Synergistic Optimization of Thermoelectric Performance in P-Type Bi0.48Sb1.52Te3/Graphene Composite

Abstract

:1. Introduction

2. Experimental Section

2.1. Synthesis of BiSbTe/Graphene Powders and Bulk Materials

2.2. Materials Characterizations

2.3 Thermoelectric Properties Measurements

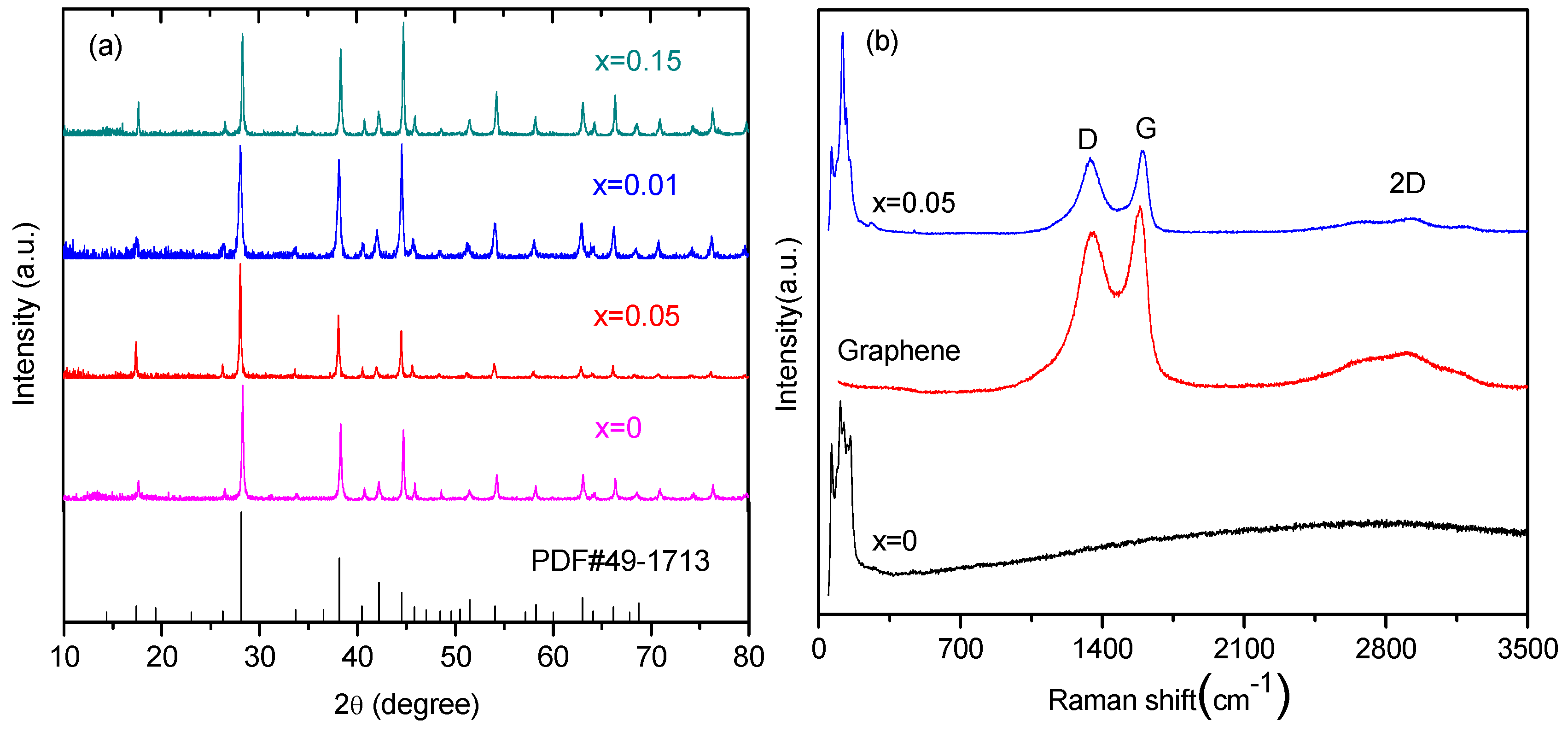

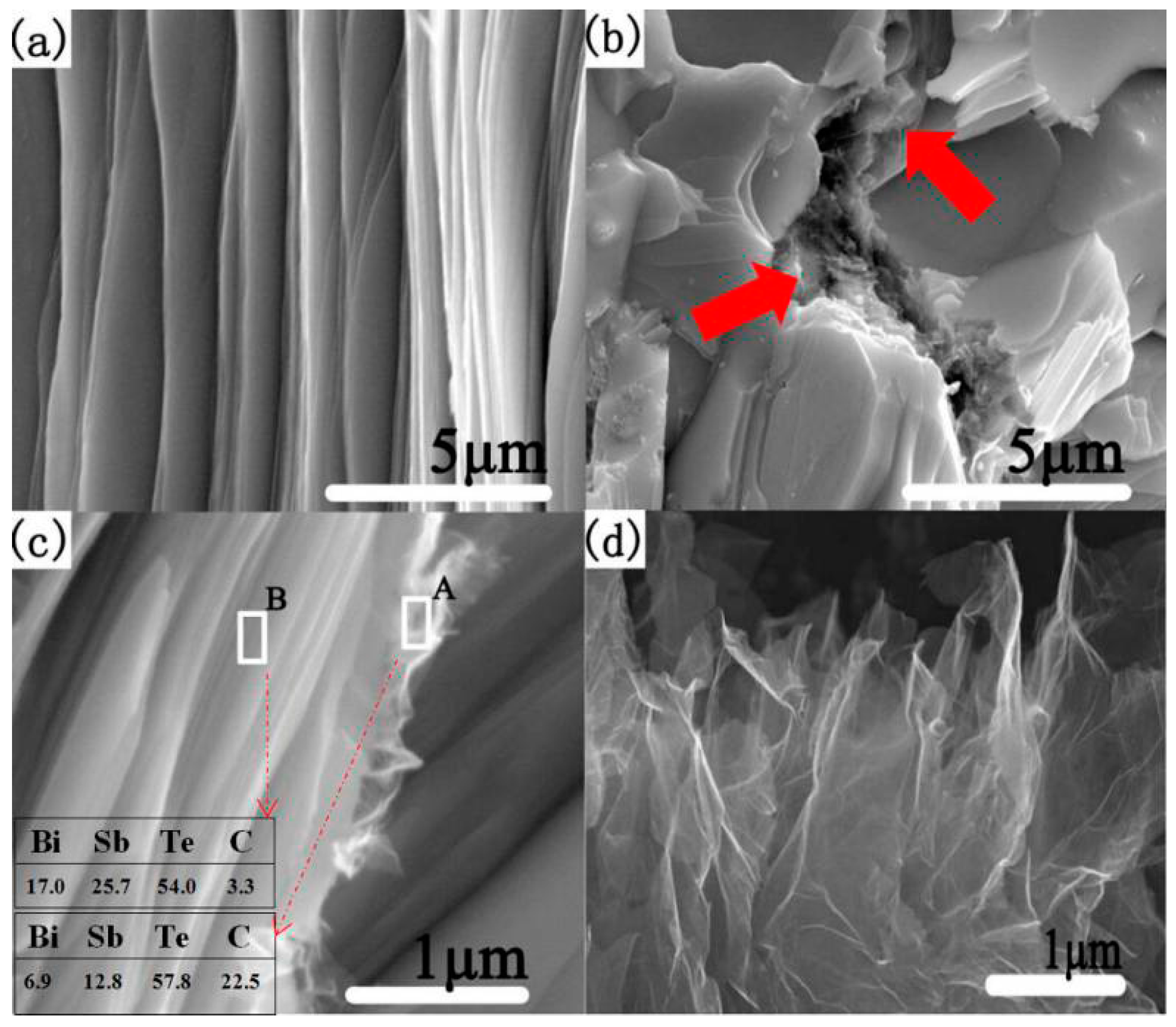

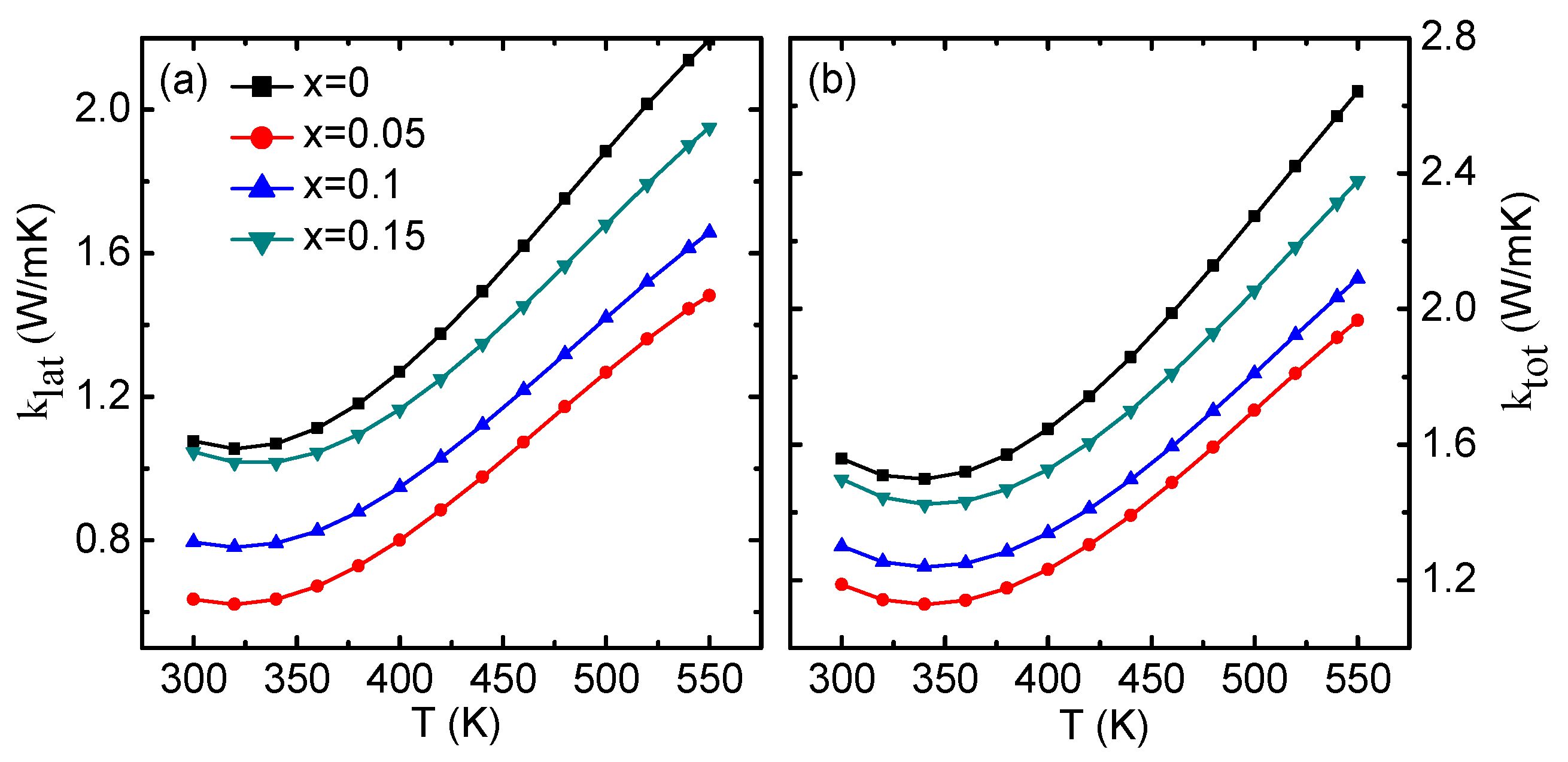

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Goldsmid, H.J. Bismuth telluride and its alloys as materials for thermoelectric generation. Materials 2014, 7, 2577–2592. [Google Scholar] [CrossRef]

- Bell, L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Dresselhaus, M.S.; Dresselhaus, G.; Fleurial, J.P.; Caillat, T. Recent developments in thermoelectric materials. Int. Mater. Rev. 2003, 48, 45–66. [Google Scholar] [CrossRef]

- Rowe, D.M. CRC Handbook of Thermoelectrics; CRC Taylor and Francis: Boca Raton, FL, USA, 2012; pp. 16.1–16.33. [Google Scholar]

- Zhang, T.; Jiang, J.; Xiao, Y.; Zhai, Y.; Yang, S.; Xu, G. Enhanced thermoelectric figure of merit in p-type BiSbTeSe alloy with ZnSb addition. J. Mater. Chem. A 2013, 1, 966–969. [Google Scholar] [CrossRef]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Hao, Q.; Poudel, B.; Lan, Y.; Yu, B.; Wang, D.; Chen, G.; Ren, Z. Enhanced thermoelectric figure-of-merit in p-type nanostructured bismuth antimony tellurium alloys made from elemental chunks. Nano Lett. 2008, 8, 2580–2584. [Google Scholar] [CrossRef] [PubMed]

- Medlin, D.L.; Ramasse, Q.M.; Spataru, C.D.; Yang, N.Y.C. Structure of the (0001) basal twin boundary in Bi2Te3. J. Appl. Phy. 2010, 108, 043517. [Google Scholar] [CrossRef]

- Heremans, J.P.; Jovovic, V.; Toberer, E.S.; Saramat, A.; Kurosaki, K.; Charoenphakdee, A.; Snyder, G.J. Enhancement of thermoelectric efficiency in PbTe by distortion of the electronic density of states. Science 2008, 321, 554–557. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Zhang, T.; Xiao, Y.; Jiang, J.; Yang, S.; Xu, G. Enhanced thermoelectric performance in n-type Bi2Te2.994Cl0.006/In2Te3 composite. J. Alloy. Compd. 2013, 563, 285–288. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O'quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; LaLonde, A.D.; Pei, Y.; Snyder, G.J. The criteria for beneficial disorder in thermoelectric solid solutions. Adv. Funct. Mater. 2013, 23, 1586–1596. [Google Scholar] [CrossRef]

- Zhao, L.D.; Zhang, B.P.; Liu, W.S.; Li, J.F. Effect of mixed grain sizes on thermoelectric performance of Bi2Te3 compound. J. Appl. Phy. 2009, 105, 023704. [Google Scholar] [CrossRef]

- Lan, Y.; Poudel, B.; Ma, Y.; Wang, D.; Dresselhaus, M.S.; Chen, G.; Ren, Z. Structure study of bulk nanograined thermoelectric bismuth antimony telluride. Nano Lett. 2009, 9, 1419–1422. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.D.; Zhang, B.P.; Li, J.F.; Zhou, M.; Liu, W.S.; Liu, J. Thermoelectric and mechanical properties of nano-SiC-dispersed Bi2Te3 fabricated by mechanical alloying and spark plasma sintering. J. Alloy. Compd. 2008, 455, 259–264. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, Q.; Jiang, J.; Xiong, Z.; Chen, J.; Zhang, Y.; Li, W.; Xu, G. Enhanced thermoelectric performance in p-type BiSbTe bulk alloy with nanoinclusion of ZnAlO. Appl. Phy. Lett. 2011, 98, 022104. [Google Scholar] [CrossRef]

- Xiao, Y.; Chen, G.; Qin, H.; Wu, M.; Xiao, Z.; Jiang, J.; Xu, G. Enhanced thermoelectric figure of merit in p-type Bi0.48Sb1.52Te3 alloy with WSe2 addition. J. Mater. Chem. A 2014, 2, 8512–8516. [Google Scholar]

- Zhang, Q.; Ai, X.; Wang, L.; Chang, Y.; Luo, W.; Jiang, W.; Chen, L. Improved Thermoelectric Performance of Silver Nanoparticles-Dispersed Bi2Te3 Composites Deriving from Hierarchical Two-Phased Heterostructure. Adv. Funct. Mater. 2015, 25, 966–976. [Google Scholar] [CrossRef]

- Zhang, Q.; Ai, X.; Wang, W.; Wang, L.; Jiang, W. Preparation of 1-D/3-D structured AgNWs/Bi2Te3 nanocomposites with enhanced thermoelectric properties. Acta Mater. 2014, 73, 37–47. [Google Scholar] [CrossRef]

- Pasricha, R.; Gupta, S.; Srivastava, A.K. A Facile and Novel Synthesis of Ag–Graphene-Based Nanocomposites. Small 2009, 5, 2253–2259. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Liu, W.; Li, H.; Su, X.; Tang, X.; Uher, C. In situ synthesis and thermoelectric properties of PbTe–graphene nanocomposites by utilizing a facile and novel wet chemical method. J. Mater. Chem. A 2013, 1, 12503–12511. [Google Scholar] [CrossRef]

- Feng, B.; Xie, J.; Cao, G.; Zhu, T.; Zhao, X. Enhanced thermoelectric properties of p-type CoSb3/graphene nanocomposite. J. Mater. Chem. A 2013, 1, 13111–13119. [Google Scholar] [CrossRef]

- Chen, H.; Yang, C.; Liu, H.; Zhang, G.; Wan, D.; Huang, F. Thermoelectric properties of CuInTe2/graphene composites. Cryst. Eng. Comm. 2013, 15, 6648–6651. [Google Scholar] [CrossRef]

- Li, A.H.; Shahbazi, M.; Zhou, S.H.; Wang, G.X.; Zhang, C.; Jood, P.; Peleckis, G.; Du, Y.; Cheng, Z.X.; Wang, X.L.; Kuo, Y.K. Electronic structure and thermoelectric properties of Bi2Te3 crystals and graphene-doped Bi2Te3. Thin Solid Films 2010, 518, e57–e60. [Google Scholar] [CrossRef]

- Liang, B.; Song, Z.; Wang, M.; Wang, L.; Jiang, W. Fabrication and Thermoelectric Properties of Graphene/Bi2Te3 Composite Materials. J. Nanomater. 2013, 6, 210767:1–210767:5. [Google Scholar]

- Kim, J.I.; Lee, E.S.; Kim, J.Y.; Choi, S.M.; Lee, K.H.; Seo, W.S. Thermoelectric properties of unoxidized graphene/Bi2Te2.7Se0.3 composites synthesized by exfoliation/re-assembly method. Phy. Status Solidi RRL 2014, 8, 357–361. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, J.; Xiao, Y.; Zhai, Y.; Yang, S.; Xu, G. In Situ Precipitation of Te Nanoparticles in p-Type BiSbTe and the Effect on Thermoelectric Performance. ACS Appl. Mater. Interfaces 2013, 5, 3071–3074. [Google Scholar] [CrossRef] [PubMed]

- Suh, D.; Lee, S.; Mun, H.; Park, S.H.; Lee, K. H.; Kim, S.W.; Choi, J.Y.; Baik, S. Enhanced thermoelectric performance of Bi0.5Sb1.5Te3-expanded graphene composites by simultaneous modulation of electronic and thermal carrier transport. Nano Energy 2015, 13, 67–76. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, L.; Bai, S.; Yao, Q.; Wang, Q. Thermoelectric properties of p-type (Bi2Te3)x(Sb2Te3)1−x crystals prepared via zone melting. J. Cryst. Growth 2005, 277, 258–263. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, L.; Yao, Q.; Wang, Q. Preparation and properties of p-type (Bi2Te3)x(Sb2Te3)1-x thermoelectric materials. Mater. Trans. 2005, 46, 959–962. [Google Scholar] [CrossRef]

- Kim, S.I.; Lee, K.H.; Mun, H.A.; Kim, H.S.; Hwang, S.W.; Roh, J.W.; Yang, D.J.; Shin, W.H.; Li, S.H.; Lee, Y.H.; et al. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 2015, 348, 109–114. [Google Scholar] [CrossRef] [PubMed]

- Tuinstra, F.; Koenig, J.L. Raman spectrum of graphite. The Journal of Chemical Physics. 1970, 53, 1126–1130. [Google Scholar] [CrossRef]

- Zhang, T.; Jiang, J.; Xiao, Y.; Zhai, Y.; Yang, S.; Xu, G.; Ren, Z. Effect of dehydrated-attapulgite nanoinclusions on the thermoelectric properties of BiSbTe alloys. RSC Adv. 2013, 3, 4951–4953. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Suh, D.; Lee, D.; Kang, C.; Shon, I.J.; Kim, W.; Baik, S. Enhanced thermoelectric properties of tungsten disulfide-multiwalled carbon nanotube composites. J. Mater. Chem. 2012, 22, 21376–21381. [Google Scholar] [CrossRef]

- Zhao, L.D.; He, J.; Hao, S.; Wu, C.I.; Hogan, T.P.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Raising the thermoelectric performance of p-type PbS with endotaxial nanostructuring and valence-band offset engineering using CdS and ZnS. J. Am. Chem. Soc. 2012, 134, 16327–16336. [Google Scholar] [CrossRef] [PubMed]

- May, A.F.; Fleurial, J.P.; Snyder, G.J. Thermoelectric performance of lanthanum telluride produced via mechanical alloying. Phy. Rev. B 2008, 78, 125205. [Google Scholar] [CrossRef]

- Johnsen, S.; He, J.; Androulakis, J.; Dravid, V.P.; Todorov, I.; Chung, D.Y.; Kanatzidis, M.G. Nanostructures boost the thermoelectric performance of PbS. J. Am. Chem. Soc. 2011, 133, 3460–3470. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.H.; Huang, X.Y.; Bai, S.Q.; Shi, X.; Uher, C.; Chen, L.D. Thermoelectric Devices for Power Generation: Recent Progress and Future Challenges. Adv. Eng. Mater. 2016, 18, 194–213. [Google Scholar] [CrossRef]

| x | S | RH | σ | n | μ | m* |

|---|---|---|---|---|---|---|

| 0 | 211 | 0.235 | 1.0 | 2.66 | 235 | 0.85 |

| 0.05 | 204 | 0.202 | 1.15 | 3.09 | 231 | 0.92 |

| 0.1 | 206 | 0.192 | 1.04 | 3.25 | 203 | 0.96 |

| 0.15 | 215 | 0.215 | 0.95 | 2.91 | 201 | 0.92 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, D.; Xu, J.; Liu, G.; Liu, Z.; Shao, H.; Tan, X.; Jiang, J.; Jiang, H. Synergistic Optimization of Thermoelectric Performance in P-Type Bi0.48Sb1.52Te3/Graphene Composite. Energies 2016, 9, 236. https://doi.org/10.3390/en9040236

Xie D, Xu J, Liu G, Liu Z, Shao H, Tan X, Jiang J, Jiang H. Synergistic Optimization of Thermoelectric Performance in P-Type Bi0.48Sb1.52Te3/Graphene Composite. Energies. 2016; 9(4):236. https://doi.org/10.3390/en9040236

Chicago/Turabian StyleXie, Dewen, Jingtao Xu, Guoqiang Liu, Zhu Liu, Hezhu Shao, Xiaojian Tan, Jun Jiang, and Haochuan Jiang. 2016. "Synergistic Optimization of Thermoelectric Performance in P-Type Bi0.48Sb1.52Te3/Graphene Composite" Energies 9, no. 4: 236. https://doi.org/10.3390/en9040236