1. Introduction

With the depletion of fossil fuel and increasingly severe global warming issues, renewable energy sources and high-efficiency energy consumption technologies are attracting wide interest [

1]. Traditionally, heat and electricity are provided with boilers and thermal power plants separately, whose overall efficiency is very low [

2]. The low energy utilization efficiency means a waste of resources and a large amount of greenhouse gas emissions particularly carbon dioxide [

3]. The existing problems provide incentives to utilize energy more efficiently.

The combined heat and power (CHP) system is a very promising technology in reducing fuel cost and greenhouse gases emission [

4,

5,

6,

7]. A CHP system is able to produce heat and electricity in a single process from oil or natural gas at an efficiency of over 80% compared to an average of 30%–35% for conventional thermal generation [

8,

9,

10,

11]. The extraction condensing steam turbine CHP is increasingly used in both industry and residency because the ratio between heat and electricity output of CHPs can be adjusted to satisfy different heat and electric demand [

12,

13,

14,

15].

The output of CHP is driven by load demand [

16,

17]. Heat to electricity ratio (HTER) is introduced in this paper to characterize the heat and electricity output proportion of CHPs. When heat demand is high, the CHP is operated with the heat leading (HL) strategy to mainly satisfy heat load, and HTER is at a high value correspondingly. When electricity load is large, the CHP is operated with electricity leading (EL) strategy to supply electric load first, where HTER is at a low level [

18]. During valley hours, the output of CHP has to be decreased.

In most research, the heat and electricity output of CHPs is only to meet the demand of residential, commercial or industrial users, which are called isolated CHPs in this paper. For isolated CHPs, they only produce heat and electricity for customers and have no interactions with heat and electricity networks. In [

19], the domestic energy cost savings of isolated CHPs are investigated with demand response based on the proposed model-predictive control strategy. Results show that the energy cost reduces dramatically in the real-time market. The authors in [

20] construct environmental impact models for a traditional separation production and isolated combined cooling heat and powers (CCHPs), respectively, to analyze their energy consumption. The energy savings and emission reductions are maximized when the capacity of the CCHP system is optimized by a genetic algorithm. A multi-objective optimization model, including technical, economic, energetic and environmental indicators, is developed in [

21] for the design of CHP plants in realistic conditions. The main drawback of the above research is that CHP is optimized in either EL or HL strategies, and they also neglect that HTER varies with the overall efficiency and loading level of CHPs [

22].

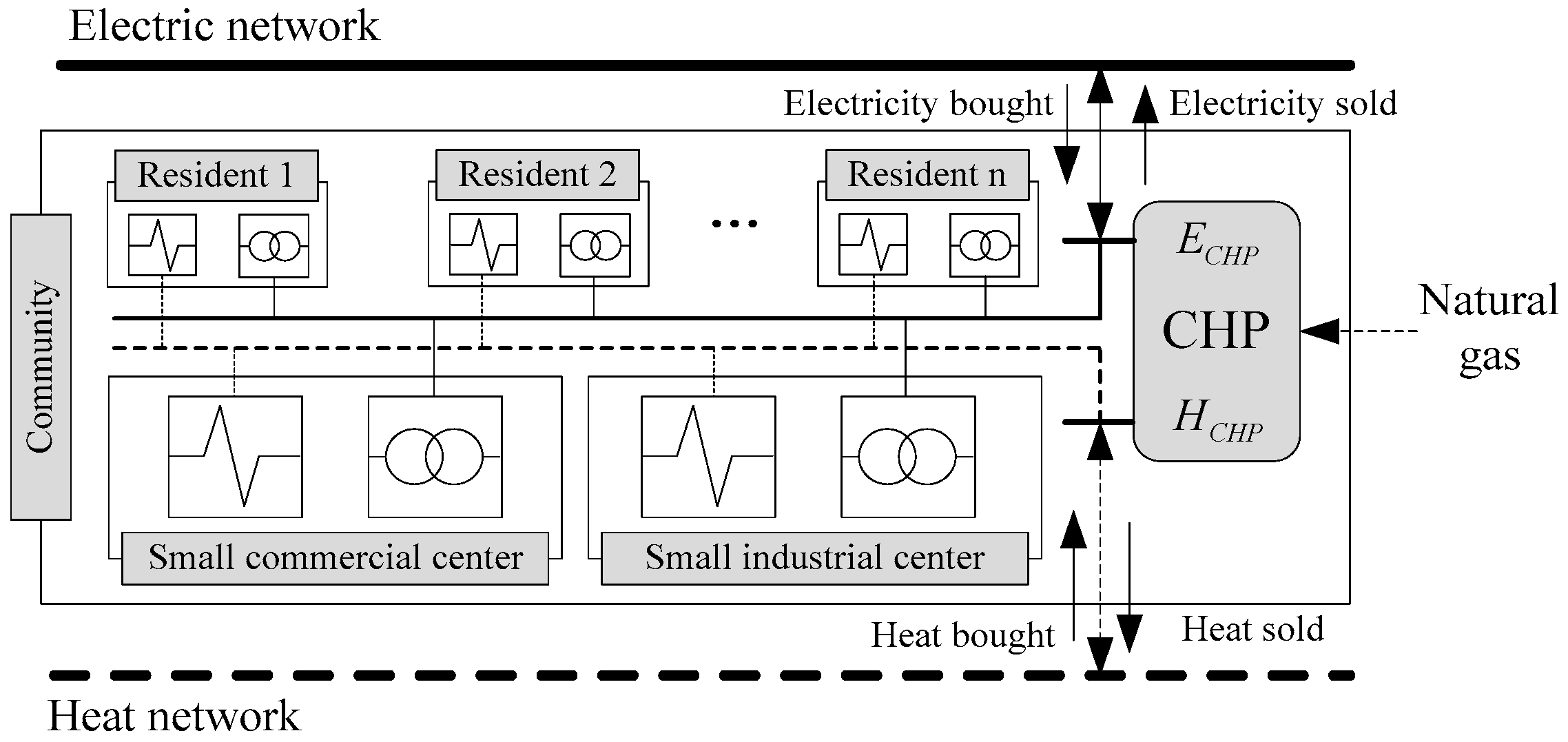

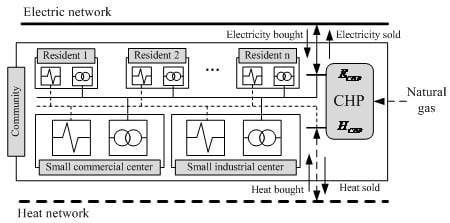

To achieve energy consumption in a more efficient way, different energy carrier networks are connected together [

23]. Then, network-connected CHPs are the core of such an energy system, which are connected to heat and electric networks. Surplus heat and electricity are exported to corresponding heat and electricity networks after the load in the community is satisfied. The matching analysis is conducted in [

24] to access the capability of CHP from electrical grid feed-in and heat grid feed-in strategies, respectively. Results show that the matching results have no linear relation with the energy consumption. Reference [

25] is focused on reducing the operational cost of a CHP-based microgrid through multi-objective self-scheduling optimization. A techno-economic model for CHP is developed in [

26] based on dynamic economics, and the heating cost of the system is reduced to the least with the application of CHP in regulating peak load. Aforementioned literature is mainly concentrated on the least operation cost or least emissions, which does not necessarily mean high profit.

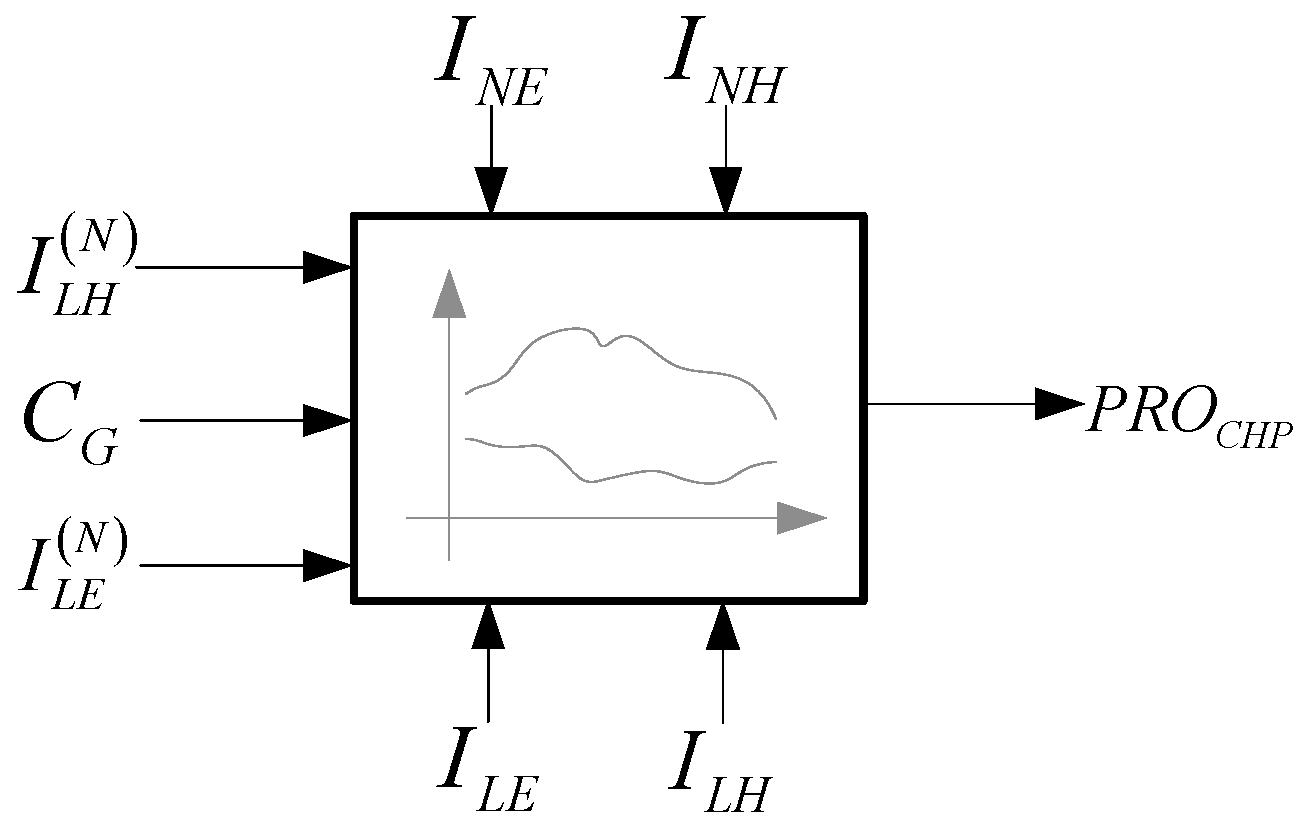

In this paper, the network-connected CHPs owned by the community have the characteristics that both overall efficiency and HTER vary with the system loading level. After the demand in the community is satisfied, surplus heat and electricity are sold to the heat and electricity networks. Then, based on the relationship between community heat and electric demand and CHP output, four operation modes are obtained. Finally, a discrete optimization model is derived, which is determined by the price intervals (30 min) and operation modes of CHP together. After demonstrating the proposed model on a 1 MW network-connected CHP, both energy purchasing costs and profits are optimized. Results show the profit is maximized during valley hours, and the cost of buying additional energy is minimized during peak hours.

The novelty of this paper is that it: (i) proposes a network-connected CHP model with time-varying bi-directional energy flow between itself and networks; (ii) constructs the profit models for network-connected CHPs under different load conditions; and (iii) proposes a discrete optimization strategy to maximize profit in real time.

The remaining parts of this paper are organized as follows: in

Section 2, the model of a network-connected CHP is presented; the profit model for the CHP is established in

Section 3, followed by the discrete optimization model in real time; in

Section 4, a 1 MW CHP is optimized with the proposed models; finally, conclusions are drawn in

Section 5.

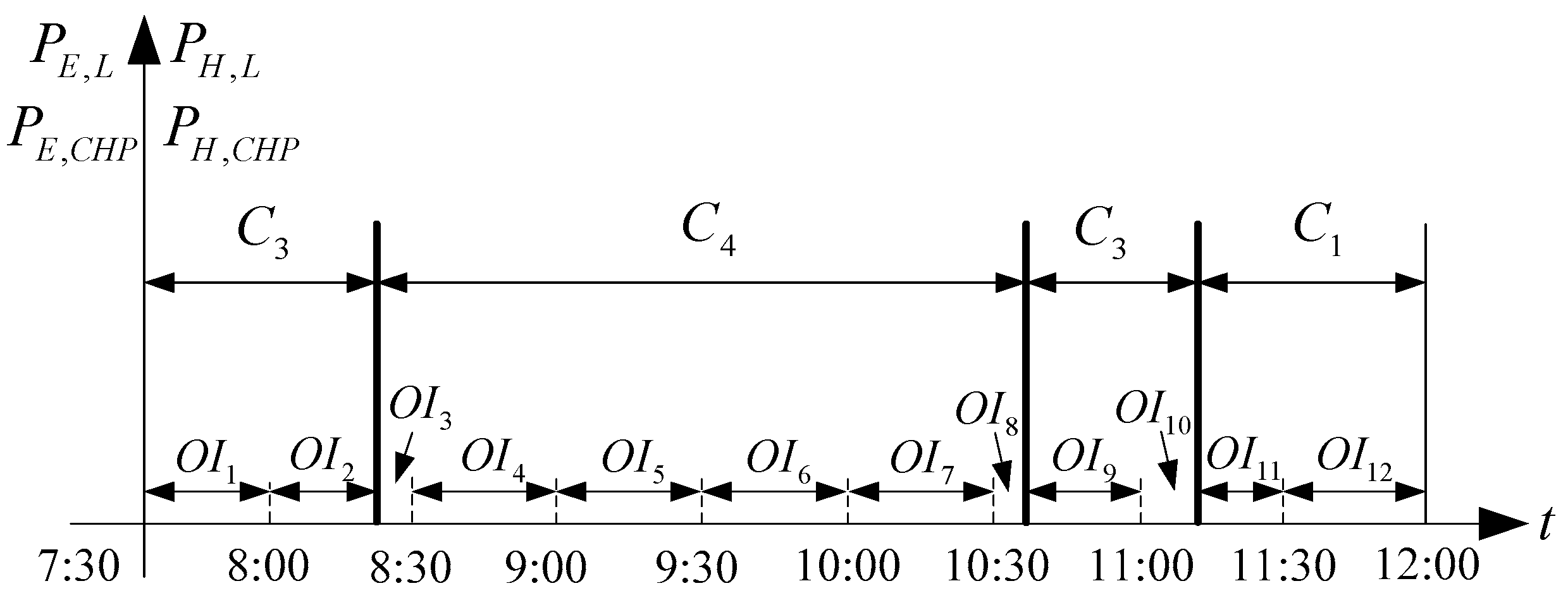

4. Demonstration Examples

In this paper, the nominal capacity of the adopted network-connected CHP is 1 MW. Other parameters are shown in

Table A2 in the

Appendix. In

Figure 8, the heat and electric demand are from historical data of a new residential district in Braunschweig Germany, which was measured and recorded at intervals of fifteen minutes during one year [

30,

31].

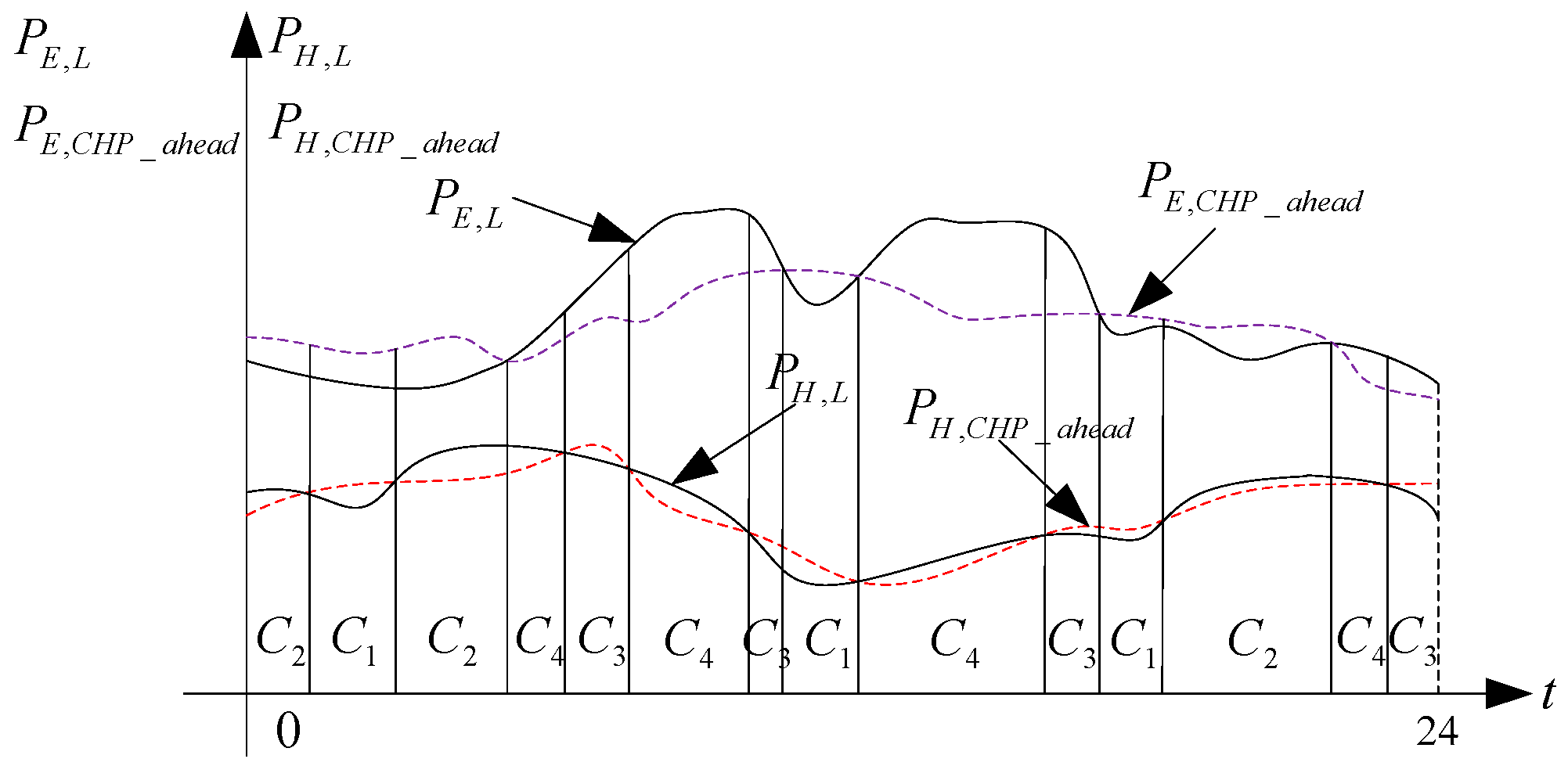

PE,CHP and

PH,CHP are the electric and heat output of CHP, respectively, which are obtained from the day-ahead operating data. It is easily found that the sum of

PE,CHP and

PH,CHP is the nominal capacity of the CHP, 1 MW. The heat load is high at night, about 0.7 MW, and low in the daytime, reaching a minimum value 0.35 MW at about 14:30. On the contrary, the electric load is low at night, the minimum being 0.3 MW at 24:00, and rather high in the daytime, reaching a maximum 1 MW at 11:00. Around 12:00, the electric load drops a little for the short break at noon. The load condition determines the operation modes of the CHP. During the night, the output of CHP is mainly in the form of heat to satisfy heat demand and the HTER is at a high value. In the daytime, the CHP is operated at a low HTER level to produce more electricity to satisfy the electric demand.

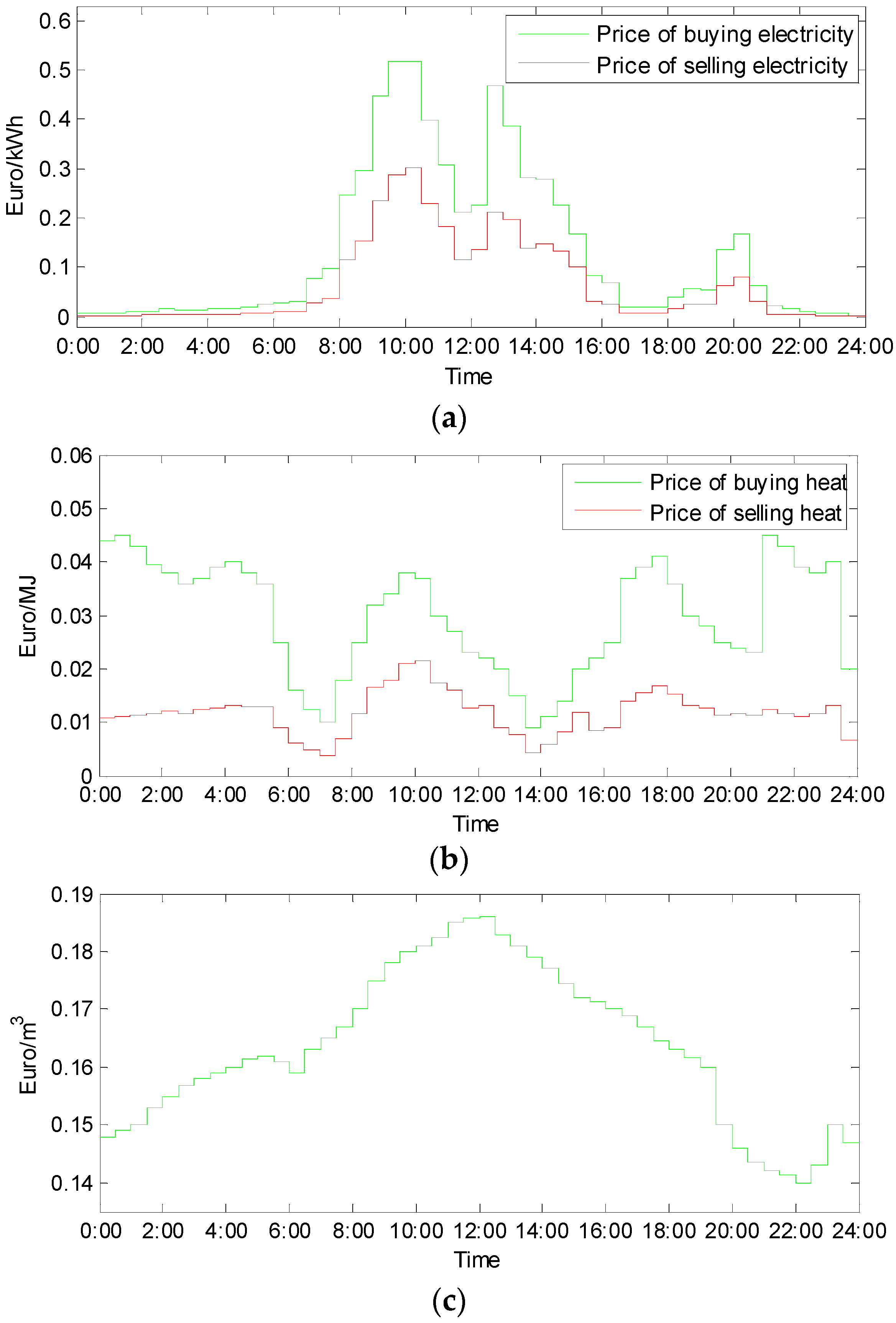

The prices of natural gas, buying and selling heat and electricity are shown in

Figure 9 [

32]. From

Figure 9a,b, we can find that the prices of selling heat and electricity to the networks are lower than those of buying them. The highest electricity buying and selling price are at around 10:00, about 0.519 Euro/kWh and 0.3 Euro/kWh, respectively. The lowest prices happen at 24:00, just about 0.003 Euro/kWh and 0.001 Euro/kWh, respectively. While the highest heat buying price (0.045 Euro/MJ) and selling price (0.02 Euro/MJ) occurs at 1:00 and 10:30, respectively. The lowest two prices for heat are 0.009 Euro/kWh and 0.003 Euro/MJ at 14:00 and 7:30, respectively. Compared to the heat and electricity price, the price of the natural gas fluctuates at a smaller range.

Based on

Figure 8 and

Figure 9, the operation modes of the CHP can be identified, shown in

Table 1. All four modes occur in one day, and C

3 appears with the maximum number. In Mode C

3, the electric demand is high, and the deficit is satisfied by buying additional electricity from the network. Modes C

2 and C

4 also exist, where additional heat or both additional heat and electricity are bought from the corresponding networks. However, Mode C

1 only exists between 21:50 and 22:15, 23:30 and 24:00. Only at night, when the heat and electric demand happen to be both at a low level, are the extra heat and electricity sold to the networks. In the other modes, the CHP is modified to a certain level of HTER to satisfy at least one kind of load as much as possible.

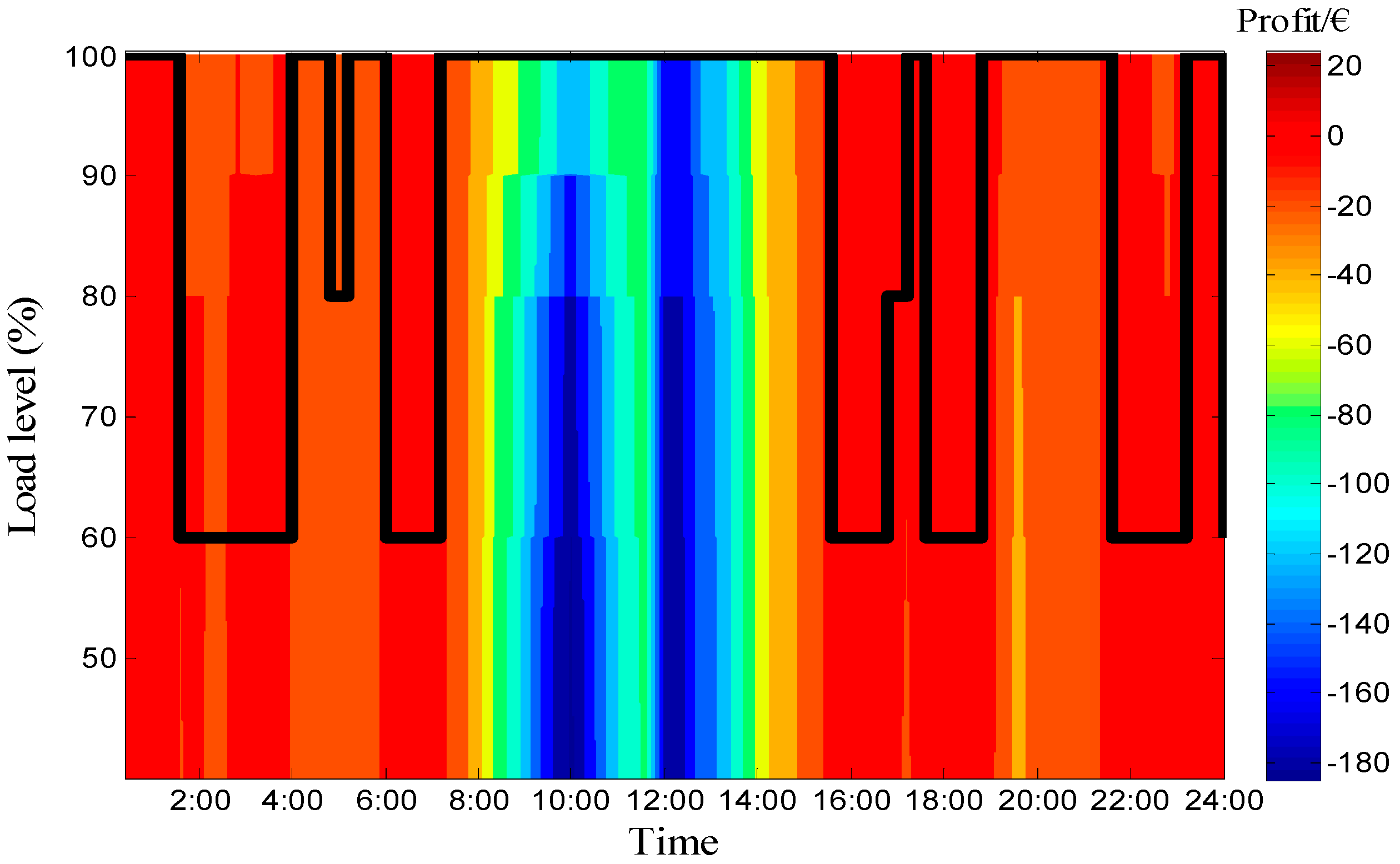

Based on the 60

OIs in

Table 1, the profits of the CHP at different operation points in real time are obtained, shown in

Figure 10.

In

Figure 10, the colorful figure is the profit distribution for CHP at different loading levels. The black line is the optimal operation points for CHP where the profits are maximized, and the value is shown in

Table 2. The positive value in

Table 2 means extra profit is obtained, and the negative value means the energy purchasing fee has to be paid, which has been minimized. From

Figure 10, the maximum profits occur between 0:00 and 7:00, 15:00 and 24:00, where the profits are mostly positive. The profit reaches its maximum (12.07 Euro) between 19:30 and 19:50. Between 7:10 and 16:45, the profits for CHP are all negative. The phenomenon is caused by the high electric demand. The electric load cannot be satisfied at noon, although the electricity output of CHP reaches its maximum. Thus, a lot of electricity has to be bought from the electric network at a high price. The maximum energy purchasing fee is about 150 Euro between 12:30 and 13:00. Of course, the fee has been minimized through modifying the output of the CHP. It can be found that the profit of CHP is determined a lot by the electricity price for its value is higher than that of the heat. Through optimization, the community’s expense to buy energy is reduced to the minimum, and net profit reaches the maximum in real time.

Before optimization, the profit of the CHP is shown in

Table 3. The community’s total profit for a day is −1,637.82 Euro. By comparison, the optimized total profit from

Table 2 is −1,443.46 Euro, reducing community’s energy cost by about 11.87%.

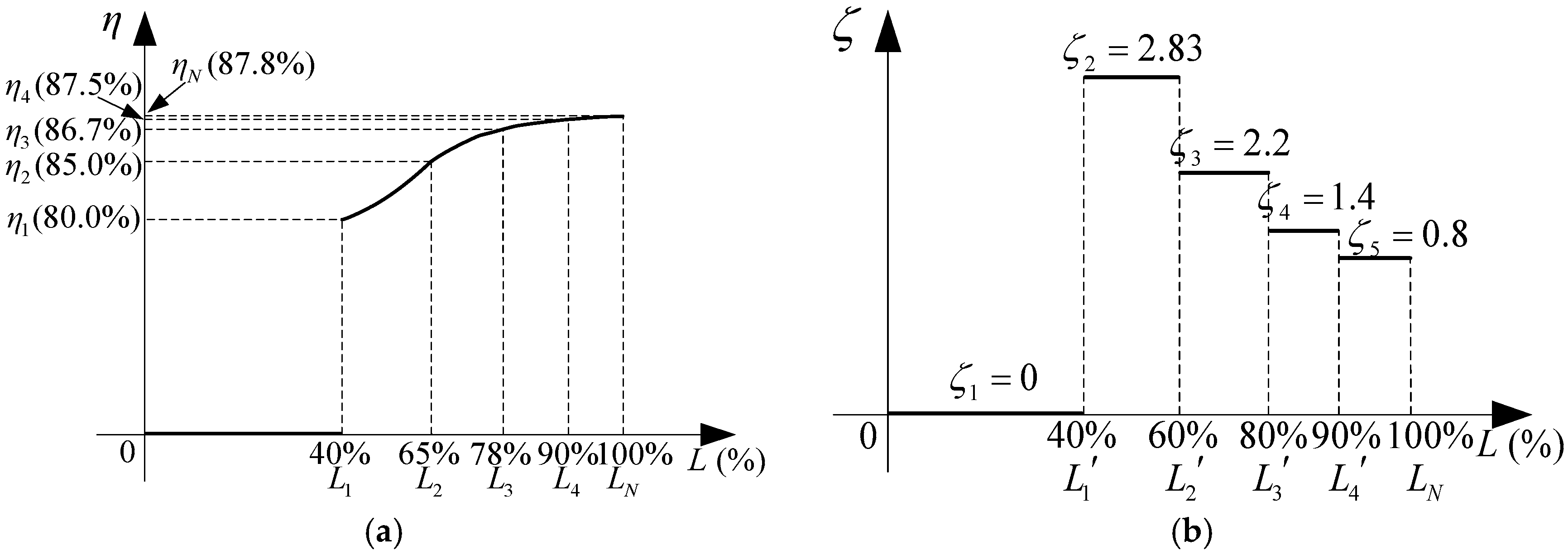

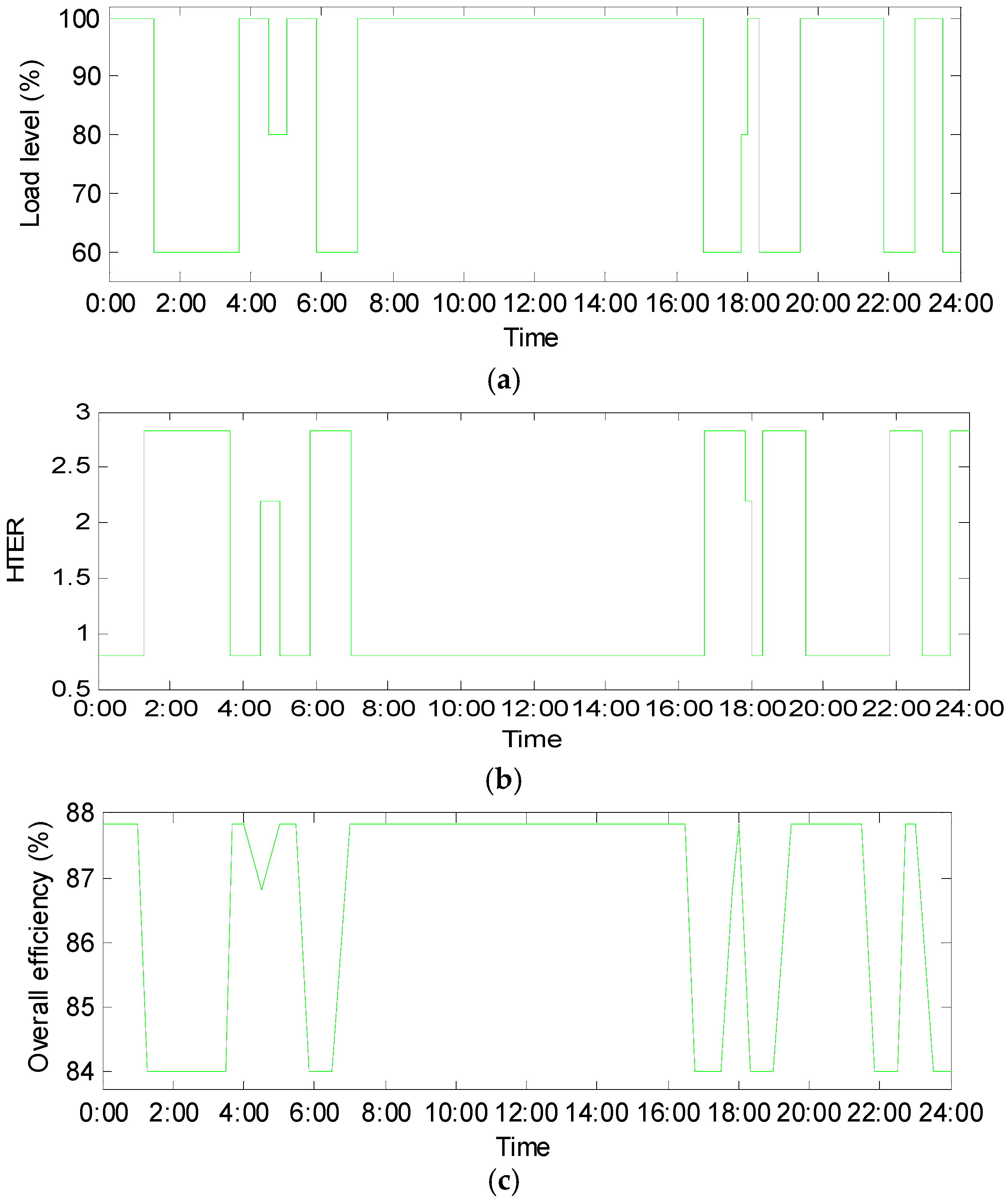

The loading level, HTER and overall efficiency for the optimal operation points in

Figure 10 are shown in

Figure 11. The optimal loading level varies a lot in the night time, mostly at 60%, and the corresponding HTER is at a high value of 2.83, with the optimal efficiency around just 84%. In the daytime, the CHP is at full load, with a low HTER and high efficiency, 0.8% and 87.8%, respectively.

It is also found that high loading level does not always mean high profit for the residents. The HTER also affects the profit a lot. Comparing

Figure 11a to

Figure 11b, when the loading level is high, the HTER is at a low value to produce more electricity. Correspondingly, when the loading level is low, the HTER is at a high value to produce more heat to satisfy the heat load first. The HTER and efficiency are both functions of the loading level.