A Novel Design of Radio Frequency Energy Relays on Power Transmission Lines

Abstract

:1. Introduction

2. Theoretical Considerations

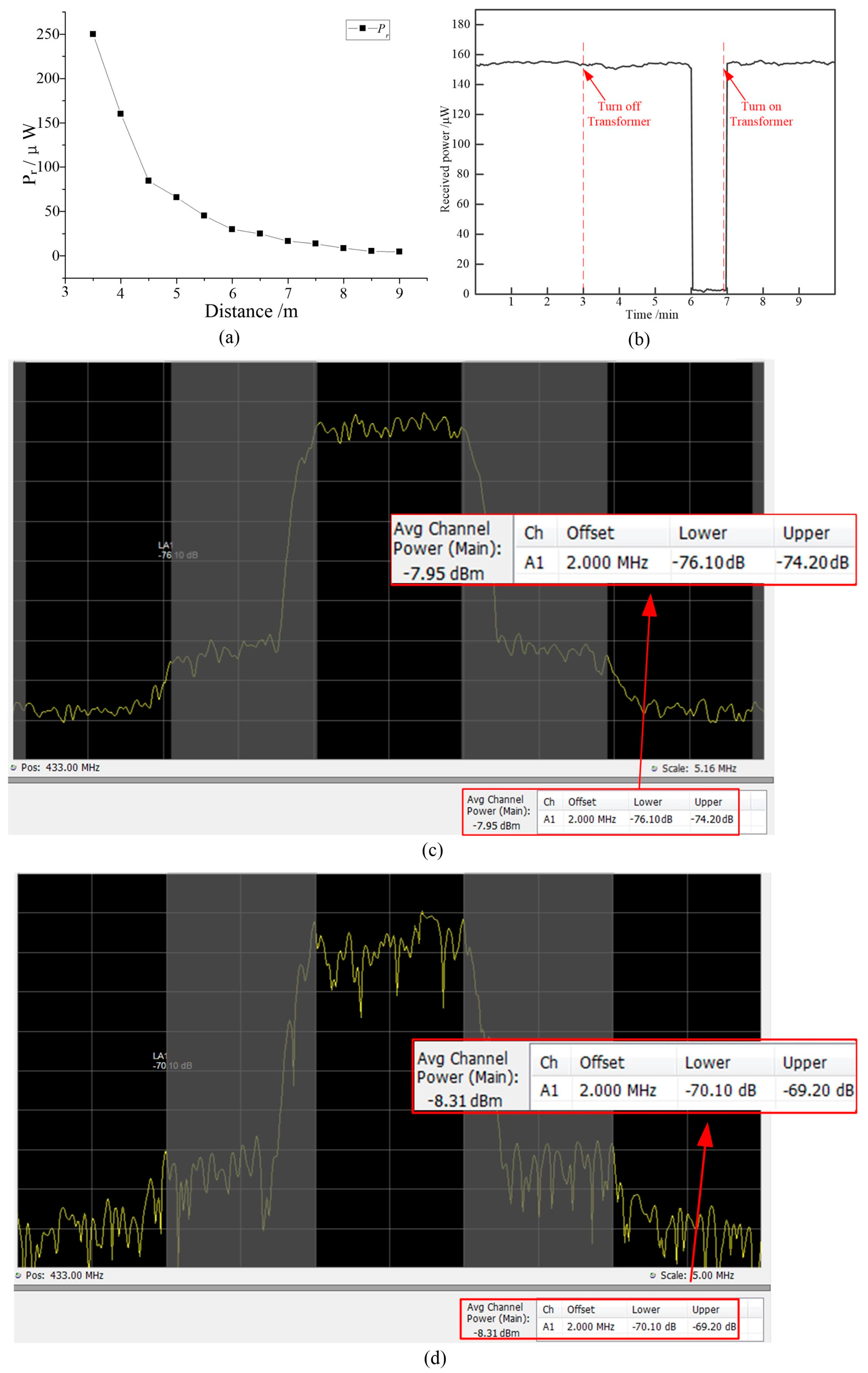

2.1. Power Source of RFID Tags

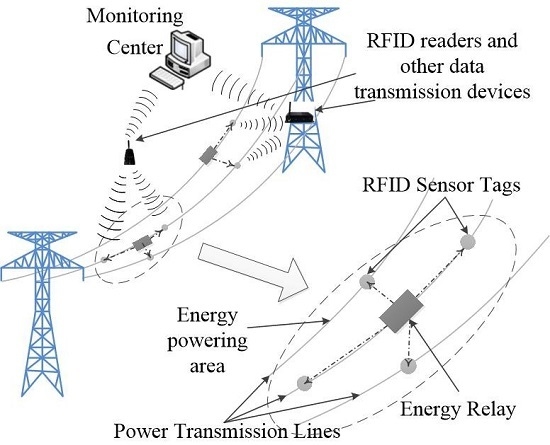

2.2. Principle of RFID-Based Monitoring Networks

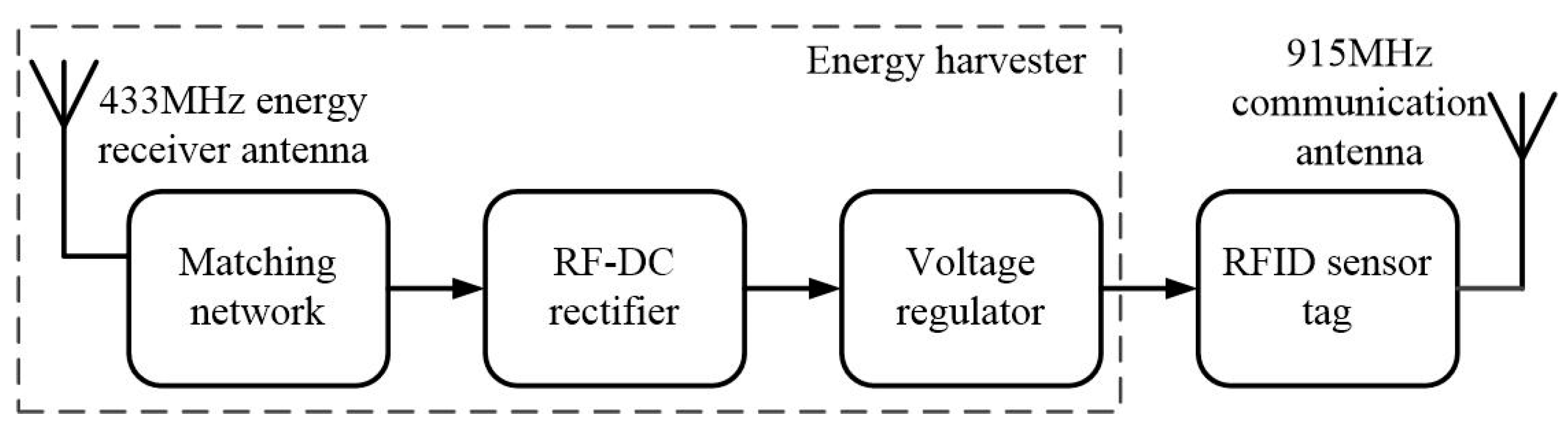

2.3. Model of RF Wave Transmission

2.4. Influence of Electromagnetism

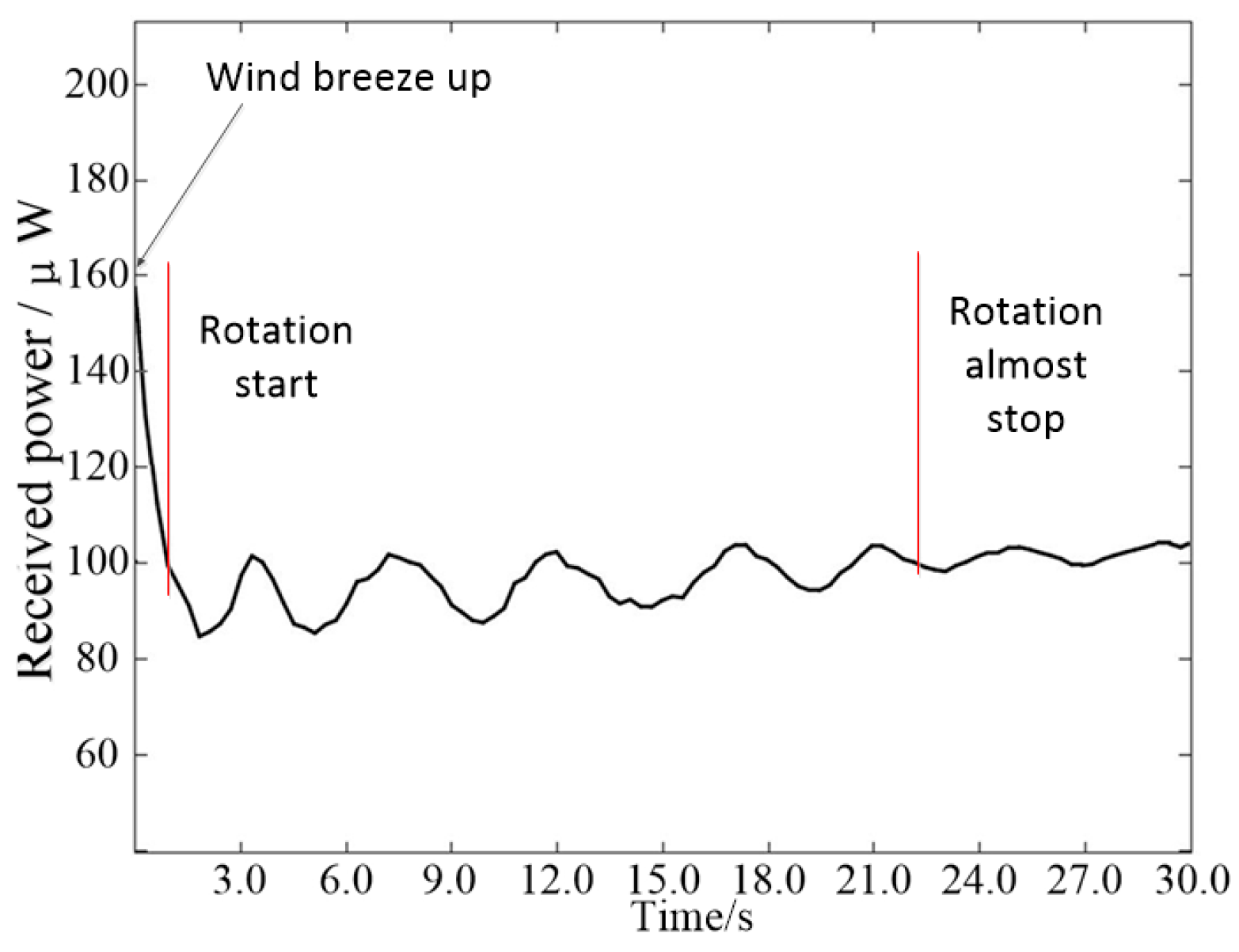

2.5. Influence of Wind

3. Prototype Design

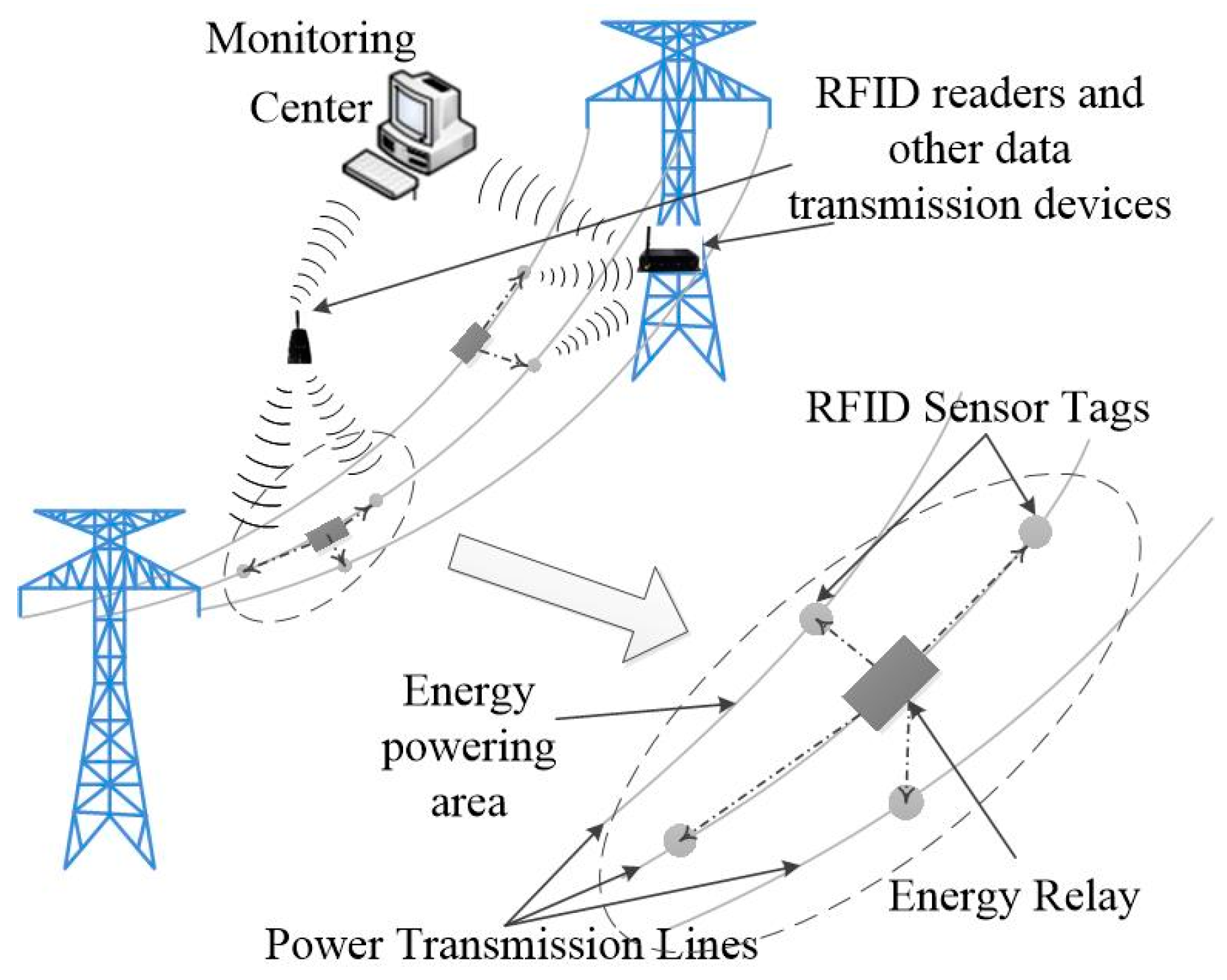

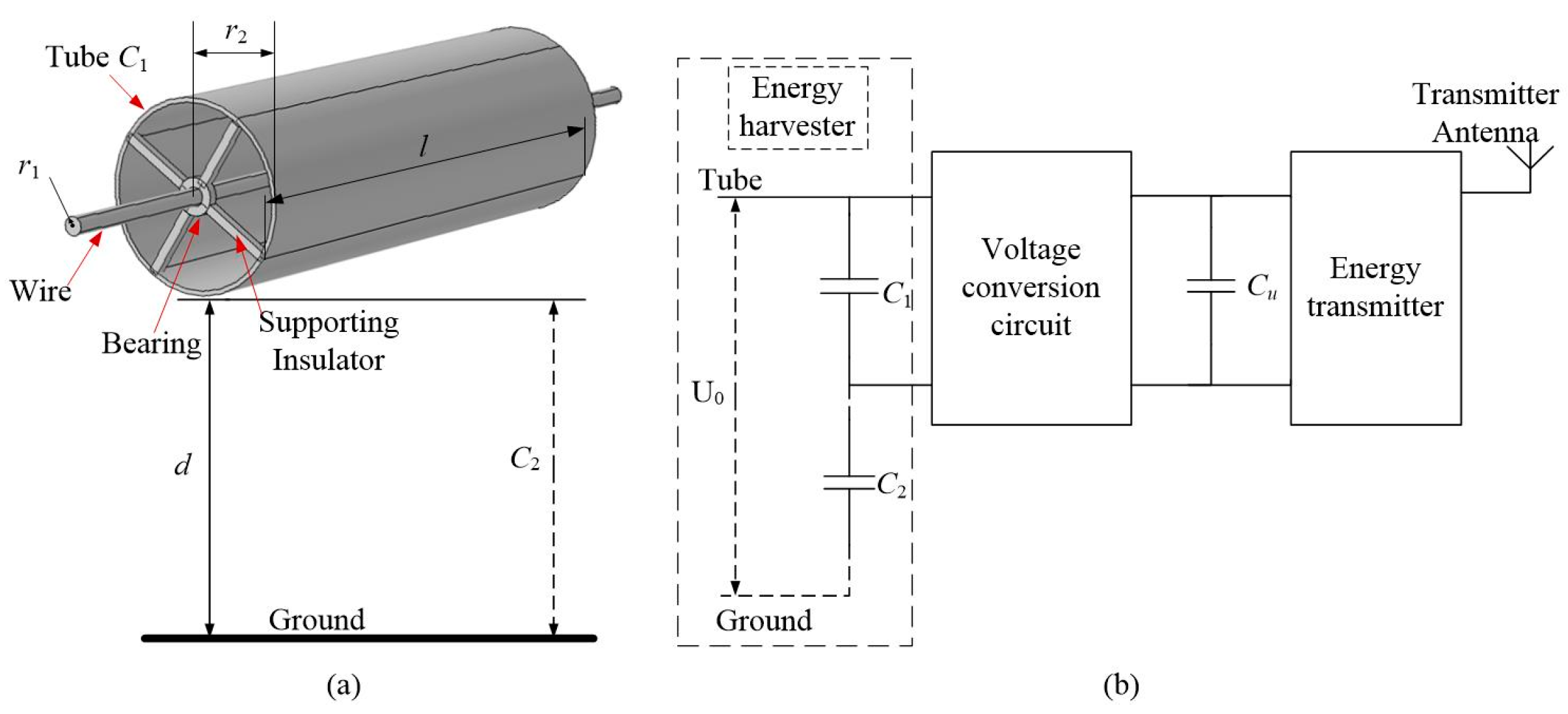

3.1. Energy Harvester on 110 kv Lines

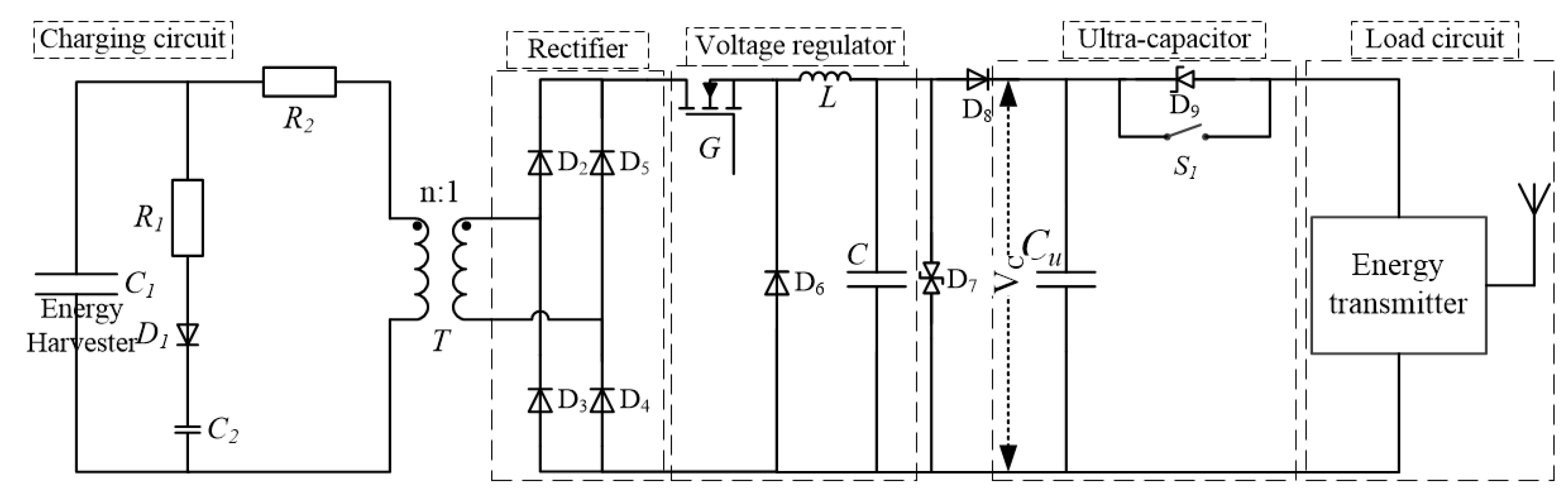

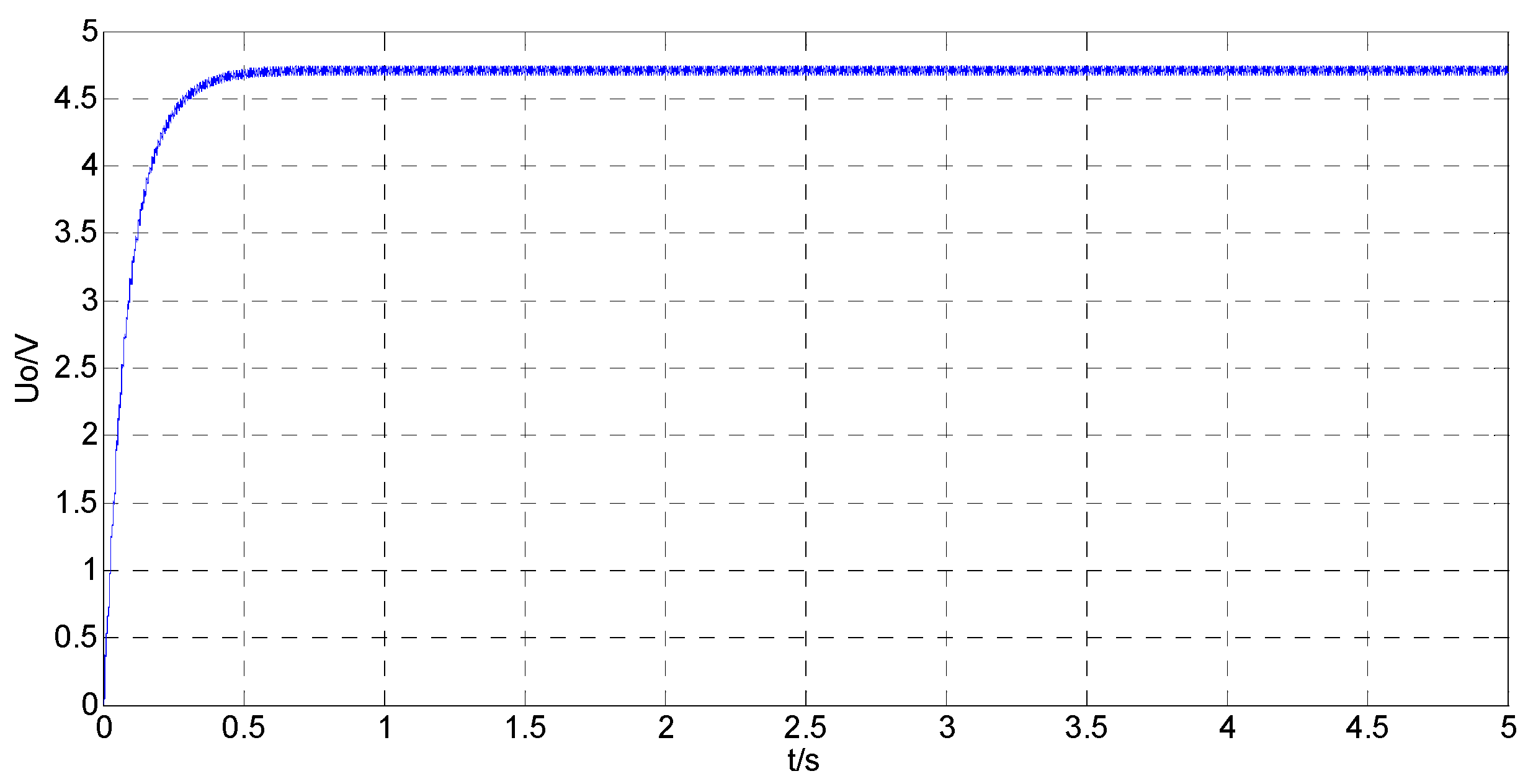

3.2. Voltage Conversion Circuit

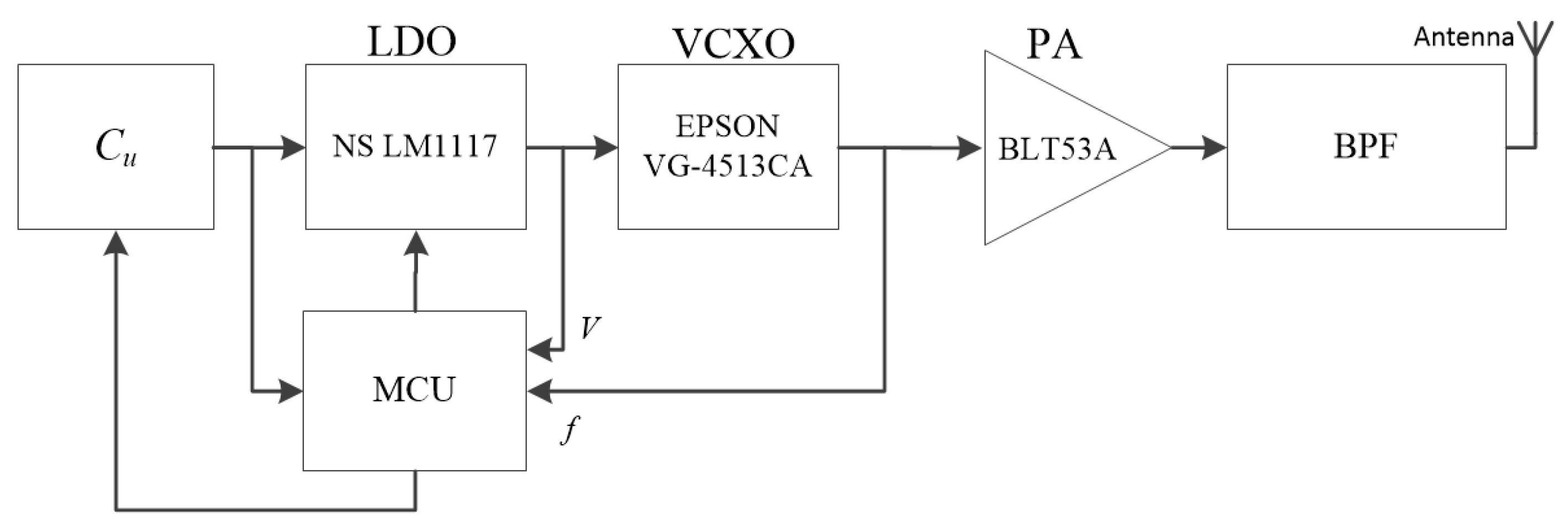

3.3. Energy Transmitter

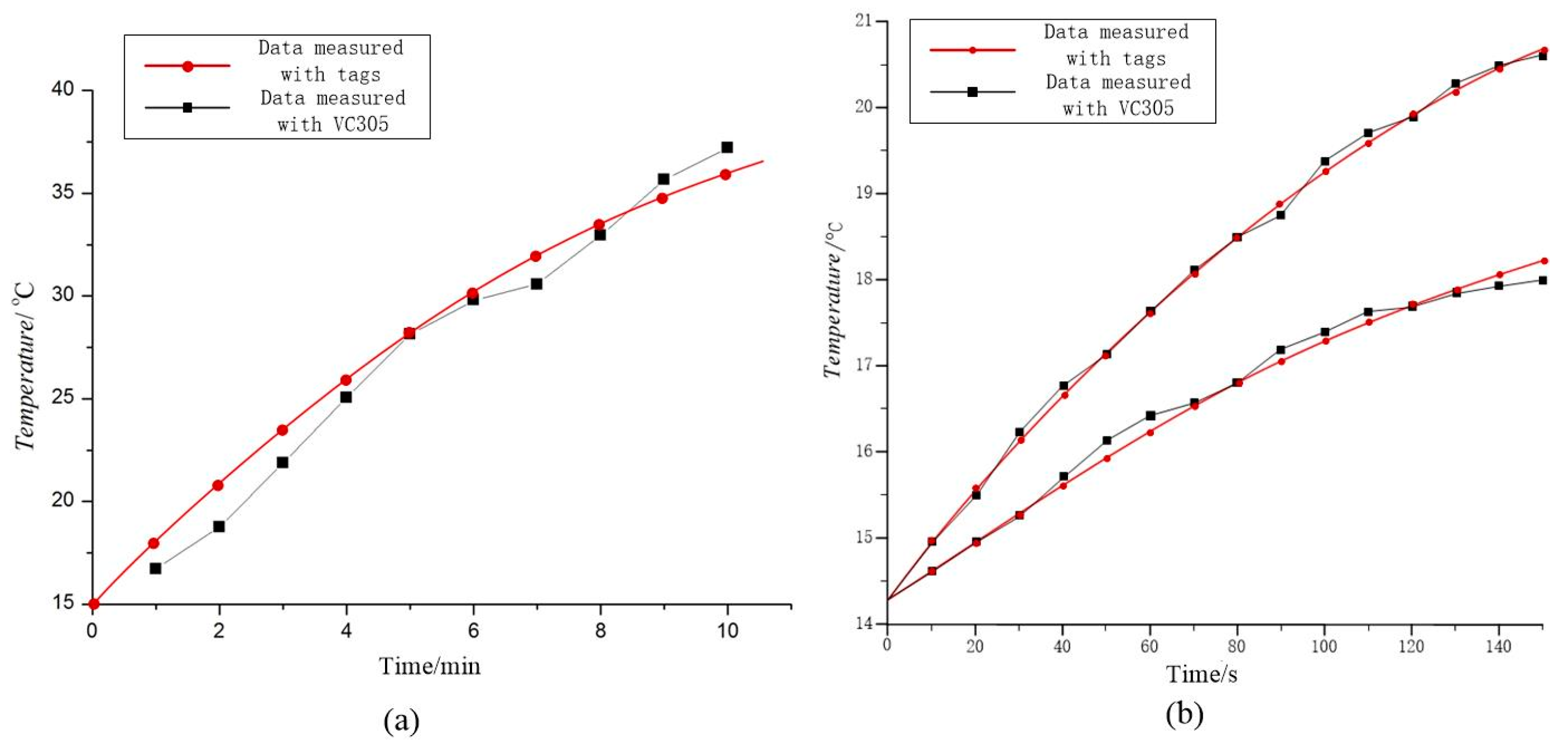

4. Experiment and Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| RFID | Radio Frequency Identification Devices |

| RF | Radio frequency |

| EMC | Electromagnetic compatibility |

References

- Sheng, Q.Y.; Li, J.; Xu, T.Y. Study on the monitoring technology for overhead transmission line icing. In Proceedings of the 2011 IEEE Power Engineering and Automation Conference (PEAM), Wuhan, China, 8–9 September 2011; pp. 168–171.

- Guo, Z.; Ye, F.; Guo, J.; Liang, Y.; Xu, G.; Zhang, X.; Qian, Y. A wireless sensor network for monitoring smart grid transmission lines. In Proceedings of the 2014 23rd International Conference on IEEE Computer Communication and Networks (ICCCN), Shanghai, China, 4–7 August 2014; pp. 1–6.

- Sun, X.; Lui, K.S.; Wong, K.K.; Lee, W.K.; Hou, Y.; Huang, Q.; Pong, P.W. Novel application of magnetoresistive sensors for high-voltage transmission-line monitoring. IEEE Trans. Magnet. 2011, 47, 2608–2611. [Google Scholar] [CrossRef] [Green Version]

- Zhou, G.; Huang, L.; Li, W.; Zhu, Z. Harvesting ambient environmental energy for wireless sensor networks: A survey. J. Sens. 2014, 2014, 1–20. [Google Scholar] [CrossRef]

- Moghe, R.; Lambert, F.C.; Divan, D. Smart “stick-on” sensors for the smart grid. IEEE Trans. Smart Grid 2012, 3, 241–252. [Google Scholar] [CrossRef]

- Hill, C.A.; Such, M.C.; Chen, D.; Gonzalez, J.; Grady, W.M. Battery energy storage for enabling integration of distributed solar power generation. IEEE Trans. Smart Grid 2012, 3, 850–857. [Google Scholar] [CrossRef]

- Zangl, H.; Bretterklieber, T.; Brasseur, G. A feasibility study on autonomous online condition monitoring of high-voltage overhead power lines. IEEE Trans. Instrum. Meas. 2009, 58, 1789–1796. [Google Scholar] [CrossRef]

- Wu, Z.; Wen, Y.; Li, P. A Power supply of self-powered online monitoring systems for power cords. IEEE Trans. Energy Convers. 2013, 28, 921–928. [Google Scholar] [CrossRef]

- Tan, Y.K.; Hoe, K.Y.; Panda, S.K. Energy harvesting using piezoelectric igniter for self-powered radio frequency (RF) wireless sensors. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Mumbai, India, 15–17 December 2006; pp. 1711–1716.

- Washiro, T. Applications of RFID over power line for Smart Grid. In Proceedings of the 16th IEEE International Symposium on Power Line Communications and Its Applications (ISPLC), Beijing, China, 27–30 March 2012; pp. 83–87.

- Vaidya, B.; Makrakis, D.; Mouftah, H.T. Authentication mechanism for mobile RFID based Smart grid network. In Proceedings of the 2014 IEEE 27th Canadian Conference on Electrical and Computer Engineering (CCECE), Toronto, ON, Canada, 4–7 May 2014; pp. 1–6.

- Huettner, J.; Kurz, F.; Metz, G.; Ziroff, A. Lightweight power line communications for Smart Grid applications with standard RFID tags. In Proceedings of the IEEE Global Communications Conference (GLOBECOM), Anaheim, CA, USA, 3–7 December 2012; pp. 3165–3170.

- Kang, S.H.; Kim, Y.H.; Lee, E.J.; Lee, S.G.; Min, B.C.; An, J.; Kim, D.H. Implementation of Smart Floor for multi-robot system. In Proceedings of the 2011 5th International Conference on Automation, Robotics and Applications (ICARA), Wellington, New Zealand, 6–8 December 2011; pp. 46–51.

- Sabesan, S.; Crisp, M.J.; Penty, R.V.; White, I.H. Wide area passive UHF RFID system using antenna diversity combined with phase and frequency hopping. IEEE Trans. Antennas Propag. 2014, 62, 878–888. [Google Scholar] [CrossRef]

- Cho, H.; Kim, J.; Baek, Y. Large-scale active RFID system utilizing ZigBee networks. IEEE Trans. Consum. Electron. 2011, 57, 379–385. [Google Scholar] [CrossRef]

- Peng, Q.; Zhang, C.; Zhao, X.; Sun, X.; Li, F.; Chen, H.; Wang, Z. A low-cost UHF RFID system with OCA tag for short-range communication. IEEE Trans. Ind. Electron. 2015, 62, 4455–4465. [Google Scholar] [CrossRef]

- Cheng, X.; Lu, J.; Cheng, W. A Survey on RFID Applications in Vehicle Networks. In Proceedings of the 2015 International Conference on Identification, Information, and Knowledge in the Internet of Things, Beijing, China, 22–23 October 2015; pp. 146–151.

- Catarinucci, L.; Colella, R.; Esposito, A.; Tarricone, L.; Zappatore, M. RFID sensor-tags feeding a context-aware rule-based healthcare monitoring system. J. Med. Syst. 2012, 36, 3435–3449. [Google Scholar] [CrossRef] [PubMed]

- Ashidate, S.I.; Murashima, S.; Fujii, N. Development of a helicopter-mounted eye-safe laser radar system for distance measurement between power transmission lines and nearby trees. IEEE Trans. Power Deliv. 2002, 17, 644–648. [Google Scholar] [CrossRef]

- Catarinucci, L.; Colella, R.; de Donno, D.; Tarricone, L. RFID augmented devices for autonomous sensing and computation. In Proceedings of the 2013 European Microwave Conference (EuMC), Nuremberg, Germany, 6–10 October 2013; pp. 999–1002.

- Yang, P.; Wu, W.; Moniri, M.; Chibelushi, C.C. Efficient object localization using sparsely distributed passive RFID tags. IEEE Trans. Ind. Electron. 2013, 60, 5914–5924. [Google Scholar] [CrossRef]

- Deng, F.; He, Y.; Li, B.; Zuo, L.; Wu, X.; Fu, Z. A CMOS pressure sensor tag chip for passive wireless applications. Sensors 2015, 15, 6872–6884. [Google Scholar] [CrossRef] [PubMed]

- Deng, F.; He, Y.; Zhang, C.; Feng, W. A CMOS humidity sensor for passive RFID, sensing applications. Sensors 2014, 14, 8728–8739. [Google Scholar] [CrossRef] [PubMed]

- Deng, F.; He, Y.; Li, B.; Zhang, L.; Wu, X.; Fu, Z.; Zuo, L. Design of an embedded CMOS temperature sensor for passive RFID tag chips. Sensors 2015, 15, 11442–11453. [Google Scholar] [CrossRef] [PubMed]

- Okrainskaya, I.S.; Sidorov, A.I.; Gladyshev, S.P. Electromagnetic environment under over head power transmission lines 110–500 kV. In Proceedings of the 2012 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italy, 20–22 June 2012; pp. 796–801.

- Choi, J.; Cho, J.K.; Seo, C. Analysis on transmission efficiency of wireless energy transmission resonator based on magnetic resonance. In Proceedings of the 2011 IEEE MTT-S International Microwave Workshop Series on Innovative Wireless Power Transmission: Technologies, Systems, and Applications (IMWS), Uji, Japan, 12–13 May 2011; pp. 199–202.

- Pescovitz, D. The power of small tech. In Proceedings of the Colloquium on Structural Information & Communication Complexity, Andros, Greece, 10–12 June 2002; Volume 127, pp. 173–184.

- De Donno, D.; Colella, R.; Tarricone, L.; Catarinucci, L. Novel fully-passive multifunction RFID-enabled devices. In Proceedings of the IEEE Microwave Conference, Rome, Italy, 6–9 October 2014; pp. 271–274.

- De Donno, D.; Catarinucci, L.; Tarricone, L. RAMSES: RFID augmented module for smart environmental sensing. IEEE Trans. Instrum. Meas. 2014, 63, 1701–1708. [Google Scholar] [CrossRef]

- Fiebig, U.C. Modeling rain fading in satellite communications links. In Proceedings of the Vehicular Technology IEEE Conference, Houston, TX, USA, 16–20 May 1999; Volume 3, pp. 1422–1426.

- Meng, Y.S.; Lee, Y.H.; Ng, B.C. The effects of tropical weather on radio-wave propagation over foliage channel. IEEE Trans. Veh. Technol. 2009, 58, 4023–4030. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. General Administration of Quality Supervision, Inspection and Quarantine. Code for Designing of 110~750 kV Overhead Transmission Line; Standard GB50545-2010; China Planning Press: Beijing, China, 2010. (In Chinese)

- Uenishi, K.; Araki, K.; Ishii, H. Transmitter multiplexing system in UHF mobile radio. IEEE Trans. Veh. Technol. 1969, 18, 1–11. [Google Scholar] [CrossRef]

- Alvarez, J.; Chiodo, R.; McDaniel, L.; van Rheeden, D. Frequency and waveform agile receiver covering the ultra high frequency band. In Proceedings of the Aerospace IEEE Conference, Big Sky, MT, USA, 1–8 March 2014; pp. 1–8.

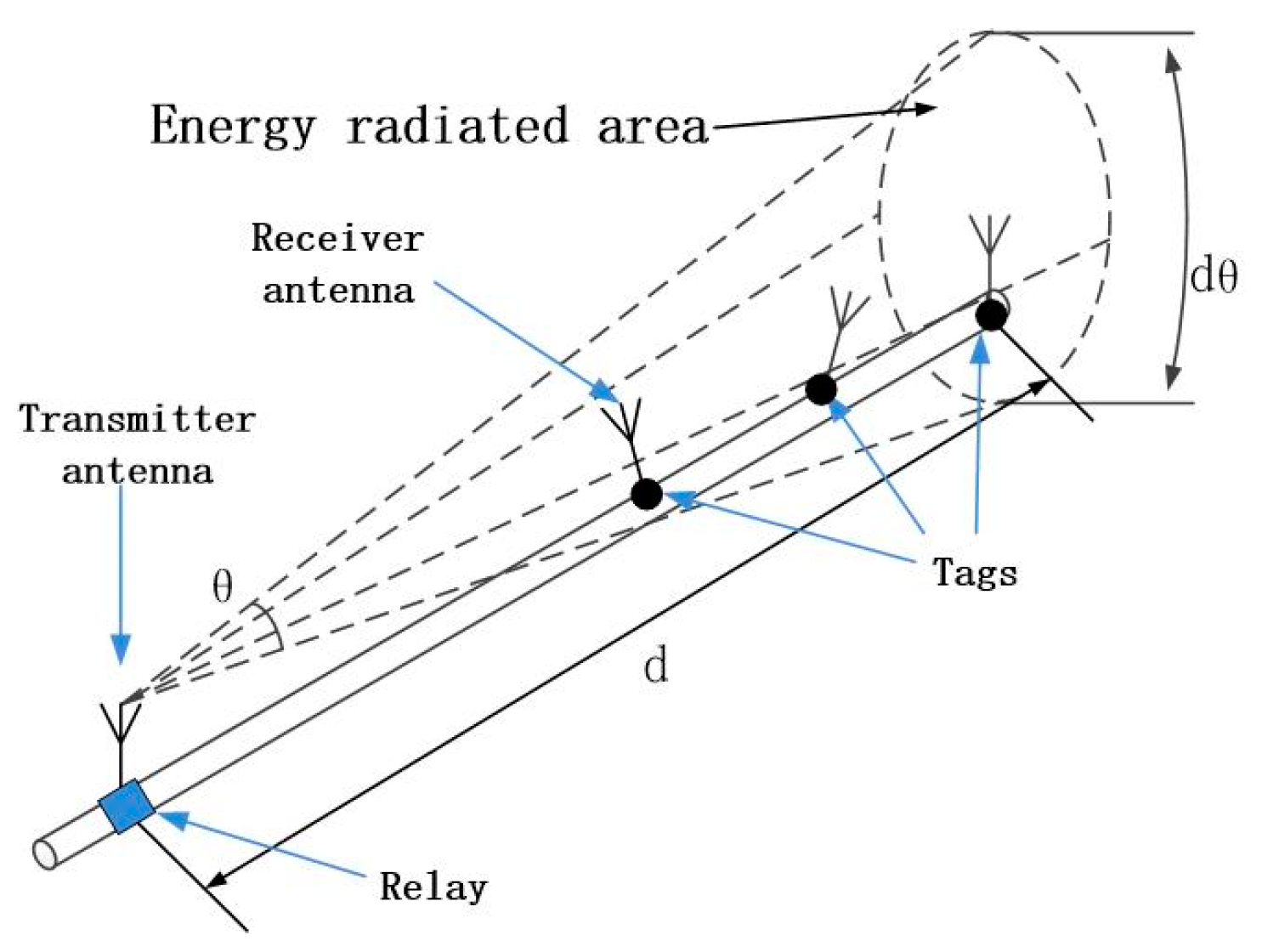

| Power Source | Advantage | Disadvantage |

|---|---|---|

| Lithium battery | Small, light, high power density, low cost | Cannot work for years without charging [16] |

| Photovoltaic panel | Can work even when power line is turn off | Not always available (nights, occlusion with snow etc.), can be destroyed by hail, requires high capacity energy storage [7] |

| Thermobattery | Light enough to installation, can work under harsh environment | Requires electric current in the conductor, needs radiator [27] |

| Vibration-power generating battery | Can work even when power line is turn off | Not always stable, requires high capacity energy storage, moving parts can hardly be mounted on a power line [9] |

| Radio frequency (RF) energy powered from relay (This work) | Light, have simple circuit architecture | Needs a self-powered relay |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, J.; He, Y.; Li, B.; Deng, F.; Wang, T. A Novel Design of Radio Frequency Energy Relays on Power Transmission Lines. Energies 2016, 9, 476. https://doi.org/10.3390/en9060476

Tong J, He Y, Li B, Deng F, Wang T. A Novel Design of Radio Frequency Energy Relays on Power Transmission Lines. Energies. 2016; 9(6):476. https://doi.org/10.3390/en9060476

Chicago/Turabian StyleTong, Jin, Yigang He, Bing Li, Fangming Deng, and Tao Wang. 2016. "A Novel Design of Radio Frequency Energy Relays on Power Transmission Lines" Energies 9, no. 6: 476. https://doi.org/10.3390/en9060476