Mechanical Properties of Longmaxi Black Organic-Rich Shale Samples from South China under Uniaxial and Triaxial Compression States

Abstract

:1. Introduction

2. Materials and Methods

2.1. Studying Idea

2.2. Sample Preparation

2.2.1. Description of the Studied Shale

2.2.2. Shale Sample Preparation

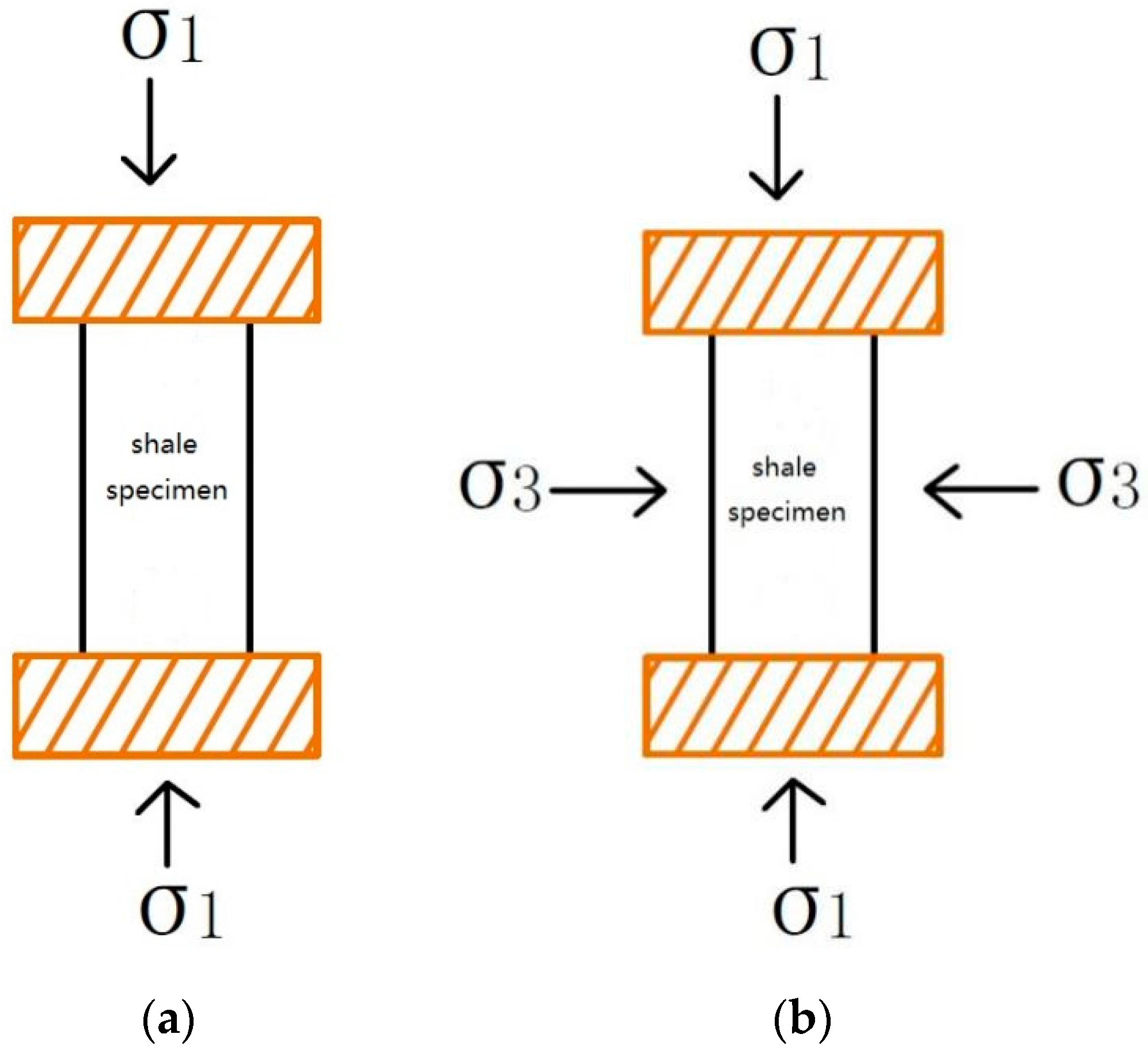

2.3. Experimental Process

3. Experimental Results and Analysis

3.1. Analysis of Shale Stress-Strain Curves

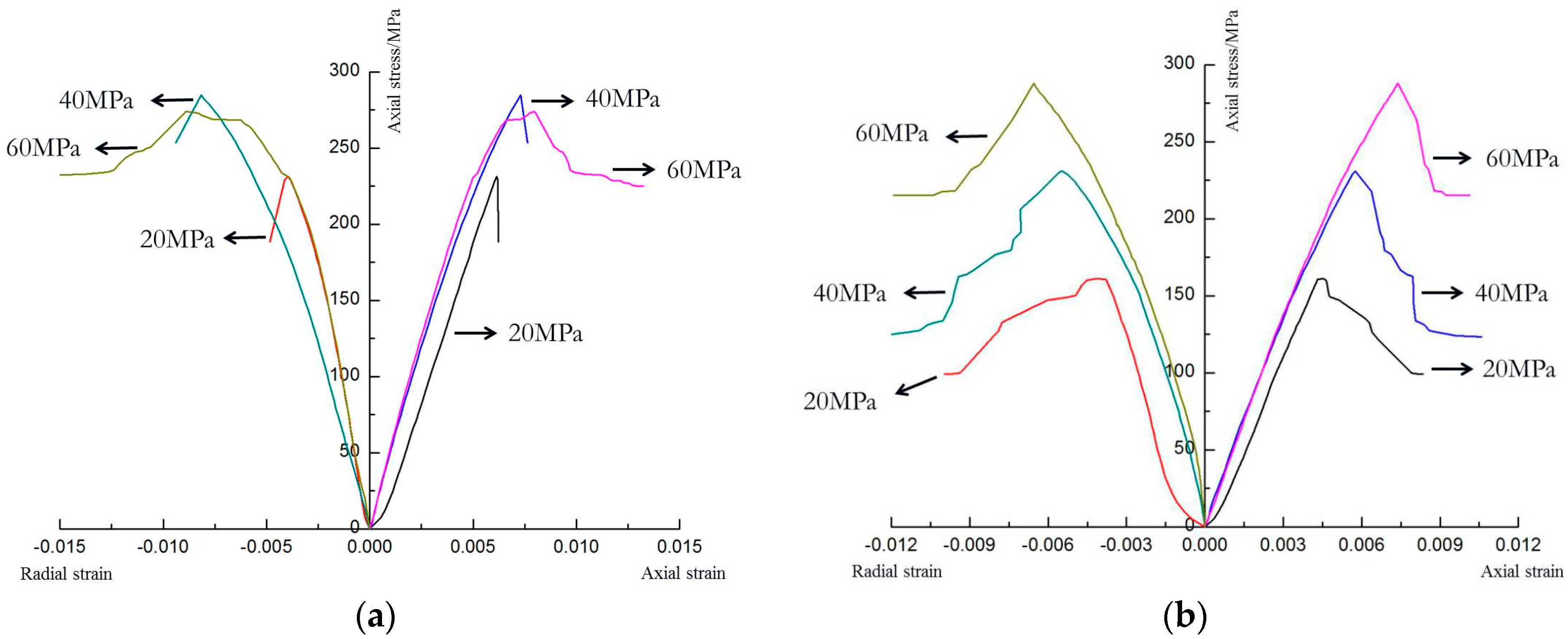

3.1.1. Uniaxial Compression Tests

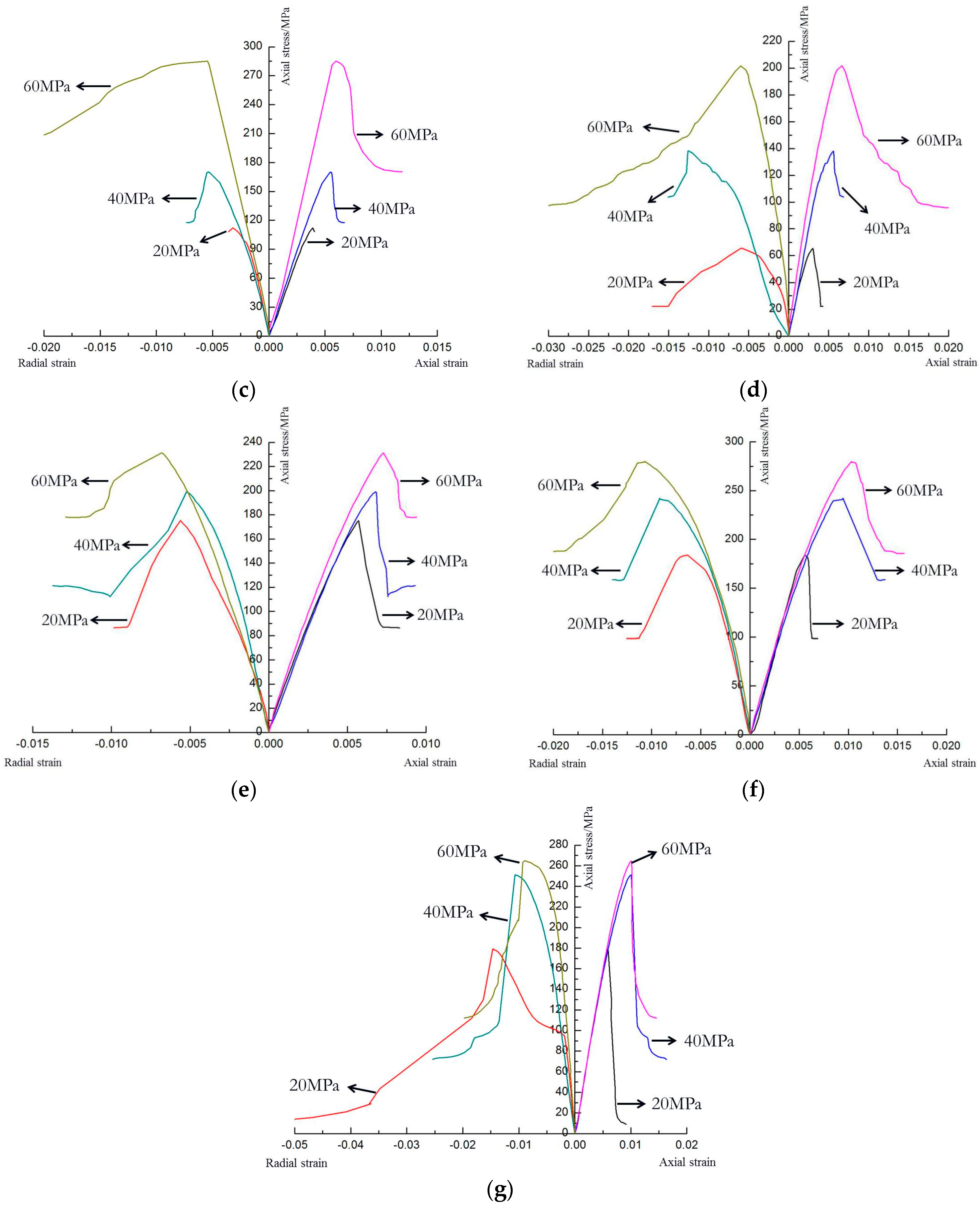

3.1.2. Triaxial Compression Tests

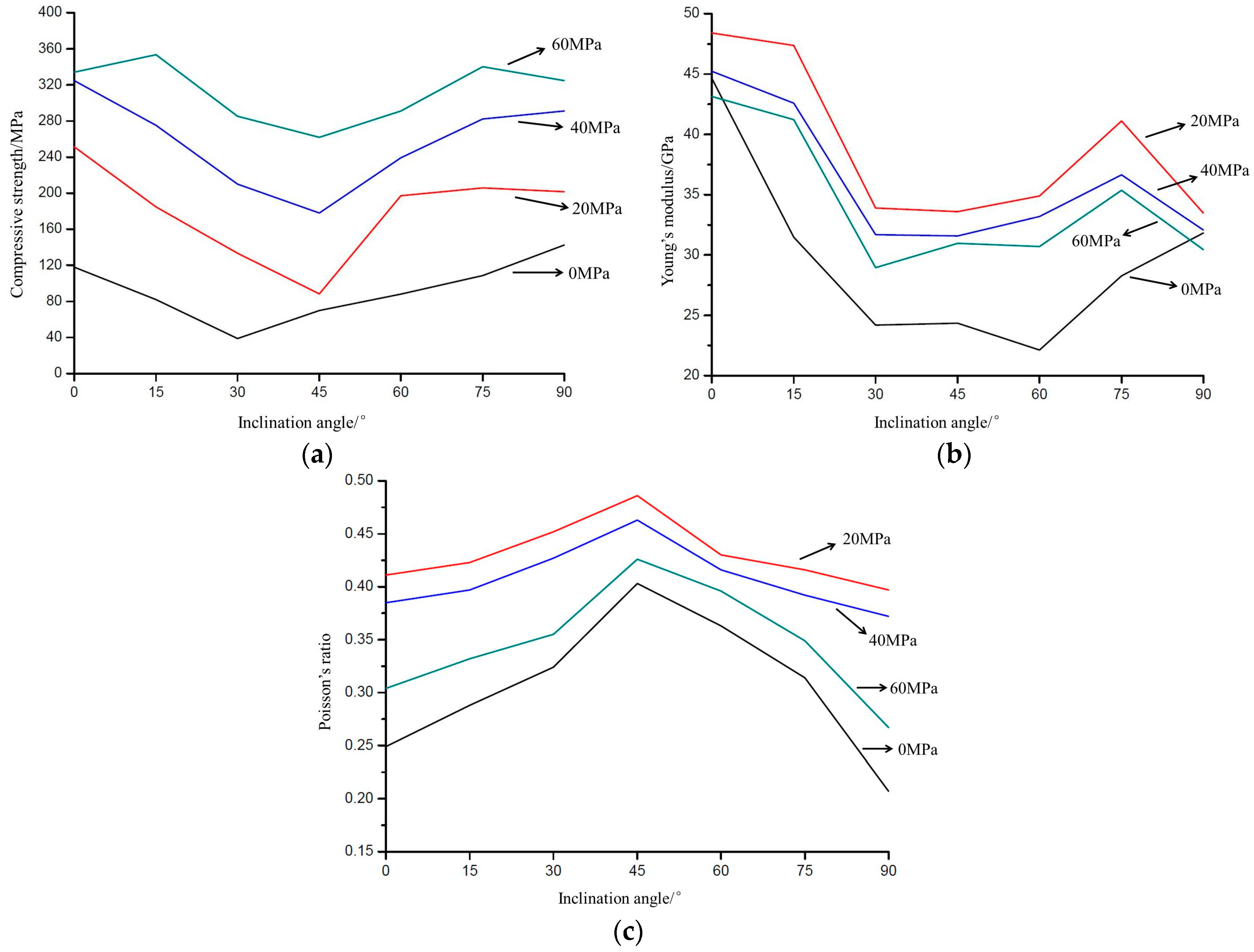

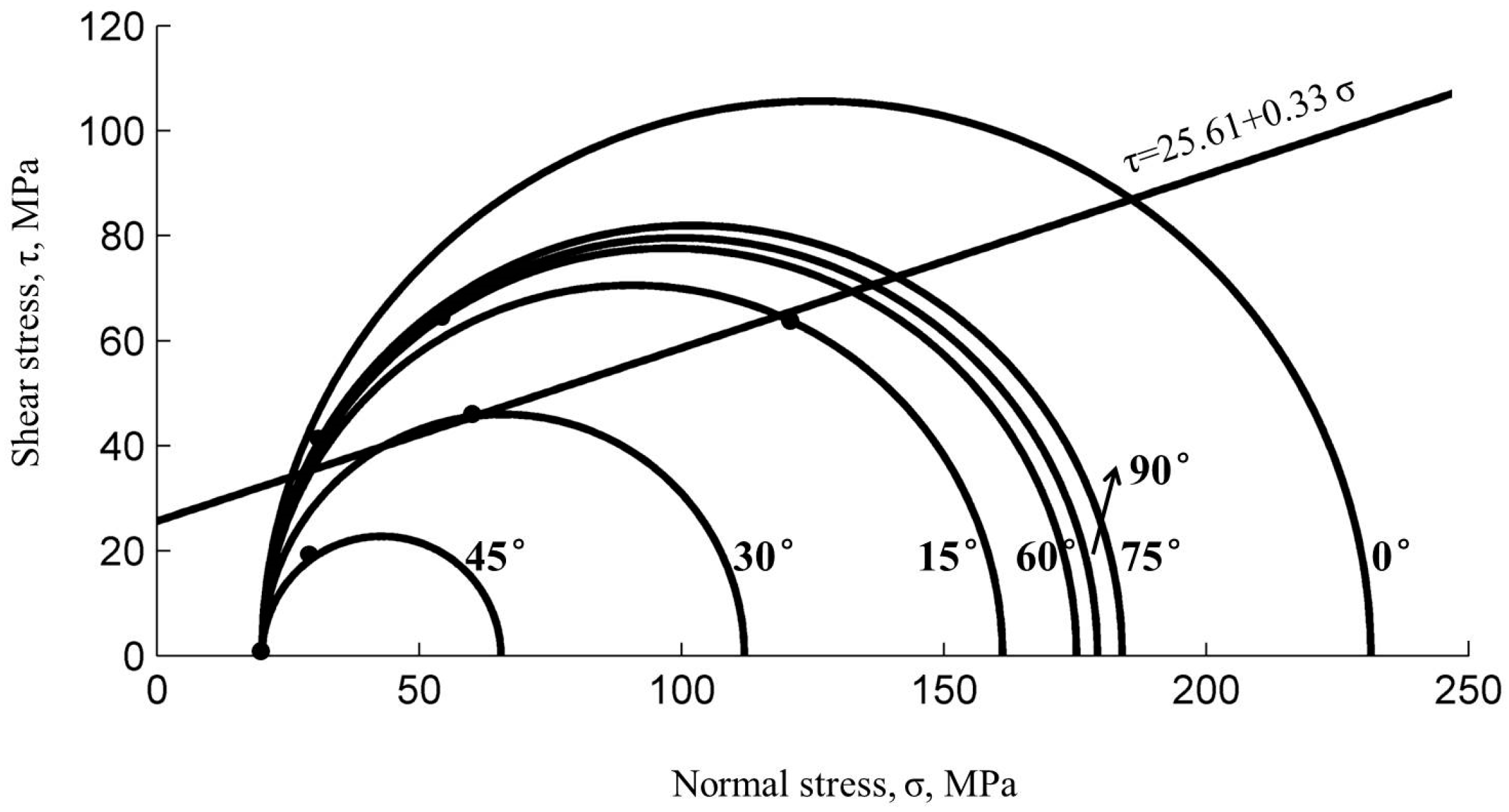

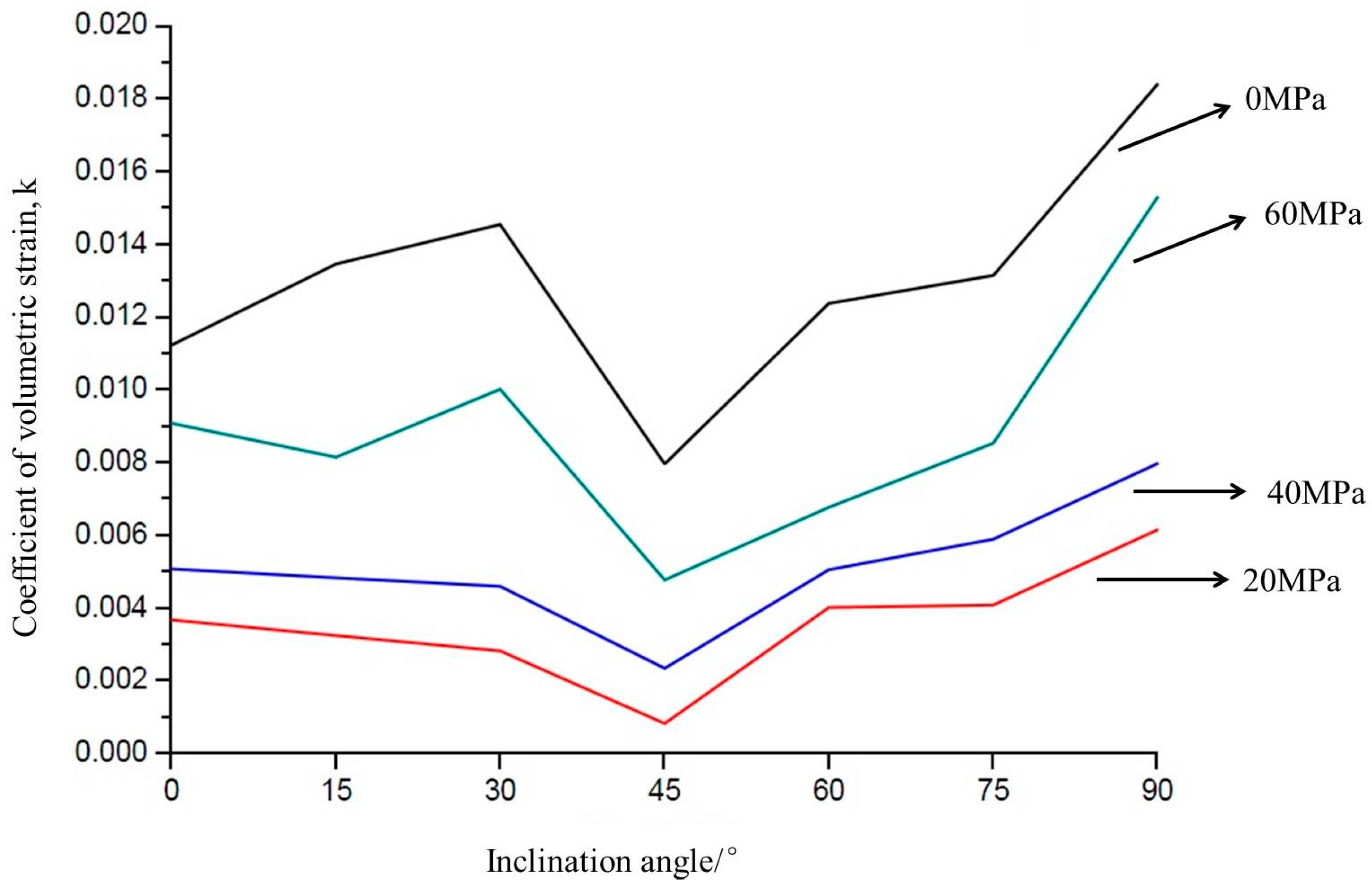

3.2. Varying Characteristics of Shale Strength and Mechanical Parameters

3.3. Deformation and Failure Characteristics of Shale Subjected to Uniaxial and Triaxial Compression

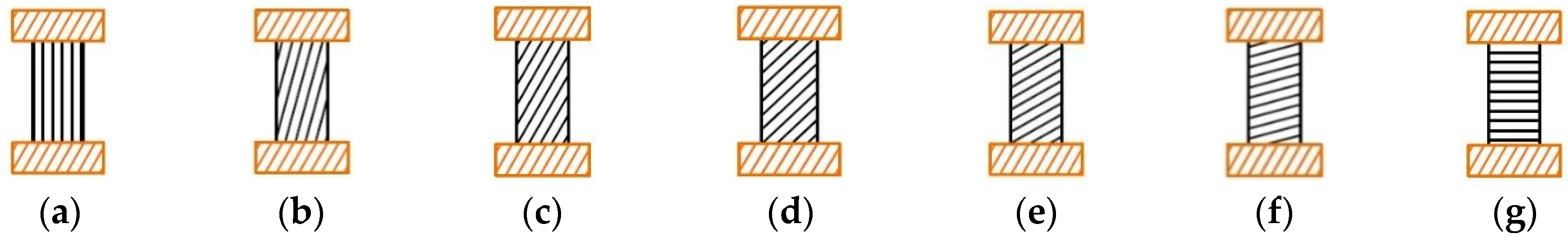

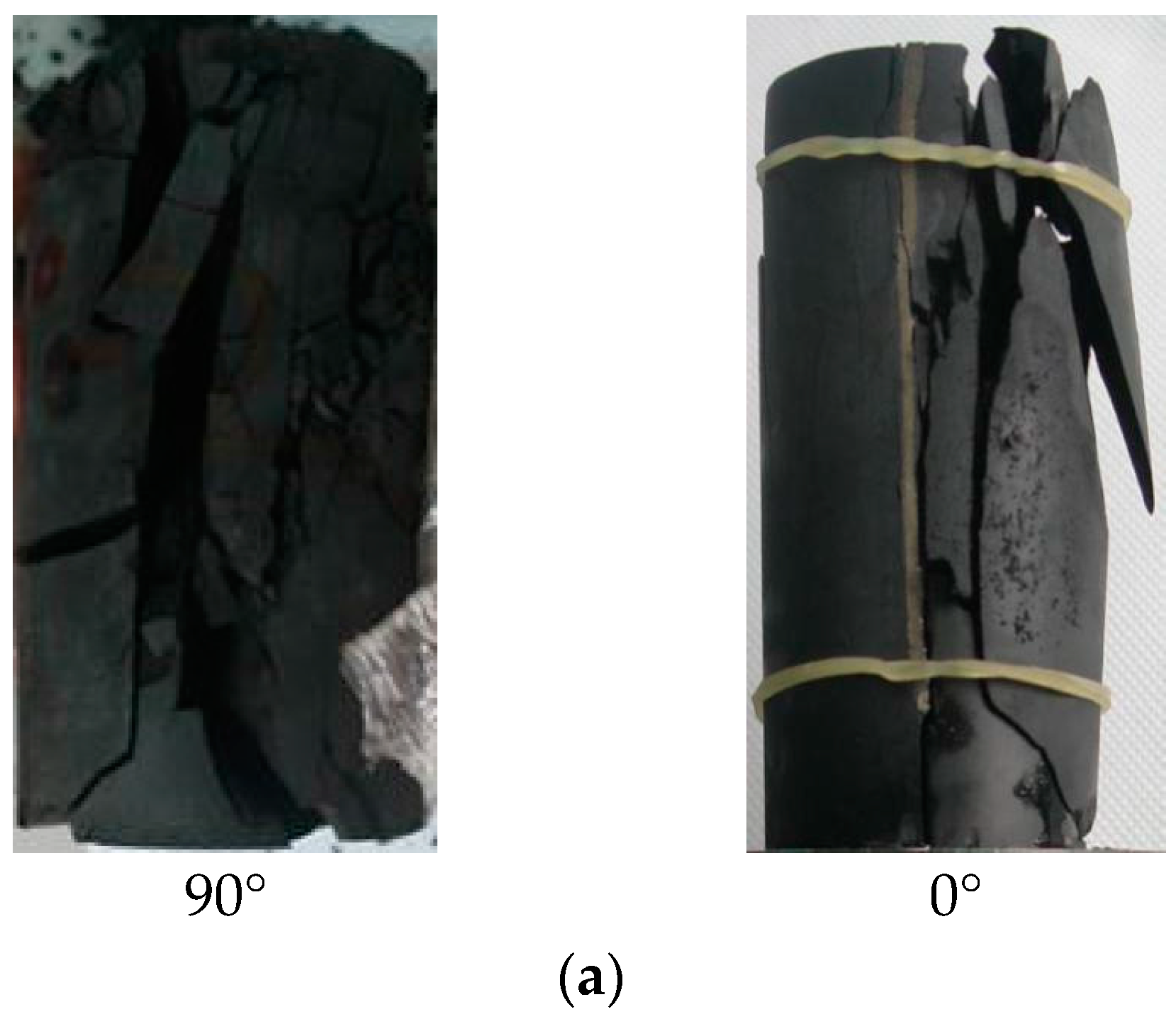

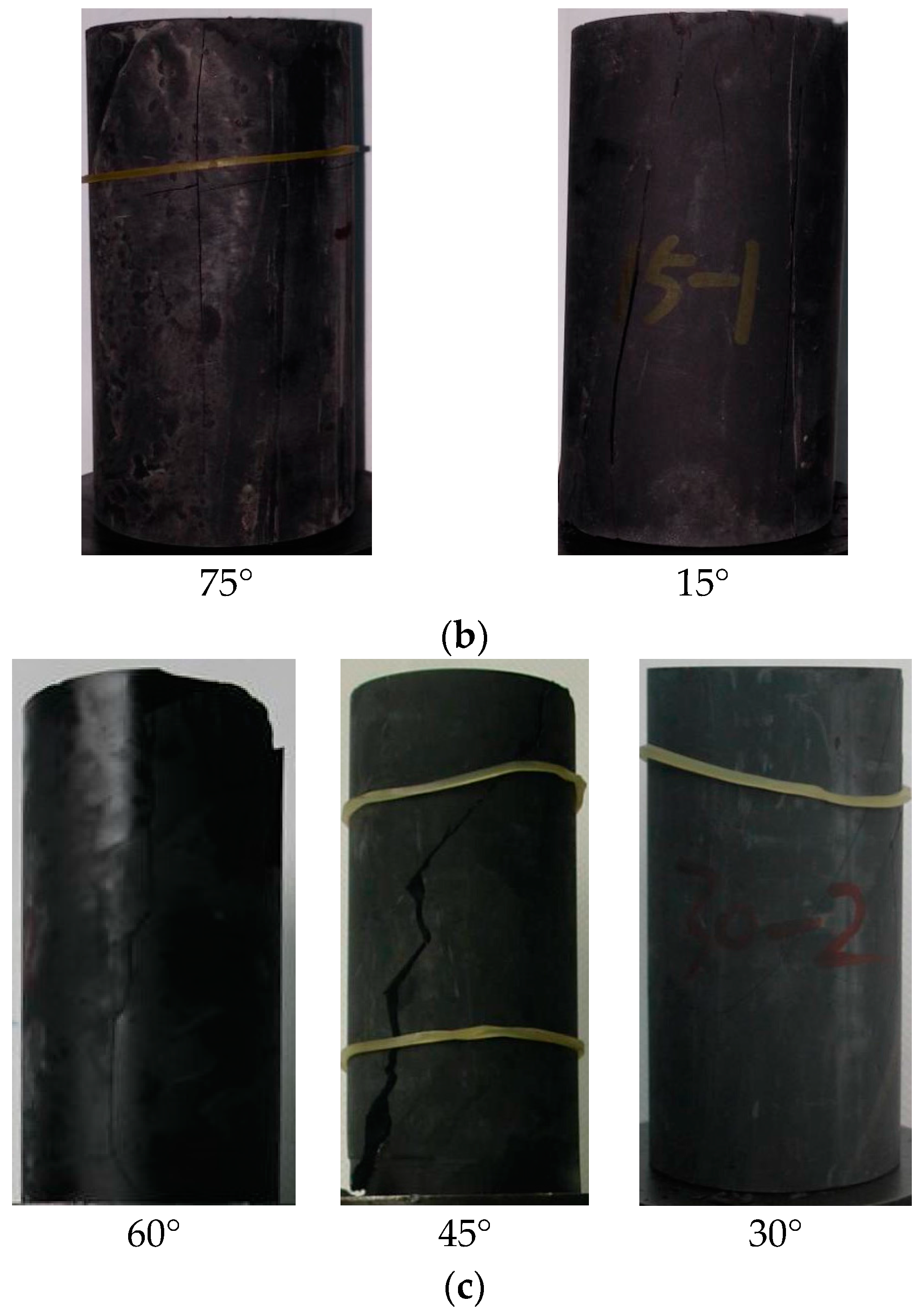

3.3.1. Failure Characteristics of Samples Subjected to Uniaxial Compression

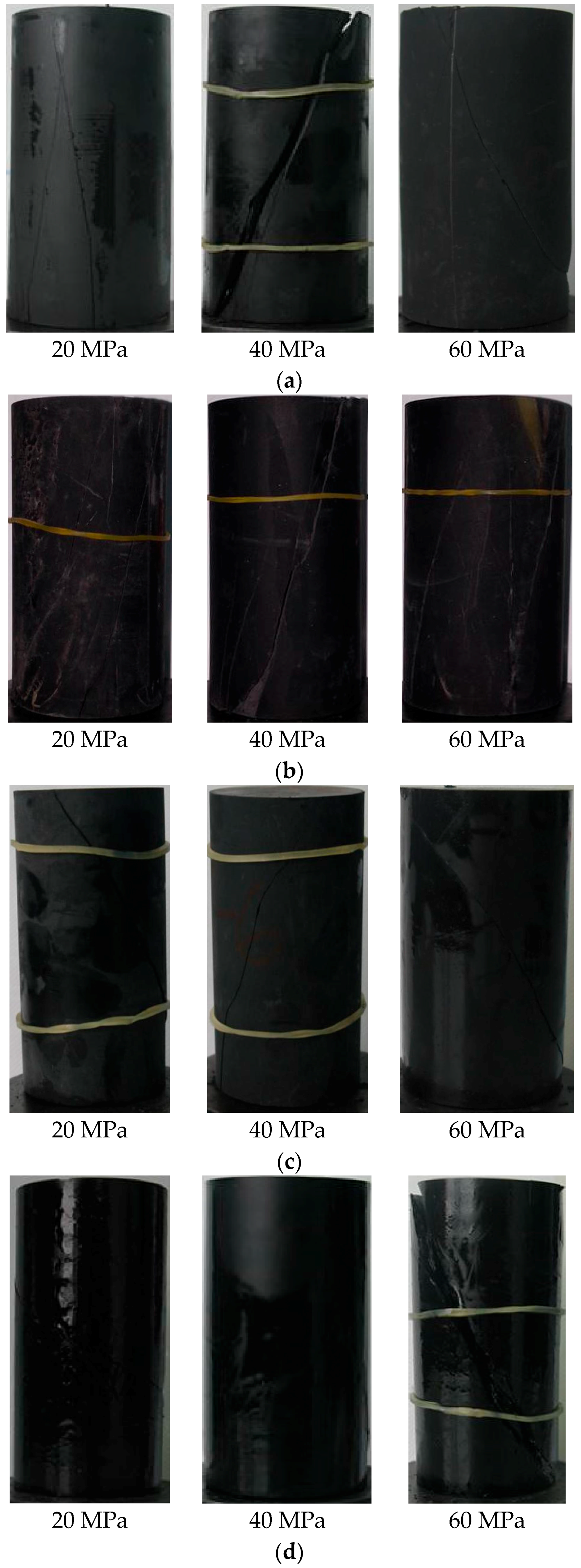

3.3.2. Failure Characteristics of Samples Subjected to Triaxial Compression

4. Discussion

5. Conclusions

- The development and distribution of shale’s bedding planes significantly impact its mechanical properties. Shale samples with different inclinations (β) show greater differences in uniaxial compressive strength, triaxial compressive strength, as well as deformation and failure characteristics.

- Under low confining pressure, shale samples show obvious brittle characteristics. With the confining pressure increasing, its mechanical behavior begins to transform from brittle to plastic characteristics. When the confining pressure reaches a certain value, shale samples show obvious plastic characteristics.

- Shale samples with different inclinations (β) have different sensitivities to the confining pressure, i.e., the critical confining pressures transforming from brittle to plastic under each inclination (β) are different. The samples with 45° inclinations (β) are least sensitive that is, the highest confining pressure is required for transformation from brittle to plastic characteristics; the sample with 60° inclination (β) are most sensitive to the confining pressure, that is, the lowest confining pressure is required for the sample to transform from brittle to plastic characteristics.

- Shale samples with different inclinations (β) have different compressive strengths, indicating that the strength of bedding planes is significantly lower than that of shale matrix, or the bedding planes are weakly cemented ones; splitting and shear planes fracture mostly along the bedding plane, revealing that tensile failure and shear failure generally tend to occur along the bedding planes.

- When hydraulic fracturing was conducted in shale formation with depth less than 2.25 km, different modes of failure will occur at different locations in the reservoir, depending on the orientation of bedding inclined from the principle stress, which can probably explain the phenomenon why there are fractures along and cross the bedding planes during hydraulic fracturing treatment.

- When hydraulic fracturing was conducted in shale formation with depth greater than 2.25 km, however, hydraulic fractures may not crack along the bedding surfaces to some extent.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Geng, J.B.; Ji, Q.; Fan, Y. The impact of the North American shale gas revolution on regional natural gas markets: Evidence from the regime-switching model. Energy Policy 2016, 96, 167–178. [Google Scholar] [CrossRef]

- Aruga, K. The U.S. shale gas revolution and its effect on international gas markets. J. Unconv. Oil Gas Resour. 2016, 14, 1–5. [Google Scholar] [CrossRef]

- Hu, D.S.; Xu, S.Q. Opportunity, challenges and policy choices for China on the development of shale gas. Energy Policy 2013, 60, 21–26. [Google Scholar] [CrossRef]

- Guo, T.K.; Zhang, S.C.; Qu, Z.Q.; Zhou, T.; Xiao, Y.S.; Gao, J. Experimental study of hydraulic fracturing for shale by stimulated reservoir volume. Fuel 2014, 128, 373–380. [Google Scholar] [CrossRef]

- Hou, P.; Gao, F.; Yang, Y.G.; Zhang, X.X.; Zhang, Z.Z. Effect of the layer orientation on mechanics and energy evolution characteristics of shales under uniaxial loading. Int. J. Min. Sci. Technol. 2016, 26, 857–862. [Google Scholar] [CrossRef]

- Chen, P.; Han, Q.; Ma, T.S.; Lin, D. The mechanical properties of shale based on micro-indentation test. Petrol. Explor. Dev. 2015, 42, 723–732. [Google Scholar] [CrossRef]

- Ma, Y.; Pan, Z.J.; Zhong, N.N.; Connell, L.D.; Down, D.I.; Lin, W.L.; Zhang, Y. Experimental study of anisotropic gas permeability and its relationship with fracture structure of Longmaxi Shales, Sichuan Basin, China. Fuel 2016, 180, 106–115. [Google Scholar] [CrossRef]

- Rybacki, E.; Reinicke, A.; Meier, T.; Makasi, M.; Dresen, G. What controls the mechanical properties of shale rocks?—Part I: Strength and Young’s modulus. J. Pet. Sci. Eng. 2015, 135, 702–722. [Google Scholar] [CrossRef]

- Rybacki, E.; Meier, T.; Dresen, G. What controls the mechanical properties of shale rocks?—Part II: Brittleness. J. Pet. Sci. Eng. 2016, 144, 39–58. [Google Scholar] [CrossRef]

- Holt, R.M.; Fjær, E.; Stenebraten, J.F.; Nes, O.M. Brittleness of shales: Relevance to borehole collapse and hydraulic fracturing. J. Pet. Sci. Eng. 2015, 131, 200–209. [Google Scholar] [CrossRef]

- Donath, F.A. Experimental study of shear failure in anisotropic rocks. Geol. Soc. Am. Bull. 1961, 72, 985–990. [Google Scholar] [CrossRef]

- Chenevert, M.E.; Gatlin, C. Mechanical anisotropies of laminated sedimentary rocks. J. Soc. Pet. Eng. 1965, 5, 67–77. [Google Scholar] [CrossRef]

- McLamore, R.; Gray, K.E. The mechanical behavior of anisotropic sedimentary rocks. J. Eng. Ind. Res. 1967, 89, 62–76. [Google Scholar] [CrossRef]

- Smith, M.B.; Cheatham, J.B. A three-dimensional anisotropic yield condition for Green River shale. J. Energy Res. 1980, 102, 184–189. [Google Scholar] [CrossRef]

- Swan, G.; Cook, J.; Bruce, S.; Meehan, R. Strain rate effects in Kimmeridge Bay shale. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1989, 26, 135–149. [Google Scholar] [CrossRef]

- Ibanez, W.D.; Kronenberg, A.K. Experimental deformation of shale: Mechanical properties and microstructural indicators of mechanisms. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 723–734. [Google Scholar] [CrossRef]

- Kwon, O.; Kronenberg, A.K. Deformation of Wilcox shale: Undrained strengths and effects of strain rate. In Proceedings of the 1st North American Rock Mechanics Symposium, Austin, TX, USA, 1–3 June 1994; American Rock Mechanics Association: Alexandria, VA, USA, 1994; pp. 757–765. [Google Scholar]

- Martin, H.R.; Jørn, S.; Erling, F. Static vs. Dynamic Behavior of Shale. In Proceedings of the 46th US Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012.

- Cho, J.W.; Kim, H.; Jeon, S.; Min, K.B. Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist. Int. J. Rock Mech. Min. 2012, 50, 158–169. [Google Scholar] [CrossRef]

- Tan, J.Q.; Horsfield, B.; Frank, R.; Krooss, B.; Schulz, H.M.; Rybacki, E.; Zhang, J.C.; Boreham, C.J.; Graas, G.V.; Tocher, B.A. Shale gas potential of the major marine shale formations in the Upper Yangtze Platform, south China, Part III: Mineralogical, lithofacial, petrophysical, and rock mechanical properties. Energy Fuel 2014, 28, 2322–2342. [Google Scholar] [CrossRef]

- Xu, J.B. Experimental Study on the Hydraulic Fracturing of Shale. Master’s Thesis, Chinese Academy of Sciences, Wuhan, China, 2012. [Google Scholar]

- Chen, S.B.; Zhu, Y.M.; Wang, H.Y.; Liu, H.L.; Wei, W.; Fang, J.H. Characteristics and significance of mineral compositions of Lower Silurian Longmaxi Formation shale gas reservoir in the southern margin of Sichuan Basin. Acta Pet. Sin. 2011, 32, 775–782. [Google Scholar]

- Zhang, J.P.; Tang, S.H.; Guo, D.X. Shale gas favorable area prediction of the Qiongzhusi Formation and Longmaxi Formation of Lower Palaeozoic in Sichuan Basin, China. Geol. Bull. China 2011, 30, 357–363. [Google Scholar]

- Ma, Y.Q.; Fan, M.J.; Lu, Y.C.; Guo, X.S.; Hu, H.Y.; Chen, L.; Wang, C.; Liu, X.C. Geochemistry and sedimentology of the Lower Silurian Longmaxi mudstone in southwestern China: Implications for depositional controls on organic matter accumulation. Mar. Pet. Geol. 2016, 75, 291–309. [Google Scholar] [CrossRef]

- Pedersen, D.K. Thin, fine-grained storm layers in a muddy shelf sequence: An example from the Lower Jurassic in the Stenlille 1 well, Denmark. J. Geol. Soc. 1985, 142, 357–374. [Google Scholar] [CrossRef]

- Wignall, P.B. Sedimentary dynamics of the Kimmeridge Clay: Tempests and earthquakes. J. Geol. Soc. 1989, 146, 273–284. [Google Scholar] [CrossRef]

- Macquaker, J.H.S. A lithofacies study of the Peterborough Member, Oxford Clay Formation (Jurassic), UK: An example of sediment bypass in a mudstone succession. J. Geol. Soc. 1994, 151, 161–172. [Google Scholar] [CrossRef]

- Macquaker, J.H.; Keller, M.A.; Davies, S.J. Algal blooms and “marine snow”: Mechanisms that enhance preservation of organic carbon in ancient finegrained sediments. J. Sediment. Res. 2010, 80, 934–942. [Google Scholar] [CrossRef]

- Bowker, K.A. Barnett shale gas production, Fort Worth Basin: Issues and discussion. AAPG Bull. 2007, 91, 523–533. [Google Scholar] [CrossRef]

- Hickey, J.; Henk, B. Lithofacies summary of the Mississippian Barnett shale, Mitchell 2 TP Sims well, Wise County, Texas. AAPG Bull. 2007, 91, 437–443. [Google Scholar] [CrossRef]

- Loucks, R.G.; Ruppel, S.C. Mississippian Barnett Shale: Lithofacies and depositional setting of a deep-water shale-gas succession in the Fort Worth Basin, Texas. AAPG Bull. 2007, 91, 579–601. [Google Scholar] [CrossRef]

- Schieber, J.; Sur, S.; Banerjee, S. Benthic microbial mats in black shale units from the Vindhyan Supergroup, Middle Proterozoic of India: The challenges of recognizing the genuine article. In Atlas of Microbial Mat Features Preserved within the Clastic Rock Record; Schieber, J., Bose, P.K., Eriksson, P.G., Banerjee, S., Sarkar, S., Altermann, W., Catuneau, O., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 189–197. [Google Scholar]

- Konitzer, S.F.; Davies, S.J.; Stephenson, M.H.; Leng, M.J. Depositional controls on mudstone lithofacies in a basinal setting: Implications for the delivery of sedimentary organic matter. J. Sediment. Res. 2014, 84, 198–214. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, J.J.; Yan, S.Y.; Gu, Z.D.; Wang, X.X. Detrital quartz and quartz cement in Upper Triassic reservoir sandstones of the Sichuan Basin: Characteristics and mechanisms of formation based on cathodoluminescence and electron backscatter diffraction analysis. Sediment. Geol. 2012, 267, 104–114. [Google Scholar] [CrossRef]

- Chen, X.; Bergstrom, S.M.; Zhang, Y.D.; Wang, Z.H. A regional tectonic event of Katian (Late Ordovician) age across three major blocks of China. Chin. Sci. Bull. 2013, 58, 4292–4299. [Google Scholar] [CrossRef]

- Wang, H.; Mo, X. An outline of the tectonic development of China. Episodes 1995, 18, 1–11. [Google Scholar]

- Chen, X.; Rong, J.Y.; Fan, J.X.; Zhan, R.B.; Mitchell, C.E.; Harper, D.A.T.; Melchin, M.J.; Peng, P.A.; Finney, S.C.; Wang, X.F. The global boundary stratotype section and point (GSSP) for the base of the Hirnantian stage (the uppermost of the Ordovician system). Episodes 2006, 29, 183–196. [Google Scholar]

- Guo, T.L. Evaluation of highly thermally mature shale-gas reservoirs in complex structural parts of the Sichuan Basin. J. Earth Sci. 2013, 24, 863–873. [Google Scholar] [CrossRef]

- Guo, T.L.; Zhang, H.R. Formation and enrichment mode of Jiaoshiba shale gas field, Sichuan Basin. Pet. Explor. Dev. 2014, 41, 31–40. [Google Scholar] [CrossRef]

- Mu, E.Z.; Li, J.J.; Ge, M.Y.; Chen, X.; Ni, Y.N.; Lin, Y.K. The late Ordovician palaeogeographical map in central China and its synopsis. J. Stratigr. 1981, 5, 165–170. [Google Scholar]

- Chen, X.; Rong, J.Y.; Li, Y.; Boucot, A.J. Facies patterns and geography of the Yangtze region, south China, through the Ordovician and Silurian transition. Palaeogeogr. Palaeocl. 2004, 204, 353–372. [Google Scholar]

- Guo, T.L.; Liu, R.B. Implications from marine shale gas exploration breakthrough in complicated structural area at high thermal stage: Taking Longmaxi Formation in Well JY1 as an example. Nat. Gas. Geosci. 2013, 24, 643–651. (In Chinese) [Google Scholar]

- Chen, Z.Q. Quantitative seismic prediction technique of marine shale TOC and its application: A case from the Longmaxi Shale Play in the Jiaoshiba area, Sichuan Basin. Nat. Gas Ind. 2014, 34, 24–29. [Google Scholar]

- Zoback, M.D. Reservoir Geomechanics, 1st ed.; Petroleum Industry Press: Beijing, China, 2012; pp. 58–61. [Google Scholar]

- Hakala, M.; Kuula, H.; Hudson, J.A. Estimating the transversely isotropic elastic intact rock properties for in situ stress measurement data reduction: A case study of the Olkiluoto mica gneiss, Finland. Int. J. Rock Mech. Min. 2007, 44, 14–46. [Google Scholar] [CrossRef]

- Nasseri, M.H.B.; Rao, K.S.; Ramamurthy, T. Anisotropic strength and deformational behavior of Himalayan schists. Int. J. Rock Mech. Min. 2003, 40, 3–23. [Google Scholar] [CrossRef]

- Nasseri, M.H.N.; Rao, K.S.; Ramamurthy, T. Failure mechanism in schistose rocks. Int. J. Rock Mech. Min. 1997, 34, 219.e1–219.e15. [Google Scholar] [CrossRef]

- Gottschalk, R.R.; Kronenberg, A.K.; Russell, J.E.; Handin, J. Mechanical anisotropy of gneiss: Failure criterion and textural sources of directional behavior. J. Geophys. Res. 1990, 95, 21613–21634. [Google Scholar] [CrossRef]

- Shea, W.T.; Kronenberg, A.K. Strength and anisotropy of foliated rocks with varied mica contents. J. Struct. Geol. 1993, 15, 1097–1121. [Google Scholar] [CrossRef]

| Number | Quartz/% | Albite/% | Potash Feldspar/% | Calcite/% | Chlorite/% | Illite/% | Pyrite/% |

|---|---|---|---|---|---|---|---|

| Sample-1 | 27.33 | 11.96 | 11.51 | 1.03 | 6.02 | 37.50 | 4.65 |

| Sample-2 | 31.39 | 10.01 | 6.06 | 1.89 | 6.52 | 40.32 | 3.80 |

| Sample-3 | 27.80 | 11.85 | 7.11 | 0.83 | 3.43 | 45.30 | 3.7 |

| Sample-4 | 27.95 | 12.23 | 5.42 | - | 7.56 | 42.76 | 4.09 |

| 0 MPa | 20 MPa | 40 MPa | 60 MPa | |

|---|---|---|---|---|

| 0° |  |  |  |  |

| 15° |  |  |  |  |

| 30° |  |  |  |  |

| 45° |  |  |  |  |

| 60° |  |  |  |  |

| 75° |  |  |  |  |

| 90° |  |  |  |  |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Li, X.; He, J.; Zheng, B. Mechanical Properties of Longmaxi Black Organic-Rich Shale Samples from South China under Uniaxial and Triaxial Compression States. Energies 2016, 9, 1088. https://doi.org/10.3390/en9121088

Wu Y, Li X, He J, Zheng B. Mechanical Properties of Longmaxi Black Organic-Rich Shale Samples from South China under Uniaxial and Triaxial Compression States. Energies. 2016; 9(12):1088. https://doi.org/10.3390/en9121088

Chicago/Turabian StyleWu, Yusong, Xiao Li, Jianming He, and Bo Zheng. 2016. "Mechanical Properties of Longmaxi Black Organic-Rich Shale Samples from South China under Uniaxial and Triaxial Compression States" Energies 9, no. 12: 1088. https://doi.org/10.3390/en9121088