The Study of Fuzzy Proportional Integral Controllers Based on Improved Particle Swarm Optimization for Permanent Magnet Direct Drive Wind Turbine Converters

Abstract

:1. Introduction

2. Analysis of Converter Control Strategy

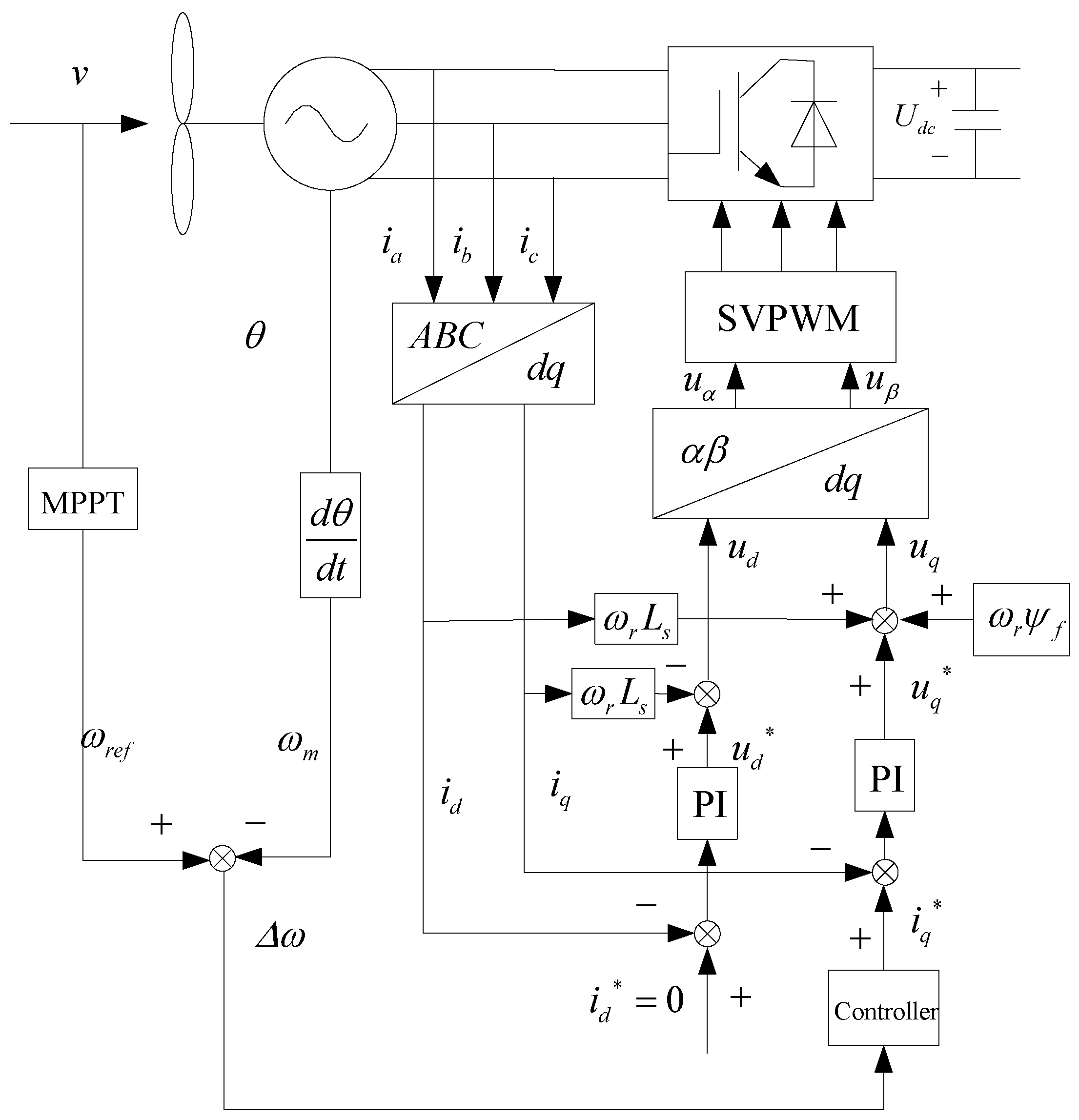

2.1. The Control Strategy of Generator Side Converter

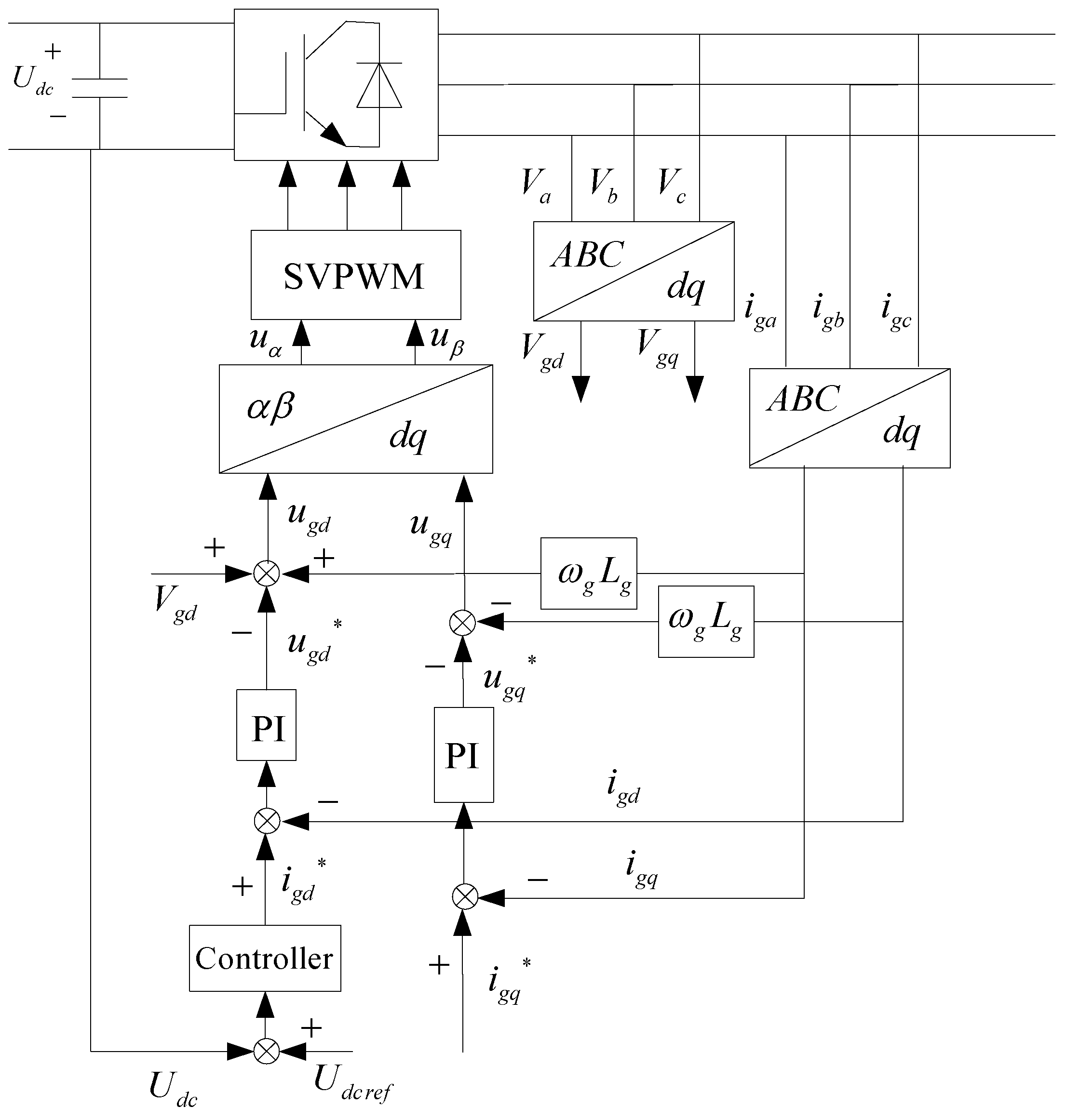

2.2. The Control Strategy of Grid Side Converter

3. Fuzzy PI Controller of the Converter Based on Improved Particle Swarm Optimization

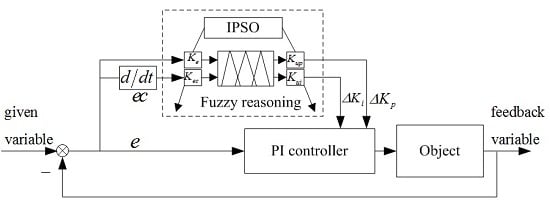

3.1. The General Fuzzy PI Controller

3.2. Improved Particle Swarm Optimization

3.3. The Design of Fuzzy PI Controller Based on Improved Particle Swarm Optimization

- (1)

- Initializing the particle swarm. The initial position and velocity of every particle are randomly generated in the allowable range. Then the individual extremum pbest is the initial position and global extremum gbest is the optimal value of the individual extremum.

- (2)

- By bringing the initial values into Equations (12)–(15); new position and velocity of the particle (for next iteration) will be determined. A new individual extremum and global extremum can be then obtained after calculating the fitness function . If the new global extremum is better than the last one, the global extremum is updated with the new one.

- (3)

- Particles continue searching in the search space until the performance index of the system is satisfied or the maximum number of iterations is reached. After that, the program stops and the particle position renders the optimal values of the four parameters of ke, kec, kup and kui of the fuzzy controller. Otherwise, the program goes back to step (2) for further searching.

4. Simulation Analysis

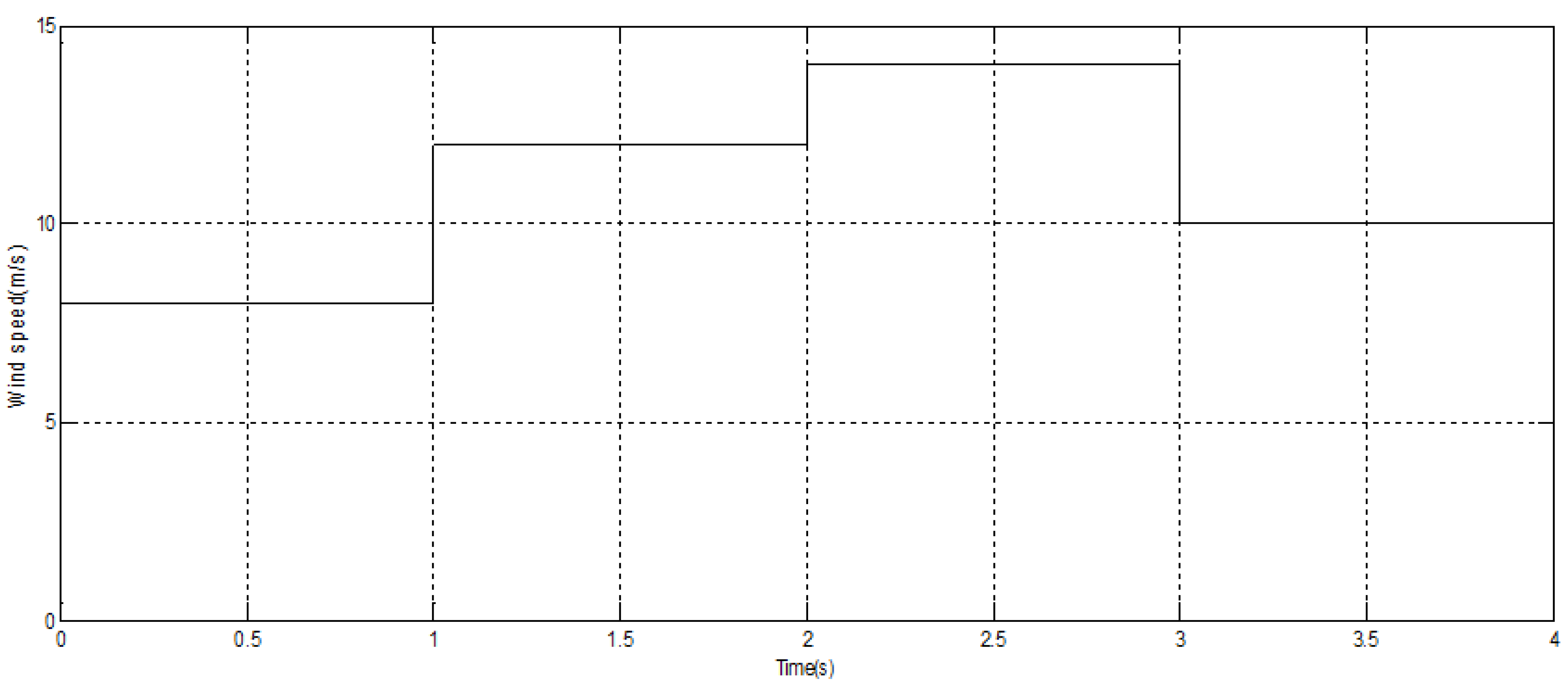

4.1. Simulation Model

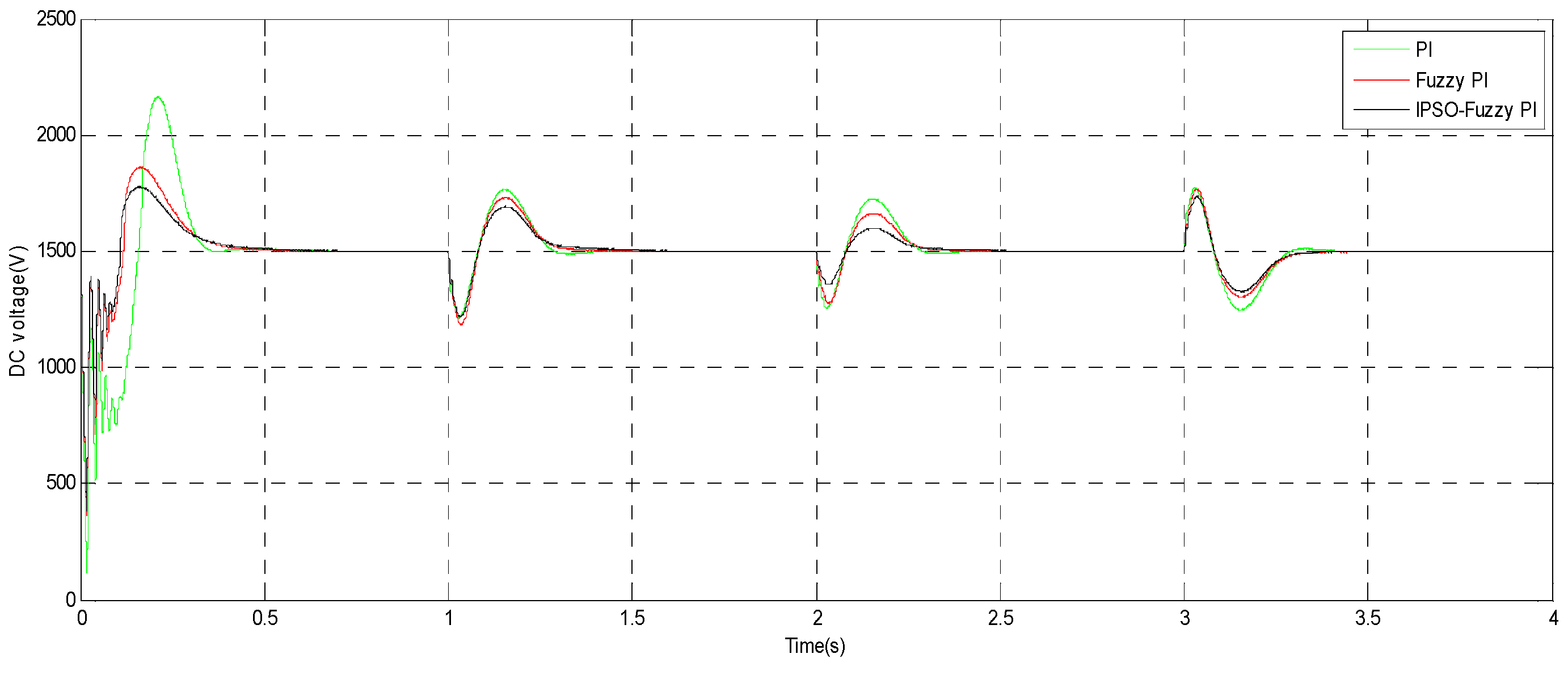

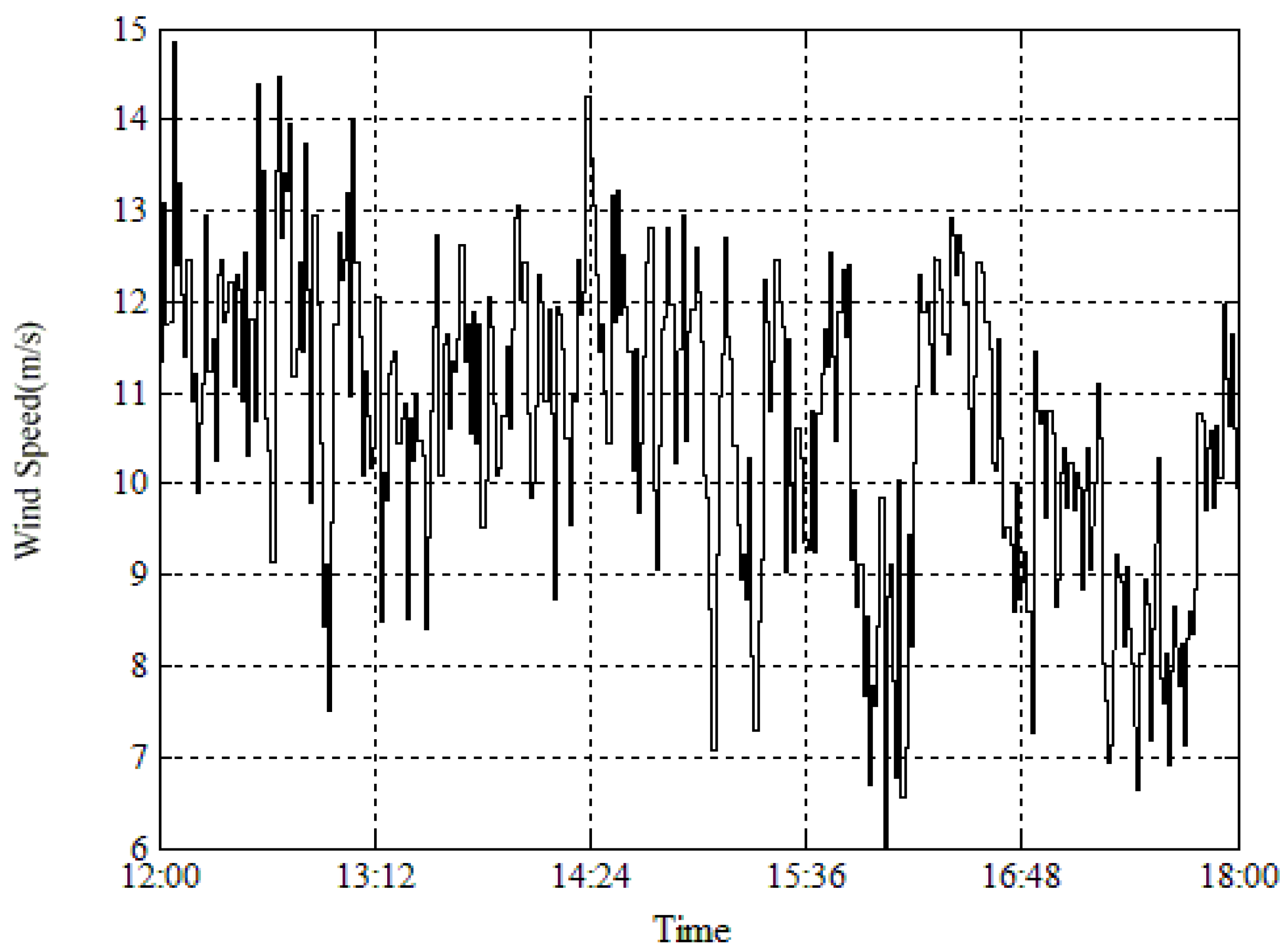

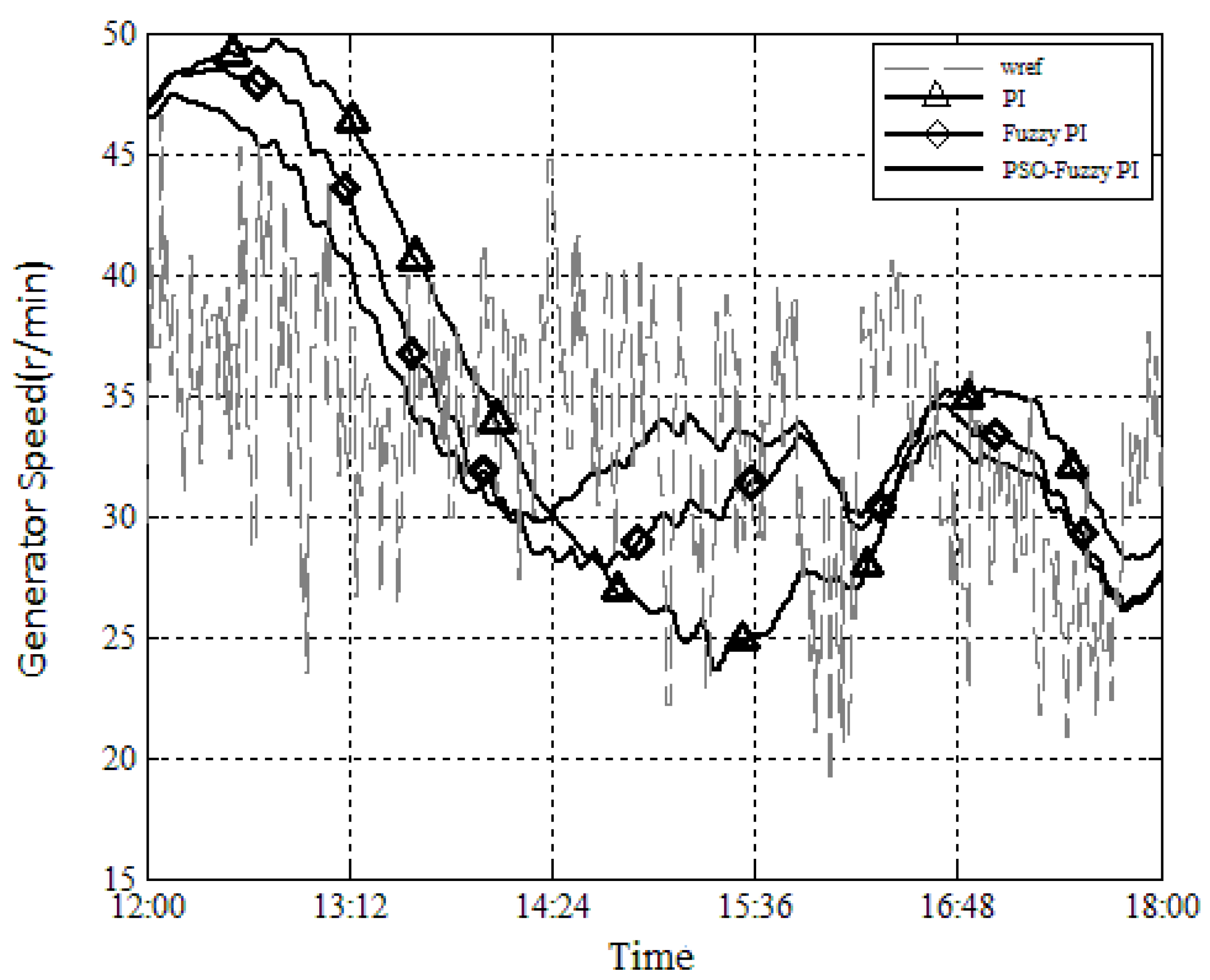

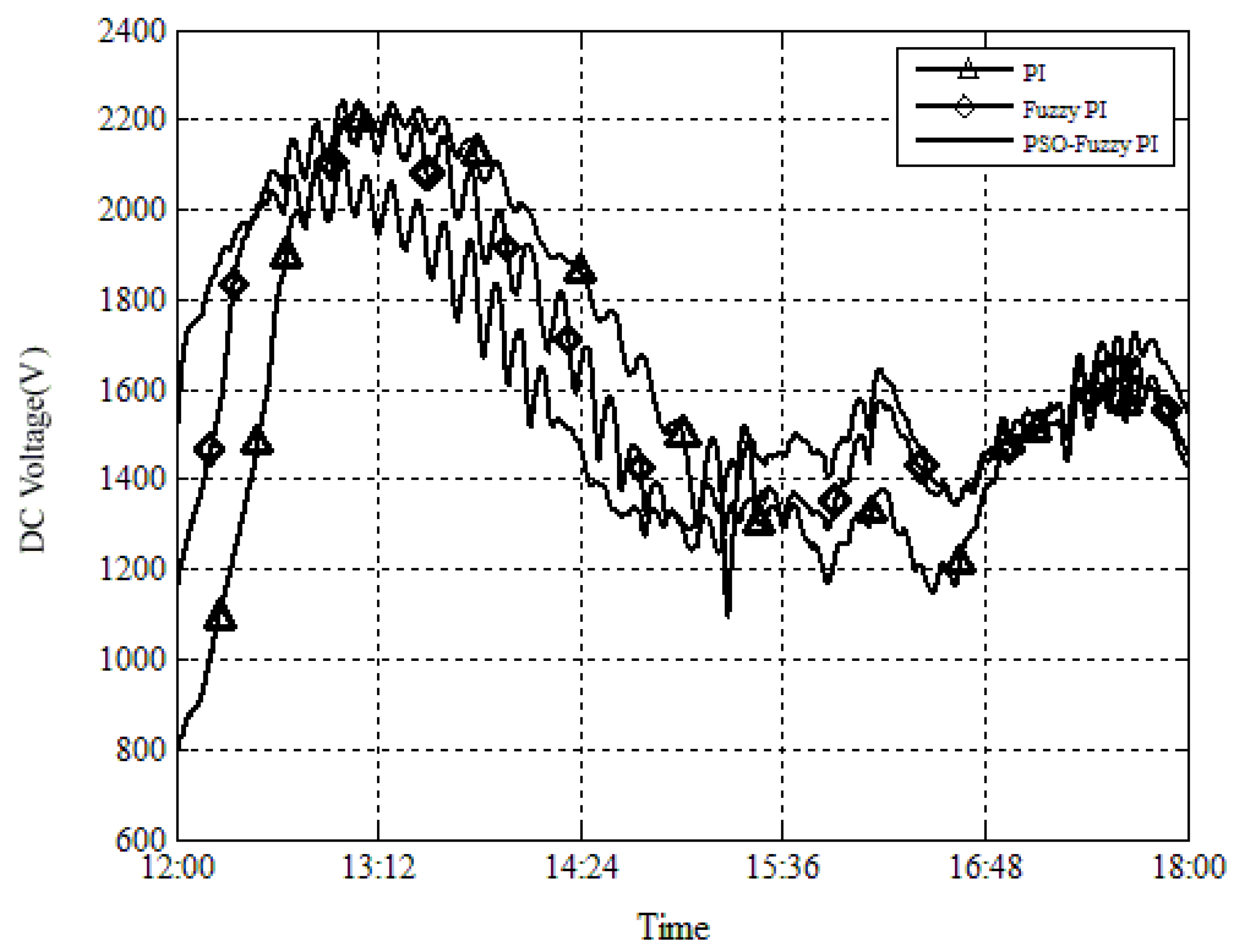

4.2. Analysis of Simulation Results

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- The US Department of Energy (US DoE). Chapter 4: The Wind Vision Roadmap: A Pathway Forward in Wind Vision: A New Era for Wind Power in the United States. Available online: http://www.energy.gov/sites/prod/files/wv_chapter4_the_wind_vision_roadmap.pdf (accessed on 20 March 2016).

- European Wind Energy Association. Pure Power: Wind energy targets for 2020 and 2030, 2009 update. Available online: http://www.ewea.org/fileadmin/ewea_documents/documents/publications/reports/Pure_power_Full_Report.pdf (accessed on 31 July 2015).

- China May Have 500 GW of Wind Parks in 2030–Study (21 Oct 2014). Available online: http://renewables.seenews.com/news/china-may-have-500-gw-of-wind-parks-in-2030-study-444069 (accessed on 20 March 2016).

- Goudarzi, N.; Zhu, W.D. A review on the development of wind turbine generators across the world. Int. J. Dyn. Control 2013, 1, 192–202. [Google Scholar] [CrossRef]

- Poliner, H.; Van Der Pijl, F.F.A.; De Vilder, G.J.; Tavner, P. Comparison of direct-drive and geared generator concepts for wind turbines. IEEE Trans. Energy Convers. 2006, 21, 725–733. [Google Scholar] [CrossRef]

- Liserre, M.; Cardenas, R.; Molinas, M.; Rodriguez, J. Overview of multi-MW wind turbine and wind parks. IEEE Trans. Ind. Electron. 2011, 58, 1081–1095. [Google Scholar] [CrossRef]

- Sheela, J.; Mary, A.; Sivasakthi, S. A novel integrated AC/DC/AC converter for direct drive permanent magnet wind power generation system. Int. J. Eng. Res. Technol. 2013, 2, 1–12. [Google Scholar]

- Minh, H.Q.; Cuong, N.C.; Chau, T.N. A fuzzy-logic based MPPT method for stand-alone wind turbine system. Am. J. Eng. Res. 2014, 3, 177–184. [Google Scholar]

- Bao, Y.; Wang, H.; Zhang, J. Adaptive inverse control of variable speed wind turbine. Nonlinear Dyn. 2010, 61, 819–827. [Google Scholar] [CrossRef]

- Nourdine, S.; Díaz De Corcuera, A.; Camblong, H.; Landaluze, J.; Vechiu, I.; Tapia, G. Control of wind turbines for frequency regulation and fatigue loads reduction. In Proceedings of the 6th Dubrovnik Conference on Sustainable Development of Energy, Water and Environment Systems, Dubrovnik, Croatia, 25–29 September 2011; pp. 25–29.

- Wright, A.D. Modern Control Design for Flexible Wind Turbines, NREL/TP-500–35816; Technical Report for NREL: Golden, CO, USA, 2004. [Google Scholar]

- Wright, A.D.; Fingersh, L.J.; Balas, M.J. Testing state-space controls for the controls advanced research turbine. J. Sol. Energy Eng. 2006, 128, 506–515. [Google Scholar] [CrossRef]

- Sanz, M.G.; Torres, M. Aerogenerador síncrono multipolar de velocidad variable y 1.5 MW de potencia: TWT1500. Available online: http://intranet.ceautomatica.es/old/actividades/jornadas/XXIV/documentos/incon/134.pdf (accessed on 26 March 2016).

- Bianchi, F.D.; Battista, H.D.; Mantz, R.J. Wind turbine control systems. In Principles, Modelling and Gain Scheduling Design; Springer-Verlag: London, UK, 2007. [Google Scholar]

- De Corcuera, A.D.; Pujana-Arrese, A.; Ezquerra, J.M.; Segurola, E.; Landaluze, J. H∞ based control for load mitigation in wind turbines. Energies 2012, 5, 938–967. [Google Scholar] [CrossRef]

- Chen, T.X.; Dai, Q.; Tao, J. Wind power permanent magnet synchronous generator based on sliding mode variable structure cascade control. Electr. Autom. 2008, 30, 8–11. [Google Scholar]

- Boukhezzar, B.; Siguerdidjane, H. Nonlinear control of a variable-speed wind turbine using a two-mass model. IEEE Trans. Energy Convers. 2011, 26, 149–162. [Google Scholar] [CrossRef]

- Bououden, S.; Chadli, M.; Filali, S.; El Hajjaji, A. Fuzzy model based multivariable predictive control of a variable speed wind turbine: LMI approach. Renew. Energy 2012, 37, 434–439. [Google Scholar] [CrossRef]

- Sargolzaei, J.; Kianifar, A. Neuro-fuzzy modeling tools for estimation of torque in Savonius rotor wind turbine. Adv. Eng. Softw. 2010, 41, 619–626. [Google Scholar] [CrossRef]

- Sheikhan, M.; Shahnazi, R.; Yousefi, A.N. An optimal fuzzy PI controller to capture the maximum power for variable-speed wind turbines. Neural Comput. Appl. 2013, 23, 1359–1368. [Google Scholar] [CrossRef]

- Munteanu, L.; Bratcu, A.L.; Cutululis, N.A.; Ceanga, E. Optimal Control of Wind Energy Systems; Springer-Verlag: London, UK, 2008; pp. 109–168. [Google Scholar]

- Mullane, A.; Lightbody, G.; Yacamini, R. Adaptive control of variable speed wind turbines. Available online: http://www.cder.dz/download/upec-13.pdf (accessed on 26 March 2016).

- Giraldo, E.; Garces, A. An adaptive control strategy for a wind energy conversion system based on PWM-CSC and PMSG. IEEE Trans. Power Syst. 2014, 29, 1446–1453. [Google Scholar] [CrossRef]

- Shariff, R.; Zhang, Q.J.; Cudrak, A.; Stanley, S.J.; Smith, D.W.; Baxter, C.W. Real-Time Artificial Intelligence Control and Optimization of a Full-Scale WTP; Awwa Research Foundation: Denver, CO, USA, 2006; pp. 9–20. [Google Scholar]

- Amine, B.M.; Souhila, Z.; Tayeb, A.; Ahmed, M. Adaptive fuzzy logic control of wind turbine emulator. Int. J. Power Electron. Drive Syst. 2014, 4, 233–240. [Google Scholar]

- Vanitha, K.; Shravani, C. Permanent magnet synchronous generator with fuzzy logic controller for wind energy conversion system. Int. J. Eng. Res. Technol. 2013, 2, 3943–3950. [Google Scholar]

- Minh, H.Q.; Frédéric, N.; Najib, E.; Abdelaziz, H. Control of permanent magnet synchronous generator wind turbine for stand-alone system using fuzzy logic. In Proceedings of the 7th Conference of the European Society for Fuzzy Logic and Technology, Aix-les-Bains, France, 18–22 July 2011; pp. 720–727.

- Yin, X.X.; Lin, Y.G.; Li, W.; Gu, Y.J.; Lei, P.F.; Liu, H.W. Sliding mode voltage control strategy for capturing maximum wind energy based on fuzzy logic control. Int. J. Emerg. Electr. Power Syst. 2015, 70, 45–51. [Google Scholar] [CrossRef]

- Pratap, A.; Howlader, A.M.; Senjyu, T.; Yona, A.; Urasaki, N.; Funabashi, T. Different strategies for controlling output power smoothing of a PMDG-based wind energy conversion systems. Int. J. Emerg. Electr. Power Syst. 2012, 13. [Google Scholar] [CrossRef]

- Melício, R.; Mendes, V.M.F.; Catalão, J.P.S. Fractional-order control and simulation of wind energy systems with PMSG/full-power converter topology. Energy Convers. Manag. 2010, 51, 1250–1258. [Google Scholar] [CrossRef]

- Beltran, B.; Ahmed-Ali, T.; Benbouzid, M.E.H. Sliding mode power control of variable-speed wind energy conversion systems. IEEE Trans. Energy Convers. 2008, 23, 551–558. [Google Scholar] [CrossRef] [Green Version]

- Li, S.H.; Haskew, T.A.; Xu, L. Conventional and novel control designs for direct driven PMSG wind turbines. Electr. Power Syst. Res. 2010, 80, 328–338. [Google Scholar] [CrossRef]

- Babu, N.R.; Arulmozhivarman, P. Wind energy conversion systems–A technical review. J. Eng. Sci. Technol. 2013, 8, 493–507. [Google Scholar]

- Kim, J.Y.; Kim, H.M.; Kim, S.K.; Jeon, J.H.; Choi, H.K. Designing an energy storage system fuzzy PID controller for microgrid islanded operation. Energies 2011, 4, 1443–1460. [Google Scholar] [CrossRef]

- Dorf, R.C.; Bishop, R. Modern Control System, 11th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Kortabarria, I.; Andreu, J.; De Alegri’a, I.M.; Jime’nez, J.; Gárate, J.I.; Robles, E. A novel adaptive maximum power point tracking algorithm for small wind turbines. Renew. Energy 2014, 63, 785–796. [Google Scholar] [CrossRef]

- Venkataramana, N.N.; Singh, S.P. Improved torque and flux performance of type-2 fuzzy-based direct torque control induction motor using space vector pulse-width modulation. Electr. Power Compon. Syst. 2014, 42, 658–669. [Google Scholar] [CrossRef]

- Kim, H.W.; Kin, S.S.; Ko, H.S. Modeling and control of PMSG-based variable-speed wind turbine. Electr. Power Syst. Res. 2010, 80, 46–52. [Google Scholar] [CrossRef]

- Wu, R.; Dewan, S.B.; Slemon, G.R. Analysis of an AC to DC voltage source converter using PWM with phase and amplitude control. IEEE Trans. Ind. Appl. 1991, 27, 355–364. [Google Scholar] [CrossRef]

- Gopala, K.A.; Reddy, B.A.; Bhavani, P.D. Fuzzy PI and integrating type fuzzy PID controllers of linear, nonlinear and time-delay systems. Int. J. Comput. Appl. 2010, 1, 41–47. [Google Scholar]

- Tarique, A.; Gabbar, H.A. Particle swarm optimization (PSO) based turbine control. Intell. Control Autom. 2013, 4, 126–137. [Google Scholar] [CrossRef]

- Bhattacharyya, B.; Raj, S. PSO based bio inspired algorithms for reactive power planning. Int. J. Electr. Power Energy Syst. 2016, 74, 396–402. [Google Scholar] [CrossRef]

- Sahu, R.K.; Panda, S.; Sekhar, G.T.C. A novel hybrid PSO-PS optimized fuzzy PI controller for AGC in multi area interconnected power systems. Int. J. Electr. Power Energy Syst. 2015, 64, 880–893. [Google Scholar] [CrossRef]

- Tayal, V.K.; Lather, J.S. Reduced order H∞ TCSC controller & PSO optimized fuzzy PSS design in mitigating small signal oscillations in a wide range. Int. J. Electr. Power Energy Syst. 2015, 68, 123–131. [Google Scholar]

- Esfahani, M.T.; Hosseinian, S.H.; Vahidi, B. A new optimal approach for improvement of active power filter using FPSO for enhancement power quality. Int. J. Electr. Power Energy Syst. 2015, 69, 188–199. [Google Scholar] [CrossRef]

- Khadanga, R.K.; Satapathy, J.K. Time delay approach for PSS and SSSC based coordinated controller design using gybrid PSO-GSA algorithm. Int. J. Electr. Power Energy Syst. 2015, 71, 262–273. [Google Scholar] [CrossRef]

- Samuel, G.G.; Rajan, C.C.A. Hybrid: Particle Swarm Optimization—Genetic Algorithm and Particle Swarm Optimization—Shuffled Frog Leaping Algorithm for long-term generator maintenance scheduling. Int. J. Electr. Power Energy Syst. 2015, 65, 432–442. [Google Scholar] [CrossRef]

- Kongnam, C.; Nuchprayoon, S. A particle swarm optimization for wind energy control problem. Renew. Energy 2010, 35, 2431–2438. [Google Scholar] [CrossRef]

- Li, Y.G.; Gui, W.H.; Yang, H.H.; Li, J. Improved PSO algorithm and its application. J. Cent. South Univ. Technol. 2005, 12, 222–226. [Google Scholar] [CrossRef]

- Langdon, W.B.; Poli, R. Evolving problems to learn about particle swarm optimizers and other search algorithm. Evol. Comput. 2007, 11, 561–578. [Google Scholar] [CrossRef]

- Ratnaweera, A.; Halgamuge, S. Self-organizing hierarchical particle swarm optimizer with time-varying acceleration coefficients. Evol. Comput. 2004, 8, 240–255. [Google Scholar] [CrossRef]

| Control techniques | Advantage | Disadvantage |

|---|---|---|

| Fuzzy logic [21] | Maximizing the harvested power from the wind; improved dynamic response; fuzzy controller is more flexible. | Context dependence on the wind site features, wind turbine types, etc.; requiring quite consistent a priori knowledge; may not guarantee an optimal response [22]. |

| Adaptive | Does not need a priori information about the bounds on those uncertain or time-varying parameters of a dynamic system, mainly for pitch control, turbine and generator shaft torque control. | Require an adequate initialization of the controller parameters and detailed system data [23]. |

| Linear quadratic | Linear quadratic performance indicator is regarded as the objective function to determine the relationship between variables. | The resulting control is not optimal, but it is feasible and effective. |

| Quantitative feedback theory (QFT) [21] | For robust control; effective for nonlinear systems with parameter uncertainty using both linearized and nonlinear model. | Based on the frequency-domain analysis; requires a lot of computational and graphical analysis. |

| Linear parameter varying (LPV) | Nonlinear dynamic system, only the parameters are variable, commonly used measure performance based on norm, stable and robust control. | Complex modeling; a large amount of calculation; complex control strategies. |

| H∞ | Good robust control; the design idea is clear, especially for multi-input multi-output system to use. | Theory complexity; large calculation cost and limited parameter change scope. |

| Sliding mode variable structure cascade control | Fast response, simple, robust. | Prone to buffeting. |

| State feedback control | Fully reflect the characteristics of the internal system; effectively improve the system performance. | State variables often cannot be measured directly from outside of the system; as a result, its implementation is often more complex. |

| Predictive control | Convenience for modeling, not require in-depth understanding of the internal mechanism of the process; robust control. | Stability constraints may affect the achievement of the control performance and it will also affect the real-time algorithm. For nonlinear systems, state trajectory generation tends to be more difficult. |

| Artificial neural network (ANN)-based control | With parallel processing and self-learning ability. | Requires a lot of training samples to train the network; preparation of datasets for ANN training is largely user- dependent; ANN models do not yield explicit mathematical formulae [24]. |

| Wind speed (m/s) | Overshoot (%) | Regulating time (s) | ||||

|---|---|---|---|---|---|---|

| PI | Fuzzy PI | IPSO-Fuzzy PI | PI | Fuzzy PI | IPSO-Fuzzy PI | |

| 8 | 36.2 | 29.5 | 18.4 | 0.399 | 0.233 | 0.203 |

| 12 | 12.5 | 11 | 7.7 | 0.183 | 0.173 | 0.132 |

| 14 | 6.7 | 5.8 | 4.0 | 0.179 | 0.169 | 0.124 |

| 10 | 12.3 | 10.4 | 6.1 | 0.182 | 0.173 | 0.134 |

| Wind speed (m/s) | Overshoot (%) | Regulating time (s) | ||||

|---|---|---|---|---|---|---|

| PI | Fuzzy PI | IPSO-Fuzzy PI | PI | Fuzzy PI | IPSO-fuzzy PI | |

| 8 | 44.4 | 24.1 | 18.5 | 0.312 | 0.308 | 0.3 |

| 12 | 17.7 | 15.3 | 12.6 | 0.242 | 0.239 | 0.234 |

| 14 | 15.1 | 10.9 | 6.5 | 0.240 | 0.236 | 0.233 |

| 10 | 16.9 | 13.1 | 9.5 | 0.258 | 0.249 | 0.241 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Zhang, T.; Ding, Z.; Li, C. The Study of Fuzzy Proportional Integral Controllers Based on Improved Particle Swarm Optimization for Permanent Magnet Direct Drive Wind Turbine Converters. Energies 2016, 9, 343. https://doi.org/10.3390/en9050343

Xiao Y, Zhang T, Ding Z, Li C. The Study of Fuzzy Proportional Integral Controllers Based on Improved Particle Swarm Optimization for Permanent Magnet Direct Drive Wind Turbine Converters. Energies. 2016; 9(5):343. https://doi.org/10.3390/en9050343

Chicago/Turabian StyleXiao, Yancai, Tieling Zhang, Zeyu Ding, and Chunya Li. 2016. "The Study of Fuzzy Proportional Integral Controllers Based on Improved Particle Swarm Optimization for Permanent Magnet Direct Drive Wind Turbine Converters" Energies 9, no. 5: 343. https://doi.org/10.3390/en9050343