Performance Evaluation of a Helical Coil Heat Exchanger Working under Supercritical Conditions in a Solar Organic Rankine Cycle Installation

Abstract

:1. Introduction

2. Supercritical Heat Transfer in the Concentrated Photovoltaic/Thermal-Rankine Set-up

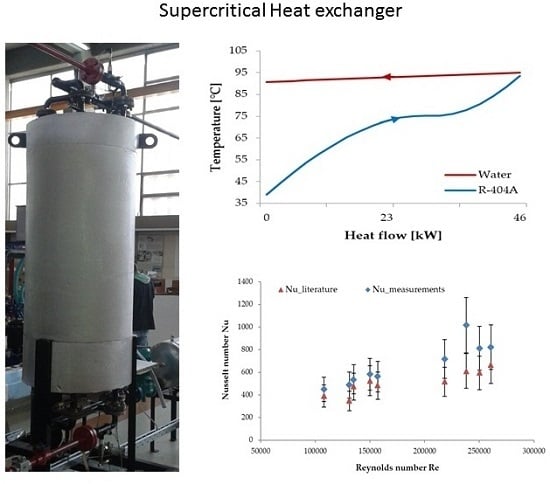

2.1. Transcritical Organic Rankine Cycle and Supercritical Heat Transfer in the Heat Exchanger

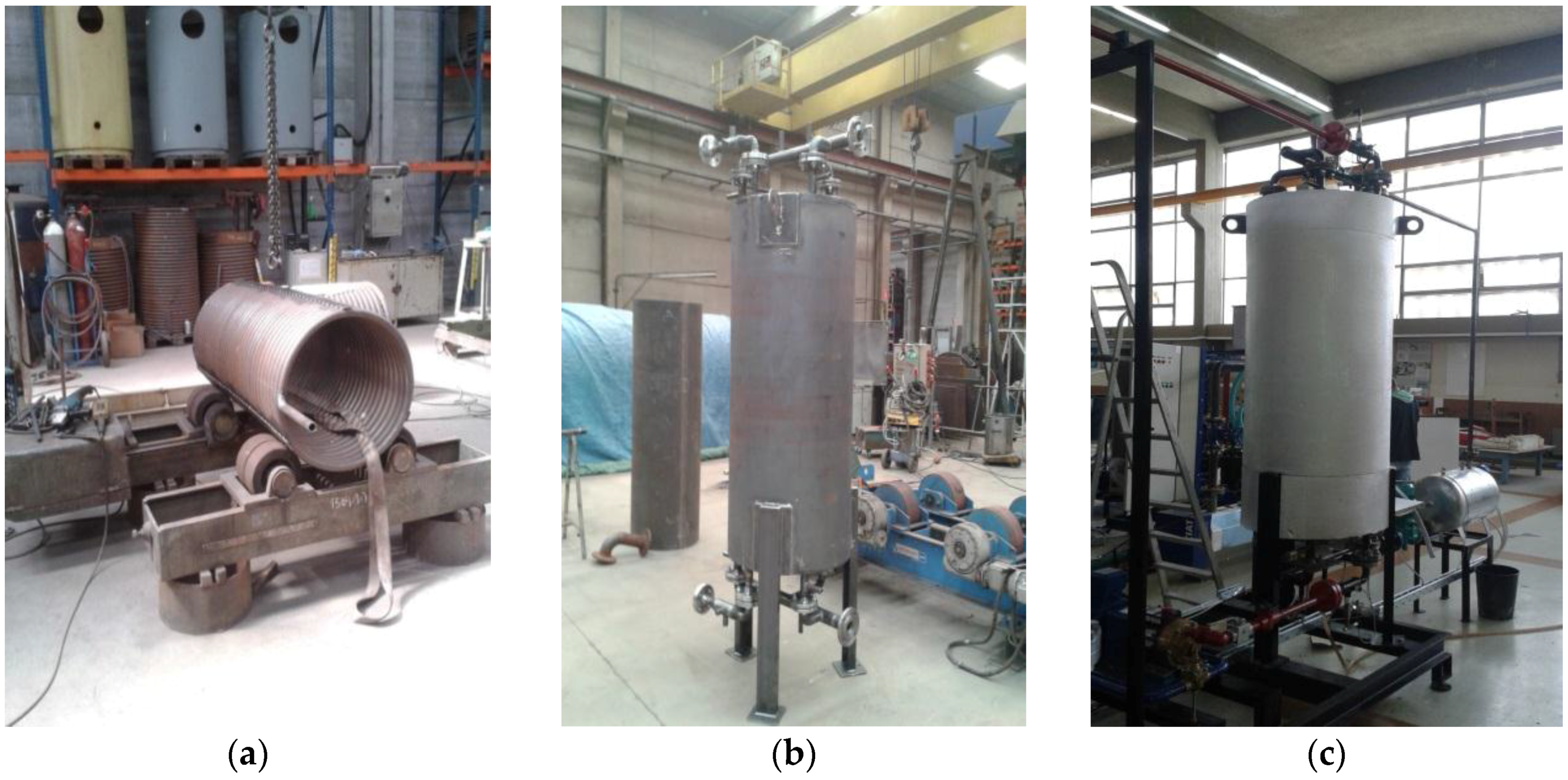

2.2. Description of the Concentrated Photovoltaic/Thermal-Rankine Set-up

Uncertainty Analysis

3. Design Procedure of the Supercritical Heat Exchanger

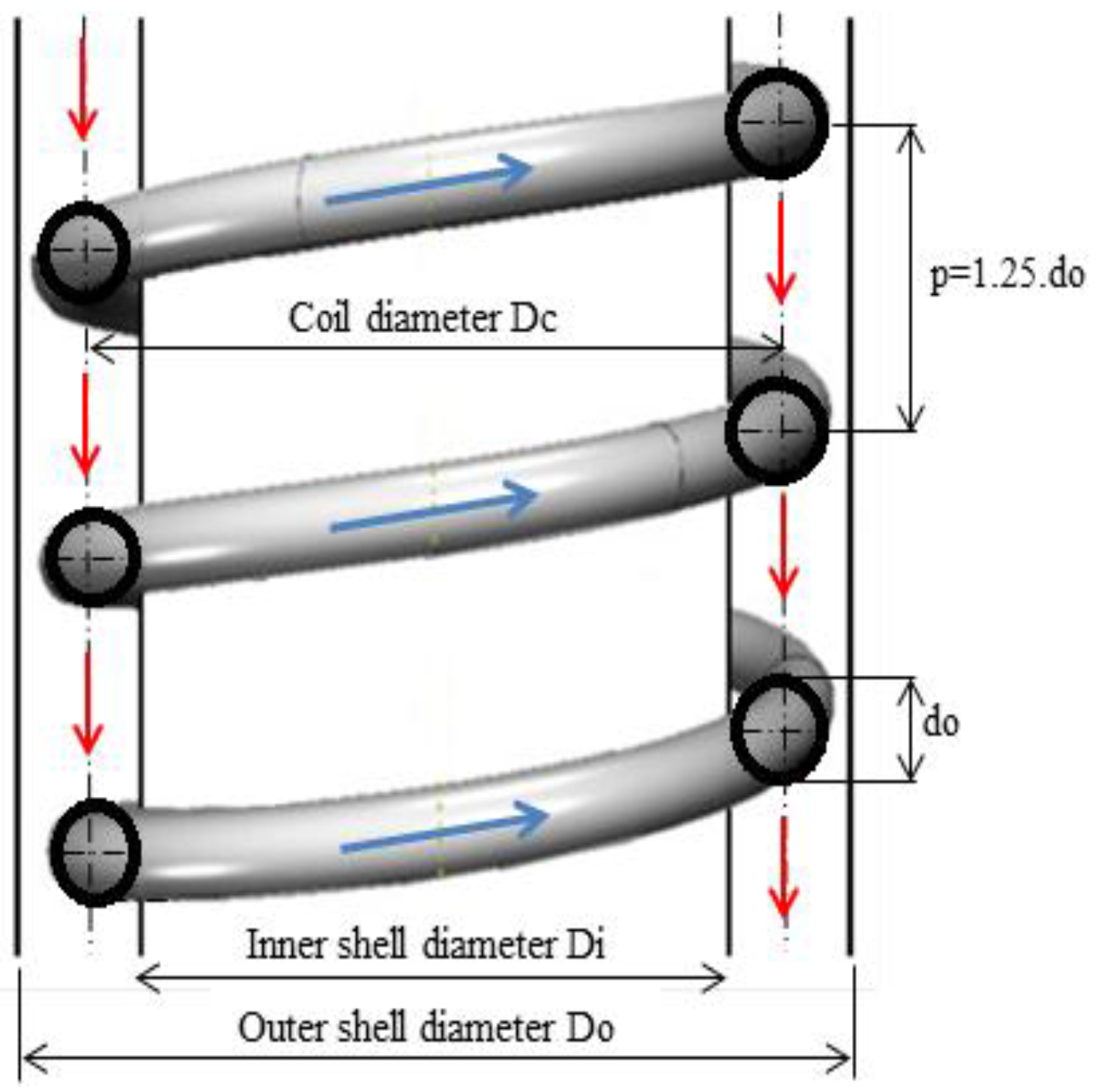

3.1. Design Characteristics of the Helical Coil Heat Exchanger

Design Parameters of the Helical Coil Heat Exchanger

- -

- The coil length Lcoil, needed to make Ncoil turns:

- -

- The volume occupied by the coil:

- -

- The volume of the shell-side (annulus):

- -

- The volume available for the flow of fluid in the annulus:

- -

- The shell-side equivalent diameter of the coiled tube:

3.2. Methodology for Designing the Heat Exchanger

3.2.1. Determining the Heat Transfer Coefficient at the Outside of the Helical Coil

3.2.2. Determining the Heat Transfer Coefficient Inside the Coiled Tube

3.3. Computational Results and Final Dimensions of the Heat Exchanger

4. Testing of the Heat Exchanger

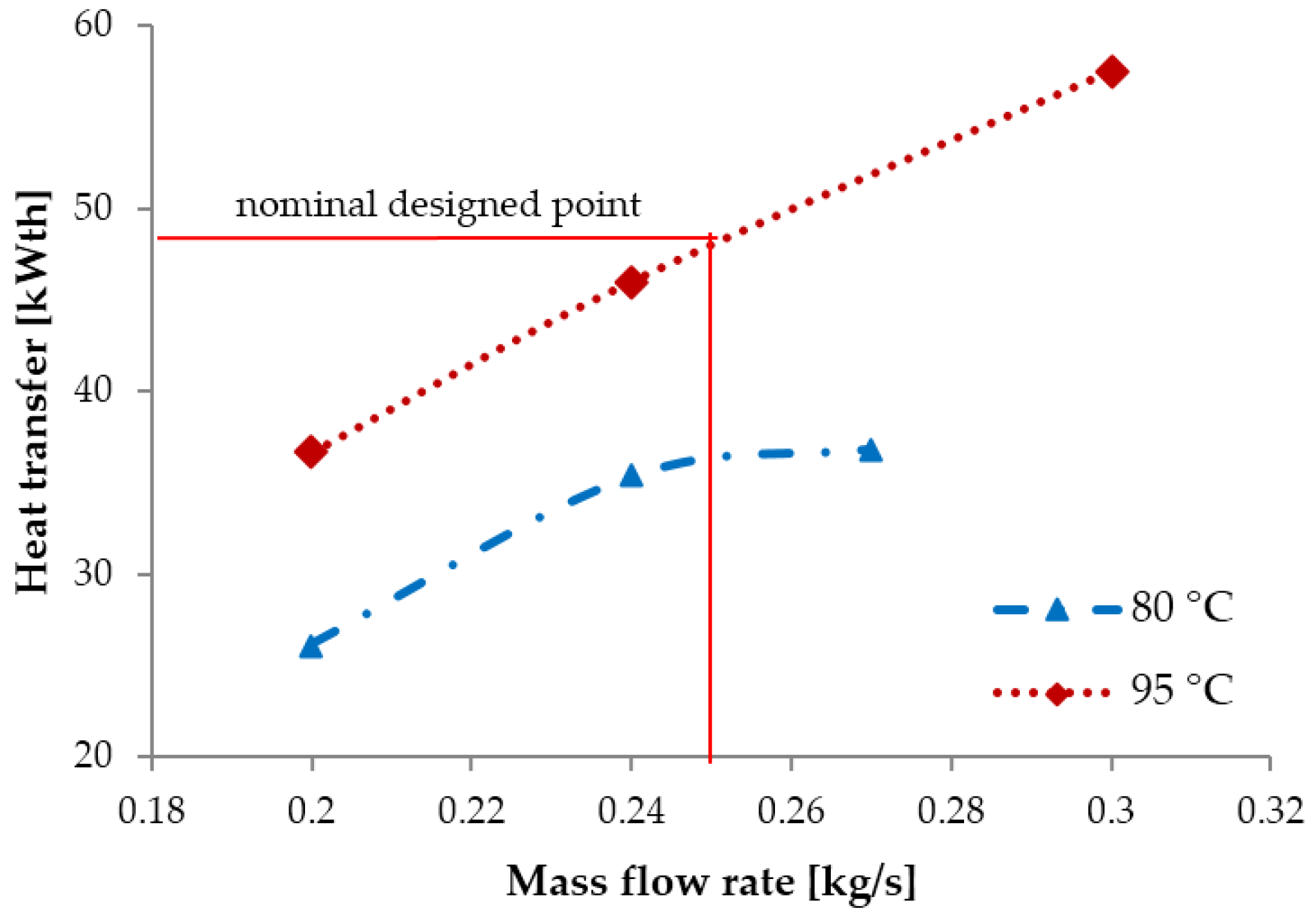

4.1. Performance Evaluation of the Heat Exchanger at Variable Mass Flow Rate of the Organic Fluid and at Heat Source Inlet Temperatures of 80 °C and 95 °C

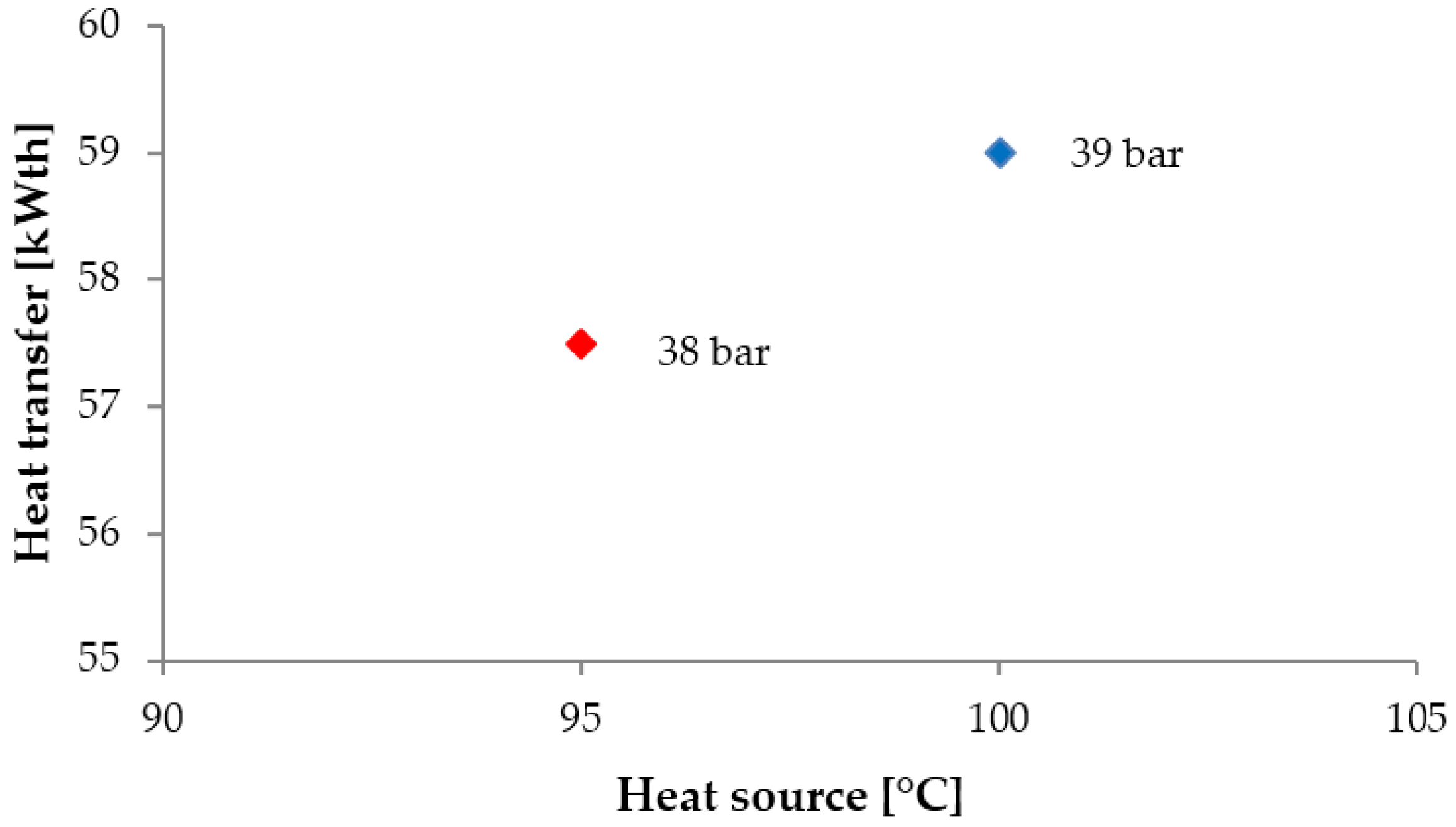

4.2. Comparison of the Performance at Constant Mass Flow Rate of 0.30 kg/s and Heat Source Inlet Temperatures of 95 °C and 100 °C

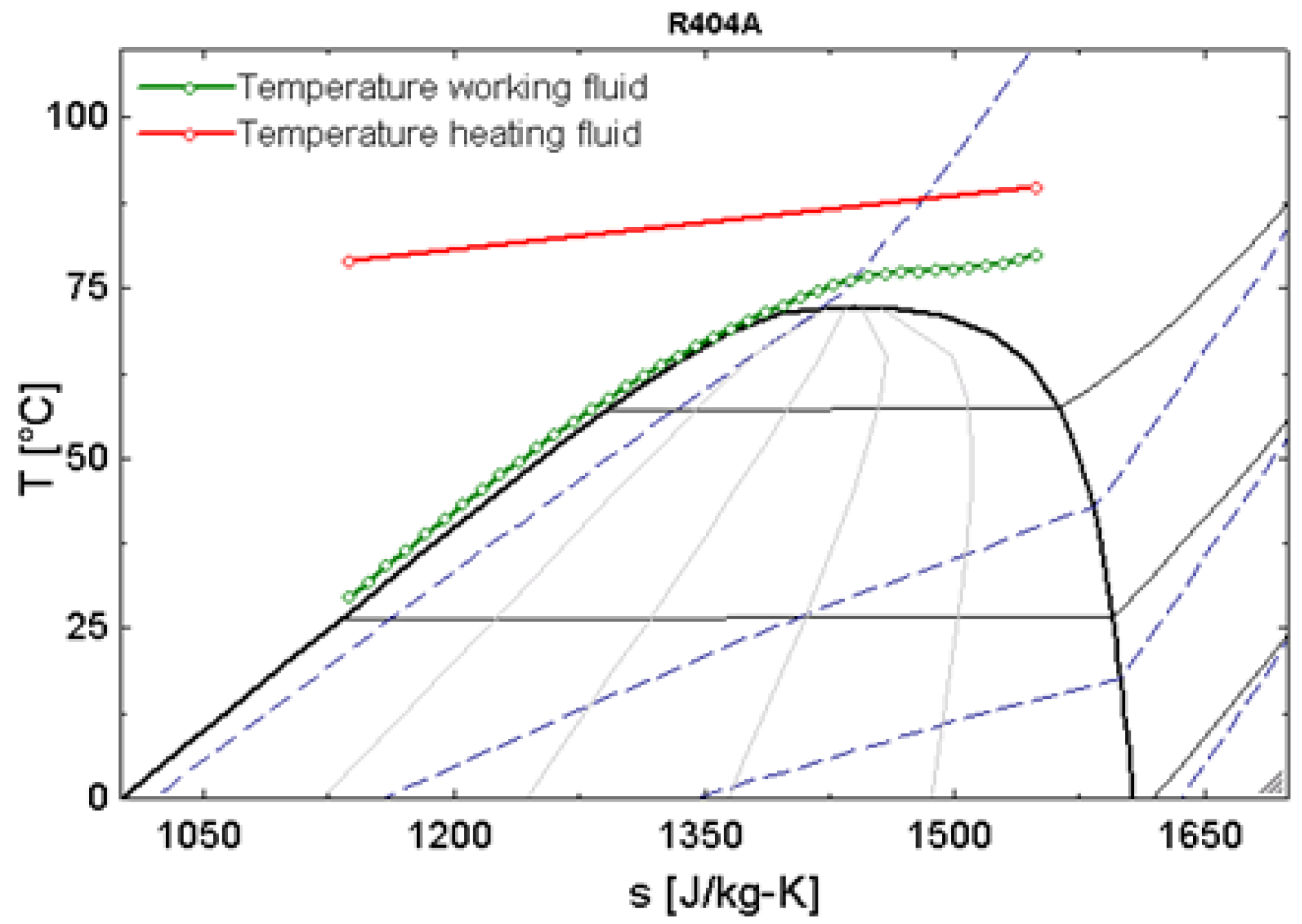

4.3. Analysis of the Thermal Match in the Helical Coil Heat Exchanger at 95 °C

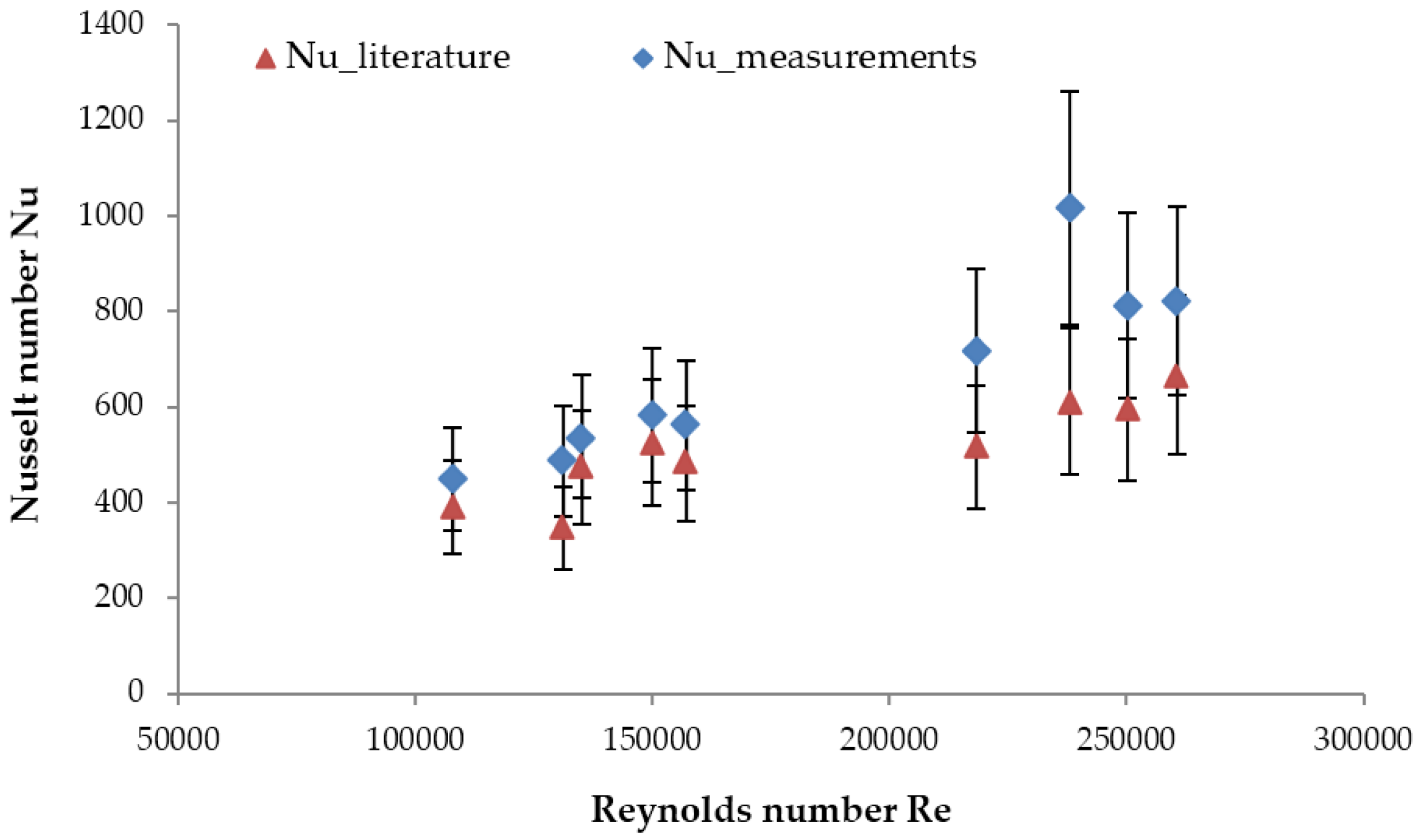

4.4. Measurement Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| A | Total heat transfer area (m2) |

| CO2 | Carbon dioxide |

| CPV/T | Concentrated Photovoltaic/Thermal |

| Cp | Specific heat capacity (J/kg·K) |

| di | Tube inner diameter (mm) |

| do | Tube outer diameter (mm) |

| Dc | Coil diameter (m) |

| De | Shell-side equivalent diameter of the coiled tube (m) |

| Di | Inner shell diameter (m) |

| Di_out | Outer side of the inner shell diameter (m) |

| Do | Outer shell diameter (m) |

| Do_in | Inner side of the outer shell diameter (m) |

| dbaseline | Baseline diameter (mm) |

| dactual | Actual diameter of the tube (mm) |

| EES | Engineering equation solver |

| f | Friction factor (-) |

| G | Mass flux (kg/m2s) |

| HTC | Heat transfer coefficient (W/m2k) |

| Hcoil | Height of the HX (m) |

| ∆h | Average enthalpy |

| LMTD | Logarithmic mean temperature difference (∆Tlog) |

| L | Coil length (m) |

| m | Mass flow rate (kg/s) |

| Ncoil | Number of coil turns |

| ORC | Organic Rankine Cycle |

| p | Pressure (bar) |

| ∆p | Pressure drop (bar) |

| pitch | Spacing between consecutive coil turns |

| Rc: | Coil radius (m) |

| ri | Tube radius (m) |

| Q | Heat transfer (kw) |

| Qi | Heat transferred in one control volume (kw) |

| T | Temperature (°C) |

| ∆T | Temperature difference (°C) |

| t | Tube thickness (mm) |

| U | Overall heat transfer coefficient (W/m2k) |

| Va | Volume of the shell-side (annulus) (m3) |

| Vc | Volume occupied by the coil (m3) |

| Vf | Volume available for the flow of fluid in the annulus (m3) |

| De | Dean number |

| Pr | Prandtl number |

| Re | Reynolds number |

| Nu | Nusselt number |

| µ | Fluid’s bulk viscosity (kg/ms) |

| μw | Fluid’s viscosity at the wall temperature (kg/ms) |

| λ | Thermal conductivity of the tube (W/mk) |

| δ | Curvature ratio (-) |

References

- Lecompte, S.; Huisseune, H.; van den Broek, M.; Vanslambrouckb, B.; de Paepea, M. Review of organic Rankine cycle (ORC) architectures for waste heat recovery. Renew. Sustain. Energy Rev. 2015, 47, 448–461. [Google Scholar] [CrossRef]

- Bringer, R.P.; Smith, J.M. Heat transfer in the critical region. AIChE J. 1957, 3, 49–55. [Google Scholar] [CrossRef]

- Dickinson, N.L.; Weich, C.P. Heat Transfer to Supercritical Water; The American Society of Mechanical Engineers: New York, NY, USA, 1958; pp. 745–751. [Google Scholar]

- Shitsman, M.E. Heat transfer to water, oxygen and carbon dioxide in the approximately critical range. Teploenergetiky 1959, 1, 68–72. [Google Scholar]

- Krasnoshchekov, E.A.; Protopopov, V.S. Heat transfer at supercritical region in flow of carbon dioxide and water in tubes. Therm. Eng. 1959, 12, 26–30. (In Russian) [Google Scholar]

- Petukhov, B.S.; Krasnoshchekov, E.A.; Protopopov, V.S. An Investigation of Heat Transfer to Fluids Flowing in Pipes under Supercritical Conditions; ASME University of Colorado: Boulder, CO, USA, 1961; pp. 569–578. [Google Scholar]

- Shitsman, M.E. Impairment of the heat transmission at super-critical pressures. Teplofiz. Vysok. Temp. 1963, 1, 267–275. (In Russian) [Google Scholar]

- Bishop, A.A.; Sandberg, R.O.; Tong, L.S. Forced Convection Heat Transfer to Water at Near Critical Temperatures and Supercritical Pressures; WCAP-5449; CONF-650603-1; Westinghouse Electric Corp.: Pittsburgh, PA, USA, February 1964. [Google Scholar]

- Ackermann, J.W. Pseudo-boiling heat transfer to supercritical pressure water in smooth and ribbed tubes. J. Heat Transf. 1970, 92, 490–498. [Google Scholar] [CrossRef]

- Yamagata, K.; Nishikawa, K.; Hasegawa, S.; Fujii, T.; Yoshida, S. Forced convection heat transfer to supercritical water flowing in tubes. Int. J. Heat Mass Transf. 1972, 15, 2575–2593. [Google Scholar] [CrossRef]

- Jackson, J.D.; Fewster, J. Forced Convection Data for Supercritical Pressure Fluids. Heat Transf. Fluid Flow Serv. 1975, 21540. [Google Scholar]

- Vikrev, Y.V.; Lokshin, V. An experimental study of temperature conditions in horizontal steam generating tubes at supercritical pressures. Teploenergetika 1 1964, 11, 12–16. [Google Scholar]

- Jackson, J.D.; Hall, W.B. Influences of buoyancy on heat transfer to fluids flowing in vertical tubes under turbulent conditions. In Turbulent Forced Convection in Channels and Rod Bundles; Hemisphere Publishing Corporation: Washington, DC, USA, 1979; Volume 2, pp. 613–640. [Google Scholar]

- Garimella, S. High Condensing Temperature Heat Transfer Performance of Low Critical Temperature Refrigerants; ARTI 21CR Program Contract number 610-20060; Air-Conditioning and Refrigeration Technology Institute: Arlington, VA, USA, 2006. [Google Scholar]

- Mokry, S.; Pioro, I.; Farah, A.; King, K.; Gupta, S.; Peiman, W.; Kirillov, P. Development of supercritical water heat-transfer correlation for vertical bare tubes. Nucl. Eng. Des. 2011, 241, 1126–1136. [Google Scholar] [CrossRef]

- Lazova, M.; Daelman, S.; Kaya, A.; Henk, H.; De Paepe, M. Heat transfer in horizontal tubes at supercritical pressures for ORC application. In Proceedings of the 10th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics, Orlando, FL, USA, 14–16 July 2014.

- Haskins, H.J.; Taylor, R.M.; Osborn, D.B. Development of solar receiver for an organic Rankine cycle engine. In Proceedings of the 16th Intersociety Energy Conversion Engineering Conference ‘Technologies for the Transition’, Atlanta, GA, USA, 9–14 August 1981; Volume 2, pp. 1764–1769.

- Amon, C.H.; Mikicb, B. Spectral Element Simulations of Unsteady Forced Convective Heat Transfer: Application to Compact Heat Exchanger Geometries. Numer. Heat Transf. A 1991, 19, 1–19. [Google Scholar] [CrossRef]

- Schuster, A.; Karellas, S.; Leontaritis, A.D. Influence of supercritical ORC parameters on plate heat exchanger design. Appl. Therm. Eng. 2012, 33–34, 70–76. [Google Scholar]

- Shao, Y.-L.; Yang, L.; Zhang, C.-L. Comparison of heat pump performance using fin-and-tube and microchannel heat exchangers under frost conditions. Appl. Energy 2010, 87, 1187–1197. [Google Scholar] [CrossRef]

- Lecompte, S.; Lemmens, S.; Huisseune, H.; van den Broek, M.; de Paepe, M. Multi-Objective Thermo-Economic Optimization Strategy for ORCs Applied to Subcritical and Transcritical Cycles for Waste Heat Recovery. Energies 2015, 8, 2714–2741. [Google Scholar] [CrossRef] [Green Version]

- Klein, S.A. Engineering Equation Solver (EES); F-Chart Software: Madison, WI, USA, 2013. [Google Scholar]

- Liu, H.; Kakaç, S.; Pramuanjaroenkij, A. Heat Exchangers, Selection, Rating, and Thermal Design; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Kosmadakis, G.; Manolakos, D.; Papadakis, G. Experimental investigation of a low-temperature organic Rankine cycle (ORC) engine under variable heat input operating at both subcritical and supercritical conditions. Appl. Therm. Eng. 2016, 92, 1–7. [Google Scholar] [CrossRef]

- Lazova, M.; Daenens, D.; Kaya, A.; van Belleghem, M.; Huisseune, H.; Kosmadakis, G.; Manolakos, D.; de Paepe, M. Design of a Supercritical Heat Exchanger for an Integrated CPV/T-RANKINE Cycle. In Proceedings of the Third International Seminar on ORC Power Systems, Brussels, Belgium, 12–14 October 2015.

- Kosmadakis, G.; Manolakos, D.; Papadakis, G. Experimental testing of a small-scale supercritical ORC at low-temperature and variable conditions. In Proceedings of the 3rd International Seminar on ORC Power Systems (ASME-ORC2015), Brussels, Belgium, 12–14 October 2015.

- Lemmon, E.W. Pseudo-Pure Fluid Equations of State for the Refrigerant Blends R-410A, R-404A, R-507A, and R-407C. Int. J. Thermophys. 2003, 24, 991–1006. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; Mc Linden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2007.

- Engineering Equation Solver. Available online: http://www.fchart.com/ees/ (accessed on 30 May 2016).

- Deconinck-Wanson. Available online: http://www.deconinck.be/en (accessed on 30 May 2016).

- Patil, R.K.; Shende, B.W.; Ghosh, P.K. Designing a helical-coil heat exchanger. Chem. Eng. 1982, 13, 85–88. [Google Scholar]

- Cayer, E.; Galanis, N.; Nesreddine, H. Parametric study and optimization of a transcritical power cycle using a low temperature source. Appl. Energy 2010, 87, 1349–1357. [Google Scholar] [CrossRef]

- Roy, P.; Désilets, M.; Galanis, N.; Nesreddine, H.; Cayer, E. Thermodynamic analysis of a power cycle using a low-temperature source and a binary NH3–H2O mixture as working fluid. Int. J. Therm. Sci. 2010, 49, 48–58. [Google Scholar] [CrossRef]

- Claesson, J. Correction of logarithmic mean temperature difference in a compact brazed plate evaporator assuming heat flux governed flow boiling heat transfer coefficient. Int. J. Refrig. 2005, 28, 573–578. [Google Scholar] [CrossRef]

- Coates, J.; Pressburg, B.S. Heat Transfer to Moving Fluids. Chem. Eng. 1959, 67–72. [Google Scholar]

- Kern, D.Q. Process Heat Transfer; McGraw-Hill: New York, NY, USA, 1950. [Google Scholar]

- Dean, W.R. Note on the Motion of Fluid in a Curved Pipe. Philos. Mag. 1927, 4, 208–223. [Google Scholar] [CrossRef]

- Dean, W.R. The Streamline Motion of Fluid in a Curved Pipe (second paper). Philos. Mag. 1928, 7, 673–695. [Google Scholar] [CrossRef]

- Schmidt, E.F. Warmeubergang und Druckverlust in Rohrschlangen. Z. Tech. Chem. Verfahr. Appar. 1967, 13, 781–832. [Google Scholar] [CrossRef]

- Petukhov, B.S.; Kirillov, V.V. On heat exchange at turbulent flow of liquid in pipes. Teploenergetika 1 1958, 4, 63–81. [Google Scholar]

| Parameters | Unit | Range | Error% |

|---|---|---|---|

| Heat input to ORC | kWth | 12–48 | 2.62 |

| Expander power production | kWe | 0.5–3 | 2.62 |

| Thermal efficiency | % | 0–4.2 | 3.71 |

| Pressure ratio | / | 1.7–2.6 | 1.40 |

| Volume flow rate | L/min | 5.0–25.0 | 2.00 |

| Expansion efficiency | bar | 3 | 2.66 |

| Parameters | Unit | Water | R-404A |

|---|---|---|---|

| Inlet temperature | °C | 95 | 27.37 |

| Outlet temperature | °C | 90.8 | 85 |

| Mass flow rate | kg/s | 2.5 | 0.25 |

| Operating pressure | bar | 3 | 38.5 |

| Pinch point | °C | 10 | |

| Heat transfer | kW | 41 | |

| p/pcr | Liquid-Like | Pseudo-Critical Transition | Gas-Like |

|---|---|---|---|

| 1.0 | T < 64.25 °C | 64.25 °C < T < 74.45 °C | 74.45 °C < T |

| 1.1 | T < 65.05 °C | 65.05 °C < T < 81.55 °C | 81.55 °C < T |

| 1.2 | T < 65.70 °C | 65.70 °C < T < 88.35 °C | 88.35 °C < T |

| Reference | Fluid | Correlations | ||

|---|---|---|---|---|

| Petukhov et al. [6] | CO2 | (16) | ||

| B is the bulk fluid temperature, and w is the wall temperature | ||||

| (17) | ||||

| is calculated by using Petukhov-Kirillov correlation (1958) [40] is the Darcy Friction factor ; is the average specific heat | ||||

| Garimella [14] | Liquid-like region | R-404A R-410A | (18) | |

| Pressure drop model | (19) | |||

| Pseudo-critical transition | (20) | |||

| Pressure drop model | ||||

| Gas-like region | (21) | |||

| Pressure drop model | ||||

| Mokry et al. [15] | Water | (22) | ||

| Parameters | do | Ao | hhf | hwf | Ltube | Hcoil | Ncoil | G | vwf | vhf | pwf |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Units | (m) | (m2) | (W/m2K) | (W/m2K) | (m) | (m) | (-) | (kg/m2s) | (m/s) | (m/s) | (Pa) |

| Pethukov | 0.028 | 5.228 | 424.5 | 2356 | 59.44 | 1.131 | 31.53 | 517.2 | 0.9914 | 0.03333 | 40,805 |

| 0.030 | 5.389 | 421.4 | 2044 | 57.18 | 1.167 | 30.33 | 443.5 | 0.85 | 0.03333 | 27,136 | |

| Garimella | 0.026 | 4.896 | 427.6 | 3546 | 59.95 | 1.059 | 31.8 | 611.1 | 1.171 | 0.03333 | 44,762 |

| 0.028 | 5.054 | 424.5 | 2916 | 57.46 | 1.095 | 30.48 | 517.2 | 0.9914 | 0.03333 | 27,196 | |

| 0.030 | 5.21 | 421.4 | 2455 | 55.28 | 1.13 | 29.32 | 443.5 | 0.85 | 0.03333 | 17,187 | |

| Mokry | 0.028 | 5.042 | 424.5 | 3112 | 57.32 | 1.092 | 30.4 | 517.2 | 0.9914 | 0.03333 | 39,120 |

| 0.030 | 5.179 | 421.4 | 2633 | 54.96 | 1.123 | 29.15 | 443.5 | 0.85 | 0.03333 | 25,900 |

| Parameter | Unit | Value |

|---|---|---|

| Tube outer diameter, do | mm | 33.7 |

| The tube thickness, t | mm | 4 |

| Inner shell diameter, Di | m | 0.526 |

| Outer shell diameter Do | m | 0.674 |

| Coil diameter, Dc | m | 0.6 |

| Height of the HX, Hcoil | m | 1.508 |

| Coil length, Lcoil | m | 66 |

| Number of coil turns, Ncoil | - | 35 |

| Total heat transfer area, A | m2 | 6.988 |

| Overall heat transfer coefficient, U | W/m2K | 248 |

| Average heat transfer coefficient, hhf_avg | W/m2K | 403 |

| Average heat transfer coefficient, hwf_avg | W/m2K | 2200 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazova, M.; Huisseune, H.; Kaya, A.; Lecompte, S.; Kosmadakis, G.; De Paepe, M. Performance Evaluation of a Helical Coil Heat Exchanger Working under Supercritical Conditions in a Solar Organic Rankine Cycle Installation. Energies 2016, 9, 432. https://doi.org/10.3390/en9060432

Lazova M, Huisseune H, Kaya A, Lecompte S, Kosmadakis G, De Paepe M. Performance Evaluation of a Helical Coil Heat Exchanger Working under Supercritical Conditions in a Solar Organic Rankine Cycle Installation. Energies. 2016; 9(6):432. https://doi.org/10.3390/en9060432

Chicago/Turabian StyleLazova, Marija, Henk Huisseune, Alihan Kaya, Steven Lecompte, George Kosmadakis, and Michel De Paepe. 2016. "Performance Evaluation of a Helical Coil Heat Exchanger Working under Supercritical Conditions in a Solar Organic Rankine Cycle Installation" Energies 9, no. 6: 432. https://doi.org/10.3390/en9060432