CFD Analysis on the Thermal Hydraulic Performance of an SAH Duct with Multi V-Shape Roughened Ribs

Abstract

:1. Introduction

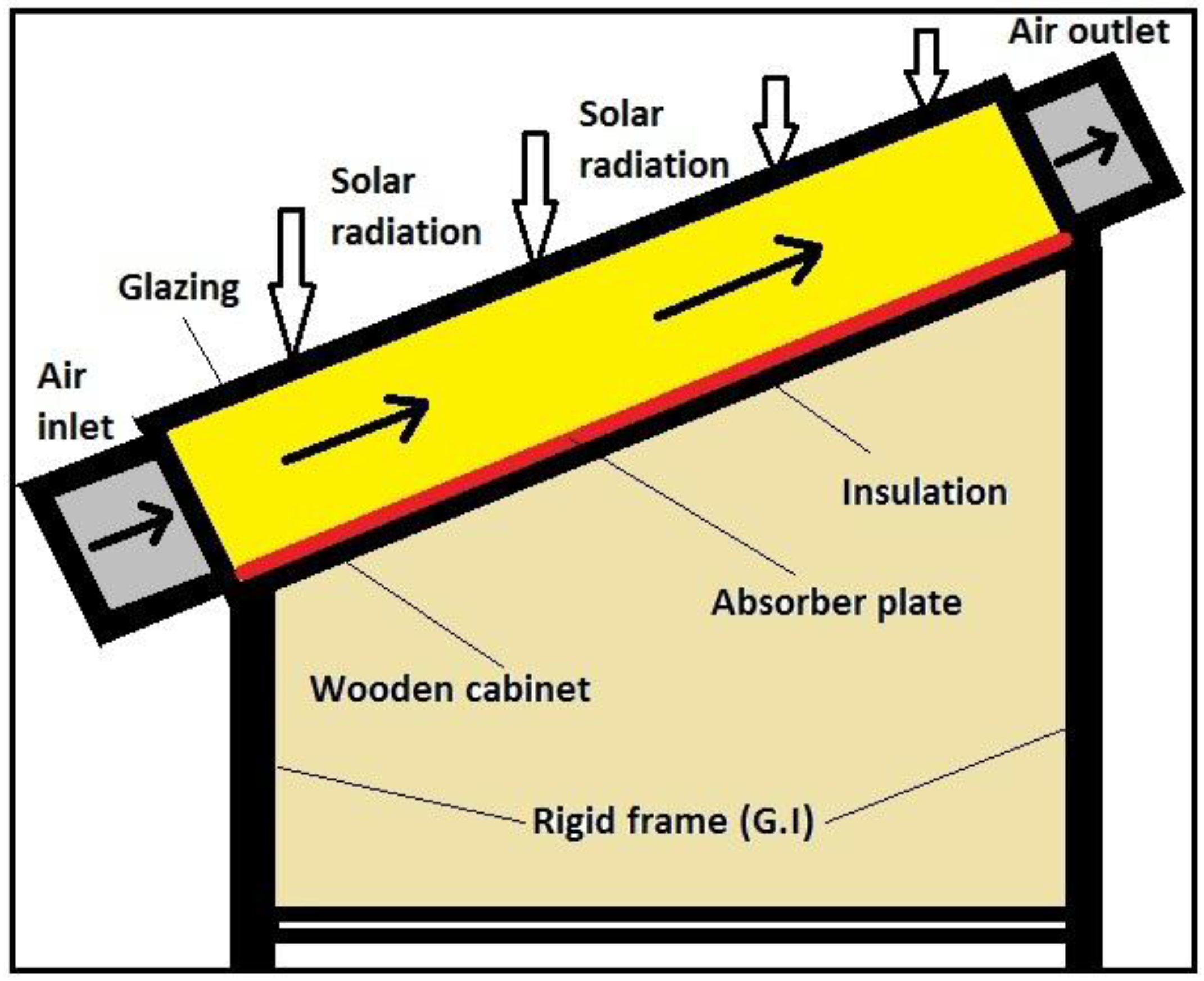

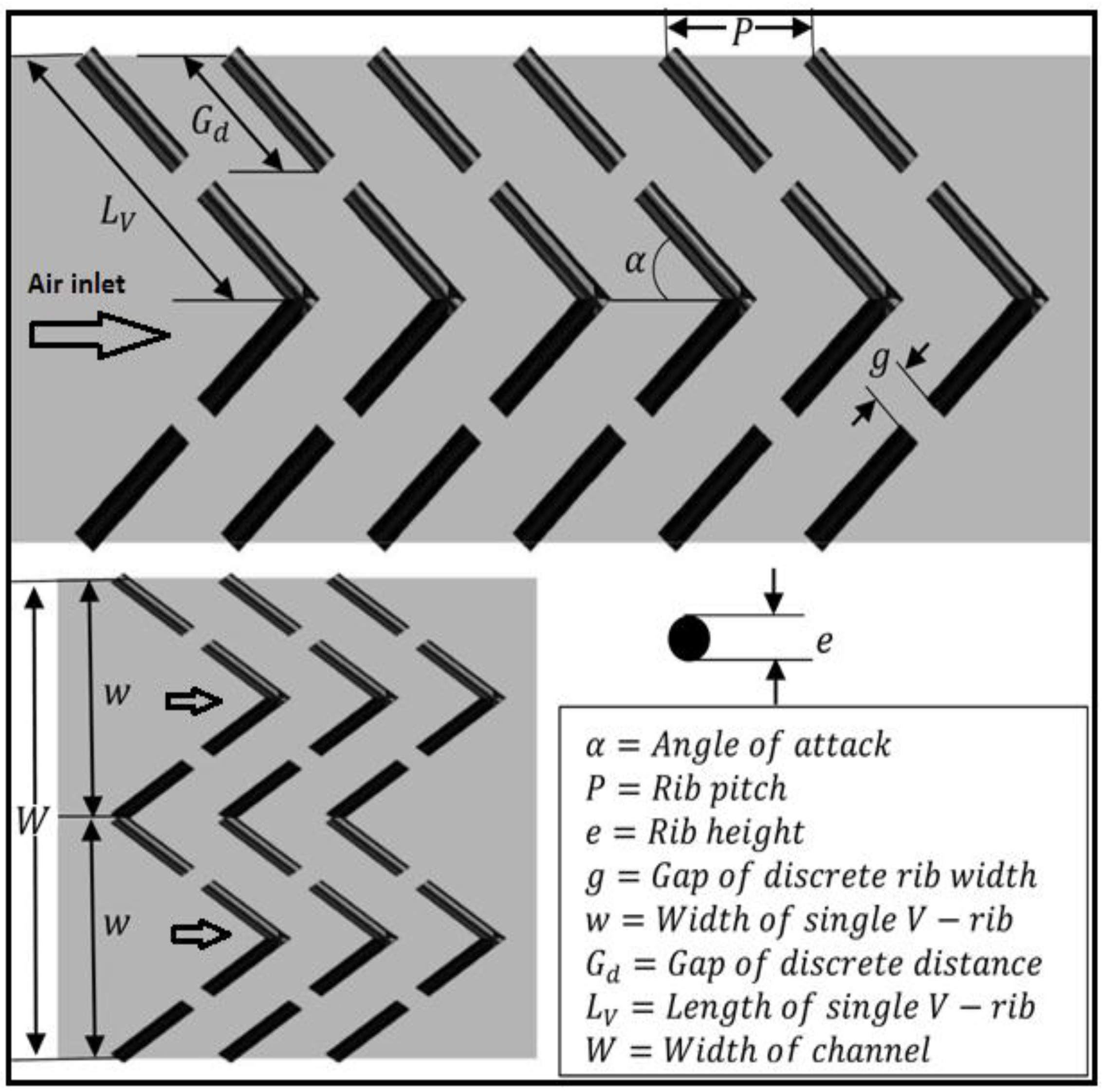

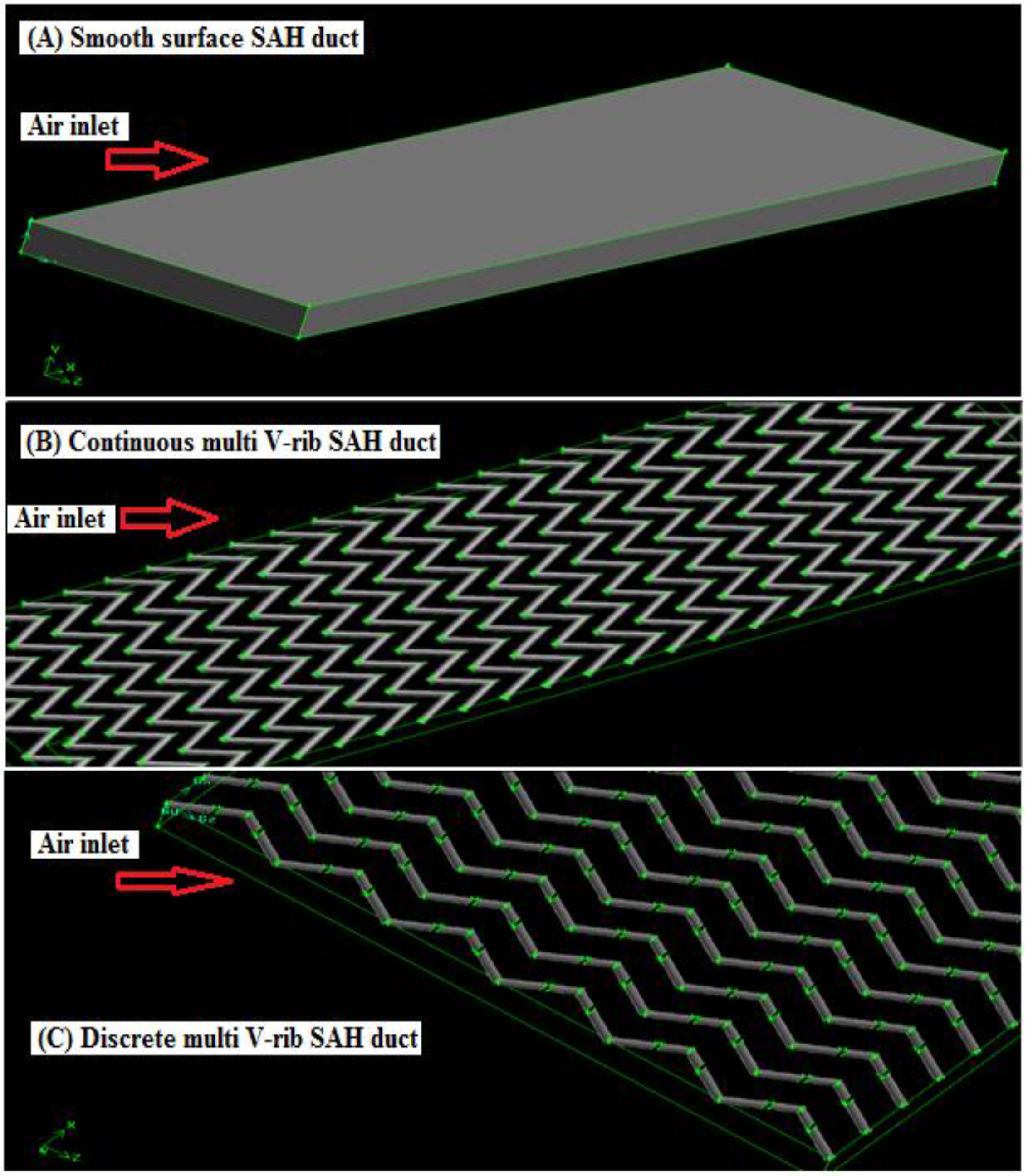

2. CFD Analysis

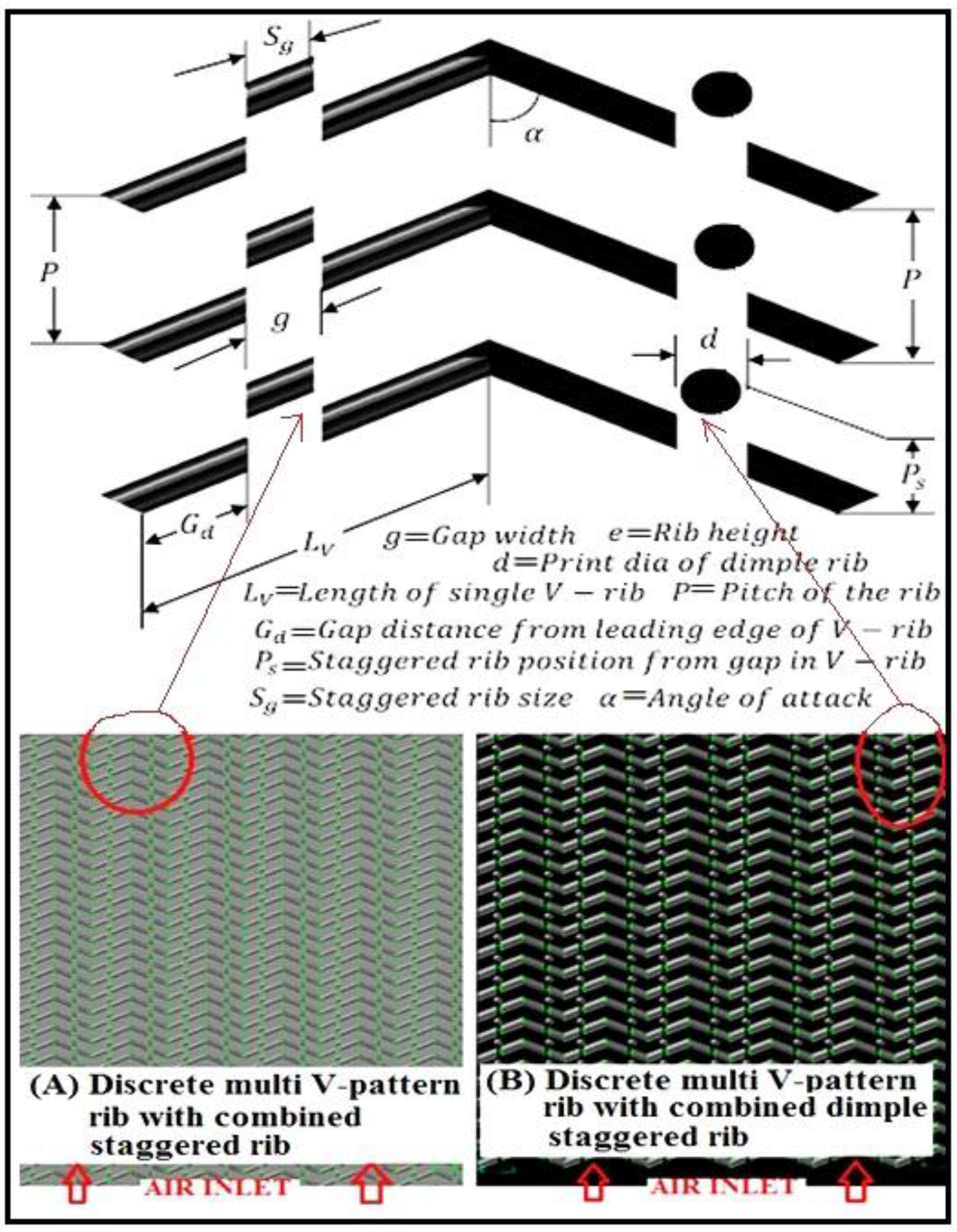

2.1. Computational Geometry

2.2. Governing Equations

- The flow is steady, fully developed, turbulent and three-dimensional.

- The thermal conductivity of the duct wall, absorber plate and roughness material are independent of temperature.

- The duct wall, absorber plate and roughness material are homogeneous and isotropic.

- The working fluid (air) is assumed to be incompressible for operating range of solar air heaters since variation in density is very less.

- No-slip boundary condition is assigned to the walls in contact with the fluid in the model.

- Negligible radiation heat transfer and other heat losses.

2.3. Boundary Conditions

2.4. Numerical Scheme

2.5. Grid Independence Test

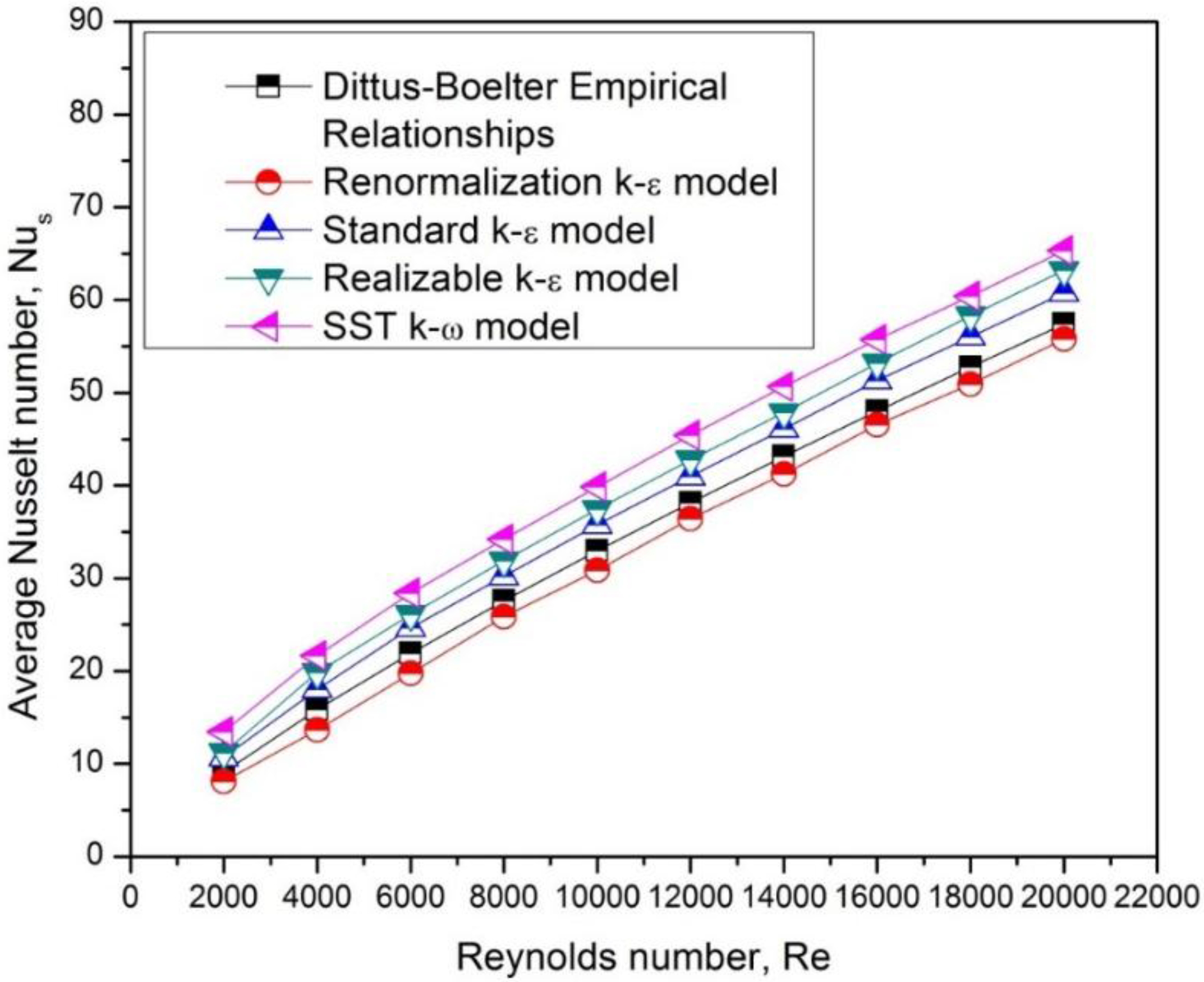

2.6. Model Selection and Validation

3. Results and Discussion

3.1. Temperature Profile

3.2. Velocity Profile

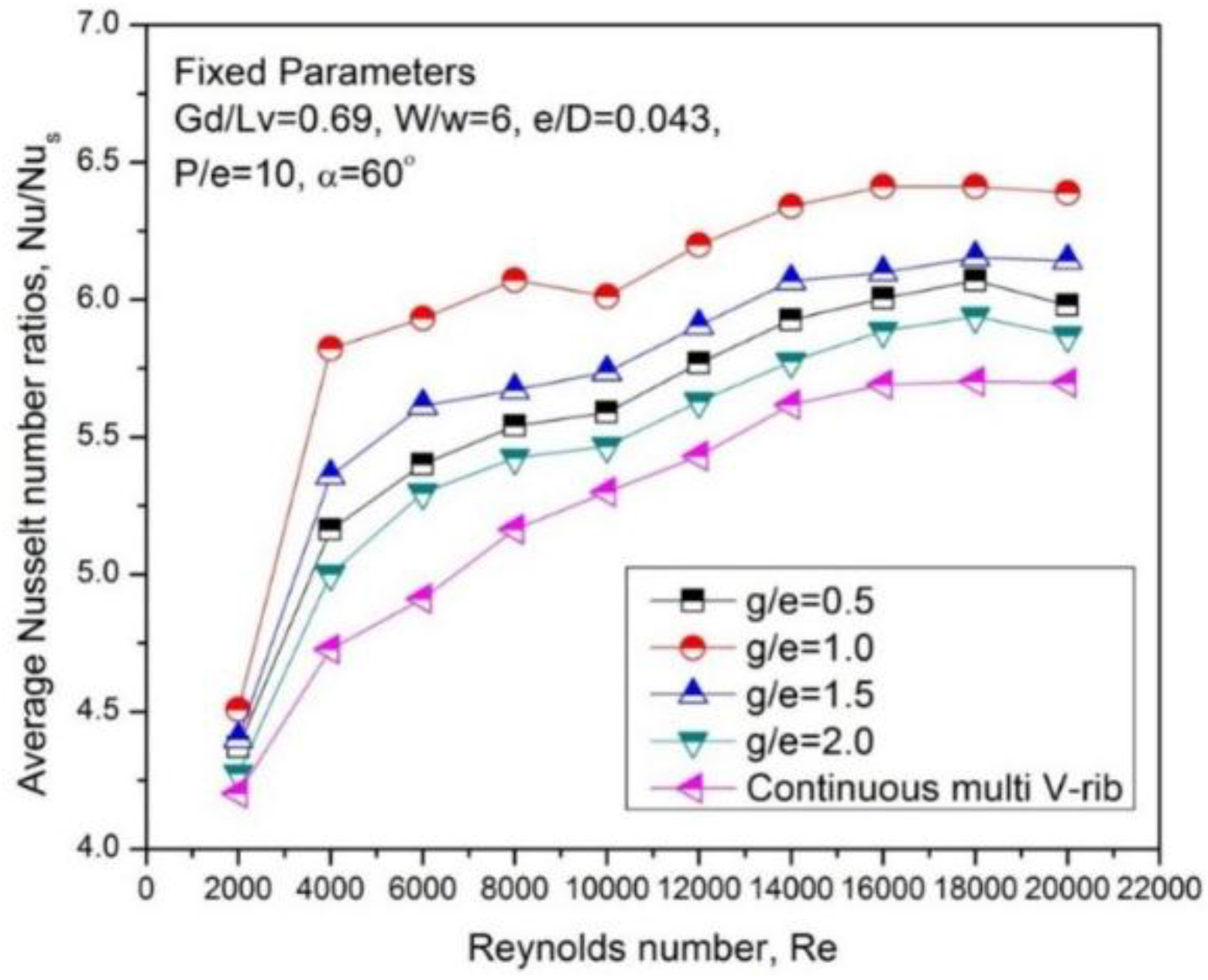

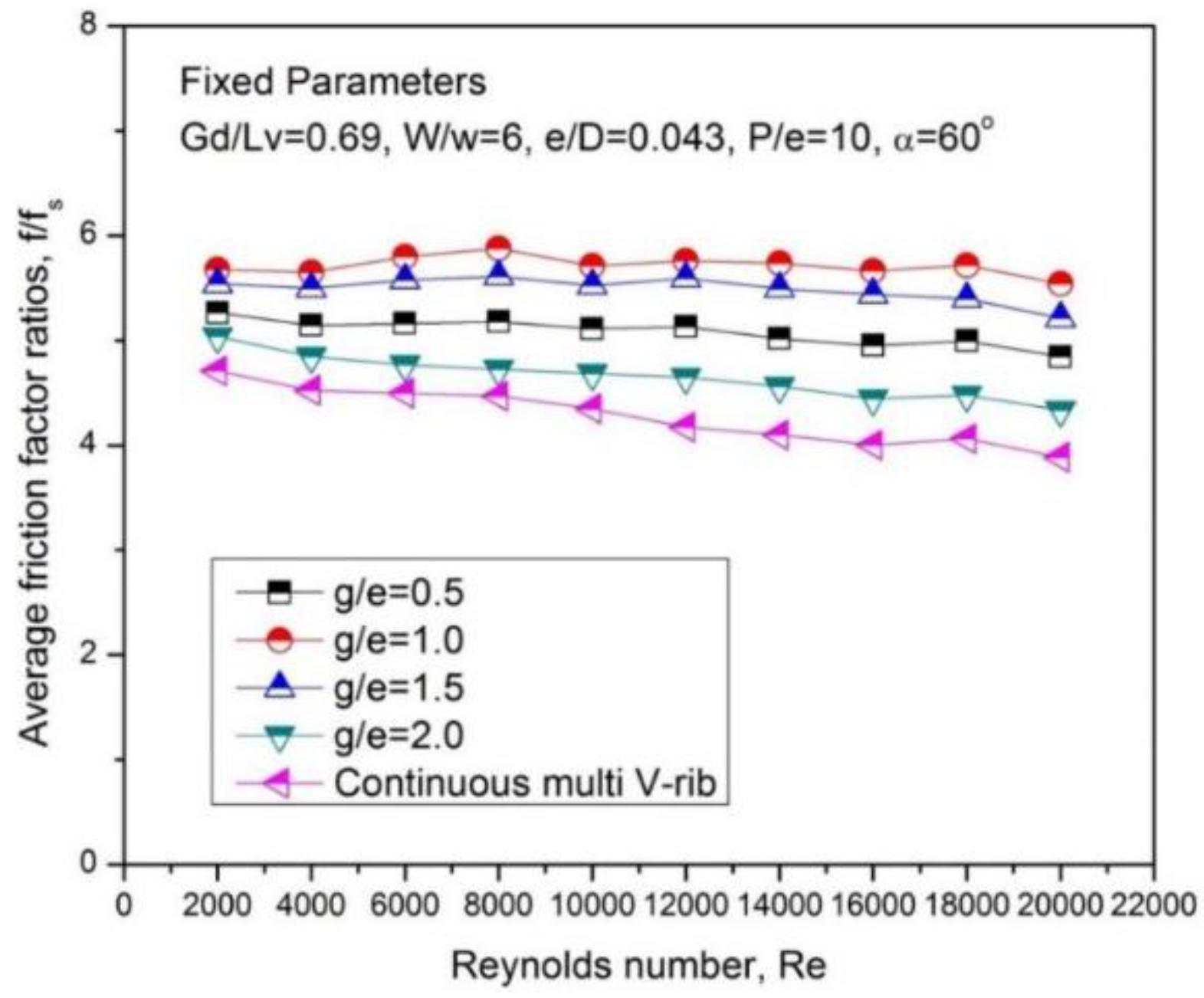

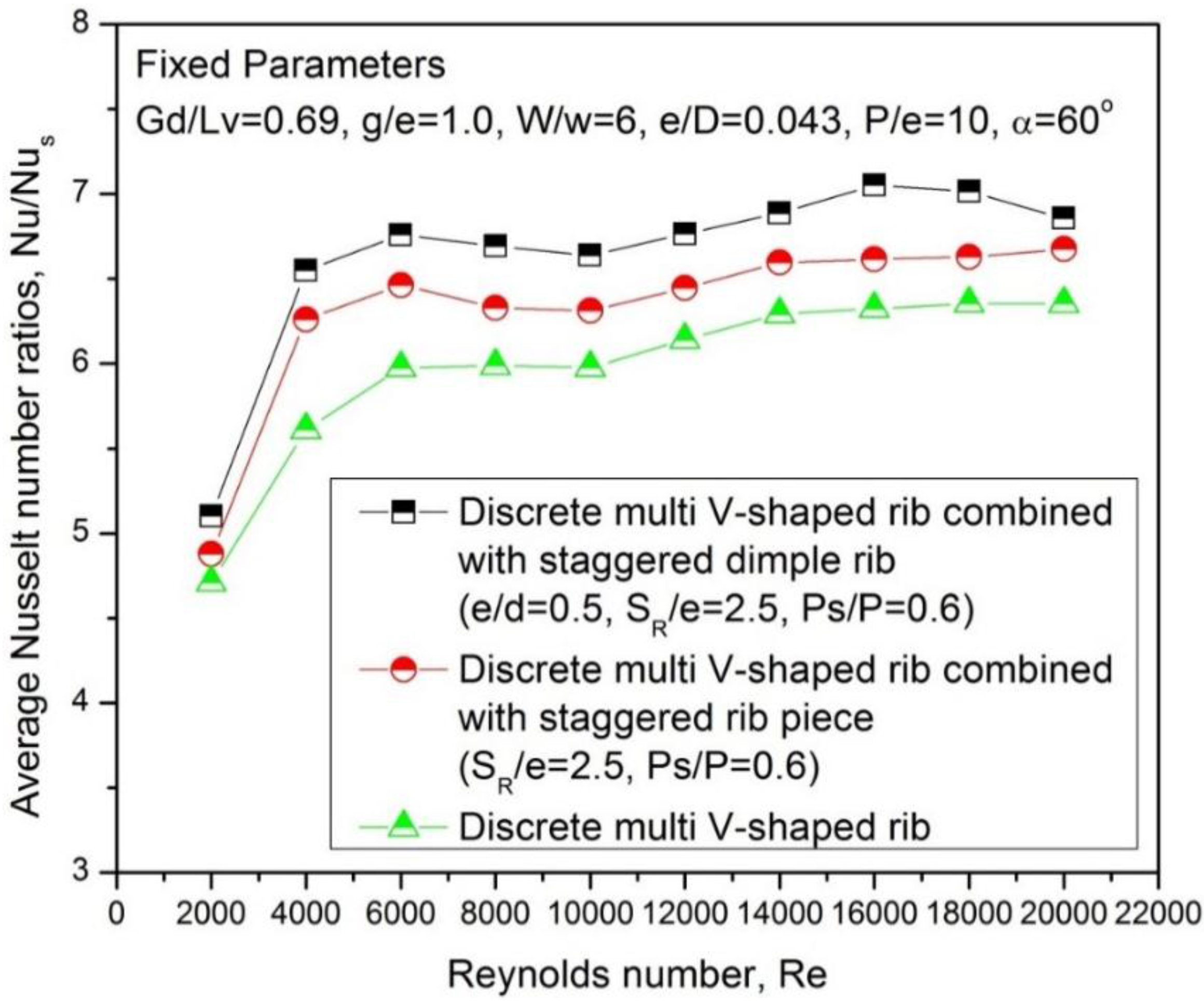

3.3. Heat Transfer and Friction Factor

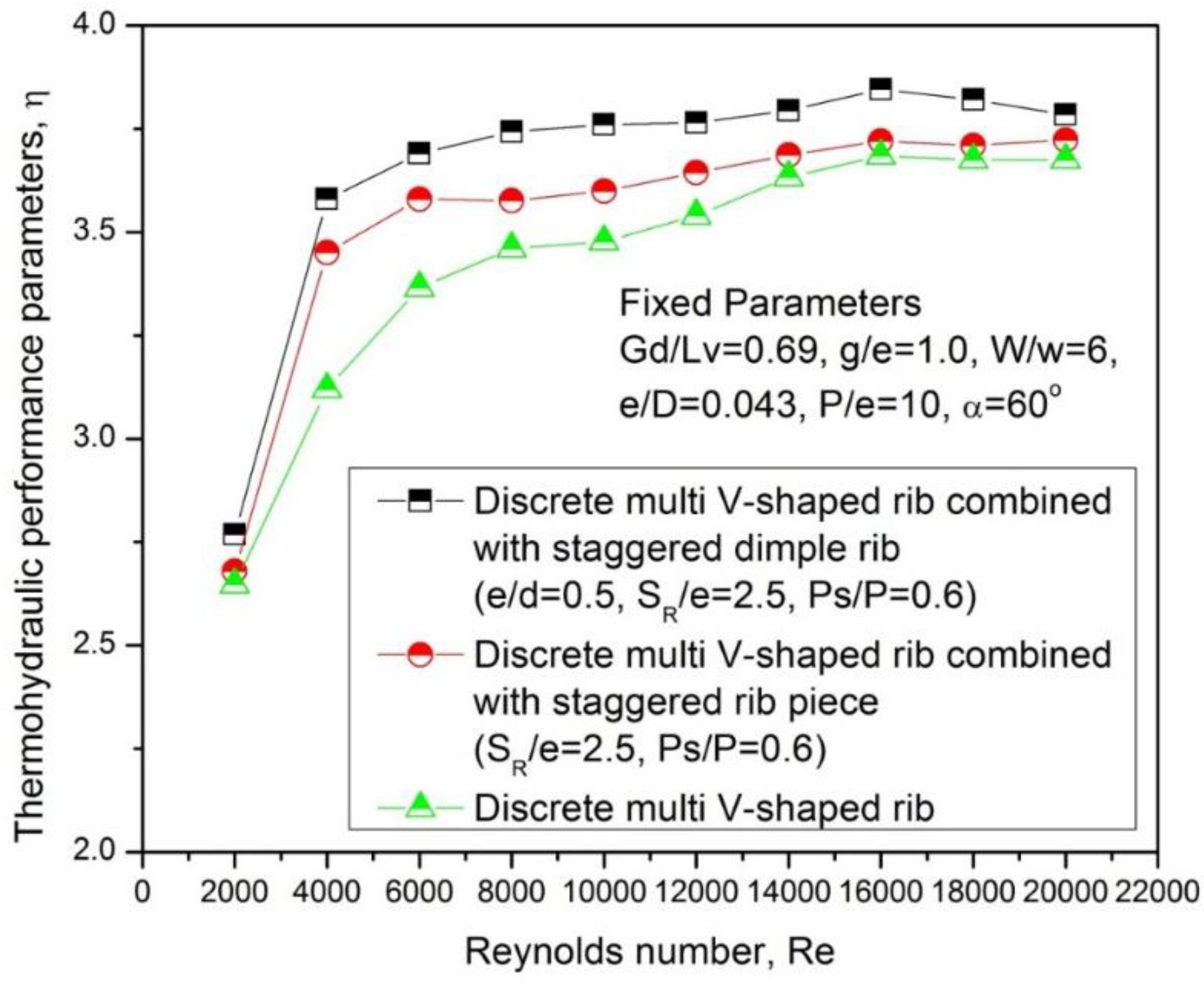

3.4. Thermo-Hydraulic Performance

4. Shape Optimization

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Print diameter of dimple, () | |

| Hydraulic diameter of channel, () | |

| Relative discrete position | |

| Rib height, () | |

| Relative roughness height | |

| Ratio of dimple depth to print diameter | |

| Energy, () | |

| Friction factor of smooth wall | |

| Friction factor of roughened wall | |

| Discrete or gap width, () | |

| Relative discrete width | |

| Discrete distance for rib, () | |

| Relative discrete distance | |

| Depth of channel, () | |

| Solar intensity, () | |

| Turbulent kinetic energy, () | |

| Length of metal grit rib, (m) | |

| Length of a single V-shaped rib, () | |

| Mass flow rate, () | |

| Turbulent Mach number | |

| Nusselt number of roughened channel | |

| Nusselt number of smooth channel | |

| Pitch of the rib, () | |

| Relative rib pitch | |

| Distance from the discrete or discrete | |

| Pressure, () | |

| Prandtl number | |

| Turbulent Prandtl number | |

| Relative staggered rib position | |

| Reynolds number | |

| Coefficient of determination | |

| Distance of metal grit rib parallel to direction of stream, () | |

| Staggered rib size, () | |

| Relative discrete position or distance | |

| Velocity in -direction, () | |

| Overall velocity vector, () | |

| Width of channel, () | |

| Width of a single V-shaped rib, () | |

| Relative rib width | |

| Channel aspect ratio | |

| Dimensionless distance from walls | |

| Greek Symbols | |

| Angle of attack, degree | |

| Thermal expansion coefficient, | |

| µ | Dynamic viscosity, () |

| µt | Turbulent viscosity, () |

| Density, () | |

| Thermo-hydraulic performance parameter | |

| Model constant | |

| Turbulent kinetic energy dissipation rate, () | |

| Prandtl number for | |

| Prandtl number for | |

| , | RNG - model constant |

| Subscript | |

| Computational fluid dynamics | |

| Solar air heater | |

References

- Kumar, A.; Kim, M.-H. Thermohydraulic performance of rectangular ducts with different multiple V-rib roughness shapes: A comprehensive review and comparative study. Renew. Sustain. Energy Rev. 2016, 54, 635–652. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, R.P.; Saini, J.S. A review of thermo-hydraulic performance of artificially roughened solar air heaters. Renew. Sustain. Energy Rev. 2014, 37, 100–122. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering Thermal Processes; John Wiley: New York, NY, USA, 1991. [Google Scholar]

- Bhuiyan, A.A.; Amin, M.R.; Karim, M.R.; Islam, A.K.M.S. Plate fin and tube heat exchanger modeling: Effects of performance parameters for turbulent flow regime. Int. J. Autom. Mech. Eng. 2014, 9, 1768–1781. [Google Scholar]

- Karim, M.R.; Akhande, M.A.R. Study of a hybrid photovoltaic thermal solar system using different ribbed surfaces opposite to absorber plate. J. Eng. Technol. 2011, 9, 17–30. [Google Scholar]

- Kumar, A.; Saini, R.P.; Saini, J.S. Heat and fluid flow characteristics of roughened solar air heater ducts—A review. Renew. Energy 2012, 47, 77–94. [Google Scholar] [CrossRef]

- Prasad, K.; Mullick, S.C. Heat transfer characteristics of a solar air heater duct used for drying purposes. Appl. Energy 1983, 13, 83–93. [Google Scholar] [CrossRef]

- Prasad, B.N.; Saini, J.S. Effect of artificial roughness on heat transfer and friction factor in a solar air heater. Sol. Energy 1988, 41, 555–560. [Google Scholar] [CrossRef]

- Han, J.C.; Zhang, Y.M.; Lee, C.P. Augmented heat transfer in square channels with parallel crossed and V-shaped angled ribs. J. Heat Trans. 1991, 113, 590–596. [Google Scholar] [CrossRef]

- Kukreja, R.T.; Lau, S.C.; McMillian, R.D. Local Heat and Mass transfer distribution in a square channel with full and V-shaped rib. Int. J. Heat Mass Trans. 1993, 36, 2013–2020. [Google Scholar] [CrossRef]

- Taslim, M.E.; Li, T.; Krecher, D.M. Experimental heat transfer and friction in channel roughened with angled, v-shaped and discrete ribs on two opposite walls. J. Turbomach. 1996, 118, 20–28. [Google Scholar] [CrossRef]

- Karwa, R.K. Experimental studies of augmented heat transfer and friction in asymmetrically heated rectangular ducts with ribs on heated wall in transverse, inclined, v-continuous and v-discrete pattern. Int. Commun. Heat Mass Trans. 2003, 30, 241–250. [Google Scholar] [CrossRef]

- Wang, L.; Sunden, B. An experimental investigation of heat transfer and fluid flow in a rectangular duct with broken v-shaped ribs. Exp. Heat Trans. 2004, 17, 243–359. [Google Scholar] [CrossRef]

- Wright, L.M.; Fu, W.L.; Han, J.C. Thermal performance of angled V-shaped and W-shaped rib turbulators in rotating rectangular cooling channels (AR = 4:1). J. Turbomach. 2004, 126, 604–614. [Google Scholar] [CrossRef]

- Maithani, R.; Saini, J.S. Heat transfer and friction factor correlations for a solar air heater duct roughened artificially with V-ribs with symmetrical gaps. Exp. Ther. Fluid Sci. 2016, 70, 220–227. [Google Scholar] [CrossRef]

- Hans, V.S.; Saini, R.P.; Saini, J.S. Heat transfer and friction correlations for a solar air heater duct roughened artificially with multiple v-ribs. Sol. Energy 2010, 84, 898–911. [Google Scholar] [CrossRef]

- Saini, S.K.; Saini, R.P. Development of correlations for Nusselt number and friction factor for solar air heater with roughened duct having arc-shaped wire as artificial roughness. Solar Energy 2008, 82, 1118–1130. [Google Scholar] [CrossRef]

- Bhushan, B.; Singh, R. Nusselt number and friction factor correlations for solar air heater duct having artificially roughened heated plate. Solar Energy 2011, 85, 1109–1118. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, R.P.; Saini, J.S. Development of correlations for Nusselt number and friction factor for solar air heater with roughened duct having multi V-shaped with gap rib as artificial roughness. Renew. Energy 2013, 58, 151–163. [Google Scholar] [CrossRef]

- Anil, S.Y.; Bhagoria, J.L. A CFD (computational fluid dynamics) based heat transfer and fluid flow analysis of a solar air heater provided with circular transverse wire rib roughness on the heated plate. Energy 2013, 55, 1127–1142. [Google Scholar]

- Chaube, A.; Sahoo, P.K.; Solanki, S.C. Analysis of heat transfer augmentation and flow characteristics of a solar air heater. Renew. Energy 2006, 31, 317–331. [Google Scholar] [CrossRef]

- Kumar, S.; Saini, R.P. CFD based performance analysis of a solar air heater duct provided with artificial roughness. Renew. Energy 2009, 34, 1285–1291. [Google Scholar] [CrossRef]

- Gandhi, B.K.; Singh, K.M. Experimental and numerical investigations on flow through wedge shape rib roughened duct. J. Inst. Eng. (India) Mech. Eng. Div. 2010, 90, 13–18. [Google Scholar]

- Sharma, A.K.; Thakur, N.S. CFD based fluid flow and heat transfer analysis of a v-shaped roughened surface solar air heater. Int. J. Eng. Sci. Technol. 2012, 4, 2115–2121. [Google Scholar]

- Karmare, S.V.; Tikekar, A.N. Analysis of fluid flow and heat transfer in a grit roughened surface solar air heater using CFD. Sol. Energy 2010, 84, 409–417. [Google Scholar] [CrossRef]

- Singh, S.; Singh, B.; Hans, V.S.; Gill, R.S. CFD (computational fluid dynamics) investigation on Nusselt number and friction factor of solar air heater duct roughened with non-uniform cross section transverse rib. Energy 2015, 84, 509–517. [Google Scholar] [CrossRef]

- Kumar, A.; Kim, M.-H. Effect of roughness width ratios in discrete multi V-rib with staggered rib roughness on overall thermal performance of solar air channel. Solar Energy 2015, 119, 399–414. [Google Scholar] [CrossRef]

- Kumar, A.; Kim, M.-H. Convective heat transfer enhancement in solar air channels. Appl. Ther. Eng. 2015, 89, 239–261. [Google Scholar] [CrossRef]

- Kumar, A.; Kim, M.-H. Numerical optimization of solar air heaters with different roughness shapes on the heated plate-technical note. Energy 2014, 72, 731–738. [Google Scholar] [CrossRef]

- Kumar, A.; Kim, M.-H. Heat transfer and fluid flow characteristics in air duct with various V-pattern rib roughness on the heated plate: A comparative study. Energy 2016, 103, 75–85. [Google Scholar] [CrossRef]

- Fluent Inc. Fluent 6.3 User’s Guide 2006; Fluent Inc.: Lebanon, NH, USA, 2006. [Google Scholar]

| Flow and Rib Parameters | Ranges |

|---|---|

| 2000–20,000 | |

| 0.69 | |

| 0.5–2.0 | |

| 6.0 | |

| 0.043 | |

| 10 | |

| 60° |

| Model | Coefficient of Determination |

|---|---|

| Shear Stress Transport (SST) k-ω | 0.994 |

| Realizable k-ε | 0.995 |

| Standard k-ε | 0.996 |

| Renormalization k-ε | 0.998 |

| Rib Shapes | Parameters | Experimental/NUMERICAL Results | η |

|---|---|---|---|

Transverse rib | e/D = 0.021–0.034, P/e = 10–20, Re = 5000–50,000 | Experimental results Prasad and Saini [8] | 1.66 |

Transverse rib | e/D = 0.022–0.0424, P/e = 7.16–35.72, Re = 3800–18,000 | Numerical results Yadav et al. [20] | 1.62 |

Angled rib | e/D = 0.019–0.054, P/e = 10, α = 45°–90°, Re = 3000–18,000 | Experimental results Kumar et al. [2] | 1.79 |

Inclined with discrete rib | e/D = 0.038, P/e = 10, d/W = 0.167–0.668, g/e = 0.5–2.0, α = 60°, Re = 3000–18,000 | Experimental results Kumar et al. [2] | 1.87 |

Arc shaped rib | e/D = 0.029–0.0426, P/e = 10, α = 30°–60°, Re = 6000–18,000 | Numerical results Kumar and Saini [22] | 1.77 |

V-pattern rib | e/D = 0.02–0.034, P/e = 10, α = 30°–75°, Re = 2500–18,000 | Experimental results Taslim et al. [11] | 2.19 |

Single V-pattern rib with discrete rib | e/D = 0.015–0.043, P/e = 4.0–12, d/W = 0.2–0.8, g/e = 0.5–2.0, α = 30°–75°, Re = 3000–15,000 | Experimental results Kumar and Kim [2] | 2.63 |

Single discrete V-shaped with staggered rib piece | e/D = 0.043, P/e = 10, SR/e = 0.2–0.8, Ps/P = 0.2–0.8, g/e = 1.0, α = 60°, Re = 3000–17,000 | Experimental results Kumar et al. [2] | 2.87 |

Arc shaped rib | e/D = 0.021–0.036, P/e = 10–20, α = 45°–75°, Re = 3600–18,000 | Experimental results Kumar et al. [2] | 2.12 |

Metal grit rib | e/D = 0.044, P/e = 17.5, α = 60°, l/s = 1.72, Re = 3600–17,000 | Numerical results Karmare and Tikekar [25] | 2.10 |

Discrete W-pattern rib | e/D = 0.0168–0.338, P/e = 10, α = 30°–75°, Re = 3000–15,000 | Experimental results Kumar et al. [2] | 2.32 |

Continuous multi V-pattern rib | e/D = 0.019–0.043, P/e = 8–12, W/w = 1–10, α = 30°–75°, Re = 2000–20,000 | Experimental results Hans et al. [16] | 3.47 |

Multi V-pattern with discrete rib | e/D = 0.021–0.0435, P/e = 8–12, W/w = 1–10, Gd/Lv = 0.24–0.80, g/e = 0.5–1.5, α = 30°–75°, Re = 2000–20,000 | Experimental results Kumar et al. [2] | 3.64 |

Discrete multi V-pattern rib | e/D = 0.043, P/e = 10, W/w = 6.0, Gd/Lv = 0.69, g/e = 0.5–2.0, α = 60°, Re = 2000–20,000 | Numerical results (Present study) | 3.65 |

Discrete multi V-pattern rib with staggered rib | e/D = 0.043, P/e = 10, W/w = 6.0, Gd/Lv = 0.69, g/e = 1.0, α = 60°, SR/e = 2.5, Ps/P = 0.6, Re = 2000–20,000 | Numerical results (Present study) | 3.73 |

Discrete multi V-pattern rib with dimple staggered rib | e/D = 0.043, P/e = 10, W/w = 6.0, Gd/Lv = 0.69, g/e = 1.0, α = 60°, SR/e = 2.5, Ps/P = 0.6, e/d = 0.5, Re = 2000–20,000 | Numerical results (Present study) | 3.82 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A.; Kim, M.-H. CFD Analysis on the Thermal Hydraulic Performance of an SAH Duct with Multi V-Shape Roughened Ribs. Energies 2016, 9, 415. https://doi.org/10.3390/en9060415

Kumar A, Kim M-H. CFD Analysis on the Thermal Hydraulic Performance of an SAH Duct with Multi V-Shape Roughened Ribs. Energies. 2016; 9(6):415. https://doi.org/10.3390/en9060415

Chicago/Turabian StyleKumar, Anil, and Man-Hoe Kim. 2016. "CFD Analysis on the Thermal Hydraulic Performance of an SAH Duct with Multi V-Shape Roughened Ribs" Energies 9, no. 6: 415. https://doi.org/10.3390/en9060415