Cavitation Inception in Crossflow Hydro Turbines

Abstract

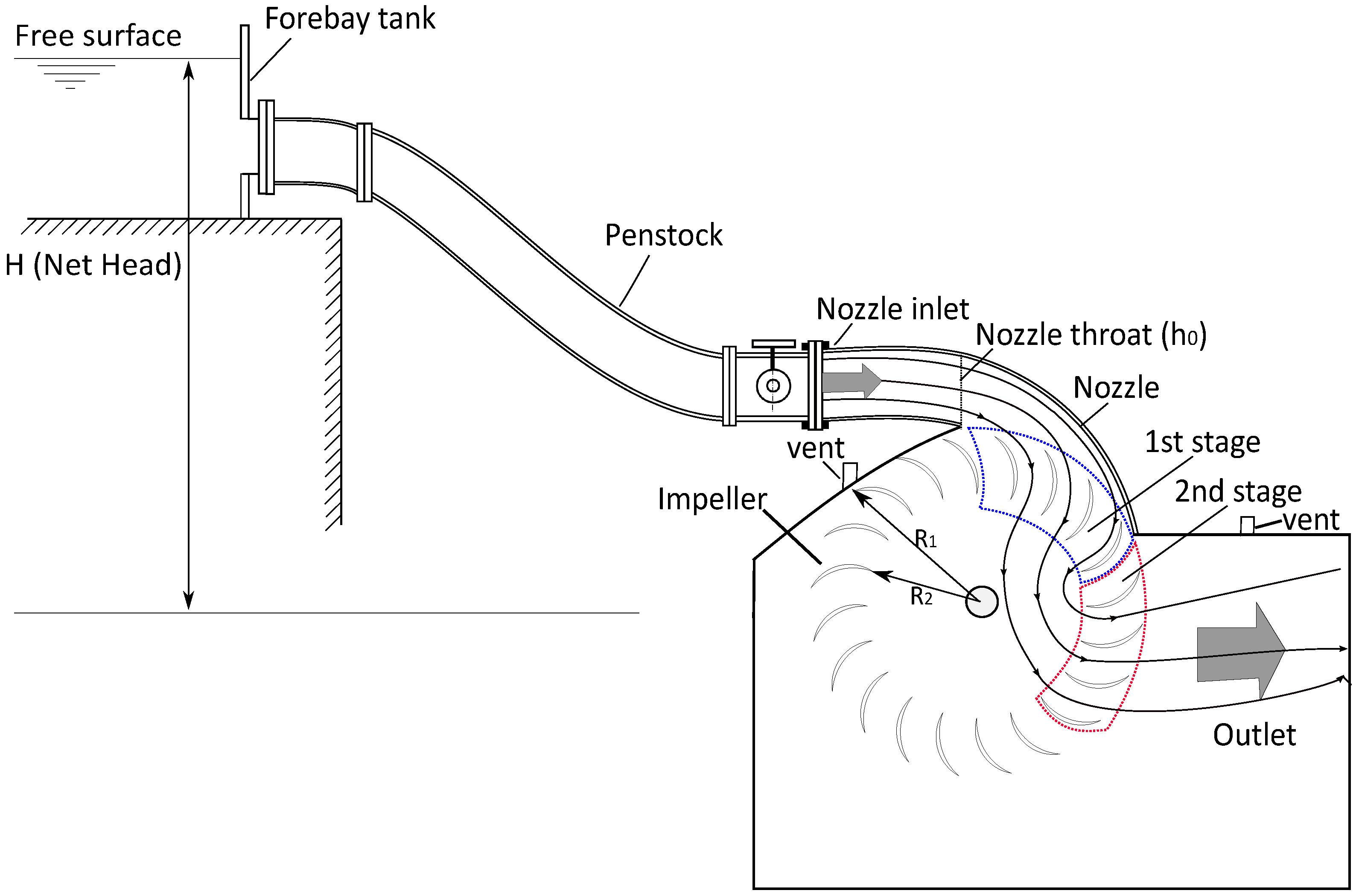

:1. Introduction

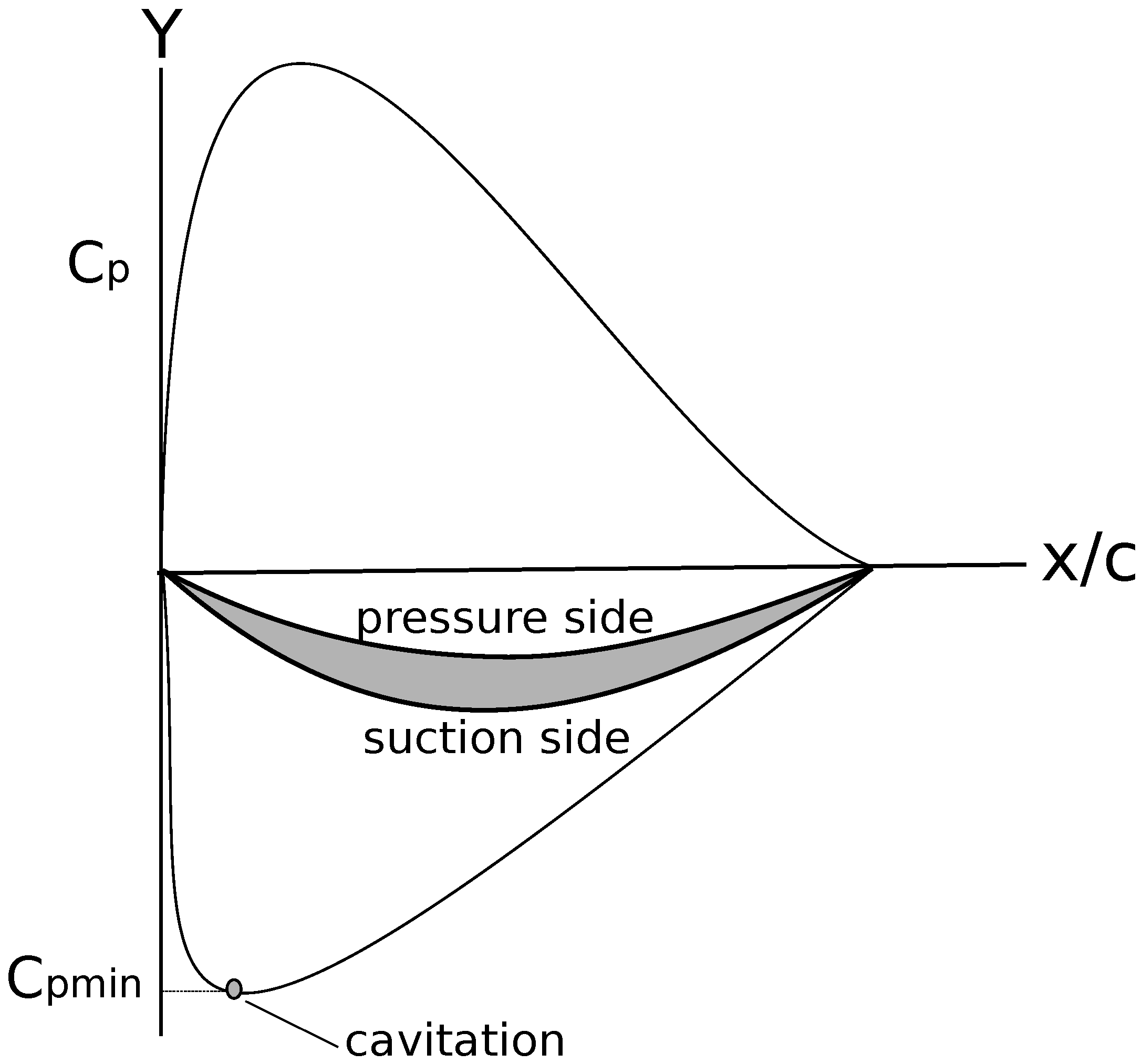

2. Cavitation

3. Computational Methodology

3.1. Multiphase and Turbulence Modelling

3.2. Computational Domain and Boundary Conditions

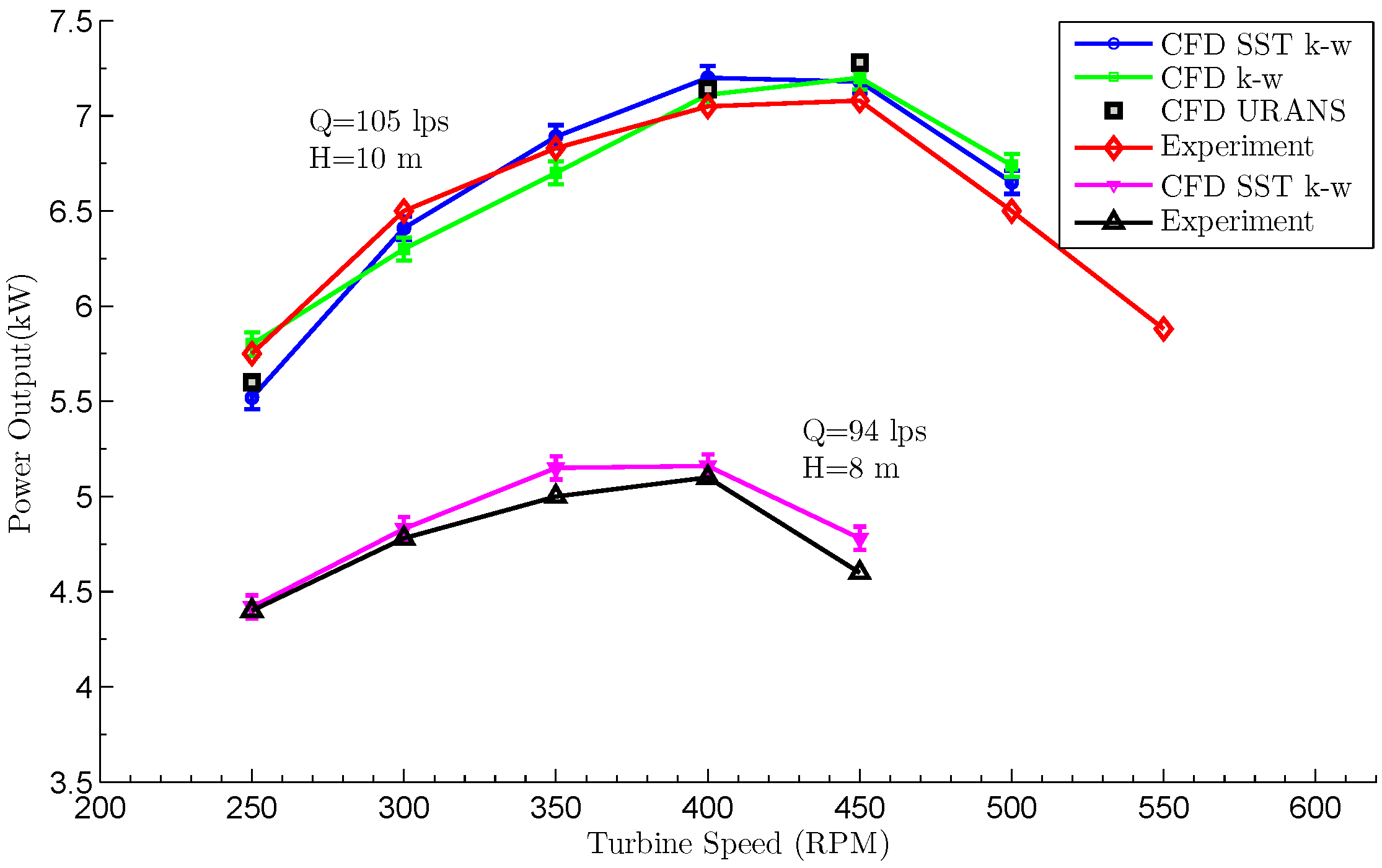

4. Results and Discussion

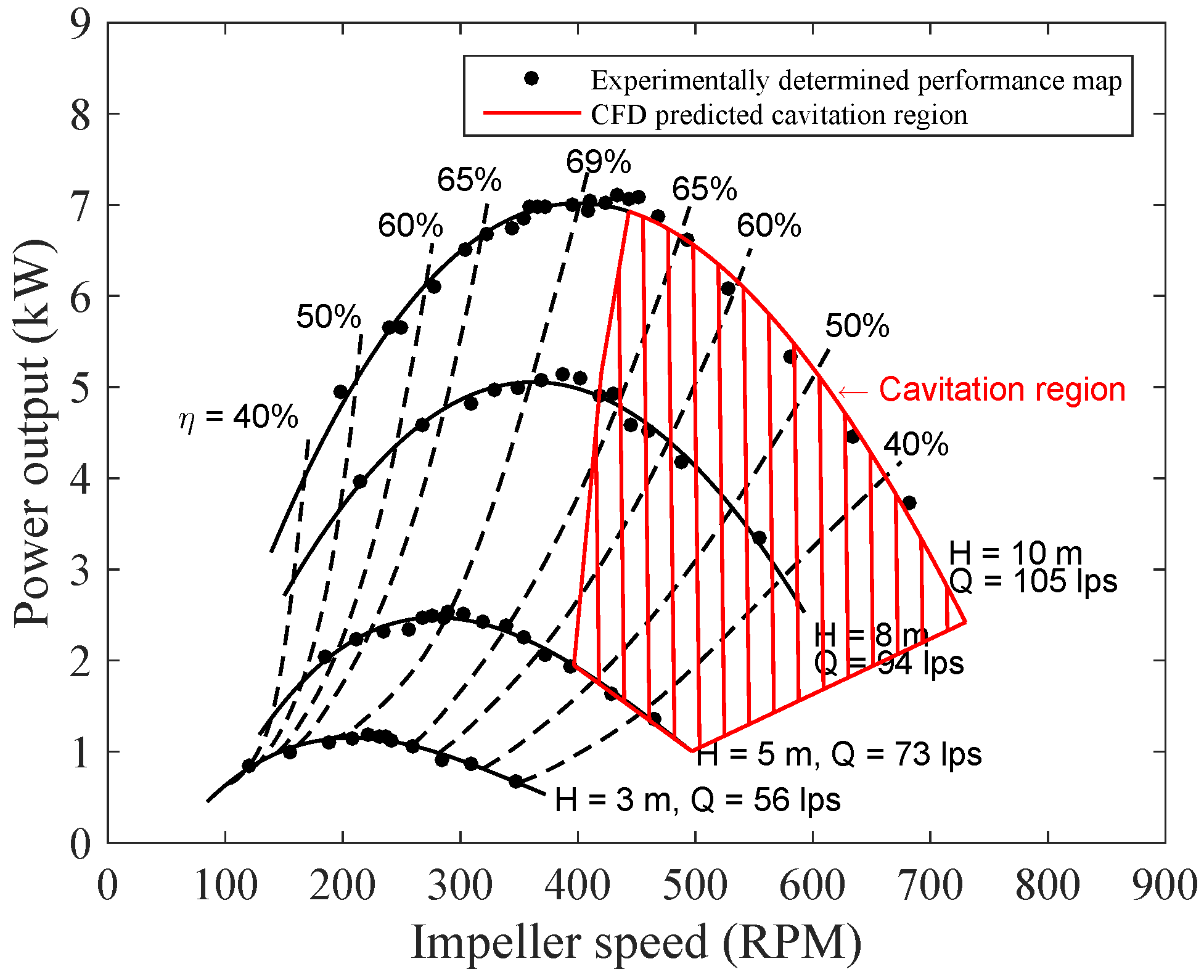

4.1. Numerical Validation

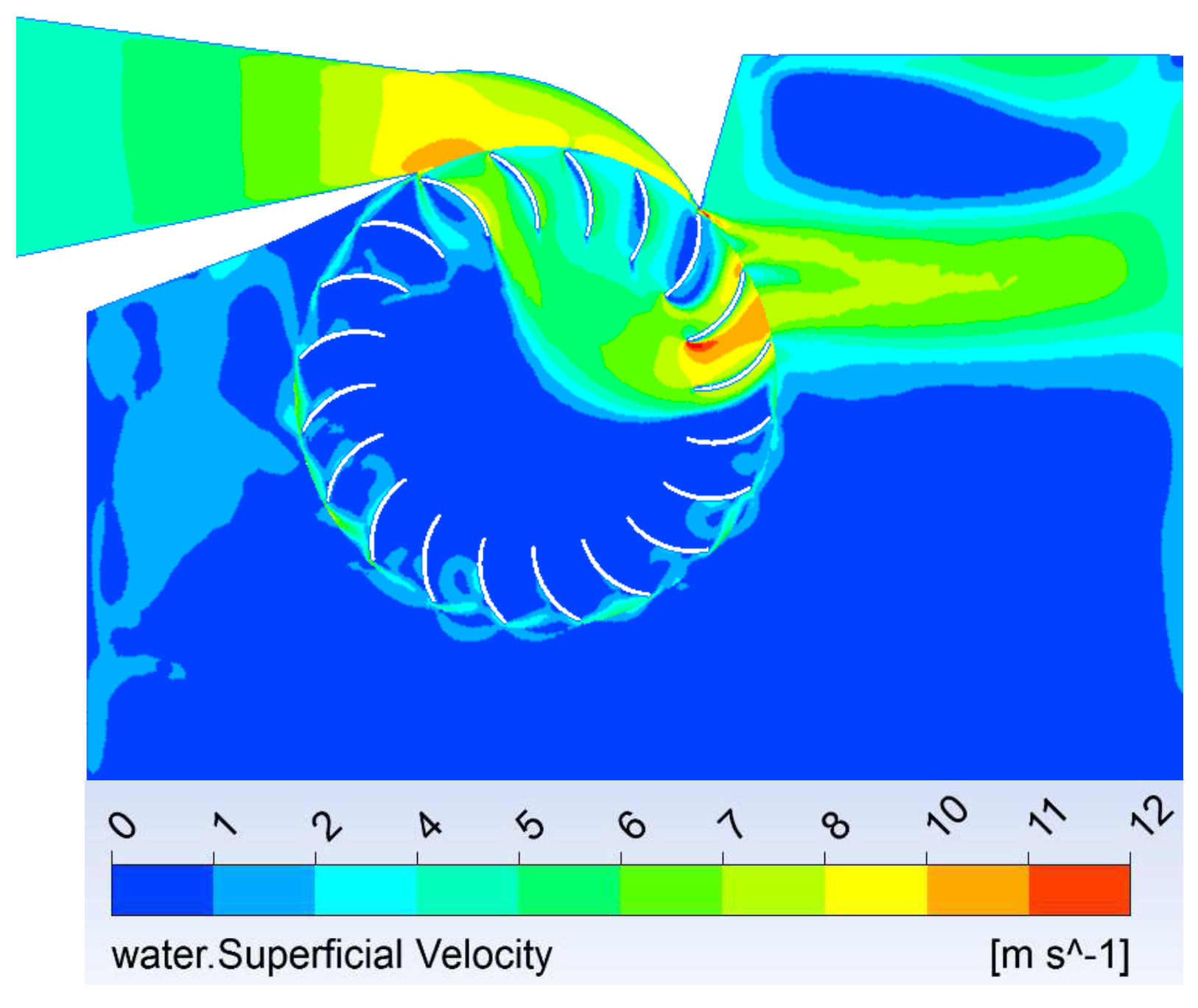

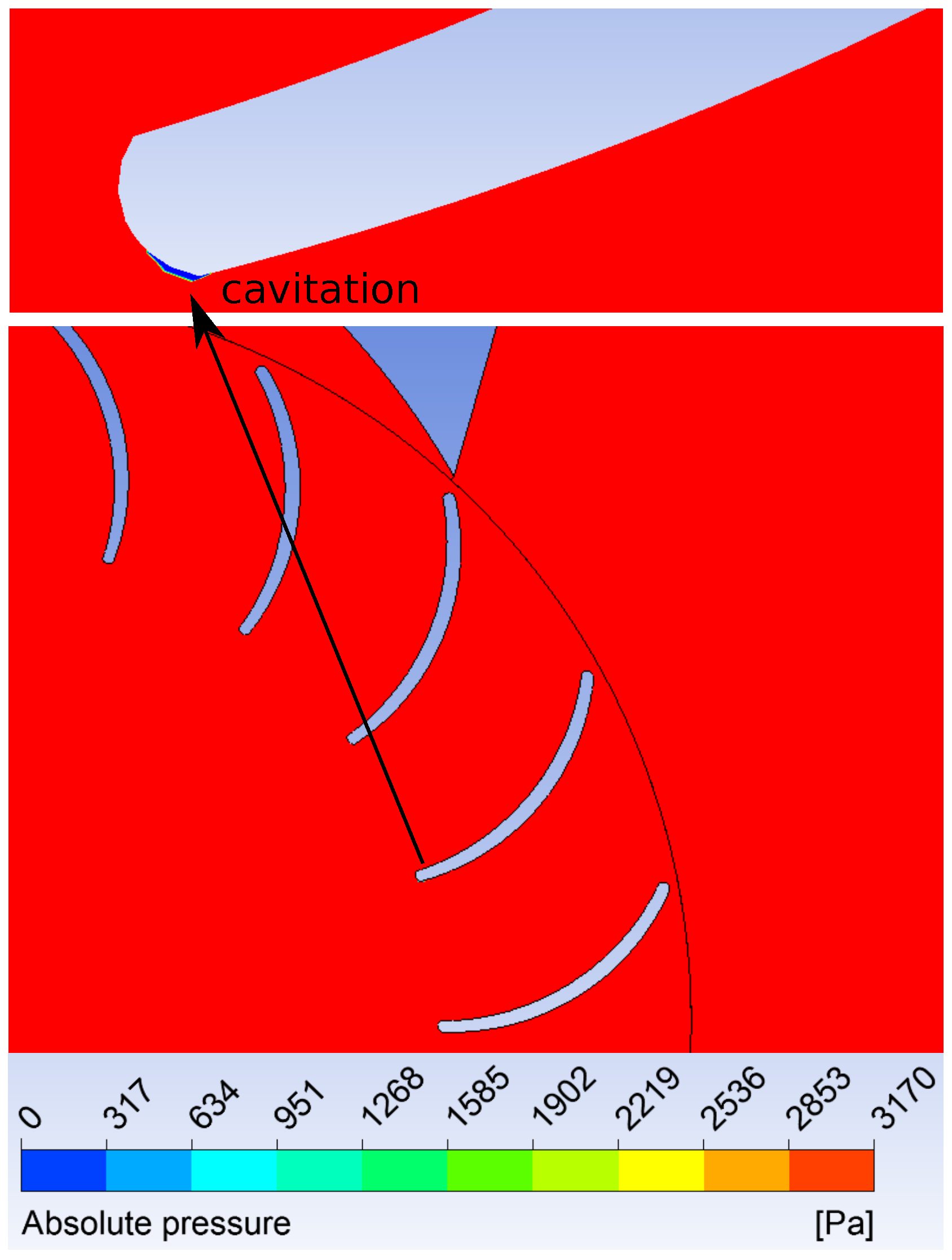

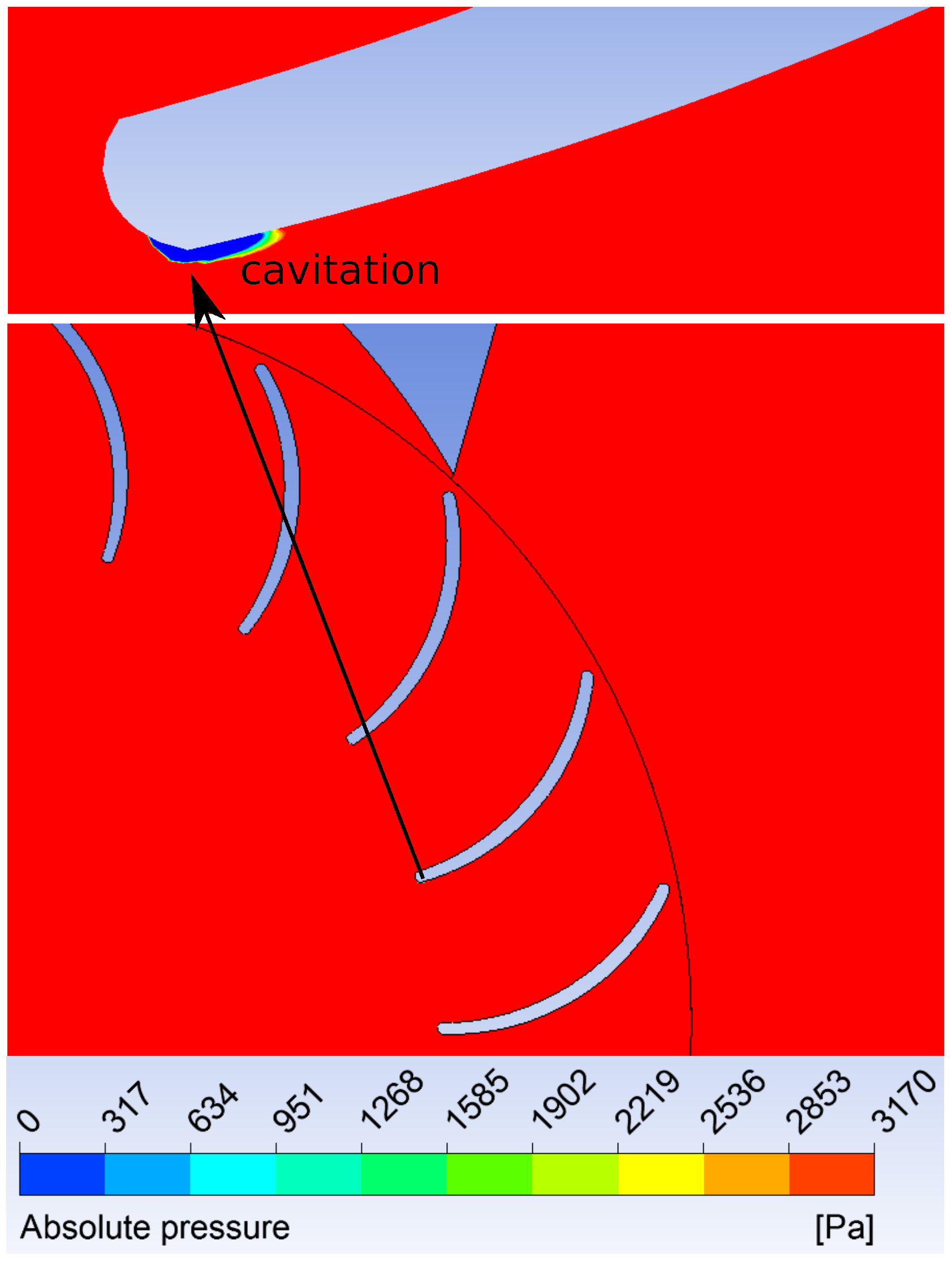

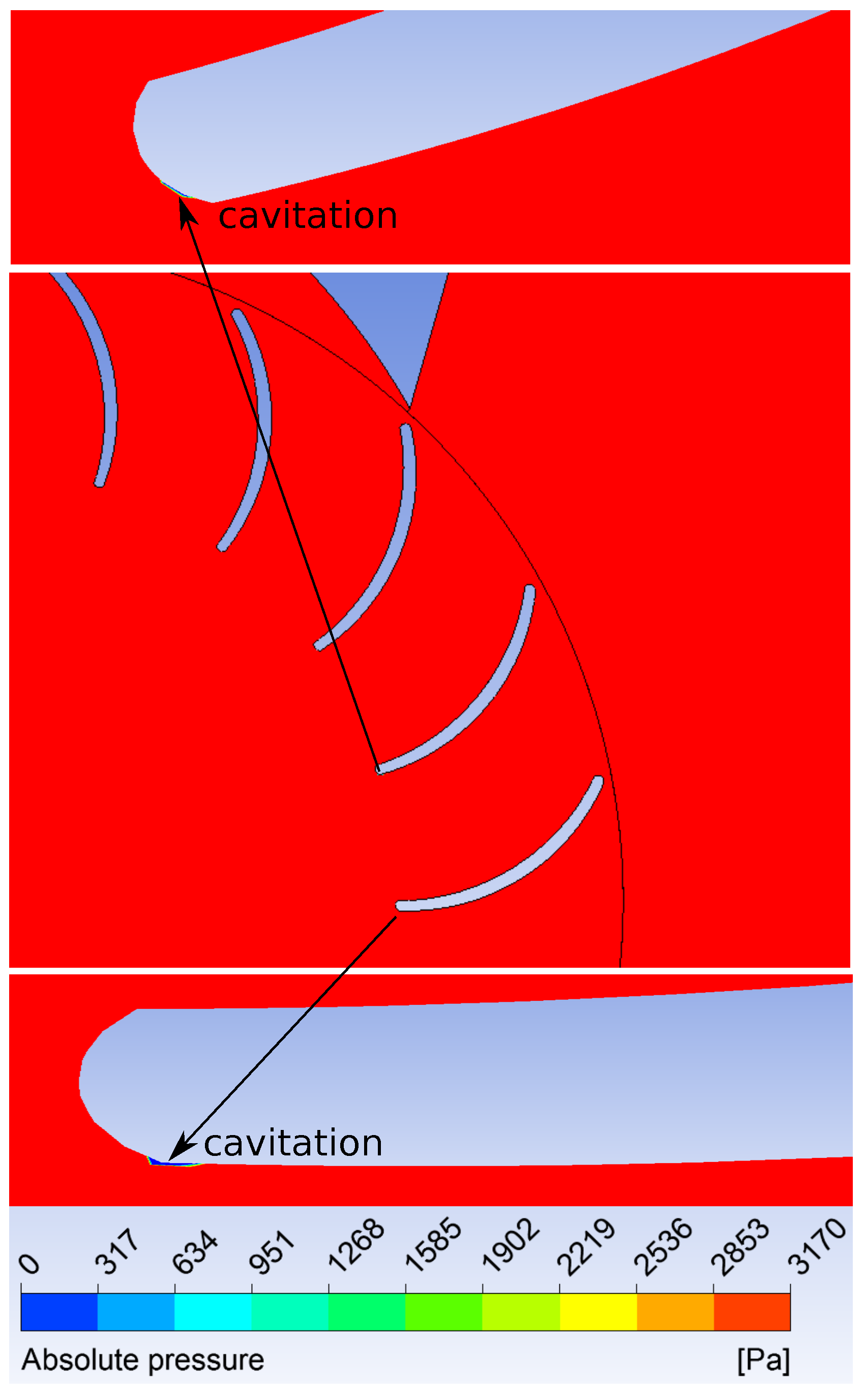

4.2. Analysis of the Pressure Field and Cavitation

5. Conclusions

Acknowledgments

Author Contributions

Conflict of Interest

References

- Michell, A.G.M. Impulse-Turbine, Assigne. U.S. Patent 760898, 24 May 1904. [Google Scholar]

- White, F.M. Viscous Fluid Flow; McGraw-Hill, Inc.: New York, NY, USA, 1991. [Google Scholar]

- Escaler, X.; Egusquiza, E.; Farhat, M.; Avellan, F.; Coussirat, M. Detection of cavitation in hydraulic turbines. Mech. Syst. Signal Process. 2006, 20, 983–1007. [Google Scholar] [CrossRef]

- Mockmore, C.A.; Merryfield, F. The Banki Water Turbine. In Bulletin Series, Engineering Experiment Station; Oregon State System of Higher Education, Oregon State College: Corvallis, OR, USA, 1949. [Google Scholar]

- Durali, M. Design of Small Water Turbine for Farms and Small Communities. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1976. [Google Scholar]

- Khosrowpanah, S. Experimental Study of the Crossflow Turbine. Ph.D. Thesis, Colorado State University, Fort Collins, CO, USA, 1984. [Google Scholar]

- Tongco, A.F. Field Testing of a Crossflow Turbine. Ph.D. Thesis, Oklahoma State University, Stillwater, OK, USA, 1988. [Google Scholar]

- Desai, V.R. A Parametric Study of the Cross-Flow Turbine Performance. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 1993. [Google Scholar]

- Aziz, N.M.; Totapally, H.G.S. Design Parameter Refinement for Improved Cross-Flow Turbine Performance; Engineering Report; Department of Civil Engineering, Clemson University: Clemson, SC, USA, 1994. [Google Scholar]

- Nakase, Y.; Fukatomi, J.; Watanaba, T.; Suetsugu, T.; Kubota, T.; Kushimoto, S.A. Study of Cross-Flow Turbine (Effects of Nozzle Shape on Its Performance). In Proceedings of the Winter Annual Meeting, Phoenix, AZ, USA, 14–19 November 1982.

- Choi, Y.; Lim, J.; Kim, Y.; Lee, Y. Performance and internal flow characteristics of a cross-flow hydro turbine by the shapes of nozzle and runner blade. J. Fluid Sci. Technol. 2008, 3, 398–409. [Google Scholar] [CrossRef]

- Andrade, J.; Curiel, C.; Kenyery, F.; AguillÃşn, O.; VÃąsquez, A.; Asuaje, M. Numerical investigation of the internal flow in a Banki turbine. Int. J. Rotating Mach. 2011, 2011. [Google Scholar] [CrossRef]

- Sammartano, V.; AricÚ, C.; Carravetta, A.; Fecarotta, O.; Tucciarelli, T. Banki-Michell Optimal Design by Computational Fluid Dynamics: Testing and Hydrodynamic Analysis. Energies 2013, 6, 2362–2385. [Google Scholar] [CrossRef] [Green Version]

- Brennen, C.E. Fundamentals of Multiphase Flow; Cambridge University Press: New York, NY, USA, 2005. [Google Scholar]

- Batchelor, G.K. An Introduction to Fluid Dynamics; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Silva, P.A.S.F.; Shinomiya, L.D.; de Olivera, T.F.; Vaz, J.R.P.; Mesquita, A.L.A.; Brasil, A.C.P., Jr. Analysis of cavitation for the optimized design of hydrokinetic turbines using BEM. Appl. Energy 2016, in press. [Google Scholar] [CrossRef]

- ANSYS Academic Research, CFX 15.0 Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2013.

- Dakers, A.J.; Martin, G. Development of a Simple Cross-Flow Water Turbine for Rural Use. In Proceedings of the Conference on Agricultural Engineering, Armidale, Australia, 22–24 August 1982.

- Menter, F.R. Two-Equation Eddy-Viscosity Turbulence Models for Engineering Applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Wilcox, D.C. Turbulence Modeling for CFD; DCW Industries: La Canada, CA, USA, 1998. [Google Scholar]

| Design Parameters | Units | Value |

|---|---|---|

| Outer radius () | mm | 158 |

| Inner radius () | mm | 107.4 |

| Angle of attack (α) | 16 | |

| Blade radius () | mm | 52.14 |

| Number of blades | - | 20 |

| Turbine and Nozzle width | mm | 150 |

| Nozzle thickness or throat () | mm | 65 |

| Nozzle outlet arc () | 69 |

| Mesh | No. of Elements | Power Output (kW) | Numerical Uncertainty (%) |

|---|---|---|---|

| Mesh 1 | 2.12 millions | 7.091 | - |

| Mesh 2 | 2.96 millions | 7.122 | 0.43 |

| Mesh 3 | 3.47 millions | 7.157 | 0.49 |

| Mesh 4 | 3.94 millions | 7.169 | 0.16 |

| Mesh 5 | 4.53 millions | 7.181 | 0.16 |

| Mesh 6 | 5.24 millions | 7.192 | 0.15 |

| Mesh 7 | 5.40 millions | 7.199 | 0.10 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adhikari, R.C.; Vaz, J.; Wood, D. Cavitation Inception in Crossflow Hydro Turbines. Energies 2016, 9, 237. https://doi.org/10.3390/en9040237

Adhikari RC, Vaz J, Wood D. Cavitation Inception in Crossflow Hydro Turbines. Energies. 2016; 9(4):237. https://doi.org/10.3390/en9040237

Chicago/Turabian StyleAdhikari, Ram Chandra, Jerson Vaz, and David Wood. 2016. "Cavitation Inception in Crossflow Hydro Turbines" Energies 9, no. 4: 237. https://doi.org/10.3390/en9040237