Nisak, K.; Segundo, S. A simple approach for fast controller prototyping for a three phase interleaved DC-DC converter. In Proceedings of the 2012 IEEE International Symposium on Industrial Electronics (ISIE), Hangzhou, China, 28–31 May 2012; pp. 2015–2019.

- Zwysen, J.; Gelagaev, R.; Driesen, J.; Goossens, S.; Vanvlasselaer, K.; Symens, W.; Schuyten, B. Multi-objective design of a close-coupled inductor for a three-phase interleaved 140kW DC-DC converter. In Proceedings of the IECON 2013–39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 1056–1061.

- Higure, H.; Hoshi, N.; Haruna, J. Inductor current control of three-phase interleaved DC-DC converter using single DC-link current sensor. In Proceedings of the 2012 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Bengaluru, India, 16–19 December 2012; pp. 1–5.

- Albuquerque, L.L.O.; Andersen, R.L. Interleaved association of ZVS-PWM three-phase current-fed push-pull DC-DC converters with series output connection. In Proceedings of the 2015 IEEE 13th Brazilian Power Electronics Conference and 1st Southern Power Electronics Conference (COBEP/SPEC), Fortaleza, Brazil, 29 November–2 December 2015; pp. 1–6.

- Wang, H.; Han, M.; Josep, M.G.; Luan, W. Optimization Design of DC Micro-grid Stability Controller Based on the Autonomous Decentralized System. Proc. CSEE 2016, 36, 360–367. [Google Scholar]

- Zhang, J.; Gao, Z.; Ren, Y.; Du, X.; Yin, X. A economic operation optimization for microgrid with battery storage and load transfer. In Proceedings of the 2014 2nd International Conference on Systems and Informatics (ICSAI), Shanghai, China, 15–17 November 2014; pp. 186–191.

- Wang, Y.; Tan, K.T.; So, P.L. Coordinated control of battery energy storage system in a microgrid. In Proceedings of the 2013 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Hong Kong, China, 8–11 December 2013; pp. 1–6.

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Han, M.; Yan, W.; Zhao, G.; Guerrero, J.M. A Feed-Forward Control Realizing Fast Response for Three-Branch Interleaved DC-DC Converter in DC Microgrid. Energies 2016, 9, 529. https://doi.org/10.3390/en9070529

Wang H, Han M, Yan W, Zhao G, Guerrero JM. A Feed-Forward Control Realizing Fast Response for Three-Branch Interleaved DC-DC Converter in DC Microgrid. Energies. 2016; 9(7):529. https://doi.org/10.3390/en9070529

Chicago/Turabian StyleWang, Haojie, Minxiao Han, Wenli Yan, Guopeng Zhao, and Josep M. Guerrero. 2016. "A Feed-Forward Control Realizing Fast Response for Three-Branch Interleaved DC-DC Converter in DC Microgrid" Energies 9, no. 7: 529. https://doi.org/10.3390/en9070529