A New Predictive Model Based on the ABC Optimized Multivariate Adaptive Regression Splines Approach for Predicting the Remaining Useful Life in Aircraft Engines

Abstract

:1. Introduction

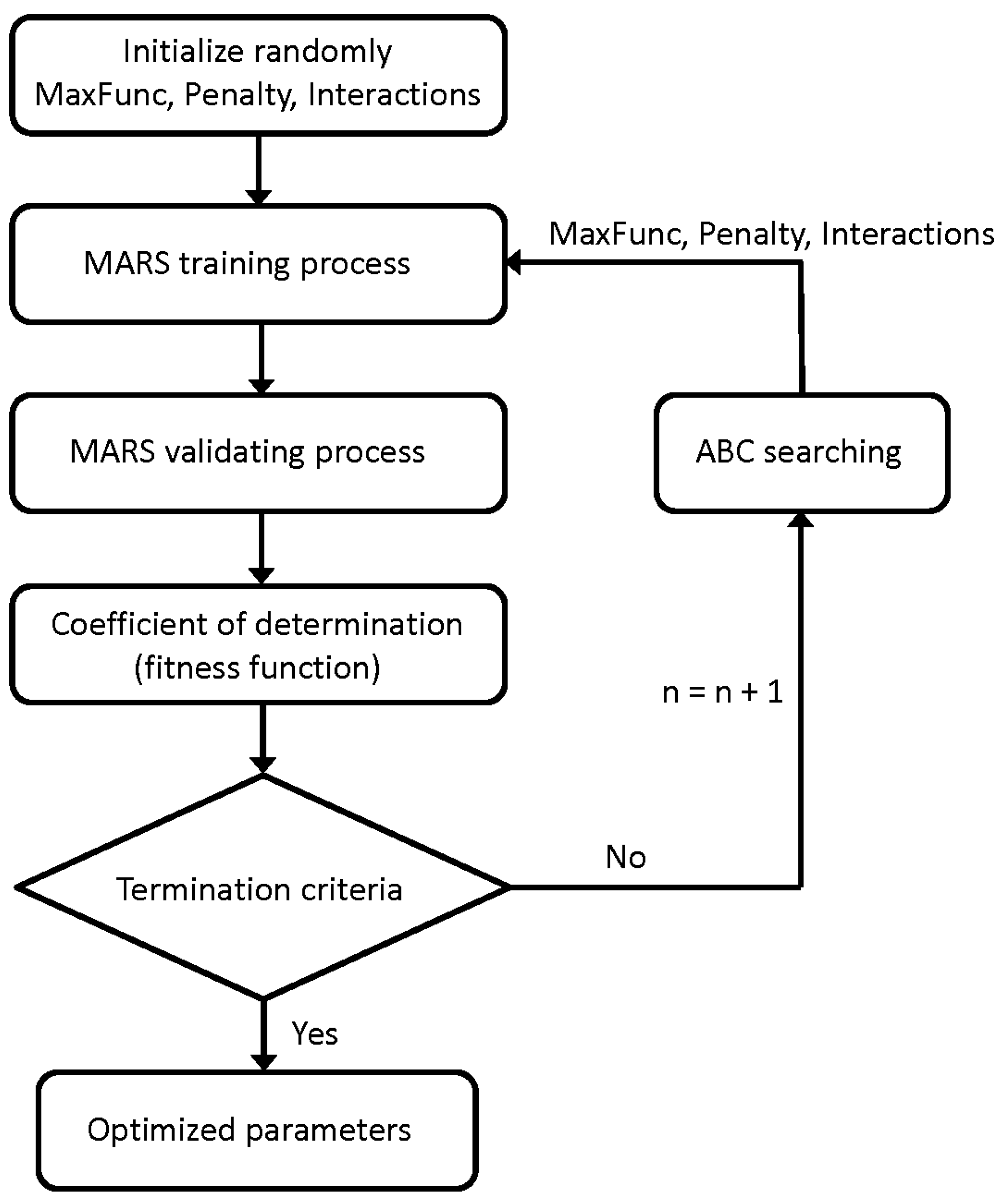

2. Materials and Methods

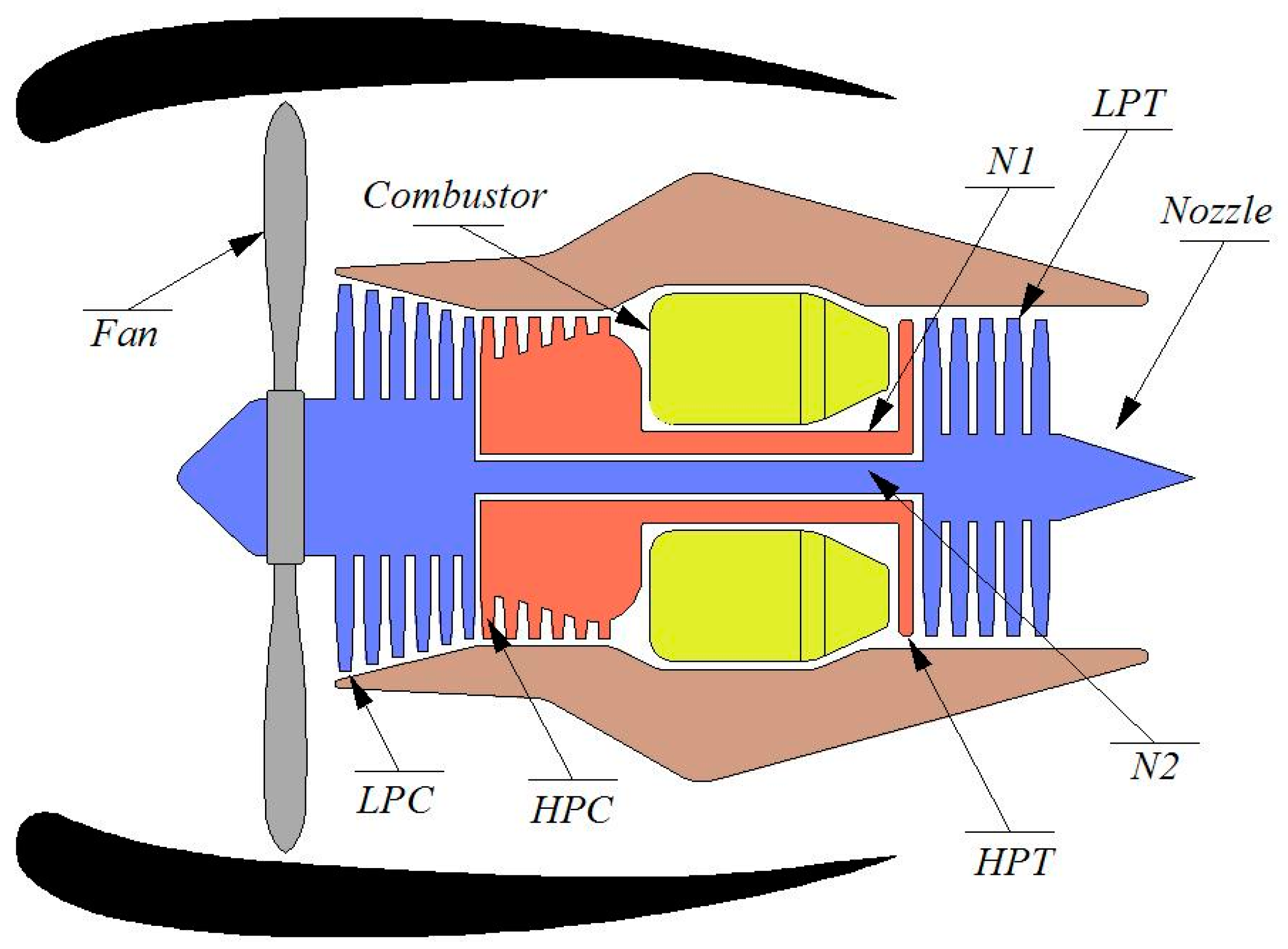

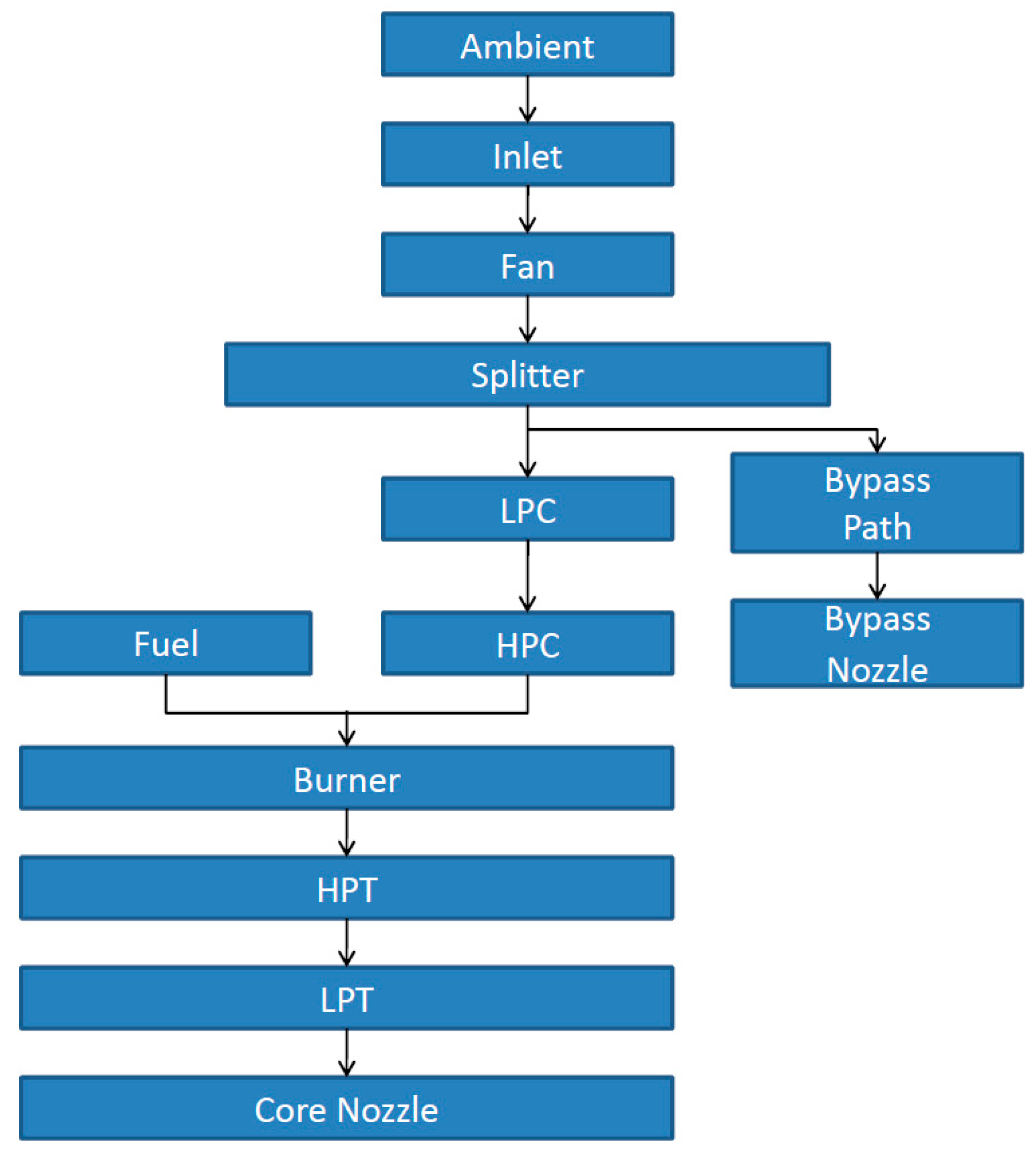

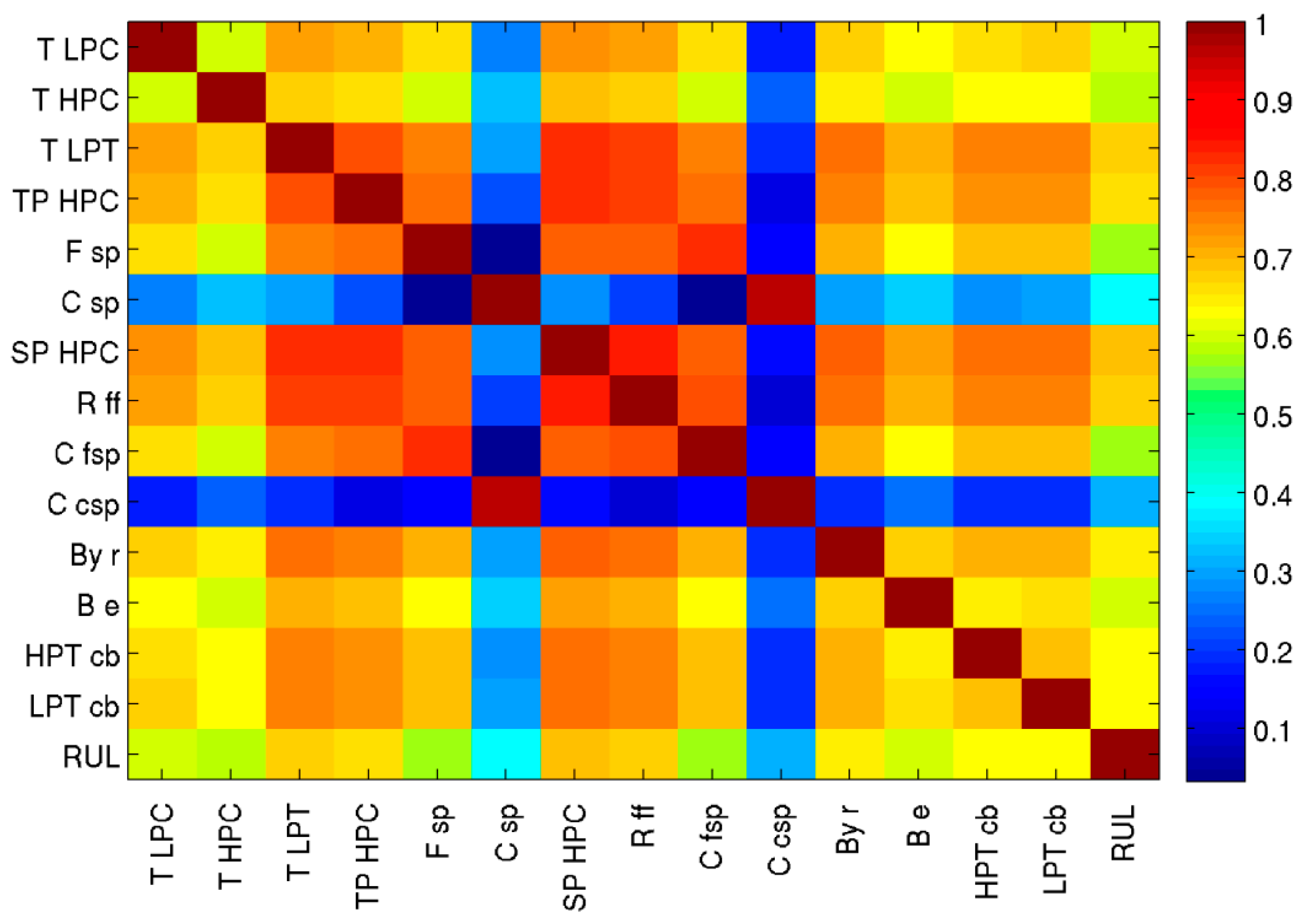

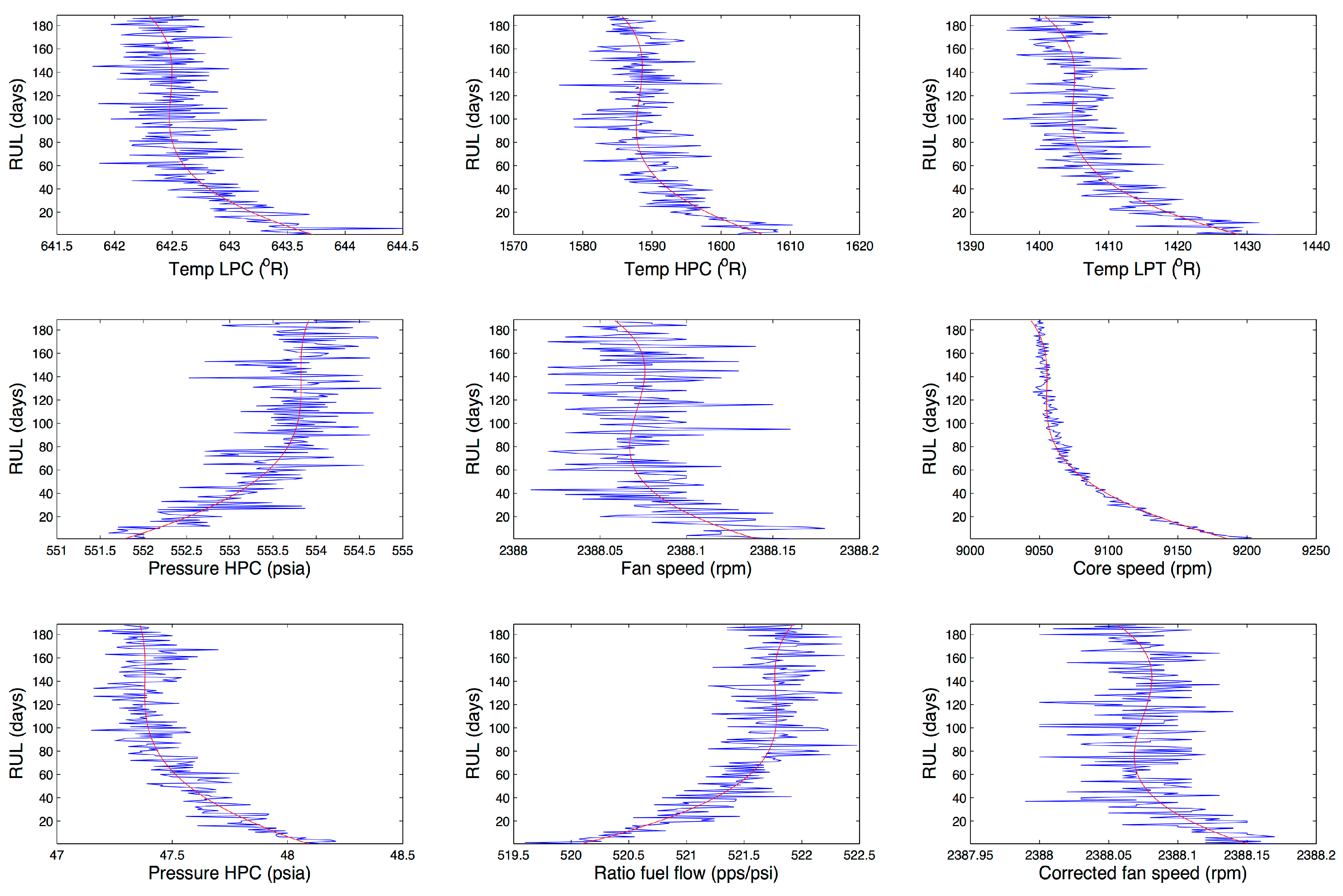

2.1. Experimental Dataset

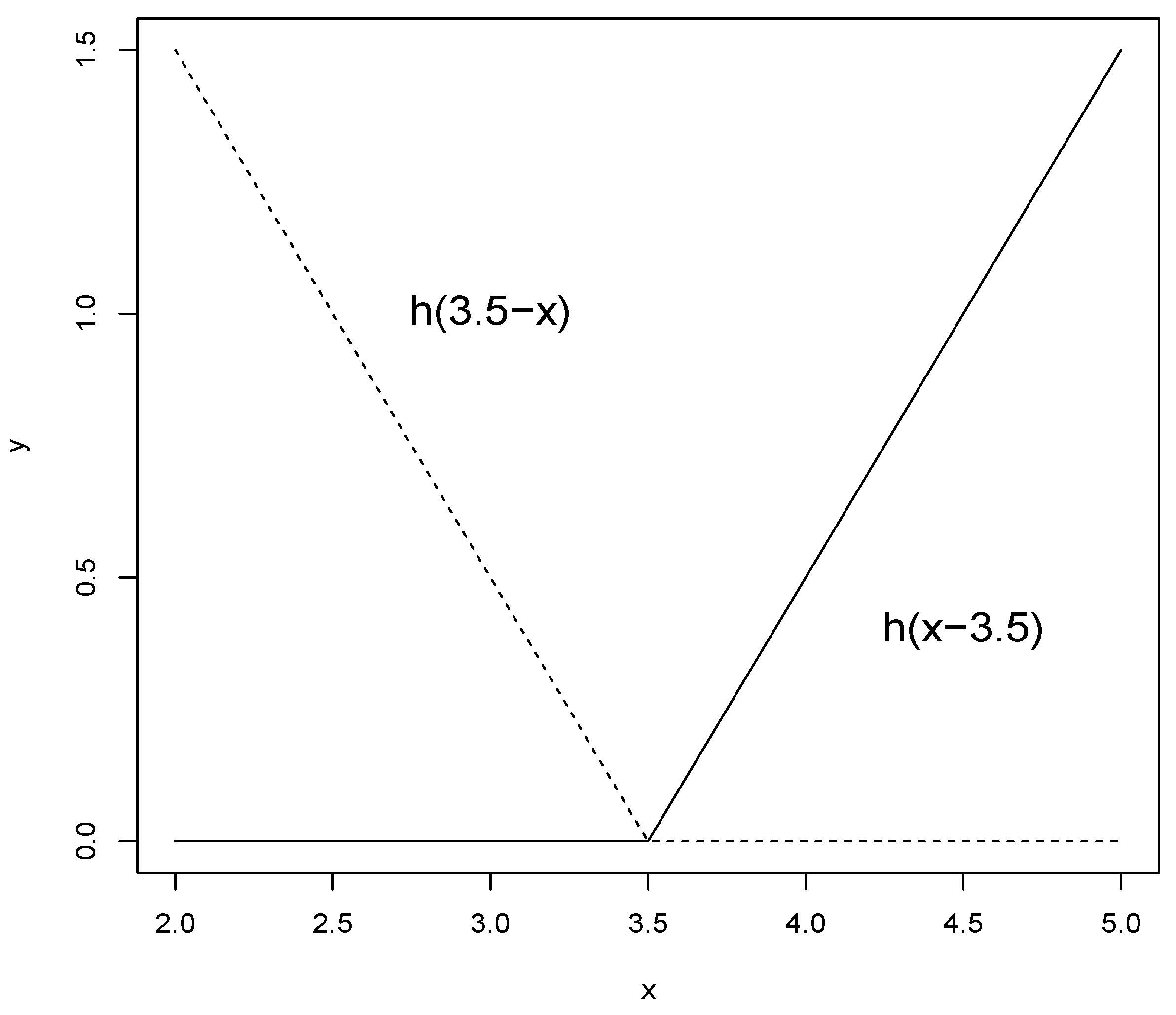

2.2. Multivariate Adaptive Regression Splines (MARS)

2.3. The Artificial Bee Colony (ABC) Algorithm

- The Employee Bee Phase

- The Onlooker Bee Phase

- The Scout Bee Phase

2.4. Algorithm Goodness-of-Fit Measurement

- : The total sum of squares, proportional to the sample variance.

- : The regression sum of squares, also called the explained sum of squares.

- : The residual sum of squares.

3. Analysis of Results and Discussion

- Maximum number of basis functions (Maxfuncs): Maximum number of model terms before pruning, i.e., the maximum number of terms created by the forward pass.

- Penalty parameter (d): The Generalized Cross Validation (GCV) penalty per knot. A value of 0 penalizes only terms, not knots. The value −1 means no penalty.

- Interactions: Maximum degree of interaction between variables.

4. Conclusions

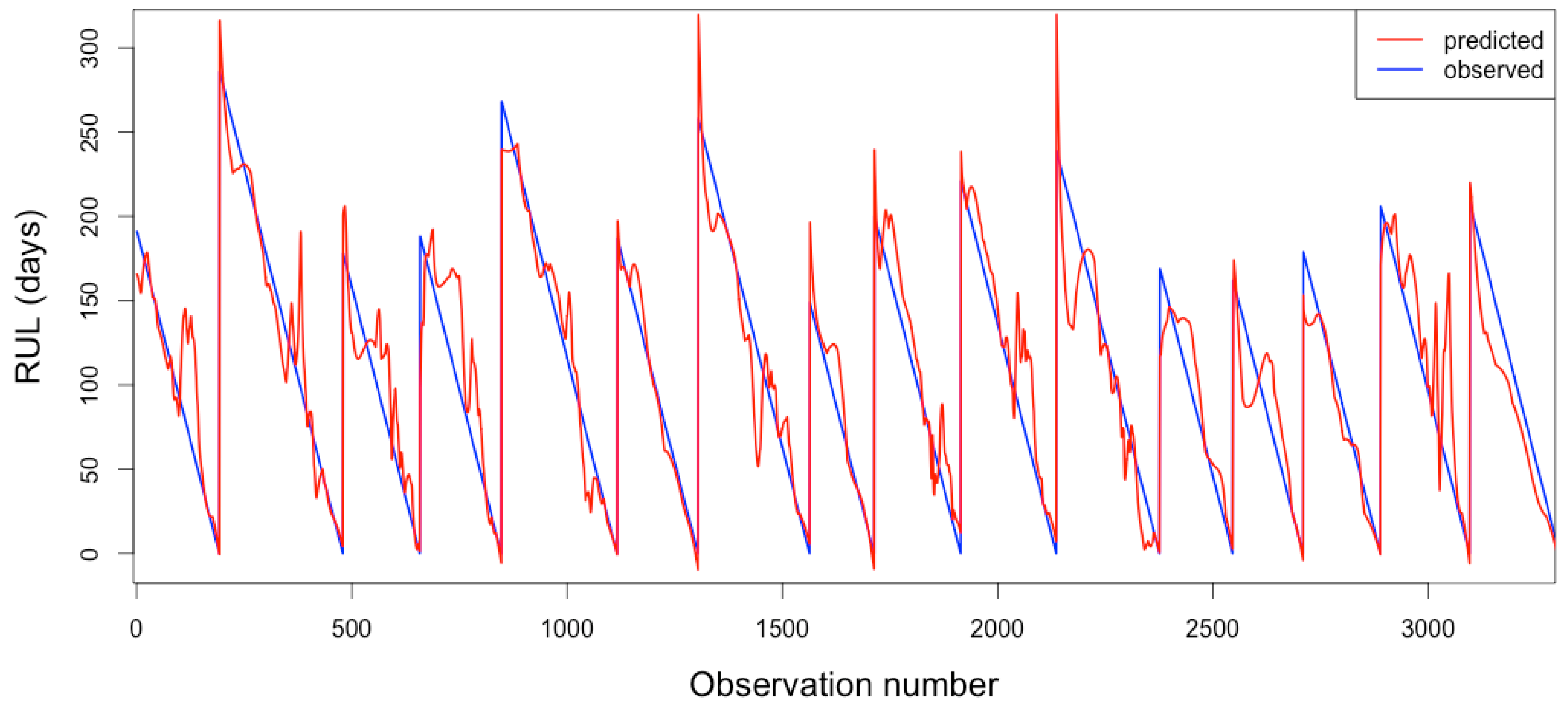

- Firstly, the hypothesis that RUL diagnosis can be accurately modeled using a hybrid ABC–MARS-based model was confirmed. Indeed, a correlation coefficient equal to 0.92 was obtained when this hybrid ABC–SVM-based model with a radial basis function (RBF) as kernel was applied to experimental. Indeed, the predicted results for this model have been proved to be consistent with the observed RUL (see Figure 8).

- Secondly, this study has developed a hybrid ABC–MARS-based model in which ABC technique was used to optimize the hyperparameters corresponding to the best MARS model for the RUL prediction from the other measured quality variables with success, in order to lower costs in the prediction of RUL.

- Finally, another additional contribution of this research work was how the parameters setting of the MARS approach in the RUL regression affects the performance. From the obtained predicted results for the RUL, we can suggest the use of the MARS approach in combination with ABC technique for predicting the RUL values on account of its superior generalization capability compared to traditional regression techniques. The results verify that the ABC–MARS regression method significantly improves the generalization capability achievable with only the MARS-based regressor.

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix

| Definition | ||

|---|---|---|

| 1 | 24.0 | |

| h(1597.13T_HPC) | −38 | |

| h(T_HPC1597.13) | −3 | |

| h(2388.1F_sp) | 3181 | |

| h(2388.12C_fsp) | −3337 | |

| h(C_fsp2388.12) | 118 | |

| h(T_LPC642.787)h(LPT_cb23.2394) | −1850 | |

| h(1597.13T_HPC)h(T_LPT1406.23) | −6 | |

| h(1597.13T_HPC)h(TP_HPC554.245) | −19 | |

| h(1597.13T_HPC)h(554.245TP_HPC) | 8 | |

| h(1587.11T_HPC)h(2388.1F_sp) | −1056 | |

| h(T_HPC1587.11)h(2388.1F_sp) | 1069 | |

| h(1597.13T_HPC)h(SP_HPC47.3243) | 79 | |

| h(1597.13T_HPC)h(47.3243SP_HPC) | −66 | |

| h(1597.13T_HPC)h(R_ff522.297) | −118 | |

| h(1597.13T_HPC)h(522.297R_ff) | 63 | |

| h(1590.19T_HPC)h(2388.12C_fsp) | 1426 | |

| h(T_HPC1590.19)h(2388.12C_fsp) | −984 | |

| h(1597.13T_HPC)h(C_fsp2388.12) | −249 | |

| h(1597.13T_HPC)h(2388.12C_fsp) | −243 | |

| h(1597.13T_HPC)h(LPT_cb23.3384) | 253 | |

| h(1597.13T_HPC)h(23.3384LPT_cb) | 440 | |

| h(1399.42T_LPT)h(2388.12C_fsp) | −158 | |

| h(T_LPT1399.42)h(2388.12C_fsp) | 560 | |

| h(TP_HPC552.966)h(F_sp2388.1) | 3728 | |

| h(553.367TP_HPC)h(C_fsp2388.12) | −94 | |

| h(TP_HPC553.367)h(C_fsp2388.12) | 194,839 | |

| h(2388.1F_sp)h(R_ff522.264) | 4672 | |

| h(2388.1F_sp)h(522.264R_ff) | −10,382 | |

| h(2388.1F_sp)h(C_fsp2388.04) | 37,628 | |

| h(2388.1F_sp)h(LPT_cb23.3955) | 32,232 | |

| h(642.298T_LPC)h(1597.13T_HPC)h(1406.23T_LPT) | −2 | |

| h(T_LPC642.298)h(1597.13T_HPC)h(1406.23T_LPT) | 8 | |

| h(642.787T_LPC)h(1597.13T_HPC)h(SP_HPC47.3243) | −604 | |

| h(T_LPC642.787)h(1597.13T_HPC)h(SP_HPC47.3243) | −138 | |

| h(642.787T_LPC)h(B_e393.013)h(LPT_cb23.2394) | 2316 | |

| h(642.787T_LPC)h(393.013B_e)h(LPT_cb23.2394) | 1673 | |

| h(1587.11T_HPC)h(T_LPT1398.34)h(2388.1F_sp) | 99 | |

| h(1587.11T_HPC)h(1398.34T_LPT)h(2388.1F_sp) | −356 | |

| h(1587.11T_HPC)h(T_LPT1402.38)h(2388.1F_sp) | 905 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(F_sp2388.08) | 187 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(2388.08F_sp) | 129 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(SP_HPC47.2194) | −8 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(47.2194SP_HPC) | −9 | |

| h(1597.13T_HPC)h(T_LPT1410.83)h(SP_HPC47.3243) | 13 | |

| h(1597.13T_HPC)h(1410.83T_LPT)h(SP_HPC47.3243) | −5 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(C_fsp2388.05) | 52 | |

| h(1587.11T_HPC)h(TP_HPC554.349)h(2388.1F_sp) | 1926 | |

| h(1587.11T_HPC)h(554.349TP_HPC)h(2388.1F_sp) | −1900 | |

| h(1597.13T_HPC)h(553.358TP_HPC)h(SP_HPC47.3243) | 153 | |

| h(1597.13T_HPC)h(TP_HPC554.245)h(B_e391.853) | −77 | |

| h(1597.13T_HPC)h(TP_HPC554.245)h(391.853B_e) | −51 | |

| h(1597.13T_HPC)h(TP_HPC553.505)h(23.3384LPT_cb) | 236 | |

| h(1597.13T_HPC)h(554.245TP_HPC)h(LPT_cb23.375) | 2360 | |

| h(1597.13T_HPC)h(554.245TP_HPC)h(23.375LPT_cb) | −399 | |

| h(1597.13T_HPC)h(F_sp2388.01)h(R_ff522.297) | 8036 | |

| h(1597.13T_HPC)h(2388.01F_sp)h(R_ff522.297) | −643 | |

| h(1597.13T_HPC)h(F_sp2388.08)h(2388.12C_fsp) | −7110 | |

| h(1597.13T_HPC)h(2388.08F_sp)h(2388.12C_fsp) | −1875 | |

| h(T_HPC1587.11)h(2388.1F_sp)h(LPT_cb23.3398) | −17,936 | |

| h(1597.13T_HPC)h(F_sp2388.06)h(LPT_cb23.3384) | −11,761 | |

| h(1597.13T_HPC)h(2388.06F_sp)h(LPT_cb23.3384) | −11,664 | |

| h(1597.13T_HPC)h(SP_HPC47.3243)h(R_ff521.611) | 533 | |

| h(1597.13T_HPC)h(SP_HPC47.3243)h(521.611R_ff) | −249 | |

| h(1597.13T_HPC)h(522.297R_ff)h(HPT_cb38.894) | −81 | |

| h(1597.13T_HPC)h(522.297R_ff)h(38.894HPT_cb) | 74 | |

| h(1597.13T_HPC)h(R_ff522.315)h(LPT_cb23.3384) | 261 | |

| h(1597.13T_HPC)h(522.315R_ff)h(LPT_cb23.3384) | 164 | |

| h(1597.13T_HPC)h(By_r8.41459)h(LPT_cb23.3384) | −23,851 | |

| h(1597.13T_HPC)h(B_e392.68)h(LPT_cb23.3384) | 5485 | |

| h(1597.13T_HPC)h(392.68B_e)h(LPT_cb23.3384) | 98 | |

| h(1399.42T_LPT)h(SP_HPC47.1847)h(2388.12C_fsp) | −16,641 | |

| h(1399.42T_LPT)h(47.1847SP_HPC)h(2388.12C_fsp) | 5308 | |

| h(1399.42T_LPT)h(2388.12C_fsp)h(By_r8.39473) | 17,357 | |

| h(TP_HPC553.934)h(2388.1F_sp)h(C_fsp2388.04) | −539,229 | |

| h(2388.1F_sp)h(C_fsp2388.04)h(HPT_cb38.8679) | −1,599,185 | |

| h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | 649,885 | |

| h(642.298T_LPC)h(1597.13T_HPC)h(1406.23T_LPT)h(B_e392.1) | 55 | |

| h(642.298T_LPC)h(1597.13T_HPC)h(1406.23T_LPT)h(392.1B_e) | 2 | |

| h(T_LPC642.298)h(1597.13T_HPC)h(1406.23T_LPT)h(F_sp2388.06) | −960 | |

| h(T_LPC642.298)h(1597.13T_HPC)h(1406.23T_LPT)h(2388.06F_sp) | −418 | |

| h(T_LPC642.298)h(1597.13T_HPC)h(1406.23T_LPT)h(R_ff521.725) | 20 | |

| h(T_LPC642.298)h(1597.13T_HPC)h(1406.23T_LPT)h(521.725R_ff) | 165 | |

| h(T_LPC642.298)h(1597.13T_HPC)h(1406.23T_LPT)h(B_e392.604) | −44 | |

| h(T_LPC642.298)h(1597.13T_HPC)h(1406.23T_LPT)h(392.604B_e) | 20 | |

| h(642.787T_LPC)h(T_HPC1584.11)h(TP_HPC554.005)h(LPT_cb23.2394) | −210 | |

| h(642.787T_LPC)h(T_HPC1584.11)h(554.005TP_HPC)h(LPT_cb23.2394) | 1848 | |

| h(642.787T_LPC)h(1597.13T_HPC)h(SP_HPC47.3243)h(B_e392.72) | 197 | |

| h(642.787T_LPC)h(1597.13T_HPC)h(SP_HPC47.3243)h(392.72B_e) | −407 | |

| h(642.787T_LPC)h(T_HPC1584.11)h(522.147R_ff)h(LPT_cb23.2394) | 1530 | |

| h(642.787T_LPC)h(T_HPC1584.11)h(By_r8.4459)h(LPT_cb23.2394) | 211,345 | |

| h(642.787T_LPC)h(T_HPC1588.92)h(393.013B_e)h(LPT_cb23.2394) | −6066 | |

| h(642.787T_LPC)h(1588.92T_HPC)h(393.013B_e)h(LPT_cb23.2394) | −247 | |

| h(T_LPC642.15)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | 23,278,307 | |

| h(T_LPC642.39)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | −21,335,093 | |

| h(1597.13T_HPC)h(T_LPT1401.3)h(554.245TP_HPC)h(LPT_cb23.375) | 7823 | |

| h(T_HPC1587.11)h(T_LPT1402.61)h(2388.1F_sp)h(LPT_cb23.3398) | −76,722 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(SP_HPC47.326)h(2388.05C_fsp) | 2947 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(C_fsp2388.05)h(HPT_cb38.931) | 1070 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(C_fsp2388.05)h(38.931HPT_cb) | 1091 | |

| h(1597.13T_HPC)h(T_LPT1404.49)h(392.68B_e)h(LPT_cb23.3384) | −10,156 | |

| h(T_HPC1587.11)h(TP_HPC553.743)h(2388.1F_sp)h(LPT_cb23.3398) | 60,136 | |

| h(1597.13T_HPC)h(TP_HPC554.245)h(F_sp2387.99)h(B_e391.853) | 15,571 | |

| h(1597.13T_HPC)h(TP_HPC554.056)h(522.297R_ff)h(HPT_cb38.894) | 706 | |

| h(1597.13T_HPC)h(554.056TP_HPC)h(522.297R_ff)h(HPT_cb38.894) | 1170 | |

| h(1597.13T_HPC)h(553.505TP_HPC)h(HPT_cb38.7938)h(23.3384LPT_cb) | 9516 | |

| h(1597.13T_HPC)h(553.505TP_HPC)h(38.7938HPT_cb)h(23.3384LPT_cb) | −882 | |

| h(1597.13T_HPC)h(F_sp2388.13)h(522.297R_ff)h(38.894HPT_cb) | 686 | |

| h(1597.13T_HPC)h(2388.13F_sp)h(522.297R_ff)h(38.894HPT_cb) | −1888 | |

| h(T_HPC1585.11)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | −1,906,032 | |

| h(T_HPC1586.75)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | 3,083,141 | |

| h(1597.13T_HPC)h(522.297R_ff)h(By_r8.4177)h(HPT_cb38.894) | 54,655 | |

| h(1597.13T_HPC)h(R_ff522.42)h(392.68B_e)h(LPT_cb23.3384) | 395 | |

| h(T_LPC642.15)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | 23,278,307 | |

| h(T_LPC642.39)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | −21,335,093 | |

| h(1597.13T_HPC)h(T_LPT1401.3)h(554.245TP_HPC)h(LPT_cb23.375) | 7823 | |

| h(T_HPC1587.11)h(T_LPT1402.61)h(2388.1F_sp)h(LPT_cb23.3398) | −76,722 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(SP_HPC47.326) h(2388.05C_fsp) | 2947 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(C_fsp2388.05)h(HPT_cb38.931) | 1070 | |

| h(1597.13T_HPC)h(1406.23T_LPT)h(C_fsp2388.05)h(38.931HPT_cb) | 1091 | |

| h(1597.13T_HPC)h(T_LPT1404.49)h(392.68B_e)h(LPT_cb23.3384) | −10156 | |

| h(T_HPC1587.11)h(TP_HPC553.743)h(2388.1F_sp)h(LPT_cb23.3398) | 60,136 | |

| h(1597.13T_HPC)h(TP_HPC554.245)h(F_sp2387.99)h(B_e391.853) | 15,571 | |

| h(1597.13T_HPC)h(TP_HPC554.056)h(522.297R_ff)h(HPT_cb38.894) | 706 | |

| h(1597.13T_HPC)h(554.056TP_HPC)h(522.297R_ff)h(HPT_cb38.894) | 1170 | |

| h(1597.13T_HPC)h(553.505TP_HPC)h(HPT_cb38.7938)h(23.3384LPT_cb) | 9516 | |

| h(1597.13T_HPC)h(553.505TP_HPC)h(38.7938HPT_cb)h(23.3384LPT_cb) | −882 | |

| h(1597.13T_HPC)h(F_sp2388.13)h(522.297R_ff)h(38.894HPT_cb) | 686 | |

| h(1597.13T_HPC)h(2388.13F_sp)h(522.297R_ff)h(38.894HPT_cb) | −1888 | |

| h(T_HPC1585.11)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | −1,906,032 | |

| h(T_HPC1586.75)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | 3,083,141 | |

| h(1597.13T_HPC)h(522.297R_ff)h(By_r8.4177)h(HPT_cb38.894) | 54,655 | |

| h(1597.13T_HPC)h(R_ff522.42)h(392.68B_e)h(LPT_cb23.3384) | 395 | |

| h(1597.13T_HPC)h(522.42R_ff)h(392.68B_e)h(LPT_cb23.3384) | −712 | |

| h(1597.13T_HPC)h(522.297R_ff)h(38.894HPT_cb)h(LPT_cb23.3154) | 13,920 | |

| h(1597.13T_HPC)h(522.297R_ff)h(38.894HPT_cb)h(23.3154LPT_cb) | 805 | |

| h(TP_HPC554.065)h(2388.1F_sp)h(C_fsp2388.04)h(LPT_cb23.3088) | 11,978,365 | |

| h(2388.1F_sp)h(R_ff521.936)h(C_fsp2388.04)h(LPT_cb23.3088) | 12,019,857 | |

| h(2388.1F_sp)h(C_fsp2388.04)h(By_r8.42486)h(LPT_cb23.3088) | −805,713,430 | |

| h(2388.1F_sp)h(C_fsp2388.04)h(By_r8.41503)h(LPT_cb23.3088) | −337,807,089 | |

| h(2388.1F_sp)h(C_fsp2388.04)h(By_r8.4216)h(LPT_cb23.3088) | 517,391,406 |

References

- El-Sayed, A.F. Aircraft Propulsion and Gas Turbine Engines; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Wild, T.; Sterkenburg, R. Aircraft Turbine Engines; Avotek Information Resources: New York, NY, USA, 2008. [Google Scholar]

- Treager, I. Aircraft Gas Turbine Engine Technology; McGraw-Hill Science: New York, NY, USA, 2002. [Google Scholar]

- Soares, C. Gas Turbines: A Handbook of Air, Land and Sea Applications; Butterworth-Heinemann: San Diego, CA, USA, 2008. [Google Scholar]

- Saravanamuttoo, H.I.H.; Rogers, G.F.C.; Cohen, H.; Straznicky, P.V. Gas Turbine Theory; Pearson Education: London, UK, 2009. [Google Scholar]

- Frederick, D.; De Castro, J.; Litt, J. User’s Guide for the Commercial Modular Aero-propulsion System Simulation (C-MAPSS); Technical Manual TM2007-215026; NASA/ARL: Cleveland, OH, USA, 2007. [Google Scholar]

- Vachtsevanos, G.; Lewis, F.; Roemer, M.; Hess, A.; Wu, B. Intelligent Fault Diagnosis and Prognosis for Engineering Systems; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Brotherton, T.; Jahns, G.; Jacobs, J.; Wroblewski, D. Prognosis of Faults in Gas Turbine Engines. In Proceedings of the 2000 IEEE Aerospace Conference, Big Sky, MT, USA, 25 March 2000; pp. 163–171.

- Goebel, K.; Qiu, H.; Eklund, N.; Yan, W. Modeling Propagation of Gas Path Damage. In Proceedings of the 2007 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2007; pp. 1–8.

- Pecht, M.G. Prognostics and Health Management of Electronics; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Tang, S.; Yu, C.; Wang, X.; Guo, X.; Si, X. Remaining useful life prediction of lithium-ion batteries based on the Wiener process with measurement error. Energies 2014, 7, 520–547. [Google Scholar] [CrossRef]

- Zhao, M.; Tang, B.; Tan, Q. Bearing remaining useful life estimation based on time–frequency representation and supervised dimensionality reduction. Measurement 2016, 86, 41–55. [Google Scholar] [CrossRef]

- Son, J.; Zhou, S.; Sankavaram, C.; Du, X.; Zhang, Y. Remaining useful life prediction based on noisy condition monitoring signals using constrained Kalman filter. Reliab. Eng. Syst. Saf. 2016, 152, 38–50. [Google Scholar] [CrossRef]

- Kapur, K.C.; Pecht, M.G. Reliability Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Walsh, P.; Fletcher, P. Gas Turbine Performance; Wiley-Blackwell: Oxford, UK, 2008. [Google Scholar]

- Kulikov, G.G.; Thompson, H.A. Dynamic Modelling of Gas Turbines: Identification, Simulation, Condition Monitoring and Optimal Control; Springer: New York, NY, USA, 2010. [Google Scholar]

- Si, X.S.; Wang, W.; Hu, C.H.; Zhou, D.H. Remaining useful life estimation—A review on the statistical data driven approaches. Eur. J. Oper. Res. 2011, 213, 1–14. [Google Scholar] [CrossRef]

- Kalbfleisch, J.D.; Prentice, R.L. The Statistical Analysis of Failure Time Data; Wiley: New York, NY, USA, 2002. [Google Scholar]

- Lawless, J.F. Statistical Models and Methods for Lifetime Data; Wiley-Interscience: New York, NY, USA, 2002. [Google Scholar]

- Zio, E.; Di Maio, F. A data-driven fuzzy approach for predicting the remaining useful life in dynamic failure scenarios of a nuclear system. Reliab. Eng. Syst. Saf. 2010, 95, 49–57. [Google Scholar] [CrossRef] [Green Version]

- Ahmadzadeh, F.; Lundberg, J. Remaining useful life prediction of grinding mill liners using an artificial neural network. Miner. Eng. 2007, 53, 1–8. [Google Scholar] [CrossRef]

- Friedman, J.H. Multivariate adaptive regression splines. Ann. Stat. 1991, 19, 1–141. [Google Scholar] [CrossRef]

- Sekulic, S.S.; Kowalski, B.R. MARS: A tutorial. J. Chemometr. 1992, 6, 199–216. [Google Scholar] [CrossRef]

- Friedman, J.H.; Roosen, C.B. An introduction to multivariate adaptive regression splines. Stat. Methods Med. Res. 1995, 4, 197–217. [Google Scholar] [CrossRef] [PubMed]

- Vapnik, V. Statistical Learning Theory; Wiley-Interscience: New York, NY, USA, 1998. [Google Scholar]

- Hastie, T.; Tibshirani, R.; Friedman, J.H. The Elements of Statistical Learning; Springer-Verlag: New York, NY, USA, 2003. [Google Scholar]

- Xu, Q.S.; Daszykowski, M.; Walczak, B.; Daeyaert, F.; de Jonge, M.R.; Heeres, J.; Koymans, L.M.H.; Lewi, P.J.; Vinkers, H.M.; Janssen, P.A.; et al. Multivariate adaptive regression splines—Studies of HIV reverse transcriptase inhibitors. Chemometr. Intell. Lab. Syst. 2004, 72, 27–34. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. A powerful and efficient algorithm for numerical function optimization: Artificial bee colony (ABC) algorithm. J. Glob. Optim. 2007, 39, 459–471. [Google Scholar] [CrossRef]

- Eberhart, R.C.; Shi, Y.; Kennedy, J. Swarm Intelligence; Morgan Kaufmann: San Francisco, CA, USA, 2001. [Google Scholar]

- Clerc, M.; Kennedy, J. The particle swarm—Explosion, stability, and convergence in a multidimensional complex space. IEEE Trans. Evolut. Comput. 2002, 6, 58–73. [Google Scholar] [CrossRef]

- Olsson, A.E. Particle Swarm Optimization: Theory, Techniques and Applications; Nova Science Publishers: New York, NY, USA, 2011. [Google Scholar]

- Dorigo, M.; Stützle, T. Ant Colony Optimization; The MIT Press: Cambridge, MA, USA, 2004. [Google Scholar]

- Simon, D. Evolutionary Optimization Algorithms; Wiley: New York, NY, USA, 2013. [Google Scholar]

- Yang, X.-S.; Cui, Z.; Xiao, R.; Gandomi, A.H.; Karamanoglu, M. Swarm Intelligence and Bio-Inspired Computation: Theory and Applications; Elsevier: London, UK, 2013. [Google Scholar]

- Chou, S.-M.; Lee, S.-M.; Shao, Y.E.; Chen, I.-F. Mining the breast cancer pattern using artificial neural networks and multivariate adaptive regression splines. Expert Syst. Appl. 2004, 27, 133–142. [Google Scholar] [CrossRef]

- De Cos Juez, F.J.; Sánchez Lasheras, F.; García Nieto, P.J.; Suárez Suárez, M.A. A new data mining methodology applied to the modelling of the influence of diet and lifestyle on the value of bone mineral density in post-menopausal women. Int. J. Comput. Math. 2009, 86, 1878–1887. [Google Scholar] [CrossRef]

- García Nieto, P.J.; Martínez Torres, J.; de Cos Juez, F.J.; Sánchez Lasheras, F. Using multivariate adaptive regression splines and multilayer perceptron networks to evaluate paper manufactured using Eucalyptus globulus. Appl. Math. Comput. 2012, 219, 755–763. [Google Scholar] [CrossRef]

- García Nieto, P.J.; Álvarez Antón, J.C. Nonlinear air quality modeling using multivariate adaptive regression splines in Gijón urban area (Northern Spain) at local scale. Appl. Math. Comput. 2014, 235, 50–65. [Google Scholar] [CrossRef]

- García Nieto, P.J.; Sánchez Lasheras, F.; de Cos Juez, F.J.; Alonso Fernández, J.R. Study of cyanotoxins presence from experimental cyanobacteria concentrations using a new data mining methodology based on multivariate adaptive regression splines in Trasona reservoir (Northern Spain). J. Hazard. Mater. 2011, 195, 414–421. [Google Scholar] [CrossRef] [PubMed]

- García Nieto, P.J.; Alonso Fernández, J.R.; Sánchez Lasheras, F.; de Cos Juez, F.J.; Díaz Muñiz, C. A new improved study of cyanotoxins presence from experimental cyanobacteria concentrations in the Trasona reservoir (Northern Spain) using the MARS technique. Sci. Total Environ. 2012, 430, 88–92. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.G.; Goh, A.T.C. Multivariate adaptive regression splines for analysis of geotechnical engineering systems. Comput. Geotech. 2013, 48, 82–95. [Google Scholar] [CrossRef]

- Saxena, A.; Goebel, K.; Simon, D.; Eklund, N. Damage Propagation Modeling for Aircraft Engine Run-to-failure Simulation. In Proceedings of the 2008 IEEE International Conference on Prognostics and Health Management (PMH 2008), Denver, CO, USA, 6–9 October 2008; pp. 1–9.

- Wang, T.; Yu, J.; Siegel, D.; Lee, J. A Similarity-based Prognostics Approach for Remaining Useful Life Estimation of Engineered Systems. In Proceedings of the 2008 IEEE International Conference on Prognostics and Health Management (PMH 2008), Denver, CO, USA, 6–9 October 2008; pp. 1–6.

- Sun, J.; Zuo, H.; Wang, W.; Pecht, M.G. Application of a state space modeling technique to system prognostics based on a health index for condition-based maintenance. Mech. Syst. Signal Proc. 2012, 28, 585–596. [Google Scholar] [CrossRef]

- Wasserman, L. All of Statistics: A Concise Course in Statistical Inference; Springer: New York, NY, USA, 2003. [Google Scholar]

- Freedman, D.; Pisani, R.; Purves, R. Statistics; W.W. Norton & Company: New York, NY, USA, 2007. [Google Scholar]

- Ranganai, E. Quality of fit measurement in regression quantiles: An elemental set method approach. Stat. Probabil. Lett. 2016, 111, 18–25. [Google Scholar] [CrossRef]

- Picard, R.; Cook, D. Cross-validation of regression models. J. Am. Stat. Assoc. 1984, 79, 575–583. [Google Scholar] [CrossRef]

- Barnes, J.P.; Johnston, P.R. Application of robust Generalised Cross-Validation to the inverse problem of electrocardiology. Comput. Biol. Med. 2016, 69, 213–225. [Google Scholar] [CrossRef] [PubMed]

- Milborrow, S. Earth: Multivariate Adaptive Regression Spline Models, R Package, version 3.2–7; R Foundation for Statistical Computing: Vienna, Austria, 2014. [Google Scholar]

- Vega Yong, G.; Muñoz, E. ABCoptim: Implementation of Artificial Bee Colony (ABC) Optimization, R Package, version 0.13.11; R Foundation for Statistical Computing: Vienna, Austria, 2013. [Google Scholar]

| Input Variables | Symbol | Mean | Standard Deviation |

|---|---|---|---|

| Total temperature at fan inlet (°R) | T_f | ||

| Total temperature at LPC outlet (°R) | T_LPC | ||

| Total temperature at HPC outlet (°R) | T_HPC | 6.13 | |

| Total temperature at LPT outlet (°R) | T_LPT | 9.00 | |

| Pressure at fan inlet (psia) | P_f | ||

| Total pressure in bypass-duct (psia) | TP_by | ||

| Total pressure at HPC outlet (psia) | TP_HPC | ||

| Physical fan speed (rpm) | F_sp | ||

| Physical core speed (rpm) | C_sp | ||

| Engine pressure ratio | E_pr | 1.30 | |

| Static pressure at HPC outlet (psia) | SP_HPC | ||

| Ratio of fuel flow to Ps30 (pps/psi) | R_ff | ||

| Corrected fan speed (rpm) | C_fsp | ||

| Corrected core speed (rpm) | C_csp | ||

| Bypass ratio | By_r | 8.44 | |

| Burner fuel-air ratio | B_far | ||

| Bleed enthalpy | B_e | 1.55 | |

| Demanded fan speed (rpm) | D_fsp | 0.00 | |

| Demanded corrected fan speed (rpm) | D_cfsp | 0.00 | |

| HPT coolant bleed (lbm/s) | HPT_cb | ||

| LPT coolant bleed (lbm/s) | LPT_cb |

| MARS Hyperparameters | Lower Limit | Upper Limit |

|---|---|---|

| Maximum number of basis functions (MaxFuncs) | 3 | 200 |

| Penalty parameter (d) | −1 | 4 |

| Interactions | 1 | 4 |

| Hyperparameter | Values of Optimal Hyperparameters |

|---|---|

| Maximum number of basis functions (MaxFuncs) | 164 |

| Penalty parameter (d) | 2 |

| Interactions | 4 |

| Input Variable | Nsubsets | GCV | RSS |

|---|---|---|---|

| T_HPC | 122 | 100.0 | 100.0 |

| C_fsp | 122 | 98.2 | 98.2 |

| T_LPC | 120 | 62.5 | 62.8 |

| TP_HPC | 120 | 62.5 | 62.8 |

| F_sp | 120 | 62.5 | 62.8 |

| R_ff | 120 | 62.5 | 62.8 |

| LPT_cb | 120 | 62.5 | 62.8 |

| T_LPT | 117 | 56.6 | 56.9 |

| By_r | 115 | 52.5 | 52.9 |

| HPT_cb | 109 | 46.1 | 46.5 |

| B_e | 106 | 43.8 | 44.3 |

| SP_HPC | 100 | 40.9 | 41.3 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García Nieto, P.J.; García-Gonzalo, E.; Bernardo Sánchez, A.; Menéndez Fernández, M. A New Predictive Model Based on the ABC Optimized Multivariate Adaptive Regression Splines Approach for Predicting the Remaining Useful Life in Aircraft Engines. Energies 2016, 9, 409. https://doi.org/10.3390/en9060409

García Nieto PJ, García-Gonzalo E, Bernardo Sánchez A, Menéndez Fernández M. A New Predictive Model Based on the ABC Optimized Multivariate Adaptive Regression Splines Approach for Predicting the Remaining Useful Life in Aircraft Engines. Energies. 2016; 9(6):409. https://doi.org/10.3390/en9060409

Chicago/Turabian StyleGarcía Nieto, Paulino José, Esperanza García-Gonzalo, Antonio Bernardo Sánchez, and Marta Menéndez Fernández. 2016. "A New Predictive Model Based on the ABC Optimized Multivariate Adaptive Regression Splines Approach for Predicting the Remaining Useful Life in Aircraft Engines" Energies 9, no. 6: 409. https://doi.org/10.3390/en9060409

APA StyleGarcía Nieto, P. J., García-Gonzalo, E., Bernardo Sánchez, A., & Menéndez Fernández, M. (2016). A New Predictive Model Based on the ABC Optimized Multivariate Adaptive Regression Splines Approach for Predicting the Remaining Useful Life in Aircraft Engines. Energies, 9(6), 409. https://doi.org/10.3390/en9060409